Abstract

In this work, graphitic carbon nitride-supported l-arginine (g-C3N4@l-arginine) nanocatalyst was synthesized and evaluated using FT-IR, EDX, XRD, TGA, and FESEM analyses. The performance of the prepared nanocatalyst was examined in the synthesis of 1,4-dihydropyridine, 4H-chromene, and 2,3-dihydro quinazoline derivatives. The novel g-C3N4@l-arginine nanocatalyst showed high thermal stability, easy separation from reaction media, the capability to be used in various multicomponent reactions, and acceptable reusability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

These days, most chemical processes are carried out in the presence of catalysts. Among various catalysts, supported catalysts have more application than other catalysts. Synthesis of this class of catalysts requires a support with high surface area for the adequate dispersion of primary catalyst. For this reason, using a suitable support is of high importance in the synthesis of such catalysts1,2,3,4.

Graphitic carbon nitride (g-C3N4) can be used as a metal-free catalyst or catalyst support due to its excellent properties and exceptional performance. g-C3N4 sheets are an important class of conjugated polymers for the synthesis of new heterogeneous catalysts due to their unique electronic band structure, excellent physical, chemical, and thermal stability, high abrasion resistance, high hardness, low density, versatile performance, low synthesis cost, and recyclability 5,6. On the other hand, amino acids are one of the most interesting catalyst substrates due to their unique structure 7. Arginine is one of the main and semi-essential amino acids in the body of living organisms with advantages such as nontoxicity, ability to easily bind to catalytic support, and low cost for the preparation of acidic catalysts. In addition, acidic catalysts play an important role in the synthesis of organic compounds. Heterocyclic compounds are one of the best candidates in organic synthesis and pharmaceutical chemistry. They are mainly used as medicines, chemicals, veterinary products, disinfectants, expanders, and antioxidants 8.

The use of inexpensive and non-toxic reagents as well as low waste production is of great importance in green chemistry reactions. Hence, multicomponent reactions (MCRs) are considered as a useful method for the synthesis of heterocyclic organic molecules. Significant advantages of MCRs are the elimination of intermediates, short reaction times, high reaction yield, and easy separation of products 9,10,11,12. Compounds such as 1,4-dihydropyridine, tetrahydro-4H-chromenes, and dihydroquinazolines, which have high medicinal activity, are synthesized by MCRs.

Dihydropyridines are divided into two classes; symmetrical and asymmetrical. The latter is synthesized by the reaction of an aldehyde, 2 mmol of two different β-keto esters, and a nitrogen donor such as ammonium acetate or ammonia. The product of the initial reaction is dihydropyridine that can later be converted to pyridine. These compounds are an important class of antihypertensive drugs, vasodilators, hypnotic, anti-tumor 13,14, anti-inflammatory15,16, anti-diabetic, anti-anxiety, anti-mutation, and are known as calcium channel blockers17.

Tetrahydro-4H-chromenes are an important class of heterocyclic compounds with simple structure and low side effects. They are synthesized by the single-step condensation of aldehydes with malononitrile and dimedone18. In addition, their derivatives have important activities such as anticancer, antiviral, anti-inflammatory, antibacterial, antifungal, antioxidant, and anticoagulant. They are also used as cognitive enhancers to treat Alzheimer's disease19,20.

Dihydroquinazolines are the building blocks of about 150 natural alkaloids which are prepared by the reaction between aldehydes, isotonic anhydride, and ammonium acetate. Moreover, they have a range of pharmaceutical and biological activities such as anti-inflammatory, antimalarial, antibacterial, anticancer, and antiviral activities 21,22. Hence, many efforts have been made to synthesize such high-yield compounds. There are various methods for the synthesis of these compounds using different catalysts such as MCM-41@Schiff base-Co (OAC)223, Yb (NPf2)324, MCM-41@serine@Cu(II) 25, titanium silicon oxide nanopowder26, Y(NO3)3.6H2O 27, etc. despite their numerous advantages, they have some limitations such as long reaction time, expensive reagents, and the possibility of their contamination in final products.

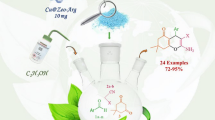

In this paper, new g-C3N4@l-arginine catalyst with the ability to perform various multi-combination reactions with high yield, short reaction time, recyclability, and easy separation from the reaction mixture is synthesized and examined (Fig. 1).

Results and discussion

The g-C3N4@l-arginine synthesis process consists of three main steps, as shown in Fig. 1. The first step is the synthesis of nanosheet g-C3N4 from melamine, which melamine was polymerized to bulk g-C3N4, then nanosheet g-C3N4 is synthesized by liquid exfoliation and sonication. In the second step, g-C3N4 nanosheets were modified by 1,3-dibromopropane at 100 °C for 24 h under nitrogen atmosphere. Finally, the g-C3N4@l-arginine was obtained via the reaction between l-arginine and modified g-C3N4 nanosheets. In this work, various techniques such as FTIR, EDX, XRD, FESEM, and TGA have been used to identify and characterize the novel nanocatalyst.

FTIR spectra of g-C3N4 nanosheets (Fig. 2a) and g-C3N4@l-arginine nanocatalyst (Fig. 2b) are shown in Fig. 2. The strong and broad peak in the range of 3000–3300 cm−1 is related to stretching vibration of N–H bonds, breadth peak can be assigned to N–H groups involved in H-bonding or the presence of O–H groups due to water adsorption by nanosheets g-C3N428,29. The stretching vibration peak of C=N can be observed at 1602 cm−1. The peaks at 1303 and 1082 cm−1 are attributed to the stretching vibration of C–N bonds formed between triazine and N–H groups, while the stretching vibration of C–N bonds in the ring is easily visible at 1448 and 1379 cm−1 29,30. In addition, the peak at 786 cm−1 is associated with the vibration of tri-s-triazine units 1 (Fig. 3a). Figure 3b shows that the g-C3N4 nanosheets has been modified with 1,3-dibromopropane; the peak at 3000–2800 cm−1 is related to C-H stretching vibration.

The spectrum of g-C3N4@l-arginine is presented in Fig. 3c in which the existence of l-arginine on the surface of g-C3N4 nanosheets can be confirmed based on the 1705 cm−1 and 1307 cm−1 peaks relating to the stretching vibration of C = O and C-O bonds, respectively. O–H and C-H bonds already existed in the structure of modified nanosheets g-C3N4.

The presence of carbon and nitrogen elements in the structure of g-C3N4 nanosheets is visible in Fig. 4a. The presence of Br element in the structure proves that g-C3N4 nanosheets have been modified by 1,3-dibromopropane (Fig. 4b). Finally, the presence of carbon, nitrogen, and oxygen in the final structure (g-C3N4@l-arginine) confirmed the synthesis of g-C3N4@l-arginine nanocatalyst (Fig. 4c).

The morphology of g-C3N4 nanosheets and g-C3N4@l-arginine was investigated by FE-SEM. Figure 5a-d shows FE-SEM images of g-C3N4 nanosheets. As shown in Figs. 5a-c, the g-C3N4 nanosheets have a smooth and flat surface, while in Fig. 5d, g-C3N4 nanosheets are irregular and connected together. FE-SEM images of g-C3N4@l-arginine are shown in Fig. 5e-h. It can be seen from Fig. 5e-g that g-C3N4 nanosheets have a flake-like morphology with a relatively rough surface, mainly due to the presence of l-arginine on the surface of g-C3N4 nanosheets. In Fig. 5h, more irregular-shape g-C3N4 nanosheets with tiny particles on the surface are observed, which again confirms the deposition of l-arginine on the g-C3N4 nanosheets.

XRD patterns of g-C3N4 nanosheets and g-C3N4@l-arginine are shown in Figs. 6a and 4b, respectively. The diffraction peaks at 2θ = 27.69 and 15.96 (Fig. 6a) prove the successful synthesis of g-C3N4 nanosheets 1,7,28, while the diffraction peaks at 2θ = 6.07, 10.85, 12.21, 23.60, and 30.97 (Fig. 6b) correspond to l-arginine (JCPDS card no. 00–004-0180), confirming the presence of l-arginine on the surface of g-C3N4 nanosheets.

Figure 7 shows the thermal stability of the synthesized g-C3N4@l-arginine in the range of 50–800 °C. As can be seen, the weight ratio has gradually decreased by increasing the temperature from 100 to 200 °C, which is most likely related to the removal of water absorbed on the surface of g-C3N4@l-arginine. Then, another weight loss is observed in the range of 200 to 400 °C, which is attributed to the separation of l-arginine from the structure. Finally, there is another weight loss in the range of 400 to 700 °C due to the decomposition of g-C3N4 nanosheets 31.

Model reactions

The performance of the prepared g-C3N4@l-arginine nanocatalyst was evaluated for the synthesis of 1,4-dihydropyridine, 4H-chromene, and 2,3-dihydro quinazoline derivatives. For this purpose, various parameters such as reaction time, catalyst concentration, and the solvent were examined (Table 1). The reaction of 4-chlorobenzaldehyde (1 mmol), ethyl acetoacetate (1 mmol), dimedone (1 mmol), and ammonium acetate (1 mmol) for the synthesis of 1,4-dihydropyridine derivatives, the reaction of 4-chlorobenzaldehyde (1 mmol), dimedone (1 mmol), and malononitrile (1 mmol) for the synthesis of 4H-chromene derivatives, and the reaction of 4-chlorobenzaldehyde (1 mmol), isotonic anhydride (1 mmol), and ammonium acetate (1 mmol) for the synthesis of 2,3-dihydro quinazoline derivatives were considered as model reactions with and without g-C3N4@l-arginine nanocatalyst under different conditions. The reaction progress was monitored by Thin-layer chromatography (TLC). As can be seen in Table 1 (entries 1 and 2), no progress was observed for the model reactions without nanocatalyst. By introducing 1.00 mg of g-C3N4@l-arginine (Table 1, entry 3), however, the model reactions occurred easily. Then, the influence of other parameters including catalyst concentration, reaction time, and solvent were examined. As can be seen, time had not significant effect on the reaction progress, thus 15 min was considered as the optimum reaction time for all the model reactions (Table 1, entries 7, 8, and 9). Furthermore, the highest product yield was obtained using ethanol as solvent at 80 °C in the presence of 20.00 mg of g-C3N4@l-arginine (Table 1, entry 5).

In the following, various aldehydes were applied for the synthesis of 1,4-dihydropyridine, 4H-chromene, and 2,3-dihydro quinazoline derivatives under optimal reaction conditions. Based on model reactions that are provided in Tables 2, 3 and 4, a wide range of different derivatives of the desired multicomponent reactions were prepared with high yield.

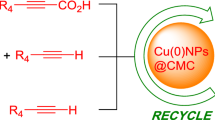

Reusability of g-C3N4@l-arginine nanocatalyst

According to the importance of recovery and recyclability in green chemistry, in this section, the reusability of g-C3N4@l-arginine was examined for the synthesis of 1,3-dihydropyridine 5b, 4H-chromene 9b, and 2,3-dihydroquinazoline 13b products. For this purpose, after the first reaction (run 1), g-C3N4@l-arginine catalyst was separated from the reaction media, washed with ethanol, and dried in an oven at 70 °C. Then, the catalyst was reused for the next run. This was repeated for five times and the obtained yields were acceptable for catalytic reactions, and although performed reaction yields were decreased at each run bit by bit, in run 5th, the observed decrement was impressive in comparison with other runs (Fig. 8). EDX and FTIR spectra after the 5th run showed no significant changes in the primary structure of the g-C3N4@l-arginine nanocatalyst, as shown in Fig. 9.

Mechanistic study of the prepared nanocatalyst in the synthesis of 1,4-dihydropyridine, 4H-chromene, and 2,3-dihydro quinazoline derivatives

In Fig. 10, the suitable mechanism for the formation of 1,4-dihydropyridine, 2,3-dihydro quinazoline, and 4H-chromene derivatives are provided. In each reaction, the presence of g-C3N4@l-arginine can activate reactants and different intermediates. As can be seen in Fig. 10a, 1,4-dihydropyridine derivatives can be synthesized in two methods. In the first method, aldehyde and dimedone produce intermediate I in the presence of g-C3N4@l-arginine, and the intermediate II is formed from the reaction between ethyl acetoacetate and ammonium acetate. But in the second method, dimedone and ammonium acetate produce intermediate III in the presence of g-C3N4@l-arginine, and the reaction between ethyl acetoacetate and aldehyde forms intermediate IV. Both methods ultimately lead to the formation of product V.

A suggested mechanism for the formation of 2,3-dihydro quinazoline derivatives is shown in Fig. 10b. At first, isotonic anhydride reacts with ammonium acetate in the presence of g-C3N4@l-arginine and produces intermediate I, then aldehyde activates by g-C3N4@l-arginine and adds to intermediate II. Finally, after removing H, the desired product IV is synthesized.

Figure 10c presents a probable method for the synthesis of 4H-chromene derivatives in the presence of g-C3N4@l-arginine is. In this mechanism, intermediate I is produced from the reaction between aldehyde and dimedone. Then, addition of malononitrile leads to the formation of intermediate II. At last, product IV is obtained.

Catalytic activity of the synthesized nanocatalyst

Tables 5, 6 and 7 show the performance of g-C3N4@l-arginine in comparison with the catalysts reported in the literature for the synthesis of 1,4-dihydropyridine, 4H-chromene, and 2,3-dihydro quinazoline derivatives. For this purpose, various parameters such as catalyst concentration, reaction time, reaction temperature, and reaction yield were investigated. According to the data presented in each table, g-C3N4@l-arginine can be considered as a unique heterogonous nanocatalyst that can be used in a wide range of condensation reactions in addition to simple separation conditions of the reaction mixture. On the other hand, this nanocatalyst exceptionally showed higher synthesis yield at shorter reaction times.

Experimental

Reagents and apparatus

All chemicals were purchased from Merck and Sigma-Aldrich Co. Fourier Transform Infrared (FTIR) spectra were recorded on Tensor27. Nuclear Magnetic Resonance (NMR) data were acquired on a Varian-Inova 500 MHz. X-Ray Diffraction (XRD) patterns were obtained using Dron-8 diffractometer. Energy-dispersive X-ray (EDX) spectrum was recorded on Numerix DXP–X10P. Thermal gravimetric analysis (TGA) was performed using STA 504 instrument under argon atmosphere. Field Emission Scanning Electron Microscopy (FESEM) images were recorder with TESCAN-MIRA III.

Preparation of bulk g-C3N4 and g-C3N4 nanosheets

For the synthesis of bulk g-C3N4, the melamine was heated at 550 °C in a furnace at the heating rate of 2.5 °C min−1 in static air for 4 h. A yellow powder was obtained which was then grounded in a ball mill. For the synthesis of g-C3N4 nanosheets, bulk g-C3N4 (1.0 g) was first stirred in H2SO4 (20 mL) at 90 °C for 5 h. The solution was then diluted with ethanol (200 mL) and stirred again at room temperature for 2 h. The resulting product was dispersed in 100.0 mL water/isopropanol (1:1) solution and sonicated for 6 h. Finally, the formed suspension was centrifuged at 5000 rpm to separate g-C3N4 nanosheets.

Preparation of g-C3N4@l-arginine

g-C3N4 (1.0 g) nanosheets were dispersed in dry toluene (20.0 mL). Then, the reaction mixture was refluxed under N2 atmosphere for 24 h after addition of 1,3-dibromopropane (2.0 mL). Finally, the product was filtered and washed with ethyl acetate, and dried at room temperature. The resulting product was dissolved in a mixture of water and methanol (1:1) followed by the addition of l-arginine (1 mmol), K2CO3 (1.0 mmol), and NaI (1.0 mmol). The solution was stirred at room temperature for 24 h. the reaction mixture was then washed with water and methanol and dried at room temperature.

General procedure for the synthesis of 1,4-dihydropyridine derivatives

A mixture of aldehyde (1.0 mmol), ethyl acetoacetate (1.0 mmol), dimedone (1.0 mmol), ammonium acetate (1.0 mmol), g-C3N4@l-arginine (20.0 mg), and ethanol (2.0 mL) was added in a round bottom flask and refluxed at 70 °C. When the reaction was completed (monitored by TLC), the catalyst was separated by filtration and washed with ethanol, and then to purifying the product was used recrystallization.

General procedure for the synthesis of 2,3-dihydro quinazoline derivatives

In a round bottom flask, aldehyde (1.0 mmol), isotonic anhydride (1.0 mmol), ammonium acetate (2.0 mmol), and g-C3N4@l-arginine (20.0 mg) were added and refluxed in ethanol (2.0 mL) at 70 °C. After reaction completion (monitored by TLC), the catalyst was removed by filtration and washed with ethanol, and then to purifying the product was used recrystallization.

General procedure for the synthesis of 4H-chromene derivatives

In a round bottom flask was added aldehyde (1.0 mmol), dimedone (1.0 mmol), malononitrile (1.0 mmol), g-C3N4@l-arginine (20.0 mg), and ethanol (2.0 mL). The mixture was then refluxed at 70 °C until the reaction was completed (monitored by TLC). At last, catalyst separation by filtration and washed with ethanol, and then to purifying the product was used recrystallization.

Conclusions

In summary, heterogeneous g-C3N4@-arginine nanocatalyst was prepared and used for the synthesis of 1,4-dihydropyridine, 4H-chromene, and 2,3-dihydro quinazoline derivatives as important products in pharmacologically active compounds. The main advantages of this nanocatalyst is its reusability, simple separation from the reaction mixture, applicability for a broad range of high efficiency condensation reactions, and short reaction time. In addition, the use of an easy and convenient method for the preparation of the nanocatalyst is another advantage of this catalyst over other reported catalysts.

Selected spectral data

Ethyl 2,7,7-trimethyl-5-oxo-4-(4-hydroxylphenyl)-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate (5c)

FTIR (KBr, cm-1): 3270, 3194, 3071, 2957, 1678, 1645, 1481, 1377, 1214 cm-1. 1H NMR (500 MHz, DMSO): δ H (ppm) = 0.85(s, 3H, CH3), 1.0(s, 3H, CH3), 1.13(t, 3H, CH3), 1.9–2.41(m,4H, 2CH2), 2.25(s, 3H, CH3), 3.95–3.99(q, 2H, OCH2), 4.73(s, 1H, Ar–CH), 6.54(d, 2H, Ar–H), 6.93(d, 2H, Ar–H), 8.95(s, 1H, NH), 9.01(s,1H, OH).

Ethyl 1,4,7,8-tetrahydro-2,7,7-trimethyl-4-(4-nitrophenyl)-5(6H)-oxoquinoline-3-carboxylate (5d)

FTIR (KBr, cm-1): 3276, 3210, 3076, 2969, 2902, 1703, 1641, 1530, 1379 cm-1. 1H NMR (500 MHz, DMSO): δH (ppm) = 0.83(s, 3H, CH3), 1.01(s, 3H, CH3), 1.11(t, 3H, CH3), 1.96–2.46(m,4H, 2CH2), 2.31(s, 3H, CH3), 3.93–4.0(m, 2H, OCH2), 4.97(s, 1H, Ar–CH), 7.5–7.61 (m, 4H, Ar–H), 7.97(s, 1H, NH), 9.23(s,1H, OH).

2-amino-4-(4-nitrophenyl)-7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile (9c)

FTIR(KBr, cm-1): 3403, 3312, 3170, 2969, 2881,2181, 1668, 1626, 1517, 1345, 856 cm-1.1 H NMR (500 MHz, DMSO): δ H (ppm) = 0.95(s, 3H, CH3), 1.04(s, 3H, CH3), 2.09–2.53(m, 4H, 2CH2), 4.36(s, 1H, CH), 7.1(s, 2H, NH2), 7.43–8.17(m, 4H, Ar–H).

2-phenyl-2, 3-dihydro-4(1H)-quinazolinone (13a)

FTIR (KBr, cm-1): 3300, 3176, 2981, 1651, 1610, 1507, 1440, 1385, 745 cm-1. 1H NMR (500 MHz, DMSO): δ H (ppm) = 5.75(s, 1H, CH), 6.67(t, 1H, Ar–H), 6.74(d, 1H, Ar–H), 7,1(s, 1H, NH), 7.23(t, 1H, Ar–H), 7.34(t, 1H, Ar–H), 7.38(t, 1H, Ar–H), 7.49(d, 1H, Ar–H), 7.60(d, 1H, Ar–H), 8.27(s, 1H, CONH).

2-(4-chloro-phenyl)-2, 3-dihydro-1H-quinazoline-4-one (13b)

FTIR (KBr, cm-1): 3305, 3184, 3062, 1654, 1606, 1431, 1090, 749 cm-1. 1H NMR (500 MHz, DMSO): δ H (ppm) = 5.77(s, 1H, CH), 6.68(t, 1H, Ar–H), 6.74(d, 1H, Ar–H), 7,1(s, 1H, NH), 7.24(t, 1H, Ar–H), 7.45(d, 1H, Ar–H), 7.50(d, 1H, Ar–H), 7.61(d, 1H, Ar–H), 8.27(s, 1H, CONH).

References

Rashidizadeh, A., Ghafuri, H., Esmaili Zand, H. R. & Goodarzi, N. Graphitic carbon nitride nanosheets covalently functionalized with biocompatible vitamin B1: synthesis, characterization, and its superior performance for synthesis of quinoxalines. ACS Omega 4(7), 12544–12554. https://doi.org/10.1021/acsomega.9b01635 (2019).

Rahmati, M. & Ghafuri, H. Catalytic Strecker reaction: gC 3 N 4-anchored sulfonic acid organocatalyst for the synthesis of α-aminonitriles. Research on Chemical Intermediates, 1–14 (2021). https://www.x-mol.com/paperRedirect/1359656597111214080

Zhang, Z., Liu, K., Feng, Z., Bao, Y. & Dong, B. Hierarchical sheet-on-sheet ZnIn2S4/gC3N4 heterostructure with highly efficient photocatalytic H2 production based on photoinduced interfacial charge transfer. Sci. Rep. 6, 1–10. https://doi.org/10.1038/srep19221 (2016).

Kumar, R., Barakat, M. & Alseroury, F. Oxidized gC3N4/polyaniline nanofiber composite for the selective removal of hexavalent chromium. Sci. Rep. 7, 1–11. https://doi.org/10.1038/s41598-017-12850-1 (2017).

Dong, G., Zhang, Y., Pan, Q. & Qiu, J. A fantastic graphitic carbon nitride (g-C3N4) material: electronic structure, photocatalytic and photoelectronic properties. J. Photochem. Photobiol. C Photochem. Rev. 20, 33–50. https://doi.org/10.1016/j.jphotochemrev.2014.04.002 (2014).

Wu, Y. et al. Electrocatalytic performances of gC3N4-LaNiO3 composite as bi-functional catalysts for lithium-oxygen batteries. Sci. Rep. 6, 1–8. https://doi.org/10.1038/srep24314 (2016).

Han, H. et al. Cu and boron doped carbon nitride for highly selective oxidation of toluene to benzaldehyde. Molecules 20, 12686–12697. https://doi.org/10.3390/molecules200712686 (2015).

Davarpanah, J., Ghahremani, M. & Najafi, O. Synthesis of 1, 4-dihydropyridine and polyhydroquinoline derivatives via Hantzsch reaction using nicotinic acid as a green and reusable catalyst. J. Mol. Struct. 1177, 525–535. https://doi.org/10.1016/j.molstruc.2018.10.002 (2019).

Kusampally, U., Dhachapally, N., Kola, R. & Kamatala, C. R. Zeolite anchored Zr-ZSM-5 as an eco-friendly, green, and reusable catalyst in Hantzsch synthesis of dihydropyridine derivatives. Mater. Chem. Phys. 242, 122497. https://doi.org/10.1016/j.matchemphys.2019.122497 (2020).

Alponti, L. H., Picinini, M., Urquieta-Gonzalez, E. A. & Corrêa, A. G. USY-zeolite catalyzed synthesis of 1,4-dihydropyridines under microwave irradiation: Structure and recycling of the catalyst. J. Mol. Struct. 1227, 129430. https://doi.org/10.1016/j.molstruc.2020.129430 (2021).

Das, D. Multicomponent reactions in organic synthesis using copper-based nanocatalysts. ChemistrySelect 1, 1959–1980. https://doi.org/10.1002/slct.201600414 (2016).

Domling, A., Wang, W. & Wang, K. Chemistry and biology of multicomponent reactions. Chem. Rev. 112, 3083–3135. https://doi.org/10.1021/cr100233r (2012).

Khazaei, A., Moosavi-Zare, A. R., Mohammadi, Z., Khakyzadeh, V. & Afsar, J. Nano-TiO2 as an efficient catalyst for tandem Knoevenagel–Michael-cyclocondensation reaction of dimedone with aromatic aldehydes and ammonium acetate or aromatic amines under solvent-free conditions. J. Chin. Chem. Soc. 63, 165–170. https://doi.org/10.1002/jccs.201500384 (2016).

Aute, D., Kshirsagar, A., Uphade, B. & Gadhave, A. Aluminized polyborate-catalysed green and efficient synthesis of polyhydroquinolines under solvent-free conditions. Res. Chem. Intermed. 46, 3491–3508. https://doi.org/10.1007/s11164-020-04158-z (2020).

Zhang, Q., Ma, X.-M., Wei, H.-X., Zhao, X. & Luo, J. Covalently anchored tertiary amine functionalized ionic liquid on silica coated nano-Fe3O4 as a novel, efficient and magnetically recoverable catalyst for the unsymmetrical Hantzsch reaction and Knoevenagel condensation. RSC Adv. 7, 53861–53870. https://doi.org/10.1039/C7RA10692K (2017).

Kiyani, H. & Ghorbani, F. Boric acid-catalyzed multi-component reaction for efficient synthesis of 4H-isoxazol-5-ones in aqueous medium. Res. Chem. Intermed. 41, 2653–2664. https://doi.org/10.1007/s11164-013-1411-x (2015).

Yü, S.-J., Wu, S., Zhao, X.-M. & Lü, C.-W. Green and efficient synthesis of acridine-1,8-diones and hexahydroquinolines via a KH2PO4 catalyzed Hantzsch-type reaction in aqueous ethanol. Res. Chem. Intermed. 43, 3121–3130. https://doi.org/10.1007/s11164-016-2814-2 (2017).

Zhang, Q., Wei, H., Li, J., Zhao, X. & Luo, J. One-pot synthesis of benzopyrans catalyzed by silica supported dual acidic ionic liquid under solvent-free conditions. Heterocycl. Commun. 23, 411–414. https://doi.org/10.1515/hc-2017-0163 (2017).

Lu, J., Fu, X., Zhang, G. & Wang, C. β-Cyclodextrin as an efficient catalyst for the one-pot synthesis of tetrahydrobenzo [b] pyran derivatives in water. Res. Chem. Intermed. 42, 417–424. https://doi.org/10.1007/s11164-015-2027-0 (2016).

Malviya, J., Kala, S., Sharma, L. & Singh, R. Efficient three-component one-pot synthesis of 4 H-Pyrans. Russ. J. Org. Chem. 55, 686–693. https://doi.org/10.1134/S1070428019050178 (2019).

Mirjalili, B. B. F., Zaghaghi, Z. & Monfared, A. Synthesis of 2,3-dihydroquinazolin-4 (1H)-ones in the presence of Fe3O4@ nano-cellulose–OPO3H as a bio-based magnetic nanocatalyst. J. Chin. Chem. Soc. 67, 197–201. https://doi.org/10.1002/jccs.201900264 (2020).

Rao, A. D. et al. Sulfonic acid functionalized Wang resin (Wang-OSO3H) as polymeric acidic catalyst for the eco-friendly synthesis of 2,3-dihydroquinazolin-4 (1H)-ones. Tetrahedron Lett. 56, 4714–4717. https://doi.org/10.1080/00397911.2016.1213850 (2015).

Pan, S. et al. MCM-41@ Schiff base-Co (OAc) 2 as an efficient catalyst for the synthesis of pyran derivatives. Res. Chem. Intermed. 46, 1353–1371. https://doi.org/10.1080/00397911.2016.1213850 (2020).

Hong, M. & Cai, C. Ytterbium(III) bis (perfluorooctanesulfonyl) imide catalyzed one-pot synthesis of tetrahydrobenzo [b] pyrans in fluorous biphase system. J. Chem. Res. 34, 568–570. https://doi.org/10.3184/030823410X12863845344182 (2010).

Tamoradi, T., Ghadermazi, M. & Ghorbani-Choghamarani, A. Synthesis of polyhydroquinoline, 2,3-dihydroquinazolin-4 (1H)-one, sulfide and sulfoxide derivatives catalyzed by new copper complex supported on MCM-41. Catal. Lett. 148, 857–872. https://doi.org/10.1007/s10562-018-2311-x (2018).

Mekala, R. et al. Efficient synthesis of 2, 3-dihydroquinazolin-4 (1H)-ones catalyzed by titanium silicon oxide nanopowder in aqueous media. Synth. Commun. 47, 121–130. https://doi.org/10.1080/00397911.2016.1254801 (2017).

Khan, A. A., Mitra, K., Mandal, A., Baildya, N. & Mondal, M. A. Yttrium nitrate catalyzed synthesis, photophysical study, and TD-DFT calculation of 2,3-dihydroquinazolin-4 (1H)-ones. Heteroat. Chem. 28, e21379. https://doi.org/10.1002/hc.21379 (2017).

Guo, X., Duan, J., Li, C., Zhang, Z. & Wang, W. Highly efficient Z-scheme gC3N4/ZnO photocatalysts constructed by co-melting-recrystallizing mixed precursors for wastewater treatment. J. Mater. Sci. 55, 2018–2031. https://doi.org/10.1007/s10853-019-04097-0 (2020).

Yang, X., Tang, B., Wu, T. & Cao, X. g-C3N4/TiO2 composite photocatalyst and its application to asphalt for NO removal. J. Mater. Civ. Eng. 31, 04019141. https://doi.org/10.1061/%28ASCE%29MT.1943-5533.0002763 (2019).

Li, X. et al. Synergistic effect of efficient adsorption g-C3N4/ZnO composite for photocatalytic property. J. Phys. Chem. Solids 75, 441–446. https://doi.org/10.1016/j.jpcs.2013.12.001 (2014).

Rahmati, M., Ghafuri, H., Ghanbari, N. & Tajik, Z. 1,4-butanesultone functionalized graphitic carbon nitride: efficient catalysts for the one-pot synthesis of 1,4-dihydropyridine and polyhydroquinoline derivative through Hantzsch reaction. Polycycl. Arom. Compd. https://doi.org/10.1080/10406638.2020.1852583 (2020).

Maleki, A., Eskandarpour, V., Rahimi, J. & Hamidi, N. Cellulose matrix embedded copper decorated magnetic bionanocomposite as a green catalyst in the synthesis of dihydropyridines and polyhydroquinolines. Carbohyd. Polym. 208, 251–260. https://doi.org/10.1016/j.carbpol.2018.12.069 (2019).

Brahmachari, G., Laskar, S. & Banerjee, B. Eco-friendly, one-pot multicomponent synthesis of pyran annulated heterocyclic scaffolds at room temperature using ammonium or sodium formate as non-toxic catalyst. J. Heterocycl. Chem. 51, E303–E308. https://doi.org/10.1002/jhet.1974 (2014).

Qareaghaj, O. H., Mashkouri, S., Naimi-Jamal, M. R. & Kaupp, G. Ball milling for the quantitative and specific solvent-free Knoevenagel condensation+ Michael addition cascade in the synthesis of various 2-amino-4-aryl-3-cyano-4 H-chromenes without heating. RSC Adv. 4, 48191–48201. https://doi.org/10.1039/C4RA06603K (2014).

Dekamin, M. G. & Eslami, M. Highly efficient organocatalytic synthesis of diverse and densely functionalized 2-amino-3-cyano-4 H-pyrans under mechanochemical ball milling. Green Chem. 16, 4914–4921. https://doi.org/10.1039/C4GC00411F (2014).

Ghafuri, H., Goodarzi, N., Rashidizadeh, A. & Fard, M. A. D. ompg-C 3 N 4/SO 3 H: an efficient and recyclable organocatalyst for the facile synthesis of 2, 3-dihydroquinazolin-4 (1 H)-ones. Res. Chem. Intermed. 45, 5027–5043 (2019).

Pourhasan-Kisomi, R., Shirini, F. & Golshekan, M. Introduction of organic/inorganic Fe3O4@MCM-41@ Zr-piperazine magnetite nanocatalyst for the promotion of the synthesis of tetrahydro-4H-chromene and pyrano [2,3-d] pyrimidinone derivatives. Appl. Organomet. Chem. 32, e4371. https://doi.org/10.1002/aoc.4371 (2018).

Zhang, Q., Gao, Y.-H., Qin, S.-L. & Wei, H.-X. Facile one-pot synthesis of amidoalkyl naphthols and benzopyrans using magnetic nanoparticle-supported acidic ionic liquid as a highly efficient and reusable catalyst. Catalysts 7, 351. https://doi.org/10.3390/catal7110351 (2017).

Khodabakhshi, M. R., Kiamehr, M. & Karimian, R. Efficient one-pot synthesis of 1,4-dihydropyridine and polyhydroquinoline derivatives using sulfanilic acid-functionalized boehmite nano-particles as an organic-inorganic hybrid catalyst. Polycyclic Aromat. Compd. 1–15. https://doi.org/10.1080/10406638.2021.1884100 (2021).

Karhale, S., Bhenki, C., Rashinkar, G. & Helavi, V. Covalently anchored sulfamic acid on cellulose as heterogeneous solid acid catalyst for the synthesis of structurally symmetrical and unsymmetrical 1, 4-dihydropyridine derivatives. New J. Chem. 41, 5133–5141. https://doi.org/10.1039/C7NJ00685C (2017).

Tekale, S. U., Munde, S. B., Kauthale, S. S. & Pawar, R. P. An efficient, convenient, and solvent-free synthesis of 2,3-dihydroquinazolin-4 (1 H)-ones using montmorillonite-KSF clay as a heterogeneous catalyst. Org. Prep. Proced. Int. 50, 314–322. https://doi.org/10.1080/00304948.2018.1462058 (2018).

Acknowledgements

We are grateful for the financial support from The Research Council of Iran University of Science and Technology (IUST), Tehran, Iran.

Author information

Authors and Affiliations

Contributions

All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghafuri, H., Tajik, Z., Ghanbari, N. et al. Preparation and characterization of graphitic carbon nitride-supported l-arginine as a highly efficient and recyclable catalyst for the one-pot synthesis of condensation reactions. Sci Rep 11, 19792 (2021). https://doi.org/10.1038/s41598-021-97360-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-97360-x

- Springer Nature Limited

This article is cited by

-

Fe3O4@gC3N4@Thiamine: a novel heterogeneous catalyst for the synthesis of heterocyclic compounds and microextraction of tebuconazole in food samples

Scientific Reports (2024)

-

Green one-pot synthesis of 2-amino-4H-pyranes catalyzed by copper–arginine complex decorated on nano-NaY zeolite

Research on Chemical Intermediates (2024)

-

Ultrasound-Promoted preparation and application of novel bifunctional core/shell Fe3O4@SiO2@PTS-APG as a robust catalyst in the expeditious synthesis of Hantzsch esters

Scientific Reports (2023)

-

Investigation of biological activity and hyperthermia application of a quaternary magnetic nanobiocomposite based on functionalized carbon nitride nanosheets by carboxymethyl cellulose hydrogel and silk fibroin

Cellulose (2023)

-

Novel F-modification of g-C3N4/ZnAl–LDHs binary heterojunction with notable 2D/2D configuration for efficient visible-light-driven photocatalytic elimination of organic pollutants

Journal of Materials Science: Materials in Electronics (2023)