Abstract

High pressure processing (HPP) is an emerging non-thermal food processing technology, which inhibits pathogenic and spoilage microorganisms without significantly compromising the nutritional and organoleptic quality of the food. Flexible petroleum-based materials are often selected as packaging for HPP food, but they pose great threats to the environment. Packagings based on biopolymers are proposed as promising alternatives to address the associated environmental issues. Some studies have investigated the effect of HPP on the morphology, mechanical, thermal, and mass transport properties of the biopolymers. Therefore, it is important to consolidate available information and provide a better understanding of the effects of HPP parameters and the time it applied in the material fabrication process. The main objective of this study is to make a critical literature review on the performance change of biopolymer packaging materials undergoing HPP treatments before and after film-forming and the current knowledge of the effects of different processing conditions on their properties, making the use of biopolymer-based films for HPP food packaging applications feasible.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the last decades, a growing demand for hygienic food products with natural flavor and taste with minimal processing has prevailed in the food industry (Joaquín [1]). High pressure processing (HPP), one of the most successful non-thermal technologies in commercial applications, has received intense attention for its potential to inactivate microorganisms without significantly compromising nutritional and organoleptic characteristics [2]. This novel technology applies to the product ranging from 100 to 1000 MPa using pressure-transmitting medium [3], leading to microbial and enzyme inactivation as well as protein denaturation (Kyung Won [4]). It was first commercially introduced in Japan in 1992 and widely applied in fruit juice and jam production [2]. Additionally, HPP has been accepted as a post-intervention process in ready-to-eat (RTE) meat production by the United States Department of Agriculture-Food Safety and Inspection Service (USDA-FSIS) [5]. Nowadays, a wide range of HPP products, including RTE meats, tomato salsa, apple sauce, orange juice, and oysters, has appeared in the market in Europe, the USA, Japan, and elsewhere including China [6].

Commercial HPP systems are available in batch, semi-continuous, and continuous formats. Compared to the latter two, one of the unique features of the batch HPP system is that food products need to be pre-packaged in the sealed packages and then immersed in the pressure-transmitting medium. It is estimated that approximately 90% of commercial HPP food products are processed in batch systems, where flexible or partially rigid material was used for primary packaging [7]. These packages must withstand changes induced by HPP and maintain their integrity as well as barrier properties to protect enclosed food products from contamination [8, 9]. The additional desire for mechanical strength is also required to avoid damages to the packages in the processing and distribution of the products [10].

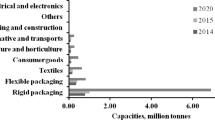

Petroleum-based polymers have been widely used as packaging materials for HPP food products due to their excellent thermo-mechanical properties and commercial availability [11], among which PET, PE, PP, and EVOH are the most common materials used [7]. For example, M J Galotto et al. [12] developed a PE/EVOH/PE multilayer packaging film and submitted it to 400 MPa HPP at 20 °C for 30 min, with no detrimental effect observed. The PP/EVOH/PP structured film manufactured by The Nippon Synthetic Chemical Industry Co. Ltd. can endure HPP treatments up to 800 MPa and maintain its physical integrity [13]. Although it exhibited excellent suitability for HPP, polymeric-based packaging is non-biodegradable and non-renewable [14]. It is estimated that 150 million tons of plastic wastes are produced annually around the world [15], as resource exhaustion and difficulty in natural degradation poses a great challenge to the environment [16].

Driven by the growing demand for green consumerism, considerable research efforts have been conducted to develop biopolymer-based materials as environment-friendly alternatives (J. [17]). As HPP food packaging materials, biopolymers, including polysaccharides, proteins, and lipids, are regarded as potential candidates to replace conventional plastics due to their safety, biocompatibility, and rapid biodegradation rates [18]. These biopolymers can be obtained from fishing, agricultural, and cattle farming byproducts, making them sustainable materials (J. [17]).

According to Swain and Mohanty [19], polymers and polymers bio-derived from monomer units or produced by microorganisms can be defined as biopolymers. Previous studies have highlighted that while polysaccharides and proteins are good film-forming material with moderate gas barrier and mechanical properties, they were highly sensitive to moisture as a result of their hydrophilic nature, leading to inferior water vapor barrier properties [20,21,22]. According to Le Chatelier’s principle, any state favoring volume reduction will be promoted. Hence, when films were subjected to the HPP, the enhancement of mechanical strength and barrier property can be achieved by denser structure. Therefore, HPP has been proposed as an effective technique to address these problems as it could modify the functional properties of macromolecular, including protein denaturation, starch gelatinization, and the interactions between food components [23]. As a result, much denser and finer biopolymer-based films with better performance have been developed using HPP. Wei et al. [24] reported that soy protein isolate (SPI) films developed using HPP exhibited a more compact structure, resulting in water resistance and mechanical performance enhancement.

So far, HPP has been successfully applied in polysaccharide (Sujin [25]) and protein [26] film preparation, which may be a promising approach to broaden the range of biopolymer-based packaging applications. The effect of HPP on the characteristics of biopolymer-based films can be categorized into two major types based on when the HPP was applied. As shown in Fig. 1(A), HPP can be used to modify the film-forming solution before the film was fabricated. Alternatively, it can be applied directly to pre-formed packaging films (Fig. 1(B)). The sequence of HPP treatment and processing conditions resulted in the discrepancy in the morphology, mechanical, thermal, and mass transport properties of the film. Many articles have summarized the feasibility of polymeric-based material for the HPP packaging application. However, to our best knowledge, no reviews have focused on the application of biopolymer-based packaging materials for HPP food. The main objective of this study is to make a critical literature review on the performance change of biopolymer packaging material undergoing HPP treatments before and after film-forming and the current knowledge of the effects of different processing conditions on their properties.

Effect of HPP When Applied Before Film-Forming

Biopolymers such as polysaccharides and proteins as potential alternatives to synthetic polymer for their good film-forming ability have been evaluated [18]. The properties of these bio-macromolecules can be modified by physical intervention. HPP has been efficiently utilized to modify macromolecules such as protein denaturation and starch gelatinization, which may influence the properties of resulting films [23]. However, the interaction mechanism between the film-forming solution and HPP vary with chemical structure (as summarized in Table 1).

Polysaccharides

The excellent film-forming ability of polysaccharides has been extensively demonstrated in the case of cellulose, chitosan, starch, pectin, alginate, carrageenan, pullulan, and kefira [31]. Among them, starch is one of the most promising polysaccharides for food packaging due to its low cost, excellent renewability, and superior biodegradability [32, 33]. The primary effects of HPP on starch-based films were directly related to its ability to induce starch gelatinization at ambient temperature when the pressure applied was sufficiently intensive. Conventional thermal gelatinization of starch has two main stages. In the first stage, the amorphous phase was reversibly hydrated, leading to the swelling of starch granules and distortion of the crystalline phase. In the second stage, irreversible hydration occurs in the crystalline phase, leading to the disruption of granule [34]. Compared to conventional heat gelatinization, pressurized starch granules retain a more intact structure with almost no leaching of amylose [35]. Thus, pressurized starch is more resistant to moisture, and a higher degree of crystallinity is obtained.

When buckwheat starch film-forming solution was subjected to HPP at 600 MPa for 20 min and subsequent casting, the resulting packaging film showed a reduction of water solubility by more than 40% (Sujin [25]). Besides, buckwheat starch films prepared with HPP-induced gelatinization exhibited higher water vapor barrier and superior mechanical properties compared to those obtained by thermal processing (90 °C/20 min), reflecting their higher moisture content and more intact crystalline structure. The effect of HPP on tapioca starch films was less evident when identical processing conditions were employed, which might be related to the structural discrepancy between starch types used. The extent of gelatinization also varied depending on the type of starch, water concentration, and processing parameters, such as pressure level, holding time, and processing temperature [34]. Generally, starch can be categorized into “A” (cereal starches), “B” (legume starches, and “C” (tuber starches) in terms of their X-ray diffraction pattern. Among them, type A starch is most sensitive to HPP, causing more pronounced characteristic changes in the packaging materials obtained [36].

Another commonly used polysaccharides for packaging is chitosan, a β-1,4 linked glucosamine and N-acetyl glucosamine biopolymer. It is the product of the deacetylation of chitin, which can be obtained from invertebrates and fungi or collected from industrial shellfish processing [37, 38]. The growing concern about shellfish waste disposal and the unique antimicrobial characteristics of chitosan makes it an excellent material for food packaging and edible films. To improve the properties of edible chitosan film, HPP was used to modify the film-forming solution. Niu et al. [15] investigated the effect of HPP on chitosan films and found that HPP could enhance the film’s tensile strength and lower the elongation percentage, water vapor permeability, and oxygen permeability when the applied pressure increased up to 400 MPa. HPP could also be used to improve the mechanic properties of chitosan film when blended with polyvinyl alcohol (PVA). A more compact structure was obtained after the HPP (600 MPa/25 °C/15 min) was applied to the mixture due to new hydrogen bonds formed between PVA and chitosan, improving the film barrier property and tensile strength. The tensile strength of films prepared with HPP-modified PVA–chitosan was double compared to those from PVA–chitosan with no HPP treatment.

HPP treatment can also influence the migration of active film ingredients. For example, the hydrophilic nature of the film promotes the TiO2 migration into the food in PVA-chitosan films enriched with TiO2 for performance enhancement. When the active films were used for packaging olive oil, only trace amounts of TiO2 were detected after immersing the HPP-treated films for 11 h, whereas the migration test could not be performed on films used for water packaging due to swelling and deformation of films after 3 h, which would pose a health risk. When HPP treated the same films, the resulting compact structure effectively delayed the migration of TiO2 into olive oil, which would substantially increase the safety of the food packaging material [27].

Protein

Pressure-induced starch gelatinization mainly depends on the hydration of granule, whereas gel formation of protein is primarily associated with protein denaturation, including molecular unfolding, dissociation-association, and aggregation. During HPP treatments, functional groups in the unfolded protein are exposed and interacted with each other, and a more compact network structure is eventually achieved [39]. The effect of HPP on the protein-based films is summarized in Table 1.

Huimin et al. [28] was the first to use HPP to treat SPI film-forming solution and demonstrated that HPP (400 MPa/25 °C/10 min) enhanced the oxygen barrier property and tensile strength of the resulting film by more than 50%, likely reflecting a denser structure. Similar HPP-induced mechanic and barrier property improvements were observed in nisin-SPI [24], wheat gluten film [30], pigskin gelatin [26], and amaranth protein film [29]. As expected, the water solubility of amaranth protein film decreased with pressures up to 600 MPa as a consequence of the higher crosslinking of proteins induced by HPP [29]. Nevertheless, changes in the secondary structures were found to be primarily responsible for such performance improvement. Wei et al. [24] discovered that more random coils and β-turns in the SPI appeared after HPP treatment, indicating the occurrence of protein unfolding. In addition, elevated interactions between polypeptide resulted in a tougher structure formation to keep the system energy to a minimum. There is no doubt that hydrogen and disulfide bonds play a crucial role in these processes as well, which can be detected by differential solubility of films [29]. Consequently, a positive association between film performance and HPP treatment has been established. When HPP is applied before film-forming, significant improvement of mechanical property, barrier property, and water resistance can be achieved, which is facilitated by hydrogen and disulfide bonds.

Effect of HPP on Prepared Biopolymer Material

In a typical batch HPP system, the food products are sealed in their final primary packages in advance before being subjected to HPP. Therefore, in order to effectively transmit pressure, the food packages should have at least one side flexible enough to withstand the volume changes up to 12% without compromising their integrity and performance [40]. Additionally, the food packages should be strong enough to maintain their barrier and mechanical properties after HPP processing. Industrial norms suggest that the deviation of barrier and mechanical property within 12% and 25%, respectively, is generally considered acceptable [7]. Numerous efforts have been made to estimate the impact of HPP on petroleum-based food packaging. The research results revealed that HPP had almost no adverse effect on petroleum-based polymer materials when the processing temperature is near ambient, except for the possible delamination in packages containing metal layers. The significant compression difference between the metal and polymer layers is responsible for delamination and the subsequent loss in their barrier property. The adverse effects are more severe after exposure to high-pressure–high-temperature treatments, and only a few materials could survive these harsh conditions [10]. Compared to the extensive literature on petroleum-based food packaging materials, little has been reported on the feasibility of biopolymer-based material for HPP food packages. In this section, the effect of HPP on prepared biopolymer-based packaging material was reviewed and summarized in Table 2.

The most popular and thoroughly studied biopolymer-based material for the HPP applications is poly(lactic acid) (PLA). As the most close-to-market biodegradable polymer derived from agricultural byproducts, PLA has gained extensive attention for its universal processability, resilient mechanical properties, and superior intrinsic gas and water barrier properties, which makes PLA competitive with petroleum-derived plastics [47]. Based on the current literature, no significant effects on PLA were observed even after being submitted to HPP treatments up to 700 MPa and 40 °C for 5 min [9]. HPP treatments with an initial temperature equal or below 60 °C did not decrease the glass transition temperature and crystallinity nor compromise the mechanical properties of PLA pouches. Consequently, PLA is a potential candidate to manufacture packages for minimally processed carrots, carrot juices, and puree treated by HPP.

Biopolymer-based packages usually have inadequate water resistance, which severely limits its applications in liquid food. HPP can moderately enhance the water resistance of PLA films as the result of structural modifications. However, PLA showed significantly elevated water vapor permeability after HPP treatment compared to commercial plastic packages based on PE and PP. M.J. Galotto et al. [41] reported that HPP increased the water vapor permeability of PLA films by up to 2170% due to the plasticization effect of water on PLA. A substantial increase of oxygen permeability was also displayed on the HPP-treated PLASiOx/PLA material, making it unsuitable for HPP packaging applications. On the contrary, much smaller changes were observed when the films were in contact with olive oil. It was estimated that the oxygen and water vapor barrier properties of the film only decreased by 31% and 71%, respectively, after HPP, suggesting PLA might be ideal for packaging HPP food with high-fat content. Therefore, although slight changes occurred after films being subjected to HPP, it is crucial to evaluate their performance in the context of specific food packaging applications.

Additionally, the integrity of packaging also plays a vital role in food safety, which can be characterized by adsorption and migration [7]. Mauricio-Iglesias et al. [44] assessed the migration of Uvitex OB®, a packaging additive, and found that the migration was so low that no change was detected after PLA films submitted to 800 MPa at mild temperatures ranging from 20 to 40 °C. The following study found that 0.05% Uvitex OB® in respect to dry basis detected after storage at 40 °C for 10 days, which is far from a specific migration limit of 0.6 mg/kg [45]. Interestingly, HPP treatment (800 MPa/40 °C/5 min) favored the decrease of free volume in PLA films, resulting in a significant reduction of aroma adsorption exceeding a 50% reduction when compared to PLA film at atmospheric pressure [46]. However, PLA film reinforced by nano-Ag displayed a profound increase in migration of nano-Ag when subjected to 400 MPa for 10 min, along with unsatisfactory mechanical properties [42]. Such performance posed a threat to the application of active biopolymer-based films enriched with inorganic material, and thus investigating film property changes under HPP is necessary. Nevertheless, biopolymer-based materials appear to be a promising alternative packaging for HPP products.

In general, commercial HPP is carried out at a pressure ranging from 100 to 600 MPa and a temperature between 5 and 65 °C, which is insufficient to achieve bacterial spore inactivation. Thus, the HPP treatment with an initial temperature above 60 °C and elevated working temperature up to 120 °C has been applied to low-acid foods, which was also referred to as the HPP sterilization or pressure-assisted thermal sterilization (PATS) [48]. However, none of the existing biopolymer-based materials could survive such extreme processing conditions. Significant opacification of PLA was observed for pressure treatments at 90 to 110 °C, which could be explained by re-crystallization induced by hydrolysis [9]. Wheat gluten nanocomposite films could not withstand HPP sterilization as they melted after being subjected to 800 MPa at 90–115 °C for 5 min [45].

Moreover, the glass transition temperature of PLA is around 60 °C, and the transition from glassy state to rubbery state occurs at HPP sterilization conditions to form more free volume. At this processing condition, the scalping of aroma compounds was enhanced, which led to a detrimental effect on food quality. It is noteworthy that ethyl hexanoate losses were up to 60% at 800 MPa/115 °C, while only 17% of losses were demonstrated at 800 MPa/40 °C [46]. Such deterioration of food quality is unacceptable, especially when the consumers generally expect HPP food to be fresh-like.

Applications of HPP and Biopolymer Packaging for Food Preservation

As aforementioned, currently developed biopolymer-based materials are not suitable for HPP food packaging applications when processing temperature exceeds 60 °C or at extremely high working pressures. Low-temperature–low-pressure HPP is not applicable for low-acid food, such as RTE meat and seafood. In order to broaden the application of biopolymer-based packaging for HPP, antimicrobial agents are often infused in the packaging to provide an additional hurdle to lower the processing pressure and temperature. Since sublethally injured cells resulted from HPP are more susceptible to antimicrobial agents [49], many efforts have been contributed to decreasing HPP intensity by using antimicrobial-enriched biopolymer-based packaging, especially in meat products and solid food simulants preservation, as summarized in Table 3.

Ahmed et al. [43] found that synergism of HPP and PLA films enriched with cinnamon oil could achieve similar pathogen reduction at reduced pressure intensity, which did not compromise thermal and mechanical performance at all, indicating that antimicrobial packaging may be a promising tool to maintain biopolymer-based packaging integrity under HPP. Compared with adding preservative directly, the incorporation of antimicrobials into packaging material could be in contact with the food surface where contamination frequently occurs [54], while avoiding a reduction of antimicrobial activity due to the interaction between active agents and food constituents [55]. A synergistic antimicrobial effect between antimicrobial packaging and HPP has been demonstrated by Ahmed et al. [50]. They found that a reduction of 6 log10 CFU/g Listeria monocytogenes (L. monocytogenes) incubated on chicken could be achieved via a combination of HPP (150 MPa/20 °C/10 min) and PLA films enriched with cinnamon oil, whereas the same reduction was achieved at 350 MPa when only the HPP was applied. Raouche et al. [51] also demonstrated that no growth of Botrytis cinerea was observed during 10 days of storage at 22 °C when potato dextrose agar media (PDA) packed in PLA-based antimicrobial films were subjected to 300 MPa HPP for 5 min. It was more effective than an 800 MPa HPP treatment used alone, which only extended the lag phase for 3.3 days. A similar result was obtained when treating trout fillets. Albertos et al. [52] reported that a remarkable synergistic effect of HPP (300 MPa/12 °C/10 min) and chitosan films with clove essential oil on the reduction of mesophilic aerobics and coliforms.

Biopolymer-based active packaging could also prevent microorganism recovery after HPP treatment (Joaquín [1]). Cold-smoked sardine wrapped with edible films kept microbial counts and oxidation indices far below those in other groups during refrigerated storage over 2 weeks after a 300 MPa treatment at 20 °C for 15 min (J. [53]). Furthermore, antimicrobial packaging could protect food products during temperature abuse if the cold chain is compromised. Marcos et al. [5] assessed the effect of HPP and enterocin-infused alginate packaging on the L. monocytogenes during the storage of cooked ham and reported that HPP alone (400 MPa/17 °C/10 min) could achieve a complete reduction around the detection limit at 1 °C for 60 days. However, both antimicrobial packaging and HPP were necessary to maintain microorganisms stable when cooked hams subjected to temperature abuse at 20 °C for 24 h, which was 6.78 log10 CFU/g lower than that treated by HPP alone after storage for a month. The combination of biopolymer-based antimicrobial packaging and HPP not only reduces processing intensity but also prevents sublethally injured cell from recovering during storage.

Future Research Needs

As mentioned above, a much denser biopolymer-based packaging can be prepared after HPP treatment since compression promotes any state favoring volume reduction. However, only a few studies were conducted to evaluate the interaction between HPP and biopolymer-based packaging, and most of them focused on the effect of HPP on film fabricated with a single material. In theory, the HPP may alter the non-covalent bonds between different materials and cause significant changes in the performance of the treated films. As a result, the biopolymer films made with two or even more compounds need to be further investigated.

Numerous researches have been carried out on polymer-based packaging to explore the feasibility of HHP treatment, while limited information is available on biopolymer-based materials. Since reported research results obtained from different works of literature are not all consistent, a thorough understanding of the biopolymer’s performance changes after HPP remains nearly impossible. More details on integrity, barrier properties, mechanical properties, and migration as well as scalping of aroma should be evaluated, and further studies need to be performed in a pilot plant or industrial scale in order to provide the foundation for the optimization of packaging materials.

Additionally, nanotechnology has been utilized to engineer the structure of packaging materials at the molecular level to obtain desired functions. However, the migration of nanomaterials may pose a threat to human safety and packaging performance. It is critical to develop reliable models to evaluate the performance and safety of these novel materials during their processing, storage, and distribution. Up to date, several studies have focused on the microbial safety achieved by the combination of HPP and antimicrobial packaging. The release kinetics of active compounds under HPP are also interesting fields to be further explored.

Conclusions

In brief, the effect of HPP on the characteristic changes of the biopolymer-based films was reviewed, including HPP applied before and after film-forming. HPP applied to the biopolymer film-forming solutions resulted in more compact and uniform materials with superior barrier and mechanical properties. On the other hand, HPP treatments could cause reversible or irreversible changes when applied to pre-formed packages. When the processing temperature is relatively low, packaging changes induced by HPP are acceptable. However, significant opacification in the packaging material could be observed after HPP sterilization when the processing temperature was higher than 60 °C, which limited their commercial applications. Antimicrobial packaging, a novel hurdle technology, makes biopolymer-based packaging applications more feasible in the food industry by lowering the intensity of the HPP parameters. All available evidence considered, the biopolymer-based material may be a suitable and environmentally friendly packaging alternative, but more complete studies are required to pave the way to develop optimized packaging for HPP food products.

Data Availability

Not applicable.

Abbreviations

- HPP:

-

High pressure processing

- RET:

-

Ready-to-eat

- PET:

-

Polyethylene terephthalate

- PE:

-

Polyethylene

- PP:

-

Polypropylene

- EVOH:

-

Ethylene-vinyl alcohol

- SPI:

-

Soy protein isolate

- PVA:

-

Polyvinyl alcohol

- PLA:

-

Poly(lactic acid)

- TiO2 :

-

Titanium dioxide

- SiOx :

-

Silicon oxide

- USDA:

-

The United States Department of Agriculture

- FDA:

-

Food and Drug Administration

- FSIS:

-

Food Safety and Inspection Service

References

Gómez-Estaca J, López-Caballero ME, Martínez-Bartolomé MÁ, de Lacey AML, Gómez-Guillen MC, Montero MP (2018) The effect of the combined use of high pressure treatment and antimicrobial edible film on the quality of salmon carpaccio. Int J Food Microbiol 283:28–36. https://doi.org/10.1016/j.ijfoodmicro.2018.06.015

Murchie LW, Cruz-Romero M, Kerry JP, Linton M, Patterson MF, Smiddy M, Kelly AL (2005) High pressure processing of shellfish: a review of microbiological and other quality aspects. Innovative Food Sci Emerg Technol 6(3):257–270. https://doi.org/10.1016/j.ifset.2005.04.001

Moltó-Puigmartí C, Permanyer M, Castellote AI, López-Sabater MC (2011) Effects of pasteurisation and high-pressure processing on vitamin C, tocopherols and fatty acids in mature human milk. Food Chem 124(3):697–702. https://doi.org/10.1016/j.foodchem.2010.05.079

Kim KW, Kim Y-T, Kim M, Noh B-S, Choi W-S (2014) Effect of high hydrostatic pressure (HHP) treatment on flavor, physicochemical properties and biological functionalities of garlic. LWT Food Sci Technol 55(1):347–354. https://doi.org/10.1016/j.lwt.2013.08.027

Marcos B, Aymerich T, Monfort JM, Garriga M (2008) High-pressure processing and antimicrobial biodegradable packaging to control Listeria monocytogenes during storage of cooked ham. Food Microbiol 25(1):177–182. https://doi.org/10.1016/j.fm.2007.05.002

Oliveira TLCD, Ramos ALS, Ramos EM, Piccoli RH, Cristianini M (2015) Natural antimicrobials as additional hurdles to preservation of foods by high pressure processing. Trends Food Sci Technol 45(1):60–85. https://doi.org/10.1016/j.tifs.2015.05.007

Juliano P, Koutchma T, Sui Q, Barbosa-Cánovas GV, Sadler G (2010) Polymeric-based food packaging for high-pressure processing. Food Eng Rev 2(4):274–297. https://doi.org/10.1007/s12393-010-9026-0

Ghanbarzadeh B, Oleyaei SA, Almasi H (2015) Nanostructured materials utilized in biopolymer-based plastics for food packaging applications. Crit Rev Food Sci Nutr 55(12):1699–1723. https://doi.org/10.1080/10408398.2012.731023

Sansone L, Aldi A, Musto P, Di Maio E, Amendola E, Mensitieri G (2012) Assessing the suitability of polylactic acid flexible films for high pressure pasteurization and sterilization of packaged foodstuff. J Food Eng 111(1):34–45. https://doi.org/10.1016/j.jfoodeng.2012.01.034

Ayvaz H, Balasubramaniam VM, Koutchma T (2016) High pressure effects on packaging materials. In: Balasubramaniam VM, Barbosa-Cánovas GV, Lelieveld HLM (eds) High pressure processing of food: principles, technology and applications. Springer New York, New York, pp 73–93. https://doi.org/10.1007/978-1-4939-3234-4_5

Vigneshwaran N, Ammayappan L, Huang Q (2011) Effect of Gum arabic on distribution behavior of nanocellulose fillers in starch film. Appl Nanosci 1(3):137–142. https://doi.org/10.1007/s13204-011-0020-5

Galotto MJ, Ulloa PA, Hernández D, Fernández-Martín F, Gavara R, Guarda A (2008) Mechanical and thermal behaviour of flexible food packaging polymeric films materials under high pressure/temperature treatments. Packag Technol Sci 21(5):297–308. https://doi.org/10.1002/pts.807

López-Rubio A, Lagarón JM, Hernández-Muñoz P, Almenar E, Catalá R, Gavara R, Pascall MA (2005) Effect of high pressure treatments on the properties of EVOH-based food packaging materials. Innovative Food Sci Emerg Technol 6(1):51–58. https://doi.org/10.1016/j.ifset.2004.09.002

Othman SH (2014) Bio-nanocomposite materials for food packaging applications: types of biopolymer and nano-sized filler. Agric Agric Sci Procedia 2:296–303. https://doi.org/10.1016/j.aaspro.2014.11.042

Niu YQ, Chen SS, Gao YP, Ma ZS (2012) The properties of ultra-high pressure treated chitosan edible films. Adv Mater Res 573-574:131–134

Papong S, Malakul P, Trungkavashirakun R, Wenunun P, Chom-in T, Nithitanakul M, Sarobol E (2014) Comparative assessment of the environmental profile of PLA and PET drinking water bottles from a life cycle perspective. J Clean Prod 65:539–550. https://doi.org/10.1016/j.jclepro.2013.09.030

Gómez-Estaca J, López de Lacey A, López-Caballero ME, Gómez-Guillén MC, Montero P (2010) Biodegradable gelatin–chitosan films incorporated with essential oils as antimicrobial agents for fish preservation. Food Microbiol 27(7):889–896. https://doi.org/10.1016/j.fm.2010.05.012

Mohammad Zadeh E, O’Keefe SF, Kim Y-T, Cho J-H (2018) Evaluation of enzymatically modified soy protein isolate film forming solution and film at different manufacturing conditions. J Food Sci 83(4):946–955. https://doi.org/10.1111/1750-3841.14018

Swain SK, Mohanty F (2018) Polysaccharides-based bionanocomposites for food packaging applications. In: Jawaid M, Swain SK (eds) Bionanocomposites for packaging applications. Springer International Publishing, Cham, pp 191–208. https://doi.org/10.1007/978-3-319-67319-6_10

Jiang S-J, Zhang T, Song Y, Qian F, Tuo Y, Mu G (2019) Mechanical properties of whey protein concentrate based film improved by the coexistence of nanocrystalline cellulose and transglutaminase. Int J Biol Macromol 126:1266–1272. https://doi.org/10.1016/j.ijbiomac.2018.12.254

Kaewprachu P, Osako K, Rawdkuen S (2018) Effects of plasticizers on the properties of fish myofibrillar protein film. J Food Sci Technol 55(8):3046–3055. https://doi.org/10.1007/s13197-018-3226-7

Petersson M, Stading M (2005) Water vapour permeability and mechanical properties of mixed starch-monoglyceride films and effect of film forming conditions. Food Hydrocoll 19(1):123–132. https://doi.org/10.1016/j.foodhyd.2004.04.021

Devi AF, Buckow R, Hemar Y, Kasapis S (2014) Modification of the structural and rheological properties of whey protein/gelatin mixtures through high pressure processing. Food Chem 156:243–249. https://doi.org/10.1016/j.foodchem.2014.01.097

Wei J, Zhang Z, Cai Q, Peng B (2018) Effects of high hydrostatic pressure on structural and physical properties of nisin-SPI film. Int J Biol Macromol 111:976–982. https://doi.org/10.1016/j.ijbiomac.2018.01.128

Kim S, Yang S-Y, Chun HH, Song KB (2018) High hydrostatic pressure processing for the preparation of buckwheat and tapioca starch films. Food Hydrocoll 81:71–76. https://doi.org/10.1016/j.foodhyd.2018.02.039

Molinaro S, Cruz-Romero M, Sensidoni A, Morris M, Lagazio C, Kerry JP (2015) Combination of high-pressure treatment, mild heating and holding time effects as a means of improving the barrier properties of gelatin-based packaging films using response surface modeling. Innovative Food Sci Emerg Technol 30:15–23. https://doi.org/10.1016/j.ifset.2015.05.005

Lian Z, Zhang Y, Zhao Y (2016) Nano-TiO2 particles and high hydrostatic pressure treatment for improving functionality of polyvinyl alcohol and chitosan composite films and nano-TiO2 migration from film matrix in food simulants. Innovative Food Sci Emerg Technol 33:145–153. https://doi.org/10.1016/j.ifset.2015.10.008

Huimin, B. I., Zhongsu, M. A., Yan, G. H., Xinxin, L. I., Shi, J., & Wang, X. (2004). Study on effects of high pressure solution treatment on SPI edible films. Foodence

Condés MC, Añón MC, Mauri AN (2015) Amaranth protein films prepared with high-pressure treated proteins. J Food Eng 166:38–44. https://doi.org/10.1016/j.jfoodeng.2015.05.005

Koehler P, Kieffer R, Wieser H (2010) Effect of hydrostatic pressure and temperature on the chemical and functional properties of wheat gluten III. Studies on gluten films. J Cereal Sci 51(1):140–145. https://doi.org/10.1016/j.jcs.2009.11.004

Cazón P, Velazquez G, Ramírez JA, Vázquez M (2017) Polysaccharide-based films and coatings for food packaging: a review. Food Hydrocoll 68:136–148. https://doi.org/10.1016/j.foodhyd.2016.09.009

Hu X-P, Zhang B, Jin Z-Y, Xu X-M, Chen H-Q (2017) Effect of high hydrostatic pressure and retrogradation treatments on structural and physicochemical properties of waxy wheat starch. Food Chem 232:560–565. https://doi.org/10.1016/j.foodchem.2017.04.040

Kyung Kim J, Jo C, Jin Park H, Woo Byun M (2008) Effect of gamma irradiation on the physicochemical properties of a starch-based film. Food Hydrocoll 22(2):248–254. https://doi.org/10.1016/j.foodhyd.2006.11.010

Li W, Bai Y, Mousaa SAS, Zhang Q, Shen Q (2012) Effect of high hydrostatic pressure on physicochemical and structural properties of rice starch. Food Bioprocess Technol 5(6):2233–2241. https://doi.org/10.1007/s11947-011-0542-6

Buckow R, Heinz V, Knorr D (2007) High pressure phase transition kinetics of maize starch. J Food Eng 81(2):469–475. https://doi.org/10.1016/j.jfoodeng.2006.11.027

Yang Z, Gu Q, Hemar Y (2013) In situ study of maize starch gelatinization under ultra-high hydrostatic pressure using X-ray diffraction. Carbohydr Polym 97(1):235–238. https://doi.org/10.1016/j.carbpol.2013.04.075

Pranoto Y, Rakshit SK, Salokhe VM (2005) Enhancing antimicrobial activity of chitosan films by incorporating garlic oil, potassium sorbate and nisin. LWT Food Sci Technol 38(8):859–865. https://doi.org/10.1016/j.lwt.2004.09.014

Samuels RJ (1981) Solid state characterization of the structure of chitosan films. J Polym Sci Polym Phys Ed 19(7):1081–1105. https://doi.org/10.1002/pol.1981.180190706

Batista AP, Portugal CAM, Sousa I, Crespo JG, Raymundo A (2005) Accessing gelling ability of vegetable proteins using rheological and fluorescence techniques. Int J Biol Macromol 36(3):135–143. https://doi.org/10.1016/j.ijbiomac.2005.04.003

Caner C, Hernandez RJ, Harte BR (2004) High-pressure processing effects on the mechanical, barrier and mass transfer properties of food packaging flexible structures: a critical review. Packag Technol Sci 17(1):23–29. https://doi.org/10.1002/pts.635

Galotto MJ, Ulloa PA, Guarda A, Gavara R, Miltz J (2009) Effect of high-pressure food processing on the physical properties of synthetic and biopolymer films. J Food Sci 74(6):E304–E311. https://doi.org/10.1111/j.1750-3841.2009.01212.x

Fan C, Cui R, Lu W, Chen H, Yuan M, Qin Y (2019) Effect of high pressure treatment on properties and nano–Ag migration of PLA-based food packaging film. Polym Test 76:73–81. https://doi.org/10.1016/j.polymertesting.2019.03.005

Ahmed J, Mulla M, Arfat YA (2017) Application of high-pressure processing and polylactide/cinnamon oil packaging on chicken sample for inactivation and inhibition of Listeria monocytogenes and Salmonella typhimurium, and post-processing film properties. Food Control 78:160–168. https://doi.org/10.1016/j.foodcont.2017.02.023

Mauricio-Iglesias M, Jansana R, Peyron R, Gontard R, Guillard R (2010a) Effect of high-pressure/temperature (HP/T) treatments of in-package food on additive migration from conventional and bio-sourced materials. Food Addit Contam 27(1):118–127

Mauricio-Iglesias M, Peyron S, Guillard V, Gontard N (2010b) Wheat gluten nanocomposite films as food-contact materials: migration tests and impact of a novel food stabilization technology (high pressure). J Appl Polym Sci 116(5):2526–2535. https://doi.org/10.1002/app.31647

Mauricio-Iglesias M, Peyron S, Chalier P, Gontard N (2011) Scalping of four aroma compounds by one common (LDPE) and one biosourced (PLA) packaging materials during high pressure treatments. J Food Eng 102(1):9–15. https://doi.org/10.1016/j.jfoodeng.2010.07.014

Zhu J-Y, Tang C-H, Yin S-W, Yang X-Q (2018) Development and characterization of novel antimicrobial bilayer films based on polylactic acid (PLA)/pickering emulsions. Carbohydr Polym 181:727–735. https://doi.org/10.1016/j.carbpol.2017.11.085

Serment-Moreno V, Barbosa-Cánovas G, Torres JA, Welti-Chanes J (2014) High-pressure processing: kinetic models for microbial and enzyme inactivation. Food Eng Rev 6(3):56–88. https://doi.org/10.1007/s12393-014-9075-x

Del Olmo A, Calzada J, Nuñez M (2012) Effect of lactoferrin and its derivatives against gram-positive bacteria in vitro and, combined with high pressure, in chicken breast fillets. Meat Sci 90(1):71–76. https://doi.org/10.1016/j.meatsci.2011.06.003

Ahmed J, Hiremath N, Jacob H (2016) Efficacy of antimicrobial properties of polylactide/cinnamon oil film with and without high-pressure treatment against Listeria monocytogenes and Salmonella typhimurium inoculated in chicken sample. Food Packag Shelf Life 10:72–78. https://doi.org/10.1016/j.fpsl.2016.10.003

Raouche S, Mauricio-Iglesias M, Peyron S, Guillard V, Gontard N (2011) Combined effect of high pressure treatment and anti-microbial bio-sourced materials on microorganisms’ growth in model food during storage. Innovative Food Sci Emerg Technol 12(4):426–434. https://doi.org/10.1016/j.ifset.2011.06.012

Albertos I, Rico D, Diez AM, González-Arnáiz L, García-Casas MJ, Jaime I (2015) Effect of edible chitosan/clove oil films and high-pressure processing on the microbiological shelf life of trout fillets. J Sci Food Agric 95(14):2858–2865. https://doi.org/10.1002/jsfa.7026

Gómez-Estaca J, Montero P, Giménez B, Gómez-Guillén MC (2007) Effect of functional edible films and high pressure processing on microbial and oxidative spoilage in cold-smoked sardine (Sardina pilchardus). Food Chem 105(2):511–520. https://doi.org/10.1016/j.foodchem.2007.04.006

Guo M, Jin TZ, Wang L, Scullen OJ, Sommers CH (2014) Antimicrobial films and coatings for inactivation of Listeria innocua on ready-to-eat deli turkey meat. Food Control 40:64–70. https://doi.org/10.1016/j.foodcont.2013.11.018

Kashiri M, Cerisuelo JP, Domínguez I, López-Carballo G, Hernández-Muñoz P, Gavara R (2016) Novel antimicrobial zein film for controlled release of lauroyl arginate (LAE). Food Hydrocoll 61:547–554. https://doi.org/10.1016/j.foodhyd.2016.06.012

Acknowledgments

The authors would like to thank the organizer of the International Nonthermal Processing Workshops and Short Courses 2019 in Monterrey, Mexico, especially J. Antonio Torres for his kind invitation.

Code Availability

Not applicable.

Funding

This research was partially supported by the National Key R&D Program of China (2018YFD0400500 and 2018YFD0400504) and the National Key R&D Program of China (2017YFE0109700).

Author information

Authors and Affiliations

Contributions

Liang Zhao, Yongtao Wang, Xiaomeng Wu, and Xiaojun Liao conceptualized and designed the project. Ting Li wrote the first draft of the manuscript. Liang Zhao, Yongtao Wang, Xiaomeng Wu, and Xiaojun Liao contributed to the manuscript editing. Xiaomeng Wu had primary responsibility for the final content. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, T., Zhao, L., Wang, Y. et al. Effect of High Pressure Processing on the Preparation and Characteristic Changes of Biopolymer-Based Films in Food Packaging Applications. Food Eng Rev 13, 454–464 (2021). https://doi.org/10.1007/s12393-020-09265-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09265-6