Abstract

Despite its widespread use and status as a groundbreaking construction material, concrete presents challenges due to its susceptibility to degradation. Due to this reason, concrete structures require regular maintenance, and traditional concrete crack repair methods are resource-intensive and expensive, while also having limitations in their applicability to different crack types. Microbially induced calcite precipitation (MICP) is a promising technique for the maintenance of concrete structures due to its novel approach in concrete technology for healing. The concept of MICP holds promise for sustainable infrastructure development by reducing the need for maintenance and repairs. This paper aims to provide a thorough review of published knowledge on MICP for concrete maintenance to assess and identify effective techniques and methods for MICP in concrete crack healing; this helps practitioners and designers in their decision-making processes. The study focuses on (1) MICP healing efficacy, (2) bacterial species, (3) nutrient supply methods, (4) crack remediation strategies and material compatibility, and (5) environmental conditions. This paper discusses and summarizes effective techniques and methods for MICP healing of concrete. Finally, potential future research directions for further optimizing and implementing MICP in practical applications are discussed. The significance of this work is to provide a concise review summary of the effective strategies and methods of applying MICP to the healing of concrete cracks for researchers and professionals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Concrete, the ubiquitous building material of modern civilization, forms the backbone of countless structures, from towering skyscrapers and sprawling bridges to intricate dams and humble homes. Despite its immense strength and versatility, concrete is inherently susceptible to cracking due to various factors such as shrinkage, thermal expansion, and contraction, imposed loads, and environmental deterioration (Jamil et al. 2019). These cracks, if left unaddressed, can compromise the structural integrity and durability of concrete structures, potentially leading to safety concerns and substantial repair costs (Lu et al. 2023).

Traditional methods for repairing concrete cracks, primarily using cementitious materials like mortar or grout, are readily available and widely used solution (Lu et al. 2023). However, these methods have certain limitations. Their effectiveness diminishes in the face of specific crack types, such as those caused by ongoing structural movement or excessive water infiltration (Jamil et al. 2019). In addition, the rigid nature of cementitious repairs can lead to compatibility issues with the original concrete, potentially causing future cracking or spalling (Jamil et al. 2019). Additionally, the esthetic mismatch between the repaired area and the surrounding concrete can detract from the visual appeal of the structure.

In recent years, researchers have explored innovative approaches for addressing the challenges associated with traditional concrete crack repair methods. One promising avenue lies in the field of bioremediation, where naturally occurring biological processes can be harnessed to improve the environment and infrastructure improvement (Gowthaman et al. 2021; Islam et al. 2020; Eryürük et al. 2015). Among these bio-inspired solutions, microbially induced calcite precipitation (MICP) has emerged as a compelling technology with significant potential for self-healing concrete (Chuo et al. 2020).

During the last 3 decades bacterial concrete has attracted the attention of many researchers, and several scientific documents have been published. As shown in Fig. 1, the number of publications increased starting in the 1990s. From 2010 onwards, the number of published scientific publications has increased rapidly based on the ScienceDirect and Scopus databases (Fig. 1).

In the literature review conducted using the keywords “Microbially induced calcite precipitation, bio-cementation, self-healing concrete,” a total of 3255 academic studies, including conference papers and indexed journal articles, were found (WOS, 2024). The distribution of the obtained studies over the years and the relationships between the selected keywords were visualized using Vos Viewer (VOSviewer, 2022) software to facilitate the investigation (Fig 2). Figure 2 indicates that self-healing concrete and bio-cementation have gained importance in civil engineering in recent years for improvement.

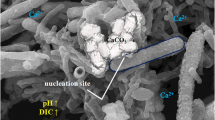

MICP utilizes the metabolic activity of specific bacteria, particularly those belonging to the genus Bacillus, to promote the precipitation of calcium carbonate (CaCO₃), commonly known as calcite) within the concrete matrix (DeJong et al. 2010). This idea was also mentioned by (Karimi and Mostofinejad 2020). These bacteria produce the enzyme urease, which catalyzes the hydrolysis of urea, a readily available nutrient source, into ammonia and carbonic acid (H₂CO₃) (Dhami et al. 2017). Carbonic acid reacts with readily available calcium ions (Ca2⁺) present in the concrete pore solution, leading to the precipitation of calcite precipitates (CaCO₃) (Chaparro et al. 2021). This biomineralization process effectively fills cracks and voids within concrete, promoting self-healing and enhancing the overall structural integrity of the material (Kıvanç et al 2018). Several aspects have contributed to the growing interest in MICP for concrete crack repair. First, it offers a potentially more sustainable and eco-friendlier alternative to traditional repair methods (Lee and Park 2018). Unlike cementitious materials, which often require significant energy consumption and resource extraction for production, MICP uses readily available natural resources and bioprocesses, minimizing the environmental footprint (Raveh-Amit and Tsesarsky 2020).

Additionally, MICP demonstrates promising self-healing properties, potentially reducing maintenance costs and improving the long-term durability of concrete structures (Sharma et al. 2021; Rahman et al. 2020).

Similarly, MICP exhibits remarkable versatility in terms of potential applications. Beyond its core function in concrete crack repair, MICP has potential for various geotechnical applications, including soil stabilization and ground improvement (Gowthaman et al. 2021; Islam et al. 2020; Lin et al. 2018; Z. Wang et al. (2018). Studies have investigated the effectiveness of MICP in enhancing the mechanical properties of soils, preventing soil erosion, and providing resistance against environmental challenges (Gowthaman et al. 2021; Z. Wang et al. (2018). Moreover, MICP’s applicability extends to heritage site preservation, with research demonstrating its potential in strengthening and restoring historical structures (Mu et al. 2021).

MICP offers several advantages in concrete restoration, including enhancing the compressive strength of concrete, as shown in studies in which bacterial remediation led to improvements in this mechanical property (Balam et al. 2021) and reducing water absorption in concrete (Hosseini Balam et al. 2017b), which is crucial for increasing the durability and longevity of structures (Balam et al. 2021). The use of bacteria in concrete can decrease chloride permeability, thereby enhancing the resistance of concrete to chloride ion penetration (Karimi and Mostofinejad 2020; Tayebani and Mostofinejad 2019a), a common cause of concrete deterioration (Balam et al. 2021), and improve electrical resistivity (Parastegari et al. 2019), which is essential for mitigating the corrosion of reinforcement within concrete structures (Parastegari et al. 2022). The ability of MICP to autonomously heal cracks in concrete through bacterial activity, as demonstrated by the self-healing bacterial mortar, is a significant advantage that can prolong the service life of concrete structures (Tayebani and Mostofinejad 2019b).

Despite its benefits, MICP in concrete restoration also presents some challenges like the need for careful consideration of the curing environment and surface treatment to optimize the concrete permeability, as highlighted in studies investigating the effects of various factors on concrete permeability (Tayebani and Mostofinejad 2019b). Another drawback is the potential variability in the effectiveness of bacterial remediation on different types of concrete, such as lightweight aggregate concrete, which may require tailored approaches to achieve optimal results (Salmasi and Mostofinejad, 2020). The use of bacteria in concrete may introduce complexities in terms of maintenance and monitoring to ensure the continued effectiveness of the MICP process over time (Nosouhian and Mostofinejad 2016).

Although the potential of MICP for concrete crack repair and other applications is undeniable, it is crucial to acknowledge that this technology is still under development. Extensive research is ongoing to optimize and refine MICP techniques, focusing on aspects such as bacterial strain selection, nutrient composition, and environmental control (Bakkour et al. 2023; Ghasemi and Montoya 2022; Kıvanç et al. 2018). In addition, the long-term performance and durability of MICP-treated concrete in real-world scenarios require further investigation and monitoring (Kıvanç et al. 2018).

MICP is a new technology in the construction industry, and it has not well addressed its practical application in real-world construction; therefore, it is very important to assess the knowledge and research results to shape them in a way that enables professionals and designers to draw a solid conclusion regarding MICP techniques and methods to heal concrete cracks. There have been several published and unpublished research papers on the applications of MICP for concrete healing, but there is a gap in the analysis of the techniques and methods that are comparatively effective for healing concrete cracks or deteriorations. This paper intends to present an analytical summary regarding concrete healing Fig 3, and suitability of different MICP techniques and methods for concrete crack healing, and to draw up reasonable recommendations regarding the topic.

2 Methods

The research design of this review paper involves a systematic and rigorous approach to identify, select, and analyze relevant literature. The review begins with a comprehensive search of scholarly databases such as Scopus, Web of Science, Springer Link, and ScienceDirect to identify articles, reviews, and research studies related to MICP and its application in concrete healing. The search strategy included keywords such as “MICP concrete,” “MICP concrete healing,” “bacterial concrete,” and related terms to ensure a thorough retrieval of relevant literature.

Following the literature search, a meticulous screening process was performed to assess the titles, abstracts, and full texts of the identified studies. The inclusion and exclusion criteria were predefined to ensure the selection of studies. Five main study areas were identified that align with the objectives of the review. (1) MICP healing efficacy, (2) bacterial species, (3) nutrient supply method (4) crack remediation strategies and material compatibility, and (5) environmental conditions.

The review adopted a structured approach to data extraction and synthesis, and the findings from the selected literature were organized into coherent themes and subtopics. The synthesis process involved identifying and grouping the above subtopics as well as identifying gaps in the existing literature that could inform future research directions. The review also aims to provide a critical analysis of the synthesized information, providing insights into the current state of knowledge and potential areas for further investigation.

3 Results

The results of the thorough review of the collection of articles are structured into the following sections. (3.1) MICP healing efficacy, (3.2) effective bacterial species for treating concrete, (3.3) effective nutrient supply methods (3.4) crack remediation strategies and material compatibility, and (3.5) the effect of environmental conditions.

3.1 MICP Healing Efficacy

3.1.1 Crack Closure

Concrete cracks, a common structural defect, originate from various factors such as drying, shrinkage, thermal expansion, and external loads. These fractures compromise the concrete’s integrity, facilitating water ingress, reinforcement corrosion (Otieno et al., 2010), and ultimately structural failure. Consequently, concrete cracking is a primary cause of deterioration (Wang et al. 2016) and necessitates effective repair solutions. MICP has shown promising results for closing cracks of different sizes, depths, and types. Studies have shown that MICP products often exhibit enhanced strength, durability, and self-healing properties (Chuo et al. 2020). Research has indicated that MICP is effective in closing subterranean cracks in the vicinity of wellbores, suggesting its potential for crack closure (Phillips et al. 2016). MICP has been found to effectively repair both natural and simulated cracks on various surfaces, including brick walls (Mu et al. 2021). Field-scale bio-cementation tests have shown that with further optimization, MICP could be viable for larger-scale applications, indicating its potential for addressing cracks of different scales (Gomez et al. 2015).

MICP has demonstrated potential for repairing concrete cracks by improving their material strength, durability, and self-healing properties (Seifan et al. 2016). Research has shown that certain bacterial strains can effectively close concrete cracks of varying widths, with some strains achieving the closure of cracks up to 400 µm within 28 days (Erşan et al. 2015). MICP has been proven to decrease the permeability of concrete and enhance its strength, indicating its promise for crack repair (Shi et al. 2022).

In contrast, traditional concrete repair techniques, such as chemical and polymer applications, are associated with health and environmental hazards and are generally effective only in the short term (Seifan et al. 2016). The long-term effectiveness of traditional repair methods in achieving crack closure and enhancing concrete durability may be limited compared to MICP. MICP has been found to obstruct the ingress of aggressive substances, suggesting its potential for enduring crack closure (Bandyopadhyay et al. 2023).

MICP has been observed to seal concrete cracks more efficiently near surface than in deeper pores, demonstrating its ability to address cracks at various depths (Mu et al. 2021). This underscores the versatility of MICP in the repair of concrete cracks throughout the material. The use of carbonate-producing microorganisms encased in modified alginate in concrete has been identified as a promising approach for crack self-healing, further highlighting the potential of MICP for concrete repair (J. Wang et al. (2015).

Figure 4 shows a concrete cube before and after MICP treatment. The experimental finding by (Mu et al. 2021) showed that the original cube, MICP-treated cube, and MICP-untreated cube had compressive strengths of (20.67 \(\pm\) 1.98, 17.33 \(\pm \hspace{0.17em}4.69,\) 9.84 \(\pm\) 1.02) MPa respectively. From Fig. 4, we can understand that MICP treatment can restore up to 80% of the concrete strength.

Compressive strength of concrete cubes treated by MICP (Mu et al. 2021)

3.1.2 Strength Recovery

Concrete strength is a critical property influencing its structural performance and durability (Sun et al. 2024a, 2024b). However, the development of cracks compromises this strength, reducing the load-bearing capacity and resistance of concrete to environmental factors (Chen et al. (2023). Restoring concrete strength through effective repair techniques like using fibers (Chen et al. (2024) reported that it is essential to maintain structural integrity and extend the service life of concrete structures. MICP can significantly contribute to the restoration of mechanical properties in concrete. By incorporating high numbers of bacteria and specific amino acids into the concrete matrix, MICP has been found to effectively maintain compressive, tensile, and flexural strength, minimizing strength loss during crack healing processes (Bandyopadhyay et al. 2023; Hosseini Balam et al. 2017a). This highlights the critical role of MICP in preserving the mechanical integrity of concrete structures, even after they have developed cracks (Wang et al., (2015).

MICP treatment can result in a notable increase in the compressive strength of cementitious materials, with improvements ranging from 13 to 27% compared with unassisted recovery processes (Van der Bergh et al. 2020). This enhancement in compressive strength underscores the efficacy of MICP in strengthening the mechanical properties of concrete. MICP has been observed to enhance the mechanical properties of simulated cracked bricks, leading to variations in the failure load and compressive strength after post-treatment (Mu et al. 2021). These results suggest that MICP positively influences the recovery of mechanical strength in concrete, making it a valuable technique for the repair and reinforcement of cracked structures.

The use of MICP in self-healing concrete has been linked to a significant recovery of compressive strength in cracked samples after a healing period, serving as a mechanical indicator of the healing process (Mahmood et al. 2022). This demonstrates the capacity of MICP to rejuvenate the mechanical properties of concrete, thereby contributing to its long-term durability and performance.

Studies have shown that the precipitation of calcite is directly linked to concrete strength improvement. The precipitation of calcite is influenced by factors such as cell concentration, ionic strength, and pH of the medium, and plays a crucial role in determining the extent of strength enhancement (Achal et al. 2009; Liu et al. 2022a, b). The more significant the amount of calcite produced through MICP, the greater is the potential for strength improvement in concrete structures (Achal et al. 2009).

The isolation and identification of bacteria, such as Sporosarcina pasteurii, have been instrumental in enhancing urease and calcite production and improving concrete strength (Achal et al. 2009). The application of microorganisms in concrete, such as MICP, has been recognized as a sustainable strategy for enhancing concrete durability, with calcite precipitation playing a key role in this process (Wang et al. 2015). The mineralogical sequence of self-healing products in cracked marine concrete has highlighted the dominance of calcite precipitation as a self-healing mechanism, emphasizing its significance in improving concrete properties (Danner et al. 2019; Liu et al. 2022a, b).

3.1.3 Durability Improvement

Concrete durability is of paramount importance for ensuring the long-term performance and safety of structures. A durable concrete structure can withstand the aggressive effects of environmental factors. Li et al. 2024; Nosouhian et al. 2016; Sun et al. 2023), reducing the need for repair and replacement. Investing in concrete durability translates into significant cost savings and minimal maintenance over the structure's lifespan. MICP contributes to reducing water permeability and porosity in concrete, thereby enhancing its resistance to degradation mechanisms. The application of MICP and fibers has been associated with decreased capillary water absorption and improved durability by preventing the penetration of corrosion promoters, suggesting their effectiveness in enhancing concrete’s resistance to water ingress and chloride penetration (Castro-Alonso et al. 2019; Doostkami et al. 2022; Lu et al. 2023).

Discussing the potential long-term benefits of MICP for extending the service life of concrete structures requires considering how MICP can improve the durability and mechanical properties of concrete over time. MICP has been reported to aid in the development of bio-concrete, leading to improvements in the mechanical and durability properties of concrete structures (Kulkarni et al. 2020). By reducing water permeability, porosity, and chloride-ion permeation, MICP and fibers can enhance the long-term performance of concrete, potentially extending the service life of structures (Doostkami et al. 2022; Lv et al. 2023; Sun et al. 2024c). The self-healing properties of MICP, such as crack sealing and reduced water absorption, contribute to maintaining the structural integrity of concrete over time, highlighting its long-term benefits of this innovative technology (Doostkami et al. 2022; Kulkarni et al. 2020).

The water permeability of concrete specimens decreases with an increase in Mill-Rejected Granular Cement (MRGC) content, both for uncracked specimens and after the crack-healing period (Asrat and Ghebrab 2020; Mostofinejad et al. 2020). MICP research on creating self-healing mortar or concrete and crack sealing indicates the potential to reduce permeability and porosity through bacterial action (Chuo et al. 2020; Doostkami et al. 2022). These findings indicate that MICP has the potential to reduce the permeability and porosity of concrete after crack healing, enhancing its material properties and long-term performance.

3.2 Effective Treatment of Concrete with Bacterial Species

3.2.1 Selection Criteria for Effective Bacteria

Because there are different species of bacteria with a variety of biological characteristics, it is important to select the right species of bacteria for specific concrete healing task. So0me of the main effective bacterial species selection criteria are listed below.

3.2.2 Ureolytic Activity

Several bacterial species have been identified for their ureolytic activities, which play key roles in biomineralization processes like MICP. These studies highlighted the importance of ureolytic bacteria, which are well known for their effective calcifying properties and include Bacillus subtilis and Sporosarcina pasteurii (Eryürük 2022; Omoregie et al. 2019; Gat et al. 2016). Bacterial isolates with high ureolytic activity, including JA1, JB2, JB3, and Sporosarcina pasteurii strains, emphasizing their potential as calcium carbonate precipitation inducers were also identified by researchers (Idris et al. 2022; Zulaika et al. 2019).

The significance of urease activity in bacterial infections and the modulation of ureolysis, as well as insights into the association between bacterial nickel import and urease activity were illuminated by researchers (Svane et al. 2020; Konieczna et al. 2012). Understanding the ureolytic capabilities of bacterial species is crucial for selecting suitable candidates for MICP applications aimed at enhancing the mechanical properties of concrete via efficient calcite precipitation.

3.2.3 Alkaline Tolerance

To identify bacterial species with the best alkaline tolerance for thriving in high pH environments like concrete, it is crucial to consider their adaptability to extreme conditions. Studies have highlighted the resilience of sulfur-oxidizing bacteria and their communities in concrete, reflecting their ability to withstand alkaline environments (Kiledal et al. 2021; Okabe et al. 2007). On the other hand, researchers have investigated the survival of bacteria like Halomonas desiderata and indigenous cement isolates in highly alkaline habitats, indicating their alkaline tolerance (Alquier et al. 2014; Achal et al. 2009).

3.2.4 Spore Formation

Spore-forming bacteria enhance the viability and resilience of microbial activities during the concrete mixing and placement process. Some researchers have argued the significance of spore-forming ureolytic strains like Bacillus sphaericus for self-healing concrete applications (Wang et al. 2017; Sharma et al. 2017). These bacteria form spores that shield them in alkaline environments, enabling efficient calcite precipitation and crack repair in concrete structures. The role of spore-forming bacteria, such as Sporosarcina pasteurii and Bacillus megaterium, in enhancing the strength and permeation properties of concrete through their spore production and germination capabilities was also highlighted (Nasser et al. 2022; Van der Bergh et al. 2020).

Moreover, some studies demonstrated high levels of urea decomposition and robust spore germination by bacterial strains, indicating their potential for use in spore-based applications in self-healing concrete (Pungrasmi et al. 2019; Reeksting et al. 2020). These bacteria, through their spore-forming abilities, contribute to calcium carbonate formation and improve the durability of concrete structures. Overall, spore-forming bacteria, particularly ureolytic strains like Bacillus sphaericus and Sporosarcina pasteurii, exhibit excellent alkaline tolerance and spore formation capabilities, making them effective for concrete applications.

3.3 Compatibility with Concrete Components

The compatibility of the bacterial species with the host concrete is crucial for enhancing the concrete healing process. Bacillus megaterium is an effective bacterial species for concrete healing (Krishnapriya et al. 2015). This species, along with Bacillus sphaericus and Bacillus licheniformis, has been shown to substantially increase the strength of concrete and facilitate complete crack healing. Additionally, B. sphaericus was encapsulated in a modified alginate hydrogel, demonstrating good compatibility with both bacteria and concrete (Wang et al 2015).

The compatibility of Bacillus strains, including B. pseudofirmus and B. cohnii, with concrete has been investigated (Wiktor and Jonkers 2016), highlighting their potential for self-healing concrete applications. Bacillus subtilis has been studied for its impact on the strength and self-healing of bacterial concrete (Ahiwale and Khartode 2021). These bacterial species have substantial effects on concrete strength and self-healing mechanisms. Additionally, B. licheniformis and B. sphaericus have been investigated for their influence on concrete strength and durability (Bandlamudi et al. 2023; Li et al. 2022).

3.3.1 Common Bacterial Strains

Bacillus megaterium is a beneficial bacterial species for concrete healing (Krishnapriya et al. 2015). It has been demonstrated that these species, together with B. sphaericus and B. licheniformis, significantly strengthens concrete and accelerates fracture healing. Furthermore, it has been reported that B. sphaericus can be encapsulated inside a modified alginate hydrogel, exhibiting good compatibility with both the bacteria and concrete (Wang et al. 2015).

Moreover, it has been discovered that Sporosarcina pasteurii, another spore-forming bacterial species, enhances the strength and durability of concrete. This species and some Bacillus strains have been successfully used for concrete crack healing (Shahid et al. 2020). The compatibility of various Bacillus strains with concrete, including B. pseudofirmus and B. cohnii, was investigated, and it was found that they could be useful in self-healing concrete applications (Wiktor and Jonkers 2016).

Furthermore, the use of Bacillus subtilis has been studied for its impact on the strength and self-healing of bacterial concrete (Ahiwale and Khartode 2021). This bacterial species exerted substantial effects on concrete strength and self-healing mechanisms. Additionally, B. licheniformis and B. sphaericus have been investigated for their influence on concrete strength and durability (Bandlamudi et al. 2023; Li et al. 2022). In conclusion, the Bacillus strain is one of the most commonly used bacterial species and has been proven for its efficient healing characteristics.

3.3.2 Comparative Analysis of Bacterial Efficiency

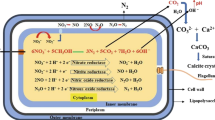

Sporosarcina pasteurii has been extensively studied for MICP and has shown effectiveness in inducing calcite precipitation, the mechanism of which is explained in Fig. 5 (Chuo et al. 2020; Eryürük et al. 2015a, 2015b).

Mechanism of microbially induced calcite precipitation (MICP) with resting cells of Sporosarcina pasteurii (Eryürük, 2015)

Some researchers have highlighted Sporosarcina pasteurii as the most studied bacterium for MICP, emphasizing its ability to promote calcium carbonate precipitation in concrete, which contributes to self-healing mechanisms and enhances concrete durability (Chuo et al. 2020; Reeksting et al. 2020).

Erşan et al. (2015) demonstrated effective crack closure of up to 0.5 mm through calcite precipitation using a self-protected nitrate-reducing culture, highlighting the role of bacteria in enhancing concrete durability. Autogenous healing of cracks by various bacterial strains, including Bacillus cohnii, Bacillus pseudofirmus, and Bacillus subtilis, highlighting their potential for concrete healing were also reported (Castro-Alonso et al. 2019) (Table 1).

Krishnapriya et al. (2015) observed a significant increase in concrete strength and crack healing by using B. megaterium, B. licheniformis, and B. megaterium strains. Harnpicharnchai et al. (2022) demonstrated that a mixed culture of ureolytic and non-ureolytic bacterial strains precipitates large amounts of calcium carbonate, underscoring the usefulness of MICP for concrete.

3.4 Effective Nutrient Supply Methods

When it comes to bacterial activity and calcite precipitation, efficient nutrition delivery is essential for MICP in concrete. The presence of nutrients, such as urea (Amiri and Bundur 2018), calcium ions, and organic precursors, is necessary to stimulate bacterial metabolism and precipitate calcite, both of which aid in the strengthening and healing of concrete (Metwally et al. 2020; Nain et al. 2019). Research has demonstrated that the availability of nutrients affects the effectiveness of MICP, with high levels of urea and calcium chloride facilitating bacterial metabolism.

Various methods can be used to deliver essential nutrients to bacteria within concrete for MICP. Some of the most effective nutrient delivery methods are pre-encapsulated bacteria, preconditioning, and continued to feed.

3.4.1 Pre-Encapsulated Bacteria

One technique for providing nutrients to bacteria in concrete for MICP is the use of pre-encapsulated bacteria (Wang et al. 2015). Using this method, bacteria and nutrients can be enclosed in micro–or macro-capsules, which can have a spherical or cylindrical form. The method of encapsulation ensures the survival and functionality of bacteria and nutrients by providing a protective environment within the concrete (Espitia-Nery et al., 2019). Pre-encapsulating bacteria increases their chances of survival and keeps them isolated from germination stimuli until they are mixed into the concrete (Mostofinejad et al. 2022; Seifan et al. 2016). This helps the MICP process by increasing the self-healing characteristics of concrete constructions.

Pre-encapsulated bacteria offer a protective and controlled delivery method for ensuring the viability and sustained activity of bacteria in concrete, thus enhancing the efficiency of MICP processes. On the other hand, this technique has its own drawbacks, which can be seen in Table 2.

However, there are different methods of encapsulation, based on fissure repair efficiency, melanin-based microencapsulation and expanded clay coated in a geopolymer layer comprising sodium silicate solution and metakaolin yielded maximum repair widths of 0.96 mm and 0.79 mm (Wang et al. 2014), respectively, which are the most effective bacterial encapsulation techniques (Seifan et al. 2016)

3.4.2 Preconditioning Bacteria

Pre-treatment of concrete with nutrients before introducing bacteria into MICP is a method that involves conditioning the concrete substrate to optimize its environment for bacterial activity and calcite precipitation. (Wang et al. 2017) explored the use of pre-soaking concrete samples with a calcium lactate solution before introducing Myxobacteria for MICP. By introducing nutrients into the concrete prior to the addition of bacteria, the substrate can effectively support microbial growth and biomineralization processes effectively (Chen et al. 2022).

The pre-treatment method aims to create favorable conditions for bacteria to thrive and efficiently utilize nutrients for calcium carbonate precipitation, ultimately enhancing the self-healing properties and durability of concrete structures (Mi et al. 2023). Pre-treatment of concrete with nutrients can improve the success and efficiency of MICP applications by ensuring that the environment is conducive to bacterial activity and calcite formation. This method is simpler and more cost-effective than other methods like encapsulation, (Huang and Kaewunruen 2020).

3.4.3 Continuous Feeding

Continuous feeding of bacteria in concrete to precipitate calcite involves providing a sustained supply of nutrients to support bacterial metabolism and biomineralization processes over an extended period (Garg et al. 2023; Khaudiyal et al. 2022). This method ensures that bacteria have access to the nutrients required for calcite precipitation, promoting ongoing self-healing and strengthening of the concrete structure. Continuous feeding can involve the regular addition of nutrients, such as calcium ions and urea, to the concrete environment to sustain bacterial activity and enhance the efficiency of MICP (Chen et al. 2022).

3.5 Crack Remediation Strategies and Material Compatibility

3.5.1 Crack Remediation Strategies

Concrete degradation, such as structural cracks, is mostly caused by overloads, temperature changes, shrinkage, or seismic activity, and can significantly weaken concrete and compromise the safety of structures. These cracks can lead to the ingress of water, chemicals, and aggressive agents, initiating degradation processes and corrosion of reinforcing bars. In return, these scenarios lead to the propagation of cracks, reducing the overall strength and service life of concrete (Safiuddin et al. 2018; Martínez-Ibernón et al. 2020; Zhang et al. 2022; Poor et al. 2016). On the other hand, non-structural cracks, although they do not affect the load-bearing capacity, can still be detrimental to concrete performance. Cracks can decrease the durability and esthetics of the concrete, allowing water and chemicals to penetrate the material, further reducing its lifespan (Jyothi and Charya, 2021; Yao et al. 2014).

Various methods have been proposed to detect and characterize cracks in concrete structures, such as image analysis (Berrocal et al. 2016), fiber optic sensors, and non-destructive testing techniques. These methods help identify the type, size, and extent of cracks, allowing for timely repairs and maintenance to prevent further deterioration (Bao et al. 2010; Grzesiak et al. 2023). Efforts have also been made to develop self-healing concrete materials that can autonomously repair cracks and enhance the durability and longevity of concrete structures. These self-healing mechanisms involve the use of bacteria, composite materials, and innovative technologies to promote the healing and sealing of cracks in concrete (Chen et al. 2016; Jonkers and Schlangen 2008; Abudoleh et al. 2019).

Traditional crack repair methods, such as patching and injection, have high costs, complexity, and temporary effectiveness (Han et al. 2019). However, these methods often fail to provide long-lasting and sustainable solutions for concrete crack repair, indicating the need for alternative technologies (Seifan et al. 2016). In contrast, MICP has emerged as a bio-based and self-healing approach with several potential advantages over traditional methods (Bandyopadhyay et al. 2023; Castro-Alonso et al. 2019).

One of the key advantages of MICP is its ability to autonomously repair cracks without the need for human intervention, thereby reducing the maintenance costs associated with manual repair methods (Han et al. 2019). Furthermore, the biomineralization process of MICP not only seals cracks but also blocks the penetration of aggressive substances, enhancing the durability and longevity of concrete structures (Bandyopadhyay et al. 2023). MICP has also shown promise in reducing the environmental impact of concrete repair processes, making it an attractive option for sustainable construction practices (Mahmood et al. 2022).

MICP has been proven effective for repairing various types and sizes of cracks in concrete. Research has shown that MICP can successfully repair concrete cracks, ranging from small surface cracks to larger structural cracks, by inducing the precipitation of calcium carbonate through bacterial action (Chuo et al. 2020). The self-healing performance of MICP has been observed to be comparable to popular axenic strains used in self-healing concrete studies, indicating its efficacy in addressing cracks up to 400 μm in width (Erşan et al. 2015). Additionally, MICP has been found to reduce the permeability characteristics of concrete, enhance its strength, and improve its durability by sealing cracks and preventing the ingress of aggressive substances (Shi et al. 2022). The biomineralization process of MICP, which influences the quality and quantity of precipitated crystals, plays a crucial role in the effectiveness of surface crack remediation, highlighting the potential of MICP for repairing different types and sizes of cracks in concrete (Bandyopadhyay et al. 2023). Overall, MICP presents a promising solution for mitigating cracks in concrete structures, enhancing their longevity, and improving their performance.

3.5.2 Material Compatibility

Material compatibility in the context of MICP refers to the ability of microbial-generated calcium carbonate to effectively integrate with the existing concrete matrix. Research has demonstrated that the MICP mineralization process can lead to the formation of CaCO₃ crystals that exhibit good compatibility with cement-based materials (Li et al. 2022). This compatibility is crucial because it ensures that the newly formed CaCO₃ effectively seals the cracks, preventing the ingress of water, air, and aggressive substances (Li et al. 2022). More importantly, the biomineralization process significantly influences the quality and quantity of the precipitated crystals, underscoring the importance of material compatibility in ensuring the effectiveness of MICP for concrete healing (Li et al. 2022).

Ensuring compatibility between bacteria, their metabolic processes, and concrete components is crucial for successful crack repair in concrete. The effectiveness of MICP for concrete healing relies on the ability of bacteria to withstand alkaline conditions and reactivate their metabolic activity upon exposure to water and other substances from concrete cracks (Castro-Alonso et al. 2019; Erşan et al. 2015; Reeksting et al. 2020). Strategies such as encapsulating bacteria in protective carriers, optimizing spore formation and germination conditions, and using modified alginate hydrogels have been explored to enhance the compatibility between bacteria and concrete (Jakubovskis et al. 2021; Wang et al. 2015; Jiang et al. 2020). Studies have shown that incorporating high numbers of bacteria and providing the necessary nutrients into the concrete matrix can lead to satisfactory crack healing (Bandyopadhyay et al. 2023).

3.5.3 Impact of MICP Bacteria on Concrete

Negative interactions between MICP bacteria and concrete components can occur due to various factors. For instance, the production of ammonia during the hydrolysis of urea by ureolytic bacteria can lead to environmental nitrogen loading and chemical reactions between the bacteria and concrete components, potentially causing negative effects on the material itself (Wiktor and Jonkers 2016). Additionally, the pH changes induced by urease-positive bacteria compared with non-ureolytic strains can impact the local environment, affecting the biomineralization process (Reeksting et al. 2020). The complexity of the MICP process can result in excessive calcium chelation by monosaccharides or acidification from carbohydrate metabolism, which may interfere with biomineralization and reduce the effectiveness of crack repair (Hoffmann et al. 2021). These negative interactions underscore the importance of understanding the compatibility between bacteria and concrete components.

Many bacteria struggle to survive in the high-pH environment of concrete. To enhance the alkali tolerance of bacteria for applications like MICP in concrete healing, selecting bacteria from extreme environments with high pH levels, such as saline alkali soil or extremely alkaline sites, can provide a natural source of alkali-tolerant strains (Zhang et al. 2023). In addition to bacterial selection, genetic engineering approaches (Qu et al. 2021) and encapsulating bacteria (Wang et al. 2015) can enhance the alkali tolerance of bacteria.

3.5.4 Comparison of the Effectiveness of MICP in Treating Concrete

MICP has been lauded for its potential in repairing concrete cracks through microbial carbonate precipitation; however, contrasting views and challenges have been identified.

One contradiction lies in the effectiveness of MICP in the repair of concrete cracks of different widths. Some studies have shown that MICP can effectively repair cracks of varying sizes, demonstrating its versatility and potential for various applications (Fan et al. 2023). However, other studies have suggested that the MICP process may have limitations in terms of crack width and depth, raising questions about its universal applicability across all types of concrete cracks (Yamasamit et al. 2023).

Another contradiction arises from the durability and longevity of the bivalents used in MICP. Although MICP offers a sustainable and environmentally friendly approach to concrete healing, concerns have been raised regarding the survival and effectiveness of the bivalents under harsh conditions during concrete mixing and throughout the service life of the structure (Rahmaninezhad et al. 2023). This contradiction highlights the need for further research to address the challenges associated with maintaining the viability of bivalents for successful MICP in concrete crack repair.

Furthermore, the environmental impact of MICP is contradictory. Although MICP is considered an eco-friendly method for repairing concrete cracks, some studies have pointed out potential disadvantages, such as ammonia release into the air and nitric acid production, which could have negative environmental implications (Ganendra et al. 2014). This contradiction underscores the importance of considering the overall environmental footprint of MICPs in concrete repair applications.

In conclusion, the contradictions surrounding the use of MICP for concrete crack repair highlight the need for further research to address the challenges related to the limited crack width, bivalent durability, and environmental impacts. By addressing these contradictions, researchers can optimize the effectiveness and sustainability of MICP as a viable solution for enhancing the durability and longevity of concrete structures.

3.5.5 Effects of Environmental Conditions

The efficiency of MICP in concrete can be influenced by temperature, pH, and moisture content. Research has indicated that the process of calcium carbonate precipitation by MICP bacteria is significantly influenced by temperature; higher temperatures generally promote faster and more extensive mineralization (Peng and Liu 2019). However, pH levels have a big influence on how effective MICP is (Bandyopadhyay et al. 2023). Maintaining an optimal pH range (Wei et al. 2015), typically between 7 and 9, is essential for maximizing the efficiency of MICP for concrete healing (Wang et al. 2017). The optimal pH for MICP has been studied extensively, with research indicating that an initial pH of at least 9.0 (Tsesarsky et al. 2018) is optimal for carbonate precipitation in reactions lasting 18 h (Druckenmiller et al. 2006; Gomez et al. 2019). This alkaline pH environment is conducive to the formation of calcite crystals (Druckenmiller et al. 2006). Temperature and pH and moisture content in concrete also affect the availability of water necessary for bacterial metabolic processes and calcium carbonate precipitation, with adequate moisture levels being vital for the success of MICP in crack repair (Erdmann and Strieth 2022; Zhu and Dittrich 2016).

MICP is a promising technology for construction applications, and its feasibility in different climates and construction environments depends on various factors. These studies highlighted the potential of MICP in construction and geotechnical applications, highlighting its versatility across different environments (Chuo et al. 2020). Factors such as temperature, pH, and moisture content are crucial for the efficiency of MICP, as discussed above and in references by Cunningham et al. and Kim et al. (Cunningham et al. 2019; Kim et al. 2018). Strategies like encapsulating bacteria, optimizing sporulation and germination, and controlling pH levels can enhance MICP efficiency (Ma et al. 2020).

Some studies have explored the application of MICP in seawater environments, demonstrating its adaptability to diverse conditions (Wang et al. 2024; Hu et al. 2023). Additionally, some studies have discussed the influence of cell concentration on the engineering applications of MICP, indicating its potential in various construction scenarios (Zhang et al. 2023; Murugan et al. 2021).

Although MICP shows promise for sustainable construction practices, challenges such as high costs and long construction periods (Xuwen et al. 2022; Wahab et al. 2021) must be addressed for widespread implementation. Ongoing research efforts aim to optimize conditions and enhance the technology’s effectiveness, thus supporting the feasibility of MICP in different climates and construction environments.

4 Conclusion

Microbially induced precipitation of calcite is an encouraging and promising approach for treating concrete cracks. This review has explored aspects of MICP, such as MICP healing efficacy, effective bacterial species for treating concrete, effective nutrient supply methods, crack remediation strategies, material compatibility, and the effect of environmental conditions. The following points were drawn from the study to summarize the main findings.

-

1.

MICP has significant potential for self-healing concrete. It effectively sealed fractures, increased strength, and reduced water permeability, suggesting its potential for crack repair and enhanced long-term concrete performance. It has a direct link with calcite precipitation and improved strength, highlighting the importance of optimizing bacterial activity and nutrient delivery for efficient crack healing across different scales.

-

2.

Selecting the appropriate bacteria is key for successful MICP. Species like Sporosarcina pasteurii, Bacillus strains, and Bacillus subtilis are favored due to their efficient calcite production (ureolytic activity). For concrete applications, bacteria with high resilience in alkaline environments are crucial. Spore-forming ureolytic bacteria, particularly Bacillus sphaericus and Sporosarcina pasteurii, which can withstand the high pH of concrete and produce protective spores that increase survival, are particularly well suited.

-

3.

Nutrient availability is critical for MICP success. High levels of urea and calcium chloride promote bacterial activity and calcite precipitation. Encapsulating bacteria before their introduction into concrete protects them from premature germination and improves their survival rates. This isolation allows them to be activated when mixed with the concrete, promoting self-healing and improving crack repair in concrete structures. Studies have shown that specific encapsulation techniques, like melanin-based microcapsules or geopolymer-coated expanded clay, can achieve significant repair widths.

-

4.

Optimizing MICP for concrete requires addressing several factors. Encapsulating bacteria, managing spore formation and germination, and using compatible materials like modified-alginate hydrogels can improve bacteria-concrete interactions. High bacterial counts and sufficient nutrients in concrete are necessary for successful crack healing, but environmental factors also play a role. Temperature significantly affects calcite precipitation, with warmer conditions promoting faster and more extensive mineralization. Additionally, maintaining a near-neutral pH level (between 7 and 9) is crucial for optimal MICP efficiency in concrete.

5 Suggestions for New Studies

Future research should focus on enhancing the performance and practical application of Microbially Induced Calcium Carbonate Precipitation (MICP) for concrete repair. Studies should delve deeper into the long-term durability of MICP-treated concrete under various environmental conditions and explore methods to optimize the MICP process, such as improving bacterial strains and nutrient delivery systems. Large-scale field trials are necessary to assess the technology’s feasibility in real-world settings.

To fully realize the potential of MICP, research should also investigate the fundamental mechanisms of calcite precipitation and explore novel applications beyond crack repair, such as incorporating MICP into concrete production for preventive self-healing. Exploring novel bacterial strains with enhanced calcite precipitation rates and specific desirable traits, as well as utilizing genetic engineering to optimize bacterial properties for improved performance, are key areas of interest. By screening diverse microbial populations and isolating bacteria with superior MICP capabilities, researchers can identify strains with enhanced efficiency for concrete applications. Genetic engineering techniques can modify bacterial traits such as urease activity and survival in harsh concrete environments, leading to the development of customized strains with advanced capabilities for promoting calcite precipitation in concrete healing.

By addressing these research areas, the construction industry can benefit from more effective and sustainable concrete repair solutions, ultimately revolutionizing concrete repair technologies and enhancing the sustainability of construction practices.

Author contributions

6 MDG: Conceptualization, Methodology, Reviews and Literature review; KE: Reviews, Literature review, Editing and Supervision.

Data availability

No datasets were generated or analysed during the current study.

References

Abudoleh SM, Mahayreh AA, Frejat AA, Hulaisy FA, Hamdan SO (2019) Bioconcrete development using calcite—precipitating bacteria isolated from different sources in Jordan. MATEC Web Conf 278:01011. https://doi.org/10.1051/matecconf/201927801011

Achal V, Mukherjee A, Basu PC, Reddy MS (2009) Strain improvement of Sporosarcina pasteurii for enhanced urease and calcite production. J Ind Microbiol Biotech 36(7):981–988. https://doi.org/10.1007/s10295-009-0578-z

Ahiwale D, Khartode R (2021) Determination of bacterial concrete strength using Bacillus subtilis and lightweight expandable clay aggregate. Am J Agric Science, Eng Technol. 5(2):351–362

Alquier M, Kassim C, Bertron A, Sablayrolles C, Rafrafi Y, Albrecht A, Erable B (2014) Halomonas desiderata as a bacterial model to predict the possible biological nitrate reduction in concrete cells of nuclear waste disposals. J Environ Manage 132:32–41. https://doi.org/10.1016/j.jenvman.2013.10.013

Amiri A, Bundur ZB (2018) Use of corn-steep liquor as an alternative carbon source for biomineralization in cement-based materials and its impact on performance. Constr Build Mater 165:655–662. https://doi.org/10.1016/j.conbuildmat.2018.01.070

Asrat FS, Ghebrab TT (2020) Effect of mill-rejected granular cement grains on healing concrete cracks. Materials 13(4):840. https://doi.org/10.3390/ma13040840

Bakkour A, Ouldboukhitine SE, Biwole P, Godi G, Amziane S (2023) Experimental and numerical investigation of hygrothermal transfer through bio-based materials: an application to wood-cement walls. Buildings 13(12):2986. https://doi.org/10.3390/buildings13122986

Balam N, Tayebani B, Mostofinejad D (2021) Seawater used as a natural medium for curing bacterially-treated concrete with either lightweight or normal weight aggregates. J Mater Civ Eng 33:10. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003857

Bandlamudi RK, Kar A, Ray DJ (2023) A review of durability improvement in concrete due to bacterial inclusions. Front Built Environ 19(9):1095949

Bandyopadhyay A, Saha A, Ghosh D, Dam B, Samanta AK, Dutta S (2023) Microbial repairing of concrete & its role in CO2 sequestration: a critical review. Beni-Suef Univer J Basic App Sci 12(1):7. https://doi.org/10.1186/s43088-023-00344-1

Bao T, Wang J, Yao Y (2010) A fiber optic sensor for detecting and monitoring cracks in concrete structures. Sci China Technol Sci 53(11):3045–3050. https://doi.org/10.1007/s11431-010-4111-4

Berrocal CG, Löfgren I, Lundgren K, Görander N, Halldén C (2016) Characterisation of bending cracks in R/FRC using image analysis. Cem Concr Res 90:104–116. https://doi.org/10.1016/j.cemconres.2016.09.016

Castro-Alonso MJ, Montañez-Hernandez LE, Sanchez-Muñoz MA, Macias Franco MR, Narayanasamy R, Balagurusamy N (2019) Microbially induced calcium carbonate precipitation (MICP) and Its potential in bioconcrete: microbiological and molecular concepts. Front Mater 10(6):126

Chaparro S, Rojas HA, Caicedo G, Romanelli G, Pineda A, Luque R, Martínez JJ (2021) Whey as an alternative nutrient medium for growth of sporosarcina pasteurii and its effect on CaCO3 polymorphism and fly ash bioconsolidation. Materials 14(10):2470. https://doi.org/10.3390/ma14102470

Chen H, Qian C, Huang H (2016) Self-healing cementitious materials based on bacteria and nutrients immobilized respectively. Constr Build Mater 126:297–303. https://doi.org/10.1016/j.conbuildmat.2016.09.023

Chen L, Song Y, Fang H, Feng Q, Lai C, Song X (2022) Systematic optimization of a novel, cost-effective fermentation medium of Sporosarcina pasteurii for microbially induced calcite precipitation (MICP). Constr Build Mater 348:128632. https://doi.org/10.1016/j.conbuildmat.2022.128632

Chen Z, Wang X, Ding L, Jiang K, Liu X, Liu J, Wu Z (2023) Spalling resistance and mechanical properties of ultra-high performance concrete reinforced with multi-scale basalt fibers and hybrid fibers under elevated temperature. J Build Eng 77:107435. https://doi.org/10.1016/j.jobe.2023.107435

Chen Z, Wang X, Jiang K, Zhao X, Liu X, Wu Z (2024) The splitting tensile strength and impact resistance of concrete reinforced with hybrid BFRP minibars and micro fibers. J Build Eng 88:109188. https://doi.org/10.1016/j.jobe.2024.109188

Chuo SC, Mohamed SF, Mohd Setapar SH, Ahmad A, Jawaid M, Wani WA, Yaqoob AA, Mohamad Ibrahim MN (2020) Insights into the current trends in the utilization of bacteria for microbially induced calcium carbonate precipitation. Materials 13(21):4993. https://doi.org/10.3390/ma13214993

Cunningham AB, Class H, Ebigbo A, Gerlach R, Phillips AJ, Hommel J (2019) Field-scale modeling of microbially induced calcite precipitation. Comput Geosci 23(2):399–414. https://doi.org/10.1007/s10596-018-9797-6

Danner T, Jakobsen UH, Geiker MR (2019) Mineralogical sequence of self-healing products in cracked marine concrete. Minerals 9(5):284. https://doi.org/10.3390/min9050284

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010) Bio-mediated soil improvement. Ecol Eng 36(2):197–210. https://doi.org/10.1016/j.ecoleng.2008.12.029

Dhami NK, Alsubhi WR, Watkin E, Mukherjee A (2017) Bacterial community dynamics and biocement formation during stimulation and augmentation: implications for soil consolidation. Front Microbiol 11(8):1267

Doostkami H, JdeJE C, Formagini S, Roig-Flores M, Serna P (2022) Self-healing of concrete containing commercial bacteria by means of water and chlorides permeability. MATEC Web Conf 361:05010. https://doi.org/10.1051/matecconf/202236105010

Druckenmiller ML, Maroto-Valer MM, Hill M (2006) Investigation of carbon sequestration via induced calcite formation in Natural gas well brine. Energy Fuels 20(1):172–179. https://doi.org/10.1021/ef050115u

Erdmann N, Strieth D (2022) Influencing factors on ureolytic microbiologically induced calcium carbonate precipitation for biocementation. World J Microbiol Biotechnol 39(2):61. https://doi.org/10.1007/s11274-022-03499-8

Erşan YÇ, Gruyaert E, Louis G, Lors C, De Belie N, Boon N (2015) Self-protected nitrate reducing culture for intrinsic repair of concrete cracks. Front Microbiol 4(6):1228

Eryürük K (2015) Microbial CaCO3 precipitation for decreasing the hydraulic conductivity of porous media. Dissertation, Nagoya University. https://nagoya.repo.nii.ac.jp/records/19988

Eryürük K (2022) Effect of cell density on decrease in hydraulic conductivity by microbial calcite precipitation. AMB Expr 12:104. https://doi.org/10.1186/s13568-022-01448-0

Eryürük K, Yang S, Suzuki D, Sakaguchi I, Akatsuka T, Tsuchiya T, Katayama A (2015a) Reducing hydraulic conductivity of porous media using CaCO3 precipitation induced by Sporosarcina pasteurii. J Biosci Bioeng 119:331–336. https://doi.org/10.1016/j.jbiosc.2014.08.009

Eryürük K, Yang S, Suzuki D, Sakaguchi I, Katayama A (2015b) Effects of bentonite and yeast extract as nutrient on decrease in hydraulic conductivity of porous media using CaCO3 precipitation induced by Sporosarcina pasteurii. J Biosci Bioeng 120:411–418. https://doi.org/10.1016/j.jbiosc.2015.01.020

Fan L, Zheng J, Peng S, Xun Z, Chen G (2023) Experimental investigation on the influence of crack width of asphalt concrete on the repair effect of microbially induced calcite precipitation. Materials 16(9):3576. https://doi.org/10.3390/ma16093576

Ganendra G, De Muynck W, Ho A, Arvaniti EC, Hosseinkhani B, Ramos JA, Rahier H, Boon N (2014) Formate oxidation-driven calcium carbonate precipitation by METHYLOCYSTIS parvus OBBP. Appl Environ Microbiol 80(15):4659–4667. https://doi.org/10.1128/AEM.01349-14

Garg R, Garg R, Eddy NO (2023) Microbial induced calcite precipitation for self-healing of concrete: A review. J Sustain Cem-Based Mater 12(3):317–330. https://doi.org/10.1080/21650373.2022.2054477

Gat D, Ronen Z, Tsesarsky M (2016) Soil bacteria population dynamics following stimulation for ureolytic microbial-induced CaCO3 precipitation. Environ Sci Technol 50(2):616–624. https://doi.org/10.1021/acs.est.5b04033

Ghasemi P, Montoya BM (2022) Effect of treatment solution chemistry and soil engineering properties due to microbially induced carbonate precipitation treatments on vegetation health and growth. Acs Est Eng 2(12):2196–2205. https://doi.org/10.1021/acsestengg.2c00196

Gomez MG, Martinez BC, DeJong JT, Hunt CE, deVlaming LA, Major DW, Dworatzek SM (2015) Field-scale bio-cementation tests to improve sands. Proce Institut Civ Eng Ground Improv 168(3):206–216. https://doi.org/10.1680/grim.13.00052

Gomez MG, Graddy CMR, DeJong JT, Nelson DC (2019) Biogeochemical changes during bio-cementation mediated by stimulated and augmented ureolytic microorganisms. Sci Rep 9(1):11517. https://doi.org/10.1038/s41598-019-47973-0

Gowthaman S, Chen M, Nakashima K, Kawasaki S (2021) Effect of scallop powder addition on MICP treatment of amorphous peat. Front Environ Sci 12(9):690376

Grzesiak S, Barisin T, Schladitz K, Pahn M (2023) Analysis of the bond behavior of a GFRP rebar in concrete by in-situ 3D imaging test. Mater Struct 56(9):163. https://doi.org/10.1617/s11527-023-02247-0

Han S, Choi EK, Park W, Yi C, Chung N (2019) Effectiveness of expanded clay as a bacteria carrier for self-healing concrete. Appl Biol Chem 62(1):19. https://doi.org/10.1186/s13765-019-0426-4

Harnpicharnchai P, Mayteeworakoon S, Kitikhun S, Chunhametha S, Likhitrattanapisal S, Eurwilaichitr L, Ingsriswang S (2022) High level of calcium carbonate precipitation achieved by mixed culture containing ureolytic and nonureolytic bacterial strains. Lett Appl Microbiol 75(4):888–898. https://doi.org/10.1111/lam.13748

Hoffmann TD, Paine K, Gebhard S (2021) Genetic optimisation of bacteria-induced calcite precipitation in Bacillus subtilis. Microb Cell Fact 20(1):214. https://doi.org/10.1186/s12934-021-01704-1

Hosseini Balam N, Mostofinejad D, Eftekhar M (2017a) Effects of bacterial remediation on compressive strength, water absorption, and chloride permeability of lightweight aggregate concrete. Constr Build Mater 145:107–116. https://doi.org/10.1016/j.conbuildmat.2017.04.003

Hosseini Balam N, Mostofinejad D, Eftekhar M (2017b) Use of carbonate precipitating bacteria to reduce water absorption of aggregates. Constr Build Mater 141:565–577. https://doi.org/10.1016/j.conbuildmat.2017.03.042

Hu J, Yang Y, Zhou Y, Xiang H, Wei K (2023) Experimental study of MICP-solidified calcareous sand based on ambient temperature variation in the South China sea. Sustainability 15(10):8245. https://doi.org/10.3390/su15108245

Huang X, Kaewunruen S (2020) Self-healing concrete. In: Samui P, Kim D, Iyer NR, Chaudhary S (eds) New materials in civil engineering. Butterworth-Heinemann, Elsevier, Amsterdam, pp 825–856

Idris I, Rustandi B, Rahmat TRS et al (2022) Bioprospecting ureolytic rock bacteria for calcium carbonate precipitation inducer. Evergreen 9(4):962–972. https://doi.org/10.5109/6622882

Iqbal DM, Wong LS, Kong SY (2021) Bio-cementation in construction materials: a review. Materials 14(9):2175. https://doi.org/10.3390/ma14092175

Islam MT, Chittoori BCS, Burbank M (2020) Evaluating the applicability of biostimulated calcium carbonate precipitation to stabilize clayey soils. J Mater Civ Eng 32(3):04019369. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003036

Jakubovskis R, Jankutė A, Guobužaitė S, Boris R, Urbonavičius J (2021) Prolonging bacterial viability in biological concrete: coated expanded clay particles. Materials 14(11):2719. https://doi.org/10.3390/ma14112719

Jamil M, Kaish ABMA, Sahari EI, Fong NL, Nahar L (2019) Self-consolidating mortar incorporating higher volume blended pozzolans for concrete repair. MATEC Web Conf 276:01016. https://doi.org/10.1051/matecconf/201927601016

Jiang L, Jia G, Wang Y, Li Z (2020) Optimization of sporulation and germination conditions of functional bacteria for concrete crack-healing and evaluation of their repair capacity. ACS Appl Mater Interfaces 12(9):10938–10948. https://doi.org/10.1021/acsami.9b21465

Jonkers HM, Schlangen E (2008) Development of a bacteria-based self healing concrete. Tail Made Concrete Struct 7(1):425–430

Jyothi C, Singara Charya MA (2021) Isolation and Identification of Bacillus Strains for Bioconcrete. Int Res J Adv Sci Hub 3:1–6

Karimi N, Mostofinejad D (2020) Bacillus subtilis bacteria used in fiber reinforced concrete and their effects on concrete penetrability. Constr Build Mater 230:117051. https://doi.org/10.1016/j.conbuildmat.2019.117051

Khaudiyal S, Rawat A, Das SK, Garg N (2022) Bacterial concrete: a review on self-healing properties in the light of sustainability. Mater Today Proce 60:136–143. https://doi.org/10.1016/j.matpr.2021.12.277

Kiledal EA, Keffer JL, Maresca JA (2021) Bacterial communities in concrete reflect its composite nature and change with weathering. Msystems 6(3):10–128

Kim G, Kim J, Youn H (2018) Effect of temperature, pH, and reaction duration on microbially induced calcite precipitation. Appl Sci 8(8):1277. https://doi.org/10.3390/app8081277

Kıvanç M, Barutca B, Koparal AT, Göncü Y, Bostancı SH, Ay N (2018) Effects of hexagonal boron nitride nanoparticles on antimicrobial and antibiofilm activities, cell viability. Mater Sci Eng C 91:115–124. https://doi.org/10.1016/j.msec.2018.05.028

Konieczna I, Zarnowiec P, Kwinkowski M, Kolesinska B, Fraczyk J, Kaminski Z, Kaca W (2012) Bacterial urease and its role in long-lasting human diseases. Curr Protein Pept Sci 13(8):789–806

Krishnapriya S, Venkatesh Babu DL, Arulraj GP (2015) Isolation and identification of bacteria to improve the strength of concrete. Microbiol Res 174:48–55. https://doi.org/10.1016/j.micres.2015.03.009

Kulkarni PB, Nemade PD, Wagh MP (2020) Healing of generated cracks in cement mortar using MICP. Civ Eng J 6(4):679–692

Lee YS, Park W (2018) Current challenges and future directions for bacterial self-healing concrete. Appl Microbiol Biotechnol 102(7):3059–3070. https://doi.org/10.1007/s00253-018-8830-y

Li K, Guan W, He P, Li KJ (2022) Comparison of bacterial communities on the surface of concrete breakwater structures and ambient bacterioplankton. Lett Appl Microbiol 75(5):1193–1202. https://doi.org/10.1111/lam.13787

Li Y, Sun Z, Li Y, Dong J, He W (2024) Time-dependent combined index seismic resilience assessment of shear-critical RC bridge piers with height-varying corrosion. Eng Struct 308:117957. https://doi.org/10.1016/j.engstruct.2024.117957

Lin H, Suleiman MT, Jabbour HM, Brown DG (2018) Bio-grouting to enhance axial pull-out response of pervious concrete ground improvement piles. Can Geotech J 55(1):119–130. https://doi.org/10.1139/cgj-2016-0438

Liu C, Zhang W, Liu H, Lin X, Zhang R (2022a) A compressive strength prediction model based on the hydration reaction of cement paste by rice husk ash. Constr Build Mater 340:127841. https://doi.org/10.1016/j.conbuildmat.2022.127841

Liu C, Zhang W, Liu H, Zhu C, Wu Y, He C, Wang Z (2022b) Recycled aggregate concrete with the incorporation of rice husk ash: mechanical properties and microstructure. Constr Build Mater 351:128934. https://doi.org/10.1016/j.conbuildmat.2022.128934

Lu C, Li Z, Wang J, Zheng Y, Cheng L (2023) An approach of repairing concrete vertical cracks using microbially induced carbonate precipitation driven by ion diffusion. J Build Eng 73:106798. https://doi.org/10.1016/j.jobe.2023.106798

Lv W, Sun Z, Li Y, Su L, He W, Zhang T (2023) Hybrid machine learning-based model for predicting chloride ion concentration in coral aggregate concrete and its ethically aligned graphical user interface design. Mater Today Commun 37:107053. https://doi.org/10.1016/j.mtcomm.2023.107053

Ma L, Pang AP, Luo Y, Lu X, Lin F (2020) Beneficial factors for biomineralization by ureolytic bacterium Sporosarcina pasteurii. Microb Cell Fact 19(1):12. https://doi.org/10.1186/s12934-020-1281-z

Mahmood F, Kashif Ur Rehman S, Jameel M, Riaz N, Javed MF, Salmi A, Awad YA (2022) Self-healing bio-concrete using Bacillus subtilis encapsulated in iron oxide nanoparticles. Materials 15(21):7731. https://doi.org/10.3390/ma15217731

Martínez-Ibernón A, Roig-Flores M, Lliso-Ferrando J, Mezquida-Alcaraz EJ, Valcuende M, Serna P (2020) Influence of cracking on oxygen transport in UHPFRC Using stainless steel sensors. Appl Sci 10(1):239. https://doi.org/10.3390/app10010239

Metwally GA, Mahdy M, El-Raheem AH (2020) Performance of bio concrete by using Bacillus pasteurii bacteria. Civ Eng J 6(8):1443–1456

Mi T, Peng L, Yu K, Zhao Y (2023) Optimizing microbial- and enzyme-induced carbonate precipitation treatment regimes to improve the performance of recycled aggregate concrete. Case Stud Constr Mater 19:e02261. https://doi.org/10.1016/j.cscm.2023.e02261

Mostofinejad D, Hosseini SM, Nosouhian F, Ozbakkaloglu T, Nader Tehrani B (2020) Durability of concrete containing recycled concrete coarse and fine aggregates and milled waste glass in magnesium sulfate environment. J Build Eng 29:101182. https://doi.org/10.1016/j.jobe.2020.101182

Mostofinejad D, Karimi N, Tayebani B (2022) Effect of bacterial spore in surface-treated fiber-reinforced concrete. ACI Mater J 119:263–272. https://doi.org/10.14359/51737198

Mu B, Gui Z, Lu F, Petropoulos E, Yu Y (2021) Microbial-induced carbonate precipitation improves physical and structural properties of nanjing ancient city walls. Materials 14(19):5665. https://doi.org/10.3390/ma14195665

Murugan R, Suraishkumar GK, Mukherjee A, Dhami NK (2021) Insights into the influence of cell concentration in design and development of microbially induced calcium carbonate precipitation (MICP) process. PLoS ONE 16(7):e0254536. https://doi.org/10.1371/journal.pone.0254536

Nain N, Surabhi R, Yathish NV, Krishnamurthy V, Deepa T, Tharannum S (2019) Enhancement in strength parameters of concrete by application of Bacillus bacteria. Constr Build Mater 202:904–908. https://doi.org/10.1016/j.conbuildmat.2019.01.059

Nasser AA, Esmail RF, Abbas RY, Sorour NM (2022) Effect of Bacillus megaterium bacteria and different calcium source on strength and permeation properties of concrete. ERJ Eng Res J 45(3):401–412

Nery ME, Pulido DE, Oliveros PA, Medina JA, Bello QY, Fuentes MS (2019) Mechanisms of encapsulation of bacteria in self-healing concrete. Dyna 86(210):17–22

Nosouhian F, Mostofinejad D (2016) Reducing permeability of concrete by bacterial mediation on surface using treatment gel. ACI Mater J 113(3):287

Nosouhian F, Mostofinejad D, Hasheminejad H (2016) Concrete durability improvement in a sulfate environment using bacteria. J Mater Civ Eng 28(1):04015064

Okabe S, Odagiri M, Ito T, Satoh H (2007) Succession of sulfur-oxidizing bacteria in the microbial community on corroding concrete in sewer systems. Appl Environ Microbiol 73(3):971–980. https://doi.org/10.1128/AEM.02054-06

Omoregie AI, Ong DEL, Nissom PM (2019) Assessing ureolytic bacteria with calcifying abilities isolated from limestone caves for biocalcification. Lett Appl Microbiol 68(2):173–181. https://doi.org/10.1111/lam.13103

Otieno MB, Mg A, Beushausen HD (2010) Corrosion in cracked and uncracked concrete—influence of crack width, concrete quality and crack reopening. Mag Concr Res 62(6):393–404. https://doi.org/10.1680/macr.2010.62.6.393

Parastegari N, Mostofinejad D, Poursina D (2019) Use of bacteria to improve electrical resistivity and chloride penetration of air-entrained concrete. Constr Build Mater 210:588–595. https://doi.org/10.1016/j.conbuildmat.2019.03.150

Parastegari N, Mostofinejad D, Poursina D (2022) An Investigation on bacterial air-entrained concrete permeability using statistical modeling. Adv Civ Eng Mater 11(1):1–16. https://doi.org/10.1520/ACEM20210010

Peng J, Liu Z (2019) Influence of temperature on microbially induced calcium carbonate precipitation for soil treatment. PLoS ONE 14(6):e0218396. https://doi.org/10.1371/journal.pone.0218396

Phillips AJ, Cunningham AB, Gerlach R, Hiebert R, Hwang C, Lomans BP, Westrich J, Mantilla C, Kirksey J, Esposito R, Spangler L (2016) Fracture sealing with microbially-induced calcium carbonate precipitation: a field study. Environ Sci Techol 50(7):4111–4117. https://doi.org/10.1021/acs.est.5b05559

Poor AMR, Zanjani MMK, Bonyadian S, Saboori NA (2016) Using NDT methods for evaluating the cementitious material after repair according to ACI 224 procedure. Fourth International Conference on Sustainable Construction Materials and Technologies pp 1753–1762. https://doi.org/10.18552/2016/SCMT4M127

Pungrasmi W, Intarasoontron J, Jongvivatsakul P, Likitlersuang S (2019) Evaluation of microencapsulation techniques for MICP bacterial spores applied in self-healing concrete. Sci Rep 9(1):12484

Qu Z, Guo S, Zheng Y, Giakoumatos EC, Yu Q, Voets IK (2021) A simple method to create hydrophobic mortar using bacteria grown in liquid cultures. Constr Build Mater 297:123744. https://doi.org/10.1016/j.conbuildmat.2021.123744

Rahman MM, Hora RN, Ahenkorah I, Beecham S, Karim MR, Iqbal A (2020) State-of-the-art review of microbial-induced calcite precipitation and its sustainability in engineering applications. Sustainability 12(15):6281. https://doi.org/10.3390/su12156281

Rahmaninezhad SA, Khaneghahi MH et al (2023) Understanding the importance of endosporulation methods for generating endospores that can resist harsh conditions and produce calcite in bio self-healing of concrete. MATEC Web of Conf 378:02004. https://doi.org/10.1051/matecconf/202337802004

Raveh-Amit H, Tsesarsky M (2020) Biostimulation in desert soils for microbial-induced calcite precipitation. Appl Sci 10(8):2905. https://doi.org/10.3390/app10082905

Reeksting BJ, Hoffmann TD, Tan L, Paine K, Gebhard S (2020) In-depth profiling of calcite precipitation by environmental bacteria reveals fundamental mechanistic differences with relevance to application. Appl Environ Microbiol 86(7):e02739-e2819

Rollakanti CR, Srinivasu K (2022) Self-healing concrete based on bacteria for sustainable infrastructure: a state-of-the-art review. In: PG Kumar, KVL Subramaniam, SM. Santhakumar, N Satyam D (eds), Recent Advances in Civil Engineering, Springer Nature, pp 171–181. https://doi.org/10.1007/978-981-19-0189-8_15

Safiuddin M, Kaish ABMA, Woon C-O, Raman SN (2018) Early-age cracking in concrete: causes, consequences, remedial measures, and recommendations. Appl Sci 8(10):1730. https://doi.org/10.3390/app8101730

Salmasi F, Mostafinejad D (2020) Investigating the effects of bacterial activity on compressive strength and durability of natural lightweight aggregate concrete reinforced with steel fibers. Constr Build Mater 251:119032. https://doi.org/10.1016/j.conbuildmat.2020.119032

Seifan M, Samani AK, Berenjian A (2016) Bioconcrete: Next generation of self-healing concrete. Appl Microbiol Biotechnol 100(6):2591–2602. https://doi.org/10.1007/s00253-016-7316-z

Shahid S, Aslam MA, Ali S, Zameer M, Faisal M (2020) Self-healing of cracks in concrete using Bacillus strains encapsulated in sodium alginate beads. Chem Select 5(1):312–323. https://doi.org/10.1002/slct.201902206

Sharma TK, Alazhari M, Heath A, Paine K, Cooper RM (2017) Alkaliphilic Bacillus species show potential application in concrete crack repair by virtue of rapid spore production and germination then extracellular calcite formation. J Appl Microbiol 122(5):1233–1244. https://doi.org/10.1111/jam.13421

Sharma M, Satyam N, Tiwari N, Sahu S, Reddy KR (2021) Simplified biogeochemical numerical model to predict pore fluid chemistry and calcite precipitation during biocementation of soil. Arab J Geosci 14(9):807. https://doi.org/10.1007/s12517-021-07151-x

Shi Y, Chen T, Shaw P, Wang PY (2022) Manipulating bacterial biofilms using materiobiology and synthetic biology approaches. Front Microbiol 7(13):844997

Sun Z, Li Y, Li Y, Su L, He W (2023) Prediction of chloride ion concentration distribution in basalt-polypropylene fiber reinforced concrete based on optimized machine learning algorithm. Mater Today Commun 36:106565. https://doi.org/10.1016/j.mtcomm.2023.106565

Sun Z, Li Y, Li Y, Su L, He W (2024a) Investigation on compressive strength of coral aggregate concrete: hybrid machine learning models and experimental validation. J Build Eng 82:108220. https://doi.org/10.1016/j.jobe.2023.108220

Sun Z, Li Y, Yang Y, Su L, Xie S (2024b) Splitting tensile strength of basalt fiber reinforced coral aggregate concrete: optimized XGBoost models and experimental validation. Constr Build Mater 416:135133. https://doi.org/10.1016/j.conbuildmat.2024.135133

Sun Z, Li Y, Su L, Niu D, Luo D, He W, Xie S (2024c) Investigation of electrical resistivity for fiber-reinforced coral aggregate concrete. Constr Build Mater 414:135011. https://doi.org/10.1016/j.conbuildmat.2024.135011

Svane S, Sigurdarson JJ, Finkenwirth F, Eitinger T, Karring H (2020) Inhibition of urease activity by different compounds provides insight into the modulation and association of bacterial nickel import and ureolysis. Sci Rep 10(1):8503. https://doi.org/10.1038/s41598-020-65107-9

Tayebani B, Mostofinejad D (2019a) Penetrability, corrosion potential, and electrical resistivity of bacterial concrete. J Mater Civ Eng 31(3):04019002

Tayebani B, Mostofinejad D (2019b) Self-healing bacterial mortar with improved chloride permeability and electrical resistance. Constr Build Mater 208:75–86. https://doi.org/10.1016/j.conbuildmat.2019.02.172

Tsesarsky M, Gat D, Ronen Z (2018) Biological aspects of microbial-induced calcite precipitation. Environ Geotech 5(2):69–78. https://doi.org/10.1680/jenge.15.00070

Van der Bergh JM, Miljević B, Šovljanski O, Vučetić S, Markov S, Ranogajec J, Bras A (2020) Preliminary approach to bio-based surface healing of structural repair cement mortars. Constr Build Mater 248:118557. https://doi.org/10.1016/j.conbuildmat.2020.118557

Wahab NA, Roshan MJ, Rashid ASA, Hezmi MA, Jusoh SN, Nik Norsyahariati ND, Tamassoki S (2021) Strength and durability of cement-treated lateritic soil. Sustainability 13(11):6430. https://doi.org/10.3390/su13116430

Wang JY, Soens H, Verstraete W, De Belie N (2014) Self-healing concrete by use of microencapsulated bacterial spores. Cem Concr Res 56:139–152. https://doi.org/10.1016/j.cemconres.2013.11.009

Wang HL, Dai JG, Sun XY, Zhang XL (2016) Characteristics of concrete cracks and their influence on chloride penetration. Constr Build Mater 107:216–225. https://doi.org/10.1016/j.conbuildmat.2016.01.002

Wang J, Jonkers HM, Boon N, De Belie N (2017) Bacillus sphaericus LMG 22257 is physiologically suitable for self-healing concrete. Appl Microbiol Biotechnol 101(12):5101–5114. https://doi.org/10.1007/s00253-017-8260-2

Wang Z, Zhang N, Ding J, Lu C, Jin Y (2018) Experimental study on wind erosion resistance and strength of sands treated with microbial-induced calcium carbonate precipitation. Adv Mater Sci Eng 2018(1):3463298

Wang Z, Chen W, Tong Z, Wu W, Chen X, Deng X, Xie Y (2024) Research on the effect of natural seawater in domesticating Bacillus pasteurii and reinforcing calcareous sand. J Mar Sci Eng 12(4):542. https://doi.org/10.3390/jmse12040542

Wang J, Mignon A, Snoeck D, Wiktor V, Van Vliergerghe S, Boon N, De Belie N (2015) Application of modified-alginate encapsulated carbonate producing bacteria in concrete: a promising strategy for crack self-healing. Front Microbiol 6. https://doi.org/10.3389/fmicb.2015.01088

Wei S, Cui H, Jiang Z, Liu H, He H, Fang N (2015) Biomineralization processes of calcite induced by bacteria isolated from marine sediments. Braz J Microbiol 46:455–464. https://doi.org/10.1590/S1517-838246220140533

Wiktor V, Jonkers HM (2016) Bacteria-based concrete: from concept to market. Smart Mater Struct 25(8):084006. https://doi.org/10.1088/0964-1726/25/8/084006

Xuwen T, Hongbin X, Zhenyu L, Hunayu S, Qianwen O, Shenping L, Xinpei Y (2022) A Fractional order creep damage model for microbially improved expansive soils. Front Earth Sci 21(10):942844