Abstract

The tremendous growth in the construction industry has led to a shortage of natural water and aggregates for concrete. It is an acute problem faced by the construction industry in recent years. To overcome this problem, attention is focused on finding alternatives to provide an amicable solution to this problem. Using industrial waste as coarse aggregate and treated wastewater for mixing is a great opportunity. In the present research, the microbiologically induced calcium carbonate precipitation technique is adopted by using steel slag as coarse aggregate, different types of wastewaters for mixing, and isolated bacteria to develop bio-concrete with maximum strength and durability. Optimum conditions of the parameters are determined using the Taguchi approach L9 (33) orthogonal array layout. Analysis of means indicates that optimum conditions for maximum compressive strength and durability of bio-concrete are reported as 50% steel slag aggregate replacement with natural aggregate, 75 ml bacterial solution with treated wastewater through construction wetland. Analysis of variance indicates that steel slag aggregate has made the greatest impact on the compressive strength and durability of bio-concrete followed by mixing water and bacterial solution. Furthermore, SEM and XRD results show the compact microstructure of concrete due to the microbiological precipitation of calcium carbonate by bacteria.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid urbanization has led to the increasing demand for ingredients for concrete, which promotes the use of recycled waste materials in place of depleting natural materials conventionally used for the purpose of concreting. The requirement of stone aggregates will be a minimum of 2 to a maximum of 10.3 billion tones by the year 2027 [1]. Considering this heavy demand, it would not be possible to satisfy the demand through available natural resources but find alternative materials such as steel slag, a by-product of the steel industry [2,3,4]. In the study of Papayianni and Anastasiou [5], the compressive strength of concrete was found to be increased by 21% when steel slag aggregates were used to replace natural aggregate. Maslehuddin et al. [6] also reported that when steel slag aggregate was used to replace limestone aggregate, the compressive strength increased by 36%. However, the strength of concrete made with steel slag aggregate depends on the quality of steel slag aggregate [7].

Another critical ingredient for the concrete mix proportions is water. The presence of fresh and clean water is limited; hence it leads to the use of treated wastewater as an alternative for mixing concrete. The wastewater adversely affects the strength of concrete when it is in untreated form. The wastewater in treated form minimizes the adverse effect on the properties of concrete. Noruzman et al. [8] reported the fall in the compressive strength of concrete because inorganic substances in wastewater more than the specified limits resulted in delayed cement hydration.

In the present research, the Microbiologically Induced Calcium Carbonate Precipitation (MICCP) technique is adopted to tackle the problem of pores due to the use of wastewater and steel slag aggregate. For this purpose, Bacillus bacteria were isolated from soil and used to prepare bio-concrete by replacing natural water with treated wastewater and natural coarse aggregate with steel slag. In the previous studies, Achal [9] isolated the Bacillus bacteria from cement, used them to prepare the mortar, and found a 36% increment in compressive strength due to the precipitation of calcite. A bacterial strain, Sporosarcina pasteurii, was also found to increase the strength of mortar by 17% [10]. Sarkar et al. [11] observed a 30% improvement in compressive strength by incorporating E. coli in the mortar.

Therefore, in the current study, the whole idea of applying steel slag and wastewater with the addition of bacteria in the development of bio-concrete was done with a view to achieve the sustainability of concrete.

For performing the experiments, the design of experiments for the present research is done using the Taguchi method, as Taguchi's design is a specific exercise that enhances the optimization of process parameters with fewer numbers of experiments. It helps to reach the optimum levels with minimum trials at minimum cost. This method makes the process easy to know which material and in what proportions mainly affect the quality of concrete. Tanyildizi and Şahin [12] also used the Taguchi method to reduce the number of experiments and discovered that the 0% polypropylene fiber and 600 °C temperature were the optimum values to obtain the highest compressive strength and ultrasonic pulse velocity. Türkmen et al. [13] optimized the amounts of mineral admixture, w/c ratio, cure regime and curing time by using the Taguchi approach and found that at (5% silica fume + 10% blast furnace slag), 0.5 w/c and lime saturated curing regime at 28 days, yielded the highest strength and ultrasonic pulse velocity of concrete.

As such, the research was conducted using the MICCP technique to develop a bio concrete using steel slag, treated wastewater and Bacillus bacteria in replacement of natural water and coarse aggregate in concrete. Taguchi approach was used to determine the influence of various parameters on the strength and durability of concrete.

Materials and methods

Preparation of concrete and its testing

Ordinary Portland Cement (OPC) 43-grade [14] was used throughout the study. Basalt aggregate was used as a natural coarse aggregate in the present study. Steel slag from Electric Arc Furnace (EAF) was used to replace natural basalt aggregate in proportions of 25%, 50% and 75%. The picture of steel slag aggregate is depicted in Fig. 1. The WD XRF (Wavelength Dispersive X-ray Fluorescence) test was conducted to determine the chemical composition of steel slag. The significant oxides found in the steel slag were CaO (51.4%), SiO2 (15.6%), Fe2O3 (3.75%), and Al2O3 (18.9%). Different tests were also conducted to determine the physical properties of steel slag aggregate as per BIS 2386 [15] and elucidated in Table 1.

Natural sand was utilized as a fine aggregate procured from the local supplier. The super-plasticizing admixture based on sulfonated naphthalene was used to achieve a target slump of 100 mm. Different types of water were used for mixing concrete, such as treated domestic wastewater from Constructed Wetland (CWL), treated domestic wastewater from Sewage Treatment Plant (STP), and untreated domestic wastewater. The characteristics of all three kinds of water are given in Table 2. For preparing the bacterial solution, freshly isolated Bacillus cereus strains were inoculated in nutrient broth media and incubated for 48 h at 37 °C [16,17,18]. Three different quantities of bacterial solutions (i.e., 50, 75 and 100 ml) were used to prepare concrete. The growth of bacteria in bacterial solution was examined by an optical density test which was performed by using a spectrophotometer at 600 nm wavelength. The optical densities before and after incubation were obtained as 0.0035 and 1.71, respectively. The increment in the optical density of bacterial solution indicates the remarkable growth of bacteria. Figure 2 shows the bacterial solution before and after incubation. For achieving the target strength of 25 MPa and a slump of 100 ± 10 mm, a concrete mix design was computed as per the BIS 10262 [19] and BIS 456 [20] provisions. A water to cement ratio of 0.5 was used to design all concrete mixes. The concrete specimens were cured in the solution, which is composed of 2 g/l urea and 4 g/l CaCl2.2H2O to provide a sufficient substrate and calcium source for the formation of calcium carbonate. For conducting a compressive strength test, cube specimens (150 mm size) were prepared and tested after 28 days of curing according to BIS 516 [21]. Durability is another essential parameter which chiefly influenced by the permeability of concrete. High permeable concrete attributes to the entry of chlorides and other impurities in concrete which disintegrates the properties of concrete and reduces the service life of the concrete. To assess the durability of concrete, Rapid Chloride Permeability Test (RCPT) was performed as per ASTM C1202-12 [22] after 90 days of curing, and the specimen size of 100 mm diameter and 50 mm thickness were tested for RCPT. Sodium chloride solution (3.0%) and sodium hydroxide solution (0.3 N) were used for performing RCPT. In the RCPT, the total charge passed through the specimen in six hours was measured and related to the chloride permeability of concrete. The higher permeability of chloride ions exhibited a greater value of the overall charge passed by the concrete specimen. The microstructure of concrete was also accessed through the Scanning Electron Microscopy (SEM) test and the deposition of minerals was analyzed by X-ray diffraction (XRD) test. The SEM test was executed as per the guidelines of ASTM C1723-10 [23]. A piece of concrete was taken out from the inner core of the concrete cube after the 28 days compressive strength test. The concrete piece was coated with palladium, using a fine auto coater of JEOL JFC 1600 and SEM analysis was performed by using JOEL 6380A. The XRD testing was also performed on concrete to confirm the presence of calcium carbonate. An XPERT-PRO X-ray diffractometer was used for XRD analysis. The XRD-spectra was gained by a copper anode (40 kV and 45 mA) scanning from 2θ values of 10° to 99°.

Statistical analysis

To study different parameters of concrete, the Taguchi method was used, which minimizes the required number of experiments to be performed. The aim of the study is to choose the best combination of control parameters to achieve the highest strength and lowest chloride permeability of concrete. For Taguchi analysis, the details of the used process parameters and the three levels of each process parameter are tabulated in Table 3. It can be reported from Table 3 that three parameters, i.e., different percentages of steel slag aggregate (25, 50 and 75%), different types of mixing water (treated wastewater from CWL, treated wastewater from STP and untreated wastewater) and three different quantity of bacterial solution (50 ml, 75 ml and 100 ml) were used in this research.

Selection of orthogonal array

It is necessary to compute the minimum number of the experimental run before choosing an orthogonal array. It can be determined by Eq. 1:

where NTaguchi = Number of experiments to be conducted, NP = Number of parameters, L = Number of levels. The equation gives the value of NTaguchi as 7. However, there are two Taguchi arrays for an experiment with 3 parameters and 3 levels. First, a 6-run array for testing each level of each parameter twice. Second, a 9-run array for testing each level of each parameter three times. The 9-run array is more desirable because, for each level of anyone parameter, all three levels of the other parameters are tested. Therefore, in the present research, a 9-run orthogonal array L9 (33) was employed for the experimentation [24]. Table 4 shows the experimental runs designed for the L9 orthogonal array.

S/N ratio

Taguchi's design aims at minimizing the variance while keeping the mean on target. The objective of variance reduction while maintaining the mean at the target is achieved by optimizing the Signal to Noise ratio (S/N ratio). This approach includes design parameters and noise factors. The design parameters can be regulated by designers with no trouble. On the other hand, noise factors cannot be regulated by designers, for example, environmental features. These factors ultimately affect the quality of the product. Generally, the S/N ratio is analyzed for the three performance characteristics, i.e., higher the better, lower the better and nominal the better. In the present research, for achieving a higher quality of concrete, the compressive strength of concrete should be higher and chloride permeability should be lower. Hence, higher the better performance characteristic in the case of compressive strength and lower the better performance characteristic for chloride permeability were selected for computing the S/N ratio and calculated by Eqs. (2) and (3), respectively.

For higher the better

For lower the better

where n indicates the number of replications of an experiment, Ch and Rh indicate compressive strength and chloride permeability of concrete respectively at hth experimental trial of both tests run. For each response, the S/N ratio is determined differently depending on the type of performance characteristics. In this experimental study, no interaction effects of parameters were considered. Statistical analysis was performed to determine the statistically significant factors. Three replications were made to test compressive strength and RCP, and three samples were tested for each replication. Hence, for conducting 9 experiments, 81 samples were tested.

Analysis of mean (ANOM)

Various process parameters such as the percentage of steel slag aggregate, types of mixing water, and quantity of bacterial solution are optimized by employing the Analysis of Mean (ANOM) method to maximize the compressive strength and minimize the chloride permeability. ANOM method was implemented to calculate the optimum condition of process parameters. The S/N ratio gives the best database based on minimal deviation and assists in choosing the optimum level of each parameter in the study. The average S/N ratio value of each process parameter for compressive strength and rapid chloride permeability at a particular level was estimated by Eq. 4.

where \(\left[{\left(Q\right)}_{\mathrm{Level}=i}^{\mathrm{Parameter}=p}\right]\) shows the mean of the S/N ratio of parameter P at level h, \(\left[{\left(\frac{S}{N}\right)}_{\mathrm{Level}=h}^{\mathrm{Parameter}=P}\right]\) shows the value of S/N ratio of parameter P at level ‘h’ in its kth appearance in Tables 5 and 6 for compressive strength and Rapid Chloride Permeability (RCP), respectively and its kth value is elucidated in Table 7, where (k = 1, 2, 3, 4…..nPh) and nPh indicates the number of appearances of parameter P in level h. The S/N response (Table 7) was built by determining the mean of the S/N ratios for all the parameters at different levels. In the case of maximum compressive strength of concrete, the optimum condition of various process parameters is determined by selecting the parameter levels which have the highest S/N ratio from Table 7. Conversely, for obtaining minimum chloride permeability of concrete, the optimum condition of various process parameters is calculated by selecting the parameter levels with the lowest S/N ratio in Table 7.

Analysis of variance (ANOVA)

The statistical significance of the contributed parameters on compressive strength and rapid chloride permeability of bio concrete using wastewater and steel slag aggregate is determined by employing the Analysis of Variance (ANOVA) approach. ANOVA method estimates the percentage contribution of each parameter i.e., (1) steel slag aggregate (2) mixing water and (3) bacterial solution for obtaining the process outcome. The percentage contribution of all the process parameters \({(\rho }_{p})\) on compressive strength and chloride permeability of concrete is computed by Eq. 5.

where SSF denotes the factorial sum of squares and is calculated by Eq. 6.

In the above equation, \({\overline{G} }_{T}\) represents the cumulative average of compressive strength or RCP of concrete obtained in the current study and is mathematically symbolized as:

where ‘m’ indicates the number of experiments conducted and ‘n’ shows the number of replications of each experiment. G denotes the compressive strength or RCP values obtained in the ith replication experiment.

In Eq. (6), \({\overline{G} }_{j}^{P}\) is the cumulative average of compressive strength or RCP with a specific parameter P at the jth level and is expressed as:

or

where \({\left[{(\overline{C })}_{\mathrm{Level}=j}^{\mathrm{Parameter}=P}\right]}_{k}\) and \({\left[{(\overline{R })}_{\mathrm{Level}=j}^{\mathrm{Parameter}=P}\right]}_{k}\) represent the average compressive strength \((\overline{C })\) and rapid chloride permeability \((\overline{R })\) with a parameter P at level j in its kth appearance in Tables 5 and 6, respectively and is the kth value in Table 8 (where k = 1, 2, 3, 4…\({n}_{Pj}\)) and \({n}_{Pj}\) is the number of appearances of parameter P at level j.

In Eq. (5), DOF indicates degree of freedom of each parameter, which is calculated as (number of levels – 1) for each parameter. VEr represents the variance of error and is mathematically expressed as:

where SST is the total sum of squares and is calculated as:

F-value is determined by Eq. (12)

where FA is the F-value for parameter A and VA is the variance for parameter A.

Results and discussion

The average compressive strength \({\overline{C} }_{h}\) and rapid chloride permeability \({\overline{R} }_{h}\) was evaluated by calculating the average of compressive strength \({C}_{h}\) and rapid chloride permeability \({R}_{h}\) observed in the experimental runs performed in triplicate under the same experimental conditions as shown in Table 4. The S/N ratios in Tables 5 and 6 are determined by using Eqs. (2) and (3), respectively. The average S/N value at a specific parameter and at a particular level i.e., \(\left[{\left({\text{Q}}\right)}_{\mathrm{Level}}^{\mathrm{Parameter}}\right]\) is determined by Eq. (4). The calculated mean S/N ratios for different factors at different levels are elucidated in the S/N ratio response (Table 7). The compressive strength and rapid chloride permeability responses (Table 8) were also made in the same trend after determining the cumulative average compressive strength and rapid chloride permeability at a specific parameter and a particular level \({\left(\overline{G }\right)}_{j}^{P}\) by Eqs. (8) and (9). The above procedure was adopted for compressive strength and rapid chloride permeability of concrete separately.

Analysis of various parameters for compressive strength of concrete by ANOM approach

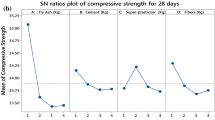

Compressive strength is one of the main properties of the concrete which also decides its durability. Therefore, the effect of various parameters on the compressive strength of concrete was studied so that the actual performance of the concrete could be determined. After employing the Taguchi approach, it was noticed that the optimum percentage of steel slag coarse aggregate for achieving the maximum compressive strength is 50%. It is also shown in Fig. 3a that the highest S/N value, i.e., 28.62 is obtained at 50% steel slag aggregate (L2). The higher strength of concrete is obtained due to the porous and rough surface texture of steel slag coarse aggregates. This property improves the contact between the steel slag coarse aggregate and the cement-sand matrix. Mauthoor et al. [25] also found that the porous surface of steel slag aggregate resulted in higher bonding with cement. The effect of different kinds of treated and untreated wastewater for mixing concrete is shown in Fig. 3b. It was observed that the treated wastewater from constructed wetland (L1) gives the maximum strength and the highest S/N ratio. The values of sulfates, chlorides, solids and BOD were also found lower in the treated wastewater from CWL as compared to the treated wastewater from STP (L2) and untreated wastewater (L3). Therefore, the concrete prepared with treated wastewater from CWL exhibited higher strength. Figure 3c shows the effect of different quantities of bacterial solution, i.e., 50 (L1), 75 (L2) and 100 ml (L3), on the compressive strength of concrete. The Taguchi approach suggests that the optimum quantity of bacterial solution is 75 ml (L2) which gives the maximum strength and highest S/N value. This improvement in compressive strength was undoubtedly due to the precipitation of calcium carbonate by the bacteria, which tends to plug the pores of the concrete and provides a denser and compact microstructure [26,27,28].

Analysis of various parameters for rapid chloride permeability of concrete by ANOM approach

If chloride ions penetrate the concrete, corrosion of steel reinforcement starts. Therefore, the RCP test was carried out to observe the chloride permeation property of concrete. Figure 4a depicts the effect of the addition of different proportions of steel slag aggregate on the rapid chloride permeability of concrete. The maximum S/N value was reported at a 50% proportion of steel slag aggregate (L2). This could be due to the improved bond between the steel slag coarse aggregate and the cement mortar, providing more dense and compact concrete. The results demonstrating the impact of different types of mixing water on the chloride permeability of concrete are depicted in Fig. 4b. On analyzing the results, it was reported that the use of treated wastewater from constructed wetland (L1) provided optimal results. On the other hand, the untreated wastewater (L3) and treated wastewater from STP (L2) were observed to impart more chloride permeability due to more impurities than CW treated wastewater. The more amounts of solid particles, organic matter and other contaminants in wastewater inhibit the hydration reaction of concrete and hence there are additional pores in concrete. The pores increase the chloride permeability of concrete, which induces cracks in concrete, thereby reducing durability. However, the sufficient treatment of wastewater decreases the concentration of solids and harmful chemicals in wastewater which can increase the life span of concrete [29]. Furthermore, an optimum amount of bacterial solution obtained using the Taguchi analysis for minimum chloride permeability of concrete was observed as 75 ml (L2). Figure 4c shows that concrete containing 75 ml bacterial solution has shown the best performance in terms of minimum chloride permeability. Chloride permeability for 75 ml bacterial solution was reported as 158.2 coulombs. Microbially induced calcium carbonate precipitation (MICCP) is found to reduce the permeability of concrete by bacteria. These inbuilt bacteria biologically produce limestone (CaCO3) to fill the voids and micro-cracks in the concrete and decrease the permeability of concrete to work until the end of their service life without the problem of deterioration [30, 31]. Chahal et al. [32] also observed that the concrete with fly ash and bacteria Sporosarcina pasteurii reduced the chloride permeability about eight times at 28 days compared to reference concrete which was likely due to the deposition of calcite in the concrete matrix. Nosouhian et al. [33] studied that the application of bacteria is tended to increase the resistance of concrete toward chloride permeation due to the formation of calcite layer in concrete specimens.

ANOVA technique for compressive strength and RCP of concrete

The sum of factors and percentage contribution for all three parameters calculated using the ANOVA technique are given in Tables 9 and 10 for compressive strength and RCP of concrete, respectively, at a 95% confidence level. The results of the ANOVA test reveal that the percentage contribution of each parameter on the compressive strength of concrete was reported as steel slag coarse aggregate (55.45%) > mixing water (29.85%) > bacterial solution (12.32). The percentage contribution of each parameter on rapid chloride permeability of concrete was found as steel slag coarse aggregate (46.22%) > mixing water (39.10%) > bacterial solution (11.57), respectively and also depicted in Fig. 5a, b. It was observed that steel slag aggregate had a significant effect on the compressive strength and chloride permeability of concrete compared to mixing water and bacterial solution. Aggregates are the vital constituent in the concrete and the coarse aggregate occupies about 40 – 50% of the volume of concrete. Therefore, it affects the concrete strength and durability significantly [34]. Thus, the percentage contribution of steel slag aggregate is also higher than other parameters. Water is also a key ingredient for the concrete mix proportions. It occupies around 10–15% volume of concrete which is used to mix with cement and make a paste that holds the sand and coarse aggregate together. It initiates the hydration reaction of cement and forms calcium silicates which impart strength to concrete [35]. The ANOVA analysis also suggests that after coarse aggregate, the mixing water contributes to the strength and durability of concrete. The bacterial solution was also found to provide additional strength to concrete. The treatment of concrete surface by bacteria leads to precipitation of carbonates on the surface of concrete and plugs the pores in the concrete, thus improving the strength and durability of concrete [36]. The percentage influence of bacteria on the strength and durability of concrete was reported as 12.32 and 11.57, respectively. Furthermore, the F-test and percentage contribution of all the parameters as presented in Table 9 reveal that both steel slag aggregate and type of water have a significant effect on the compressive strength of concrete because their F-ratios are higher than the critical value (18.51) at the 95% confidence level (or 5% significance level). However, the effect of the bacterial solution is observed as not significant with a 12.32% contribution. Similarly, the ANOVA results of RCP, as presented in Table 10, indicate that steel slag aggregate and type of mixing water impact the RCP of concrete significantly. On the other hand, the bacterial solution provides no significant impact on RCP since its F-ratio is observed to be lower than the critical value (18.51).

Prediction of optimum quality characteristics

From the analysis of the S/N ratio and the mean response, optimum levels of control parameters were computed as A2, B1 and C2. Hence, the predicted mean of the quality characteristics (compressive strength and RCP) has been calculated by Eq. (13) according to the study of Chaulia and Das [37].

where Y̅ is the overall mean of performance characteristics. Ā2, B̅1 and C̅2 represent the average values of the compressive strength or RCP with process parameters at their respective optimum levels. Using Eq. (13), the values of S for compressive strength and RCP were predicted as 46.37 MPa and 161.52 Coulomb.

As per the study of Das and Chatterjee [38], the 95% Confidence Interval (CI) for the predicted mean of optimum quality characteristics was computed by applying Eqs. (14) and (15).

where \(F (\alpha ,1,{f}_{e})\) is the F-ratio at a confidence interval of (1 − α) against DOF 1, fe is DOF for error, VEr is the error variance, R is the number of replications for the confirmation experiment, and Neff is the effective number of replications. N is the total number of experiments and TDOF is the total degrees of freedom associated with estimating the mean optimum. For a 95% confidence interval, the compressive strength and RCP were found as 46.37 ± 1.52 and 161.52 ± 8.774, respectively. Thus, the 95% confidence interval of the predicted optimal compressive strength is 44.85 < Compressive strength < 47.89 MPa and predicted 95% confidence interval for RCP is 152.75 < RCP < 170.29 Coulomb.

Confirmation experiment

In Taguchi’s optimization technique, an essential step is conducting confirmation experiments to validate the predicted results [39]. To test predicted results, confirmation experiments have been performed by conducting another three replications at the optimum values of process parameters for compressive strength and RCP. The results are presented in Table 11. It is observed that the mean compressive strength and RCP are 46.28 MPa and 162.29 Coulomb, respectively, which fall within the predicted 95% confidence interval.

Microstructure study of concrete

SEM test was performed to analyze the microstructure characteristics of concrete as it provides good insight into the physical, mechanical and durability properties of concrete. SEM test was conducted on the two concrete samples which gave the highest and lowest compressive strengths. As per Table 5, a concrete mix of experiment number 3 (25% steel slag aggregate, untreated wastewater and 100 ml bacterial solution) and experiment number 4 (50% steel slag aggregates, treated wastewater from CWL and 75 ml bacterial solution or optimum parameters). It was observed that when untreated wastewater was used for the mixing of concrete, pores appeared in the SEM images of concrete (Fig. 6a). It may be due to the presence of more amounts of solid particles, oil, organic matter and other impurities in untreated wastewater which inhibit the hydration reaction of concrete and hence there are additional pores in concrete [8, 29]. Moreover, the organic material present in wastewater leads to absorbing the water from the cement matrix and provides additional pores in cement mortar which tend to increase the drying shrinkage of concrete [40]. On the other hand, a dense microstructure was found in a concrete sample made from treated wastewater from CWL in experiment number 4 (Fig. 6b). The pores were found to be filled with a white color precipitate in this concrete sample. To confirm the mineralogy of white color crystals, an XRD test was performed which confirmed the presence of calcium carbonate as depicted in Fig. 7. This calcium carbonate could be precipitated by bacteria that filled the concrete's pores and provided a denser microstructure.

Conclusion

The present research shows that the Taguchi method achieves a good prediction of compressive strength and rapid chloride permeability of bio concrete, made with treated wastewater and waste materials. Based on the ANOM analysis, it can be concluded that among the three selected levels of steel slag aggregate, the 50% ratio of steel slag (L2) as a partial replacement for natural basalt aggregate imparts the highest compressive strength and lowest chloride permeability to concrete. Also, the treated wastewater from constructed wetland (L1) and 75 ml quantity of bacterial solution (L2) provide maximum compressive strength and the lowest chloride permeability to concrete. The Analysis of Variance (ANOVA) shows that the steel slag coarse aggregate is the most significant parameter influencing the strength and durability of concrete. The percentage contributions are 55.45% for compressive strength and 46.22% for chloride permeability of concrete. However, the percentage contributions of mixing water and bacterial solution on concrete strength are found as 29.85% and 12.32%, respectively and 39.10% and 11.57% on the rapid chloride permeability of concrete. At the optimum settings of the process parameters determined from the analysis, the confirmation test verifies that the mean response parameters lie within the predicted 95% CI. This analysis justifies the optimized output results. Hence, the study shows that the Taguchi technique can be employed cost-effectively and efficiently for working out the optimum process parameters.

Data availability

All data and materials support the published claims and comply with field standards.

Code availability

Not applicable.

References

Aggregate Business International (2013) Booming Indian aggregates market. Available at: http://www.aggbusiness.com/sections/market-reports/features/booming-indian-aggregatesmarket/

Palankar N, Shankar AR, Mithun BM (2016) Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. J Clean Prod 129:437–448

Anastasiou E, Filikas KG, Stefanidou M (2014) Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr Build Mater 50:154–161

Sezer Gİ, Gülderen M (2015) Usage of steel slag in concrete as fine and/or coarse aggregate. Indian J Eng Mater Sci 22:339–344

Papayianni I, Anastasiou E (2010) Production of high-strength concrete using high volume of industrial by-products. Constr Build Mater 24:1412–1417

Maslehuddin M, Sharif AM, Shameem M, Ibrahim M, Barry MS (2003) Comparison of properties of steel slag and crushed limestone aggregates concrete. Constr Build Mater 17(2):105–112

Abu-Eishah SI, El-Dieb AS, Bedir MS (2012) Performance of concrete mixtures made with electric erc furnace (EAF) steel slag aggregate produced in the Arabian Gulf region. Constr Build Mater 34:249–256

Noruzman AH, Muhammad B, Ismail M, Abdul-Majid Z (2012) Characteristics of treated effluents and their potential applications for producing concrete. J Environ Manag 110:27–32

Achal V (2010) Microbial remediation of defects in building materials and structures. PhD Thesis, Thapar University, Patiala, India

Achal V, Mukherjee A, Basu PC, Reddy MS (2009) Lactose mother liquor as an alternative nutrient source for microbial concrete production by Sporosarcina Pasteurii. J Ind Microbiol Biotechnol 36(3):433–438

Sarkar M, Alam N, Chaudhuri B, Chattopadhyay B, Mandal S (2015) Development of an improved E. Coli bacterial strain for green and sustainable concrete technology. RSC Adv 5:32175–32182

Tanyildizi H, Şahin M (2015) Application of Taguchi method for optimization of concrete strengthened with polymer after high temperature. Constr Build Mater 79:97–103

Türkmen İ, Gül R, Çelik C, Demirboğa R (2003) Determination by the Taguchi method of optimum conditions for mechanical properties of high strength concrete with admixtures of silica fume and blast furnace slag. Civ Eng Environ Syst 20(2):105–118

BIS 269 (2015) Ordinary Portland Cement—specification. Bureau of Indian Standards, New Delhi, India

BIS 2386 (1963) Methods of test for aggregates for concrete, (Part I–IV). Bureau of Indian Standards, New Delhi, India

Kumar AP, Akila D (2015) An experimental work on concrete by adding Bacillus subtilis. Int J Emerg Technol Eng 2:69–73

ParvezAlam A, Anwar K, Ansari M (2016) Bacterial concrete-A remedy for micro cracks. Thesis, Anjuman-I-Islam’s Kalsekar Technical Campus, Navi Mumbai, India

Ravindranatha KN, Likhit ML (2014) Self-healing material bacterial concrete. Int J Res Eng Technol 3:656–659

BIS 10262 (2009) Concrete mix proportioning-guidelines. Bureau of Indian Standards, New Delhi, India

BIS 456 (2000) Plain and reinforced concrete-code of practice. Bureau of Indian Standards, New Delhi, India

BIS 516 (1959) Methods of tests for strength of concrete. Bureau of Indian Standards, New Delhi, India

ASTM C1202 (2012) Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. American Society for Testing and Materials, Philadelphia

ASTM C1723 (2010) Standard guide for examination of hardened concrete using scanning electron microscopy. American Society for Testing and Materials, Philadelphia.

Cimbala JM (2014) Taguchi orthogonal arrays. Pennsylvania State University, pp 1–3

Mauthoor S, Mohee R, Kowlesser P (2016) Characterisation of electric arc furnace slags as concrete aggregate in a small island developing state: a preliminary study. Constr Build Mater 105:459–464

Li M, Zhu X, Mukherjee A, Huang M, Achal V (2017) Biomineralization in metakaolin modified cement mortar to improve its strength with lowered cement content. J Hazard Mater 329:178–184

Khaliq W, Ehsan MB (2016) Crack healing in concrete using various bio influenced self-healing techniques. Constr Build Mater 102:349–357

Wong LS (2015) Microbial cementation of ureolytic bacteria from the genus Bacillus: a review of the bacterial application on cement-based materials for cleaner production. J Clean Prod 93:5–17

Al-ghusain I, Terro MJ (2003) Use of treated wastewater for concrete mixing in Kuwait. Kuwait J Sci Eng 30(1):213–228

Siddique R, Chahal NK (2011) Effect of ureolytic bacteria on concrete properties. Constr Build Mater 25:3791–3801

Pacheco-Torgal F, Labrincha JA (2013) Biotech cementitious materials: some aspects of an innovative approach for concrete with enhanced durability. Constr Build Mater 40:1136–1141

Chahal N, Siddique R, Rajor A (2012) Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr Build Mater 28:351–356

Nosouhian F, Mostofinejad D, Hasheminejad H (2015) Influence of biodeposition treatment on concrete durability in a sulphate environment. Biosys Eng 133:141–152

Gambhir ML (2013) Concrete technology: theory and practice. Tata McGraw-Hill Education

Neville AM (2012) Properties of concrete, 5th edn. Pearson Education Limited, England

Balam NH, Mostofinejad D, Eftekhar M (2017) Use of carbonate precipitating bacteria to reduce water absorption of aggregates. Constr Build Mater 141:565–577

Chaulia PK, Das R (2008) Process parameter optimization for fly ash brick by Taguchi method. Mater Res 11:159–164

Das D, Chatterjee A (2013) Taguchi and ANOVA approach for optimization of flow characteristics of self-compacting concrete. Emerg Mater Res 3:37–45

Lafifi B, Rouaiguia A, Boumazza N (2019) Optimization of geotechnical parameters using Taguchi’s design of experiment (DOE), RSM and desirability function. Innov Infrastruct Solut 4:1–12

Yan S, Sagoe-crentsil K, Shapiro G (2012) Properties of cement mortar incorporating de-inking wastewater from waste paper recycling. Constr Build Mater 29:51–55

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Saxena, S., Tembhurkar, A.R. Optimization of process parameters by Taguchi method for maximizing strength and durability of bio concrete. Innov. Infrastruct. Solut. 7, 258 (2022). https://doi.org/10.1007/s41062-022-00850-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00850-8