Abstract

The current study examines the effective use of bottom ash, which is mixed with lime and sodium hexametaphosphate (SHMP), to stabilize the expansive soil in order to make a composite subgrade material for flexible pavement design. The study involves performing laboratory tests on expansive soil samples containing bottom ash and lime alone and along with (NAPO3)6. The tests such as differential free swell, consistency limits, compaction characteristics, unconfined compressive strength tests and California bearing ratio are performed. The results showed that adding an optimal amount of bottom ash (15%), lime (6%), and (SHMP) (4.5%), both alone and in combination, reduces the differential free swell and consistency limits of expansive soil and increased the CBR values, accomplishing it into an effective subgrade material. The thickness of flexible pavement was designed using IITPAVE software. The design was done by utilising obtained CBR values, it met the required parameters based on the IRC: 37-2018 recommendations. The software analysis revealed a reduction in pavement thickness for different commercial vehicle traffic volumes (1000, 2000, and 5000), with the highest reduction in layer thickness and construction costs observed when expansive soil was combined with bottom ash (15%), lime (6%), and (SHMP) (4.5%). This technology not only improves the geotechnical characteristics of subgrade soil, but it is also cost-effective and tackles the bottom ash disposal issue. Overall, this research proposes a novel method for developing a composite soil subgrade material for flexible pavement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Expansive soil is a type of soil that contains a mixture of both silt and clay particles. It is a relatively clayey soil that has a high water-holding capacity and tends to be poorly drained. Expansive soil is a problematic soil as they are often compacted and may have a high degree of cohesion, which makes them difficult to work with. The properties of expansive soils are influenced by the relative proportions of silt and clay particles. Soils with a higher proportion of clay particles tend to be more cohesive, less permeable, and more prone to waterlogging. Soils with a higher proportion of silt particles, on the other hand, tend to be more free-draining and easier to work with. Expansive soils can be found in a variety of environments, including river floodplains, lake basins, and areas that have been glaciated. They are often used for agriculture, but may require special management practices, such as drainage or the addition of organic matter, to improve their productivity. As result of their behavior, which produces differential settlements in the buildings that are supported by these soils, it is typically recommended that construction be avoided over these soils since it presents significant issues when used in construction (Gautam et al. 2021; Al-Taie et al. 2023; Bhatt et al. 2021).

Population growth can have a significant impact on construction activity, particularly in relation to the demand for new infrastructure, housing, and public facilities. As the population grows, the need for new construction and development increases. This can include the expansion of urban areas to accommodate more people, which may require the construction of new buildings, roads, and other infrastructure. Additionally, the demand for new housing and commercial facilities, such as schools and hospitals, may also increase, driving construction activity in these sectors. However, population growth can also place pressure on resources such as land, water, and energy. This can affect the availability and cost of resources and can impact the types of construction projects that can be undertaken (Anand et al. 2021; Singh et al. 2022).

In developing countries such as India having population density of 429 per km2 of land (according to data.worldbank.org/indicator), it is very difficult to acquire soil that is suitable for activities related to construction activities. Engineers are forced to design foundations over these soils which may lead to damage if not properly treated. Stabilizing the soil is a general treatment given to soils which poses poor geotechnical properties and may be in the form of physical and/or chemical stabilization (Verma and Abhishek 2019; Nabizadeh Mashizi et al. 2023; Singh et al. 2022; Bhatt et al. 2021; Anburuvel et al. 2023; Bhardwaj and Sharma 2020; Bhardwaj et al. 2021; Anand et al. 2021; Sharma and Sharma 2019; Sharma and Sharma 2021a, b; Bhardwaj and Sharma 2022; Al-Taie et al. 2023).

The samples stabilized with Cement Kiln Dust had a higher strength than those stabilized with Cement Kiln Dust combined with Rafsanjan Natural Pozzolan due to the formation of a greater amount of gel and a stable microstructure. The findings of this research promote sustainable ground improvement techniques using waste by-products (Nabizadeh Mashizi et al. 2023). When coal is burned in thermal power plants, a type of waste known as bottom ash (BA) is produced. Large quantities of bottom ash are produced, which contributes to disposal issues as well as issues with the surrounding environment. Bottom ash has been used in previous studies to stabilise clayey soils, and those studies have shown that the soil’s geotechnical properties have improved (Forteza et al. 2004; Kumar and Stewart, 2003; Kumar and Raju 2014; López et al. 2015; Sudhakaran et al. 2018; Bhurtel and Eisazadeh 2020).

Lime being a traditional binding material has been used in soil stabilization from very early ages and has been proven to good admixture to improve strength (Ikeagwuani et al. 2019). The geotechnical testing carried out on two different soil samples revealed that, the consistency limits, UCS and compaction improved on adding 56% lime (Dash and Hussain 2012). It was deduced that as the amount of lime and fly ash in clayey soil increases its strength increases (Krithiga et al. 2016). It was investigated the effects of lime in consistency limits, failure characteristics and coefficient of brittleness of the clayey soil (Zhu et al. 2019). It was concluded that the unconfined compressive strength of the clayey soil improves from the first day it was allowed to cure after the use of hydrated lime in clayey soil (Bharathi et al. 2019). The three types of clayey soil samples were collected from different regions and are treated with lime found that geotechnical characteristics of three clays was improved and each has a different level of plasticity which is improved after the blending process (Zagvozda et al. 2022).

Additionally, the compressive strength of the mixture improves when the amount of slag and lime used in the mixture is increased (Moghal and Sivapullaiah 2012). It was experimented that maximum dry density of clayey soil has a gradual decrease with the addition of fly ash and lime, which improves the CBR value (Athanasopoulou 2014). It was found that with the addition of lime the shrinkage limit of clayey soil increases and also increases the strength of clayey soil at 18% use of lime (Dash and Hussain 2015). Clayey soil was mixed with lime at 4%, it was deduced that there is an increase in test results value when compared with the value obtained from testing virgin soil (Jha and Sivapullaiah 2016). It was observed that the properties of Bangkok clay that were stabilised with 50% bottom ash and 12% lime exhibited an improvement in terms of both their strength and their durability (Bhurtel and Esazadeh 2019).

It is evident from the review of the relevant literature that the addition of bottom ash and lime, either on their own or in addition with sodium hexametaphosphate, improves the geotechnical properties of expansive soil. On the other hand, the application of bottom ash, lime and sodium hexametaphosphate in the process of stabilizing is still the subject of ongoing research.

2 Materials and methodology

2.1 Materials

2.1.1 Soil

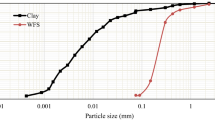

The soil that was used in the present investigation was brought from Madhya Pradesh village of Niwas in district of Mandla (India) (shown in Fig. 1). The gradation curve of various materials used in current research is shown in Fig. 2. The soil samples were collected from a depth ranging from 1 to 1.5 m after removing all organic matter and then packed in sealed bags and brought to geotechnical engineering laboratory at Chandigarh University in Mohali, Punjab, India. The gradation curve that was produced by using a wet sieve and hydrometer analysis showed that the soil contains significant amount clay. According to the plasticity chart, the soil falls into the category of high plastic clay (CH), as per IS-1498 (1970). The numerous physical characteristics of expansive soils are presented in Table 1.

2.1.2 Bottom ash

The bottom ash (BA) was taken from the Guru Gobind Singh Power Plant, Ropar, Punjab, India. Bottom ash falls under the category of poorly graded sand (SP) as per dry sieve analysis. Table 1 tabulates the different physical characteristics of bottom ash. The reason of choosing bottom ash as a stabilizer in expansive soil is due to its high void ratio as compared to clayey soil and also due to the granular particle size which when mixes with the clayey soil possesses appropriate strength. Also, in order to reduce the dumping problem of the bottom ash in the open area which leads to increase in pollution. So, use of bottom ash as a soil stabilizer is a step towards the waste control.

2.1.3 Lime

Lime is prepared by boiling limestone, which is more or less calcium carbonate in its purest form. As an additive, lime alters the design properties of the soil. The lime used in the present study was obtained from a local hardware shop in Kharar, Mohali, Punjab, India. It was packed in a sealed bag after each testing so as to avoid any presence of moisture.

2.1.4 Sodium hexametaphosphate (NAPO3)6

Sodium Hexametaphosphate chemical used in the current research was taken from a local shop in Kharar, Mohali, Punjab, India. It was received in a sealed container and in a powdered form. The reason for choosing (SHMP) as a soil stabilizer is because of the presence of fine contents which are more evenly distributed throughout the soil and enhances the strength of expansive soil.

2.2 Methodology

For the current study, various tests were carried out in accordance with the IS standards mentioned in Table 2.

The first part of the research consists of determining the optimal percentages of materials (bottom ash, lime, and (NAPO3)6) by performing differential free swell (DFS) and consistency limit tests on clayey soil with a variety of admixtures. The second part of this study investigates the compaction behaviour and California bearing ratio testing of clayey soil with and without the addition of the optimal amount of a variety of materials. In the third and final part, the pavement thickness is computed for the optimal combinations, and the resilience modulus of each layer is found using IIT PAVE. The percentage of material mix used in the present research is shown in Table 3.

3 Results and discussions

3.1 Differential free swell

The DFS value for clayey soil was found to be 26%, with a significant degree of expansion. As the percentages of bottom ash, lime, and (SHMP) decreased, so did the DFS value (Fig. 2). The bottom ash lowered the DFS value of clayey soil to 0 at 15% bottom ash content, and no change in the DFS value was observed with further addition of bottom ash to clay soil. The decrease in differential free swell value could also be due to coarser nature of bottom ash. Earlier studies also demonstrated a reduction in DFS with the addition of BA in poor soils (Phani Kumar and Sharma 2004; Prabakar et al. 2004).

For lime, at 9% lime content, the DFS value of clayey soil was reduced to zero. When the amount of lime is increased beyond 9%, the DFS value begins to increase, and hence the best content for clayey soil stabilisation is 9% lime content. The fall in DFS value caused by lime addition could be due to the replacement of other cations in calcium (Bozbey and Garaisayev 2010). The decrease in DFS value on addition of lime may be attributed to the substitution of other cations by calcium which is present in lime and also due to the pozzolanic action between soil particles and lime.

The differential free swell (DFS) value of clayey soil can be reduced by adding certain percentages of (NAPO3)6. It is a water-soluble compound that acts as a dispersant and flocculant, reducing the swelling potential of the soil. As the amount of (SHMP) added to the soil increases, the DFS value decreases to 0 at 4.5% of (NAPO3)6. However, the effectiveness of (SHMP) in reducing DFS value depends on various factors such as the type of clay mineral present in the soil, the concentration of (SHMP) which is used. The results of DFS with various additives are shown in Fig. 3.

3.2 Consistency limits

3.2.1 Soil: bottom ash

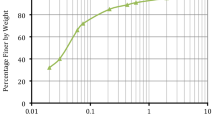

Soil was found to be expansive in nature based on liquid limit tests. The liquid limit of soil reduced from 62.6 to 34.2% at 15% bottom ash content, while the plastic limit decreased from 40.3 to 28.5%, indicating a decrease in the overall plasticity index from 22.3 to 5.7% at 15% bottom ash content. This could be because of to the inclusion of bottom ash particles, which are coarser than expansive soil particles (as shown by the gradation curve in Fig. 4). As the BA percentage was increased above 15%, there was little change in the liquid limit or plastic limit value; thus, 15% BA may be considered optimal. When bottom ash was added to expansive soil, the texture of the expansive soil changes due to flocculation of clayey particles which reduces the percentage of clay in the expansive soil and an increase in the percentage of coarse particles. The presence of coarse particles in expansive soil improves the material’s workability, lowers its plasticity index, and so lowers Atterberg’s limit (Phani Kumar and Sharma 2004).

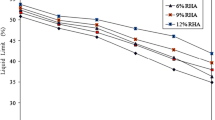

3.2.2 Soil: lime

With the addition of lime (3, 6, 9, and 12%) in clayey soil, the plasticity index (Ip) reduced from 22.3 to 6.4%. The liquid limit of soil reduced from 62.6 to 47% at 9% of lime, while the plastic limit decreased from 40.3 to 41.1%, indicating a decrease in the overall plasticity index from 22.3 to 9% at 9% of lime content. This could be because of to the pozzolanic action of lime particles with expansive soil particles. As the lime percentage was increased above 9%, there was little change in the liquid limit or plastic limit value; thus, 9% of lime may be considered optimal. Lime causes cation exchange when mixed with soil and there is a pozzolanic reaction between the soil particles is a reason for the reduction of overall plasticity index of soil. This reduction in liquid limit also may be due to the release of Ca+ ions into pore fluid which leads to an increase in the electrolyte absorption of pore water. This process decreases the thickness of diffuse double layer and lowers the liquid limit of expansive soil (Fig. 5).

3.2.3 Soil: BA: lime

Soil was mixed with different percentages of bottom ash and lime. From the results of liquid limit tests, it was found that the soil is expansive in nature. With the addition of bottom ash and lime in various percentages, liquid limit of soil reduced from 60.2 to 57% at 15% bottom ash and 6% of lime content, while the plastic limit decreased from 42.4 to 37.4%, indicating a decrease in the overall plasticity index from 22.2 to 19.6% at 15% bottom ash and 6% of lime content. This could be because of to the inclusion of bottom ash particles, which are coarser than expansive soil particles and due to the pozzolanic action of lime. As the percentage of lime was increased above 6%, there was little change in the liquid limit or plastic limit value; thus, 6% of lime with 15% of bottom ash may be considered as optimal. When bottom ash was added to expansive soil, the texture of the expansive soil changes due to flocculation of clayey particles, results in a reduction in the percentage of clay in the expansive soil and an increase in the percentage of coarse particles. Also, due to the cation exchange between the particles of lime in expansive soil improves the material's workability, lowers its plasticity index, and so lowers Atterberg’s limit (Fig. 6).

3.3 Compaction characteristics

3.3.1 Soil: BA

Compaction tests were carried out on soil alone as well as with bottom ash in various mixtures containing different percentages of BA for determination of OMC and MDD of soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. As percentage of BA in the virgin soil increased, so did values of the OMC; while on increasing the percentage of BA to expansive soil, MDD value decreased from 1.79 to 1.55 g/cc with a BA percentage of up to 15%, and value of OMC increased from 16.2 to 21.5% with 15% of bottom ash content in soil. By adding BA beyond 15%, no increase in OMC value was noticed and a decrease in MDD value was observed. Decrease in MDD with addition of BA may be due to the lower specific gravity of BA in comparison to expansive soil. Increase in OMC of the composite may be attributed to higher value of OMC of bottom ash in comparison with expansive soils. The results are appropriate and are in agreement with observations given by some researchers (Sezer et al. 2006; Eskioglou and Oikonomou 2008; Chauhan et al. 2008) (Fig. 7).

3.3.2 Soil: lime

With the addition of lime in expansive soil in different percentages, the compaction test was performed to determine the OMC and MDD of the soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. As percentage of lime in the virgin soil increased, so did values of the OMC, while on increasing the percentage of lime to expansive soil, MDD value decreased from 1.79 to 1.48 g/cc with a lime percentage of up to 9%, and value of OMC increased from 16.2 to 23% with 9% of lime content in soil. By adding lime beyond 9%, there is an increase noticed in the MDD but after it the rapid fall in MDD and increase in OMC value was noticed and a decrease in MDD value was observed. Decrease in MDD with addition of lime may be due to the lower specific gravity of lime as compared to the soil and also may be due to the pozzolanic reaction between lime and soil particles which leads to an increase in OMC of the composite may be attributed to higher value of OMC of lime in comparison with expansive soils. The results are appropriate and are in agreement with observations given by some researchers (Sharma and Sharma 2020) (Fig. 8).

3.3.3 Soil: (NAPO3)6

On adding (SHMP) in expansive soil in different percentages, the compaction test was carried out to determine the OMC and MDD of the soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. As percentage of (SHMP) in the virgin soil increased, so did values of the OMC, while on increasing the percentage of (SHMP) to expansive soil, MDD value decreased from 1.79 to 1.42 g/cc with a (SHMP) percentage of up to 4.5%, and value of OMC increased from 16.2 to 24% with 4.5% of (SHMP) content in soil. By adding (SHMP) beyond 6%, no increase in OMC value was noticed and a decrease in MDD value was observed (Fig. 9).

3.3.4 Soil:BA: (SHMP)

With the addition of BA 15% and (SHMP) in different percentages in expansive soil, the compaction test was carried out to determine the OMC and MDD of the soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. The percentage of BA was taken as 15% which is constant throughout the test and (SHMP) percentage in the virgin soil increased, so did values of the OMC, while on increasing the percentage of (SHMP) to expansive soil, MDD value decreased from 1.79 to 1.53 g/cc with a (SHMP) percentage of up to 4.5%, and value of OMC increased from 16.2 to 23% with 4.5% of (SHMP) and 15% of bottom ash content in soil. By adding (SHMP) beyond 6% and bottom ash 15%, no increase in OMC value was noticed and a decrease in MDD value was observed (Fig. 10).

3.3.5 Soil:BA: lime

The compaction test was carried by adding bottom ash in a constant amount and varying the lime content. Adding lime in expansive soil in different percentages and bottom ash at constant amount that is 15%, the compaction test was performed to determine the OMC and MDD of the soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. As percentage of lime in the virgin soil increased, so did values of the OMC, while on increasing the percentage of lime to expansive soil, MDD value decreased from 1.79 to 1.53 g/cc with a lime percentage of up to 6%, and value of OMC increased from 16.2 to 23% with 6% of lime and 15% of bottom ash content in soil. By adding lime beyond 6% and bottom ash 15%, there is an increase noticed in the MDD but after sometime an increase in OMC value and a decrease in MDD value was observed. Decrease in MDD with addition of lime may be due to the pozzolanic reaction of lime and soil particles which leads to an increase in OMC of the composite may be attributed to higher value of OMC of lime and due to the coarser nature of the bottom ash in comparison with expansive soils (Fig. 11).

3.3.6 Soil: lime: (NAPO3)6

Adding lime in a constant amount and varying the (SHMP) content, compaction test was performed. (NAPO3)6is added in expansive soil in different percentages and lime at constant amount that is 6%, the compaction test was performed to determine the OMC and MDD of the soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. As percentage of (SHMP) in the virgin soil increased, so did values of the OMC, while on increasing the percentage of (SHMP) to expansive soil, MDD value decreased from 1.79 to 1.49 g/cc with a lime percentage of up to 6%, and value of OMC increased from 16.2 to 23.4% with 6% of lime and 4.5% of (SHMP) content in soil. By adding lime beyond 6% and 4.5% (NAPO3)6, there is an increase noticed in the MDD but after sometime an increase in OMC value and a decrease in MDD value was observed. Decrease in MDD with addition of lime may be due to the pozzolanic reaction of lime and soil particles also may be due to the difference in specific gravity of the different materials which leads to an increase in OMC of the composite may be attributed to higher value of OMC (Fig. 12).

3.3.7 Soil: BA: lime: (NAPO3)6

The compaction test was carried by adding bottom ash, lime and (SHMP) in a mix and percentage of bottom ash and lime was taken as a constant amount and varying the (SHMP) percentage. Adding bottom ash and lime in expansive soil in constant percentages that is 15% and 6% respectively and varying the percentage of (NAPO3)6, the compaction test was performed to determine the OMC and MDD of the soil. MDD of virgin soil was 1.79 g/cc at 16% OMC. As percentage of (SHMP) in the virgin soil increased, so did values of the OMC, while on increasing the percentage of (SHMP) with lime and bottom ash to expansive soil, MDD value decreased from 1.79 to 1.49 g/cc with a (SHMP) percentage of up to 4.5%, and value of OMC increased from 16.2 to 23.4% with 4.5% of (NAPO3)6, 6% of lime and 15% of bottom ash content in soil. By adding (SHMP) beyond 4.5%, 6%lime and bottom ash 15%, there is an increase noticed in the MDD but after sometime an increase in OMC value and a decrease in MDD value was observed. Decrease in MDD with addition of lime may be due to the pozzolanic reaction of lime and also may be due to the coarser nature of bottom ash particles (Fig. 13).

3.4 Unconfined compressive strength test (UCS)

In order to obtain the effects of various admixtures on strength characteristics of expansive soil, unconfined compressive strength tests were conducted on expansive soil alone and along with various mixes of bottom ash, lime and (SHMP) in accordance with IS: 2720 (Part-10) and are shown in Fig. 14a–c. The unconfined compression strength (UCS) value of expansive soil after 28 days was obtained as 518 kPa shown in Fig. 14c. On adding 15% of bottom ash, 6% lime and 4.5% of (SHMP) alone to expansive soil, the unconfined compressive strength of the composite after curing period of 28 days increased to 734 kPa, 656 kPa and 620 kPa respectively shown in Fig. 15. The combined action of optimum contents of waste, admixture and chemical was further studied in order to check their effect on unconfined compressive strength. It was revealed that on adding bottom ash and lime in combination to expansive soil in optimum amount (S:BA:L:: 79:15:6), the UCS value after a curing period of 28 days attained was 766 kPa; on adding lime and (SHMP) in combination to expansive soil in optimum amount (S:L:(NAPO3)6:: 89.5:6:4.5), the UCS value attained was 823 kPa; and finally on adding bottom ash, lime, and (SHMP) all together in expansive soil in optimum amount (S:BA:L:(NAPO3)6:: 74.5:15:6:4.5), the highest value of UCS was obtained as 895 kPa.

The increase in UCS value on addition of bottom ash may be due to the coarser nature of the particles of bottom ash and with the addition of lime, UCS values increased can be due to the transition of small sized particles into large sized particles which causes various chemical reactions such as cation exchange, pozzolanic reaction and cementation. These large sized particles resist more compressive load than untreated small sized particles of expansive soil.

3.5 California bearing ratio

A common method for assessing the load-bearing capacity of subgrades used in the construction of flexible pavements is the California bearing ratio test (CBR). In accordance with IS-2720 (part-16) recommendations, a series of CBR experiments were conducted under soaking conditions on treated and untreated clayey soil. The samples were compacted to an optimum moisture content and their maximum dry density, as shown by standard Proctor compaction tests. In order to simulate subgrade water infiltration following significant rainfall, the samples were submerged in a water tank for 4 days.

After 4 days the samples were taken out of the water tank and the readings were taken after placing it in the CBR testing machine. According to the test results of the soaked CBR tests, expansive soil had a CBR value of 1.97%, and soils with a CBR value of less than 5% are typically regarded as poor as per IS 2720-16-1987, so using such soil in construction without taking additional steps to stabilize it is not advised. Adding lime to soil can instantly increase CBR and keep doing so over time due to pozzolanic reactions. The incorporation of additives lime, bottom ash and chemical (SHMP) increased the bearing strength of clayey soil significantly despite the short curing time.

3.5.1 Soil:BA

Based on outcomes of the compaction, soaked CBR tests were conducted in various optimum mixes of soil, bottom ash which are presented in Fig. 16. Soaked CBR of expansive soil was 1.97%, which is very low, and cannot be used in the pavement subgrade. The addition of bottom ash from 0 to 15% to the expansive soils increased soaked CBR values from 1.97 to 7.15% which is almost 137.5% of the value of virgin expansive soil and also proves to be a very good subgrade material that can be used in the subgrade of the pavements. With the addition of bottom ash beyond 15%, no incrementation in CBR value is seen; taking this into consideration, the addition of 15% of bottom ash is taken as optimum content. Some researchers have noted the behaviour of an increase in CBR value by adding BA (Prabakar et al. 2004; Edil et al. 2006; Fırat et al. 2012; Bose 2012).

3.5.2 Soil:lime

CBR value of clayey soil increased from 1.97 to 8.30% when optimum lime (9%) was mixed with expansive soil (Fig. 16); even though untreated expansive soil had the lowest CBR, when lime was added, the CBR value increased because of the high concentration of clay minerals that react with the binder. The increase in the strength of lime stabilized clay is due to the binding and coating of soil particles, with the formation of a densely packed and compacted structure that reflects the consumption of cementitious gel in filling voids and binding particles. Further, the CBR results of optimum combinations are studied and it is found that there is enormous increase in the CBR value of clayey soil.

3.5.3 Soil:(NAPO3)6

With the addition of (SHMP) at 4.5% to the expansive soil, the CBR value of expansive soil increased from 1.97 to 6.80% when (SHMP) in percentage of 4.5% was mixed with expansive soil (Fig. 16); even the untreated expansive soil had the lowest CBR, when (SHMP) was added, the CBR value increased because of the high concentration of clay particles that reacts with the chemical. The increase in the strength of expansive soil is due to the presence of various chemicals in (SHMP) and combining with soil particles, which leads to the densely packed and compacted structure that reflects the reduction of voids between particles.

3.5.4 Soil:BA:lime

The addition of bottom ash and lime in different percentages to the expansive soils. The percentage of bottom ash was kept constant at 15% and the lime was varied in different percentages. The values of soaked CBR increases from 1.97 to 5.78% by adding 15% of bottom ash and 6% of lime to expansive soil which is more than the value of virgin expansive soil. The CBR value of soil many be increased due to the pozzolanic action of the lime with the soil particles and also due to the coarser nature of bottom ash particles. With the addition of lime beyond 6%, no incrementation in CBR value is seen; by keeping it in consideration, the addition of 6% lime and 15% of bottom ash is taken as optimum content.

3.5.5 Soil:BA:(NAPO3)6

Soaked CBR tests were conducted in various optimum mixes of soil with different percentages of bottom ash and (SHMP) which are also presented in (Fig. 16). Soaked CBR of expansive soil was 1.97%, which is very low, and cannot be used in the pavement subgrade. The addition of bottom ash is 15% and (SHMP) is added of 4.5% to the expansive soil increased soaked CBR values from 1.97 to 6.48% which proves to be a very good subgrade material that can be used in the subgrade of the pavements. The value increases due to the coarser nature of the bottom ash and the chemical reaction of the (SHMP) with soil particles. With the addition of (SHMP) beyond 4.5%, no incrementation in CBR value is seen; considering this, the addition of 4.5% of (SHMP) is taken as optimum content.

3.5.6 Soil:L:(NAPO3)6

By adding lime at a constant percentage that is 6% and (SHMP) at 4.5% to the expansive soil, the CBR value of expansive soil increased from 1.97 to 9.81% when optimum lime (6%) was mixed with expansive soil (Fig. 16); untreated expansive soil had the lowest CBR, when (SHMP) was added, the CBR value increased because of the high concentration of clay particles that reacts with the chemical. The increase in the strength of expansive soil is due to the presence of various chemicals in (SHMP) and combining with soil particles, which leads to the densely packed and compacted structure that reflects the reduction of voids between particles and also due to the pozzolanic reaction of lime with the soil particles.

3.5.7 Soil:BA:L:(NAPO3)6

The admixtures are added in a different percentage as bottom is added 15% and lime is added at 6% and (SHMP) at 4.5% to the expansive soil, the CBR value of expansive soil increased from 1.97 to 11.41% when (SHMP) at 4.5% was mixed with expansive soil (Fig. 16); untreated expansive soil had the lowest CBR, when the different admixtures were added, the CBR value increased because of the high concentration of clay particles that reacts with the chemicals. The increase in the strength of expansive soil is due to the presence of various chemicals in (SHMP) which reacts when combining with soil particles, which leads to the densely packed and compacted structure that reflects the reduction of voids between particles and also due to the pozzolanic reaction of lime with the soil particles and the coarser nature of the bottom ash particles, these all admixtures leads to increase the CBR value.

4 Pavement design

4.1 IITPAVE

The IITPAVE software is intended for the analysis of linear elastic layered pavement systems. It is a software program that uses mechanistic analytical pavement designs to evaluate pavement layout. The purpose of this procedure is to calculate the total thickness of the pavement structure, as well as the thickness of individual structural components, required to carry the predicted traffic load while retaining appropriate pavement performance under present climatic conditions. This software can calculate the strains, stresses, and deflections induced at various points in the pavement by a uniformly distributed single load on the road surface. The input values in the program are shown in Table 4.

The above table shows the overlay thickness must be presumed to be that the stress/strain formed is below the permissible stress/strain values calculated using an elastic linear layer model as per IRC-37.

4.2 Analysis of results

Allowable horizontal tensile strain (εt) and allowable vertical compressive strain (εv) are determined by using IITPAVE software (Table 5). In stabilized clayey soil, the horizontal tensile strain (εt) that produces fatigue cracks and vertical compressive strain (εv) which causes rutting decreases as compared to untreated expansive soil. For the same design traffic, CBR value of subgrade increases which reduces the necessary design thickness and improves the serviceability as shown in Table 5. With the increase in value of CBR, the thickness of the pavement decreases in a nearly uniform manner and also total thickness increases with increasing the traffic value for all values of CBR of subgrade.

4.3 Cost analysis of a flexible pavement section

The Public Works Department of Himachal Pradesh (HPPWD 2020) publishes the unit pricing of each material and also its engineering properties, every year for all flexible pavement layers. For the estimation of cost for each layer, the Schedule of Rates 2022 handbook is being used. In the present study, the road length assumed was 1000 m and pavement is designed for a single subgrade soil. The different layers considered are as follows:

-

Subgrade (SG)

-

Subbase (SB)

-

Water-bound macadam (WBM)

-

Dense bituminous macadam (DBM)

-

Bituminous concrete (BC).

In Tables 6, 7, 8, 9, 10, 11, 12 and 13, the cost analysis of the subgrade course in Indian Rupee (INR) is presented. The construction costs of different layers, including subgrade layer made of expansive soil, is shown in tables below for 1000, 3000, and 5000 CVPD. These tables also show the construction costs of various layers, including the subgrade layer, which is formed of expansive soil mixed with the optimum combination (S:BA:L:(NAPO3)6: 74.5:15:6:4.5). According to the analysis, the cost of saving is 33.10%, if the subgrade is made up of the optimum combination (S:BA:L:(NAPO3)6: 74.5:15:6:4.5).

5 Conclusions

According to the results of this study it is clear that expansive soil can be suitably stabilised for use as a subgrade material. The findings are significant because the findings show with the addition of smaller amounts of lime lowers construction costs and can provide stronger subgrade material. Suitable results were obtained using only 15% Bottom ash, 6% lime, and 4.5% sodium hexametaphosphate, which were required for optimal expansive soil stabilisation. Bottom ash is a by-product of industries and is available at low cost, utilizing it in pavement subgrade construction can help to reduce environmental pollution. Conclusions mentioned below can be drawn from this study:

-

1.

On adding various admixtures to expansive soil alone, the differential swell reduces. With the addition of admixtures as bottom ash (15%), lime (6%) and (SHMP) (4.5%) the differential swell reduced to zero.

-

2.

Addition of bottom ash, lime and (SHMP) in combination with expansive soil, the plasticity index of the clayey soil decreases.

-

3.

The OMC value of expansive soil decreases with the addition of bottom ash and lime and increases with the addition of lime alone.

-

4.

Soaked CBR tests were conducted for all the optimum combinations, CBR values of expansive soil increases with the addition of bottom ash, lime and (SHMP) alone and in combination with expansive soil. The maximum value of soaked CBR is noticed in the combination of S:BA:L:(NAPO3)6: 71.5:15:6:4.5 from other combinations that are S:BA:L: 76:15:6, S:BA:(NaPO3)6: 80.5:15:4.5 and S:L:(NAPO3)6: 86.5:6:4.5.

-

5.

The pavement layer thickness designed for the CBR value of optimum combinations using IIT Pave software shows the reduction in layer thickness from 598 to 510 mm for 1000 CVPD, 778 to 748 mm for 3000 CVPD and 870 to 715 mm for 5000 CVPD. The maximum reduction in layer thickness is noticed for S:BA:L:(SHMP):: 74.5:15:6:4.5.

-

6.

The addition of a subgrade layer which is formed from an optimal combination of materials (S:BA:L:(NAPO3)6: 74.5:15:6:4.5) to pavement structure, results in the reduction of 33.10% in total cost compared to a pavement structure which contains expansive soil in subgrade layer. These results show that the use of 15% of bottom ash, 6% of lime and 4.5% of (SHMP) in expansive soil improves the strength of subgrade layer and also reduces the cost of construction of a flexible pavement design. So, from this, it is concluded that this optimal combination of materials is a cost-effective solution for pavement construction.

-

7.

The results of present study involve the use of waste with lime and (SHMP) in various combinations and its application to expansive soil has shown that these materials alone or in combination can effectively reduce differential free swell and pavement thickness, while also improving the California bearing ratio. In selecting the optimal material for this process, the use of bottom ash incorporation with lime is good to be the primary choice as it is broadly available.

References

Al-Taie A et al (2023) Mechanical and physical properties and cyclic swell-shrink behaviour of expansive clay improved by recycled glass. Int J Pavement Eng 24(1):2204436

Anand D, Sharma RK, Sharma A (2021) Improving swelling and strength behavior of black cotton soil using lime and quarry dust. In: Sustainable development through engineering innovations: select proceedings of SDEI 2020. Springer, Singapore

Athanasopoulou A (2014) Addition of lime and fly ash to improve highway subgrade soils. J Mat Civil Eng 26(4):773–775

Anburuvel A et al (2023) Characteristic evaluation of geopolymer based lateritic soil stabilization enriched with eggshell ash and rice husk ash for road construction: an experimental investigation. Constr Build Mater 387:131659

Bhardwaj A, Sharma RK (2020) Effect of industrial wastes and lime on strength characteristics of clayey soil. J Eng Des Technol 18(6):1749–1772. https://doi.org/10.1108/JEDT-12-2019-0350

Bhardwaj A, Sharma RK, Sharma A (2021) Stabilization of clayey soil using waste foundry sand and molasses. In: Sustainable development through engineering innovations: select proceedings of SDEI 2020. Springer, Singapore

Bhardwaj A, Sharma RK (2022) Designing thickness of subgrade for flexible pavements incorporating waste foundry sand, molasses, and lime. Innov Infrastruct Solut 7(1):132

Bhatt M et al (2021) Valorization of solid waste using advanced thermo-chemical process: a review. J Environ Chem Eng 9(4):105434

Bhurtel A, Eisazadeh A (2020) Strength and durability of bottom ash and lime stabilized Bangkok clay. KSCE J Civ Eng 24:404–411

Bose B (2012) Geo engineering properties of expansive soil stabilized with fly ash. Electron J Geotech Eng 17(1):1339–1353

Bozbey I, Garaisayev S (2010) Effects of soil pulverization quality on lime stabilization of an expansive clay. Environ Earth Sci 60(6):1137–1151

Chauhan MS, Mittal S, Mohanty B (2008) Performance evaluation of silty sand subgrade reinforced with fly ash and fibre. Geotext Geomembr 26(5):429–435

Dash SK, Hussain M (2012) Lime stabilization of soils: reappraisal. J Mater Civ Eng 24(6):707–714

Dash SK, Hussain M (2015) Influence of lime on shrinkage behavior of soils. J Mat Civil Eng 27(12):04015041

Edil TB, Acosta HA, Benson CH (2006) Stabilizing soft fine-grained soils with fly ash. J Mater Civ Eng 18(2):283–294

Eskioglou P, Oikonomou N (2008) Protection of environment by the use of fly ash in road construction. Glob NEST J 10(1):108–113

Fırat S et al (2012) Utilization of marble dust, fly ash and waste sand (Silt-Quartz) in road subbase filling materials. KSCE J Civ Eng 16:1143–1151

Forteza R, Far M, Seguı C, Cerdá V (2004) Characterization of bottom ash in municipal solid waste incinerators for its use in road base. Waste Manage 24(9):899–909

Gautam KK, Sharma RK, Sharma A (2021) Effect of municipal solid waste incinerator ash and lime on strength characteristics of black cotton soil. In: Sustainable development through engineering innovations: select proceedings of SDEI 2020. Springer, Singapore

HPPWD (2020) Schedule of rates. Himachal Pradesh Public Works Department, Shimla

IS 1498 (1970) Classification and identification of soils for general engineering purpose

Ikeagwuani CC, Obeta IN, Agunwamba JC (2019) Stabilization of black cotton soil subgrade using sawdust ash and lime. Soils Found 59(1):162–175

IS 2720 Part 40 (1977) Methods of tests for soil, part 40. Determination of free swell index of soil. Bureau of Indian Standards, New Delhi

Jha AK, Sivapullaiah PV (2016) Volume change behavior of lime treated gypseous soil—influence of mineralogy and microstructure. Appl Clay Sci 119:202–212

Krithiga N, Pujitha D, Palayam T, Revathy Sri Muthukumaran A (2016) Soil stabilization using lime and fly ash 8

Kumar S, Stewart J (2003) Utilization of Illinois PCC dry bottom ash for compacted landfill barriers. Soil Sedim Contam 12(3):401–415

Kumar GRMA, Raju GVRP (2014) Swelling properties of expansive soils treated with chemicals and flyash. Am J Eng Res 4:245–250

Kumar N, Sharma A, Singh K (2022) Influence of pond ash on compaction and strength of clayey soil mixed with terrazyme. In: Advances in construction materials and sustainable environment: select proceedings of ICCME 2020. Springer, Singapore

López EL et al (2015) Bearing capacity of bottom ash and its mixture with soils. Soils Found 55(3):529–535

Moghal A, Sivapullaiah P (2012) Role of lime leachability on the geotechnical behavior of fly ashes. Int J Geotech Eng 6(1):43–51

Nabizadeh Mashizi M et al (2023) Mechanical and microstructural properties of a stabilized sand using geopolymer made of wastes and a natural pozzolan. Sustainability 15(4):2966

Prabakar J, Dendorkar N, Morchhale RK (2004) Influence of fly ash on strength behavior of typical soils. Cons Build Mat 18(4):263–267

Phani Kumar BR, Sharma RS (2004) Effect of fly ash on engineering properties of expansive soils. J Geotech Geoenviron Eng 130(7):764–767

Sezer A et al (2006) Utilization of a very high lime fly ash for improvement of Izmir clay. Build Environ 41(2):150–155

Sharma A, Sharma RK (2019) Effect of addition of construction–demolition waste on strength characteristics of high plastic clays. Innov Infrastruct Solut 4(1):27

Sharma A, Sharma RK (2020) Strength and drainage characteristics of poor soils stabilized with construction demolition waste. Geotech Geol Eng 38(5):4753–4760

Sharma A, Sharma RK (2021a) An experimental study on uplift behaviour of granular anchor pile in stabilized expansive soil. Int J Geotech Eng 15(8):950–963

Sharma A, Sharma RK (2021b) Sub-grade characteristics of soil stabilized with agricultural waste, constructional waste, and lime. Bull Eng Geol Env 80(3):2473–2484

Singh M, Singh K, Sharma A (2022) Strength characteristics of clayey soil stabilized with brick kiln dust and sisal fiber. In: Advances in construction materials and sustainable environment: select proceedings of ICCME 2020. Springer, Singapore

Sudhakaran SP, Sharma AK, Kolathayar S (2018) Soil stabilization using bottom ash and areca fiber: Experimental investigations and reliability analysis. J Mat Civil Eng 30(8):04018169

Verma V, Abhishek (2019) Stabilization of clayey soils using fly ash and RBI grade 81. In: Proceedings of the 1st international conference on sustainable waste management through design: IC_SWMD 2018 1. Springer International Publishing, pp 95–102

Zagvozda M, Rukavina T, Dimter S (2022) Wood bioash effect as lime replacement in the stabilisation of different clay subgrades. Int J Pavement Eng 23(8):2543–2553

Zhu F, Li Z, Dong W, Yangyun Ou (2019) Geotechnical properties and microstructure of lime-stabilized silt clay. Bull Eng Geol Environ 78(4):2345–2354

Author information

Authors and Affiliations

Contributions

SR have done all the experiments in the laboratory physically and written the manuscript with the help of other authors. SS have given the guidance in writing manuscript. AS give his contribution in whole laboratory work and also helped in writing manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest associated with the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rana, S., Singh, S. & Sharma, A. Utilizing bottom ash, lime and sodium hexametaphosphate in expansive soil for flexible pavement subgrade design. Multiscale and Multidiscip. Model. Exp. and Des. 7, 1625–1642 (2024). https://doi.org/10.1007/s41939-023-00210-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-023-00210-8