Abstract

The application of boron (B) fertilizers is challenging due to the high solubility of commonly used B compounds, the small requirement by crops, and the narrow range between toxicity and deficiency levels for plants. The application of a B-only fertilizer without a macronutrient carrier is inefficient due to the high cost of double handling and the poor distribution of the micronutrient in the field. An improved efficiency B fertilizer is proposed using a wax- or elemental sulfur (ES)–coated core of granulated colemanite within a pellet composed of diammonium phosphate (DAP). We assessed the dissolution rate, release in soil, and crop uptake in two consecutive crops under simulated leaching conditions. The fertilizers with the wax- or ES-coated colemanite core showed a much slower release of B compared to DAP pelleted with borax or uncoated colemanite. A soil incubation experiment showed initially elevated extractable B concentrations (> 5 mg kg−1) around the fertilizer with the uncoated B powders. The coated fertilizers showed a more gradual release of B, with 32–38% of the B still in the pellets 8 weeks after application to soil. In plant growth experiments, 24–37% of the added B was lost in leachates for the uncoated products compared to only 1–2% for the coated products which resulted in higher B uptake and higher yield for coated fertilizers. We infer from the results that these novel compound fertilizers released B at a rate slow enough to prevent large leaching losses of B but fast enough to meet plant B demand.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Boron (B) is a micronutrient that has a significant role in improving the growth, productivity, and quality of crops. Boron is considered phloem-immobile in most plant species and is essential at all stages of growth, though requirements vary during the plant life cycle and are generally highest during flowering and fruit/seed development. Deficiency of B affects the plant’s reproductive development resulting in severe yield penalty due to floral abortion or seed set failure (Ahmad et al. 2012). The most prominent B deficiency symptoms include reduction in growth and flower formation, and chlorosis of new leaves (Benton 2003). Boron deficiency is considered the second most widespread micronutrient deficiency after zinc which severely affects the growth of crops on a global scale (Ahmad et al. 2012).

The total concentration of B in soil varies from 2 to 200 mg kg−1, but less than 5–10% is in plant-available form (Diana 2006). Therefore, an appropriate supply of B, especially in B-sensitive crops, is crucial and could result in significant economic benefits (Rashid 2006). The most common B fertilizers, borax (Na2B4O7.10H2O) and boric acid (H3BO3), are water soluble and therefore have low fertilizer use efficiency under high rainfall conditions. These highly soluble sources of B can result in substantial leaching losses in light-textured soils (Abat et al. 2014; Byers et al. 2001; Mortvedt 1994). Moreover, highly soluble B sources also pose a threat of B toxicity to newly planted seedlings (Kmecl and Bukovec 1999). Considering the issues related to B fertilization, a slow release and steady supply of this micronutrient throughout the plant life cycle is preferable. Less soluble B fertilizer sources include colemanite (Ca2B6O11.5H2O), B frits (silicate matrix), and ulexite (NaCaB5O9.8H2O) (Mortvedt and Woodruff 1993). Among them, B frits are comparatively expensive and farmers do not use it, while ulexite has relatively high solubility and hence the release may be too fast to prevent leaching. Colemanite is less soluble than ulexite, but unless relatively large particle sizes are used, colemanite dissolves rapidly in soils (Rowell and Grant 1975; Windsor 1950).

The management of B fertilization can also be challenging because there is a narrow range of B supply between its deficiency and toxicity for most crops (da Silva et al. 2018). A hot water extractable concentration below 0.5 mg B kg−1 in the soil is considered deficient, while 0.5–5 mg kg−1 is adequate and above 5 mg kg−1 is toxic (Reisenauer et al. 1973). Soil application is the most commonly used method to supply B compared to foliar application or seed priming (Wojcik et al. 2008). The response of plants to B fertilization varies greatly depending on the plant species and on the soil characteristics, e.g., CaCO3 and organic matter content, moisture content, and B concentration in soil (Welch et al. 1991; Moraghan and Mascagni 1991).

The uniform distribution of micronutrients like B especially under field conditions is also a problem as only small amounts of B are required (Mortvedt and Woodruff 1993). Bulk blending of B fertilizers with macronutrients is currently the main strategy to supply fertilizer B (da Silva et al. 2018). However, the difference in particle sizes or densities of borates compared to macronutrient fertilizers results in a quick segregation of B and its poor distribution (Mortvedt 1968), which may result in issues of B deficiency and toxicity in the same field or even in the same plant at different stages (Mortvedt and Woodruff 1993). Incorporating B into or coating onto a macronutrient fertilizer granule is a suitable approach to overcome this issue (da Silva et al. 2018; Ferguson et al. 2013).

Improving the efficiency of fertilizers along with minimizing the risks of deficiency or toxicity effects has been a core goal of researchers (Shaviv 2000, 2005; Trenkel 2010). Innovative fertilizer technology can contribute in minimizing nutrient losses from different fertilizer sources, e.g., through the development of coated (Baxter et al., 2019; Trenkel 2010) or co-granulated/co-compacted (pelletized) products (Ferguson et al. 2013). Meanwhile, such slow-release products could have high residual value for succeeding crops because of the slow and gradual release of nutrients along with reduced losses (Abat et al. 2015a). Incorporating the slow-release B minerals ulexite and colemanite into phosphatic fertilizers does not result in slow-release B products (Abat et al. 2015a, b). This results from the enhanced dissolution of the less soluble B mineral through precipitation of Ca by phosphorus (P) released from the phosphatic fertilizer (Abat et al. 2015b). The current study aimed therefore to formulate new slow-release B fertilizers using the macronutrient fertilizer diammonium phosphate (DAP) as a carrier for slowly supplying B to plants. Fertilizers were designed in which a colemanite core was coated with wax or elemental sulfur (ES) and then encapsulated within DAP, in order to achieve slow release of B without affecting the release of the macronutrients. The yield response of canola was tested in a B-deficient soil in two consecutive canola crops and compared to fertilizers containing uncoated colemanite.

2 Materials and Methods

2.1 Fertilizer Manufacturing

The fertilizers were prepared using ground colemanite (Etimine USA Inc., 15.7% B) and borax (Dehybor® sodium tetraborate, anhydrous borax, 30 mesh, U.S. Borax Inc.; 21.4% B) as B sources, and DAP (The Mosaic Company, LLC) as the P source. A homogeneous mixture of ground DAP and borax was prepared by separately passing the P and B sources through a 250-μm sieve to achieve similar particle size and then regrinding the DAP and borax together (to achieve 0.6% B-containing fertilizer) using a mortar and pestle to ensure homogeneity. The material was further mixed in a Spex™ 8000M mixer mill for 30 s at 1080 cycles min−1. Similarly, a mixture of DAP and colemanite of the same size (< 250 μm) was used to produce 0.6% B-containing fertilizers. A control fertilizer (DAP only) was prepared from the ground DAP. The homogenized materials were pelletized by applying 10 kg force for nominally 5 s using a pellet press to achieve similar-sized pellets (0.1 g) of all products.

For the development of the slow-release B fertilizers, a colemanite core was produced by granulation of the colemanite powder using a laboratory granulator (~20 rpm) consisting of a stainless steel pan granulator (18-cm diameter), a peristaltic pump delivering demineralized water to an air-assisted spray nebulizer. The granules were then sieved through ~1.5-mm sieve and weighed to obtain 3.83 ± 0.2 mg granules with an average diameter of ~1 mm. These colemanite granules were coated with wax (candelilla wax, Euphorbia cerifera, Aussie Soap Supplies) or ES (< 125 μm, VWR, BDH, Prolabo, Belgium) to make two different fertilizers, each containing 0.6% B but varying only in coating material (wax or ES) for the colemanite. The wax and ES were heated on a hot plate separately at 80–90 °C and 140–145 °C, respectively. The temperature was maintained above their melting points (70 °C for wax and 115 °C for ES) by checking occasionally using a temperature gun. Each granule of colemanite was coated by dipping into the hot and melted coating material. The final pellet formulations were made by co-compacting milled DAP with the coated “core” colemanite. Each core granule was weighed at each step to ensure all granules with the same coating material were uniform. The colemanite core was 3.8 mg, the wax- and ES-coated colemanite granules were ~10 and ~25 mg, respectively, and the whole co-compacted pellet (coated colemanite with DAP) was 100 mg regardless of the core coating material used. The resulting products were oven-dried at 60 °C overnight.

2.2 Acid Digestion of Fertilizers

To confirm the B content in the fertilizer formulations, the pellets were acid-digested in triplicate (Abat et al. 2015b). A pellet (0.1 g) of each fertilizer was placed in a Greiner™ tube. The digestion of coated colemanite required grinding of the pellets (especially those with ES coatings of the core) to ensure the complete digestion of the fertilizer. Hydrochloric acid (HCl 36%, UNIVAR, UN No. 1789) and nitric acid (70%, RCI Labscan Limited, CAS No. 7697-37-2) were added at 1.8 mL and 0.6 mL as aqua regia mixture (HCl:HNO3 = 3:1). The tubes were hand-tightened, vortexed briefly, and predigested overnight at room temperature. The tubes were then re-vortexed and placed in a digest block at 80 °C for 45 min. The pressure inside the tubes was relieved and the temperature was further increased up to 125 °C for 165 min. The tubes were left to cool down and final volume was made up to 20 mL using deionized water. The solution was re-vortexed for 15 s and filtered, and the B, P, and sulfur (S) concentrations in the digest solutions were determined using inductively coupled plasma-optical emission spectroscopy (ICP-OES).

2.3 Kinetics of Dissolution

A column dissolution experiment was performed to analyze the release of B and P from the fertilizers using the method described by Baird et al. (2019). The (Sigma-Aldrich) glass wool used in the column perfusion test is silanized, which shields active silanol groups on the untreated glass surfaces rendering it hydrophobic to ensure no chemical interactions. In brief, 1 g of fertilizer pellets was placed between glass wool in a column and deionized water was pumped at a constant flow rate (10 mL h−1) from the bottom of the column to the top. Leachates containing soluble nutrients from the fertilizers were collected in a mechanized fraction collector at specific time intervals. The column dissolution was performed in duplicate. The B concentrations in the leachates were determined by ICP-OES. Also, the residues in the columns were recovered, acid-digested, and analyzed to check for complete B mass balance.

2.4 Soil Incubation

The top layer (0–10 cm) of a soil near Monarto (South Australia) was collected, air-dried, and sieved to a particle size of less than 2 mm. The soil is classified as an Alfisol with sandy loam texture (clay 83, silt 71, and sand 810 g kg−1), less than 0.2% CaCO3, 0.22 mg kg−1 hot water extractable B, and pH (water) of 7.8 (da Silva et al. 2018). The soil was low in extractable B concentrations and therefore considered as B deficient for agricultural crops as stated by Sims and Johnson (1991). The same soil was used for the soil incubation and pot experiment.

Petri dishes were filled with 30 g of soil moistened to field capacity (13 mL demineralized water per 100 g) and a fertilizer pellet (0.1 g) was inserted in the center ensuring that it was properly covered with soil. Each treatment was replicated three times. All Petri dishes were covered with lids and placed in zip lock plastic bags to retain moisture. The samples were incubated in the dark at 30 °C and analyzed at 3, 7, 14, 28, and 56 days after fertilizer application. At each sampling time, the remaining fertilizer pellet was recovered and the soil was sampled from the center at three concentric distances (0–7.5, 7.5–15, and 15–26.5 mm). The fertilizer pellets were digested separately, while soil samples were extracted using 0.5 mM CaCl2 solution and concentrated acid (Degryse and McLaughlin 2014). The concentrations of B in these solutions were determined by ICP-OES.

2.5 Pot Experiment

A pot experiment was carried out with 2 consecutive crops. The soil was leached after fertilizer application and before planting of the second crop to represent a rainfall event. A fabric cloth with a mesh size of 0.5 mm was glued to the bottom of the perforated pots (12-cm diameter) to prevent loss of soil during leaching. The pots were filled with 1-kg air-dried and sieved (< 2 mm) soil. For each fertilizer, 3 pellets (ca. 0.1 g per pellet) were placed at a depth of 4 cm distributed uniformly across the pot. A treatment containing DAP only was used as a control. Each treatment was replicated four times. After the addition of fertilizer, each pot was placed in a water-filled container to attain field capacity and then leached with 3 pore volumes (PV) of deionized water. The soil leachate was collected after 1 day and the volume was recorded. About 10 mL of leachate was filtered (0.45-μm Sartorius filter) and analyzed for B concentrations by ICP-OES.

The pots were left for 2–3 days and four canola (Brassica napus L.) seeds per pot were sown. The treatments were arranged according to a completely randomized design. Two weeks after germination, seedlings were reduced to two plants per pot. Then, a basal macronutrient solution containing 20 mg N, 15 mg K, 7.5 mg Ca, 14 mg S, and 12 mg Mg was applied to each pot. The DAP+B fertilizers had different P concentrations, so additional P (as mono-ammonium phosphate) was added as a solution to balance the P concentration at 60 mg kg−1 for all treatments. A micronutrient solution containing Cu, Mn, and Zn was applied equivalent to the rate of 1, 1.5, and 2 mg kg−1 soil, respectively. The germinated seedlings were thinned to one plant 3 days after the nutrient application. The soil was moistened to field capacity on a daily basis. The plants were harvested during flowering, 6 weeks after transplanting. The plants were cut at about 1 cm above the soil surface and roots were left in the pots to leave the soil and fertilizer pellets undisturbed for the second crop. The shoots were dried in an oven at 60 °C for 3 days and weight was recorded. The oven-dried shoot material was milled and then digested in 3:1 ratio of HCl:HNO3 (Wheal et al. 2011). The digests were analyzed for nutrient concentrations using ICP-OES.

After harvesting the first crop, another leaching event was carried out on the same pots with 3 PVs using the same procedure as for the first leaching. Four canola seedlings (grown for 3 days on Monarto soil) were transplanted into the leached pots. The germinated seedlings were thinned to two plants after 1 week and further reduced to one plant per pot after 2 weeks. Macro- and micronutrient solutions were applied at the same rates as for the first crop. Also, an additional 35 mg P per pot was applied but no additional B was added. Half of the nutrient dose was applied during the first week of transplantation and the other half dose was added just before the onset of flowering. Both crops were harvested after 45 days of transplanting at the flowering stage with BBCH code 60-61 (Lancashire et al. 1991). After the harvest of second crop, the roots of both crops were removed, and plant samples were digested and analyzed by ICP-OES.

2.6 Statistical Analysis

The effects of different treatments were evaluated by analysis of variance (ANOVA) technique. Tukey’s honestly significant difference (HSD) test was applied to separate significantly different treatment means (Steel et al. 1997) by using Statistix 8.1 software (Analytical Software, Tallahassee, FL, USA). Significant differences among treatments were considered at P ≤ 0.05.

3 Results

3.1 Concentration of B in Different Fertilizers

The composition of all the fertilizers is given in Table 1 and optical microscope images of granules and pellets are shown in Fig. 1. There was no detectable B in the control fertilizer. The other pellets contained around 0.5% B, slightly lower than the target concentration (0.6%).

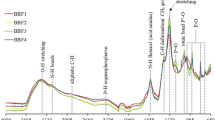

3.2 Kinetics of Dissolution of B from Fertilizers

Figure 2 shows the kinetics of dissolution of B from the different fertilizers. The fertilizers manufactured as a wax- or ES-coated colemanite core in DAP showed much slower release of B in the eluates than the uncoated colemanite-DAP fertilizers. For example, ~90% of B release was observed after 8 and 14 h of column dissolution from DAP with uncoated colemanite fertilizer and DAP with borax fertilizers, respectively. However, only 2.9 and 2.1% of B was released even after 72 h of dissolution from the wax- and ES-coated colemanite fertilizers, respectively. The fertilizer with wax-coated colemanite showed slower release of B than the ES-coated colemanite. After 10 h, 0.55% of B was released for the wax-coated fertilizer compared to 2.1% for the ES-coated fertilizer.

3.3 Soil Incubation

The diffusion of CaCl2-extractable B or soluble B (Table 2) and the total B (recovered by acid extraction; Fig. 3) was compared with time at different distances, i.e., < 7.5, 7.5–15, and > 15 mm from the fertilizer pellet. Similar conclusions can be drawn about the release of B into soil from the soluble B concentrations and from the total B distribution.

Percentage of total B recovered (by acid extraction) in the pellet (granule) or in the soil at < 7.5 mm (In), 7.5–15 mm (Mid), and 15.5–26.5 mm (Out) from the application point at different times. Data are shown as mean of four replications. Cole, colemanite; B, boron; ES, elemental sulfur; d, days; w, weeks

Borax and uncoated colemanite treatments showed fast release and thus rapid diffusion through the soil. After 3 days of incubation, only 4 and 7% B was retained in the DAP pellets, respectively. Diffusion of B away from the pellet resulted in a decrease in the total and soluble concentrations in the inner section over time and an increase in the outer section. Initial concentrations near the pellet were high until B was diffused with time into the middle and outer soil. The release was slightly faster for borax than colemanite in the DAP pellet.

The pellets with coated colemanite granules showed much slower release compared to those with borax or uncoated colemanite. After 3 days, there was ≥ 85% of B retained in the coated pellets and after 8 weeks, it was still around 40%. The soluble B concentrations close to the pellet with (either wax or ES) coated colemanite granule were lower and changed less over time than for the non-coated fertilizers. The concentrations in the outer section increased over time but were lower than for the non-coated fertilizers containing either borax or colemanite. The release of B in soil was faster for the pellets containing ES-coated colemanite granules than for those with wax coatings.

3.4 Pot Trial: Leaching of B

The amount of B in the leachates was determined (Table 3). The overall B leached was significantly higher for uncoated fertilizers compared to the wax- and ES-coated fertilizers. In the first leaching, 21% of the added B was leached for the borax treatment and 12% for the colemanite treatment. In the second leaching, there was no significant difference between the borax and colemanite treatment (12–16% of added B). There was no significant leaching of B from the wax-coated pellets (0.06 mg of B leached kg−1 soil) or the ES-coated pellets (0.07 mg of B leached kg−1 soil) compared to the control (no B added to soil) (0.04 mg of B leached kg−1 soil). Over the two leaching events, 37% from the borax-containing fertilizer and 24% from the colemanite-containing fertilizer were recovered in the leachate, compared to only 1–2% for the coated fertilizers. Thus, the data clearly demonstrated that the coating treatment strongly reduced B leaching.

3.5 Pot Trial: Yield and B Uptake

Table 4 gives the dry matter yield and B concentration in shoots of the two consecutive crops, as well as the dry matter yield of roots recovered at the end of the experiment. The dry matter yields followed the same order for both crops: ES-coated ≥ wax-coated ≥ uncoated colemanite > borax ≥ control.

The B concentrations in the shoot followed the same order as the dry matter yield, with the highest concentrations for the coated-treatments. Higher B concentrations were observed for the first crop than for the second crop, likely due to the losses by leaching and uptake in the first crop. The B concentrations in the shoot (37–63 mg kg−1) were much higher than those in the root (9–13 mg kg−1). Table 5 shows how much of the added B was recovered in the leachates and in the different plant parts. Overall, 1–37% of the added B was recovered in the leachates and 8–31% in the shoots and roots. The amount of B remaining in the soil (i.e., not recovered in the leachates or in the plants) ranged from 55% for the borax treatment to 70% for the wax-coated treatment. Much higher percentages of added B were leached from the borax and uncoated colemanite products (24–37%) compared to the coated treatments (1–2%). As a result, there was a much higher recovery of B in plants for the coated products.

4 Discussion

The provision of B to crops through fertilization is a challenging practice, as B is highly mobile in soil and leaches easily; B has a narrow range between deficient and toxic levels; and a B-only fertilizer presents a problem for uniform distribution when applied in a dry blend. The fertilizers used for correcting B deficiency are the soluble B sources such as borax, usually applied at the time of sowing (Bell and Dell 2008). However, the direct application of some nutrients, e.g., B, may result in burning of leaves (Rehman et al. 2012). Moraghan and Mascagni (1991) showed that the soluble fertilizer sources can cause B toxicity even at optimum rates of application; thus, a slow-release fertilizer formulation could provide significant advantages for this nutrient.

When B is incorporated into a fertilizer containing macronutrients, the problems associated with uniform spreading of B can be overcome. However, it is important to choose a suitable carrier to avoid adverse interactions related to availability of other nutrients. It has been reported that the availability of P was decreased by increasing B concentrations when tri-calcium phosphate fertilizers supplemented with borate were used (Terman and Brown 1958). However, B is a micronutrient and so the very low concentration of this nutrient is unlikely to affect the availability of a macronutrient carrier, instead the macronutrient carrier could affect B release (da Silva et al. 2018). Abat et al. (2015b) explained that mono-ammonium phosphate (MAP) can have negative effects on slow-release borate materials. This effect is related to the high concentrations of P associated with low pH within and around the granule on dissolution. Calcium concentrations are reduced through precipitation of Ca-P compounds, thus increasing the solubility of sparingly soluble slow-release B sources containing Ca like ulexite and colemanite. The same problem is likely to arise using single, double, or triple superphosphate fertilizers. Thus, B availability to plants can vary depending on chemical reactions taking place during fertilizer formulation (Magda et al. 2010) or after their application to the soils (da Silva et al. 2018). Furthermore, colemanite cogranulated with MAP caused B toxicity to seedlings (Abat et al. 2015c). In the present study, we tried to slow down colemanite dissolution by protecting the Ca2+ in the colemanite granule via wax or ES coating thereby restricting the reactions of P with Ca2+. Diammonium phosphate was selected as a source of P (22%) and N (18%) for plants, as it is being widely used in many developing countries.

The development of fertilizer products was followed by column dissolution experiments which confirmed that the products with higher solubility showed higher B release than the less soluble or slow-release fertilizers as reported by da Silva et al. (2018) and Saleem et al. (2011). While Abat et al. (2015a) described B toxicity in canola through the use of ulexite, borax, and cogranulated colemanite with MAP at a similar B rate (1.8 mg B kg−1) in a deficient soil, we did not find any toxicity symptoms due to the application of co-pelleted anhydrous borax or colemanite with DAP. The reason could be the lower concentration of B (0.6%) used in tested products as compared to Abat et al. (2015a) who used 1% B in their fertilizers. Also, we used Dehybor® anhydrous borax compared to borax decahydrate. The solubility of anhydrous borax is 2.5% (25 g L−1) while borax decahydrate has twofold solubility which is 5% (50 g L−1) at 20 °C. The coated products (wax and ES) showed negligible release of B even with the outer core of DAP which means the P in DAP was unable to react with Ca2+ present in the coated colemanite contrary to the cogranulation of MAP with colemanite (Abat et al. 2015b).

The wax- or ES-coated fertilizers released B slowly with time resulting in only small amounts moving to the outer soil even after several weeks of incubation. Degryse (2017) described that the slow-release fertilizers of B should not only slow down leaching losses but also protect the seedling from expected toxicity along with supplying enough B to cure crop B deficiency. In the wax- and ES-coated B fertilizers, slow but continuous release of B with time not only enhanced the yield but also reduced the leaching and resulted in higher B availability to the plant over both crops (Tables 4 and 5).

Application of B improves meristematic growth (Bohnsack and Albert 1977) and increases elongation and division of cells (Mouhtaridou et al. 2004). The B concentrations in the shoot were above the critical value of 56 mg kg−1 (Reuter and Robinson 1997) for the fertilized treatments, unlike that in the control (Table 4). The positive relationship between shoot dry weight and shoot B concentrations (Fig. 4a) and B uptake (Fig. 4b) illustrates the positive effect of B addition on plant growth. Concentrations of B in roots were lower than those in shoots as observed by Abat et al. (2015a). Samreen (2019) also found an increase in B concentration of shoots and roots by the application of bioaugmented B-coated DAP leading to better plant growth. The higher B concentrations in shoots and higher yields in the coated treatments are likely due to the less leaching losses of B caused by slow release/coated fertilizers contrary to that in the uncoated treatments. This hypothesis is supported by the positive relationship between shoot dry weight and net B addition (=added B – leached B, Fig. 4c).

Although it was expected that the slow-release granules will better withstand the losses of B due to leaching and more B will be retained for plant uptake (Abat et al. 2015a), the concern was that the release rate of the B might be too slow for adequate crop nutrition. However, it is evident from the data that the developed fertilizers were able to provide sufficient B over at least 2 cropping cycles (under leaching conditions) under the conditions of the pot trial. Depending on crop species and fertilizer rate, the release rate of the wax-coated fertilizers might be too slow to meet the peak demand under field conditions, but reducing coating thickness would increase the release rate. Slow-release B fertilizers based on boron phosphate (BPO4) also reduced B leaching and supplied more B to the plant over longer period of time compared to soluble B fertilizers (Abat et al. 2015b). However, Eguchi and Yumda (1997) found that cropping on soils in high rainfall areas (> 2000 mm per annum) receiving a slow-release B fertilizer resulted in 40 to 60% of added B leached, 10% was taken up by plants, and 30–40% of the added B was retained in soil. There were few details of the fertilizer provided but it was stated the product contained no water-soluble B. In our experiment, the total recovery in plant and leachates (Table 5) was around 25–45%. The remainder of the B was likely retained in the soil, due to B adsorption in the alkaline soil, and within the coated fertilizers.

Coated colemanite (wax- or ES-coated) co-compacted/pelletized with DAP was found to be a more effective B source to include in DAP than borax or uncoated colemanite, as the coated formulations were able to prevent leaching losses of B yet provide enough B for crop nutrition.

5 Conclusions

The novel wax- or elemental sulfur (ES)–coated colemanite co-compacted (pelletized) in diammonium phosphate (DAP) could be used as an efficient slow-release boron (B) fertilizer, solving many problems related to B management. For example, the application of a single fertilizer can provide nitrogen (N), phosphorus (P), and B together, and also can ensure uniform distribution of B. Leaching losses of B are minimal with these formulations, yet the formulations provide adequate B for crop nutrition as well as being “seedling safe.” It is suggested that the effectiveness of these products should be further evaluated under field conditions using different crops, soils, and variable climate.

References

Abat M, Degryse F, Baird R, McLaughlin MJ (2014) Formulation, synthesis and characterization of boron phosphate (BPO4) compounds as raw materials to develop slow-release boron fertilizers. J Plant Nutr Soil Sci 177:860–868. https://doi.org/10.1002/jpln.201400234

Abat M, Degryse F, Baird R, McLaughlin MJ (2015a) Responses of canola to the application of slow-release boron fertilizers and their residual effect. Soil Sci Soc Am J 79:97–103. https://doi.org/10.2136/sssaj2014.07.0280

Abat M, Degryse F, Baird R, McLaughlin MJ (2015b) Slow-release boron fertilizers: co-granulation of boron sources with mono-ammonium phosphate (MAP). Soil Res 53:505–511. https://doi.org/10.1071/SR14128

Abat M, Degryse F, Baird R, McLaughlin MJ (2015c) Boron phosphates (BPO4) as a seedling-safe boron fertilizer source. Plant Soil 391:153–160. https://doi.org/10.1007/s11104-015-2424-6

Ahmad W, Zia MH, Malhi SS, Niaz A, Saifullah (2012) Boron deficiency in soils and crops. A review. In: Goyal DA (ed) Crop Plant, pp 77–114 ISBN: 978-953-51-0527-5

Baird R, da Silva RC, Degryse F, McLaughlin MJ (2019) A column perfusion test to assess the nutrient release kinetics by soluble, sparingly soluble and coated granular fertilizers. Plant Nutri Soil Sci 182:763–771. https://doi.org/10.1002/jpln.201800666

Baxter AE, Maguire RO, Whitehurst G, Holshouser D, Reiter M (2019) Novel fertilizer as an alternative for supplying manganese and boron to soybeans. Commun Soil Sci Plant Anal 50:65–76. https://doi.org/10.1080/00103624.2018.1547393

Bell RW, Dell B (2008) Micronutrients in sustainable food, feed, fibre and bioenergy production. Int Ferti Ind Assoc (IFA), Paris

Benton JJ (2003) Agronomic handbook; management of crops, soils and their fertility. CRC press, Boca Raton

Bohnsack CW, Albert LS (1977) Early effects of boron deficiency on indoleacetic acid oxidase levels of squash root tips. Plant Physiol 59:1047–1050. https://doi.org/10.1104/pp.59.6.1047

Byers DE, Mikkelsen RL, Cox FR (2001) Greenhouse evaluation of four boron fertilizer materials. J Plant Nutr 24:717–725. https://doi.org/10.1081/PLN-100103665

da Silva RC, Baird R, Degryse F, McLaughlin MJ (2018) Slow and fast-release boron sources in potash fertilizers: spatial variability, nutrient dissolution and plant uptake. Soil Sci Soc Am J 82:1437–1448. https://doi.org/10.2136/sssaj2018.02.0065

Degryse F (2017) Boron fertilizers: use, challenges and the benefit of slow-release sources–a review. Bor Dergisi 2:111–122

Degryse F, McLaughlin MJ (2014) Phosphorus diffusion from fertilizer: visualization, chemical measurements, and modeling. Soil Sci Am J 78:832–842. https://doi.org/10.2136/sssaj2013.07.0293

Diana G (2006) Boron in the soil, from deficit to toxicity. Inf Agrar 62:54–58

Eguchi S, Yamada Y (1997) Long-term field experiment on the application of slow-release boron fertilizer. Part 2. Behavior of boron in the soil. In: Bell RW, Rerkasem B (eds) Boron in soils and plants: proceedings of the international symposium on boron in soils and plants, Springer, Berlin, pp. 49–56

Ferguson D, Olson R, Heinbigner C (2013) US Patent 20130031943 A1. In: Compacted muriate of potash fertilizers containing micronutrients and methods of making same. US Patent Office, Washington, DC

Kmecl P, Bukovec P (1999) Boron phosphate: its synthesis, gradual crystallisation and characterisation of bulk properties. Acta Chim Slov 46:161–171

Lancashire PD, Bleiholder H, Van Den Boom T, Langelüddeke P, Stauss R, Weber E, Witzenberger S (1991) A uniform decimal code for growth stages of crops and weeds. Ann Appl Biol 119:561–601. https://doi.org/10.1111/j.1744-7348.1991.tb04895.x

Magda A, Pode R, Muntean C, Medeleanu M, Popa A (2010) Synthesis and characterization of ammonium phosphate fertilizers with boron. J Serbian Chem Soc 75:951–963. https://doi.org/10.2298/JSC090228064M

Moraghan JT, Mascagni HJ (1991) Environmental and soil factors affecting micronutrient deficiencies and toxicities. In: Mortvedt JJ, Cox FR, Shuman LM, Welch RM (eds) Micronutrients in agriculture, 2nd edn. Soil Sci Soc Am Inc, Madison, pp 371–425

Mortvedt JJ (1968) Availability of boron in various boronated fertilizers. Soil Sci Soc Am J 32:433–437. https://doi.org/10.2136/sssaj1968.03615995003200030045x

Mortvedt JJ (1994) Boron diet essential for crops. Farm Chem 2

Mortvedt JJ, Woodruff JR (1993) Technology and application of boron fertilizers for crops. In: Gupta UC (ed) Boron and its role in crop production. CRC Press, Boca Raton, pp 156–176

Mouhtaridou GN, Sotiropoulos TE, Dimassi KN, Therios IN (2004) Effects of boron on growth, and chlorophyll and mineral contents of shoots of the apple rootstock MM106 cultured in vitro. Biol Plant 48:617–619

Rashid A (2006) Boron deficiency in soils and crops of Pakistan. In: Diagnosis and management, vol 8. Pak Agric Res Coun (PARC), Islamabad, p 34

Rehman AU, Farooq M, Nawaz A, Iqbal S, Rehman A (2012) Optimizing the boron seed coating treatments for improving the germination and early seedling growth of fine grain rice. Int J Agric Biol 14:453–456

Reisenauer H, Walsh L, Hoeft R (1973) Testing soils for sulphur, boron, molybdenum, and chlorine. In: Walsh L, Beaton J (eds) Soil testing and plant analysis, 3rd edn. Soil Sci Soc Am, USA, pp 173–200

Reuter DJ, Robinson JB (1997) Plant analysis. An interpretation manual, 2nd edn. CSIRO Publishing, Melbourne

Rowell AWG, Grant PM (1975) A comparison of fertilizer borate and colemanite incorporated in granular fertilizers. Rhod J Agric Res 13:63–66

Saleem M, Khanif YM, Ishak YMF, Samsuri AW (2011) Solubility and leaching of boron from borax and colemanite in flooded acidic soils. Commun Soil Sci Plant Anal 42:293–300. https://doi.org/10.1080/00103624.2011.538882

Samreen T (2019) Effectiveness of organically-complexed bioaugmented boron coated DAP on growth, yield and oil content of Brassica (Unpublished doctoral dissertation). Univ Agric, Faisalabad

Shaviv A (2000) Advances in controlled release of fertilizers. Adv Agron 71:1–49

Shaviv A (2005) Controlled release fertilizers. IFA International workshop on enhanced-efficiency fertilizers, Frankfurt. Int Ferti Indus Associ, Paris

Sims JT, Johnson GV (1991) Micronutrient soil tests. In: Mortvedt JJ (ed) Micronutrients in agriculture. Book series 4. Soil Sci Soc Am, Madison, pp 427–476

Steel RGD, Torrie JH, Dickey D (1997) Principles and procedures of statistics: a biometrical approach, 2nd edn. McGraw Hill Book Co Inc, New York

Terman G, Brown B (1958) Crop response to boronated fused tricalcium phosphates. Soil Sci 86:47–53. https://doi.org/10.1097/00010694-195807000-00008

Trenkel ME (2010) Slow- and controlled-release and stabilized fertilizers: an option for enhancing nutrient use efficiency in agriculture. Int Ferti Indus Associ (IFA), Paris

Welch RM, Allaway WH, House WA, Kubota J (1991) Geographic distribution of trace element problems. In: Mortvedt JJ (ed) Micronutrients in agriculture, 2nd edn. Madison, WI, USA, pp. 31–57

Wheal MS, Fowles TO, Palmer LT (2011) A cost-effective acid digestion method using closed polypropylene tubes for inductively coupled plasma optical emission spectrometry (ICP-OES) analysis of plant essential elements. Anal Methods 3:2854–2863. https://doi.org/10.1039/C1AY05430A

Winsor HW (1950) Boron sources of moderate solubility as supplements for sandy soils. Soil Sci 69:321–332

Wojcik P, Wojcik M, Klamkowski K (2008) Response of apple trees to boron fertilization under conditions of low soil boron availability. Sci Hortic (Amsterdam) 116:58–64. https://doi.org/10.1016/j.scienta.2007.10.032

Acknowledgements

Tayyaba Samreen is highly obliged to the Australian Government for providing the Endeavour Research Fellowship which enabled her to work in the Fertilizer Technology Research Center (FTRC), University of Adelaide, Australia, under the supervision of Prof. Michael McLaughlin and supported by The Mosaic Company, LLC. She is also grateful to the University of Agriculture, Faisalabad, Pakistan, for leave, and for moral support from Liellie McLaughlin and Mihiri Seneviratne during her stay in Australia. We are thankful to Colin Rivers, Bogumila Tomzcak, Ivan Andelkovic, and Ashleigh Broadbent for their technical assistance.

Funding

This work was supported by the Endeavour Research Fellowship, Australia, and The Mosaic Company, LLC.

Author information

Authors and Affiliations

Contributions

Tayyaba Samreen: conceptualization, formal analysis, writing—original draft. Fien Degryse: conceptualization, investigation, drafting. Roslyn Baird and Rodrigo Coqui da Silva: conceptualization, drafting. Zahir Ahmad Zahir: drafting. Abdul Wakeel, Sidra-Tul-Muntaha, and Muhammad Zulqernain Nazir: statistical analysis, drafting. Michael McLaughlin: conceptualization, drafting, supervision.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samreen, T., Degryse, F., Baird, R. et al. Development and Testing of Improved Efficiency Boron-Enriched Diammonium Phosphate Fertilizers. J Soil Sci Plant Nutr 21, 1134–1143 (2021). https://doi.org/10.1007/s42729-021-00428-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42729-021-00428-w