Abstract

A simple, efficient and less expensive protocol for the synthesis of Cu(II) immobilized on MCM-41@Serine has been reported. This nanohybrid material was carefully characterized by Fourier transform infrared spectroscopy, scanning electron microscopy, energy-dispersive X-ray spectroscopy, inductively coupled plasma optical emission spectroscopy, X-ray diffraction, TEM, thermal gravimetric analysis, and N2 adsorption and desorption. The obtained nanostructured compound were also employed as a green, efficient, heterogeneous and reusable catalytic system for the synthesis of polyhydroquinoline, 2,3-dihydroquinazolin-4(1H)-one, sulfide and sulfoxide derivatives. High surface area, convenient recovery and reusability for several times without any significant loss of activity, the use of a commercially available, eco-friendly, cheap and chemically stable reagents, good reaction times, simple practical methodology and ease of use all make Cu(II) immobilized on MCM-41@Serine a promising candidate for potential applications in some organic reactions; makes this protocol both attractive and economically viable.

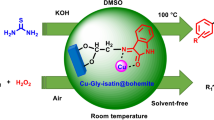

Graphical Abstract

MCM-41 nanostructured was prepared via simple and versatile procedure and directly immobilized with a new type of Cu–serine complex. After characterization of this catalyst, the catalytic activity of this nanostructure compound has been investigated for the synthesis of polyhydroquinoline, 2,3-dihydroquinazolin-4(1H)-one, sulfide and sulfoxide derivatives.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Diaryl sulfides and their derivatives have been intensively investigated in recent years. They have been attracting much attention, due to their wide applications in areas such as biological and pharmaceutical systems and organic synthesis. More importantly, they have found widespread application as precursors or synthetic intermediates in numerous drugs such as those against diabetes, Alzheimer’s disease, inflammation, cancer, Parkinson’s disease and HIV [1,2,3,4,5,6,7,8,9]. It should be noted that sulfides were important substrate source for the synthesis of sulfoxides. Recently, considerable interest in sulfoxide compounds was occurred because they are versatile reagents for organic synthesis. Indeed, sulfoxide derivatives have a wide range of important potential applications as precursors or intermediates in the synthesis of natural products and valuable physiologically and pharmacologically active molecules and as well as important integral and supplementary parts in many pharmaceutical and biological active molecules such as omeprazole and fipronil [10,11,12,13,14,15,16,17,18,19]. In addition, six membered heterocyclic ring molecules-containing organic molecules are very well-known; particularly, polyhydroquinoline (PHQ) derivatives have been employed as imperative molecules in biological and pharmaceutical such as vasodilator, hepatoprotective, antiatherosclerotic, bronchodilator, antitumor, geroprotective, antidiabetic activity and also their ability to modulate calcium channels [20,21,22,23,24,25]. As reported in several well-documented reviews, 2,3-dihydroquinazolin-4(1H)-one derivatives can seek the opportunities in an important class of heterocyclic compounds in the production of industrially important chemicals and biological products such as antitumor, antibiotic, antidefibrillatory, antipyretic, antihistamine, vasodilating behavior, analgesic, antihypertonic, diuretic and antidepressant [26, 27]. Since then, various catalytic systems have emerged for the reactions mentioned above. Some of these procedures have various disadvantages including hazardous reaction conditions, difficulty in preparation and/or storage of reagents or catalysts, toxic chemicals and tedious workup, operational costs and product purity, use of strong acids, difficulty in separation of catalyst from the products, poor yields and long reaction times [28,29,30,31,32,33]. Furthermore, a versatile and environmentally friendly procedure has been reported to overcome these drawbacks. In this regard, mesoporous silica materials with nano-sized pores and controllable porous structure and pore volume were offered as suitable operation procedure for the synthesis of organic molecules because of their large specific surface areas, high dispersion of metal nanoparticles, facility in the access of substrates to active sites and facility in the separation of the catalyst upon reaction completion [34,35,36,37,38,39]. In recent years, the copper heterogeneous catalysts have been widely utilized for the organic synthesis because of their chemical, economic, and environmental aspects [40,41,42]. Therefore, in the development of greener and sustainable processes for organic synthesis and nanocatalyst, we report the preparation and characterization of recoverable and efficient MCM-41@Serine@Cu(II) nanoparticles. Interestingly, the results of these studies were indicated a highly catalytic nature, easy to handle procedure, short reaction time, recycle exploitation and excellent isolated yields for the synthesis of PHQ, 2,3-dihydroquinazolin-4(1H)-one, sulfide and sulfoxide derivatives.

2 Experimental

2.1 Materials and Instrumentation

All commercially available chemicals in this study were purchased from Aldrich, Merck or Fluka and used without further purification. The thermo-gravimetric analysis (TGA) curve of the MCM-41@Serine@Cu(II) nanocatalyst was recorded using Shimadzu DTG-60 instrument in the temperature range of 50–800 °C. X-ray diffraction (XRD) patterns of samples were taken to obtain the crystallographic structure of catalyst by XRD patterns using Co radiation source with a wavelength l = 1.78897 Å, 40 kV. Measuring the Amount of copper in the synthesized nanohybrid was investigated by inductively coupled plasma optical emission spectrometry (ICP-OES).The particle size and external morphology of the nanoparticles were characterized by TEM and SEM techniques using Zeiss-EM10C TEM and FESEM-TESCAN MIRA3, respectively. Fourier transform infrared (FT-IR) spectra of samples were also recorded on a Bruker VERTEX 80 v model using the KBr pellets in the range of 400–4000 cm−1. The elemental analysis of the samples was done by energy-dispersive X-ray spectroscopy (EDAX, TSCAN).

2.2 Preparation of Mesoporous Silica-Anchored MCM-41@Serine@Cu(II)

Initially, mesoporous MCM-41 was prepared by adding 1 g of cetyltrimethylammonium bromide, as structure directing template agent, to a solution containing 3.5 mL of NaOH solution (2 M) and deionized water (480 mL) and then stirred at 80 °C followed by a dropwise addition of 5 mL of tetraethylorthosilicate as the silica source under vigorous stirring. Upon stirring for 2 h under the nearly same condition, the resulting precipitate was filtered, washed with deionized water and dried in an oven at 60 °C. Finally, the resultant white powder was calcinated at 823 K for 5 h at a rate of 2 °C min−1 to remove the residual surfactants. The final product is designated as pure silica MCM-41. Subsequently, MCM-41@Serine was synthesized by adding 1.5 g of serine to a suspension of MCM-41 (1 g) in 30 mL distilled water under reflux conditions for 48 h. Finally, the resulting mixture was filtered, washed with ethanol/water and dried in vacuum at 70 °C to give pure MCM-41@Serine. In the last step, for the synthesis of MCM-41@Serine@Cu(II) nanoparticles, 1 g MCM-41@Serine and 0.604 g Cu(NO3)2·3H2O were mixed in ethanol (30 mL) under reflux conditions for 16 h, filtered, washed thoroughly with ethanol and dried in vacuum to obtain a novel nanocatalyst.

2.3 General Procedure for the Synthesis of Sulfides

In the next study, MCM-41@Serine@Cu(II) catalyst (0.08 g) was added to a mixture of thiourea (1 mmol), aryl halide (1 mmol), KOH (0.7 g) in DMSO (2 mL) as solvent and the mixture kept under stirring at 130 °C for the appropriate time. The progress of the reaction was monitored by TLC. After reaction completion, the catalyst was collected by magnetic separation and the product was extracted with ethyl acetate. The organic extract was washed twice with water and dried with anhydrous Na2SO4. Finally, the solvent of the organic layers was evaporated to obtain corresponding sulfide.

2.4 General Procedure for the Synthesis of Sulfoxides

In order to examine the catalytic activity of the catalyst, a solution of sulfide (1 mmol) and MCM-41@Serine@Cu(II) (3 mg) was added to the round-bottomed flask containing hydrogen peroxide solution (0.5 mL) under solvent-free condition. The mixed reaction was stirred at room temperature for a time period. After completion of the reaction (monitoring by TLC), MCM-41@Serine@Cu(II) catalyst was easily separated by filtration, and then the product extracted with ethyl acetate and dried over anhydrous Na2SO4 to give the pure sulfoxide.

2.5 General Procedure for the Synthesis of Polyhydroquinolines

In a typical procedure, a mixture of dimedone (1 mmol), aldehyde (1 mmol), ethyl acetoacetate (1 mmol), ammonium acetate (1.2 mmol) and MCM-41@Serine@Cu(II) catalyst (0.05 g) in ethanol (2 mL) was magnetically stirred in the reaction flask at 80 °C. After completion of the reaction, the catalyst was separated by an external magnet and solvent was evaporated at 50 °C for reuse. Finally, a crude solid was obtained followed by crystallization from ethanol which prepared the pure product with excellent yield.

2.6 General Procedure for the Synthesis of 2,3-Dihydroquinazolin-4(1H)-ones

In order to illustrate the catalytic activity of MCM-41@Serine@Cu(II) in the synthesis of 2,3-dihydroquinazolin-4(1H)-ones, a mixture of aldehyde (1 mmol), 2-aminobenzamide (1 mmol) and catalyst (0.009 g) in ethanol (2 mL) was magnetically stirred in the reaction flask at room temperature. After the completion of the reaction indicated by TLC, the catalyst was separated by an external magnet and solvent was evaporated at 70 °C for reuse. Finally, a crude solid was obtained followed by crystallization from hot ethanol which prepared the pure product with excellent yield.

2.7 Selected Spectral Data

2.7.1 Methyl Phenyl Sulfoxide

1H NMR (400 MHz, CDCl 3 ): δH = 2.75 (s, 3H), 7.52–7.62 (m, 2H), 7.66–7.69 (m, 3H) ppm.

2.7.2 Dodecyl Methyl Sulfoxide

1H NMR (400 MHz, DMSO):δH = 0.87 (t, J = 6.8, 3H), 1.26–1.71 (m, 20H), 2.58(s, 3H), 3.09 (t, J = 8, 2H) ppm.

2.7.3 Dibenzyl Sulfoxide

1H NMR (400 MHz, CDCl 3 ): δH = 3.90 (d, 2H, J = 12.8 Hz), 3.95 (d, 2H, J = 12.8 Hz), 7.29–7.43 (m, 10H) ppm.

2.7.4 2,20-Dimethoxy Diphenyl Sulfide

1H NMR (400 MHz, DMSO): δH = 6.96–7.36 (m, 8H), 3.82 (s, 6H) ppm.

2.7.5 Diphenyl Sulfide

1H NMR (400 MHz, DMSO): δH = 6.30–7.34 (m, 6H), 7.37–7.46 (m, 4H) ppm.

2.7.6 Ethyl-4-(3,4-dimethoxyphenyl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate

1H NMR (400 MHz, DMSO): δH = 9.05 (s, 1H), 6.79–6.76 (m, 2H), 6.65–6.63 (d, J = 8, 1H), 4.80 (s, 1H), 4.04–3.99 (q, J = 7.2, 2H), 3.69–3.68 (d, J = 4.4, 5H), 2.47–2.42 (d, J = 17.2, 2H), 2.35–2.27 (m, 4H), 2.22–2.18 (d, J = 16, 1H), 2.03–1.99 (d, J = 16, 1H), 1.20–1.16 (t, J = 6.8, 3H), 1.03 (s, 3H), 0.90 (s, 3H) ppm.

2.7.7 Ethyl-4-(4-methoxyphenyl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3-carboxylate

1H NMR (400 MHz, DMSO): δH = 9.04 (s, 1H), 7.08–7.06 (d, J = 8.4, 2H), 6.77–6.75 (d, J = 8.4, 2H), 4.80 (s, 1H), 4.02–3.96 (q, J = 7.2, 2H), 3.69 (s, 3H), 2.52–2.45 (d, J = 29.2, 1H), 2.31–2.29 (m, 4H), 2.20–2.16 (d, J = 16, 1H), 2.01–1.97 (d, J = 16.4, 1H), 1.17–1.14 (t, J = 7.2, 3H), 1.02 (s, 3H), 0.87 (s, 3H).

3 Result and Discussion

3.1 Catalyst Preparation

Immobilized serine ligand on mesostructured MCM-41(MCM-41@Serine) was successfully synthesized by using the surface modification strategy as depicted in Scheme 1. The MCM-41 nanoparticles are initially prepared according to a previous report by Hajjami et al. [43] and coated with serine ligand by using stable interaction between the carboxylic groups of serine ligand and the hydroxyl groups on MCM-41 surface. Finally, the reaction of MCM-41@Serine with Cu(NO3)2·3H2O in ethanol under reflux for 16 h led to generation of immobilized serine copper(II) complex on MCM-41 nanoparticles (MCM-41@Serine@Cu(II)).

3.2 Catalyst Characterization

After successful synthesis of a new highly efficient catalyst system by the immobilization of copper complex on the surface of MCM-41 mesoporous via coordination bonding through hydroxyl group interaction (Scheme 1), the prepared catalyst has been characterized by FT-IR, XRD, TEM, SEM, TGA, EDX, ICP and BET techniques.

Figure 1a, b show the FESEM images of the MCM-41 and MCM-41@Serine@Cu(II) catalyst for investigation of the surface morphology of the obtained nanostructure. According to the SEM image, nanoparticles were made up of quite homogeneous and uniform spherical particles and no significant changes in the morphology occurred after anchoring of copper complex onto the surface of mesoporous MCM-41 silica.

As seen in Fig. 2, the XRD analysis patterns of the MCM-41, MCM-41@Serine and MCM-41@Serine@Cu(II) were recorded by powder XRD. According to the XRD pattern of MCM-41, a single intense peak and two weak peaks indicated which can be corresponds to (1 0 0), (1 1 0) and (2 0 0) reflections, respectively. These spectra reflect hexagonal mesoporous structure of MCM-41. More importantly, after post-synthetic grafting, an overall decrease in diffraction (100) in all samples is indicated which is due to the difference in the scattering contrast of the pores and the walls of nano-channels of MCM-41 [44]. As shown in powder XRD patterns of MCM-41@Serine and MCM-41@Serine@Cu(II), the absence of (110) and (200) reflections was also noticed that similar type of behavior was observed by Joseph et al. [45].

Figure 3 shows the quantitative determination of the organic groups supported on the surface of MCM-41 nanostructure by TGA. According to the TGA results, all samples indicated the small amount of weight loss below 200 °C that is due to removal of the adsorbed water as well as dehydration of the surface OH groups. The 60% mass loss at temperatures in the range of 200–500 °C is chiefly due to the decomposition of the organic layers on the surface of the synthesized mesoporous silica MCM-41 nanoparticles [46]. It should be noted that the good grafting of nanocatalyst onto the surface of magnetic nanoparticles is verified on the basis of the results obtained from the TGA curves.

Figure 4 shows the FT-IR spectra of MCM-41, MCM-41@Serine and MCM-41@Serine@Cu(II). According to the FT-IR results, the spectrum of MCM-41 shows a band at 476 cm−1 which is attributed to the Si–O bending vibration. Furthermore, absorption peaks appearing at around 1100–1200 and 3000–3600 cm−1 are due to Si–O–Si asymmetric stretching and the silanol OH groups, respectively. Also, the absorption peaks at approximately 2890–3000 cm−1 (C–H stretching vibration) and 1394 cm−1 (C–N stretching vibration) in the MCM-41@Serine spectra are due to the existence of serine ligand on the surface of nanoparticles. The FT-IR spectrum of MCM-41@Serine@Cu(II) shows absorption bands at approximately around 1100–1200 cm−1 (Si–O–Si asymmetric stretching), 3000–3600 cm−1 (silanol OH groups) and 475 cm−1 (Si–O bending vibration). Therefore, the FT-IR spectra of MCM-41@Serine@Cu(II) was indicated that the MCM-41 phase has not been destroyed during the modifications.

As shown in Fig. 5, the structural and textural properties of MCM-41 and MCM-41@Serine@Cu(II) were investigated through the N2-adsorption and desorption isotherms results. The BET analysis (Table 1) shows the surface area of 1113.7 and 216.74 for MCM-41 and MCM-41@Serine@Cu(II), respectively. According to these results, pore volume and pore size distributions of MCM-41@Serine@Cu(II) are lower than MCM-41. We can conclude that copper serine complex was successfully supported on MCM-41 mesoporous silica.

TEM image of the MCM-41@Serine@Cu(II) catalyst at different magnifications is depicted in Fig. 6. As shown in Fig. 6, MCM-41@Serine@Cu(II) was made up of quite homogeneous and uniform spherical particles and no significant changes in the morphology occurred upon the insertion of copper complex group onto MCM-41.

Immobilization of Cu complex on mesoporous MCM-41 was confirmed through presence of Cu, N, O, C, Si species in the energy-dispersive X-ray spectroscopy (EDX) analysis of this synthesized nanocatalyst (Fig. 7). Also, the exact amount of Cu loaded on surface of modified mesoporous silica is found to be 0.51 mmol g−1 using the ICP atomic emission spectroscopy technique.

3.3 Catalytic Studies

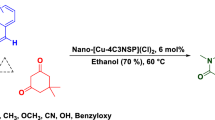

After synthesis and characterization of the catalyst, we were interested in investigation of catalytic activity in the synthesis of sulfide (Scheme 2), sulfoxide (Scheme 3), PHQ (Scheme 4) and 2,3-dihydroquinazolin-4(1H)-one (Scheme 5) derivatives using MCM-41@Serine@Cu(II) as a highly efficient and recoverable heterogeneous nanocatalyst. In order to investigate the possibility of the synthesis of sulfides using the obtained catalyst, the reaction of iodobenzene (1 mmol), KOH and thiourea (1 mmol) was selected as a model reaction. Then, influence of solvent, temperature, amount of catalyst and the type of base on the outcome of reaction has been investigated (Table 2). As shown in Table 2, the type of base, the nature of the solvent and temperature have a profound effect on both the activity of the catalyst and the yield of product. These results indicate that the best conditions were obtained in DMSO at 130 °C in the presence of 0.08 g of catalyst.

After optimization of the reaction parameters, a variety of aromatic halides were employed as substrates for the synthesis of sulfides derivatives in the presence of MCM-41@Serine@Cu(II) for the appropriate time in moderate to good yields. The results of this study are summarized in Table 3.

After successful synthesis of sulfides derivatives, a plausible reaction mechanism for the synthesis of this product is proposed in Scheme 6 [50].

In continuation of this research work, the catalytic activity of MCM-41@Serine@Cu(II) was also investigated in the oxidation of sulfides. In search of the optimized reaction conditions for the synthesis of sulfoxides, the reaction of methylphenylsulfide (1 mmol) with H2O2 in presence of MCM-41@Serine@Cu(II) as catalyst was used as a model reaction. As shown in Table 4, the solvent-free condition in the presence of MCM-41@Serine@Cu(II) (0.005 g) and H2O2 (0.5 mL) at room temperature was found to be ideal reaction conditions for the conversion of methyl phenyl sulfide to the methyl phenyl sulfoxide.

Then, under the optimized reaction conditions, a variety of sulfides with different functional groups were successfully tested to prepare the corresponding sulfoxides. As shown in Table 5, the products were obtained in high to excellent yields in a short reaction time.

A plausible reaction mechanism for the oxidation of sulfides is shown in Scheme 7. The intermediate A is obtained by reaction of H2O2 with MCM-41@Serine@Cu(II), which is converted to active oxidant B. Then, nucleophilic attack of the sulfide on this intermediate (C) produces corresponding sulfoxide [52].

We finally investigated the possibility of the synthesis of PHQ derivatives using the obtained catalyst. Initially, in order to optimize the reaction conditions, we investigated the reaction of 4-chlorobenzaldehyde (1 mmol), dimedone (1 mmol), ethyl acetoacetate (1 mmol) and ammonium acetate (1.2 mmol) in the presence of the MCM-41@Serine@Cu(II) under the effect of various parameters such as solvent, catalyst concentration and temperature. The results of this study can be seen in Table 6. As shown in Table 1, the best conditions were obtained in EtOH at 120 °C with in the presence of 0.05 g of catalyst.

In order to generalize the scope of the reaction under the optimized conditions, a series of substituted benzaldehydes were chosen for the synthesis of PHQ, with the results presented in Table 7.

On the basis of the literatures, a plausible reaction mechanism for the synthesis of PHQ derivatives in the presence of MCM-41@Serine@Cu(II) as catalyst is shown in Scheme 8. It should be noted that the role of catalyst comes in the Knoevenagel coupling of aldehydes with active methylene compounds to produce an α, β-unsaturated compound and in the Michael addition of intermediates to obtain the PHQ [52].

Finally, in view of the importance of 2,3-dihydroquinazolin-4(1H)-ones, we turned our attention towards the synthesis of 2,3-dihydroquinazolin-4(1H)-ones derivatives in high efficiency in the presence of MCM-41@Serine@Cu(II) as catalyst. In search of the optimized reaction conditions for the synthesis of 2,3-dihydroquinazolin-4(1H)-ones, the condensation of 4-chlorobenzaldehyde (1 mmol) with 2-aminobenzamide in presence of MCM-41@Serine@Cu(II) as catalyst was used as a model reaction. In order to optimize the reaction conditions, the effects of solvent and catalyst concentration were investigated for the model reaction. It can be seen that the best results were obtained in EtOH in the presence of 0.008 g of catalyst at room temperature. Our observations are summarized in Table 8.

It can be seen that a variety of aromatic aldehydes bearing electron-donating and electron-withdrawing substituents were successfully employed to prepare the corresponding 2,3-dihydroquinazolin-4(1H)-ones derivatives and it was observed that good to excellent yields of desired products were obtained (Table 9).

It can be seen that the following mechanism (Scheme 9) has been suggested for described catalytic system. Initially, anhydride is activated and then, an intermediate (A) is formed by the N-nucleophilic attacks of amine on the carbonyl. As shown in this scheme, the imine intermediate B is obtained. Subsequently, after activation of imine in this intermediate by metal, intermediate C could be generated by intramolecular nucleophilic attack of the amide nitrogen on activated imine group. Finally, 1,5-proton transfer occurred to yield the final product [54].

3.4 Reusability of the Catalyst

Notably, according to the green chemistry viewpoint, the recovery and reusability of catalyst is an outstanding issue in modern catalysis researches. After the completion of the reaction, the catalyst was recycled by filtration and washed with ethyl acetate, and then dried for the next run without considerable decrease of its catalytic activity (Fig. 8). This observation can describe the practical recyclability of this catalyst.

Then, the remaining catalyst was also used under the same experimental reaction conditions. Figure 9 shows the yield of several consecutive cycles for the preparation of methyl phenyl sulfoxide (a), 2-(4-chlorophenyl)-2,3-dihydroquinazolin-4(1H)-one (b), ethyl-4-(4-chlorophenyl)-2,7,7-trimethyl-5-oxo-1,4,5,6,7,8-hexahydroquinoline-3 carboxylate (c) and diphenyl sulfide (d).

3.5 Catalyst Leaching Study

In this research, we also report amounts of copper leaching in the synthesis of methylphenyl sulfoxide by checking the copper loading amount before and after recycling of the catalyst by ICP-OEIS technique. It can be seen that the amount of copper in fresh catalyst and the recycled catalyst after 11 times recycling is 0.51 and 0.45 mmol g−1, respectively, which indicated that copper leaching of this catalyst is very low. In order to perform hot filtration experiment, two reactions for the synthesis of methylphenyl sulfoxide has been investigated under optimized reaction conditions. In the first reaction, we found the yield of product under optimized conditions in half time of the reaction that it was 67%. Simultaneously in second reaction, the same reaction was repeated, but in the half time of the reaction, the catalyst was separated from the reaction mixture by filtration process and allowed to react further under identical reaction conditions. It is worth noting that the yield of reaction in this stage was 69% that confirmed the leaching of copper hasn’t been occurred.

3.6 Comparison of the Catalyst

In order to examine the efficiency of these procedures, we compared the results for the oxidation of sulfides in the presence of our catalyst with previously reported catalysts in the literature. It can be seen in Table 10 that the present catalyst showed shorter reaction times and better yields than the other catalysts. Noticeably, this new catalyst is comparable in terms of price, non-toxicity, ease of operation, commercially available materials, stability, and easy separation.

4 Conclusions

In conclusion, a novel and efficient heterogeneous catalyst (MCM-41@Serine@Cu(II)) was synthesized by anchoring copper on the surface of organically modified MCM-41 mesoporous nanoparticles. In the next step, this nanohybrid was carefully characterized by FT-IR, XRD, TGA, TEM, BET, SEM, EDX and ICP-OES techniques. More importantly, high surface area, the use of a commercially available, eco-friendly, low cost, chemically stable reagents, easy separation of the catalyst by simple filtration, good reaction times, high efficiency, operational simplicity, convenient recovery and ease of use all make Cu(II) immobilized on MCM-41@Serine a promising candidate for potential applications in the synthesis of PHQ, 2,3-dihydroquinazolin-4(1H)-one, sulfide and sulfoxide derivatives.

Change history

03 June 2019

An error appeared in our paper entitled ���Synthesis of Polyhydroquinoline, 2,3-Dihydroquinazolin-4(1H)-one, Sulfide and Sulfoxide Derivatives Catalyzed by New Copper Complex Supported on MCM-41��� published in Catalysis Letters. We used the wrong version of Fig. 3 in the article. The corrected Fig. 3 is shown below.

03 June 2019

An error appeared in our paper entitled ���Synthesis of Polyhydroquinoline, 2,3-Dihydroquinazolin-4(1H)-one, Sulfide and Sulfoxide Derivatives Catalyzed by New Copper Complex Supported on MCM-41��� published in Catalysis Letters. We used the wrong version of Fig. 3 in the article. The corrected Fig. 3 is shown below.

References

Liu G, Link JT, Pei ZH (2000) J Med Chem 43:4025

Rostami A, Rostami A, Iranpoor N, Zolfigol MA (2016) Tetrahedron Lett 57:192

Wang Y, Chang W, Greenlee VR (2001) Bioorg Med Chem Lett 11:891

Brigg S, Pribut N, Basson AE, Avgenikos M, Venter R, Blackie MA, van Otterlo WAL, Pelly SC (2016) Bioorg Med Chem Lett 26:1580

Alcaraz ML, Atkinson S, Cornwall P (2005) Org Process Res Dev 9:555

Nielsen SF, Nielsen E, Olsen GM (2000) J Med Chem 43:2217

Mori T, Nishimura T, Yamamoto T, Doi I, Miyazaki E, Osaka L, Takimiya K (2013) J Am Chem Soc 135:13900

Liu G, Huth JR, Olejniczak ET (2001) J Med Chem 44:1202

Okamoto T, Mitsui C, Yamagishi M, Nakahara K, Soeda J, Hirose Y, Miva K, Sato H, Yamano A, Matsushita T, Uemura T, Takeye j (2013) Adv Mater 25:6392

Gao J, Lu L, Zhou W, Gao G, He M (2008) J Porous Mater 15:127

Fernandez I, Khiar N (2003) Chem Rev 103:3651

Darabi M, Tamoradi T, Ghadermazi M, Ghorbani-Choghamarani A (2017) Transit Met Chem 42:703

Rezaeifard A, Jafarpour M, Raissi H, Ghiamati E, Tootoonchi A (2011) Polyhedron 30:592

Kazemi M, Shiri L (2015) J Sulfur Chem 36:613

Jeon HB, Kim KT, Kim SH (2014) Tetrahedron Lett 55:3905

Khanmoradi M, Nikoorazm M, Ghorbani–Choghamarani A (2017) Appl Organomet Chem. https://doi.org/10.1002/aoc.3693

Shiri L, Ghorbani-Choghamarani A, Kazemi M (2017) Res Chem Intermed 43:2707

Behroozi SJ, Kim W, Gates KS (1995) J Org Chem 60:3964

Ghorbani-Choghamarani A, Zamani P (2011) J Iran Chem Soc 8:142

Tajbakhsh M, Alinezhad H, Norouzi M, Baghery S, Akbari M (2013) J Mol Liq 177:44

Vahdat SM, Chekin F, Hatami M, Khavarpour M, Baghery S, Roshan-Kouhi Z Chin J Catal 34:758

Saikia L, Dutta D, Kumar Dutta D (2012) Catal Commun 19:1

Vahdat SM, Chekin F, Hatami M, Khavarpour M, Baghery S, Roshan-Kouhi Z (2013) Chin J Catal 34:758

Nasr-Esfahani M, Hoseini SJ, Montazerozohori M, Mehrabi R, Nasrabadi H (2014) J Mol Catal A 382:99

Baghbanian SM, Khaksar S, Vahdat SM, Farhang M, Tajbakhsh M (2010) Chin Chem Lett 21:563

Hajjami M, Tahmasbi B (2015) New J Chem 5:59194

Karimi-Jaberi Z, Zarei L, Afr S (2012) J Chem 65:36

Hajjami M, Ghorbani-Choghamarani A, Yousofvand Z, Norouzi M (2015) J Chem Sci 127:1221

Ghorbani-Choghamarani A, Taherinia Z (2016) RSC Adv 6:59410

Tajbakhsh M, Alaee E, Alinezhad H, khanian M, Jahani F, Khaksar S, Rezaee P (2012) Chin J Catal 33:1517

Li B, Liu AH, He LN, Yang ZZ, Gao J, Chen KH (2012) Green Chem 14:130

Nikoorazm M, Ghorbani-Choghamarani A, Jabbari A (2016) J Porous Mater 23:967

Bagherzadeh M, Zare M (2011) J Sulfur Chem 32:335

Davarpanah J, Kiasat AR (2014) Catal Commun 46:75

Weissbach H, Etienne F, Hoshi T, Heinemann SH, Lowther WT, Matthews B, Johne GS, Nathane C, Brote N (2002) Arch Biochem Biophys 397:172

Noori N, Nikoorazm M, Ghorbani-Choghamarani A (2017) Catal Lett 147:204

Nikoorazm M, Ghorbani-Choghamarani A, Noori N (2015) J Porous Mater 22:877

Kiasat AR, Davarpanah J (2015) Catal Commun 69:179

Hajipour AR, Mostafavi M, Ruoho AE (2009) Sulfur Silicon Relat Elem 184:1920

Zhao H, He W, Yao R, Cai M (2014) Adv Synth Catal 356:3092

Cai M, Yao R, Chen L, Zhao H (2014) J Mol Catal A 395:349

Zhao H, He W, Wei L, Cai M (2016) Catal Sci Technol 6:1488

Hajjami M, Rahmani S (2015) J Porous Mater 22:1265

Noori N, Nikoorazm M, Ghorbani-Choghamarani A (2016) Microporous Mesoporous Mater 234:166

Joseph T, Hartman M, Ernst S, Halligudi SB (2004) J Mol Catal A 207:131

Khanmoradi M, Nikoorazm M, Ghorbani‑Choghamarani A (2017) Catal Lett 147:1114

Zhao P, Yin H, Gao H, Xi C (2013) J Org Chem 78:5001

Zhou Y (2016) J Chem Res 40:305

Mackl BH, Mayrick RG (1962) Trans Faraday Soc 58:238–243

Azadi G, Taherinia Z, Naghipour A, Ghorbani-Choghamarani A (2017) J Sulfur Chem. https://doi.org/10.1080/17415993.2017.1287265

Tamoradi T, Ghorbani-Choghamarani A, Ghadermazi M (2017) New J Chem 41:11714

Tamoradi T, Ghadermazi M, Ghorbani-Choghamarani A (2018) Appl Organomet Chem. https://doi.org/10.1002/aoc.3974

Hajjami M, Ghorbani F, Yousofvand Z (2017) Appl Organomet Chem. https://doi.org/10.1002/aoc.3843

Nikoorazm M, Ghorbani-Choghamarani A, Khanmoradi M (2016) RSC Adv 6:56549

Nikoorazm M, Ghorbani-Choghamarani A, Noori N (2015) Appl Organomet Chem 29:328

Hussain S, Talukdar D, Bharadwaj SK, Chaudhuri MK (2012) Tetrahedron Lett 53:6512

Nikoorazm M, Ghorbani-Choghamarani A, Mahdavi H, Esmaeili SM (2015) Microporous Mesoporous Mater 211:174

Nikoorazm M, Ghorbani-Choghamarani A, Khanmoradi M (2016) Appl Organomet Chem 30:236

Patra AK, Dutta A, Pramanik M, Nandi M, Uyama H, Bhaumik A (2014) ChemCatChem 6:220

Acknowledgements

We gratefully acknowledge the support of this work by University of Kurdistan and University of Ilam.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tamoradi, T., Ghadermazi, M. & Ghorbani-Choghamarani, A. Synthesis of Polyhydroquinoline, 2,3-Dihydroquinazolin-4(1H)-one, Sulfide and Sulfoxide Derivatives Catalyzed by New Copper Complex Supported on MCM-41. Catal Lett 148, 857–872 (2018). https://doi.org/10.1007/s10562-018-2311-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-018-2311-x