Abstract

Nitinol is a nickel–titanium alloy widely used in medical devices for its unique pseudoelastic and shape-memory properties. However, nitinol can release potentially hazardous amounts of nickel, depending on surface manufacturing yielding different oxide thicknesses and compositions. Furthermore, nitinol medical devices can be implanted throughout the body and exposed to extremes in pH and reactive oxygen species (ROS), but few tools exist for evaluating nickel release under such physiological conditions. Even in cardiovascular applications, where nitinol medical devices are relatively common and the blood environment is well understood, there is a lack of information on how local inflammatory conditions after implantation might affect nickel ion release. For this study, nickel release from nitinol wires of different finishes was measured in pH conditions and at ROS concentrations selected to encompass and exceed literature reports of extracellular pH and ROS. Results showed increased nickel release at levels of pH and ROS reported to be physiological, with decreasing pH and increasing concentrations of hydrogen peroxide and NaOCl/HOCl having the greatest effects. The results support the importance of considering the implantation site when designing studies to predict nickel release from nitinol and underscore the value of understanding the chemical milieu at the device–tissue interface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitinol, a nearly equiatomic nickel–titanium (NiTi) alloy, is used in medical devices because of its unique pseudoelastic and shape-memory properties. The diversity of NiTi medical devices deployed throughout the human body exposes them to different physiological and pathological conditions [1], and the surface of NiTi medical devices is processed with the aim of minimizing corrosion susceptibility and Ni release [2, 3]. Limiting Ni release is important because Ni, besides potentially causing allergic reactions in sensitized individuals [4, 5], can be toxic [6], genotoxic, and carcinogenic depending on the dose and route of exposure [7]. Numerous surface treatment methods can be applied to reduce patient exposure to Ni, including mechanical polishing, electropolishing, and chemical etching [8, 9]. In vivo, NiTi stents with non-optimized finishes have been found to result in greater exposure of patients to Ni and have been associated with increased medical events/complications (including stenosis and local inflammation) compared to optimized finishes [10].

For this study, we hypothesized that physiological conditions encountered in vivo, such as acidic/basic pH [11,12,13,14,15], and reactive oxygen species (ROS) from hydrogen peroxide (H2O2) and sodium hypochlorite/hypochlorous acid (NaOCl/HOCl) produced by inflammatory cells [16,17,18] could increase the rate of Ni release from NiTi. Understanding the influence of these physiological conditions may be particularly important for cardiovascular indications where nitinol medical devices may be exposed to excursions in pH or ROS after implantation. Most body fluids and tissues are near-neutral pH, like the brain (pH 7.2), cerebrospinal fluid (pH 7.3), blood (pH 7.4 ± 0.05), and interstitial fluids in tissues (pH 7.3–7.4), although the pH may decrease as low as 5.5 in cases of inflammation [19]. Other examples of pH range include the uterus (pH 3.0–9.0 [15]) and the lumen of the digestive system where pH is lowest in the fundus of the stomach (pH ~ 1.0 to 2.0 between meals) [20, 21] and highest in the small bowel (pH ~ 5.5 to ~ 9.0) [22,23,24].

H2O2 and NaOCl/HOCl are examples of ROS present in physiological environments. H2O2 is a relatively mild oxidizing agent unless it undergoes the Fenton or Haber–Weiss reaction catalyzed by a transition metal ion like Fe2+, Cu2+, Zn2+, or Ni2+ converting it to the indiscriminately reactive and highly destructive hydroxyl radical (HO·) or superoxide radical (O2−). H2O2 concentrations above 100 µM may be found in the oral cavity (some beverages have high amounts), esophagus, stomach, kidney, urinary tract, bladder, and ocular tissues [16]. Although normal healthy blood plasma levels of H2O2 range from 1 to 5 µM, disease states can increase the range to 30–50 µM [17]. Along with H2O2, an inflammatory reaction during the destruction of foreign body particles by neutrophils and monocytes/macrophages can produce concentrations of NaOCl/HOCl as high as 25–50 mM at the inflammatory foci [18].

The extent to which Ni release from nitinol may be influenced by different physiological environments is not well characterized to date. Therefore, the present study evaluated the relationship between media conditions and Ni release from NiTi. To encompass a range of NiTi processing methods, NiTi wires with different finishes (characterized by surface oxide layer appearance and thickness) served as model test articles. These comprised NiTi wires with chemical etch (CE), amber oxide (AO), and black oxide (BO) finishes having surface oxide thicknesses (SiO2 equivalent) of about 14, 113, and 1950 nm, respectively, and measured breakdown potentials (versus saturated calomel electrode ± standard deviation) of 649.3 ± 222.3, 520.4 ± 102.4, and 442.0 ± 62.37 mV, respectively. Ni release from these NiTi wires was evaluated under conditions representing physiological factors: a range of pH was examined, as were ROS-related conditions (at physiological and supraphysiological concentrations), mimicked by the presence and concentration of H2O2 and NaOCl/HOCl.

Material and Methods

Materials

NiTi wires (straight annealed, 0.5 mm diameter) manufactured in conformance with ASTM F2063 [25] having chemical etched, amber oxide, and black oxide finishes were purchased from a commercial source (Memry Corporation). Because the details of wire processing and surface treatments are proprietary, additional testing to characterize the finishes of samples was performed (see below).

Auger Electron Spectroscopy

To characterize the oxide layer for each finish, samples were sent for Auger electron spectroscopy by Evans Analytical Group Laboratories (Sunnyvale, CA) where a single spot on each wire was analyzed. Briefly, a PHI 670 Auger Nanoprobe was used with electron beam conditions of 10 kV, 16 nA, and ion beam conditions of Ar+, 4 keV, 2 mm × 2 mm raster, with a sputter rate of 8.2 nm/min (SiO2 equivalent), and sample tilt of 30° to sample normal. SiO2 equivalent oxide thicknesses (which are approximations of absolute thicknesses) were 14, 113, and 1950 nm for CE, AO, and BO finishes, respectively.

Cyclic Potentiodynamic Polarization Testing

Due to the highly localized nature of the Auger measurements and to further characterize the corrosion resistance of finished surfaces, potentiodynamic polarization characterization was conducted using methods described in ASTM F2129-19a [26] on six samples for each of the three surface finishes. For this testing, Interface 1000 potentiostats (Gamry) with graphite carbon rod counter electrode and saturated calomel electrode (SCE) reference electrode were used. Wires were mounted using fast-drying silver paint (Ted Pella). The attached and free wire ends were insulated by covering with MICCROstop (Tolber Chemicals). The samples were then immersed in deaerated phosphate-buffered saline (PBS) and the open-circuit potential (OCP) was monitored for 1 h. After 1 h, the OCP values had stabilized and were recorded as the rest potential, Er. Er values (in mV vs. SCE ± standard deviation) for CE, AO, and BO were − 71.94 ± 12.53, − 60.26 ± 13.20, and − 260.56 ± 25.35 mV, respectively. The wires were then subjected to potentiodynamic scans to a vertex potential of 1000 mV vs. SCE and back to the rest potential at a scan rate of 1 mV/sec. Scans were reversed when either 1000 mV was reached or when the current density exceeded 25 mA/cm2. The occurrence of pitting corrosion was inferred if the current density on the forward scan exhibited a two-decade increase at (near) constant potential, i.e., breakdown potential, Eb. Pitting was confirmed in all samples that met this criterion through microscopic inspection. Measured Eb values for CE, AO, and BO were 649.3 ± 222.3, 520.4 ± 102.4, and 442.0 ± 62.37, respectively.

Chemicals

The following chemicals were obtained from Fisher Scientific (Hampton, NH): PBS 1 × powder concentrate (pH 7.4), 32–35% (w/w) Optima hydrochloric acid (HCl), 67–69% (w/w) Optima nitric acid (HNO3), 30% (w/w) H2O2, and 85% (w/w) phosphoric acid (H3PO4). The following chemicals were obtained from Sigma-Aldrich (St. Louis, MO): sodium phosphate monobasic (NaH2PO4), sodium chloride (NaCl), and sodium hydroxide (NaOH). The MICCROstop stop-off lacquer was from Tolber Chemical Division (Hope, AR).

Chemical Solutions

A 1000 ppm Ni standard stock solution was purchased from Ricca Chemical Company (Arlington, TX). Sodium hypochlorite (NaOCl) solutions with 11–15% (or 1.7–2.32 M) available chlorine was purchased from Alfa Aesar (Tewksbury, MA); the measured available chlorine during the experiments was ~11% (titration using sodium thiosulfate-iodine). Solutions of phosphate buffers with different pH values (2.2, 4.2, 6.2, 7.2, and 8.2) were made using various ratios of NaH2PO4 to H3PO4 according to a buffer calculator provided by the Centre for Proteome Research (Liverpool, UK) [27] and the ionic strength was adjusted to 154 mM using NaCl. To determine if adjusting the ionic strength of the buffer to 154 mM affected Ni release, an additional experiment was performed using non-adjusted (i.e., sub-physiological 29 mM NaCl) buffer. The effect of ionic strength (29 mM NaCl compared to 154 mM NaCl) was not found to cause a difference in the initial release of Ni on Day 1 or in the average release rate from any finish (CE, AO, or BO) in the tested pH range (results not shown).

pH values were adjusted with either HCl or NaOH and determined using an ORION STAR A215 pH meter (Thermo Fisher Scientific, Waltham, MA) after calibration with the appropriate standard pH buffer of 2, 4, 7, or 10 (Ricca Chemical Company, Arlington, TX). PBS was made from 1 × powder concentrate (pH 7.4 with an ionic strength of 154 mM NaCl) in ultrapure (≥ 18.2 MΩ/cm) deionized water (Millipore Sigma, Burlington, MA). The stock (9.79 M) H2O2 solution was diluted in PBS to final concentrations of 0.1, 1, and 20 mM (the latter two concentrations are supraphysiological). Two NaOCl/HOCl concentrations of 3.87 and 77.3 mM were prepared from a NaOCl stock solution and adjusted to pH 7.4.

Wire Immersion

NiTi wires were cut to a nominal length of 1.6 cm using a wire cutter and held with plastic tweezers while each end was capped with stop-off lacquer that was dried overnight at room temperature. 1.4 cm lengths (nominal) of exposed NiTi wires with surface areas of 0.2187 ± 0.0083 cm2 (calculated from n = 97 measured test wires) were immersed in four different types of solutions: PBS (pH 7.4), NaH2PO4/H3PO4 pH buffers (2.2, 4.2, 6.2, 7.2, and 8.2), H2O2 (0.1, 1, and 20 mM), and NaOCl/HOCl (3.87 and 77.3 mM). Wire samples were prepared in triplicate (n = 3), immersed in 2 mL of each solution in 15 mL Falcon polypropylene or polystyrene centrifuge tubes (Fisher Scientific, Hampton, NH), and incubated in a 37 °C water bath for 24 h. Every 1–2 days for 7 days, each wire was transferred with plastic tweezers to a new 15 mL centrifuge tube containing 2 mL of its corresponding fresh solution. After each time point, every 2 mL of sample solution was acidified using 8 mL of 2 vol%/2 vol% HCl/HNO3 for analysis by inductively coupled plasma mass spectrometry (ICP-MS). Sample surface area-to-volume ratios were within the suggested limits (0.1–1 cm2/mL) found in Sect. 10.1.4 of ASTM F3306-19 [28]. By checking representative worst-case samples, we determined Ni release was not limited by saturation of the solutions (data not shown).

Ni Quantification

Ni was measured in standard resolution on an X-Series 2 ICP-MS (Thermo Scientific, Waltman, MA) in kinetic energy discrimination mode with 3.55% helium, 30 ms dwell time, and 0.02 atomic mass unit separation. Instrument performance was checked with a multi-element mixture (Tune A; VHG Labs, Manchester, NH). An internal standard of 10 ppb 115Indium (PerkinElmer, Akron, OH) was used to normalize sample injection volume and instrument drift. For the Ni concentration calibration standard curves, a series of ten Ni dilutions from 1000 to 0.01 ppb in 2 vol%/ 2 vol% HCl/HNO3 were prepared in 50 mL polypropylene centrifuge tubes diluted in matrix-matched media from the 1000 ppm Ni standard stock solution. A linear regression fit for this 10-point calibration curve was used (R2 > 0.999) to determine the quantity of both 58Ni and 60Ni isotopes. The lowest observable quantity (50 pg/mL) was obtained when measuring 58Ni. All the data are normalized to the surface area (0.2187 ± 0.0083 cm2) of the NiTi wires.

To obtain the recovery of Ni after 24 h at 37 °C, solutions of PBS were spiked with 20 ppb Ni using the Ni standard stock solution. Spike and recovery tests (n = 3 per test condition) were performed using low (0.2 ppb) and high (20 ppb) Ni concentrations in each of the physiological conditions evaluated [all pH levels and maximum H2O2 (20 mM) and NaOCl/HOCl (77.3 mM) concentrations] for seven days at 37 °C. Average recovery rates ranged from 0.89 to 1.50 and 0.97–1.07 for 0.2 and 20 ppb samples, respectively. Relative standard deviation of these measurements ranged from 0.71 to 15%. No systematic gains or losses in Ni recovery could be distinguished from the typical variability observed for Ni measurements at these concentrations. Furthermore, it is noted that experimental observations reported in the Results section consisted of order-of-magnitude changes in Ni release, much greater than the error observed for individual Ni measurements.

Corrosion Inspection

After Ni release studies, wires were rinsed with deionized water and blotted dry using delicate task wipes. Wires were then imaged using 150 × magnification on a KH7700 digital reflective microscope (Hirox USA, Hackensack, NJ).

Statistical Analysis

Data in figures and supplemental tables are presented as the mean ± standard deviation of three samples. Uncertainties (standard deviations) are based on the compounded uncertainties in mass and surface area. Probability (p) value calculations of single-day Ni release compared to threshold values were performed using a single-sample right-tailed Student’s t test using Microsoft Excel with n = 3 and degrees of freedom (df) = 2. P-value calculations for comparison of single day and cumulative Ni release between test conditions was performed using two-sample, two-tailed Student’s t test assuming unequal variance using Microsoft Excel. For two-sample tests, df was calculated using the Welch–Satterthwaite equation.

Results

In experiments where Ni release was measured as a function of buffer pH, the rate of Ni release increased with decreasing pH for all finishes (Fig. 1 and Table S1). Most wires demonstrated a higher Ni release on the first day and Ni release generally decreased thereafter, as observed on days 4 and 7. BO wires (Fig. 1A) released the most Ni at pH 2.2 (day 1: 104,800 ng/cm2) and pH 4.2 (day 1: 77,830 ng/cm2). AO wires (Fig. 1B) released intermediate amounts of Ni at pH 2.2 (day 1: 325.0 ng/cm2) and pH 4.2 (day 1: 87.32 ng/cm2). Finally, CE wires (Fig. 1C) released the least amount of Ni at pH 2.2 (day 1: 135.6 ng/cm2) and pH 4.2 (day 1: 44.54 ng/cm2). The average release rates of Ni in units of ng/cm2-day are also shown in Table S1 and release magnitudes are ordered as BO > AO > CE for all pH values.

Semi-log plots of periodic Ni release (ng/cm2-day) from nitinol wires of the finishes black oxide (A), amber oxide (B), and chemical etch (C) exposed to different pH solutions (2.2-◆, 4.2-■, 6.2-▲, 7.2-●, 8.2-x). Error bars represent standard deviations. Note: The elevated Ni release and standard deviation reported in (C) for pH 4.2 on day 4 is due to a single outlier measurement

Results of Ni release from wires treated with H2O2 (0.1, 1, and 20 mM) daily for 7 days are shown in Fig. 2 and Table S2. Generally, increasing concentrations of H2O2 caused greater Ni release, with peak release rates generally observed on Day 1. Minimum H2O2 concentrations to achieve 50% increases in Ni release were 0.1 mM for BO (p = 0.0033), 1 mM for AO (p = 0.0034), and 20 mM for CE (p = 0.0010). For BO wires, all concentrations of H2O2 (0.1, 1.0, and 20 mM) resulted in a sustained daily increased release of Ni (Fig. 2A). For AO wires, only the supraphysiological conditions (1.0 and 20 mM) resulted in a sustained daily increased release of Ni (Fig. 2B). Finally, for CE wires, only 20 mM of H2O2 resulted in a sustained daily increased release of Ni (Fig. 2C).

Semi-log plots of the daily Ni release (ng/cm2-day) from nitinol wires of the finishes black oxide (A), amber oxide (B), and chemical etch (C) exposed to three concentrations of hydrogen peroxide (0 = PBS-●, 0.1 mM-▲, 1 mM-■, and 20 mM-◆) in phosphate-buffered saline. Error bars represent standard deviations

Results of daily Ni release measurements for wires treated with NaOCl/HOCl (3.87 and 77.3 mM) are shown in Fig. 3 and Table S2. NaOCl/HOCl at 3.87 mM (the lowest concentration tested and below maximum reported physiological conditions) significantly increased Ni release. For BO (Fig. 3A) and AO (Fig. 3B) wires, 3.87 mM NaOCl/HOCl produced a greater than 40-fold increase in Ni release compared to PBS and 77.3 mM (supraphysiological) produced a greater than 100-fold increase compared to PBS. CE wires exposed to 3.87 mM or 77.3 mM NaOCl/HOCl showed the lowest Ni release rate increases (Fig. 3C). Release profiles for treatment with NaOCl/HOCl appear shaped like the pH studies, generally exhibiting decreasing release rates over time.

Semi-log plots of the daily Ni release (ng/cm2-day) from nitinol wires of the finishes black oxide (A), amber oxide (B), and chemical etch (C) exposed to two concentrations of sodium hypochlorite/hypochlorous acid (0 = PBS-●, 3.87 mM-▲, and 77.3 mM-■) in phosphate-buffered saline. Error bars represent standard deviations

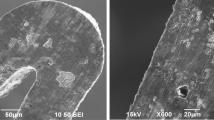

Figure 4 shows digital microscope images of representative wire samples exposed to NaOCl/HOCl. Corrosion was visually observed for AO and BO, but not for CE wires. No other conditions (pH or H2O2) caused visible corrosive damage to any of the wires (results not pictured).

Corrosion of nitinol wires after exposure to 0, 3.87, and 77.3 mM sodium hypochlorite/hypochlorous acid (NaOCl/HOCl) solutions for 7 days was visually inspected and photographed using a digital reflective microscope. Significant macroscopic damage (pitting) was observed on 3.87 and 77.3 mM-exposed black oxide (BO) and amber oxide (AO) but not chemical etch (CE) wires. No other solutions (pH or hydrogen peroxide) showed macroscopic damage (results not shown). Scale: all pictured wires are 500 µm in diameter

Discussion

We investigated whether various test media conditions, which are not captured in current testing paradigms for NiTi implant materials, can cause increases in Ni release from NiTi materials of various finishes. Typically, a determination of whether Ni release studies are needed for assessment of a medical device depends on information about the finishing process in manufacturing and corrosion resistance testing [29, 30]. Ni release is usually measured in PBS at 37 °C with pH of 7.4 and no ROS (approximating the typical blood environment) for a duration sufficient to measure maximum release rates, including any bolus release that occurs after initial release (often about 60 days). Although the experiments in the present study represent an abbreviated time course (seven days), they provide insight into how NiTi alloy of various finishes can behave when exposed to excursions in pH and ROS.

To evaluate the Ni release rates observed in this study, we considered our group’s previous work to predict local and systemic Ni levels as a result of Ni release from a cardiovascular implant (specifically, NiTi septal occluders) [31]. This earlier study predicts that if Ni release from a cardiovascular implant remains below 75 ng/(cm2-day), then local tissue levels of Ni will not exceed 5 µg/g, a concentration shown not to increase inflammation in rats [32]. Furthermore, it was calculated [31] that when total Ni release from a cardiovascular implant remains below 32 µg/day, adult Ni serum levels will not exceed the biomonitoring limit for Ni refinery workers (10 µg/L Ni in serum [33]). Based on our experience that the vast majority of implanted NiTi devices will have surface areas of less than 100 cm2, we divided by this maximum surface area to yield a release threshold of 320 ng/(cm2-day). As a conservative approach, the lesser of the release thresholds, 75 ng/(cm2-day), was used in the analysis that follows.

A simple application of the release threshold is to screen for rates of single-day release more than 75 ng/(cm2-day) in the seven-day studies performed here. Examining neutral-buffered conditions (PBS/pH 7.2) first, neither CE nor AO wires released Ni in quantities that exceeded 75 ng/(cm2-day). The threshold was consistently exceeded, however, for BO wires under the same conditions (see Tables S1 and S2) at levels no less than 452 ng/(cm2-day), regardless of the day of the observation [p-values for comparison to 75 ng/(cm2-day) range from 0.0004 to 0.0014]. Based on this analysis, BO wires as used in this study could raise concern if proposed for medical device use, which is consistent with other reports [8, 34]. CE and AO wires performed similarly to each other at neutral pH, exhibiting initial release of 38–74 ng/cm2 on day one followed by average release on the order of 10 ng/(cm2-day). Together, data suggest that the variation in wire finishes provides adequate range to evaluate Ni release in response to the in vitro test conditions of the study.

The results suggest that the thinner oxide finishes (CE and AO) can be expected to perform well at most physiological pH levels (i.e., pH 4.2–8.2), which includes typical blood pH. Notably, however, at pH 2.2, AO (p = 0.0035) and CE (p = 0.0168) demonstrated release above 75 ng/(cm2-day) on day 7, which had increased in rate from day two onward. This result suggests that finishes that appear to perform near equivalently at pH 7.2 may not provide equivalent protection in highly acidic conditions (e.g., pH 2.2). It also highlights the value of collecting time-course release data, as is typical practice. The observation of worsening corrosion resistance and increasing Ni release under acidic conditions has been documented previously [35,36,37] and incorporation of tissue-relevant physiological pH into regulatory testing is often performed. Overall, the results of pH experiments support the importance of evaluation of Ni release under physiologically relevant pH conditions, but for finishes such as CE and AO, minor shifts in pH alone (such as from localized inflammation) are not expected to considerably affect Ni release.

H2O2 experiments included physiological and supraphysiological conditions to allow estimation of concentrations of H2O2 needed to achieve increased Ni release from NiTi wires. These concentrations encompassed levels observed in normal plasma (1–5 µM) and seen in disease states (30–50 µM) [17]. For CE and AO wires, a minimum of 1 mM H2O2 was needed to elicit sustained Ni release above 75 ng/(cm2-day). Physiological H2O2 levels alone, if under 0.1 mM as described in the literature, do not appear high enough to warrant routine Ni release testing. Furthermore, it was noted that Ni release profiles in H2O2 generally appeared sustained compared to pH studies, suggesting that the mechanism of Ni release due to H2O2 is different. Other groups have investigated the effect of H2O2 on NiTi and Ti, but not at the conditions or durations studied here. In one study, NiTi wires were treated with boiling solutions of 3% (0.977 M) and 30% (9.77 M) H2O2 with the aim of improving corrosion resistance and reported “higher chemical homogeneity of the surfaces free of secondary phases and inclusions” and did not observe pitting upon electrochemical analysis [38]. While reports such as this can be useful for suggesting a mechanism for H2O2-induced Ni release, the experiments performed here were meant to specifically address potential in vivo Ni release due to H2O2 as produced by immune cells. Notably, minimal increases in Ni release were observed at these physiological levels.

NaOCl/HOCl experiments were also designed to include physiological (25–50 mM at the inflammatory foci [18]) and supraphysiological conditions, although literature information about levels specific to cardiovascular physiology could not be located. These experiments yielded information about the concentration needed to achieve increased Ni release and cause pitting of NiTi. The lowest concentration of NaOCl/HOCl tested (3.87 mM) caused initial release of Ni over 75 ng/(cm2-day) (Fig. 3) and visible pitting (Fig. 4) in AO but not CE wires (p = 0.1071 and 0.6696, respectively), suggesting that NaOCl/HOCl can cause increased damage to NiTi with thicker oxide finishes, consistent with earlier work [39]. Previous studies of NaOCl/HOCl on NiTi have generally reported the use of much higher concentrations, shorter exposure duration, and lacked adjustment of the solution pH [40]. The mechanistic effect of NaOCl on NiTi was described in two steps: (1) the presence of chloride ion facilitates dissolution of surface oxide and exposure of metallic NiTi and (2) Ni metal is converted to Ni hydroxides by direct action of NaOCl/HOCl. Observation of in vivo corrosion of stents implanted for 6 months in a minipig model with thick oxide layers (− 400 nm SiO2 equivalent) resulted in extensive pitting [41], suggesting that the local in vivo environment contains corrosive levels of NaOCl/HOCl or other ROS species that act on NiTi by a similar mechanism.

Importantly, Ni release increased for wire finishes with greater surface oxide layer thickness (lower Eb values) for all media conditions, consistent with previous work on NiTi wires and stents [3, 39, 42, 43], although it is important to note that thickness is only one of several characteristics of surface oxides that determines resistance to corrosion [44]. The effect of finish was most apparent at low pH (< 6.2) and low concentrations of NaOCl/HOCl (≥ 3.87 mM) as can be produced by inflammatory cells. The pH levels and ROS concentrations evaluated in this study were selected to encompass and exceed literature reports of extracellular pH and ROS, while being feasible to maintain and verify in vitro at 37 °C for one week. The complexity of the biological milieu including other primary, secondary, and tertiary radicals [18] was not captured here, but can be expected to further modulate the mechanism and magnitude of Ni release [10, 37]. Additionally, release of Ni may enhance inflammation and cause further Ni release in a positive feedback loop [45,46,47,48]. Furthermore, while not studied here, other ROS species are known to participate in inflammatory reactions and the presence of such species and their effects on Ni release will depend on local conditions that affect the generation, lifetime, and reaction products [49,50,51,52]. Finally, the combined effects of H2O2 and pH, as well as static and dynamic mechanical deformation may need to be considered, especially for cardiovascular medical devices that are expected to undergo cyclic motion in vivo [42, 53, 54].

In summary, we examined Ni release from NiTi under several conditions, with the understanding that the true physiological environment is multi-factorial. The data suggest that optimizing the finish through appropriate manufacturing can be an effective countermeasure for potential Ni release under pH and ROS excursions and that improved simulation of physiological conditions may lead to better predictions of Ni release from NiTi devices in vivo.

Disclaimer

The findings and conclusions in this manuscript have not been formally disseminated by the Food and Drug Administration and should not be construed to represent any agency determination or policy. The mention of commercial products, their sources, or their use in connection with material reported herein is not to be construed as either an actual or implied endorsement of such products by the Department of Health and Human Services.

References

Wadood A (2016) Brief overview on nitinol as biomaterial [Internet]. Adv Mater Sci Eng. Accessed 4 Nov, 2019. https://www.hindawi.com/journals/amse/2016/4173138/

Eliaz N (2019) Corrosion of metallic biomaterials: a review. Materials 12:407

Rosenbloom SN, Kumar P, Lasley C (2021) The role of surface oxide thickness and structure on the corrosion and nickel elution behavior of nitinol biomedical implants. J Biomed Mater Res B Appl Biomater 109:1334–1343

Saito M, Arakaki R, Yamada A, Tsunematsu T, Kudo Y, Ishimaru N (2016) Molecular mechanisms of nickel allergy. Int J Mol Sci 17:202

Mu Y, Godar DE, Merrill SJ (2017) A perspective on the challenges and issues in developing biomarkers for human allergic risk assessments. Biomark Med 11:523–526

Das KK, Reddy RC, Bagoji IB, Das S, Bagali S, Mullur L et al (2019) Primary concept of nickel toxicity—an overview. J Basic Clin Physiol Pharmacol 30:141–152

Kasprzak KS, Sunderman FW, Salnikow K (2003) Nickel carcinogenesis. Mutat Res Mol Mech Mutagen 533:67–97

Shabalovskaya S, Anderegg J, Van Humbeeck J (2008) Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater 4:447–467

Kim JH, Shin JH, Shin DH, Moon M-W, Park K, Kim T-H et al (2011) Comparison of diamond-like carbon-coated nitinol stents with or without polyethylene glycol grafting and uncoated nitinol stents in a canine iliac artery model. Br J Radiol 84:210–215

Nagaraja S, Sullivan SJL, Stafford PR, Lucas AD, Malkin E (2018) Impact of nitinol stent surface processing on in-vivo nickel release and biological response. Acta Biomater 72:424–433

Hoffman WE, Charbel FT, Edelman G (1996) Brain tissue oxygen, carbon dioxide, and pH in neurosurgical patients at risk for ischemia. Anesth Analg 82:582

Andrews RJ, Bringas JR, Alonzo G (1994) Cerebrospinal fluid pH and PCO2 rapidly follow arterial blood pH and PCO2 with changes in ventilation. Neurosurgery 34:466–470

Ohman H, Vahlquist A (1994) In vivo studies concerning a pH gradient in human stratum corneum and upper epidermis. Acta Derm Venereol 74:375–379

Ng KYB, Mingels R, Morgan H, Macklon N, Cheong Y (2018) In vivo oxygen, temperature and pH dynamics in the female reproductive tract and their importance in human conception: a systematic review. Hum Reprod Update 24:15–34

Obradović D, Husar M, Andelković V, Krstić M (1981) Tufegdzić N [Study of the pH values of uterine secretions in women with and without intrauterine devices]. Jugosl Ginekol Opstet 21:7–10

Halliwell B, Clement MV, Long LH (2000) Hydrogen peroxide in the human body. FEBS Lett 486:10–13

Forman HJ, Bernardo A, Davies KJA (2016) What is the concentration of hydrogen peroxide in blood and plasma? Arch Biochem Biophys 603:48–53

Panasenko OM, Gorudko IV, Sokolov AV (2013) Hypochlorous acid as a precursor of free radicals in living systems. Biochem Mosc 78:1466–1489

Ganong WF (1985) Review of medical physiology, 12th edn. Lange Medical Publications, California

Russell TL, Berardi RR, Barnett JL, Dermentzoglou LC, Jarvenpaa KM, Schmaltz SP et al (1993) Upper gastrointestinal pH in seventy-nine healthy, elderly, north american men and women. Pharm Res 10:187–196

Mattioli S, Pilotti V, Felice V, Lazzari A, Zannoli R, Bacchi ML et al (1990) Ambulatory 24-hr pH monitoring of esophagus, fundus, and antrum. Dig Dis Sci 35:929–938

Wilson CG (2010) The transit of dosage forms through the colon. Int J Pharm 395:17–25

Challa T, Vynala V, Allam KV (2011) Colon specific drug delivery systems: a review on primary and novel approaches. Int J Pharm Sci Rev Res 7:171–181

Nugent SG, Kumar D, Rampton DS, Evans DF (2001) Intestinal luminal pH in inflammatory bowel disease: possible determinants and implications for therapy with aminosalicylates and other drugs. Gut 48:571–577

ASTM Standard F2063-18, “Standard specification for wrought nickel-titanium shape memory alloys for medical devices and surgical implants,” ASTM International, West Conshohocken, PA, 2018. https://doi.org/10.1520/F2063-18

ASTM Standard F2129-19a, “Standard test method for conducting cyclic potentiodynamic polarization measurements to determine the corrosion susceptibility of small implant devices,” ASTM International, West Conshohocken, PA, 2019. https://doi.org/10.1520/F2129-19A

Calculator for pH buffers [Internet] (2019) Cent. Proteome Res. Liverp. Accessed 7 Nov, 2019. http://www.liverpool.ac.uk/cpr/Research/Tools/BuffferCalc/Buffer.html

ASTM Standard F3306-19, “Standard Test Method for Ion Release Evaluation of Medical Implants,” ASTM International, West Conshohocken, PA, 2019. https://doi.org/10.1520/F3306-19

Eiselstein LE, Steffey D, Nissan A, Corlett N, Dugnani R, Kus E et al (2009) Acceptance criteria for corrosion resistance of medical devices: statistical analysis of nitinol pitting in in vivo environments. J Mater Eng Perform 18:768–780

Nagaraja S, Di Prima M, Saylor D, Takai E (2016) Current practices in corrosion, surface characterization, and nickel leach testing of cardiovascular metallic implants: cardiovascular metallic implants FDA workshop. J Biomed Mater Res B Appl Biomater. https://doi.org/10.1002/jbm.b.33630

Saylor DM, Craven BA, Chandrasekar V, Simon DD, Brown RP, Sussman EM (2018) Predicting patient exposure to nickel released from cardiovascular devices using multi-scale modeling. Acta Biomater 70:304–314

Wataha JC, O’Dell NL, Singh BB, Ghazi M, Whitford GM, Lockwood PE (2001) Relating nickel-induced tissue inflammation to nickel release in vivo. J Biomed Mater Res 58:537–544

Nickel [Internet] (2020) Greenwood Village, Colorado, USA: IBM Watson Health. https://www.micromedexsolutions.com/micromedex2/librarian/CS/CC19BB/ND_PR/evidencexpert/ND_P/evidencexpert/DUPLICATIONSHIELDSYNC/6C9CCC/ND_PG/evidencexpert/ND_B/evidencexpert/ND_AppProduct/evidencexpert/ND_T/evidencexpert/PFActionId/evidencexpert.IntermediateToDocumentLink?docId=341&contentSetId=134&title=NICKEL&servicesTitle=NICKEL#close

Shabalovskaya S, Ryhänen J, Yahia L (2002) Bioperformance of nitinol: surface tendencies [Internet]. Mater Sci Forum. https://www.scientific.net/MSF.394-395.131. Accessed 16 Nov 2019

Nasakina EO, Sevost’yanov MA, Gol’dberg MA, Demin KY, Baikin AS, Goncharenko BA et al (2015) Long-term corrosion tests of nanostructural nitinol of (55.91 wt % Ni, 44.03 wt % Ti) composition under static conditions: Ion release. Inorg Mater Appl Res 6:59–66

Capoşi M, Prodana M, Ioniţă D (2011) Effect of temperature and pH on the metal release from TiNi. Sci Bull 73:27–36

Pound BG (2010) Corrosion behavior of nitinol in blood serum and PBS containing amino acids. J Biomed Mater Res B Appl Biomater 94B:287–295

Shabalovskaya SA, Anderegg JW, Undisz A, Rettenmayr M, Rondelli GC (2012) Corrosion resistance, chemistry, and mechanical aspects of Nitinol surfaces formed in hydrogen peroxide solutions. J Biomed Mater Res B Appl Biomater 100B:1490–1499

Weaver JD, Gutierrez EJ, Nagaraja S, Stafford PR, Sivan S, Di Prima M (2017) Sodium hypochlorite treatment and nitinol performance for medical devices. J Mater Eng Perform 26:4245–4254

Yokoyama K, Kaneko K, Yabuta E, Asaoka K, Sakai J (2004) Fracture of nickel–titanium superelastic alloy in sodium hypochlorite solution. Mater Sci Eng A 369:43–48

Sullivan SJL, Madamba D, Sivan S, Miyashiro K, Dreher ML, Trépanier C et al (2017) The effects of surface processing on in-vivo corrosion of Nitinol stents in a porcine model. Acta Biomater 62:385–396

Nagaraja S, Chandrasekar V, Ormonde D, Hickey H, Lipschultz K, Chao C et al (2018) The impact of fatigue testing and surface processing on nickel release in nitinol stents. Shape Mem Superelasticity 4:462–471

Sullivan SJL, Dreher ML, Zheng J, Chen L, Madamba D, Miyashiro K et al (2015) Effects of oxide layer composition and radial compression on nickel release in nitinol stents. Shape Mem Superelasticity. 1:311–327

Clarke B, Carroll W, Rochev Y, Hynes M, Bradley D, Plumley D (2006) Influence of Nitinol wire surface treatment on oxide thickness and composition and its subsequent effect on corrosion resistance and nickel ion release. J Biomed Mater Res A 79A:61–70

Taira M, Toguchi MS, Hamada Y, Takahashi J, Itou R, Toyosawa S et al (2001) Studies on cytotoxic effect of nickel ions on three cultured fibroblasts. J Mater Sci Mater Med 12:373–376

Eliades T, Pratsinis H, Kletsas D, Eliades G, Makou M (2004) Characterization and cytotoxicity of ions released from stainless steel and nickel-titanium orthodontic alloys. Am J Orthod Dentofacial Orthop 125:24–29

Shih C-C, Lin S-J, Chen Y-L, Su Y-Y, Lai S-T, Wu GJ et al (2000) The cytotoxicity of corrosion products of nitinol stent wire on cultured smooth muscle cells. J Biomed Mater Res 52:395–403

Ryhänen J, Niemi E, Serlo W, Niemelä E, Sandvik P, Pernu H et al (1997) Biocompatibility of nickel-titanium shape memory metal and its corrosion behavior in human cell cultures. J Biomed Mater Res 35:451–457

Stohs SJ, Bagchi D (1995) Oxidative mechanisms in the toxicity of metal ions. Free Radic Biol Med 18:321–336

Gilbert JL, Sivan S, Liu Y, Kocagöz SB, Arnholt CM, Kurtz SM (2015) Direct in vivo inflammatory cell-induced corrosion of CoCrMo alloy orthopedic implant surfaces. J Biomed Mater Res A 103:211–223

Bochi GV, Torbitz VD, Santos RCV, Cubillos-Rojas M, López JLR, Siebel AM et al (2016) Fenton reaction-generated advanced oxidation protein products induces inflammation in human embryonic kidney cells. Inflammation 39:1285–1290

Das TK, Wati MR, Fatima-Shad K (2015) Oxidative stress gated by Fenton and Haber Weiss reactions and its association with Alzheimer’s disease. Arch Neurosci [Internet]. 2015. http://archneurosci.com/en/articles/60038.html. Accessed 18 Nov, 2019

Kanemura T, Yokoyama K, Sakai J (2008) Effects of acid type on corrosion and fracture behavior of Ni–Ti superelastic alloy under sustained tensile load in physiological saline solution containing hydrogen peroxide. Corros Sci 50:2785–2795

Freiberg KE, Bremer-Streck S, Kiehntopf M, Rettenmayr M, Undisz A (2014) Effect of thermomechanical pre-treatment on short- and long-term Ni release from biomedical NiTi. Acta Biomater 10:2290–2295

Acknowledgements

Funding for this work was provided by the U.S. Food and Drug Administration Center for Devices and Radiological Health. The project was supported by appointments of authors (H.S., P.A.T.) to the Research Participation Program administered by the Oak Ridge Institute for Science and Education through an interagency agreement between the U.S. Department of Energy and the U.S. Food and Drug Administration. The authors would like to thank Dr. Katherine Vorvolakos for review of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Eric M. Sussman and Huiyu Shi have contributed equally to this work.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the journal Shape Memory and Superelasticity on Cardiovascular Nitinol Medical Devices. The issue was organized by Dr. Srinidhi Nagaraja, G.RAU, Inc. and Dr. Harshad M. Paranjape, Confluent Medical Technologies, Inc.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sussman, E.M., Shi, H., Turner, P.A. et al. Nitinol Release of Nickel under Physiological Conditions: Effects of Surface Oxide, pH, Hydrogen Peroxide, and Sodium Hypochlorite. Shap. Mem. Superelasticity 8, 98–106 (2022). https://doi.org/10.1007/s40830-022-00364-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-022-00364-3