Abstract

This study aims to review the potential for microbial calcium carbonate precipitation (MCP) as an effective method for environmental remediation and its application in construction restoration. This review aims to provide in-depth knowledge of microbial calcium carbonate precipitation through the concrete denitrification process. One of the critical parameters reviewed in this study is the choice of denitrifying bacteria that can be used for inclusions in concrete. There are limited reports on denitrifying bacteria used in concrete for enhancing its mechanical and durability characteristics. Hence, this study reviews the different types of denitrifying bacteria that can be used in concrete. Diaphorobacter nitroreducens and Pseudomonas aeruginosa with cell concentration in the range of 105–109 CFU/ml along with calcium formate and calcium nitrate as nutrients are found to be effective. For these bacterial inclusions, the crack healing efficiency is found to range from 350 to 590 µm for 28 days depending on the protective carrier used. Another critical parameter reviewed in this study is the suitable technique for microbial inclusions into concrete. To determine the effectiveness of self-healing, the concentration of bacterial cells required and nutrients required are also reviewed. Additionally, the capacity of denitrifying bacteria as an instrument of self-healing against crack formation is evaluated. Finally, the broad applications of microbial calcium carbonate precipitation through denitrification are discussed in various fields, and the drawbacks of application in concrete are discussed. Overall, it is discovered that the denitrification pathway is more environmentally friendly while still being as successful as current techniques in enhancing the mechanical characteristics of concrete.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Economists have opined that the expenditure on infrastructure maintenance is “overwhelming” [1]. Statistically, it is reported that 0.52% of the US Annual GDP is invested in infrastructure maintenance and repair, whereas the corresponding figures for India and China are 1.08% and 5.57% as per the 2018 global survey data [2]. It is also reported recently as of 2020 that India produces nearly 300 million tonnes per annum (MTPA) of cement for use in infrastructure development and repair [3]. Thus, it is a pressing need of the hour to develop techniques for mitigating the deterioration of existing infrastructure to reduce the associated maintenance and repair costs and also the CO2 emission associated with PC manufacture. To achieve this, concrete containing microbial inclusions (or bacterial concrete) is a concept undergoing extensive research [4,5,6,7,8,9,10]. Microbial calcium carbonate precipitation (MCP) in concrete is reportedly an effective method for environmental remediation and construction restoration [11, 12]. Bacterial concrete, a sort of self-healing concrete, can be used to treat cracks by adding a unique type of bacteria as well as a calcium-based nutrient to the concrete [13]. This method emerges from a broader type of science known as biomineralization, and it is crucial because calcium carbonate precipitation generated by microbial activity is pollution-free and natural [14]. MCP is usually attained through denitrification process [15, 16].

Carbonates in the form of limestone are important carbon sources [17]. The majority of insoluble carbonates come from bacteria, fungi, algae, and metazoans [18]. Calcium carbonate (CaCO3) is generated through the metabolism of microbial organisms in a Calcium-rich (Ca2+) environment [19]. The generated CaCO3 is available in natural form as calcite, aragonite, or vaterite [20].

CaCO3 precipitating bacteria are reportedly discovered in 1913 in the form of a denitrifying bacterial strain, “Bacterium calcis”, capable of producing calcite crystals in a liquid media [21,22,23,24]. Later research has provided evidence of at least 200 different bacterial strains capable of precipitating CaCO3 [24, 25]. These microorganisms include cyanobacteria, microalgae, sulfate-reducing bacteria, and organisms involving the nitrogen cycle [26]. The metabolic pathways followed by these microorganisms for the CaCO3 precipitation include photosynthesis, urea hydrolysis, and denitrification. Calcium ion concentration, nucleation site availability, and pH are some of the governing factors for MCP [27].

The pH and interior temperature conditions in concrete are very high [28]. Keeping these concerns in mind, the most widely used bacterial genus in concrete is Bacillus species, followed by Sporosarcina and Pseudomonas. Sporosarcina has been exclusively employed for bio-cementation [29]. Different bacterial genuses follow different metabolic pathways to produce CaCO3 precipitation in concrete. Many of the Bacillus and Sporosarcina species use the ureolysis pathway to generate calcium carbonate precipitation. But in harsh environmental circumstances including nutrient and oxygen deficiency, high pressures, and high salt concentrations, ureolytic bacteria are not always present. This may lead to a decrease in the existence of the bacteria over time. Additionally, ammonia, recognized for its toxicity in aquatic environments, is produced as a by-product. Therefore, there is a necessity to explore other microbiological processes capable of causing calcium carbonate precipitation to establish the most environmentally friendly alternative for usage in various practical applications.

The alternate pathways used in different applications for microbial calcite precipitation include denitrification, photosynthesis, methane oxidation, and sulfate reduction. However, the use of methane oxidation and sulfate reduction for real-life applications has to be investigated intensively as it produces harmful hydrogen sulfide as a by-product. Photosynthesis also produces toxic formaldehyde as a by- product. In the case of denitrification, the by-products produced at the end of the process include nitrogen gas and a small amount of carbon dioxide which are non-toxic. Presently, the ability of the denitrification pathway for microbial calcium carbonate precipitation is under-utilized. Limited applications are reported in the existing literature [15, 16]. Critical studies on this pathway are required for extensive evaluations of the benefits and drawbacks along with diverse applications, paving the way for personalized solutions. Hence, this study is aimed at reviewing key aspects of this technology and providing a comprehensive summary to enable further detailed research and widespread application.

The review provides an in-depth knowledge of microbial calcium carbonate precipitation (MCP) in concrete through the denitrification process. Section “Denitrification” of this manuscript explains the denitrification mechanism for the self-healing process. The study focuses on highlighting the distinctions between the denitrification process and other metabolic pathways. Section “Selection of denitrifying bacteria for self-healing concrete” investigates the potential denitrifying bacteria that can be used in concrete to facilitate self-healing. Section “Techniques of microbial inclusions in concrete” describes the available techniques for microbial inclusions into concrete. The various materials used for different techniques and their major findings are studied. Section “The concentration of cells and associated nutrients needed focuses on the concentration of bacterial cells and the nutrients required to test the effectiveness of self-healing. The various nutrients used for different bacterial strains are summarized. Section “Investigation of crack healing efficiency” investigates the crack healing efficiency of denitrifying bacteria and Subsequently, Sect. “Other Applications” explains the broad applications of MCP through denitrification. The drawbacks identified for the use of the denitrification mechanism in concrete are discussed in “Drawback” section.

Denitrification

As mentioned above, different metabolic pathways lead to microbial calcium carbonate precipitation.

The below table (Table 1) shows the pathways followed by different bacteria and the reactions which they undergo to precipitate calcium carbonate. Different pathways produce different by-products.

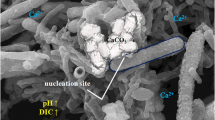

Denitrification is a biological mechanism in the nitrogen cycle in which microorganisms produce nitrite, nitric oxide, and nitrous oxide to convert nitrate to nitrogen. [34]. Bacteria can utilize this process of nitrate reduction to oxidize organic compounds which subsequently helps them in the generation of energy and also their cell growth [35]. Nitrate can be reduced by a variety of bacteria. Alcaligenes, Bacillus, Denitrobacillus, Thiobacillus, Pseudomonas, Spirillum, Micrococcus, and Achromobacter are among the denitrifying bacteria [36]. Denitrification occurs where O2 is limited, but nitrate and organic carbon are sufficiently available [37]. During this process, the pH in the surroundings rises as H + is consumed and CO2 is produced, enhancing carbonate precipitation around the cells (Fig. 1) [16]. This precipitation is useful in concrete crack healing, as mentioned earlier.

A diagram depicting the progressive reduction in nitrate to N2 [47]

Nitrogen and its oxides in different forms, viz. N2, N2O, and NO, are generated as by-products during denitrification [38]. Since the denitrifying bacteria are facultative microbes, either dissolved oxygen or nitrate can be used by them as an oxygen source for metabolism. If both are present, bacterial strains prefer dissolved oxygen to begin the process of denitrification. This is one of the major advantages of this pathway when compared to other oxygen-dependent pathways such as ureolysis and aerobic respiration. Furthermore, denitrification exhibits a negative change in Gibbs free energy (785 kJ/mol acetate) under typical conditions, surpassing the free energy of ureolysis (27 kJ/mol acetate) and the other anaerobic metabolic pathways. As a result, denitrification is thermodynamically more suited than all other metabolic routes except aerobic respiration, and it can be expected to dominate in many MICP applications at higher depths where the presence of oxygen is unlikely [39]. Moreover, denitrification produces more calcium carbonate precipitation per mole of electron source than other pathways (Table 1). This increased carbonate synthesis supports more calcium carbonate precipitation per mole of external material. Overall, microbial-induced calcium carbonate precipitation (MICP) via denitrification appears to be more sustainable for in situ applications [39].

The denitrification process is affected by the presence of sufficient organic matter, present as raw wastewater or supplementary carbon. The effectiveness of this process depends on the nitrate concentration, associated pH, temperature, and existence of organic matter [40, 41].

A suitable electron donor at an appropriate concentration is necessary for denitrification to occur. When glucose is introduced, a carbon-to-nitrate proportion of 3–4:1 is optimal [42]. It is reported that a pH in the range of 7 to 8 is optimum for the denitrification process based on observations from several bacterial cultures. However, denitrification has been observed at a varying range of pH values from 11 to 4 [43]. The ideal varies between species and enzymes [44]. The variation of denitrification with varying pH is still a topic of research for different combinations of bacterial strains and requisite enzymes.

One of the limitations of denitrification is selecting the suitable substrate composition for the growth of denitrifying bacteria. Excessive nitrate use in the substrate composition might result in the formation of compounds that are harmful to bacteria and hinder their activity [45].

It is reported that in alkaline conditions having a pH value of 9, which resembles the condition inside concrete, partial or incomplete denitrification can occur. This is primarily due to the increased NO3− a reduction that leads to the accumulation of NO2 and inhibits further NO3− reduction. This denitrification process has the potential to restrict the corrosion of embedded rebars in concrete. In the presence of chlorides, the presence of nitrites can oxidize ferrous ions to form ferric oxide which forms a relatively passive layer on the rebars and reduces the chance of further chloride attacks. It is reported that an [NO2−]: [Cl−] ratio of 0.34 – 1 is optimum for corrosion inhibition [46].

Based on the discussions in this section, it is evident that the selection of denitrifying bacteria is of utmost importance, as highlighted below.

Selection of denitrifying bacteria for self-healing concrete

The ability of different bacteria to produce calcium carbonate precipitation for the self-healing of concrete has been studied by many researchers. Table 2 presents an overview of calcite precipitation (in mg/cell mass) by different types of bacteria.

Denitrifying bacteria account for 10–15% of the microbial community in soil, water, and sediments. They obtain carbon and energy from a diverse range of inorganic and organic compounds. [52]. The commonly used denitrifiers in concrete are Pseudomonas species, which are first identified as gram-negative, rod-shaped bacteria by Migula at the end of the nineteenth century. Pseudomonas species adapt well to a hostile environment like minimal growth media and temperature shifts [53]. Environmental conditions that impact their growth are nutrient supply, salinity, the presence of toxic compounds, etc. In these bacteria, an essential role is played by the outer membrane, which senses environmental conditions like temperature [53].

At the microscopic level, different behaviors regarding denitrification have been reported. Pseudomonas stutzeri [54] have been stated to use nitrate and nitrite sequentially, with nitrate being the first to be consumed and converted into nitrogen. On the other hand, Pseudomonas alcaligenes, Pseudomonas fluorescens and Flavobacterium sp. have been reported to use nitrate and nitrite simultaneously, with some temporary accumulation of nitrite in the first two species. For further experimentation, Pseudomonas putida is selected as it has a low risk to human health, in addition to its ability to precipitate calcite at a wide range of temperatures.

Under the denitrification process, there are several known reports on the denitrification and bio- cementation of sand using calcium salt [37, 55]. Experiments are done with denitrifying bacteria Paracoccus denitrificans to check the bio-clogging of sand. There is no bioclogging and biocementation after the treatment.

Bacterial isolates of Pseudomonas (D2 and F2) and Acinetobacter (B14) are taken from a stream in Somerset in the United Kingdom and are tested for their ability to deposit calcite in a modified liquid and solid B4 medium as a measure of bio-deposition [56]. Another investigation is carried out on pressure-resistant bacteria to mend fractures in capping rocks employing a pressure close to the real-life scenario for calcification on concrete surfaces. It reported that Halomonas halo denitrificans are appropriate for such applications as they can withstand a pressure of 20 MPa [35].

To identify denitrifiers suitable for microbial self-healing in concrete, Pseudomonas aeruginosa, and Diaphorobacter nitroreducens are chosen and studied at different pH values of 7, 9.5, and 13 with and without protective carriers [15]. These bacteria can withstand mild heat, dehydration, starvation, and an alkaline environment, which makes them compatible with conditions inside concrete. Furthermore, these strains can be cost-effective, environmentally sustainable, and applicable in concrete applications as they do not need costly or toxic nutrients to induce calcite precipitation. These bacteria with cell concentrations in the range of 105–109 CFU/ml along with nutrients are found to be effective [16]. These bacteria can withstand the environment inside mortar or concrete if protective carriers like expanded clay or diatomaceous earth are used.

The potential of many Pseudomonas species to induce calcium precipitation surrounding bacterial cells is investigated [57]. The ability to precipitate is tested in 14 Pseudomonas strains spanning five distinct species. The findings offer light on the capacity of the Pseudomonas species for calcium precipitation as well as the underlying genetic control involved in biomineralization. Some of the species investigated are Pseudomonas putida, Pseudomonas fluorescens, Pseudomonas syringae, Pseudomonas savastanoi, and Pseudomonas viridiflava.

Biosurfactant from Pseudomonas fluorescens has been used in PC-based mortar to modify mechanical strength and capillary porosity [58]. The addition of 1.5 percent biosurfactant to fresh mortar increased its plasticity and enhanced its workability, but the highest compressive strength of mortar is obtained with 1% along with a curing phase of 180 days. It also lowers the capillary absorption coefficient compared to mortar without any biosurfactant.

It is clear from this section that pseudomonas bacterium strains can have widespread applications for self-healing in concrete. The next section discusses the possible techniques for the inclusion of bacteria in concrete.

Techniques of microbial inclusions in concrete

This section presents a summary of the various microbial inclusions into concrete, as reported in the existing literature. The bacteria are generally added to the concrete during the mixing stage. It is reported that the microbial inclusion technique in concrete construction governs the final cost of the project [59]. Thus, the selection of the inclusion technique is subject to the judgment of the user and the availability of resources and funds.

Direct method

In the direct method of inclusion, a solution is prepared by mixing the bacteria and necessary nutrients with the required quantity of water. An external source of calcium can also be added to the nutrient if required [6]. However, this direct addition might cause a delay in the setting times of mortar or concrete prepared with these ingredients as they are primarily composed of organic matter [60]. Hence, some other inclusion techniques have also been implemented.

Vascular network method

In this technique, bacteria are included in the concrete matrix using vessels containing bacteria along with the necessary nutrients. This system resembles the network present in the bone structure of a human body. There are two layers in this bone-like structure, i.e., a porous inner layer and a compact outer layer [61]. The bacteria are injected into the inner layer along with sufficient quantities of nutrients. In the event of a crack in a concrete structural element, the vessels of the embedded vascular network experience a break, resulting in the creation of a pressure gradient. Then, the bacteria and the nutrients migrate toward the location of the crack to restore the equilibrium of the system. The corresponding calcite deposition enables the healing of this crack. However, this method is both expensive and impractical as it is challenging to ensure that the bacteria are evenly distributed within the concrete.

Hollow tubes or pipes of different lengths have been used by various researchers to design different self- healing materials (Fig. 2) [62,63,64,65,66]. By using borosilicate glass tubes, a vascular method is examined where the tubes are embedded in beam specimens made of concrete with an exposed curved outlet on one side [67].

Hollow glass fibers [66]

In another study, a novel porous network is constructed inside concrete for uniform circulation of the healing agent. The porous network is achieved through pumps and atmospheric pressure [68]. The next technique discussed is known as the encapsulation method, which addresses the issue of protecting the bacterial cells during mixing as well as during their presence inside hardened concrete.

Encapsulation method

Both during mixing and the extended period of inactivity inside concrete, the bacterial cells should be protected from the adverse effects of hydration products. Consequently, this method is suggested as the other option for the direct inclusion of bacteria in concrete. The encapsulating or coating material should comply with the following conditions. It should be biocompatible, and the mechanical properties of concrete should not be affected. The capsule should withstand the mixing of concrete, and the chemical composition of the exterior layer should be compatible with that of the concrete matrix [69].

Many forms of encapsulation techniques such as the use of glass and ceramic tubes, microcapsules, and hydrogels have been used in concrete [70]. A trial study is reported on exploring the optimum self- healing efficiencies of various encapsulation methods [71]. Another study on enhancing the efficiency of these mechanisms shows that the implementation of polymeric microcapsules as admixtures for bacterial inclusion in concrete incurs significant costs [69].

Bacteria encapsulation is done into the hydrogel and then, incorporated into a concrete mix to study concrete's healing efficiency [72] (Fig. 3). It provides a favorable microenvironment to the bacteria with the availability of moisture and nutrients. From the findings, we understand that with hydrogel encapsulation in the concrete specimen, it healed a crack width of about 0.5 mm. Further, they worked on the application of modified alginate-based hydrogel encapsulation of bacteria for crack self-healing. It showed excellent biocompatibility with the bacteria. Modified alginate hydrogel has proper absorption and moisture uptake capacity. It has a protective effect on bacteria.

A cracked microcapsule [82]

Glass promotes an alkali-silica reaction, and it may not adjust in a hostile concrete environment [73]. However, glass carriers are being produced on an industrial scale. [74]. This has become an area of interest for many researchers [75,76,77,78]. Studies have concluded that glass can be used for encapsulation as it is brittle and water-resistant [79]. Because of differences in shell materials and environmental conditions, the performance of encapsulation for long-term applications varies. [69, 80].

Studies have been carried out on polyurethane encapsulation of bacteria in concrete self-healing [81]. The accelerated chloride penetration test revealed the formation of a partial barrier due to the release and hardening of polyurethane within the cracks. This prevented chloride ingress through the cracks, thereby decreasing the chloride concentration in the crack zone and improving the durability of reinforced concrete.

The inclusion of encapsulated bacterial cells in concrete is adopted to enhance the survival of these bacteria under the conditions present inside concrete. In case of a crack formation, the encapsulation layer breaks. This allows the embedded bacterial cells to come in contact with aerobic conditions necessary for their activity and subsequent calcite precipitation (Fig. 4). Another technique to protect the bacterial cells during their inclusions in concrete is the protective carrier method, as described below.

The image illustrates a capsule is a concrete tube containing immobilized bio-agent and nutrients [47]

Protective carrier method

Carriers can be one of the highly effective methods in concrete self-healing. Bacterial cells are potentially unable to survive the harsh environment within a concrete mix without protection. So, the inclusion of bacterial cells in concrete or mortar aided by the addition of a protective carrier is suggested. Granular bacterial cultures are a possible option for use in concrete (Fig. 5). One of the key advantages of using these granules is the uniformly ordered distribution of these cultures within the compacted concrete or mortar [83]. The objective is the introduction of bacterial cells at the location of the pores and preventing the connectivity of two or more adjacent pores. The protective carriers used include granular activated carbon, diatomaceous earth, expanded clay, zeolite, air entertainment, cyclic enriched ureolytic powder, and activated compact denitrifying core [15].

ACDC granules: A, B wet condition and C, D post dry condition [60]

It is found that diatomaceous earth can be used for transporting bacteria in a concrete environment. This is because of the high bacterial cell absorption capacity on the surface as they have a high specific surface area [84].

Pseudomonas aeruginosa and Diaphorobacter nitroreducens exhibited significant nitrate reduction activity. It is found that both strains could survive at a pH of 13 if they are protected with diatomaceous earth or expanded clay. They reduced the nitrate even further at pH 10, making them suitable for concrete applications [15]. These strains can also be used for ground improvement and wastewater treatment, and the protected bacteria can be revived in 3 to 7 days.

Research has shown that granulated bacteria can be reactivated when required. Particular granules termed "Activated Compact Denitrifying Core"(ACDC) are utilized [60]. Several advantages can be attributed to ACDC over other axenic cultures. Minimal media containing concrete admixtures as nutrients are required that could be directly mixed in concrete. Their results suggested that ACDC in concrete is a brilliant approach to enhancing the self-healing of cracks. The composition for the cultivation of ACBC is given (Table 3).

Lightweight aggregate (LWA) is generally used as a carrier for healing over the long term, and by its addition, it improved the compressive strength of concrete [71]. Iron nanoparticles have a positive result on concrete mechanical properties. Based on this, the use of 3-aminopropyltriethoxysilane (APTES)-coated iron oxide nanoparticles is proposed [61] to immobilize bacterial cells. The experiment established that cell viability gets affected by different concentrations of nanoparticles used.

Expanded clay as a medium for bacterial transport (Lysinibacillus boronitoleransYS11) from a highly alkaline environment is studied [85]. By using an electron microscope, the existence of bacteria inside the E.C. is observed. The findings indicated that bacteria with E.C. are very active in the generation of CaCO3.

The major findings from different techniques of bacterial inclusions in concrete are summarized below (Table 4).

After the selection of the bacterial inclusion techniques, it is also necessary to investigate the effects of the quantities of bacterial cells and nutrients on CaCO3 precipitation in concrete.

The concentration of cells and associated nutrients needed

Different metabolic pathways require different nutrients for the reaction medium. It is observed that intake of organic acids like acetate, citrate, and succinate by the denitrifying bacteria like Pseudomonas fluorescens, Halomonas eurihalina, Xanthobacter autotrophicus dissolves the inorganic carbon and increases the pH value which affects MCP [86, 87]. Nutrients make available the required source of energy for bacterial growth and therefore, have a strong influence on CaCO3 formation. Carbon and nitrogen are essential sources of nutrients for bacteria [88].

The reduction in nutrients and culture is a drawback in finding out the initial injection amount. Even if nutrients are provided in sufficient amounts, a restriction can occur due to heavy precipitation and clogging at the injection wall [89]. The nutrients and media used by different bacteria in bioconcrete are in Table 5.

Existing research has shown that CaCO3 precipitation yield is affected by the initial biomass concentration. The urea hydrolysis pathway is preferable to have at least 108 cells/ml [84]. It has been shown in another place that for the denitrification pathway, there is a significant increase in CaCO3 precipitation with an increase in cells and that a similar amount of CaCO3 can be precipitated in half the time [16, 95].

An optimal nutrient range for denitrification-based bioconcrete is studied [16]. Calcium formate and calcium nitrate are used as nutrient admixtures, and their weight ratio is maintained at 2.50:1.00 while testing various nutrient doses. Variation in mortar properties and nutrient bioavailability is observed, and the optimum nutrient content range is defined as 3.5% to7% depending on the expectations. To have a workable mix, the nutrient level in nitrate reduction-based self-healing bioconcrete should not exceed 7% wt by wt of cement. The addition of calcium formate and calcium nitrate improves strength development by 20% in the first 28 days but does not affect long-term compressive strength [16].

Nutrients are required for bacterial germination and proliferation within the concrete [96] (Fig. 6). It is detected that more competent precipitation of CaCO3 happens in the company of other nutrients rather than in a growth media [95], which has significant consequences for further research. Growth media has to be selected in such a way that it suits both bacteria and the concrete environment.

The next topic of discussion and potential application in construction practices is the identification of the efficiency of bacterial inclusions in healing cracks in concrete through CaCO3 precipitation.

Investigation of crack healing efficiency

Laboratory experimentations on conventional concrete properties such as mechanical strength and water permeability are not sufficient for bioconcrete specimens. The laboratory conditions are not identical to the conditions experienced by concrete in practical situations. To properly assess the effectiveness of bacterial inclusions in concrete in terms of fracture healing, it is essential to perform experiments on cracked concrete specimens under both laboratory and field conditions. Laboratory scale experimentation is usually performed by inducing cracks of known dimensions in concrete beam specimens containing bacterial inclusions. The extent of filling of these cracks with CaCO3 precipitate is then used to determine the healing capacity of bacterial inclusions. The precipitate is manifested as a superficial white layer which can be characterized using microscopic techniques. However, the situation is more complicated in case of internal cracks present in concrete specimens used for practical or field implementations. As a result, different techniques or combinations of them are employed for the characterization of internal cracks and subsequent analysis of crack-healing properties of bacterial inclusions in concrete.

X-ray computed tomography (XCT) scan is one such non-destructive technique for examining both exterior and internal aspects of specimens. This method is commonly used to measure the fracture healing effectiveness of self-healing concrete and to track the rupture behavior of healing materials [97,98,99,100,101,102].

Results obtained from experimental methodologies are synthesized into indicators of performance recovery associated with healing to articulate design approaches [103]. Index of Crack Sealing (ICS) is calculated using quantitative determination of changes in crack dimensions observed using microscopic techniques accompanied by digital image processing.

where W = width of the crack, recorded at different stages, namely pre-cracking and post-cracking. The values of ICS range between 0 at no healing (Wpost-healing = Wpre-cracking) to 1 at complete healing (Wpost- healing = 0).

ICS is applicable only for the visible closure of surface cracks. However, the internal cracks can be reconstructed using X-ray or neutron radiography, tomography, or microcomputer-tomography scanning techniques [103]. It is also reported that the closure of cracks in concrete can be observed through a stereo-microscope. The fracture closure is checked every week by removing the specimens from their treatment environments. The efficiency of crack closure can be estimated by [71, 90].

where, Wt = crack width measured at a given time, t and Winitial = width of the crack recorded at the onset of cracking [90].

Crack initiation and propagation can be detected and monitored using acoustic emission techniques correlated with digital imaging. [99, 104,105,106,107]. An experimental approach is used to observe and analyze the crack formation and capsule breaking of concrete specimens exposed to three-point flexural loading. The results of a thorough examination of the capsule's functioning revealed a clear picture of the healing activation process. For the repair of concrete cracks, self-protected nitrate-reducing bacteria (ACDC granules) are used [60]. The denitrifying bacteria are grown using concrete admixtures (calcium formate and calcium acetate) as nutrients. More than 90% of the cracks with a width of 500 μm achieved closure in comparison with the reference specimen upon 28 days of water curing (Fig. 7).

Evaluation of cracks of 28 days specimen A reference motor, B abiotic control C motor containing 0.5% activated compact denitrifying core (ACDC) and 5% Nutrients. D 1% ACDC and 5% Nutrients.) [60]

Other non-destructive techniques that can be implemented include Ultrasonic Pulse Velocity method (UPV), Surface Wave Transmission, Diffuse Ultra Sound method, and Coda wave interferometry. These techniques are often used to discover internal faults, assess fracture depth, and determine concrete compressive strength. The technique employed by various non-destructive approaches to determine the healing ratio and crack depth is depicted in the diagram below (Fig. 8).

Mechanisms of different non-destructive methods to evaluate the healing ratio and crack depth in concrete—a transmission of ultrasonic waves; b Spread of surface waves; c ultrasound diffusion; d acoustic emission [108]

A study is done on Pseudomonas aeruginosa and Diaphorobacter nitroreducens with carriers as expanded clay and granular activated carbon [90]. Crack widths of up to 350 μm achieved 100% crack closure. For width between 350 μm and 400 μm achieved more than 90% crack closure by Diaphorobacter Nitroreducens after four weeks of treatment with expanded clay as a protective carrier. Also, in the case of Pseudomonas aeruginosa, the crack width is limited to 350–400 μm. At 28 days, on using granular activated carbon, the crack closure limit is noted as 400 μm for both the bacteria, which is not too great a difference from expanded clay. Consequently, the crack closure is tested for eight weeks. The average crack width of 465 μm is realized after increasing the treatment period [90]. An overview of the crack healing efficiency of bioconcrete using denitrification is given in Table 6.

As it is evident that the healing of cracks developed in concrete takes place due to the precipitation of CaCO3 within the cracks, it is thus essential to determine the morphological and chemical composition of this precipitate. The following section discusses this important aspect.

Characterization of CaCO3 precipitate deposited on cracks

Scanning electron microscopy (SEM) along with energy-dispersive X-ray spectroscopy (EDS) is a useful and popular technique to identify the chemical composition of the precipitate accumulated within the cracks in concrete due to bacterial inclusions. The concrete samples are split into pieces with a 0.5 cm gap between them and the fracture edges. Manual force is used to separate the portion with the crack into two halves again. One surface is studied using SEM–EDS after it is carbon-coated. The energy peaks obtained from the EDS are used to quantify the elemental composition of the precipitate. SEM–EDS analysis of 6-month-old specimens with CaCO3 precipitate due to denitrification on the sample's inner crack surface after 28 days of healing is given in Fig. 9 [60].

SEM Micrographs and EDS analysis of 6-month-old specimen—CaCO3 on the inner crack surface of the sample after 28 days of healing: C2—motor containing 0.5% (ACDC) and 5% Nutrients [60]

Denitrifying bacteria rely solely on the presence of NO3 and organic carbon. Therefore, when these are found in mortar, calcium carbonate precipitation is likely to occur inside the fracture. Studies revealed that calcium carbonate is the most common component detected inside the crack in microbiological samples regardless of curing age. The discovered minerals are mostly found with bacterial impressions and bacterial residues, indicating that calcium carbonate precipitation has occurred. EDS analysis is used for elemental characterization in conjunction with morphological analyses using SEM. Existing studies show that ettringite and C–S–H are as prevalent as CaCO3 inside the fractures of premature control specimens. In contrast, forms of CaCO3 are the most abundant components in the powder obtained from microbiological specimens [60].

Most of the existing information on calcite precipitation in bacterial concrete corresponds to the ureolytic mechanism. A study using Bacillus megaterium reports the greatest calcium weight of 38.76% with a cell concentration of 30 × 105 cells/ml when compared to other mix proportions with and without bacteria in concrete. This is done by focused point chemical analysis using an EDS setup. SEM images show a variation in porosity in concrete with bacteria of different cell concentrations (Fig. 10). It is observed that bacterial concrete with a serial dilution factor of 105 (CFU/ml) exhibits lesser porosity than concrete with other cell concentrations after the deposition of calcite in the cracks. XRD analyses showed CaCO3 peaks at a 2−θ value of 27.52° to corroborate these findings. The corresponding intensity is the highest intensity in comparison with other bacteria concentrations tested [92].

Comparison of concrete porosity under different cell concentrations of bacteria [92]

XRD analysis from another study with Bacillus cohnii reveals a mix of mineral precipitations produced by bacterial concrete, including calcite, aragonite and vaterite under wet-dry and fully wet curing conditions. Aragonite is identified through distinct peaks for wet-dry and fully wet specimens at 2−θ values of 28.511° and 38.447°, respectively. The peaks at 2−θ values of 20.298°, 25.163°, 26.208°, 27.358°, 47.612°, 49.256° indicate the presence of calcite (Fig. 11) [93].

XRD analysis of bacterial concrete a wet dry curing b fully wet curing [93]

The results obtained from the chemical and mineralogical analyses confirm the compatibility of the CaCO3 precipitation with concrete applications. Thus, this technique can have widespread applications in practical scenarios. Extensive experimentation is required to optimize the parameters for desirable bacterial growth in concrete and consequent CaCO3 precipitation. Additionally, this denitrification process can be used in other applications too.

Other applications

Denitrifying bacteria requires minimal growth conditions and basic components in culture media. The biological catalysts (carbonic anhydrase) available in organisms are used in many physiological methods for the reverse hydration of carbon dioxide [109, 110]. It further diminishes the effect of global warming. There is an attempt made to study the decrease in CO2 to CaCO3 using carbonic anhydrase purified from Pseudomonas fragi [111].

The possible application of denitrifying bacteria is bioremediation (Fig. 12). It can remove various toxic impurities from the natural environment. The existing remediation techniques are usually expensive and generate inaccurate results despite consuming a large amount of energy [112,113,114,115]. These include oxidation/reduction, chemical precipitation, ion exchange, filtration, membrane technology, electrochemical treatment, evaporation recovery, and reverse osmosis [116, 117].

Bio-mediated techniques help improve the soil properties by covering the pore gaps and holding the soil particles together (Fig. 13) [118]. CaCO3 precipitation by bacteria due to the denitrification pathway can also be used as a bio-cement. It is also being studied for soil consolidation and the cementation of sand. Denitrifying bacteria in the subsurface removes the need to add non-native microorganisms. A research group at Arizona State University has developed MCP via denitrification for soil improvement, with an emphasis on reducing the number of reactants in the reaction medium.

a Uniform, b Preferential, and c Actual distribution of calcite within the soil pore space [118]

Various pre-treated wastewater is used as substrates for denitrifying bacteria growth in situ. [38]. After continuously feeding the sand column with nutrients for approximately 70 days, maximum carbonate precipitation of 1.8 mM CaCO3/h is reported for C. denitrificans. Studies are made on sand column experiments in which denitrifying microorganisms successfully precipitated CaCO3 [119]. Other than the formation of CaCO3 and the bacterial growth in biofilms, the nitrogen gas produced during denitrification partly filled the pore spaces and hence reduced the permeability of the treated sand.

Studies have also revealed that microbial denitrification can also be used in the disposal of radioactive waste. They underlined the great need for reactions that are biologically catalyzed and the need to take them into account for radioactive waste repositories [120]. A pilot device has been configured for this study, and based on the results obtained; the impact of microbial activity on the reactivity of radionuclides in the cell has been modeled.

The capability of producing and degrading several compounds during the denitrification process is useful in many biotechnological applications. Pseudomonas species produce biosurfactants and Polyhydroxyalkanoates (PHAs), which have low toxicity and biodegradability for supplementary use in various technical fields [121].

A study reported the application of denitrifying bacteria for calcium ion removal from the wastewater of paper mills. It is observed that Diaphorobacter nitroreducens and Pseudomonas aeruginosa can be used in calcium ion removal [60].

Drawbacks

With a significant number of MCP applications being researched and developed worldwide, several technical challenges remain. The long-term survivability of bacteria in concrete is unknown, and it is dependent on the bacteria used and the bacterial inclusion methods used [80, 122]. More supplementary approaches have to be developed through further research to improve the use of MCP through denitrification.

A good and thorough mathematical model should be able to make a priori predictions about behavior and the outcomes of future laboratory trials. When there are impediments to experimenting, such as expense, complexity, or ethical concerns, mathematical modeling can be especially useful. Concrete qualities have been predicted realistically using regression methodologies and advanced machine-learning techniques [123]. The regression models are developed using model trees like Random Forest (RF), M5P, Reduced Error Pruning Tree (REP Tree), Random Tree (RT), and support vector regression are established and compared to Multiple Linear Regression (MLR) to predict the compressive strength of bioconcrete. It is concluded that the RT-based model outperforms the M5P, REP Tree, and MLR-based models. [123].

In another study, a Gene Expression Programming (GEP) model is used to predict the compressive strength of bacterial concrete at various calcium, urea, yeast extract, and bacterial cell concentrations. The gene expression tree is mathematically formulated, and based on the findings, the suggested GEP model demonstrated its capacity to forecast bacterial concrete strength with values that are comparable to the experimental results [124].

The Taguchi technique L9 (33) orthogonal array arrangement is used to discover optimal parameter conditions in bacterial concrete using steel slag as coarse aggregate and various types of wastewater for mixing. According to the variance analysis, steel slag aggregate had a major effect on the compressive strength and durability of bioconcrete, followed by mixing water and bacterial solution [125].

Further, a practical method for simulating and analyzing the fracture and trigger behavior of a capsule-based self-healing cementitious material is created. Based on the true microstructure of a capsule-embedded cement paste specimen, a 3D lattice model is created. The crack behavior of microcapsule-based self-healing is then simulated using this model. This study demonstrated a link between the characteristics of specific materials and their structural behavior by combining experimental data and numerical modeling. It offers a viable path for guiding the design of capsule- based self-healing cementitious composites and, as a result, achieving optimal self-healing performance [126].

All the above studies have focused mainly on ureolytic bacteria. A similar approach to the development of mathematical models to describe MCP through the denitrification process in porous media has to be done. The observed outputs will vary depending upon the strains of bacteria selected and their respective optimal growth parameters, nutrient concentration, the internal environment in concrete, and the bacteria inclusion technique used.

Experimenting at a larger scale will help in the evaluation of MCP for engineered field applications. MCP is economically challenging because of the large-scale production of reactants and microbial cultures. Limited information is available on the non-destructive evaluations of the self-sealing performance of concrete using the denitrification technique. It is critical to undertake a study to determine the increase in durability acquired throughout the self-healing process. The phenomenon is extensively investigated, but no agreement has been reached regarding the maximum healable crack sizes. Also, a disadvantage of MCP is the microbial process that is usually slow and more complex than chemical methods. This is because it depends on environmental factors like pH, metabolites, nutrients, and acceptors of electrons [127].

When compared to the ureolytic process, denitrification has a performance disadvantage in terms of calcite precipitation. It is mostly determined by the primary bacteria concentration, rate of growth, and metabolic activity of each bacterium in that specific habitat. However, the ureolytic process generates ammonia as a toxic by-product. The nutrients and calcium precursors utilized have an impact on the properties of fresh concrete, such as its hydration kinetics, setting time, and workability [128,129,130,131].

Denitrification may be useful in practical concrete applications considering the industrial production of essential nutrients, calcium formate, and calcium nitrate. These chemicals can be used as admixtures in concrete to serve as a nutrition supply for NO-reducing bacteria without causing harm. Self-healing techniques implementing aerobic oxidation or ureolytic bacteria are inefficient in resisting the corrosive chemicals coming into contact with the steel surface during the healing period [132]. Thus, NO-reducing bacteria lead to a bi-fold advantage of corrosion inhibition and crack healing. The lack of oxygen also contributes to the same phenomena. Steel-reinforced concrete constructions will have a longer service life if they are near active oxygen-respiring microorganisms.

Currently, bioconcrete is more expensive to produce than traditional concrete. Depending on the cost of locally accessible ingredients and bacterial strains procured from central agencies, the unit cost of the bacterial mix employed is estimated to be around INR 5000 per m 3 according to the Indian scenario specific to the state of Telangana. The expenditure on bacterial concrete is 7 to 28 percent higher than that of ordinary concrete [133, 134]. Therefore, it remains that bioconcrete is not being used for large-scale projects. However, converting to bioconcrete decreases the amount of maintenance needed to keep the structure in functioning condition. Although expenses for bio- concrete are much higher, it is claimed to be a good investment. The reason for the higher cost of bioconcrete is divided into two parts that are equally important in the production of successful self- healing concrete. The first reason is the nutrient source for the bacteria. Secondly, a coating is required to keep the bacteria and nutrients safe and untouched during the mixing process. In actuality, there are no standard designs for the bacterial concrete design mix to achieve the best performance as it depends on the application, the appropriate amount, and the type of bacteria used [134].

To ascertain the environmental benefits of denitrifying bacterial inclusions in concrete, extensive life cycle assessments have to be carried out on a global scale. There are limited reports on the life cycle assessments (LCA) of these types of concrete [135], indicating the potential for denitrifying bacteria in concrete. Hence, specific assessments on different denitrifying bacteria in concrete are an important avenue for future research.

Based on these facts, we understand that the denitrification pathway for calcite precipitation has not garnered too much attention in concrete applications. A multidisciplinary approach with a clear understanding of the mechanism of denitrification driven by MCP is required to use this technology from the laboratory to the field.

Conclusions

The following findings can be drawn from a survey of available literature.

-

Bacterial inclusions in concrete can enhance the self-healing property of concrete through CaCO3 precipitation.

-

A limited number of denitrifying bacteria have been used in concrete. Diaphorobacter nitroreducens and Pseudomonas aeruginosa with cell concentration in the range of 105–109 CFU/ml along with calcium formate and calcium nitrate as nutrients are found to be effective. For these bacterial inclusions, the crack healing efficiency is found to range from 350 to 590 µm for 28 days depending on the protective carrier used. However, there is no denitrifying bacterium currently recommended as the best for denitrification-based microbial calcite precipitation.

-

Activated compact denitrifying core, self-protected non-axenic cultures, is promising microbial-based self-healing agents for concrete applications. Their application as bacterial agents in the development of microbial self-healing concrete should be researched further.

-

According to the existing healing procedures, the success of a healing procedure is influenced by the matrix and healing agent interaction with one another. The size and form of the fracture also have a role in the effective outcomes of concrete healing.

-

From an environmental perspective, the denitrification pathway can be advantageous due to the usage of environmentally friendly nutrients. Calcium formate and calcium nitrate can be included in concrete as admixtures to act as a nutrient source for denitrifying bacteria with no harmful effects.

-

An overview of various techniques of microbial inclusions in concrete is provided in this study. However, a multidisciplinary approach with a clear understanding of the mechanism of denitrification driven by MCP is required to translate this technology from the laboratory to the field.

-

The various factors which affect are the type of denitrifying bacteria, substrate volume, and environmental factors such as temperature and pH value.

Based on the observations from this study, there is potential for denitrifying bacteria in concrete to enhance crack healing by adding 105 to 109 CFU/ml cell concentrations in the presence of suitable growth media.

References

Olson P, Wessel D (2017) The case for spending more on infrastructure maintenance. The Brookings Institution. Jan 31

Statista (2019) Global investments on the construction and maintenance of infrastructure as share of GDP in 2019, bycountry.

BEEINDIA (2021) “Cement”, by Bureau of Energy Efficiency, Government of India, Ministry of Power

Ghosh P, Mandal S, Chattopadhyay BD, Pal S (2005) Use of microorganism to improve the strength of cement mortar. Cem Concr Res 35(10):1980–1983

Jonkers HM, Schlangen E (2008) A two component bacteria-based self-healing concrete. In: Concrete repair, rehabilitation and retrofitting II. CRC Press, pp 137–138

Jonkers HM, Thijssen A, Muyzer G, Copuroglu O, Schlangen E (2010) Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol Eng 36(2):230–235

Majumdar S, Sarkar M, Chowdhury T, Chattopadhyay B, Mandal S (2012) Use of bacterial protein powder in commercial fly ash pozzolana cements for high-performance construction materials. Open J Civ Eng 2(4):218–228

Vekariya MS, Pitroda J (2013) Bacterial concrete: new era for construction industry. II J E TT 4(9):4128–4137

Rao M, Reddy VS, Hafsa M, Veena P, Anusha P (2013) Bioengineered concrete-a sustainable self-healing construction material. Res J Eng Sci 2(6):45–51

Rais MS, Khan RA (2022) Development of sustainable admixture-based recycled aggregate concrete using ureolytic bacteria. Innov Infrastruct Solut 7(2):1–27

Qian C, Cheng L, Wang R, Wang J (2010) Theory and application of cement-based materials remediation by carbonate precipitation (MCP) induced by microorganism. In: Miao C, Ye, G, Chen H (Eds.) The 50-year teaching and research anniversary of Prof. Sun Wei on Advances in Civil Engineering Materials, pp 81–98

Bansal R, Dhami NK, Mukherjee A, Reddy MS (2016) Biocalcification by halophilic bacteria for remediation of concrete structures in marine environment. J Ind Microbiol 43(11):1497–1505

Ghazy MF, Maaty AA, Mohamed GR (2022) The effect of self-healing by bio- precipitation by bacteria on the properties cement-based materials—a review. Am J Eng Res 11(6):182–201

Riad IM, Elshami AA, Elshikh MMY (2022) Influence of concentration and proportion prepared bacteria on properties of self-healing concrete in sulfate environment. Innov Infrastruct Solut 7(1):1–16

Erşan YÇ, Da Silva FB, Boon N, Verstraete W, De Belie N (2015) Screening of bacteria and concrete compatible protection materials. Constr Build Mater 88:196–203

Erşan YÇ, De Belie N Boon N (2015) Microbially induced CaCO3 precipitation through denitrification: an optimization study in minimal nutrient environment. Biochem Eng J 108–118.

Ehrlich HL (1997) Microbes and metals. Appl Microbiol Biotechnol 48(6):687–692

Gadd GM (2010) Metals, minerals and microbes: geomicrobiology and bioremediation. Microbiology 156(3):609–643

Bosak T (2011) Calcite precipitation, microbially induced. In: Reitner JThiel V, (ed) Encyclopedia of geobiology. Encyclopedia of earth sciences series. Springer, Dordrecht, pp 223–227

Simkiss K (1964) Variations in the crystalline form of calcium carbonate precipitated from artificial seawater. Nature 201(4918):492–493

Boquet E, Boronat A, Ramos-Cormenzana A (1973) Production of calcite (calcium carbonate) crystals by soil bacteria is a general phenomenon. Nature 246(5434):527–529

Schraer H (2012) Biological calcification: cellular and molecular aspects. SSBM Softcover reprint of the originaled. 1970 edition (12 December 2012), 1st edn. Springer, New York

Jain SK, Khan AA, Rai MK (2016) Geomicrobiology. CRC Press, Boca Raton

Kiranmaye BR, Dutta JR, Kar A, Parimi C, Raju S (2020) Optimization of culture parameters of Pseudomonas alcaligenes for crack healing in concrete. Mater Today Proc 28:713–716

Li VC, Wu C, Wang S, Ogawa A, Saito T (2002) Interface tailoring for strain- hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). Mater J 99(5):463–472

Dessy A, Abyor N, Hadi H (2011) An overview of biocement production from microalgae. Int J sci eng 2(2):31–33

Hammes F, Verstraete W (2002) Key roles of pH and calcium metabolism in microbial carbonate precipitation. Rev Environ Sci Biotechnol 1(1):3–7

Mindess S, Young JF, Darwin D (2003) Concrete, 2nd edn. Pearson Education Inc, Upper Saddle River

Gomez MG, Graddy CM, DeJong JT, Nelson DC (2019) Biogeochemical changes during bio-cementation mediated by stimulated and augmented ureolytic microorganisms. Sci Rep 9(1):1–15

Baumgartner LK, Reid RP, Dupraz C, Decho AW, Buckley DH, Spear JR, Visscher PT (2006) Sulfate-reducing bacteria in microbial mats: changing paradigms, new discoveries. Sediment Geol 185(3–4):131–145

Achal V, Pan X, Fu Q, Zhang D (2012) Biomineralization based remediation of As (III) contaminated soil by Sporosarcina ginsengisoli. J Hazard Mater 201:178–184

Grotzinger JP, Knoll AH (1999) Stromatolites in Precambrian carbonates: evolutionary mileposts or environmental dipsticks? Annu Rev Earth Planet Sci 27(1):313–358

Reeburgh WS (2007) Oceanic methane biogeochemistry. Chem Rev 107(2):486–513

Robertson GP, Groffman PM (2007) Nitrogen transformations. In: Soil microbiology, ecology and biochemistry. Academic Press, pp 341–364

Martin D, Dodds K, Butler IB, Ngwenya B (2013) Carbonate precipitation under pressure for bioengineering in the anaerobic subsurface via denitrification. Environ Sci Technol 47(15):8692–8699

Kavazanjian E Jr, Karatas I (2008) Microbiological improvement of the physical properties of soil. international conference on case histories in geotechnical engineering. In: 6th International conference on case histories in geotechnical engineering, Missouri University of Science and Technology, Missouri, USA, pp 1–11

DeJong JT, Fritzges MB, Nüsslein K (2006) Microbially induced cementation to control sand response to undrained shear. J Geotech Geoenviron 132(11):1381–1392

Van Paassen LA, Daza CM, Staal M, Sorokin DY, van der Zon W, Van Loosdrecht MC (2010) Potential soil reinforcement by biological denitrification. Ecol Eng 36(2):168–175

Lin W, Lin W, Cheng X, Chen G, Ersan YC (2021) Microbially induced desaturation and carbonate precipitation through denitrification: a review. Appl Sci 11(17):7842

Broadbent FE, Clark F (1965) Denitrification. Soil Nitrogen 10:344–359

Albina P, Durban N, Bertron A, Albrecht A, Robinet JC, Erable B (2019) Influence of hydrogen electron donor, alkaline pH, and high nitrate concentrations on microbial denitrification: a review. Int J Mol Sci 20(20):5163

Thomas KL, Lloyd D, Boddy L (1994) Effects of oxygen, pH and nitrate concentration on denitrification by Pseudomonas species. FEMS Microbiol Lett 118(1–2):181–186

Prakasam TBS, Loehr RC (1972) Microbial nitrification and denitrification in concentrated wastes. Water Res 6(7):859–869

Gilbert P, Allison DG, Evans DJ, Handley PS, Brown MR (1989) Growth rate control of adherent bacterial populations. Appl Environ Microbiol 55(5):1308–1311

Almeida JS, Julio SM, Reis MAM, Carrondo MJT (1995) Nitrite inhibition of denitrification by Pseudomonas fluorescens. Biotechnol Bioeng 46(3):194–201

Söylev TA, Richardson MG (2008) Corrosion inhibitors for steel in concrete: state-of-the-art report. Constr Build Mater 22(4):609–622

Mamo G, Mattiasson B (2019) Alkaliphiles: the emerging biological tools enhancing concrete durability. Alkaliphiles Biotechnol 293–342

Achal V, Pan X (2014) Influence of calcium sources on microbially induced calcium carbonate precipitation by Bacillus sp. CR2 Biotechnol Appl Biochem 173:307–317

Kang CH, Han SH, ShinYJ OhSJ, So JS (2014) Bioremediation of Cd by microbially induced calcite precipitation. Biotechnol Appl Biochem 172:1929–1937

Dhami NK, Reddy MS, Mukherjee A (2013) Biomineralization of calcium carbonate polymorphs by the bacterial strains isolated from calcareous sites. J Microbiol Biotechnol 23(5):707–714

Dhami NK, Reddy MS, Mukherjee A (2014) Synergistic role of bacterial urease and carbonic anhydrase in carbonate mineralization. Biotechnol Appl Biochem 172(5):2552–2561

Ambus P, Zechmeister-Boltenstern S (2007) Denitrification and N-cycling in forest ecosystems. In Biology of the nitrogen cycle, pp 343–358

Jaouen T, Dé E, Chevalier S, Orange N (2004) Pore size dependence on growth temperature is a common characteristic of the major outer membrane protein OprF in psychrotrophic and mesophilic Pseudomonas species. Appl Environ Microbiol 70(11):6665–6669

Kodama T, Shimada K, Mori T (1969) Studies on anaerobic biphasic growth of a denitrifying bacterium, Pseudomonas stutzeri. Plant Cell Physiol 10(4):855–865

Weil X, Xiwu L (2011) Study on the influencing factors and mathematical model of denitrification phosphate uptake process. Chin J Environ Eng 10

Zamarreño DV, Inkpen R, May E (2009) Carbonate crystals precipitated by freshwater bacteria and their use as a limestone consolidant. Appl Environ Microbiol 75(18):5981–5990

Fishman MR, Giglio K, Fay D, Filiatrault MJ (2018) Physiological and genetic characterization of calcium phosphate precipitation by Pseudomonas species. Sci Rep 8(1):1–14

He H, Serres N, Meylheuc T, Wynns JT, Feugeas F (2020) Modifying mechanical strength and capillary porosity of portland cement-based mortar using a biosurfactant from Pseudomonas fluorescens. Adv Mater Sci Eng

Castro-Alonso MJ, Montañez-Hernandez LE, Sanchez-Muñoz MA, Macias Franco MR, Narayanasamy R, Balagurusamy N (2019) Microbially induced calcium carbonate precipitation (MICP) and its potential in bioconcrete: microbiological and molecular concepts. Front Mater Sci 6:126

Erşan YÇ, Gruyaert E, Louis G, Lors C, De Belie N, Boon N (2015) Self- protected nitrate reducing culture for intrinsic repair of concrete cracks. Front Microbiol 6:1228

Seifan M, Ebrahiminezhad A, Ghasemi Y, Samani AK, Berenjian A (2018) Amine-modified magnetic iron oxide nanoparticle as a promising carrier for application in bio self-healing concrete. Appl Microbiol Biotechnol 102(1):175–184

Dry C (1996) Procedures developed for self-repair of polymer matrix composite materials. Compos Struct 35(3):263–269

Motuku MJGM, Vaidya UK, Janowski (1999) Parametric studies on self- repairing approaches for resin infused composites subjected to low velocity impact. Smart Mater Struct 8(5):623

Bleay SM, Loader CB, Hawyes VJ, Humberstone L, Curtis PT (2001) A smart repair system for polymer matrix composites. Compos A Appl Sci 32(12):1767–1776

Pang JWC, Bond IP (2005) ‘Bleeding composites’—damage detection and self- repair using a biomimetic approach. Compos A Appl Sci 36(2):183–188

Aïssa B, Therriault D, Haddad E, Jamroz W (2012) Self-healing materials systems: overview of major approaches and recent developed technologies. Adv Mater Sci Eng

Joseph C, Jefferson AD, Isaacs B, Lark R, Gardner D (2010) Experimental investigation of adhesive-based self-healing of cementitious materials. Mag Concr Res 62(11):831–843

Sangadji S (2015) Porous network concrete: a bio-inspired building component to make concrete structures self-healing

Gupta S, Dai Pang S, Kua HW (2017) Autonomous healing in concrete by bio-based healing agents—a review. Constr Build Mater 146:419–428

Van Tittelboom K, De Belie N, Van Loo D, Jacobs P (2011) Self-healing efficiency of cementitious materials containing tubular capsules filled with healing agent. Cem Concr Compos 33(4):497–505

Khaliq W, Ehsan MB (2016) Crack healing in concrete using various bio influenced self-healing techniques. Constr Build Mater 102:349–357

Wang J, Van Tittelboom K, De Belie N, Verstraete W (2012) Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr Build Mater 26(1):532–540

Van Tittelboom K, De Belie N (2013) Self-healing in cementitious materials—A review. Mater 6(6):2182–2217

Minnebo P, Van Tittelboom K, Van Hemelrijck D (2015) Ideal material properties for capsules or vascular system used in cementitious self-healing materials. In 5th International Conference on Self-Healing Materials (ICSHM), Durham, NC, USA, pp 1–4

Souza LR, Kanellopoulos A, Al-Tabbaa PA (2015). Synthesis and characterization of acrylate microcapsules using microfluidics for self-healing in cementitious materials. In: Proceedings of the 5th international conference on self-healing materials, Durham, NC, USA, pp 22–24

Hilloulin B, Van Tittelboom K, Gruyaert E, De Belie N, Loukili A (2015) Design of polymeric capsules for self-healing concrete. Cem Concr Compos 55:298–307

Tsangouri E (2015) Experimental assessment of fracture and autonomous healing of concrete and polymer systems. March. Vrije Universiteit Brussel, Brussels

Van Tittelboom K, Wang J, Araújo M, Snoeck D, Gruyaert E, Debbaut B, De Belie N (2016) Comparison of different approaches for self-healing concrete in a large- scale lab test. Constr Build Mater 107:125–137

Araújo M, Chatrabhuti S, Gurdebeke S, Alderete N, Van Tittelboom K, Raquez JM, Gruyaert E (2018) Poly (methyl methacrylate) capsules as an alternative to the “proof-of-concept” glass capsules used in self-healing concrete. Cem Concr Compos 89:260–271

Wang XF, Yang ZH, Fang C, Han NX, Zhu GM, Tang JN, Xing F (2019) Evaluation of the mechanical performance recovery of self-healing cementitious materials–its methods and future development: a review. Constr Build Mater 212:400–421

Van Belleghem B, Kessler S, Van den Heede P, Van Tittelboom K, De Belie N (2018) Chloride induced reinforcement corrosion behavior in self-healing concrete with encapsulated polyurethane. Cem Concr Res 113:130–139

Wu M, Johannesson B, Geiker M (2012) A review: self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr Build Mater 28(1):571–583

Gao D, Liu L, Liang H, Wu WM (2011) Aerobic granular sludge: characterization, mechanism of granulation and application to wastewater treatment. Crit Rev Biotechnol 31(2):137–152

Wang JY, De Belie N, Verstraete W (2012) Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J Ind Microbiol Biotechnol 39(4):567–577

Han S, Choi EK, Park W, Yi C, Chung N (2019) Effectiveness of expanded clay as a bacteria carrier for self-healing concrete. Appl Biol Chem 62(1):1–5

Knorre HV, Krumbein WE (2000) Bacterial calcification. In: Microbial sediments, pp 25–31

Braissant O, Verrecchia EP, Aragno M (2002) Is the contribution of bacteria to terrestrial carbon budget greatly underestimated? Sci Nat 89(8):366–370

Anderson RKI, Jayaraman K (2003) Influence of carbon and nitrogen sources on the growth and sporulation of Bacillus thuringiensis var Galleriae for biopesticide production. Chem Biochem Eng Q 17(3):225–232

Fujita Y, Taylor JL, Gresham TL, Delwiche ME, Colwell FS, McLing TL, Smith RW (2008) Stimulation of microbial urea hydrolysis in groundwater to enhance calcite precipitation. Environ Sci Technol 42(8):3025–3032

Erşan YÇ, Hernandez-Sanabria E, Boon N, De Belie N (2016) Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem Concr Compos 70:159–170

Vijay K, Murmu M (2019) Effect of calcium lactate on compressive strength and self-healing of cracks in microbial concrete. Front Struct Civ Eng 13(3):515–525

Andalib R, Abd Majid MZ, Hussin MW, Ponraj M, Keyvanfar A, Mirza J, Lee HS (2016) Optimum concentration of Bacillus megaterium for strengthening structural concrete. Constr Build Mater 118:180–193

Sumathi A, Murali G, Gowdhaman D, Amran M, Fediuk R, Vatin NI, Gowsika TS (2020) Development of bacterium for crack healing and improving properties of concrete under wet–dry and full-wet curing. Sustainability 12(24):10346

Vijay K, Murmu M (2022) Evaluating durability parameters of concrete containing bacteria and basalt fiber. J Build Pathol Rehabil 7(1):1–6

Alazhari M, Sharma T, Heath A, Cooper R, Paine K (2018) Application of expanded perlite encapsulated bacteria and growth media for self-healing concrete. Constr Build Mater 160:610–619

Wang X, Li Y, Zhang C, Zhang X (2022) Visualization and quantification of self- healing behaviors of microcracks in cement-based materials incorporating fluorescence-labeled self-healing microcapsules. Constr Build Mater 315:125668

Lv L, Yang Z, Chen G, Zhu G, Han N, Schlangen E, Xing F (2016) Synthesis and characterization of a new polymeric microcapsule and feasibility investigation in self-healing cementitious materials. Constr Build Mater 105:487–495

Xiong W, Tang J, Zhu G, Han N, Schlangen E, Dong B, Xing F (2015) A novel capsule-based self-recovery system with a chloride ion trigger. Sci Rep 5(1):1–6

Van Tittelboom K, De Belie N, Lehmann F, Grosse CU (2012) Acoustic emission analysis for the quantification of autonomous crack healing in concrete. Constr Build Mater 28(1):333–341

Sangadji S, Schlangen E (2012) Self healing of concrete structures-novel approach using porous network concrete. J Adv Concr Technol 10(5):185–194

Wang J, Dewanckele J, Cnudde V, Van Vlierberghe S, Verstraete W, De Belie N (2014) X-ray computed tomography proof of bacterial-based self-healing in concrete. Cem Concr Compos 53:289–304

Zhang W, Zheng Q, Ashour A, Han B (2020) Self-healing cement concrete composites for resilient infrastructures: a review. Compos B Eng 189:107892

Ferrara L, Van Mullem T, Alonso MC, Antonaci P, Borg RP, Cuenca E, De Belie N (2018) Experimental characterization of the self-healing capacity of cement based materials and its effects on the material performance: a state of the art report by COST Action SARCOS WG2. Constr Build Mater 167:115–142

Aggelis DG (2011) Classification of cracking mode in concrete by acoustic emission parameters. Mech Res Commun 38(3):53–157

Ohtsu M (2010) Recommendations of RILEM Technical Committee 212-ACD: acoustic emission and related NDE techniques for crack detection and damage evaluation in concrete: 3. Test method for classification of active cracks in concrete structures by acoustic emission. Mater Struct 43(9):1187–1189

Ohno K, Ohtsu M (2010) Crack classification in concrete based on acoustic emission. Constr Build Mater 24(12):2339–2346

Tsangouri E, Aggelis DG, Van Tittelboom K, De Belie N, Van Hemelrijck D (2013) Detecting the activation of a self-healing mechanism in concrete by acoustic emission and digital image correlation. Sci World J 2013.

Kim H, Ahn E, Cho S, Shin M, Sim SH (2017) Comparative analysis of image binarization methods for crack identification in concrete structures. Cem Concr Res 99:53–61

Tripp BC, Smith K, Ferry JG (2001) Carbonic anhydrase: new insights for an ancient enzyme. J Biol Chem 276(52):48615–48618

Zhang Z, Lian B, Hou W, Chen M, Li X, Li Y (2011) Bacillus mucilaginosus can capture atmospheric CO2 by carbonic anhydrase. Afr J Microbiol Res 5(2):106–112

Sharma A, Bhattacharya A (2010) Enhanced biomimetic sequestration of CO2 into CaCO3 using purified carbonic anhydrase from indigenous bacterial strains. J Mol Catal 67(1–2):122–128

Chen G, Zeng G, Tang L, Du C, Jiang X, Huang G, Shen G (2008) Cadmium removal from simulated wastewater to biomass byproduct of Lentinus edodes. Bioresour Technol 99(15):7034–7040

Tang L, Zeng GM, Shen GL, Li YP, Zhang Y, Huang DL (2008) Rapid detection of picloram in agricultural field samples using a disposable immunomembrane-based electrochemical sensor. Environ Sci Technol 42(4):1207–1212

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manag 92(3):407–418

Guo H, Luo S, Chen L, Xiao X, Xi Q, Wei W, He Y (2010) Bioremediation of heavy metals by growing hyperaccumulaor endophytic bacterium Bacillus sp. L14. Bioresour Technol 101(22):8599–8605

Wang J, Chen C (2009) Biosorbents for heavy metals removal and their future. Biotechnol Adv 27(2):195–226

Xiao X, Luo S, Zeng G, Wei W, Wan Y, Chen L, Xi Q (2010) Biosorption of cadmium by endophytic fungus (EF) Microsphaeropsis sp. LSE10 isolated from cadmium hyperaccumulator Solanum nigrum L. Bioresour Technol 101(6):1668–1674

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010) Bio-mediated soilimprovement. Ecol Eng 36(2):197–210

Pham V, Van Paassen L, Nakano A, Kanayama M, Heimovaara T (2013) Microbially induced carbonate precipitation (MICP) by denitrification as ground improvement method-Process control in sand column experiments. In: EGU general assembly conference abstracts, April 2013, Vienna, Austria

Rafrafi Y, Ranaivomanana H, Bertron A, Albrecht A, Erable B (2015) Surface and bacterial reduction of nitrate at alkaline pH: conditions comparable to a nuclear waste repository. Int Biodeterior Biodegradation 101:12–22

Novik G, Savich V, Kiseleva E (2015) An insight into beneficial Pseudomonas bacteria. Microbiology in agriculture and human health, pp 73–105

Gardner D, Lark R, Jefferson T, Davies R (2018) A survey on problems encountered in current concrete construction and the potential benefits of self-healing cementitious materials. Case Stud Constr Mater 8:238–247

Almohammed F, Sihag P, Sammen SS, Ostrowski KA, Singh K, Prasad CVSR, Zajdel P (2022) Assessment of soft computing techniques for the prediction of compressive strength of bacterial concrete. Materials 15(2):489

Algaifi HA, Alqarni AS, Alyousef R, Bakar SA, Ibrahim MW, Shahidan S, Salami BA (2021) Mathematical prediction of the compressive strength of bacterial concrete using gene expression programming. Ain Shams Eng J 12(4):3629–3639

Saxena S, Tembhurkar AR (2022) Optimization of process parameters by Taguchi method for maximizing strength and durability of bio concrete. Innov Infrastruct Solut 7(4):1–13

Lv LY, Zhang H, Schlangen E, Yang Z, Xing F (2017) Experimental and numerical study of crack behaviour for capsule-based self-healing cementitious materials. Constr Build Mater 156:219–229

Ivanov V, Chu J (2008) Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev Environ Sci Biotechnol 7(2):139–153

He J, Gray K, Norris A, Ewing AC, Jurgerson J, Shi X (2020) Use of biological additives in concrete pavements: a review of opportunities and challenges. J Transp Eng B: Pavements 146(3):04020036

Vijay K, Murmu M, Deo SV (2017) Bacteria based self healing concrete—a review. Constr Build Mater 152:1008–1014

Luo M, Qian C (2016) Influences of bacteria-based self-healing agents on cementitious materials hydration kinetics and compressive strength. Constr Build Mater 121:659–663

Ducasse-Lapeyrusse J, Gagné R, Lors C, Damidot D (2017) Effect of calcium gluconate, calcium lactate, and urea on the kinetics of self-healing in mortars. Constr Build Mater 157:489–497

Li W, Dong B, Yang Z, Xu J, Chen Q, Li H, Jiang Z (2018) Recent advances in intrinsic self-healing cementitious materials. Adv Mater 30(17):1705679

Narayanasamy R, Alvarado A, Sanchez Medrano, J, Betancourt Hernandez J, Balagurusamy N (2013) Potential of soil bacteria from the comarca lagunera, north-east Mexico for bioconcrete development, In: ICSHM 2013: Proceedings of the 4th international conference on self-healing materials, June 2013, Delft, Netherlands

Ponraj M, Talaiekhozani A, Zin RM, Ismail M, Abd Majid M Z, Keyvanfar A, Kamyab H Bioconcrete strength, durability, permeability, recycling and effects on human health: A

Ramagiri KK, Chintha R, Bandlamudi RK, Kara De Maeijer P, Kar A (2021) Cradle-to-gate life cycle and economic assessment of sustainable concrete mixes—alkali-activated concrete (AAC) and bacterial concrete (BC). Infrastructures 6(7):104

Choi SG, Chu J, Brown RC, Wang K, Wen Z (2017) Sustainable biocement production via microbially induced calcium carbonate precipitation: use of limestone and acetic acid derived from pyrolysis of lignocellulosic biomass. ACS Sustain Chem Eng 5(6):5183–5190

Prakash D, Gabani P, Chandel AK, Ronen Z, Singh OV (2013) Bioremediation: a genuine technology to remediate radionuclides from the environment. Microb Biotechnol 6(4):349–360

Acknowledgements

The authors would like to thank Birla Institute of Technology and Science-Pilani, Hyderabad Campus for providing the resources for the work and supporting the use of the sponsorship provided by M/s Aliens Group Pvt. Ltd.

Author information

Authors and Affiliations

Contributions

Conceptualization, R.K.B., J.R.D.; and A.K.; data collection and review, R.K.B.; investigation, R.K.B.; data curation, R.K.B., J.R.D., and A.K.; writing—original draft preparation, R.K.B., J.R.D., and A.K.; writing—review and editing, J.R.D. and A.K.; supervision, J.R.D. and A.K.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

The authors confirm that they comply with all ethical standards in preparation of this manuscript.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bandlamudi, R.K., Dutta, J.R. & Kar, A. Applications of microbial calcium carbonate precipitation in concrete through denitrification: a review. Innov. Infrastruct. Solut. 8, 113 (2023). https://doi.org/10.1007/s41062-023-01075-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01075-z