Abstract

Over millions of years of evolution, nature has created organisms with overwhelming performances due to their unique materials and structures, providing us with valuable inspirations for the development of next-generation biomedical devices. As a promising new technology, 3D printing enables the fabrication of multiscale, multi-material, and multi-functional three-dimensional (3D) biomimetic materials and structures with high precision and great flexibility. The manufacturing challenges of biomedical devices with advanced biomimetic materials and structures for various applications were overcome with the flourishing development of 3D printing technologies. In this paper, the state-of-the-art additive manufacturing of biomimetic materials and structures in the field of biomedical engineering were overviewed. Various kinds of biomedical applications, including implants, lab-on-chip, medicine, microvascular network, and artificial organs and tissues, were respectively discussed. The technical challenges and limitations of biomimetic additive manufacturing in biomedical applications were further investigated, and the potential solutions and intriguing future technological developments of biomimetic 3D printing of biomedical devices were highlighted.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Traditional manufacturing methods have been used to fabricate biomedical devices for a long period [1]. However, the human body is composed of complex structures and material systems, and the current manufacturing technologies, which are limited in material selection and fabrication capability, cannot meet criteria that produce biomedical devices with complex bioinspired architectures and structures, impeding the development of biomedical devices in diverse applications [1]. A promising rapid prototyping technology, additive manufacturing (AM), also known as three-dimensional (3D) printing, has emerged to address these shortcomings [2, 3]. Currently, different types of 3D printing technologies, such as electron beam melting (EBM), two-photon polymerization (TPP), stereolithography (SLA), selective laser melting/sintering (SLM/S), direct ink writing (DIW), extrusion-based 3D printing (EBP), fused deposition modeling (FDM), laminated Object Manufacturing (LOM), and laser-induced forward transfer (LIFT), have been developed to create new opportunities for manipulating and fabricating multiscale, multi-material and multi-functional structures with precise control of details [1]. Because of the outstanding fabrication capabilities, 3D printing processes have wide applications in different fields, including biomedical engineering, automobile, aerospace, electronics, civil engineering, sustainable energy, etc. [2, 3]. As a form of 3D printing technology, bioprinting, which fabricate biomedical parts with cells, tissues, growth factors, biomaterials and other biological related materials, are also rapidly developed based on existing 3D printing technologies, such as SLA, DIW, EBP and Ink jet, could be used in bioprinting. Alterations of organism’s morphologies are delicately crafted over millions of years of evolution and the evolved high-performance biological materials and structures provide us with valuable inspiration for the design of next-generation functional structures and material systems [3,4,5,6,7]. Integration of 3D printing and biomimicry promotes advancements in the fabrication of functional material and structures for future engineering systems, which will further lead to breakthroughs of various applications in the biomedical industry [8].

Along with the progress made in biomimetic 3D printing technologies, an increasing number of materials, such as metal, ceramic, polymer, composite, and living cells, can be manufactured to mimic natural or living matter with unique structures and properties [8,9,10,11,12,13,14,15,16,17,18]. For example, conventional metallic and ceramic biomaterials have been studied and applied to the construction of bioinspired scaffold assisted microenvironments [14]. Besides, biomimetic polymeric material, such as nanocomposite and hydrogels, has drawn more attention in the growing field of tissue engineering over the past few years [15, 19, 20]. Compared with other materials, biocompatible and biodegradable hydrogels [21] and polymers [22] were long-established for the creation of 3D cell culture microenvironment. Hydrogel provides an aqueous environment to support the transportation of nutrient and cell waste [19], and reveals a lot of advantages such as structural similarity to the natural extracellular matrix (ECM), easy handling and processing, adjustable biochemical and biophysical properties [20, 21]. Mammalian sourced hydrogel can be harvested by using detergent treatment to remove cells and antigens from tissues [22, 23], and nonmammalian sourced hydrogel can be derived from marine algae [24, 25] and plants [26, 27]. For mammalian sourced hydrogel, collagen monomers enable self-assembly to form fibrillar structures and further to be crosslinked into a viscoelastic gel when temperature, pH, and ionic strength are close to physiological conditions [28]. Currently, the mammalian hydrogel is an appealing material for diverse biomimetic microenvironment applications, such as substrates for in vitro cell culture [29], and lab-on-chip systems [30]. As for nonmammalian sourced hydrogel, alginate has been massively used to produce hydrogels via many different crosslinking methods [31, 32]. As a potential material solution of bioinspired medical devices, alginate hydrogels exhibit a lot of promising properties. For instance, alginate hydrogels can be used to print bioinspired microrobots for the releasing of small molecules and proteins, due to bioactive ligands to cells and adjustable-rate degradation [33,34,35]. Besides, lots of studies have manifested the potential applications of polymers as biomaterials for the fabrication of biomimetic medical devices [36,37,38]. The food and drug administration (FDA) approved polymers, including polyglycolic acid (PGA) [39], polylactic acid (PLA) [40], poly(lactic-co-glycolic acid) (PLGA) [41] and poly(ε-caprolactone) (PCL) [42], etc., were commonly used in diverse biomedical applications, because of easy processing, consistency, adequate mechanical properties, and biodegradability [43, 44].

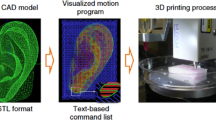

Enigmatic natural creatures, such as animal, plants, and microorganism, which possess unique structures for gathering nutrients or evading from predators, give engineers massive potential ideas to mimic the natural interior material ingredients and exterior geometric structures. For example, hydroxyapatites, known as one type of bone material, were employed to fabricate the scaffold with biomimetic bone structures to achieve the desired mechanical requirement for bone regeneration [13]. Specific bionic microenvironment to meet the demands of disparate cells has been developed, and many novel methods were investigated to realize specific medical goals based on bioinspired structures and material system [40, 45]. For instance, magnetic 3D printed micro-fish was used as a bioinspired carrier to transfer drugs into the target area under the control of the magnetic field [45]. Bionic material systems and structures have achieved remarkable functionalities, and this review summarized current progress in 3D printing of biomimetic materials and structures for biomedical applications. Inspired by natural plants and animals, unique biological structures and materials were reproduced through 3D printing technologies for various biomedical applications (refer to Fig. 1). This paper is mainly carried out in five aspects: (1) 3D printing biomimetic scaffold-based implants. (2) 3D printing biomimetic lab-on-chip. (3) 3D printing biomimetic medicine for drug delivery. (4) 3D printing biomimetic microvascular network. (5) 3D printing artificial organs and tissues. In each aspect, the investigation covers the bioinspired design scenario of the functional devices, the development of novel 3D printing techniques, the adoption of advanced biomaterials, the construction of distinguished biomimetic structures, and current achievements in specific applications. In the end, the current achievement, existing challenges, and outlook of future further work in the field of biomimetic AM of biomedical devices will be discussed.

Status of biomimetic 3D printing in the biomedical and tissue engineering. a 3D-printed scaffold with bone material using slurry-based 3D printing for long bone regeneration (copyright is from [14]). b 3D-printed biomimetic micro-texture using projection-based SLA for cell culture [43]. c 3D-printed bioinspired microneedles with mechanical reinforcement using magnetic field-assisted SLA for drug delivery (copyright is from [44]). d 3D-printed microvascular structures using SLA [140]; and e 3D-printed artificial cornea using DIW-based 3D printing (copyright is from [167])

3D printing of biomimetic scaffold-based implants

Scaffolds are designed with 3D porous structures to achieve decent mechanical properties for tissue regrowth [46]. The porous structures with adjustable hole size and distribution build up a microenvironment for cell attachment and nutrition exchanging [47]. With the advancement of tissue engineering, 3D scaffold-based implants play a vital role to replace and repair tissues and organs [47]. Researchers tried to create a biological environment similar to the native tissue environment by utilizing biomimetic scaffolds and materials. The biomimetic scaffolds must imitate the intricate properties and characteristics of the native extracellular matrix (ECM) [48]. Due to the complicated constitution of human organs and tissues, the biomimetic scaffold needs to be designed with corresponding bioinspired structures and materials for the regeneration of related tissue and organ [49]. The biomimetic design of material and structures brings challenges for the fabrication due to limited manufacturing capability and material selection. A lot of efforts have been made to develop new design and manufacturing methods of scaffolds to reproduce natural tissue structures and material system, aiming to achieve superior inter-connectivity, high porosity, suitable mechanical performance, and controllable degradation [50]. Conventional scaffold fabrication methods, such as freeze casting [51], foam replica [52], particle leaching [53], injection molding [54], and solvent casting [55], showed the shortcomings of fabricating scaffolds with complex biomimetic structures and materials. 3D printing enables the fabrication with more control and versatility benefit from the unique material accumulation principle [3]. The advanced 3D printing not only facilitates the design of scaffolds with bioinspired structures but also produces novel biomimetic microarchitectures with better anisotropic properties [56]. Besides, 3D scaffolds can be fabricated with novel materials that better imitate the natural ECM by using specifically developed printing process [14, 56,57,58,59,60,61]. Recent developments in biomimetic scaffold fabrication on both fabrication methods and biomaterials development were reviewed in this section.

The biomimetic scaffold can be utilized for tissue regeneration with the combination of different bioinspired materials and rapid prototyping techniques. Several novel bioinspired materials that promote the healing and regeneration of certain kinds of tissues have been proposed. For example, a novel bioinspired nanomaterial consisted of hydro-thermally treated nano-crystalline hydroxyapatite (nHA) and core–shell polyacid (PLGA) was developed to mimic a constructive microenvironment for the regeneration of osteochondral tissue [61]. Due to the biomimetic structure and composition of nHA, the novel bioink provided mechanical stability for the fabrication of scaffold by using 3D printing technology (Fig. 2a). Besides, the vivo experiment result indicated that such bioinspired nanomaterial enhanced human mesenchymal stem cells proliferation and osteochondral differentiation [57,58,59]. Another example is that the hybrid material incorporated chicken eggs (egg white and eggshell) and gelatin methacryloyl (GelMa) was developed to fabricate bone scaffold using photopolymerization-based printing technologies (refer to Fig. 2b) [60]. This new method extensively kept good biocompatibility and improved the mechanical properties of newly growing bone tissue based on the bioinspired material. Thus, bioinspired material-based scaffolds with, can be fabricated by 3D printing to provide a desired microenvironment for cell growth with excellent biological properties.

3D printing of biomimetic scaffolds with novel materials and structures. a Novel biological inspired nanocomposite composed of nHA and PLGA was fabricated by 3D bioprinting (copyright is from [200]). b 3D printing of haversian bone-inspired scaffolds for bone formation (copyright is from [62]). c Lotus root inspired bioscaffolds were printed using biomimetic materials (copyright is from [61]). d 3D printing of the spinal cord structure-inspired scaffold (copyright is from [65]); and e 3D-printed scaffolds with multiscale bone structures for long bone regeneration (copyright is from [63])

Moreover, biomimetic structures, which improve the porosity and mechanical performance, can prompt more effective cell delivery and tissue regeneration [61]. For example, haversian bone structures were reproduced to create functional scaffold, which demonstrated promising possibilities in multicellular delivery [62]. As shown in Fig. 2b, haversian canals, volkmann canals and cancellous bone structures were imitated in the scaffold design by using bioactive glass and bioceramic for the delivery of cell and nutrition [62]. The vivo results showed that the scaffold promoted the ingrowth of blood vessels and new bone regeneration [62]. Lotus root [61] is a common vegetable with unique parallel channels, and this parallel multichannel architectures connects the lotus root and leaves, achieving air and moisture exchange with the external environment [61]. This special architecture is an ideal structure with low density, high porosity, and low flow resistance. Inspired by such microstructure of lotus root, biomimetic materials were designed and fabricated into the scaffolds with lotus root-like structures for oxygen perfusion, cell delivery, and tissue ingrowth along the channels [61]. In addition, lotus root inspired scaffolds, composed of akermainite (AKT, Ca2MgSi2O7), were printed to regenerate bone tissue for large bone defects (refer to Fig. 2c). The lotus root inspired vascular structure facilitated the regeneration of bone defects, allowing forth of blood vessels and bone tissues to grow inside the structures [61]. To fabricate the inner bioinspired microchannel, the unique nozzle was modified and the newly developed printing process provided better flexibility to design scaffolds with complex bioinspired structures, patterns, and porosity [61]. Kim et al. [63] developed a novel 3D-printed micropatterned scaffold, which mimics microfibril structures for effective muscle cell regeneration. A PVA leaching process was utilized to obtain uniaxially aligned polycaprolactone (PCL) microfiber, and then the aligned PCL fibers were printed to produce aligned 3D structures that mimicked muscle tissues [63]. To function as a better ECM, PCL fibers were coated with collagen for the regeneration of muscle fiber [63]. The experiment results indicated that this bioinspired aligned structure provided decent mechanical properties and showed potential for more effective muscle tissue regeneration.

Compared with extrusion-based 3D printing, digital light-assisted stereolithography (SLA) presents better fabrication resolution, especially for microscale fabrication. In SLA printing process, the photocurable polymer is selectively cured to form the 3D scaffolds with complex structures, fast speed, and low cost [64]. For example, a microscale continuous projection-based SLA was applied to fabricate spinal cord inspired scaffold with central nervous system structures (refer to Fig. 2d) [65]. Hydrogel made up of poly(ethylene glycol)diacrylate (PEGDA) and GelMa was selected as the material of the scaffold, and the neural progenitor cells (NPCs) was loaded into the 3D-printed scaffolds to support axon regeneration [65]. The vivo test demonstrated that the biomimetic scaffold with NPCs enhanced the rebuilding process of central nervous system structures [65]. Besides, hydroxyapatite and tricalcium phosphate (HA/TCP) are major constituents of natural bone and teeth, and exhibit attractive biological properties for bone regeneration [13]. HA/TCP scaffolds with certain range of microporous structures have been successfully fabricated by using different 3D printing processes; however, it is hard to duplicate the natural bone structures with hierarchical porosity, which enables cell growth and nutrient transport [13]. To overcome this challenge, a microscale slurry mask image projection-based SLA was developed and a HA/TCP-based scaffold can be formed with complex geometry including biomimetic features and hierarchical porosity [13].

In this section, recent advancements in the fabrication of biomimetic scaffolds with 3D printing techniques were present. 3D printing is an effective tool that demonstrates great potentials in the fabrication of biomimetic scaffolds. As shown in Fig. 3, 3D-printed scaffolds are developed for soft tissue and hard tissue regeneration, and physical supporting implant [49]. Combining various bioinspired material and structures, 3D printed scaffolds demonstrated numerous advancements in various aspects, such as biocompatibility, complex geometries, controllable porosities, and mechanical properties. However, there are certain bottlenecks in biomimetic 3D printing of scaffolds for tissue regeneration. To be more specific, material selection is subject to the printing principle, and it is still hard to directly process most of natural material into 3D shapes by using current 3D printing technologies. A board range of natural material and corresponding manufacturing processes are required to be further investigated for future bio-fabrication. Moreover, replicating the original biological structures can potentially simulate original ECM and produce better support for cell growth and tissue regeneration. Therefore, more biomimetic structures should be extensively investigated and explored for scaffold design. The multiscale biomimetic scaffold sets higher demands on the printing capability of the 3D printing process. However, current 3D printing processes cannot accurately reproduce such multiscale natural structure, especially in micro- and nanoscales, and it still needs further development for the fabrication of scaffold with multiscale biomimetic structures for tissue regeneration. Currently, more and more researches are focused on the invention of multiscale additive manufacturing technologies, which will bring new possibilities and benefits to the fabrication of biomimetic scaffold for tissue regeneration [43, 66,67,68]. To sum up, one of the future trends in scaffold fabrication will focus on developing biomaterials and corresponding biomimetic structures that provide a better biomimetic microenvironment for specific cell regeneration and growth. The other direction to further develop multiscale and multi-material 3D printing processes for the fabrication of scaffold with distinctive biomimetic structures and material systems. Besides, bioactive cells and biomaterial are used to fabricate the scaffolds for tissue regeneration by using advanced bioprinting technologies. How to improve the cell survival rate, cell reaction, and function recovery of the cell after the printing still is a big challenge that need to be solved in the future. With developments in both biomimetic material and structure and the printing process, advancements of 3D printed biomimetic scaffolds will have a significant impact on tissue engineering in the long term and finally become available for clinical applications.

Summary of 3D printing biomimetic scaffold on resolution, material and process. a 3D printing of degradable scaffold for soft tissue regeneration (copyright is from [63]). b 3D printing of mussel-inspired scaffold for hard tissue regeneration (copyright is from [201]); and c 3D printing of nondegradable supporting implants (copyright is from [202])

3D printing of biomimetic lab-on-chip

Various methods have been established to work on reproducing the microenvironments of the living organisms in order to identify the pathological mechanism, study clinical therapeutic effects, and conduct drug screening for human wellness [69]. However, due to the limitation of manufacturing capability, most of the traditional approaches showed drawbacks and inadequacy in the representative, validation, and prediction of real cell or tissue environments [69]. For instance, recent studies have proven that the animal underlying mechanism is not quite the same as the human beings [70]; and the 2D cell culture validation method can only mimic the fragmentary phase of disease rather than the physiology in tissue or organ level, which may lead to inaccurate results [71]. The new construction technique of microenvironment is urgently needed to address these drawbacks. The development of 3D printing has brought new hope to build the bio-mimic microenvironment [43]. Benefit from the 3D printing technologies, 3D printed biomimetic scaffold, 3D printed artificial tissue, and 3D printed lab-on-chip are three main methods that have been widely used to simulate the actual microenvironment. For example, the micro-architecture of the 3D scaffold can be precisely rebuilt by using advanced printing technology so that the printed scaffolds can mimic the human tissues and create an observable medium for cell culture [72, 73]. Artificial tissue and organ are constructed through precisely controlled deposition and the combination between material and human cells, providing a direction of possibility for substitutes of the human organ [74]. 3D printed tissue and organ enables the drug screening in vitro without the animal test, increasing the accuracy and authenticity of the testing results. Besides, it may achieve in vivo transplantation to ease the problem of organ shortage for transplantation need [75].

3D-printed lab-on-chip is a technique that integrates several microfluidic components and procedures in a single chip to simulate the chemical and biological processes [76, 77]. For example, microvascular networks are fabricated to construct the lab-on-chip [78]. 3D-printed lab-on-chip is widely used for various purposes including diagnose diseases and biochemical analysis and detection [78]. The concept of lab-on-chip is that conduct cell co-cultures in a dynamic fluid combine with controlled atmospheres contact to achieve the recreation of important disease models and to understand the physiological mechanisms [79]. In lab-on-chip, not only biomaterial should be selected and developed, but also the structure of the living environment for cells should be reconstructed in order to mimic the microenvironment. For example, the muscle tissues of the heart forced the heart cells (cardiomyocytes) to couple mechanical stress to each other, and further generated elongated cell bundles, which created an anisotropic syncytium [80]. For achieving the elongation and coupling of cardiomyocytes, scientists developed unique structures with groove arrays along the surface. This designated lab-on-chip with nanostructure provided a suitable microenvironment for cardiomyocytes to elongate and align [81]. Another example is that one type of cells, which formed epithelial tissues of the human liver, is polarized to maintain efficient mass transfer between three types of surfaces [82]. To realize the function of these cells in vitro, researchers have demonstrated a method to reproduce the microenvironment using lab-on-chip for better cell polarization with modification of the surface of nanofibers [82]. There are still a great number of undiscovered unique structures in nature, which can better engineer and reproduce the microenvironment in vitro.

More and more 3D printing techniques, such as FDM, SLA, DIW, etc. are employed to fabricate the lab-on-chip for reproducing the biological microenvironment. For example, De Jaeghere et al. [83] developed a lab-on-chip with biomimetic heterocellular-shaped structures to recapitulate the tumor microenvironment of peritoneal metastases in vitro and in vivo. Ma et al. [84] adopted a novel bioprinting approach called a digital light processing (DLP)-based two-step 3D printing technique to fabricate liver lobule and vascular structures with photopolymerized gelatin GelMa and GMHA to encapsulated hiPSC-derived hepatic cells and the endothelial- and mesenchymal-originated supporting cells in complementary patterns (refer to Fig. 4a). Due to a better morphological organization, higher liver-specific gene expression levels, larger metabolic product secretion, and enhanced cytochrome P450 induction, 3D-printed biomimetic models enabled the recapitulation of the sophisticated liver microenvironment, and can be used in early personalized drug screening and liver pathophysiology studies [84].

3D printing of biomimetic lab-on-chip for microenvironment construction. a Biomimetic liver lobule and vascular structures printed by a SLA-based 3D printing (copyright is from [84]). b A lab-on-chip with airway combined with a naturally derived blood vessel printed by a hybrid 3D printing (copyright is from [85]). c An organ-on-chip with human skin transwell system fabricated by an extrusion-based and inkjet-based hybrid 3D printing method (copyright is from [86]) and d 3D printing of biomimetic inertial microfluid-based lab-on-chip (copyright is from [87])

With the development of tissue engineering, not only a single fabrication technique or single-material but also multi-fabrication techniques and multi-material methods were used to fabricate the lab-on-chip to mimic the microenvironment. As shown in Fig. 4b, Park et al. [85] utilized a hybrid 3D printing method, which contained a multi-nozzle and multi-material system, to fabricate an lab-on-chip that is comprised of airways with naturally derived blood vessel networks. The printed vascular platform was assembled with a fully differentiated airway model to reproduce a functional interface between the airway epithelium and the vascular network [85]. This model created a microenvironment that enabled the pathophysiological response to the stimulation in vitro by mimicking the mucous in the human airway. This bioinspired microenvironment can provide a forceful supplement to test the new drug preclinical drug trial in animal experiments [79]. Kim et al. [86] also developed a hybrid printing technology, which incorporated extrusion-based and inkjet-based dispensing modules, to fabricate a lab-on-chip with a functional skin inspired transwell system (refer to Fig. 4c). A collagen-based PCL mesh, which can prevent the contraction of collagen during tissue maturation, was firstly printed by the extrusion-dispending section. Then, the inkjet-based dispensing section was used to distribute the keratinocytes homogeneously [80]. Benefit from this hybrid printing capability, long-term human skin-inspired model with functional transwell systems was obtained, and a feasible microenvironment can be generated to reproduce the physiological response of the tissue [80]. Moreover, this hybrid process opens up perspectives for versatile design and also provides an attractive method in building various human skin models [80]. Besides, a chip with inertial microfluidics was fabricated by using SLA-based 3D printing process and multilayer assembly to monitor the morphological features of the cells (Fig. 4d) [87].

3D-printed lab-on-chip plays a vital role in maintaining the biological function of cells and tissues for the microenvironment construction [88,89,90]. 3D printing of lab-on-chip provides a tremendous opportunity to mimic the microenvironment in vitro and in vivo. The printing technologies and materials used in the fabrication of lab-on-chip for the microenvironment construction are summarized in Fig. 5. Various 3D printing methods and bioinspired materials were adopted to fabricate lab-on-chip to mimic the microenvironment (refer to Fig. 5). Diverse biomaterials, extracellular matrix, and growth factor, etc., were integrated to provide essential substances for cell culture, tissue growth, and drug assays and screening. Manifold unique structures were designed to mimic the microenvironment for realizing the normal function of cells. Besides, 3D printing technologies can be employed individually or integrated with other manufacturing methods to produce the biomimetic lab-on-chip. All these advanced features make it possible to understand the physiological behavior of tissue/organ and to conduct further drug screening. The biomimetic well-designed lab-on-chip enables pathophysiology studies for difficult miscellaneous diseases. However, it is still a huge challenge to build the complex lab-on-chip in vivo to complex replace the natural microenvironment. Hence, more efforts should be made to compensates these drawbacks. For example, different techniques can be combined to achieve highly simulation of the in vivo microenvironment by integrating the microfluidic systems with the newly developed biomimetic 3D matrices into the design of lab-on-chip [91]. The dynamic detection of the biomimetic microenvironment, which enables the real-time monitoring of the cells, tissues, or organs, should be studied by using advanced lab-on-chip [92]. By considering the time factor, 4D printing of biomimetic new models and systems may ultimately persuade further advanced results [93, 94]. Based on the printed biomimetic lab-on-chip, massively valuable information can be obtained for drug screening, cancer diagnosis, and pathological analysis through aforementioned strategies in the future.

3D printing of biomimetic medicine

The quantitative drug delivery, which also can be described as one-size-for-all treatments, are widely used in medical treatments [95]. Currently, the mass-produced drug delivery treatment contained the dose regimens or dosage forms, which depended on suitable therapy for the majority of the population. Because of the massive diversity and complexity of the human body, the drug function is affected by the different factors, including but not limited to age, gender, height, weight, health status, and even human genes, and it may have limited or excessive effects for different individuals [96]. Consequently, the precision medicines initiative was introduced in 2015 and aimed at the personalization of therapy [95, 97]. The main objective of personal medicines initiative is to find a suitable platform to carry the therapy to the patient based on their health status, preferences, needs, and characteristics [96]. 3D printing technologies unlock customization of personal medicines based on digital design and manufacturing [3]. By utilizing the 3D printing technologies, the dose regimens and the dosage forms can be easily customized to achieve the precise drug distribution for better therapy [96]. To control the drug-releasing profile, a wide range of biodegradable material were developed to produce numerous geometric shapes of the drug delivery components “printlets” such as tablets, microneedles, and micro/nanoscale robots, using 3D printing technologies. The shapes and material of 3D “printlet” are designed according to the natural structures to efficiently release the drug to the target place in the human body. With single or multiple drug combination in 3D “printlet”, different types of release mechanism including immediate drug release, delayed-release, and sequential release, can be accomplished [96].

3D printing technologies enable control of the drug-releasing progress because it can construct the complex biomimetic structures that can distribute biochemical cues with a controllable rate in the specific region [98,99,100]. For example, micro-swimmer, which has a double-helical biomimetic structure, was printed by the two-photon polymerization with biofunctionalized superparamagnetic iron oxide and GelMa nanoparticles [91]. Due to the magnetic precursor suspension, the material and the structures of the micro-swimmer allows itself to travel to the desired regions by controlling the magnetic field (refer to Fig. 6a) [101]. To optimize the swimming performance, the shape of micro-swimmer was designed with biomimetic structures [102]. As shown in Fig. 6b, artificial micro-fish were printed with PEGDA by using microscale projection-based SLA [102]. Both chemically mediated propulsion and magnetic field manipulation were used to induce the motion [102]. Polydiacetylene nanoparticles as indicators demonstrated the controllable drug-releasing capability of 3D printed micro-fish [102]. Motile metal–organic framework can be served as a promising microrobot platform for drug delivery [103]. Magnetic active microrobot with biomimetic helical structures was fabricated by two-photon polymerization using biocompatible and pH-responsive hydrogel (refer to Fig. 6c) [103]. The printed microrobot can swim inside a complex microfluidic channel network under the control of the magnetic field [103].

3D printing of biomimetic “printlets” for drug release. a The drug delivery mechanism of 3D-printed micro-swimmer (copyright is from [101]). b 3D-printed micro-fish for drug delivery (copyright is from [102]). c Helical microrobots printed by TPP process (copyright is from [103]). d 3D-printed micro-“printlet” with multi-drugs for target delivery (copyright is from [108]). e 3D-printed medicine with different drug release mechanisms (copyright is from [110]) and f limpet teeth-inspired microneedles printed by MF-3DP process for drug delivery (copyright is from [44])

Recently, many newly developed 3D printing methods have been examined to apply to the pharmaceutical industry for the clean and precise preparation of tablet-based medicines. The uniqueness of additive manufacturing can greatly diversify and prosper the design and manufacturing process of tablets with regard to its functions and effects. FDM [104], DIW [105], SLA [106], and inkjet printing [107] are widely used for dosage form fabrication due to its significant advantage in material selection and system simplicity. Dosage is one way widely used in drug delivery, and multi-stages dosage with different types of drugs that produced by 3D printing technologies provide more flexible and personal drug treatment. Multi-materials spherical mini “printlet” fabricated by selective laser sintering (SLS) can work as the carriers for both rapid and sustained release (refer to Fig. 6d) [108]. SLA shows more flexibility in the design of infill and the internal void structures due to the material accumulation principle, where the whole layer of material turns to be solid upon receiving enough light exposure. For example, tablets with biomimetic surface modification, such as topographical modification, protein absorption, mineral deposition, chemical functionalization, were built for regenerative medicine [109]. Besides, the tablets can be fabricated by the hybrid process where the green part of the tablet was firstly produced by SLA and then active pharmaceutical ingredients (API) were added by postprocessing such as coating and adsorption (refer to Fig. 6e) [110]. Another way was to directly print the tablets composed of active pharmaceutical ingredients (API) and the cured liquid resin using one process (refer to Fig. 6e) [110]. The drug release properties of printed tablets can be modulated by changing the crosslink density and polymer concentration [110]. For example, the angiogenic factors, such as growth factors and angiogenic peptides, embedded in the 3D printed “printlet”, were controllably released into the damaged area to promote angiogenesis [111, 112].

Compared with traditional hypodermic needles, microneedles devices show a lot of advantages for drug delivery, such as easy to use, powerful drug delivery, and less risk infection. Several works have been conducted to design and fabricate biomimetic microneedles by using microscale 3D printing processes. For example, the mosquito’s proboscis inspired microneedles, which were fabricated by 3D laser lithography, reduced insertion force due to the sharpness of the 3D printed microneedles [92]. The bioinspired microneedles had two eaves-trough parts, and they moved dependently to each other to imitate one hollow microneedle [108]. The mosquito’s proboscis inspired motion, where the two halves were inserted alternately in a unique frequency, dramatically reduced the painfulness and resistive force during insertion [113]. Bioinspired painless microneedles (MNs) were fabricated by the magnetic field-assisted 3D printing (MF-3DP) process [44]. It opens intriguing perspectives for designing MNs with high mechanical strength based on the limpet teeth inspired hierarchical structures (Fig. 6f) [44]. The magnetic particles (Fe3O4) were assembled in the magnetic field to generate the limpet teeth inspired reinforcement architectures during the printing [44]. The mechanical reinforcement of MF-3D printed MNs is related to the magnetic field intensity, the dimension of magnetic particles and the magnetic particle concentration in the printable composite [44].

The manufacturing community has benefited from 3D printing in the past 30 years since 3D printing has the capability to fabricate complex, customized products with special design and material distribution [4]. For most of the 3D printing technologies, the product is formed by accumulating the material in a layered manner, and a lot of 3D printing processes have been developed and utilized to produce medicines with different material (refer to Fig. 7) [114,115,116,117,118,119]. Biomimetic structures and the 3D printing process were refined to accomplish precise and safe drug release. Various bioinspired architectures were successfully reproduced by the developed 3D printing process to construct the “printlet”, and patternable assemblies of drug particles and degradable material were achieved by using 3D printing for multiple purpose drug delivery. Besides, 3D printed MNs with bioinspired structures show remarkable controllable drug delivery capabilities and painless treatment [112]. 3D printed MNs with bioinspired material and structures would be helpful to further understand the effect of the geometrical morphology of MNs with bioinspired materials on drug delivery and transportation. Moreover, 3D printed micro/nanoscales robots with bioinspired material and structures enable efficient drug delivery, and the advanced AM process opens intriguing perspectives for designing micro/nanoscales robots on a basis of bioinspired features.

Compared with traditional manufacturing processes, 3D printing improves the safety, efficiency, complexity, tolerability of pharmaceutical manufacturing. However, current 3D printed biomimetic objects are most tested in vitro and in vivo of animals [74]. As for the human body, the bio-environments are affected by numerous factors, such as age, gender, weight, height, living environment, and health status. Every factor would affect the efficiency of drug release and tissue regeneration [114]. Even though some of the experiments in the animals produced satisfying proofs, the clinic trial of human still needs to be studied, and the optimization and remodeling of 3D printed medicine are required based on the patients’ conditions in the future. Moreover, although FDA agency encourages the development of customized medicine by using 3D printing technology, only few of 3D printed medicine has been promoted in the market so far. This is because research experiences of 3D printed medicine products like tablets, MNs, and micro/nanoscales robots are limited, and the physical and chemical understanding of drug release from 3D printed products still requires exploration. Furthermore, the reproducibility of 3D printed medicine and quality control of mass productions should be improved in the future. Overall, 3D printing technologies provide us more possibilities in the fabrication of customized medicine for pharmaceutical use, and material, design, and process still need to be further studied and improved in the future.

3D printing of biomimetic microvascular network

Microvascular networks, which enable nutrients distribution, fluid flow, temperature regulation, tissue reparation, and energy transportation, are crucial transportation systems in the living creatures [120]. For example, xylem has an amazing water-conducting system which is contributed to the lignification of its unique vascular structures [121]. Lignification is one of the vital phenomena, which can thicken and harden the vessels in xylem after long-term evolution. Accompanied by different thickening patterns, such as helices, coils, or scalariform, the natural architectures reveals considerable advances in mechanical design that can be applied in artificial microvascular development for specific demand [122,123,124]. Similarly, microvascular systems of human show many unique functions that benefit from the shape complexity and material composition. For example, blood capillaries in the human body are divided into three kinds: continuous capillaries, fenestrated capillary, and sinusoid [125]. Different cells, pipe thickness, and structural configuration of microvascular leads to different interchange speeds of material, filtration capacity and ability to store blood [125].

Biomimetic microvascular structures shows considerable advances in tissue engineering [126], self-healing technology [120, 127, 128], lab-on-chip [75,76,77,78], and organ reconstruction [129,130,131]. For instance, one or more self-healing agents can be transported to the damaged area via an artificial microvascular system to realize the function of repairing or self-healing [132]. Microvascular networks build the basic transportation system for multiple applications of lab-on-chip [75]. Artificial organs possess the biomimetic microvascular transportation system to metabolize and exchange substances [132]. However, traditional manufacturing methods impediment the applications of the artificial microvascular network since it is challenging to reproduce the hierarchical structures of the natural microvascular network by using traditional manufacturing technologies [2, 132]. To solve this major bottleneck, 3D printing-based fabrication strategies have been put forward to build the biomimetic microvascular network. For example, 3D printing processes such as DIW, SLA, inkjet printing, and selective laser sintering (SLS), etc., are widely used in microvascular fabrication and the smallest diameter of microchannels that can be achieved by current 3D printing technologies ranges from 1 mm to 20 μm [2, 129, 133,134,135]. Moreover, compared with traditional manufacturing, 3D printing showed advantages in both the complex design and large material selections. A multitude of sophisticated biomaterial can be processed by 3D printing, enabling the efficient construction of a biomimetic microvascular network for different purposes [131].

In recent research works, newly developed 3D printing technologies provide a tool to reproduce the microvascular system by mimicking the natural architectures [2]. These printing approaches and research experiences enhanced the capability of 3D printing to realize more unique functions in building artificial microvascular. For example, 3D printing technology, named as omnidirectional Printing (ODP), was created to simplify the fabrication of microvascular systems by creatively applying two materials with different chemical and rheological properties [136]. In this process, the fugitive ink was printed in a photocurable hydrogel reservoir, which was infused with calcium chloride and thrombin (refer to Fig. 8a). After removing the material inside the channel, large-scale microvascular network was printed with complex inner structures [136]. The ODP method enables microvascular fabrication without supporting structures, high surface quality, and multiscale features [126]. Another similar supportless printing approach was developed based on the hydrogels, which were transferred from solid to the liquid along with temperature change in the reservoir [137]. Different types of material including silicones, hydrogels, colloids, and living cells were fabricated into vascular structures by using this approach [137]. Besides, naturally derived polysaccharide can be used as template material for the fabrication of microchannel networks [138]. The proposed vascularized hydrogel demonstrated the capability to support cellular viability and differentiation [138].

3D printing of biomimetic microvascular. a Schematics of omnidirectional printing of microvascular networks within a hydrogel (copyright is from [136]). b Triple-coaxial cell printing of vascular grafts using multi-material bioink (copyright is from [139]). c The design diagram and 3D-printed artificial lung network (copyright is from [140]) and d Trachea and vascular-printed using mask image projection-based SLA with silk fibroin and glycidyl methacrylate (copyright is from [141])

As shown in Fig. 8b, DIW based triple-coaxial cell printing was developed to fabricate biomimetic blood vessels, which is comprised of both smooth muscle and endothelium [139]. Specifically, the human umbilical vein endothelial cell, 3% (w/v) vascular-tissue-derived extracellular matrix, and 2% (w/v) alginate facilitated the formation and maturation of endothelialized vessels [139]. The dense muscularized vessels was created by the human aortic smooth muscle cell, 3% (w/v) vascular-tissue-derived extracellular matrix, and 0.5% (w/v) alginate [139]. The hollow tube structures can be formed directly with the extrusion of two kinds of material and the printed bioinspired blood vessels provide a promising concept to rebuild small-diameter blood vessel grafts for the treatment of cardiovascular diseases in the future [139]. For vasculogenesis and cell culture, biomimetic aortic vascular was firstly fabricated by 3D bioprinting and the spatial accuracy was greatly guaranteed by using the medical image from computer tomography and magnetic resonance imaging [140]. By planting guidance cues for vasculogenesis in a hyaluronic acid-based biomimetic hydrogel, microvascular can be generated with inside self-supporting cells [140]. Furthermore, projection-based SLA facilitated the bioprinting of vessel to fully mimic the biophysical and biochemical entanglement for different biomedical applications [141]. For example, the vessel with efficient intravascular mixer and bicuspid valves were fabricated within a few minutes by using continuous printing method (refer to Fig. 8c) [140]. Such a printing approach can be used to build artificial organs for various studies in the future [140]. Further studies of 3D printed microvascular networks regarding space-filling mathematical topologies of biological entanglement and the flow of blood in the human body have shown potential interest in the tissue repairing [140]. As shown in Fig. 8d, silk fibroin and glycidyl methacrylate-based photocurable bioink was developed to fabricate the vascular with complex structures [141]. The physical and mechanical property of printed vascular can be modulated by adjusting the concentration of glycidyl methacrylate in the bioink [141].

Many progress related to new bioprinting technologies, bionic design optimization, and functional bioink has been made for their tremendous advances to obtain microvascular systems with sound structural integrity (Fig. 9) [142]. Bioprinting processes, including embedded writing [127, 128], sacrificial printing [138], hollow tube extrusion [139], and direct printing [141], were developed to build the bioinspired vascular structures. Meanwhile, layerless bioprinting methods were investigated to improve the surface quality and printing efficiency of vascular structures [143,144,145]. The geometric morphology and material constituent of microvascular networks are crucial for the transportation systems in terms of the material interchange and debris filter. The geometries and material ingredients of artificial vessels were designed and optimized based on the natural structures (Fig. 9) [146]. However, it is still challenging to mimic the biological vessel with full functionality. For example, the printed bionic vessels can only achieve certain ranges of scales, and the detail features of natural vascular networks are hard to be reproduced. Therefore, multiscale bioprinting process requires farther exploitation and development for building the microvascular with all structural elements. Besides, even the appearance of vessels can be recreated by most of the current bioprinting process, the biological functions of bionic vessels are limited with respect to cell interaction and propagation, matter exchange, and filter [147]. Moreover, the most common materials for printing microvascular are hydrogels with alginate, agarose, gelatin, agar, hyaluronic acid, fibrin, collagen, silk, and chitosan [129, 148,149,150], and more biomaterials are needed to developed to satisfy the requires of different cell living environments for functions such as penetration, and pinocytosis [129, 148, 151]. For future work, the involvement of smart manufacturing might bring a breakthrough in microvascular fabrication. Imaging technology with a finite element method can provide vessel models with higher resolution and mechanical performance. With the development of biomimetic material, novel design, and advanced printing technologies, the gap between the artificial vessel and the natural vessel can be shrunk. Overall, bioprinting of artificial microvascular might bring new opportunities in the field of biological and medical engineering with its great potential for the treatment of various vascular diseases.

3D printing of biomimetic microvascular using different material and printing process. Examples of a artificial lung network printed by SLA process (copyright is from [140]), b microvascular networks printed by DIW process (copyright is from [136]) and c cellular structures printed by inkjet-based printing process (copyright is from [207])

3D printing of artificial organs

A large quantity of replaceable artificial organs is required to achieve better immunological matching between donor and recipient after an organ transplant surgery [152]. Nowadays, artificial organs play a vital role in many aspects, providing a potential way to produce biological substitutes of native human tissues or organs for the multiplicity of applications, such as tissue generation, organ transplantation, and drug screening, in the biomedical engineering [75]. The production of artificial organs and tissues decreases the use of animals and increases the reliability of testing results [75]. Artificial organs and tissues alleviate the shortage of organ donation for the organ transplantation issue. Plentiful approaches have been used to develop palliative methods for the construction of artificial organs and tissues [153]. However, both morphologies and material systems of human tissues and organs are sophisticated, most of current manufacturing methods could only has ability to mimic the fragmentary phase of the disease, and there are a lot of obstacles to accomplish natural tissue activities in the living organism [69]. For example, recent studies revealed that the 2D cell culture chip, which differentiated cell functions, is hard to mimic tissue or organ-level physiology, and it may generate biased results [154]. Moreover, even though a few types of tissues can be mimicked by certain methods, they were poorly suited to high-throughput validation, due to high cost, multiple complicated fabrication operations, and laborious trials [155]. Currently, 3D printing technologies were involved in the building of complex and variable 3D organs and tissues, and open intriguing perspective for on-demand production of implantable biological organs [156]. 3D printing affords more benefits in maintaining fabrication viability and promoting functional maturation. It has the capability to achieve high-order assembly of arbitrarily 3D artificial tissues and organs with multiple types of biocompatible materials and living cells using digital design and manufacturing technologies [156, 157].

Lots of exploration and attempts have been made to recreate artificial tissues and organs, such as skin, muscle, heart, and liver, using advanced bioprinting, and the artificial tissues and organs can be used for drug screening, toxicity testing, disease modeling, and organ transplantation [156, 157]. The 3D printed artificial tissues make it possible to build platforms for drug discovery, chemical analysis, biological assays, and toxicological testing [157]. For instance, airflow-assisted 3D bioprinting is a novel method to build mini tissues on spiral-based microspheres with excellent resolution and sophisticated microarchitectures (refer to Fig. 10a) [158]. The spheroids were geometrically multiple-scalar and cell-orientational, and the spiral-based spheroids were convenient for building functional organoids in vitro by embedding multiple cells into the spheroid, providing novel biomimetic asymmetrical prototypes for basic medical research and regenerative medicine [158]. Besides, heterogeneous spheroids reveal advantages such as multi-components, controllable morphology, and ease of use [159, 160].

3D printing of biomimetic artificial organs. a 3D printing of spiral-based cell-laden spheroids (copyright is from [158]). b 3D printing of soft artificial muscle (copyright is from [166]). c 3D printing of artificial corneal (copyright is from [167]). d 3D printing of artificial heart in support bath (copyright is from [169]). e Electrical field-assisted 3D printing of artificial meniscus (copyright is from [171]) and f 3D printing of artificial ear by using digital NIR based SLA (copyright is from [172])

The skin is the organ of human with largest area and contains both dermal and epidermal layers, which can protect humans from mechanical damages, micro-organisms, radiation, and chemicals [161]. Currently, scientists strive to create skin substitutes for wound treatment by mimicking human skin [162,163,164]. For instance, fused filament fabrication (FFF)-based 3D bioprinting technique was used to fabricate a human plasma-derived bilayered skin using human fibroblasts and keratinocytes, which were obtained from skin biopsies [165]. The printed human skin was useful for the treatment of diverse cutaneous pathologies, such as burns, ulcers and surgical wounds [162,163,164,165]. As shown in Fig. 10b, a self-contained soft and robust composite material was used to produce an actuator to mimic natural muscle behavior [166]. The phase-changeable ethanol was encapsulated in PDMS-based silicone elastomer to achieve high strain (up to more than 900%) and stress (up to 1.3 MPa) with low density (0.84 g/cm−3) and costs [166]. This newly developed material solution could be applied in a variety of areas, from traditional robotics to advanced biomedical needs, and may enable a new kind of entirely soft robot [152].

Recently, the pneumatic extrusion bioprinting process was developed to build artificial corneal, and keratocyte-laden corneal stromal equivalents were printed with low viscosity collagen-based bio-inks (refer to Fig. 10c) [167]. Besides, soft materials with a tensile modulus of 0.8–1.5 MPa were used to build artificial tissues of the human kidney [168]. This agarose gel outperformed other materials in terms of the density, elasticity, electrical and acoustic impedances, and the water concentration of this biomaterial can be tuned to mimic the corresponding properties of human tissues [168]. Artificial cardiac patch and hearts were also successfully fabricated by using fully personalized and unsupplemented bioink, which was prepared the extraction from the patients. Thus, these 3D printed patches did not provoke an immune response after transplantation, eliminating the need for long-term immunosuppression treatment [169, 170]. For example, cellularized artificial hearts with parenchymal cardiac tissue and blood vessel architectures were printed by using extrusion-based 3D printing (refer to Fig. 10d) [169]. The cardiomyocytes and endothelial cells differentiated from the patients’ pluripotent stem cells were mixed with hydrogel to print cardiac tissue and blood vessels respectively [169]. The immunological, cellular, biochemical, and anatomical properties of 3D printed perusable cardiac patches can achieve the normal index requirements of patients [169]. As shown in Fig. 10e, the artificial meniscus with the claws of Homarus americanus inspired bouligand type architectures were printed by electrical field-assisted nanocomposite 3D printing [171]. The human meniscus with aligned fibers was successfully reproduced by orienting the multiwall carbon nanotubes (MWCNT) in radial and circumferential directions under the electrical field [171]. The printed artificial meniscus demonstrated excellent mechanical performance with the reinforcement of aligned MWCNTs in the polymer matrix [171]. Since the near-infrared (NIR) light is able to penetrate the tissue, the artificial tissue or organs can be constructed in the living body without surgery implantation by using a digital NIR based SLA (refer to Fig. 10f) [172]. Special biocompatible NIR sensitive nanoinitiators were developed to induce the photopolymerization in situ so that this newly developed process avoided the cells injury during the photopolymerization activated by UV light [172].

What’s more, artificial organs and tissues with complicated inner cavities can be precisely rebuilt using newly developed 3D printing processes [173]. For example, the artificial urethra was fabricated with PCL/PLCL (50:50) polymers by using 3D bioprinting technology [174]. 3D-printed urethra, which was spatially arranged urothelial cells (UCs) and smooth muscle cells (SMCs), was developed to mimic mechanical property and cell growth environments of the native urethra [174]. Besides, the liver as one of the most important organs supports daily detoxification and digestion, and it has the ability to clean the body of virulence factors that are caused by venomous injuries, bacterial infections, and biological weaponry [175, 176]. Honeycomb shaped 3D structures containing fibroblast and hepatoma cells were fabricated by using the extrusion-based printing process to study the biological characteristics of the artificial liver [177]. Inspired by liver microstructures, the artificial liver-mimetic tissue, which is consisted of decellularized liver scaffolds (DLS) and polydiacetylene (PDA) nanoparticles, was fabricated by 3D bioprinting, facilitating hepatocytes to efficiently detoxify against toxins in the bloodstream [178]. This 3D printed artificial liver tissue efficiently and target-oriented removed pore-forming toxins (PFTs) without changing blood components and complement factors [178]. This approach provides a new strategy to functionalize decellularized artificial organs and tissues for medical applications [178].

3D bioprinting has been used to deposit layers of bio-inks composed of biocompatible polymer matrix and living cells to build complex artificial tissues and organs in recent years [173]. Currently, 3D bioprinting has already demonstrated certain progress in the reproduction of simple tissues and organs, such as skin [162,163,164,165], corneal [167], and ear [172]. 3D-printed artificial tissues and organs are alternatives for transplantation or regeneration of tissues and organs [173]. However, there are several challenges to reproduce the organs, which are composed of multi-material systems, hierarchical structures and multiple types of cells, using current bioprinting approach, then 3D-printed complex artificial organs, such as kidneys, livers, and hearts, still cannot act as transplantable organs with fully functionalities at this moment [179]. As shown in Fig. 11, three types of building strategies, including SLA, DIW, and Inkjet-based bioprinting, were widely used in the fabrication of artificial tissue and organs. DIW and inkjet-based bioprinting processes reflect superiorities in the multi-material fabrication. However, they getting difficulties in depositing bio-ink with high viscosity [180,181,182,183,184], and shear stress caused by the extrusion of bio-ink from the nozzle forces cell deformation [185]. SLA based bioprinting exhibits advantages in the fabrication of artificial organs and tissues with sophisticated structures and high resolution. Meanwhile, there are some shortcomings, such as multi-material fabrication, high cell viability and densities, and limited material selections [186,187,188]. Overall, all aforementioned challenges of the bioprinting technologies are necessary to be solved for the mass production of artificial organs and tissues, and the printable materials anticipated to mimic the material ingredient of target tissues and organs will be developed [189,190,191,192,193]. Even though the impressive progress of bio-ink development has been made for the fabrication of artificial tissues and organs, considerable research topics, such as cell and material compatibility, tissue maturation and functionality, and appropriate vascularization and innervation, are needed to be further explored in the future [192, 193].

3D printing of biomimetic artificial organs using different material and printing processes. Examples of a artificial liver lobule and vascular structures printed by SLA (copyright is from [84]). b Artificial human skin (copyright is from [86]) and bionic ear (copyright is from [208]) printed by DIW; and c artificial corneal (copyright is from [167]) and small-scaled human heart (copyright is from [169]) printed by inkjet-based printing

Summary and outlook

Natural structures and material systems give us unlimited inspiration regarding the novel design of biomedical devices. The combination of advanced manufacturing and biomimetic design of structures and material systems initiates the new generation of biomedical devices for healthcare. Researchers and scientists have extensively developed various advanced additive manufacturing technologies to produce biomedical functional devices with biomimetic structures and bionic material systems [194,195,196]. Biomimetic 3D printing as a promising new technique solved some the manufacturing challenges of biomedical devices with biomimetic structures and materials. The development of biomimetic 3D printing techniques provides an potential tool to develop biomedical devices with unprecedented functionalities [197]. In this review, we summarized the recent progress of biomimetic 3D printing of biomedical applications including scaffolds, lab-on-chip, medicine for drug delivery, microvascular network, and artificial organs and tissue (refer to Fig. 12). The blossomly development of 3D printing technology makes the fabrication of biomimetic structures with high complexity and multiple materials distribution possible. Current progress in biomimetic 3D printing of biomedical devices reveals the biomimetic design with various biomaterial and biomimetic structures bring new advancement for the treatment of healthcare issues in the field of biomedical engineering.

A framework for biomimetic 3D printing of biomedical applications. a Natural structures lotus root (copyright is from [61]); the gecko’s foot, inset—enhanced image of a gecko foot (copyright is from [209]); and bacterium called Escherichia coli or E. coli (copyright is from [210]). b The library of 3D printing technologies and material

Although significant progress in biomimetic 3D printing of biomedical applications has been accomplished, there are still many problems waiting to be solved for the commercialization. Currently, the selection of 3D printing technology is limited because materials have to be developed according to the printing principle of 3D printing techniques to treat certain diseases or defects. And different 3D printing techniques also have their limitations in printing scale, speed and resolution. Due to these current challenges, biomimetic 3D printing technologies only can be used to limited applications. Thus, more 3D printing process should further be developed so that the engineers can be given a much wide choice of materials and 3D printing techniques for biomedical applications. In addition, more and more researches have been focused on natural materials investigation. Novel biomaterial is a fundamental element supporting the construction of natural extracellular matrix, and enriched library of biomaterials will raise more possibilities for future biomimetic biomedical applications. Excellent performances of natural structures and material systems are attributed to unique hierarchical architectures. Even though existing 3D printing techniques showed capabilities of constructing complex structures, it is still a particular challenge for the current 3D printing technologies to accurately duplicate the natural architectures with multiscale structures, especially for microscale and nanoscale features. Besides, a tradeoff between the fabrication resolution and time efficiency exists for most of current 3D printing technologies and restrict the production of biomedical devices by using commercial biomimetic 3D printing technologies. Thus, the development of 3D printing still needs to find a breaking point in order to provide opportunities for biomimetic medical devices with high resolution and printing speed. Meanwhile, how to achieve mass production of patient-specific medical devices, or even mass customization using 3D printing technology is also an issue for the current biomimetic 3D printing of biomedical applications, which is one of reasons causing the slow speed of commercialization of biomimetic 3D printing technologies. It is essential to invent time-dependent 3D printing systems, which enable real-time monitor the growth, differentiation, and maturation of the 3D printed cell, tissue, and organ.

3D printing still needs to be further improved to fabricate biomimetic structures with better performance. One promising direction is to develop ultra-fast 3D printing technology by accomplishing volumetric printing instead of traditional layer-based printing. For example, volumetric 3D printing is an approach to solidify resin into the 3D shape within one-step, which increases the printing efficiency dramatically [198, 199]. Another potential direction is to develop multiscale and multi-material bioprinting approaches since almost all the natural structures are multiscale and multi-material. One promising approach is to combine several different printing processes, which can distributed fabricate different sections with the specific requirement of scales [66]. Moreover, the 4D printing process, which is a novel 3D printing process integrated with transformation over time, could also be a future fabrication tool for biomedical applications. Besides, 3D printing as computer-aided manufacturing will also benefit from the flourish of artificial intelligence (AI) and machine learning (ML). Smart manufacturing by integrating biomimetic 3D printing technologies with AI/ML approaches has a broad prospect in biomedical applications. AI/ML assisted biomimetic 3D printing technologies open opportunities for the fabrication of customized biomedical devices with better quality control, higher processing efficiency, less material waste, and better replacement, etc. The next revolution in the manufacturing of biomedical devices will be brought by novel smart 3D printing systems. Continuous study of multidisciplinary research, which integrates materials processing, computer modeling, medical imaging, chemistry, and biology, will promote the development of biomimetic 3D printing of biomedical applications for healthcare [193]. Last but not least, combining 3D printing with traditional manufacturing methods or other novel fabrication ways, such as robotic technology and laser machining is also a prospective direction of biomimetic 3D printing technologies for biomedical applications.

Advancement in biomimetic 3D printing research can be accelerated by identifying needs, challenges, and opportunities in biomedical industry, such as biopharmaceutical treatments, medical implant, etc. In the future, biomimetic 3D printing technology with sustainable development features will gradually take the dominant position in the fabrication of medical devices for the industry community. More advanced bioinspired materials and structures combined with advanced 3D printing will provide unprecedented possibilities for researchers to solve the challenges in biomedical engineering. Future study of biomimetic 3D printing will not only enable the extension of current researches in biomedical applications such as implantable scaffold, target drug delivery, and transplantable artificial organs, etc., but also generate more functions and applications than ever before. Based on the blossomly development in the biomimetic 3D printing, it is not hard to prospect that the more and more 3D-printed biomimetic medical devices are going to gain a foothold in the market to help doctors to solve various medical conditions [190]. The growth of biomimetic 3D printing research will construct a new biomedical industrial ecosystem for further facilitating the development of manufacturing and activating more innovations of biomedical devices for healthcare in the future.

References

Poukens J, Laeven P, Beerens M, Nijenhuis G, Sloten JV, Stoelinga P et al (2008) A classification of cranial implants based on the degree of difficulty in computer design and manufacture. Int J Med Rob Comput Assisted Surg 4(1):46–50. https://doi.org/10.1002/rcs.171

Yang Y, Song X, Li X, Chen Z, Zhou C, Zhou Q et al (2018) Recent progress in biomimetic additive manufacturing technology: from materials to functional structures. Adv Mater. https://doi.org/10.1002/adma.201706539

Leung Y-S, Kwok T-H, Li X, Yang Y, Wang CCL, Chen Y (2019) Challenges and status on design and computation for emerging additive manufacturing technologies. J Comput Inf Sci Eng doi 10(1115/1):4041913

Yang Y, Li X, Zheng X, Chen Z, Zhou Q, Chen Y (2018) 3D-printed biomimetic super-hydrophobic structure for microdroplet manipulation and oil/water separation. Adv Mater 30(9):1704912. https://doi.org/10.1002/adma.201704912

Li X, Yang Y, Liu L, Chen Y, Chu M, Sun H et al (2020) 3D-printed cactus-inspired spine structures for highly efficient water collection. Adv Mater Interfaces 7(3):1901752. https://doi.org/10.1002/admi.201901752

Li X, Yang Y, Xie B, Chu M, Sun H, Hao S et al (2019) 3D printing of flexible liquid sensor based on swelling behavior of hydrogel with carbon nanotubes. Adv Mater Technol 4(2):1800476. https://doi.org/10.1002/admt.201800476

Yang Y, Li X, Chu M, Sun H, Jin J, Yu K et al (2019) Electrically assisted 3D printing of nacre-inspired structures with self-sensing capability. Sci Adv 5(4):eaau9490. https://doi.org/10.1126/sciadv.aau9490

Ma PX (2008) Biomimetic materials for tissue engineering. Adv Drug Del Rev 60(2):184–198. https://doi.org/10.1016/j.addr.2007.08.041

Aizenberg J, Fratzl P (2009) Biological and biomimetic materials. Adv Mater 21(4):387–388. https://doi.org/10.1002/adma.200803699

Fisher OZ, Khademhosseini A, Langer R, Peppas NA (2010) Bioinspired materials for controlling stem cell fate. Acc Chem Res 43(3):419–428. https://doi.org/10.1021/ar900226q

Kushner AM, Guan Z (2011) Modular design in natural and biomimetic soft materials. Angew Chem Int Ed 50(39):9026–9057. https://doi.org/10.1002/anie.201006496

Holzapfel BM, Reichert JC, Schantz J-T, Gbureck U, Rackwitz L, Noeth U et al (2013) How smart do biomaterials need to be? A translational science and clinical point of view. Adv Drug Del Rev 65(4):581–603. https://doi.org/10.1016/j.addr.2012.07.009

Li X, Yuan Y, Liu L, Leung Y-S, Chen Y, Guo Y et al (2020) 3D printing of hydroxyapatite/tricalcium phosphate scaffold with hierarchical porous structure for bone regeneration. Bio-Des Manuf 3(1):15–29. https://doi.org/10.1007/s42242-019-00056-5

Huang G, Li F, Zhao X, Ma Y, Li Y, Lin M et al (2017) Functional and biomimetic materials for engineering of the three-dimensional cell microenvironment. Chem Rev 117(20):12764–12850. https://doi.org/10.1021/acs.chemrev.7b00094

Balakrishnan B, Banerjee R (2011) Biopolymer-based hydrogels for cartilage tissue engineering. Chem Rev 111(8):4453–4474. https://doi.org/10.1021/cr100123h

Sands RW, Mooney DJ (2007) Polymers to direct cell fate by controlling the microenvironment. Curr Opin Biotechnol 18(5):448–453. https://doi.org/10.1016/j.copbio.2007.10.004

Edalat F, Sheu I, Manoucheri S, Khademhosseini A (2012) Material strategies for creating artificial cell-instructive niches. Curr Opin Biotechnol 23(5):820–825. https://doi.org/10.1016/j.copbio.2012.05.007

Yi H-G, Lee H, Cho D-W (2017) 3D printing of organs-on-chips. Bioengineering (Basel) 4(1):10. https://doi.org/10.3390/bioengineering4010010

Hoffman AS (2012) Hydrogels for biomedical applications. Adv Drug Del Rev 64:18–23. https://doi.org/10.1016/j.addr.2012.09.010

Caliari SR, Burdick JA (2016) A practical guide to hydrogels for cell culture. Nat Methods 13(5):405–414. https://doi.org/10.1038/nmeth.3839

DeForest CA, Anseth KS (2012) Advances in bioactive hydrogels to probe and direct cell fate. In: Prausnitz JM (eds) Annual review of chemical and biomolecular engineering, vol 3, pp 421–444

Faulk DM, Johnson SA, Zhang L, Badylak SF (2014) Role of the extracellular matrix in whole organ engineering. J Cell Physiol 229(8):984–989. https://doi.org/10.1002/jcp.24532

Aamodt JM, Grainger DW (2016) Extracellular matrix-based biomaterial scaffolds and the host response. Biomaterials 86:68–82. https://doi.org/10.1016/j.biomaterials.2016.02.003

Hong S, Sycks D, Chan HF, Lin S, Lopez GP, Guilak F et al (2015) 3D printing of highly stretchable and tough hydrogels into complex, cellularized structures. Adv Mater 27(27):4035–4040. https://doi.org/10.1002/adma.201501099

Yi H-G, Kang KS, Hong JM, Jang J, Park MN, Jeong YH et al (2016) Effects of electromagnetic field frequencies on chondrocytes in 3D cell-printed composite constructs. J Biomed Mater Res A 104(7):1797–1804. https://doi.org/10.1002/jbm.a.35714

Lozano R, Stevens L, Thompson BC, Gilmore KJ, Gorkin R III, Stewart EM et al (2015) 3D printing of layered brain-like structures using peptide modified gellan gum substrates. Biomaterials 67:264–273. https://doi.org/10.1016/j.biomaterials.2015.07.022

Zander NE, Dong H, Steele J, Grant JT (2014) Metal cation cross-linked nanocellulose hydrogels as tissue engineering substrates. ACS Appl Mater Interfaces 6(21):18502–18510. https://doi.org/10.1021/am506007z

Zhu J, Kaufman LJ (2014) Collagen I self-assembly: revealing the developing structures that generate turbidity. Biophys J 106(8):1822–1831. https://doi.org/10.1016/j.bpj.2014.03.011

Miao Z, Lu Z, Wu H, Liu H, Li M, Lei D et al (2018) Collagen, agarose, alginate, and Matrigel hydrogels as cell substrates for culture of chondrocytes in vitro: a comparative study. J Cell Biochem 119(10):7924–7933. https://doi.org/10.1002/jcb.26411

Xiong R, Chai W, Huang Y (2019) Laser printing-enabled direct creation of cellular heterogeneity in lab-on-a-chip devices. Lab Chip 19(9):1644–1656. https://doi.org/10.1039/c9lc00117d

Martinsen A, Skjakbraek G, Smidsrod O (1989) Alginate as immobilization material. 1. Correlation between chemical and physical-properties of alginate gel beads. Biotechnol Bioeng 33(1):79–89. https://doi.org/10.1002/bit.260330111

Augst AD, Kong HJ, Mooney DJ (2006) Alginate hydrogels as biomaterials. Macromol Biosci 6(8):623–633. https://doi.org/10.1002/mabi.200600069

Freeman I, Kedem A, Cohen S (2008) The effect of sulfation of alginate hydrogels on the specific binding and controlled release of heparin-binding proteins. Biomaterials 29(22):3260–3268. https://doi.org/10.1016/j.biomaterials.2008.04.025

Madl CM, Mehta M, Duda GN, Heilshorn SC, Mooney DJ (2014) Presentation of BMP-2 mimicking peptides in 3D hydrogels directs cell fate commitment in osteoblasts and mesenchymal stem cells. Biomacromolecules 15(2):445–455. https://doi.org/10.1021/bm401726u

Boontheekul T, Kong HJ, Mooney DJ (2005) Controlling alginate gel degradation utilizing partial oxidation and bimodal molecular weight distribution. Biomaterials 26(15):2455–2465. https://doi.org/10.1016/j.biomaterials.2004.06.044

Rebelo R, Fernandes M, Fangueiro R (2017) Biopolymers in medical implants: a brief review. In: Fangueiro R (eds) 3rd international conference on natural fibers: advanced materials for a greener world. ICNF 2017, pp 236–243

Naumenko EA, Guryanov ID, Yendluri R, Lvov YM, Fakhrullin RF (2016) Clay nanotube-biopolymer composite scaffolds for tissue engineering. Nanoscale 8(13):7257–7271. https://doi.org/10.1039/c6nr00641h

Stoppel WL, Ghezzi CE, McNamara SL, Black LD III, Kaplan DL (2015) Clinical applications of naturally derived biopolymer-based scaffolds for regenerative medicine. Ann Biomed Eng 43(3):657–680. https://doi.org/10.1007/s10439-014-1206-2

Jiang Y, Wang Y, Wang H, Zhou L, Gao J, Zhang Y et al (2015) Facile immobilization of enzyme on three dimensionally ordered macroporous silica via a biomimetic coating. New J Chem 39(2):978–984. https://doi.org/10.1039/c4nj01947d

Singh D (2018) Investigations on biomimetic PLA scaffold fabricated by fused deposition modelling [D]

Lih E, Park KW, Chun SY, Kim H, Kwon TG, Joung YK et al (2016) Biomimetic porous PLGA scaffolds incorporating decellularized extracellular matrix for kidney tissue regeneration. ACS Appl Mater Interfaces 8(33):21145–21154. https://doi.org/10.1021/acsami.6b03771

Zhang K, Fu Q, Yoo J, Chen X, Chandra P, Mo X et al (2017) 3D bioprinting of urethra with PCL/PLCL blend and dual autologous cells in fibrin hydrogel: an in vitro evaluation of biomimetic mechanical property and cell growth environment. Acta Biomater 50:154–164. https://doi.org/10.1016/j.actbio.2016.12.008

Li X, Yang Y, Chen Y (2017) Bio-inspired micro-scale texture fabrication based on immersed surface accumulation process. In: World congress on micro and nano manufacturing conference, pp 33–36

Li X, Shan W, Yang Y, Joralmon D, Zhu Y, Chen Y, Yuan Y, Xu H, Rong J, Dai R, Nian Q, Chai Y, Chen Y (2020) Limpet teeth inspired painless microneedles fabricated by magnetic field assisted 3D printing. Adv Funct Mater. https://doi.org/10.1002/adfm.202003725