Abstract

The rapidly growing population increases the consumption of food, consequently raising the demand for packaging materials that ensure safety from contamination and have a prolonged shelf life. Fruit and vegetable products, which are rich in nutrients, can suffer from post-harvest deterioration, but these issues can be mitigated with effective packaging. However, most packaging materials for fruits and vegetables are made of plastic, which often becomes a pollutant after initial use. The disposal of plastic packaging is challenging and poses significant environmental harm. Therefore, it is essential to develop food packaging materials made from more suitable and environmentally friendly substances, such as biodegradable or natural polymers. The study aimed to synthesize biopolymer nanocomposite films using chitosan a natural polymer, combined with zinc oxide nanoparticles (ZnO NPs) and orange peel powder (OPP) to produce a reliable and biodegradable packaging material. Nanoscale ZnO was already recognised as “generally recognised as safe” for use in polymeric films. OPP, in addition to being a promising organic filler candidate, offers several advantages like it improve the photodegradability, polymer matrix’s, recyclable eminence, and ecological and economical sustainability. The structural features of the fine ZnO, OPP, and biopolymer nanocomposite films were assessed using X-ray diffraction analysis Fourier-transform infrared spectroscopy (FTIR) was used to identify the presence of various functional groups in ZnO, OPP, and the formulated biopolymer nanocomposite films. We also reported the thickness, mechanical properties, water absorption capacity, stability at room temperature, and biodegradation tests of the optimized OPP@CS-ZnO-based biopolymer nanocomposite films. This biopolymer nanocomposite film can be effectively utilized for the packaging of fruit- and vegetable-based products. Additionally, it ensures that such novel materials are suitable for food packaging, minimizes the use of plastic, and contributes to an eco-friendly environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid population growth has increased the demand for fresh food. Fruits and vegetables, which have a short shelf life, require effective packaging to maintain their nutrient content and extend preservation (Park et al. 2002; Pandey et al. 2023; Yadav et al. 2024). Food packaging plays a crucial role in modern food industries, serving multiple functions such as regulation, safety, portability, and product preservation (Ozdemir and Floros 2004; Basavegowda and Baek 2021). To meet global food packaging needs, materials like paperboard, metal, paper, plastic, and glass are used, with plastics being common for their advanced properties. However, plastic waste’s environmental impact raises concerns about waste accumulation, health, and recycling challenges (Surana et al. 2024). Environmental concerns and resource depletion from non-biodegradable plastics are driving the shift to renewable, biodegradable polymers for disposable items (Seligra et al. 2016; Medina-Jaramillo et al. 2017; Mallick et al. 2020b). Unique edible and biodegradable films aim to reduce plastic waste but struggle with strength and processability. To solve this issue, biopolymer nanocomposites offer enhanced properties as a solution (Othman 2014; Medina-Jaramillo et al. 2017; Mallick et al. 2020a; Li et al. 2021).

Chitosan (CS) is valued for its unique properties, safety, and adaptability, making it useful in medicine, tissue engineering, food packaging, and wound dressings. Its molecules contain both hydrophobic and hydrophilic components, enhancing its role as an emulsifier in food applications (Azmana et al. 2021; Stoleru et al. 2021; Jurić et al. 2023). CS has poor solubility and insufficient strength for heavy materials. Ivankovic and team found CS with 38.2 MPa tensile strength and 17% elongation ideal for sustainable food packaging films (Ivanković et al. 2017). To enhance the functional properties of CS films, using fillers is a highly preferred technique, with the incorporation of nanosized materials being extensively studied.

The application of cutting-edge materials in biodegradable polymeric packaging is remarkable. In this context, zinc oxide nanoparticles (ZnO NPs) offer significant advantages by enhancing biopolymer materials with non-toxicity, stability, and antimicrobial properties (Pattanayak et al. 2020, 2022; Nautiyal et al. 2022). ZnO NPs enhance biopolymer packaging by strongly bonding with biopolymer molecules, improving physical properties significantly with minimal quantities. In the biopolymeric packaging material, hydrogen and ionic bonds boost mechanical properties (Asiri and Lichtfouse 2019; Cui et al. 2021). The performance of CS films has improved as a result of the incorporation of ZnO NPs.

Orange peel powder (OPP) is a byproduct of oranges used to strengthen biopolymeric composites. It is biodegradable, cheap, and eco-friendly, improving composite properties while recycling waste (Mamman and Ramalan 2020; Wu et al. 2022; Upadhyay et al. 2024). Using OPP filler improves biopolymeric composites properties and supports sustainability. Terzioglu and team used chitosan/polyvinyl alcohol with orange peel (0.25–1.25 wt%), finding that even small amounts of orange peel enhance performance (Terzioğlu et al. 2021). Additionally, OPP has the potential to enhance the photodegradable and recyclable qualities of the polymer matrix (Fehlberg et al. 2020).

This study developed a unique biopolymer composite (OPP@CS–ZnO) for food packaging by synthesizing ZnO NPs and preparation of OPP, then combining them with CS. The composite and associated materials are analysed using X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR). Various tests assess the films’ properties, including mechanical strength, water absorption, thickness, stability at room temperature, and biodegradability through soil burial. These evaluations help determine the composite’s effectiveness for fruit- and vegetable-based packaging and its environmental impact.

Materials and methods

Materials

Zinc sulfate (ZnSO4.7H2O, 99% pure) was purchased from Loba Chemie Pvt. Ltd. in India. Sodium hydroxide (NaOH, 97.5% pure) pallets were obtained from Fisher Scientific India. Acetic acid (AA) glacial (99% pure) was acquired from FINAR, India. Loba Chemie Pvt. Ltd., India, supplied CS (75% deacetylated shrimp shells). Ethyl alcohol (C2H5OH, 99% pure) was received from Changshu Hongsheng Fine Chemical Co. Ltd., India. Whatman No. 42 filter paper was purchased from Global Life Sciences Solutions India. The pH of the solution was measured by the digital pH meter 335, manufactured by Systronics.

Analytical characterizations

The materials’ crystal structure and nature were determined using a PAN analytical powder X-ray diffraction (XRD) diffractometer with CuK radiation. The scanning was done in the 2θ range of 10°–80°. Further analysis of the raw data was conducted using ORIGIN Pro 2019b. The bond vibrational frequencies and distinct functional groups included in the synthesized film were estimated using FTIR (Perkin Elmer). The tensile strength and percentage of elongation at break of the OPP@CS–ZnO films were measured using a computerized universal testing machine with the ASTMD 638 method. The thickness of the films (in µm) was measured with a vernier calliper (Deli Group Co., Ltd., Ningbo, China) with an accuracy of 0.01 mm.

Preparation of ZnO NPs

The synthesis of NPs was carried out using the co-precipitation method, as described in supplementary information (Sect. 1.1, Eq. 1). Two solutions were prepared by dissolving 0.1 M and 0.2 M ZnSO4.7H2O and NaOH in distilled water, yielding 250 ml each. The precursor quantities and the final outcomes are reported in Table 1 of supplementary information, which is highly beneficial for subsequent section assessment. These solutions were added dropwise to 250 ml of distilled water under continuous stirring using a magnetic stirrer (at 500 rpm for 2 h). The dropwise addition ensured proper mixing and reaction between the precursors. After allowing the suspension to settle overnight, it was filtered through Whatman No. 42 filter paper. The pH of the precipitates was adjusted to 7.0 using a washing solution of ethyl alcohol and distilled water. Following filtration and repeated washing, the solid material was oven-dried at 105 °C for 1 h. The resulting dried white precipitates were calcined at 600 °C for 2.5 h. Finally, the obtained white powder was labelled as ZnO NPs for further use.

Preparation of OPP

Orange peels were collected from a local market and properly cleaned with distilled water. Then the orange peels were transferred to the oven for overnight at 115 °C to eliminate the moisture completely. Later on, the dried peels were crushed into a fine powder using a grinder and named OPP for further use.

Preparation of polymer composite film

The preparation of the composite film involved the utilization of CS as a polymer matrix and OPP and ZnO as fillers. The optimization of the quantity of ZnO and OPP in the CS polymer matrix was conducted in three steps. First, only OPP was incorporated into the polymer matrix. Second, the preparation of the film involved utilizing only ZnO in the polymer matrix. In the third step, both ZnO and OPP nanofillers were reinforced into the CS-based polymer matrix to study the synergistic effect of OPP and ZnO on the resulting biopolymer nanocomposite film.

Film preparation with OPP

The purpose of optimizing the amount of OPP is to prepare biopolymer films. In this process, 1 g of CS is mixed with 100 ml of 1% (v/v) AA to create a homogeneous blend. A magnetic stirrer was used at 500 rpm for 3 h to ensure uniform mixing. After this, OPP was added to the CS blend in amounts ranging from 0.1 to 0.6 wt% of the polymer matrix. To fully incorporate the OPP, the mixture was stirred for an additional 3 h at 500 rpm. All these mixtures are labelled as per their differences in weight, such as CS-0.1%OPP, CS-0.2%OPP, CS-0.3%OPP, CS-0.4%OPP, CS-0.5%OPP, and CS-0.6%OPP. The mixture was then allowed to dry overnight after the film was prepared using the casting method. Finally, the petri plates were placed in a hot air oven at 110 °C for an hour to remove any remaining moisture.

Film preparation with ZnO

To prepare a CS matrix-based film reinforced with ZnO, 1 g of CS was dissolved in 100 ml of a 1% (v/v) AA solution. To create a homogeneous blend, a magnetic stirrer was used at 500 rpm for 3 h. After this period, ZnO was introduced into the same blend at different concentrations of 0, 1, 2, and 3wt% (of the CS polymer matrix). This mixture was stirred for an additional 3 h to achieve complete dispersion of ZnO in the CS-based polymer matrix blend. These blends are labelled based on the quantity of ZnO, such as CS-0%ZnO, CS-1%ZnO, CS-2%ZnO, and CS-3%ZnO. Finally, the casting method was applied to prepare the film, and the mixture was allowed to dry overnight. The petri plates were then placed in an oven at 110 °C for an hour to remove any remaining moisture.

Film preparation of combined ZnO and OPP

Mixing CS in its pure form with water and organic solvents is not possible, while it readily dissolves in dilute minerals and organic solvents (Fu and Xiao 2017; George and Ishida 2018). Therefore, film formation was determined using 1 g of CS and 100 ml (1 v/v%) AA, mixed under continuous stirring (500 rpm for 3 h). To prepare the ZnO-incorporated solution, 0, 1, and 2 wt% ZnO (relative to the polymer matrix, CS) were dispersed into three different CS solutions, subjected to continuous stirring for 3 h, followed by 15 min of sonication at 50 °C to ensure proper dispersion. Subsequently, 0.5 wt% (of polymer matrix, CS) OPP was added and mixed for 6 h to achieve a homogeneous blend. The mixture was poured into petri plates and allowed to dry overnight. Finally, the petri plates were placed in the oven at 110 °C for an hour to remove any remaining moisture.

Thickness assessment of biopolymer nanocomposite films

To determine the thickness of the biopolymer films, a digital calliper with a precision of 0.01 mm was utilized. Five readings were obtained at various points on the biopolymer film, with the first point being the centre of the film and the remaining points being selected at various locations. To minimize any potential experimental errors, the results were averaged.

Mechanical strength assessment of biopolymer nanocomposite films

Tensile strength and percentage of elongation at break were determined using a universal testing machine (UTM) that conforms to the ASTMD 882 standards of the “American Society for Testing and Materials”. The crosshead speed was set to 2 mm/min, and the grip had an initial separation of 40 mm. To obtain accurate results, three samples of each OPP@CS–ZnO-based biopolymer nanocomposite were tested, with each sample measuring 1 × 9 cm. The results were subsequently averaged to minimize any potential experimental error (Mallick et al. 2019, 2020c).

Water absorption test of biopolymer nanocomposite films

The water absorption test was performed on completely dried pure CS and various blends of OPP@CS–ZnO biopolymer nanocomposite films. To begin the testing process, the samples were precisely weighed and then immersed in distilled water for 24 h. Subsequently, the samples were taken out of the water, and the extra water on the films’ surfaces was quickly taken down with tissue paper. Finally, the samples were weighed again to determine the amount of water absorbed (Mallick et al. 2019). The same procedure was repeated three times for each blend of pure CS and OPP@CS–ZnO-based biopolymer nanocomposite films to minimize experimental error, and the average result was reported. The water absorption of the films was calculated using Eq. 2 of supplementary information.

Stability and biodegradation test

Stability test

The stability analysis of the prepared biopolymer nanocomposite films using CS, ZnO, and OPP was conducted at normal room temperature. The test sample’s sizes were taken in specific dimensions: length = 20 mm, width = 20 mm, and thickness = 1 mm. Moreover, the shelf-life analysis of the biopolymer nanocomposite films was determined over a duration ranging from 1 to 15 days. During this period, the material was placed in the laboratory environment (room temperature). This analysis was conducted using Eq. 3 from the supplementary information (Sect. 1.3), where the weight difference was the key parameter.

Biodegradation test

To conduct this test, soil was used as a medium for decomposing the biopolymer nanocomposite films. The CS, ZnO, and OPP-derived biopolymer nanocomposite film dimensions, as mentioned in the previous section, were utilized for the biodegradation assessment. The films were placed in a pot at a depth of 5 cm and exposed to environmental conditions for 91 days (thirteen weeks). These samples were periodically removed from the soil, initially on a weekly basis and subsequently at regular intervals for the remaining months. Distilled water was used to wash the samples, removing any dirt from their surfaces, to calculate the weight loss. The weights of the samples were recorded both before and after washing. The weight difference, as per Eq. 4 of supplementary information (Sect. 1.4), was then used to calculate the biodegradation of biopolymer nanocomposite films.

Cost analysis

To synthesize a biopolymer nanocomposite film, several factors affect the cost, such as recipe cost, raw material cost, energy cost, labour cost, and several others (Gkika et al. 2019). However, to predict the cost on a laboratory scale, overall biopolymer composite cost determination is most important. In this study, the raw material cost and synthesis cost of ZnO assessment have been done by utilizing Eqs. 5 and 6 of supplementary information (Sect. 1.5).

Results and discussions

Physical appearance of the biopolymer nanocomposite films

The CS, OPP@CS-0%ZnO, OPP@CS-1%ZnO, and OPP@CS-2%ZnO nanocomposite films exhibited excellent adhesion to glass surfaces and maintained their surface texture when peeled off, as illustrated in supplementary information’s Fig. 1 (Sect. 2.1). This study primarily aimed to evaluate the interfacial adhesion behaviour of the films on substrates and the resulting surface texture of the films after drying.

X-ray diffraction analysis

The nanocrystalline sizes of ZnO and OPP were confirmed using Scherrer’s equation (D = kλ⁄β cosθ), where k is Scherrer’s constant (0.89) and D is the crystalline size in nanometres, λ represents the wavelength value of 0.1555 nm, β is the full width at half-maximum (FWHM), and θ is the angle of instance peak. The FWHM and peak intensity, position, and width can all be estimated from the XRD pattern analysis.

The XRD pattern in Fig. 1a shows that ZnO powder has good crystallinity and a small crystal size, matching the hexagonal wurtzite structure (JCPDS no. 36–1451). The similar-angle XRD spectra peaks and crystalline planes are confirmed by previous studies of ZnO (Sharmila and Tharayil 2014; Krishnan et al. 2020; Roy et al. 2021). The ZnO NPs have a crystalline size of 20.86 nm, calculated from the (101) plane peak at 36.44º using Eq. 7 from the supplementary information. An intense peak at this angle confirmed the size determination.

The XRD pattern of finely crushed OPPs is shown in Fig. 1b, and its crystallographic structure has been discussed, which is also similar to a previous study (Naik et al. 2021). The amorphous nature of carbon atoms creates noise in OPP's XRD pattern (Fig. 1b). Peaks in Fig. 1b mainly result from crystalline cellulose. Other peaks arise from amorphous lignin and hemicellulose. Low-intensity peaks indicate the presence of significant amounts of hemicellulose, amorphous cellulose, pectin, and lignin, reflecting the material’s amorphous nature (Akinhanmi et al. 2020; Guediri et al. 2020). The existence of crystalline cellulose is indicated by the presence of peaks, that is supported by the diffractograms.

Figure 1c shows the XRD analysis of the OPP@CS-ZnO biopolymer nanocomposite. Peaks at 11.74° and 18.89° confirm the presence and crystalline nature of CS in the composite (do Amaral Sobral et al. 2022; Ali et al. 2024). Figure 1d shows the same peaks in all OPP@CS-ZnO nanocomposites. However, adding AA introduces peaks at 44.78°, 65.11°, and 78.33°, indicating AA’s presence (Nogueira et al. 2014). In the OPP@CS-0%ZnO blend, OPP addition is seen at 65.11°, affecting crystallinity. ZnO addition at 44.78° alters the crystallinity of OPP@CS-1%ZnO and OPP@CS-2%ZnO blends compared to CS and OPP@CS-0%ZnO. Despite low filler usage, structural features remain mostly unchanged while functional characteristics improve. The primary crystalline phases of AA and chitosan create characteristic peaks, with minor shifts due to changes in the polymer matrix’s crystalline phase (Abdolrahimi et al. 2018).

Fourier transform-infrared analysis

The FTIR spectra of CS film, OPP, ZnO NPs, OPP@CS-0%ZnO, OPP@CS-1%ZnO, and OPP@CS-2%ZnO films are shown in Fig. 2a–c. The peak at 3600 cm−1 in Fig. 2a represents the -OH stretching vibration and the -NH2 vibration of CS, respectively. The CH2 vibrations and H2O bending mode are represented by the peaks at 2892 cm−1 and 1639 cm−1, respectively. CH2 bending vibrations are represented by the 1430 and 1375 cm−1 peaks. The existence of ZnO stretching mode is indicated by the presence of peaks about 600 cm−1 in Fig. 2b, while all other peaks are due to the presence of soluble starch. Furthermore, the shift of the peak at 1420 and 1085 cm−1 to the lower wavenumber indicated that the aliphatic and CO- groups of OPP were involved in the mixing with polymers, respectively. Finally, with the shift and intensity change at 1025 cm−1, it was possible to identify the contribution of some OPP components as C–O–C stretching of polysaccharides. Figure 2c shows the 0%, 1%, and 2% incorporated ZnO in CS matrix with 0.5% OPP, due to the reaction between the CS amine group and the metal oxide, the N–H bonded to the O–H vibration shifted towards lower frequency from 3600 cm−1 to 3569 cm−1, 3540 cm−1, and 3330 cm−1, respectively, due to its superior performance, the 2% formed ZnO film was determined to be the best. In Fig. 2c, the OPP@CS-2% ZnO nanocomposite film has been moved to 3204 cm−1 to demonstrate that effective bonding has occurred between the metal oxide, CS functional group, and essential group contained in OPP. The interactions are the responsibility of the aforementioned functional groups. These findings demonstrated that CS, ZnO NPs, and OPP were miscible.

Thickness measurement of biopolymer film

The thickness of the biopolymer nanocomposite film is a critical parameter because it can significantly affect the quality of packaged materials, as seen in the supplementary information in Fig. 2a–c. The supplementary information in Fig. 2a (Sect. 2.3) shows that adding even a small amount of OPP to the CS polymer matrix noticeably changes the biopolymer film thickness. Incorporating OPP in CS increases film thickness from 40.12 µm to 41.1 µm as OPP rises from 0.1 wt% to 0.6 wt%. Adding 1 wt% ZnO results in a thickness of 40.8 µm, compared to 40.39 µm for pure CS, and 41.61 µm for 3 wt% ZnO (supplementary information in Fig. 2b). Supplementary information in Fig. 2a and b indicates that the incorporation of both OPP and ZnO contributes to the thickness of biopolymer films. To optimize the composite, 0.5 wt% OPP and varying ZnO from 0 wt% to 2 wt% were used.

The thickness increased from 40.39 to 42.17 μm with the addition of varying amounts of OPP and ZnO, as shown in supplementary information Fig. 2c. The pure CS biopolymer film has the lowest thickness. Adding OPP and ZnO NPs increases thickness by filling gaps and interacting with the matrix. Evenly dispersed NPs (1–100 nm) maximize contact within the film (Sani et al. 2019; Krishnan et al. 2020; Wang et al. 2020). Thickening and suspending agents and interactions between components are the unique compound’s colloidal features, which are responsible for the enhancement in film thickness (Ahmad and Sarbon 2021; Roy et al. 2021). OPP acts as a thickener, increasing film viscosity and filling gaps. ZnO fills voids in the polymer matrix but doesn’t thicken it like OPP.

Mechanical strength analysis of biopolymer nanocomposite films

The mechanical strength of biopolymer nanocomposite film was analysed using tensile strength and elongation at break tests, which are inversely proportional. (Wang et al. 2007). Figure 3a of supplementary information (Sect. 2.4) shows that adding OPP to the CS matrix increases tensile strength from 54.2 MPa to 58.1 MPa as OPP content rises from 0.1 wt% to 0.5 wt%. However, 0.6 wt% OPP does not significantly change the tensile strength compared to 0.5 wt%. The elongation at break test for the OPP and CS-based compositions was highest (4.8%) with 0.1 wt% OPP and decreased with adding more OPP, with no significant difference between 0.5 wt% and 0.6 wt% OPP. Figure 3b of supplementary information shows the effect of ZnO loading (0 wt% to 3 wt%) in the CS-based matrix. Adding 1 wt% ZnO to the CS matrix increased the tensile strength to 56.7 MPa. With 2 wt% and 3 wt% ZnO, tensile strengths were 59.6 MPa and 60.2 MPa, respectively. However, increasing the loading amount of ZnO in the CS polymer matrix reduced elongation at break. The changes in elongation at break were not drastic when loading 2 wt% and 3 wt% ZnO in the CS-based polymer matrix; it is observed that 2 wt% may be the optimized quantity to prepare the OPP@CS-ZnO biopolymer nanocomposite film.

Figure 3c of supplementary information shows that adding ZnO and OPP significantly improves the polymer matrix’s tensile strength and elongation at break. CS film has the lowest tensile strength, while CS with 2 wt% ZnO and 0.5 wt% OPP has the highest. The mechanical strength of the polymer is increased due to the uniform dispersion of OPP and ZnO particles within the CS polymer matrix. This results in a stronger reaction between the CS, OPP, and ZnO, which is facilitated through the formation of ion bonds (Sani et al. 2019; Krishnan et al. 2020). Uniform particle dispersion creates strong bonds between CS, OPP, and ZnO, enhancing the polymer’s mechanical strength (Wang et al. 2020; Ahmad and Sarbon 2021). Figure 3c of supplementary information shows CS film has higher elongation at break than film with 2 wt% ZnO and 0.5 wt% OPP. This difference is due to hydrogen bond interactions between ZnO, OPP, and the CS-based polymer matrix.

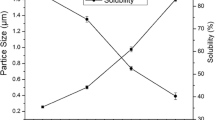

Water absorption of biopolymer film

CS is insoluble in many solvents but swells in water, showing higher water absorption than other films, as illustrated in Fig. 3a–c. CS-based polymer matrix with 0.1 wt% to 0.6 wt% loading of OPP has water absorption rates of 72.01% and 65.12%, respectively (Fig. 3a). Water absorption with 0.5 wt% and 0.6 wt% OPP in CS was 65.15% and 65.12%, respectively, not significantly improving hydrophilicity. Thus, 0.5 wt% OPP is the optimal loading quantity. Similarly, the CS polymer matrix was combined with ZnO from 0 wt% to 3 wt%. Figure 3b shows that pure CS film absorbs 72.57% of its weight in water. Adding ZnO improves hydrophobicity, with 2 wt% and 3 wt% ZnO reducing absorption to 57.88% and 57.84%, respectively. Thus, 2 wt% ZnO is effective for enhancing the hydrophobicity of the composite material.

Figure 3c shows water absorption in CS films decreased from 72.57% to 50.62% as ZnO increased from 0 wt% to 2 wt%, enhancing the water resistance of the biopolymer nanocomposite films. Using 0.5 wt% OPP and 2 wt% ZnO significantly improved properties, and the OPP@CS-2%ZnO composite exhibits enhanced hydrophobicity due to the synergistic effects of both fillers. The observed decrement in water uptake at equilibrium can be attributed to two key factors. Firstly, highly crystalline ZnO exhibits less hydrophilic properties than CS, thereby contributing to a reduction in water uptake (Khan et al. 2012). Secondly, the emergence of the filler and matrix components interact strongly to promote the formation of a more robust composite material, which is less susceptible to water absorption.

Analysis of stability and biodegradation of biopolymer nanocomposite films

The assessment of stability at room temperature and biodegradability of the potentially suitable biopolymer nanocomposite films are discussed in subsequent section.

Stability assessment of biopolymer nanocomposite films

The stability assessment of the pure CS and OPP@CS-ZnO-based biopolymer nanocomposite films are shown in Fig. 4. The shelf life under room temperature conditions was assessed from the preparation day up to 15 days. The weight difference from the preparation day was analysed. The stability of pure CS and OPP@CS-ZnO-based biopolymer nanocomposite depends on several factors, such as dehydration temperature and the presence of degrading chemical and biological compounds in the environment. Studies have reported that CS undergoes dehydration when temperatures exceed 23 °C (Rodrigues et al. 2020). The CS-based biopolymer nanocomposites containing different quantity of ZnO and fixed quantity of OPP are presented in Fig. 4. During dehydration, water bound to the hydrophilic groups of CS molecules is released. The addition of OPP and ZnO does not significantly alter the dehydration temperature of CS molecules. Additionally, environmental gases interact with the biopolymer nanocomposite films, and the release of these molecules contributes to the weight change from the originally preparation biopolymer nanocomposite films. Furthermore, biological compounds present in the environment attack the biopolymer composite material, substantially reducing its weight.

Biodegradation analysis

Nwe and his associates observed that, within a period of 1–7 days, the degradation of CS-based nanocomposites was significantly high. If biopolymer nanocomposite films are prepared using easily biodegradable materials, this result can exceed 60%, but other functional properties will be compromised (Nwe et al. 2020). Organic and inorganic fillers enhance the functional properties of CS-based biopolymer nanocomposite films. Figure 5 shows that during biodegradation, CS films undergo a complex sequence of events leading to the disintegration of polymer chains and the ultimate conversion of these films into more basic substances. Water penetration into the CS layer initiates swelling at the onset of biodegradation, as observed from 7 to 91-day periods, during which degradation is relatively minimal. This hydration process facilitates the diffusion of microorganisms and enzymes into the film matrix. Enzymatic degradation, particularly by enzymes like lysozyme, proteases, and chitosanase, plays a crucial role in breaking down glycosidic linkages in CS.

The suggested mechanism of CS degradation involves depolymerization, the random breakage of β 1,4-glycosidic links, followed by deacetylation, or the hydrolysis of N-acetyl linkage. This leads to a reduction in molecular weight and an increase in the degree of deacetylation. Our findings unequivocally demonstrate that changes in CS have a significant impact on the decomposition of tested materials (Wrońska et al. 2023). The addition of OPP plays a distinct role in degradation due to its similar nature to CS and its inherent hydrophilic properties. While OPP exhibits antimicrobial characteristics, preventing food contamination and deterioration, its resistance to microorganism action in soil-buried conditions extends the duration of degradability. However, the incorporation of ZnO has enhanced the fundamental properties of the films while extending the degradation period. Even a small amount of ZnO makes a noticeable difference in ZnO-based biopolymer films, evident in the reduced rate of degradation.

Cost analysis

The cost assessment is performed in two sections: the first portion contains the cost analysis of the synthesized ZnO NPs, while the second portion covers the cost estimation of an optimized biopolymer nanocomposite film (supplementary information, Eq. 8, Table 2). The cost assessment of the optimized biopolymer nanocomposite film, which includes materials such as ZnO, CS, AA, and OPP, was performed, focusing solely on material costs. The final cost of the optimized biopolymer nanocomposite film, OPP@CS-2%ZnO, is 29.6317 INR. This cost estimation is detailed in Eq. 9 and Table 2 of the supplementary information.

Conclusion

The successful formulation of biopolymer nanocomposite films involves incorporating ZnO NPs and OPP into the CS matrix. The properties of the OPP@CS-ZnO biopolymer nanocomposite films were thoroughly investigated, and the findings were properly analysed. The crystalline ZnO NPs, with an average size of 20.86 nm, and amorphous OPP were uniformly distributed throughout the CS-based polymer matrix. The production of ZnO NPs, OPP, and OPP@CS-ZnO-based biopolymer nanocomposite films was confirmed through XRD and FTIR analysis. The FTIR spectra indicated the formation of new bonds between OPP, CS, and ZnO NPs. The ZnO NPs and OPP significantly influenced the fundamental properties of the OPP@CS-ZnO biopolymer nanocomposite films. The optimized differently loaded amounts of ZnO NPs (0–2 wt%) and fixed loading quantity of OPP (0.5 wt%) were mixed with the CS matrix to produce the films: OPP@CS-0%ZnO, OPP@CS-1%ZnO, and OPP@CS-2%ZnO. Among these biopolymer nanocomposite blends, OPP@CS-2%ZnO exhibited highly improved properties in terms of mechanical strength, film thickness, and stability at room temperature, along with low water absorption, and a slower rate of degradation. Consequently, OPP@CS-2%ZnO outperformed other biopolymer-based films in terms of essential properties. The optimized biopolymer nanocomposite film can be prominently utilized in the food packaging sector, especially for fruits and vegetables.

References

Abdolrahimi, M., Seifi, M., Ramezanzadeh, M.H.: Study the effect of acetic acid on structural, optical and mechanical properties of PVA/chitosan/MWCNT films. Chinese J. Phys. 56, 221–230 (2018). https://doi.org/10.1016/j.cjph.2017.12.018

Ahmad, A.A., Sarbon, N.M.: A comparative study: physical, mechanical and antibacterial properties of bio-composite gelatin films as influenced by chitosan and zinc oxide nanoparticles incorporation. Food Biosci. 43, 101250 (2021). https://doi.org/10.1016/j.fbio.2021.101250

Akinhanmi, T.F., Ofudje, E.A., Adeogun, A.I., et al.: Orange peel as low-cost adsorbent in the elimination of Cd(II) ion: kinetics, isotherm, thermodynamic and optimization evaluations. Bioresour Bioprocess (2020). https://doi.org/10.1186/s40643-020-00320-y

Ali, S.A., Ali, E.S., Hamdy, G., et al.: Enhancing physical characteristics and antibacterial efficacy of chitosan through investigation of microwave-assisted chemically formulated chitosan-coated ZnO and chitosan/ZnO physical composite. Sci. Rep. 14, 1–11 (2024). https://doi.org/10.1038/s41598-024-58862-6

Asiri AM, Lichtfouse E (2019) Nanophotocatalysis and Environmental Applications Detoxi cation and Disinfection

Azmana, M., Mahmood, S., Hilles, A.R., et al.: A review on chitosan and chitosan-based bionanocomposites: promising material for combatting global issues and its applications. Int. J. Biol. Macromol. 185, 832–848 (2021). https://doi.org/10.1016/j.ijbiomac.2021.07.023

Basavegowda, N., Baek, K.H.: Synergistic antioxidant and antibacterial advantages of essential oils for food packaging applications. Biomolecules (2021). https://doi.org/10.3390/biom11091267

Cui, R., Fan, C., Dong, X., et al.: Effect of ultrahigh-pressure treatment on the functional properties of poly(lactic acid)/ZnO nanocomposite food packaging film. J. Sci. Food Agric. 101, 4925–4933 (2021). https://doi.org/10.1002/jsfa.11136

Do Amaral Sobral, P.J., Gebremariam, G., Drudi, F., et al.: Rheological and viscoelastic properties of chitosan solutions prepared with different chitosan or acetic acid concentrations. Foods (2022). https://doi.org/10.3390/foods11172692

Fehlberg, J., Lee, C.L., Matuana, L.M., Almenar, E.: Orange peel waste from juicing as raw material for plastic composites intended for use in food packaging. J. Appl. Polym. Sci. 137, 1–12 (2020). https://doi.org/10.1002/app.48841

Fu, Y., Xiao, C.: A facile physical approach to make chitosan soluble in acid-free water. Int. J. Biol. Macromol. 103, 575–580 (2017). https://doi.org/10.1016/j.ijbiomac.2017.05.066

George, J., Ishida, H.: A review on the very high nanofiller-content nanocomposites: their preparation methods and properties with high aspect ratio fillers. Prog. Polym. Sci. 86, 1–39 (2018). https://doi.org/10.1016/j.progpolymsci.2018.07.006

Gkika, D., Liakos, E.V., Vordos, N., et al.: Cost estimation of polymeric adsorbents. Polymers (basel) (2019). https://doi.org/10.3390/polym11050925

Guediri, A., Bouguettoucha, A., Chebli, D., et al.: Molecular dynamic simulation and DFT computational studies on the adsorption performances of methylene blue in aqueous solutions by orange peel-modified phosphoric acid. J. Mol. Struct. 1202, 127290 (2020). https://doi.org/10.1016/j.molstruc.2019.127290

Ivanković, A., Zeljko, K., Talić, S., Martinović Bevanda, A.: Biodegradable packaging in the food industry. ResearchGate (2017). https://doi.org/10.2376/0003-925X-68-26

Jurić, S., Bureš, M.S., Vlahoviček-Kahlina, K., et al.: Chitosan-based layer-by-layer edible coatings application for the preservation of mandarin fruit bioactive compounds and organic acids. Food Chem. X. 17, 3 (2023). https://doi.org/10.1016/j.fochx.2023.100575

Khan, A., Khan, R.A., Salmieri, S., et al.: Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr. Polym. 90, 1601–1608 (2012). https://doi.org/10.1016/j.carbpol.2012.07.037

Krishnan, R.A., Mhatre, O., Sheth, J., et al.: Synthesis of zinc oxide nanostructures using orange peel oil for fabricating chitosan-zinc oxide composite films and their antibacterial activity. J. Polym. Res. (2020). https://doi.org/10.1007/s10965-020-2033-9

Li, T., Zhao, L., Wang, Y., et al.: Effect of high pressure processing on the preparation and characteristic changes of biopolymer-based films in food packaging applications. Food Eng. Rev. 13, 454–464 (2021). https://doi.org/10.1007/s12393-020-09265-6

Mallick, N., Pal, D., Soni, A.B.: Corn-starch/polyvinyl alcohol bio-composite film for food packaging application. AIP Conf. Proc. (2019). https://doi.org/10.1063/1.5141429

Mallick, N., Pattanayak, D.S., Singh, R.K., et al.: Development of bio-nanocomposite film based on sodium alginate-CuO nanoparticles and essential oils towards medical applications. J. Indian Chem. Soc. 97, 1088–1093 (2020a)

Mallick, N., Pattanayak, D.S., Soni, A.B., Pal, D.: Starch based polymeric composite for food packaging applications. J Eng. Res. Appl. 10, 11–34 (2020b). https://doi.org/10.9790/9622-1004021134

Mallick, N., Soni, A.B., Pal, D.: Improving the mechanical, water vapor permeability, antimicrobial properties of corn-starch/poly vinyl alcoholfilm (PVA): effect of rice husk fiber (RH) & alovera gel(AV). IOP Conf. Ser. Mater. Sci. Eng. (2020c). https://doi.org/10.1088/1757-899X/798/1/012002

Mamman, R.O., Ramalan, A.M.: Mechanical and physical properties of polyester reinforced glass fibre/orange peel particulate hybrid composite. Adv. J. Grad. Res. 7, 18–26 (2020). https://doi.org/10.21467/ajgr.7.1.18-26

Medina-Jaramillo, C., Ochoa-Yepes, O., Bernal, C., Famá, L.: Active and smart biodegradable packaging based on starch and natural extracts. Carbohydr. Polym. 176, 187–194 (2017). https://doi.org/10.1016/j.carbpol.2017.08.079

Naik, P., Acharya, S.K., Sahoo, P., Pradhan, S.: Abrasive wear behaviour of orange peel (biowaste) particulate reinforced polymer composites. Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 235, 2099–2109 (2021). https://doi.org/10.1177/1350650121991412

Nautiyal, A., Shukla, S.R., Prasad, V.: ZnO-TiO2 hybrid nanocrystal-loaded, wash durable, multifunction cotton textiles. Cellulose 29, 5923–5941 (2022). https://doi.org/10.1007/s10570-022-04595-6

Nogueira, F.G.E., Assaf, P.G.M., Carvalho, H.W.P., Assaf, E.M.: Catalytic steam reforming of acetic acid as a model compound of bio-oil. Appl. Catal. B Environ. 160–161, 188–199 (2014). https://doi.org/10.1016/j.apcatb.2014.05.024

Nwe NY, Naing Z, Yee KT, Cho C (2020) Investigation of Weight Loss Percent from Biodegradable Chitosan Composite Membranes by Soil Burial Test and TG-DTA Analysis

Othman, S.H.: Bio-nanocomposite materials for food packaging applications: types of biopolymer and nano-sized filler. Agric Agric Sci Procedia 2, 296–303 (2014). https://doi.org/10.1016/j.aaspro.2014.11.042

Ozdemir, M., Floros, J.D.: Active food packaging technologies. Crit. Rev. Food Sci. Nutr. 44, 185–193 (2004). https://doi.org/10.1080/10408690490441578

Pandey, V.K., Dar, A.H., Rohilla, S., et al.: Recent insights on the role of various food processing operations towards the development of sustainable food systems. Circ Econ Sustain 3, 1491–1514 (2023). https://doi.org/10.1007/s43615-022-00248-9

Park, S.Y., Marsh, K.S., Rhim, J.W.: Characteristics of different molecular weight chitosan films affected by the type of organic solvents. J. Food Sci. 67, 194–197 (2002). https://doi.org/10.1111/j.1365-2621.2002.tb11382.x

Pattanayak, D.S., Mallick, N., Thakur, C., Pal, D.: Plant mediated green synthesis of silver nanoparticles for antimicrobial application: present status. J. Indian Chem. Soc. 97, 1108–1114 (2020)

Pattanayak DS, Pal D, Thakur C, et al (2022) Catalytic Potential of Phyto-Synthesized Silver Nanoparticles for the Degradation of Pollutants. In: Wasewar KL, Rao SN (eds) Sustainable Engineering, Energy, and the Environment, 1st Editio. Apple Academic Press. 465–481

Rodrigues, C., de Mello, J.M.M., Dalcanton, F., et al.: Mechanical, thermal and antimicrobial properties of chitosan-based-nanocomposite with potential applications for food packaging. J. Polym. Environ. 28, 1216–1236 (2020). https://doi.org/10.1007/s10924-020-01678-y

Roy, S., Priyadarshi, R., Rhim, J.W.: Development of multifunctional pullulan/chitosan-based composite films reinforced with ZnO nanoparticles and propolis for meat packaging applications. Foods (2021). https://doi.org/10.3390/foods10112789

Sani, I.K., Pirsa, S., Tağı, Ş: Preparation of chitosan/zinc oxide/Melissa officinalis essential oil nano-composite film and evaluation of physical, mechanical and antimicrobial properties by response surface method. Polym. Test. (2019). https://doi.org/10.1016/j.polymertesting.2019.106004

Seligra, P.G., Medina Jaramillo, C., Famá, L., Goyanes, S.: Biodegradable and non-retrogradable eco-films based on starch-glycerol with citric acid as crosslinking agent. Carbohydr. Polym. 138, 66–74 (2016). https://doi.org/10.1016/j.carbpol.2015.11.041

Sharmila PP, Tharayil NJ (2014) DNA Assisted Synthesis, Characterization and Optical Properties of Zinc Oxide Nanoparticles. Int J Mater Sci Eng 1–6. https://doi.org/10.12720/ijmse.2.2.147-151

Stoleru, E., Vasile, C., Irimia, A., Brebu, M.: Towards a bioactive food packaging: POLY(lactic acid) surface functionalized by chitosan coating embedding clove and argan oils. Molecules (2021). https://doi.org/10.3390/molecules26154500

Surana, M., Pattanayak, D.S., Yadav, V., et al.: An insight decipher on photocatalytic degradation of microplastics: mechanism, limitations, and future outlook. Environ. Res. 247, 118268 (2024). https://doi.org/10.1016/j.envres.2024.118268

Terzioğlu, P., Güney, F., Parın, F.N., et al.: Biowaste orange peel incorporated chitosan/polyvinyl alcohol composite films for food packaging applications. Food Packag. Shelf Life (2021). https://doi.org/10.1016/j.fpsl.2021.100742

Upadhyay, A., Pal, D., Gupta, P.K., Kumar, A.: Antimicrobial therapeutic protein extraction from fruit waste and recent trends in their utilization against infections. Bioprocess Biosyst. Eng. (2024). https://doi.org/10.1007/s00449-024-03037-w

Wang, L.Z., Liu, L., Holmes, J., et al.: Assessment of film-forming potential and properties of protein and polysaccharide-based biopolymer films. Int. J. Food Sci. Technol. 42, 1128–1138 (2007). https://doi.org/10.1111/j.1365-2621.2006.01440.x

Wang, C., Chang, T., Dong, S., et al.: Biopolymer films based on chitosan/potato protein/linseed oil/ZnO NPs to maintain the storage quality of raw meat. Food Chem. 332, 127375 (2020). https://doi.org/10.1016/j.foodchem.2020.127375

Wrońska, N., Katir, N., Nowak-Lange, M., et al.: Biodegradable chitosan-based films as an alternative to plastic packaging. Foods 12, 1–12 (2023). https://doi.org/10.3390/foods12183519

Wu, W., Liu, L., Goksen, G., et al.: Multidimensional (0D–3D ) nanofillers : fascinating materials in the field of bio-based food active packaging. Food Res. Int. 157, 111446 (2022). https://doi.org/10.1016/j.foodres.2022.111446

Yadav, V., Pal, D., Poonia, A.K.: A study on genetically engineered foods: need, benefits, risk, and current knowledge. Cell Biochem. Biophys. (2024). https://doi.org/10.1007/s12013-024-01390-x

Acknowledgements

The authors greatly acknowledge the Department of Chemical Engineering of the National Institute of Technology Raipur for providing research opportunities.

Funding

There was no particular grant for this research from any funding agencies.

Author information

Authors and Affiliations

Contributions

Experiments and manuscript drafting were performed by Venkteshwar Yadav. The draft correction and critical revision were performed by Dr. Dharm Pal and Dr. Anil Kumar Poonia. The final manuscript was reviewed and approved by all authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yadav, V., Pal, D. & Poonia, A.K. Synthesis and characterization of orange peel powder incorporated chitosan-zinc oxide (OPP@CS-ZnO) biopolymer nanocomposites. Proc.Indian Natl. Sci. Acad. (2024). https://doi.org/10.1007/s43538-024-00339-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43538-024-00339-1