Abstract

β-Ti alloys are known for their very low Young’s modulus, excellent physical properties, and biocompatibility, hence they are considered as attractive metallic materials for long-term bone implant applications. However, β-Ti alloys are poor wear resistant and typically bioinert materials, thus their surfaces need to be modified to have wear resistant and bioactive properties. In this paper, an overview is given to the available surface functionalization techniques to improve the biological properties of β-Ti alloys. Mechanical, physical, chemical, and electrochemical treatments, as well the immobilization of bio-functional molecules are discussed. Bioactivity, biocompatibility, haemocompatibility, wear and/or corrosion, behaviour of the β-Ti alloys can be improved using a proper surface modification technique, by altering the surface composition and topography or removing the undesired material from the alloy surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Several biomaterials are available for being used as implant materials, such as metals (stainless steel, Co-based alloys, Ti and its alloys), ceramics (alumina, zirconia, calcium phosphates), and synthetic or natural polymers [1]. In the last few decades, metallic biomaterials have been extensively used in biomedical applications mainly due to their excellent mechanical properties [2]. Among those, Ti and its alloys are considered as the most suitable biomaterials owing to their high strength, excellent corrosion resistance, and biocompatibility [3,4,5].

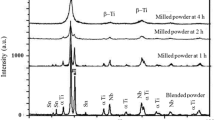

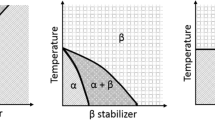

Ti alloys are classified as α, β, near-α, α + β, and metastable β phases [6]. In this context, the alloying elements are grouped into three categories: α-stabilizers such as Al, O, N, C, β-stabilizers such as Mo, V, Fe, Cr, Ni, Co, Nb, Ta, Mn, and neutrals such as Sn and Zr [5]. The α and near-α Ti alloys have good fracture toughness and corrosion resistance but have limited mechanical strength. On the other hand, the α + β Ti alloys exhibit higher strength, higher ductility, and higher low-cycles fatigue strength [5]. α + β type Ti–6Al–4V alloy (ASTM F1108) is the most popular Ti alloy and has been used for producing orthopaedic prostheses and dental implants due to its excellent specific strength, corrosion resistance, and biocompatibility [7]. However, ions of the alloying elements have been linked with various health problems such as neurological diseases and cytotoxic effects of Al and V, respectively [8,9,10,11,12,13].

Widely used α-type and α + β-type Ti-based implant materials have Youngʼs modulus values around 100–120 GPa, whereas Young’s modulus of bone is 5–6 times lower than those materials [14,15,16]. The Youngʼs modulus of human cortical bone is about 15–20 GPa, more specifically, the Youngʼs modulus of the fibula is about 15–20 GPa, the humerus is about 15–16 GPa, the tibia is about 16–19 GPa and the femur is about 13–15 GPa [17]. The difference in Youngʼs modulus between implant and bone causes the unbalanced distribution of stress on bone leading to bone resorption. Therefore, it causes poor osteointegration which may subsequently lead to loosening or failure of the implant [18,19,20]. This mechanism, that is known as stress-shielding and it can be minimized using an implant material having Young’s modulus closer to the bone.

Ti alloys with low Youngʼs modulus have been developed using biocompatible, non-toxic β-stabilizers elements such as Nb, Zr, Ta, Mo [4, 14, 21,22,23,24,25,26,27,28,29]. Niinomi et al. [3] and Abdel-Hady et al. [30] reported that Young’s modulus can be significantly reduced by adjusting the concentration of β-stabilizing elements. As reported by previous studies [31, 32], the β-type Ti alloys especially with Nb contents have been received attention and investigated extensively because of non-toxicity, good biocompatibility, also, better cell adhesion, proliferation, and differentiation in vitro. During the last two decades, many novel non-toxic and allergy-free β-Ti alloys have been produced with displaying superior corrosion resistance and good biocompatibility along with their low Youngʼs modulus [33,34,35]. Some of β-Ti alloys, such as Ti–29Nb–13Ta–4.6Zr, include high cost, non-toxic and allergy-free elements such as Nb, Ta, Zr and Mo [36]. Thus, instead of these rare and expensive elements, low-cost elements such as Fe, Cr, Mn, and Sn are also used to produce low Youngʼs modulus β-Ti alloys, like Ti–Mn–Fe [37] or Ti–Sn–Cr [38]. The load-bearing implant materials are expected to exhibit a combination of high strength and low Youngʼs modulus [39], however, the lowest Young’s modulus β-Ti alloys also have poor yield and tensile strength because, in general, these alloys are produced under solutionized conditions [40]. Therefore, the strength of β-Ti alloys needs to be increased while keeping their Youngʼs modulus, in order to improve the performance of the implants. Some available techniques to increase the strength are cold working [41], accumulative roll bonding [42], aging treatment, spark plasma sintering (SPS), and plastic deformation (especially high-pressure torsion) [43,44,45,46,47]. Datta et al. [48] used a predictive model and showed that increased content of β-stabilizers could reduce the strength of the β-Ti alloys. The incorporation of some β-stabilizers may also increase the strength of the alloys, as in the case of Ti6Al4V that presents higher strength as compared to cp-Ti. Also, the incorporation of Ta to Ti–Nb–Zr increase tensile strength and decrease Young’s modulus [28]. Nevertheless, the incorporation of elements does not always improve the mechanical properties of β-Ti alloys like in the case of incorporation of Sn to Ti–Nb which drastically decreases the tensile strength [39]. On the other hand, solid solution strengthening by oxygen is also effective in improving the strength of β-Ti alloys as maintaining their low Youngʼs modulus [49]. Niinomi and Nakai [50] reported that a small content of oxygen resulted in an increase in the strength, however, it also led to an increase in Young’s modulus for Ti–29Nb–13Ta–4.6Zr alloy.

Surface degradation of implants is one of the most important drawbacks for long-term implantation in the human body. When a metallic implant inserted into the human body, it can release metallic ions due to corrosive conditions [51]. Ti presents superior corrosion behaviour due to the spontaneously formation of a very stable oxide layer (passive film) on its surface. This passive film protects the implant materials against corrosion, reduces the release of metallic ions, and it is responsible for good biocompatibility. However, the corrosion behaviour of β-Ti alloys is determined by the role of β-stabilizing elements on the passive film.

Ti–Nb alloys have a great interest because of good biocompatibility and corrosion behaviour. Ti–Nb has better corrosion behaviour than cp-Ti [52, 53] and Ti–Mo [54]. Moreover, minor incorporation of Ru [55], In [56], and Sn [57] is reported to improve the corrosion behaviour. However, the commercial Ti–6Al–4V alloy presented better corrosion resistance than Ti–40Nb alloy through an immersion period of 21 days in NaCl solution that attributed to the formation of a more stable and thicker passive film [58]. The contribution of Zr, Ta, Mo, etc. β stabilizers in Ti–Nb alloys improved their corrosion behaviour in different physiological solution through the formation of a mixed passive oxide layer that had been reported to be more stable [59,60,61,62,63,64,65,66,67]. Ti–Mo, Ti–Zr, and Ti–Ta based β-Ti alloys are also popular alloys thanks to their unique properties such as non-toxicity, good mechanical properties, and relatively better corrosion resistance [68, 69]. Binary Ti–Mo [70,71,72], Ti–Zr [73,74,75], and Ti–Ta [76,77,78] alloys presented better corrosion resistance than cp-Ti in different solutions, while the ternary and multinary of these alloys exhibited further improvement in their corrosion behaviour [79,80,81,82].

Tribocorrosion is defined as an irreversible degradation process on the material surfaces subjected to the combined action of wear and corrosion [83]. Ti alloys are shown to possess poor wear resistance being a limiting factor in many applications [84, 85]. Although it is known that the total degradation rate after tribocorrosion can be different than the sum of the individual corrosion and wear rates, the literature reporting the synergistic interactions between corrosion and wear on β-Ti alloys is still scarce. Cvijović-Alagić et al. [86] investigated the tribocorrosion behaviour of Ti–13Nb–13Zr alloy in comparison with Ti–6Al–4V in Ringerʼs solution and found that Ti–13Nb–13Zr alloy had a substantially lower wear resistance than Ti–6Al–4V alloy. Similar behaviour was reported for Ti–40Nb alloy tested in 9 g/L NaCl solution [58]. On the other hand, Correa et al. [87] compared the tribocorrosion behaviour of Ti–15Zr–7.5Mo and Ti–15Zr–15Mo β-Ti alloys and reported a better behaviour for the Ti–15Zr–7.5Mo alloy. More et al. [88] studied the tribocorrosion behaviour of Ti–12.5Mo, Ti–13Nb–13Zr and Ti–29Nb–13Ta–4.6Zr β-Ti alloys and Ti–6Al–4Fe α + β-Ti alloy against polyethylene in Hankʼs balanced salt solution. The authors reported that the β-Ti alloys induced lower wear damage on the counter material. Besides, the addition of synovial fluid constituents (bovine serum albumin, hyaluronic acid, and dipalmitoylphosphatidylcholine) increased the wear volume loss on the Ti–29Nb–13Ta–4.6Zr alloy. Pina et al. [89] studied the influence of Sn addition on the tribocorrosion behaviour of Ti–Nb based β alloy and reported that Sn addition resulted with an increased wear volume loss in phosphate-buffered solution (PBS).

In order to improve the integration of bone and tissue, several surface modification techniques have been used to tailor the topography [21, 90,91,92,93,94,95]. When the properties of the implant surface can mimic the physical and chemical properties of the biological structure, tissue and implant surface integration is accomplished by adhesion, spreading and proliferation of cells on the implant surface [96]. On the other hand, coatings improve the surface properties including the hardness, wettability, elastic strain, coefficient of friction, and wear resistance. Coating materials used in joints replacement are fabricated by physical and chemical vapor deposition (PVD and CVD, respectively), electrodeposition, and ion implantation [97,98,99,100,101]. On the other hand, owing to their unique wear and tribocorrosion properties, metal matrix composites (MMCs) can be considered for orthopaedic and dental implants as a coating material or as a functionally graded material (FGM) [102,103,104,105,106,107,108,109]. Besides, nanostructured surfaces have also been studied to achieve better adhesion between the biomedical application and tissue [110,111,112,113,114,115].

β-Ti alloys considered as promising metallic materials for long-term bone implant applications. However, these alloys have some limitations such as poor wear resistance, still higher Youngʼs modulus compared to that of the bone, and lack of bioactivity. Therefore, a focus is given on both producing new β-Ti alloys, and improving their mechanical, tribological, electrochemical, triboelectrochemical, and biological properties. So, the studies on β-Ti alloys, particularly bio-functionalization studies are very important for the future improvements. Hence, this review aimed at gathering and summarizing the available state-of-art techniques to bio-functionalize the β-Ti alloys to obtain multifunctional implants.

2 Bio-functionalization of β-Ti Alloys

Metallic biomaterials have an attractive combination of high durability, high toughness, non-toxicity, and high strength. However, metallic biomaterials are typically artificial materials, therefore, their surfaces need modification to gain bioactive properties. The biomaterial surface plays an extremely significant role when interfacing with the biological environment (neutral tissue). Ti-based implants usually manufactured by melting, casting, forging, heat treatment, and oxidation which usually lead to a contaminated surface layer that is often stressed and plastically deformed, and non-uniform. Such native surfaces are not suitable for biomedical applications and some surface treatments should be performed. At the same time, different bio-functions are required depending on the intended implant location to achieve biological integration. For example, blood compatibility (haemocompatibility) is very important for blood-contacting biomedical devices such as stent and catheter, whereas osteointegration is a crucial parameter for bone applications. When a metallic biomaterial is implanted into a blood-contacting location, the first rapid event takes place is the blood protein adsorption leading to structural alterations that allow biological interactions. Thus, over time, a built-in protein layer is formed that affects the interaction of platelets, the adhesion, and aggregation of platelets. Concerning bone applications (orthopaedics and dentistry), once the implantation procedure occurs, the implant surface is wetted and the biologically active molecules (such as proteins) are adsorbed quickly followed by the osteoprogenitor cells that would regenerate the tissue [116]. The two main factors affecting osteointegration are the mechanical properties of the implant and the biological interactions with the metal surface, being the second the most relevant. Another important reason for the surface modification is to increase the corrosion and wear resistance of the metallic biomaterial. As a result, bioactivity, biocompatibility, haemocompatibility, wear, and corrosion resistance of the metallic biomaterials can be improved by surface modification, altering the surface chemical composition, topography, and crystal structure or removing the undesired material from the metallic biomaterial surface. For this purpose, many techniques have been applied for the surface modification of metals, some of which have also been commercialized.

It is clear that a biomaterial response is dependent on its biocompatibility and surface properties. In the literature, the bio-functionalization of metallic biomaterials, especially Ti and Ti6Al4V has been extensively studied and it is still being researched as recently reviewed by Su et al. [117]. Despite the combination of their unique features, β-Ti alloys need to be bio-functionalized to increase tissue adhesion and implant integration, to decrease bacterial adhesion, and inflammatory response or to avoid the foreign body response. In the following sections, the surface modifications that are investigated for β-Ti alloys are discussed. These treatments are being applied individually or as a combination.

2.1 Mechanical Treatments

The biomechanical properties and bioactivity of the implant surface can be improved by mechanical treatments, overviewed in Table 1, yielding with the nanostructured and ultrafine-grained surface with enhanced strength. Electric discharge machining (EDM) has been widely studied on cp-Ti and Ti–6Al–4V alloy to improve their hardness, corrosion and wear properties [118]. In the case of β-Ti alloys, the Ti–35Nb–7Ta–5Zr alloy has been studied by powder mixed electrical discharge machining (PMEDM). A schematic diagram of the PMEDM process and examples for the resulting microstructures on Ti–35Nb–7Ta–5Zr alloy is given in Fig. 1. PMEDM treated alloy presented better hardness, corrosion resistance, cell adhesion, cell spreading, and cell differentiation compared to the unmachined one, attributed to the formation of a nanoporous recast layer [119,120,121,122,123].

a Schematic diagram of PMEDM process and examples for the resulting microstructures on Ti–35Nb–7Ta–5Zr alloy b before and c after treatment (adapted from [119] with permission from Springer)

The surface mechanical attrition treatment (SMAT) is a method that can be used to tailor the mechanical and tribological properties of a surface [124, 125]. The SMAT device mainly consists of a vibration generator and a treatment chamber having balls as shown in Fig. 2a. The SMAT treatment was reported to improve the corrosion resistance, fatigue resistance, osteointegration, and haemocompatibility due to nanocrystallization of the cp-Ti surface [126]. Regarding β-Ti alloys, SMAT treated Ti–30Nb–8Zr–0.8Fe alloy having β grains around 150 µm (Fig. 2b) modified to a nanocrystalline structure having grains of several tens of nanometres (Fig. 2c) that led to an increase on the surface hardness [127]. The increased hardness of the surface decreased the wear rate of materials, such as the reduction of the fretting wear rate of Ti–34Nb–2Ta–0.5O alloy immersed in a 20% foetal bovine serum solution (pH 7.4) [128]. The corrosion behaviour of Ti–25Nb–3Mo–3Zr–2Sn and Ti–34Nb–2Ta–0.5O alloys in SBF solution was improved after SMAT treatment associated with the formation of a denser passive oxide layer resulted from the grain refinement [128, 129]. However, corrosion resistance of Ti–5Al–2Sn–2Zr–4Mo–4Cr alloy in 3.5% NaCl solution was decreased after SMAT treatment due to residual internal stress created from the treatment process [130]. The authors reported that stress relief heat treatment of 250–350 °C can significantly improve the corrosion resistance of SMAT treated alloy. In vitro cell culture studies indicated a significant improvement in cell adhesion, proliferation, differentiation, extracellular matrix mineralization, and protein absorption of SMAT treated Ti–25Nb–3Mo–2Sn–3Zr alloy as compared to the non-treated alloy due to its superior hydrophilicity, nanostructured surface, and increased surface roughness [131].

a Schematic diagram of SMAT process and representative microstructures on Ti–30Nb–8Zr–0.8Fe alloy b before and c after treatment (microstructure of alloy was taken from [127] with permission from Elsevier)

Ultrasonic nanocrystal surface modification (UNSM) is a novel method to induce severe plastic deformation at the surface to generate a gradient nanostructured surface layer on metallic materials. The process uses super-encapsulated ultrasonic vibration on the combination of static and dynamic loads to create high-strain rate plastic deformation on a material surface (Fig. 3a) [132]. Kheradmandfard et al. [133] applied the UNSM process to a Ti–29Nb–13Ta–4.6Zr alloy and obtained a significant increase on the surface hardness (≈ 385 HV) as compared to the untreated alloy (190 HV) owing to the surface structure having nanoscale lamellae and nanostructured subgrains (Fig. 3b), along with high dislocation density and α precipitates. The authors also reported that UNSM treated Ti–29Nb–13Ta–4.6Zr alloy presented significantly better wear resistance, cell adhesion, spreading, and proliferation attributed to both nanoscale grain refinement and micro-patterned surface effects (Fig. 3c) [134].

High-pressure torsion (HPT) is another commonly used severe plastic deformation technique to obtain ultrafine-grained structure for improving mechanical properties, particularly hardness and ductility as well as its biofunctionality [44, 135,136,137,138]. A schematic diagram of HPT process is given in Fig. 4a together with the representative microstructures on Ti–45Nb alloy before (Fig. 4b) and after (Fig. 4c, d) HPT deformation with 5 GPa pressure and n = 5 rotation number, where the grain size was reported to be decreased from around 20 µm to less than 100 nm [139]. As expected, HPT treatment improved the mechanical and microstructural properties of different β-Ti alloys [139,140,141,142,143,144]. Regarding corrosion, HPT treated Ti–13Nb–13Zr alloy showed significantly higher corrosion resistance in artificial saliva solution as compared to the untreated alloy associated with the grain size reduction to ultrafine range [140]. However, the quantities of released ions from HPT treated Ti–13Nb–13Zr alloy were higher than the quantities from untreated alloy, explained by its smaller grains, which was more prone to the release metallic ions [145]. In vitro cell culture tests revealed that the HPT treatment significantly increased the cell attachment, spreading, and proliferation on the treated samples influenced by their increased wettability due to their high internal energy given by the nano-sized grains having increased numbers of boundaries, interfaces, and dislocation density [140, 141]. Furthermore, alkaline treatment and the nanotubular layer formed on HPT treated β-Ti alloys presented better bioactivity as compared to the non-HPT treated one, explained by changing surface chemistry after chemical and anodic treatments [144].

a Schematic diagram of HPT process and representative microstructures: b optical microscope image of the initial Ti–45Nb alloy, c dark and d bright-field TEM images of the alloy after HPT treatment under 5 GPa pressure and 5 rotation number (adapted from [139] with permission from Elsevier)

Accumulative roll bonding (ARB) is another severe plastic deformation technique that has been applied to different β-Ti alloys to improve their functionality through grain refinement [146,147,148,149,150,151]. The studied β-Ti alloys presented better mechanical and corrosion behaviour as compared to the as-cast alloys due to the formation of nano-sized refined grains. However, biological studies are needed to understand the effect of ARB treatment on the bioactivity of β-Ti alloys.

2.2 Physical Surface Treatments

Physical surface treatments of β-Ti alloys including PVD, plasma spraying, plasma nitriding, gas nitriding, and ion implantation treatments are overviewed in Table 2 and demonstrated in Fig. 5 with the examples of surface and subsurface microstructural images. PVD processes are carried out in vacuum and the material are coated with positively charged ions during the process, resulting with a very strong bonding between the coating film and the substrate (Fig. 5c). The plasma spray process is the spraying of molten or thermally softened material to the surface to provide a coating [152]. On the other hand, ion implementation technique provides an easy control on the energy of ions, giving a good adhesion between the coating layer and the substrate resulted from gradient film coatings as shown in Fig. 5d, e. This technique allows to control the thickness of the coating, and eliminates the contamination since the process is carried out in vacuum [152].

a Schematic illustration of physical surface functionalization with resultant images: b cross-sectional SEM image of plasma sprayed HA/Ti coating on Ti–24Nb–4Zr–7.9Sn (adapted from [153] with permission from Elsevier), c cross-sectional SEM image of TiN coated on Ti–13Zr–13Nb alloy using cathodic arc physical vapor deposition (CAPVD) method (adapted from [294] with permission from MDPI, d TEM cross-section image of the nitrogen implanted Ti–35Nb–7Zr–5Ta alloy (adapted from [171] with permission from Elsevier), e cross-section SEM image of gas nitrided of Ti–15Mo–5Zr–3Al (adapted from [161] with permission from Elsevier)

Hydroxyapatite (HA, Ca10(PO4)6(OH)2) is a bio-ceramic material having a very similar chemical and crystallographic structure to human bone. HA has remarkably high biocompatibility thus it is used to improve the osteointegration process. However, its mechanical properties such as tensile strength and fracture toughness are quite poor, making it unsuitable for load-bearing implant applications. Various types of surface modification techniques have been used to deposit HA layers on Ti and its alloys, such as plasma spraying, sol–gel method, electrochemical deposition, and radio frequency (RF) sputtering. Zhao et al. [153] studied the microstructures, mechanical properties, and apatite-induction abilities of HA/Ti composite coating Ti–24Nb–4Zr–7.9Sn β-type alloy by plasma spraying. The authors reported that the microstructure, mechanical properties, and apatite-induction ability were influenced by the HA/Ti powders ratio used on processing. Also, the increase on Ti content led to an increase on the mechanical properties, however, decreased the apatite-induction ability. Zhao et al. [154] also studied the influence of the processing temperatures on Ti–24Nb–4Zr–7.9Sn alloy surface after plasma sprayed HA coating and reported that martensitic transformation and recrystallization influenced the mechanical properties resulting with a slight increase in the tensile and yield strengths but also led to a significant increase in Young's modulus (from 56.9 to 73.2 GPa). The main disadvantage of the plasma spraying technique is the poor adhesion between HA and the substrate materials. In order to improve the adhesion between HA and β-Ti alloys, some other techniques were also studied. He et al. [155] produced Ti–13Nb–13Zr–10HA composites by spark plasma sintering process at sintering temperatures varying between 950 and 1150 °C. The authors reported that mechanical properties of the composite, namely compressive strength, yield strength, and hardness were increased with the increased processing temperature. However, the processing temperatures above 1050 °C led to an intense reaction between Ti and HA increased in the metal-ceramic reaction phases. Depending on the processing technique and processing temperature, the thermal decomposition of HA during the processing of Ti–HA composites may lead to a decrease in the corrosion resistance due to the formation of locally active sites on the HA-depleted zones [156]. However, if the decomposition of HA is not observed, Ti–HA composite surfaces may increase the corrosion resistance. For instance, Kim et al. [157] studied the surface characteristics of Ti–HA composite coatings developed on Ti–35Ta–xZr alloy surfaces having 3, 7, and 15 wt% of Zr through RF and direct current (DC) sputtering and reported that the composite layer improved the corrosion resistance of the bare alloy by forming a stable barrier against corrosion.

The Al2O3–13TiO2, ZrO2 and the bilayered (ZrO2/Al2O3–13TiO2) nanoceramics coated by plasma spray technique on Ti–13Nb–13Zr alloy to improve its corrosion and wear resistance [158, 159]. The bilayered nanoceramic coating presented significantly higher corrosion resistance in Hank’s solution and wear resistance in SBF solution attributed to the presence of a large number of melted particles compared to other ceramics where they presented unmelted and melted particles, lower porosity and higher hardness for bilayered nanoceramic coating compared to other samples.

Titanium nitride (TiN) coatings by PVD, plasma nitriding, sputtering, gas nitriding, plasma immersion ion implantation, and ion implantation treatments have been widely used to improve the corrosion and wear behaviour along with the bioactivity of metallic materials. TiN has attracted attention due to its excellent properties such as high hardness, chemical stability, biocompatibility, haemocompatibility, high wear, and abrasion resistance. Because of these unique properties, TiN has been used on various applications such as dental prostheses, orthopaedic implants (hip, knee, ankle joint), heart valve prostheses, and dental surgery tools. The structure and biological properties of nitrogen treatment on different β-Ti alloys have been investigated [160,161,162,163,164,165,166,167,168,169,170,171,172,173,174]. Mohan et al. [174] performed a plasma nitriding treatment on Ti–15Mo–3Nb–3Al–0.2Si alloy using inductively coupled RF plasma and studied the corrosion behaviour by electrochemical impedance spectroscopy (EIS), potentiodynamic polarization, and immersion studies in Hank’s solution. It was found that the surface hardness of the nitrided samples increased with increasing annealing temperature and hydrogen dilution. Although nitrided surfaces presented lower corrosion resistance, nitrided samples with hydrogen dilution displayed higher potential for apatite growth compared to that of the sample nitrided with 100% nitrogen and the uncoated one. Gordin et al. [173] implanted nitrogen into Ti–25Ta–25Nb β-type alloy using an original ion implantation technique based on the use of an electron cyclotron resonance ion source to produce a multi-energetic ion beam from multi-charged ions. The corrosion resistance of the nitrogen implanted Ti alloy was evaluated in SBF complemented by in vitro cytocompatibility tests on human foetal osteoblasts. It was found lower corrosion and ion release rate for the nitrogen implanted surface than for the non-implanted one whereas in vitro tests revealed a good level of cytocompatibility for both non-treated and nitrogen implanted Ti–25Ta–25Nb alloy. A high temperature gas nitrided Ti–27Nb alloy also presented significantly better corrosion resistance than the cp-Ti and untreated Ti–27Nb alloy in artificial saliva for different pH values, together with a good level of bioactivity [160, 167]. In wear point of view, the ion implantations, plasma nitrided and gas nitrided methods are more beneficial than the PVD techniques and sputtering mainly due to the formation of a gradient hardened layer and the good bonding strength of the nitrided layer resulted from the diffusion of nitrogen ions. For instance, the dense TiN coating deposited by sputtering presented lower wear resistance as compared to a compact plasma nitrided layer associated with the hard compound layer maintaining its integrity with the hardened nitrogen diffusion zone during the wear test [164]. While nitriding improves the corrosion and wear resistance, gas nitriding in high temperature is reported to cause low fatigue strength due to severe grain coarsening [161]. A possible approach to improve the tribological behaviour of the protective coatings can be achieved by increasing fracture toughness and hardness with the replacement of monolayered coatings by multilayers. The multi-layered TiAlN/CrN coatings on Ti–45Nb alloy presented better wear resistance than the monolayered CrN and TiAlN coatings in dry sliding condition attributed to their small grain size, high surface hardness and adhesion resistance [165].

Another approach studied in the literature to improve the corrosion and wear behaviour of β-Ti surface is oxygen treatment using plasma immersion ion implantation. Mohan and Anandan [175] implanted oxygen ions into Ti–13Nb–13Zr β-type alloy by plasma immersion ion implantation and investigated the influence of oxygen ion implantation on the apatite growth and corrosion behaviour in Hanks’ solution. Results showed that the implanted samples had a higher potential for inducing apatite growth as compared to the untreated samples. Furthermore, the authors stated based on potentiodynamic polarization and EIS studies that the implanted layer behaved like a near-ideal capacitor with better passivation behaviour which can help in preventing the release of metallic ions from the implant material. Furthermore, the implanted surfaces displayed a lower coefficient of friction during dry sliding wear tests, as compared to the untreated samples.

2.3 Chemical Surface Treatments

Chemical methods are attracting more attention owing to their lower cost, easier control and stronger adhesion between bones and implant surfaces compared to the samples treated by mechanical and physical methods. Through chemical surface modification, it is possible to provide direct bonding between bone and the implant. Chemical surface treatments can be used to generate a nanopatterned surface topography which is expected to be promising for the stimulation of bone tissue growth (osteointegration of bone tissue) [176]. Acid treatment (HCl, H2SO4, HNO3, and HF, or a combination of them) is often used to remove the undesired material, to create a rough surface, and to obtain clean and uniform surface finishes. The schematic representation of chemical treatments and representative treated surfaces is given in Fig. 6, and the overview of chemical methods of β-Ti alloys are given in Table 3.

a Schematic representation of chemical treatment process and representative treated surface SEM images of b HCl etched and c subsequently immersed in NaOH surfaces of Ti–13Nb–13Zr alloy (adapted from [178] with permission from Elsevier); SEM images of d NaOH treated and e piranha etched surfaces of Ti–40Nb alloy (adapted from [180] with permission from Elsevier); f representative SEM image of HA-coated surface on Ti–29Nb–13Ta–4.6Zr by MOCVD (adapted from [192] with permission from Elsevier); g SEM image of a treated Ti–24Nb–4Zr–8Sn alloy surface in saturated Ca(OH)2 solution boiled for 30 min (adapted from [195] with permission from Elsevier)

Acid treatments commonly performed to clean metallic surfaces or surface roughening to improve bonding quality of next coating layer or improve bioactivity of surfaces. The Ti–45Nb alloy surface modified by sandblasting, followed by acid etching in different solutions, chemical treated in H2SO4:H2O2 (volume ratio of 1:1; piranha solution) with ice cooling resulted with a nanopatterned surface that stated by the authors to be expected to stimulate bone cell interactions [92]. It has been reported significantly prolonged etching duration for Ti–Nb alloy compared to cp-Ti and Ti–6Al–4 V attributed to the excellent chemical stability of Nb. Chemically treated Ti–40Nb alloy by piranha solution enhanced the adhesion and spreading of human mesenchymal stromal cells, together with better metabolic and enzyme activity [177]. However, chemically treated Ti–45Nb alloy presented lower corrosion resistance than untreated alloy due to the alterations on the surface chemistry and increase on the exposure area resulted from nanopatterning. Müller et al. [178] investigated the influence of different acid–alkali treatments on Ti–13Nb–13Zr alloy produced by powder metallurgy (P/M). The authors evaluated the rate of hydroxy carbonated apatite (HCA) formation during in vitro bioactivity tests in SBF. After etching the samples by HCl, HF/HNO3/H2O (1:6:18), H3PO4, and then soaked in 10 M NaOH aqueous solution, the authors reported that the rate of HCA formation was the highest for the samples etched in HCl.

As abovementioned, HA has excellent bioactivity, but its application has been limited in clinics due to its poor mechanical properties. Hence, the formation of a dense and uniform bone-like apatite layer grown on Ti alloys through alkaline treatment and soaking in SBF has been attractively studied as an alternative to HA coating techniques. A schematic illustration of apatite formation mechanisms in SBF is given in Fig. 7. It may be expected that the precipitated apatite coatings from soaking in SBF will be close to that of the biological apatite presents in human bone, where the SBF solution reproduces the human blood plasma. After alkaline treatment, a ~ 1 μm thick unstable sodium titanate layer is formed, and using heat treatment it is converted to a denser and mechanically stable layer. Acid and heat treatment was not effective for inducing apatite formation on Ti-based alloy attributed to enriched/remained alloying elements on their surfaces [179]. Also, while the chemical pre-treatments of alloy surfaces have a slight impact on apatite morphology, they do not affect the deposition process and its phase composition [180]. As can be seen from Fig. 7, during SBF soaking, the Ti–OH groups are formed resulted from the exchanged Na+ and H3O+ ions. The negatively charged Ti–OH groups are combined with positively charged Ca2+ ions through electrical force and form calcium titanate. Similarly, the positively charged surface combines with negatively charged phosphate ions to form amorphous calcium phosphate, and apatite grows on the surface spontaneously by consuming the calcium and phosphate ions. It is reported that apatite was grown more quickly on the β-Ti alloy than Ti–6Al–4V alloy [181].

The structure and bioactivity of alkali and heat treatment of β-Ti alloys have been investigated [180, 182,183,184,185,186,187,188,189]. Takematsu et al. [184, 190, 191] performed three different alkali solution treatments (electrochemical, hydrothermal, and hydrothermal-electrochemical) on Ti–29Nb–13Ta–4.6Zr alloy and compared the bioactivities and other characteristics of the modified surfaces. The authors showed the influence of the process to the surface morphology where electrochemical treatment resulted in a flat surface, hydrothermal treatment resulted in a smooth and fine mesh-like structure, and hydrothermal-electrochemical treatment led to a rough mesh-like structure. Moreover, apatite inductivity in SBF was reported to be influenced by surface roughness and chemical composition where increased roughness and decreased Nb content on the surface led to a higher apatite-induction ability. Also, the authors reported that a thicker oxide layer or presence of surface cracks decreased the adhesion strength, where cracks usually initiated as a result of thermal stress.

It has been reported that alkali [182] and alkali-hydrogen peroxide [185] treated Ti–15Mo alloy can induce bone-like apatite formation in vitro. The effect of alkali and hydrogen peroxide treatment on the electrochemical and biological performance of the Ti–5Mo–3Fe alloy surface was evaluated by Kumar et al. [186] and it was found that the alkali-treated alloy immersed in SBF solution exhibited notably higher corrosion resistance when compared with untreated and hydrogen peroxide treated samples. Furthermore, it was stated based on MG-63 in vitro cell culture studies that the alkali-treated samples showed better cell adhesion and spreading compared to the untreated and hydrogen peroxide treated samples. Zheng et al. [189] performed alkali treatment for calcium phosphate coatings on Ti–24Nb–4Zr–7.6Sn alloy and determined the adhesion and proliferation of rat osteoblast. The authors found that both the adhesion and proliferation of osteoblast cells on apatite formed Ti–24Nb–4Zr–7.6Sn were much better than on uncoated Ti–24Nb–4Zr–7.6Sn and cp-Ti.

Surface treatments with acid, alkali, hydrogen peroxide, and mechanical polishing, or a combination of these treatments are being applied to improve the adhesive strength of HA films [180]. Studies showed that the adhesive strength of such films can be improved by increasing the roughness of the underlying substrate. Hieda et al. [192] investigated the effect of acid treatment and mechanical polishing treatments on the adhesive strength of HA films deposited on Ti–29Nb–13Ta–4.6Zr alloy through metal–organic chemical vapor deposition (MOCVD) to increase the hard tissue compatibility. The authors reported that the adhesive strength of the HA layers formed on Ti–29Nb–13Ta–4.6Zr substrates treated with an HF solution significantly increased as compared to that of the HA film deposited on a polished Ti–29Nb–13Ta–4.6Zr surface. Also, the HA films on Ti–29Nb–13Ta–4.6Zr substrates treated with an H2SO4 solution exhibited lower adhesive strength than HA films on Ti–29Nb–13Ta–4.6Zr substrates treated with HF solution, regardless of the surface roughness of the substrates. Additionally, it was reported that the nanoscale surface asperities contributed to the adhesive strength, which was not observed for macroscale asperities.

The hydrothermal method is found to be very useful due to the formation of uniform coatings on complicated shapes, low processing temperature, low cost, and particularly because of strengthening the adhesion between the resultant coating and substrate. The surface wettability of implants is a crucial factor in their osteoconductivity because it influences the adsorption of cell-attached proteins onto the surface. In this respect, Zuldesmi et al. [193] compared the polished, hydrothermal treated, and anodic treated surfaces of Ti and four different Ti alloys (Ti–6Al–4V, Ti–6Al–7Nb, Ti–29Nb–13Ta–4.6Zr, and Ti–13Cr–1Fe–3Al). Hydrothermal treatment was performed in distilled water at 180 °C for 3 h whereas anodic treatment was performed in 0.1 M H3PO4 solution by applying potentials from 0 to 150 V with 0.1 V s−1 scanning rate. It was found that hydrothermal treatment increased the surface hydrophilicity of all types of Ti alloys and the osteoconductivity of Ti alloys after hydrothermal treatment and immersion in phosphate-buffered saline solution increased five times compared with that of the untreated samples.

Nanostructured TiO2 coatings are found to be favourable for the early osteointegration and biocompatibility due to their bioactivity. Liu et al. [194] studied the biocompatibility and early osteointegration of nano-TiO2 hydrothermally coated Ti–24Nb–4Zr–7.9Sn alloy compared with those of uncoated Ti-2448. The biocompatibility was evaluated using MTT assays, the histocompatibility was determined by observing the histological sections stained with HE (subcutaneous implantation, endosseous implantation), and the early osteointegration was tested using the alkaline phosphatase (ALP) activity and TGF-β1 expression. The authors reported an enhanced proliferation and cytocompatibility on the functionalized surfaces based on the MTT results, and better histocompatibility of the subcutaneous and endosseous implantation based on the in vivo studies. Zheng et al. [195] studied the functionalization of Ti–24Nb–4Zr–7.9Sn alloy by thermal treatment followed by hydrothermal treatments in supersaturated Ca(OH)2 solution. The treatment resulted in a layer containing CaTiO3, CaCO3, Ca(OH)2, and TiO2, and the authors reported a formation of Ca–P layer after soaking in SBF for 3 days. Tao et al. [196] investigated the surface properties of the Ti–25Nb–3Zr–2Sn–3Mo alloy after functionalization by a hydrothermal treatment in urea solution at temperatures varying between 105 and 170 °C, followed by a heat treatment at 400 °C. The authors showed that changes in temperature on hydrothermal treatment affected the surface structure where nanosheet films of ammonium titanate were observed after the treatment at 105 and 120 °C, whereas nanoparticle film of anatase TiO2 containing Nb2O5 was formed at 150 °C. Moreover, the authors reported enhanced hydrophilicity on the functionalized surfaces after water contact angle measurements around 68° and 10° for untreated and treated alloys, respectively.

2.4 Electrochemical Surface Treatments

Electrochemical processes are performed by chemical action on the metal surface under an electric current passing through an electrolyte. The electrochemical setup and the examples of resultant porous with volcano-like structure, nanotubular, and HA-containing layers are presented in Fig. 8. These methods are simple and cost-effective, allowing the incorporation of bioactive elements, and can increase the corrosion resistance of the modified materials owing to a more stable and thicker oxide layer formed on the surface [197]. Oxide layers with different morphologies, thickness, roughness, wettability, chemical compositions, and crystalline structures are formed on the substrates depending on the applied voltage and electrolyte composition [198].

a Schematic representation of the electrochemical surface modification set up, and the representative resultant surfaces with process parameters: b nanopores (adapted from [225] with permission from Elsevier, c nanotubes (adapted from [295] with permission from Elsevier), d porous oxide layer formed by MAO (adapted from [209] with permission from Elsevier), e plate-like HA, and f needle-like HA (adapted from [180] with permission from Elsevier)

2.4.1 MAO

MAO treatment has been used by several authors to modify the surfaces of Ti and its alloys for several biomedical applications. Rafieerad et al. [199] reviewed the surface characteristics and corrosion behaviour of calcium phosphate-based composite layers on Ti and its alloys via MAO treatment. The authors concluded that the fabrication of bioactive surfaces to improve the osteointegration of Ti-based implants is strongly recommended via MAO treatment. It is possible to obtain different morphologies, microstructures, thickness, and crystalline structures of the anodic layers using different electrolytes, voltages, currents or treatment time. Furthermore, this type of treatment allows the incorporation of bioactive elements such as Ca and/or P using electrolytes such as Ca(H2PO2)2 [197, 200,201,202,203,204,205,206], H3PO4 [200, 204, 206, 207] or a mixture of both [200, 208], calcium acetate (CA) [209,210,211,212,213,214,215], a mixture of CA and β-glycerophosphate (β-GP) [211, 212, 214,215,216], and NaH2PO4 [217]. Apart from bioactive elements, MAO also allows the incorporation of antimicrobial elements, such as Ag, Cu or Zn [218]. Some authors had reported the possibility of incorporation of bioactive additives into Ti-based alloys MAO layers such as tricalcium phosphate (TCP, Ca3(PO4)2), wollastonite (CaSiO3) or SiO2 particles which are known to enhance osteointegration [197, 201,202,203,204,205].

Simka et al. [200] and Kasek-Kesik et al. [201, 202] treated β-Ti alloy (Ti–15Mo) via MAO. The authors used H3PO4, Ca(H2PO2)2 or (HCOO)2Ca as an electrolyte and observed that the morphology and chemical composition of the anodic layers were strongly dependent on the applied voltage and chemical composition of the electrolyte used during the treatment. Independently of the electrolyte, when the voltage increased, the pore size of the anodic layers increased, however, more cracks were observed. The incorporation of Ca and/or P was, as well, dependent on the applied voltage. Moreover, the thickness of the anodic layers was dependent on both applied voltage and electrolyte concentration. For example, thicker anodic layers were observed for the highest concentration of (HCOO)2Ca. MAO parameters or electrolyte concentrations also influence the crystalline structure of the anodic layers. Simka et al. [200] found only a single crystalline phase TiO2 after treatment in a mixture of Ca(H2PO2)2 and H3PO4 electrolytes, indicating that TiO2 layers were amorphous. However, after decreasing the concentration of Ca(H2PO2)2, the authors reported the existence of the anatase phase.

Kazek-Kesik et al. [201, 205] used Ca(H2PO2)2 as electrolyte together with TCP, wollastonite or silica particles. The authors stated that the particles from the electrolyte suspension were successfully incorporated into the porous anodic layers for voltages higher than 150 V. However, while increased concentrations of TCP and wollastonite led to an increase in Ca and P incorporation the opposite was observed on the increased silica particle addition. Regarding the surface roughness, no significant influence was found when wollastonite or silica particles were used. However, the highest roughness value was found for the highest concentration of TCP particles. Kazek-Kesik et al. [202] also compared the influence of the substrate (Ti–6Al–7Nb, Ti–13Nb–13Zr and Ti–15Mo) on their anodic layer characteristics after MAO treatment. The authors added TCP particles into Ca(H2PO2)2 electrolyte for MAO treatment and observed that TCP particles were mainly deposited on the top of the anodic layers and filled the pores of the outer porous layer. Moreover, the formed oxide layers were different in terms of thickness, roughness, chemical composition, and crystalline structures, depending on the substrate. As well, their total thickness increased significantly with the incorporation of TCP particles. Oppositely, the roughness of the anodic layer with TCP particles decreased when compared with only anodized titanium alloys leading to an influence on the wettability. Bio-functionalization of Ti–13Nb–13Zr surface via MAO was studied by Kazek-Kesik et al. [197, 219] using a Ca(H2PO2)2 electrolyte with the addition of TCP, wollastonite or silica particles where the microstructures and chemical composition of the anodic layers were strongly dependent on the applied voltage. Moreover, the final surface roughness reported to be increased after the treatment.

Another β-Ti alloy that had been treated by the MAO process is Ti–30Nb–1Fe–1Hf [210, 214, 215]. Ou et al. [210, 215] used a calcium acetate (CA) and β-GP mixture as an MAO electrolyte and reported a three-layer structure, namely, an amorphous and crystalline outmost porous layer followed by an inner layer with several pores, and finally a thin and compact layer. Moreover, the presence of Nb promoted the formation of the amorphous phase of the anodic layer. Oppositely to cp-Ti, when the voltages on MAO treatment increased, the crystallinity of the anodic layers decreased on Ti–Nb alloys. The incorporation of Ca and P was also succeeded with a Ca/P ratio maximum of 1.91 depending on MAO parameters. On the other hand, Pan et al. [214] used similar electrolyte to modify the surface of the same alloy and reported that the presence of Nb in Ti alloy can promote both layer rupture voltage and dielectric breakdown voltage due to the mixture of oxides (Ti and Nb oxides) that are known to stabilize the amorphous structure and delay oxygen generation.

Gebert et al. [220] used a NaOH alkaline solution as electrolyte during the MAO process and reported surfaces having a compact and thin inner layer followed by a much thicker outer layer with micro-pores and micro-channels. Moreover, the presence of Nb enhanced the thickness growth of the outer layer. On the other hand, Sharkeev et al. [207] performed MAO treatment on Ti–40Nb using a mixture of H3PO4, biological HA, and calcium carbonate. The authors pointed the need for performing crystallization annealing treatment after the MAO process to obtain a crystalline structure on the anodic layer. The anodic layer was formed by a thin compact oxide layer, intermediate sublayer, and the typical porous CaP layer. As the voltage of MAO treatment increased, the thickness of the anodic layer also increased linearly from 35 to 90 μm. Moreover, when the voltage ranged between 200 and 300 V, the CaP layer presented spheres and pores. However, when the voltage increased up to 400 V, the transformation of micro-arc discharges into arcs caused the destruction and fragmentation of the spheres leading to a decrease of the anodic layer porosity. By using voltages under 200 V, XRD analysis just showed intense peaks of Ti and Nb and poor reflexes of NbO2 phases, mainly due to the small thickness of the anodic layer. The absence of TiO2 phases into the anodic layers was explained by higher thermal conductivity and lower electrical resistivity as compared to Ti. When the process voltage increased up to 300 V, the anodic layer was formed by an amorphous phase and crystalline phases such as CaHPO4 and β-Ca2P2O7. Further increase on the process voltage up to 400 V led to a decrease on the peak intensity of the characteristically crystalline phases of the anodic layers.

Tao et al. [209] studied the effect of Nb, Zr, and Sn on the characteristics of the anodic layers formed by MAO. The authors used a CA electrolyte with an applied voltage of 250 V and after the samples were heat-treated at 600 °C for 1 h in air. The anodic layer porosity increased with increasing voltage, and at 250 V, the porous structure covered uniformly all the surfaces. Although the surface roughness increased with the working voltage, it was not affected by the heat treatment. After heat treatment, the anodic layers were mainly composed of TiO2 (anatase and rutile), Nb2O5, CaO, and SnO2. However, the diffraction intensity of Nb2O5, CaO, and rutile increased after heat treatment. A study using the same alloy was reported by Gao et al. [213] where the authors also used the similar MAO treatment parameters. However, XRD analysis only detected Ti, anatase and rutile peaks while elements such as Ca, Nb, Zr, and Sn were only detected by EDS analysis. These results showed the importance of the post-heat treatment on the crystallinity of the anodic layers as reported by Tao et al. [209].

Other alloys as TiZrSnMoNb [211, 212], TiAlNb [202], TiCrAlFe [217] have also been modified by MAO. However, the effect of the alloying elements on the MAO treatment of the new alloys is yet to be fully understood. Besides, although the MAO process has been successfully used to modify β-Ti alloy surfaces mainly to increase the bioactivity, very little is known on the growth mechanisms of MAO layers including the incorporation process of the bioactive elements.

Apatite forming ability has been used to access the bioactivity, however, apatite forming ability depends not only on the chemical composition of the anodic layers but also on the volume of SBF solution used during the soaking process. Thus, due to these factors, different results are reported in the literature. Kasek-Kesik et al. [204] reported that according to the mechanism of apatite crystallization, the presence of anatase and rutile may be negatively charged in SBF and adsorbs Ca2+ ions. Ca2+ ions also attract OH− and HPO42− groups. If an anodic layer does not have phosphorous compounds, the formation of apatite may be delayed or not exist, however, it is still possible by the formation of calcium titanate (CaTiO3) on the anodic layer since the presence of CaTiO3 facilitates the adsorption of hydroxyl radicals and phosphate leading to the formation of apatite.

Several authors reported that apatite forming ability is induced on MAO-treated surfaces of β-Ti alloys, independently of the chemical composition of the substrate [204, 206, 209, 212]. Tao et al. [209] concluded that a heat treatment after MAO on Ti–24Nb–7Zr–7.9Sn alloy improved the apatite forming ability. The same behaviour was described by Kazek-Kesik et al. [204] for Ti–15Mo alloy treated by MAO and post-treated by heat treatment. On the other hand, Yu et al. [212] reported that in situ formation of apatite on the MAO-treated surfaces of Ti–3Zr–2Sn–3Mo–25Nb in SBF was related to Ca- and P-containing compounds. Moreover, apatite nuclei were formed after approximately 14 days of immersion and it continued to grow, firstly filling the pores and after spreading over the entire surface. Sowa et al. [206] modified surfaces of Ti–13Nb–13Zr alloy by MAO and the authors were able to detect small amounts of apatite precipitates formed on the modified Ti alloy surface after immersion in SBF, although the treated surfaces presented Ca/P ratios bellow 1.67 (Ca/P atomic ratio of stoichiometric HA).

Immersion of MAO-treated surfaces in SBF to promote apatite forming ability and thus bioactivity has been widely studied. However, the reliability of evaluation of bioactivity of those surfaces by simply immersing in SBF has been criticized due to the lack of proteins presence or bacterial activity. Thus, in vitro and/or in vivo studies have been reported to access the biological response of the modified surfaces. Kazek-Kesik et al. [202] developed multi-layered surfaces by electrophoretic deposition of TCP particles on MAO-treated surfaces of V-free alloy (Ti–6Al–7Nb, Ti–13Nb–13Zr, and Ti–15Mo). The number of incorporated TCP particles was higher for Ti–13Nb–13Zr and Ti–15Mo alloys than for Ti–6Al–7Nb. The adhesion and number of MG-63 osteoblast-like cells were investigated by Kazek-Kesik et al. [202] and it was observed that independently of the base alloy, none of the modified surfaces were cytotoxic. The highest biological activity was found for MAO + TCP treated Ti–15Mo alloy, while the surface modification did not significantly influence the cell proliferation on Ti–6Al–7Nb and Ti–13Nb–13Zr alloys. On the other hand, another study from the Kazek-Kesik et al. [204] modified Ti–15Mo alloy by MAO and showed that after 5 days of culture, hBMSC cells have well adhered to all modified surfaces. However, the anodic layers with the highest atomic ratio of Ti/Ca presented higher ALP activity, collagen production, and mineralization when compared with the untreated alloy. Moreover, these surfaces showed only a single strain of attached D. desulfuricans bacteria and it was not observed the formation of bacteria biofilm. Furthermore, the Zn, Cu, and Ag-doped CaP MAO composite was formed on Ti–40Nb alloy, presented an improvement on the antibacterial activity [221].

The biological performance of low Young’s modulus Ti–24Nb–4Zr–7.9Sn alloy bio-functionalized by MAO has been reported [209, 213]. After heat treatment, the anodic layers consisted of TiO2, CaO, Nb2O5, and SnO2. In vitro studies on rabbit’s osteoblast showed a considerable improvement in cell proliferation due to the increased roughness of the surfaces but as well due to the incorporation of Ca into the anodic layers [209]. Although no heat treatment was performed after MAO, Gao et al. [213] showed that MAO-treated surfaces presented significantly higher absorbance of cells when compared to the untreated alloy. Moreover, the porous structure and chemistry of the anodic layers led to a stronger and faster bone response of the modified surfaces.

Ou et al. [215] functionalized Ti–30Nb–1Fe–1Hf alloy by MAO using a Ca- and P-rich electrolyte followed by a post hydrothermal treatment. In vitro studies with MG-63 cells indicated no significant differences between the untreated and treated alloy on optical cell density and ALP activity. However, cell adhesion and cell spreading were reported to be improved by hydrothermal treatment. Sowa et al. [206, 222] modified Ti–13Nb–13Zr alloy by MAO in an electrolyte containing Ca and P elements. The authors observed that the incorporation of Ca and P into the anodic layer enhanced the differentiation of hBMCs into osteoblasts. Moreover, the increased roughness after MAO promoted cell spreading. A similar improvement was achieved for Ti–45Nb alloy through 26 days of cell culture [223].

Bioactive surfaces were produced by Zhao et al. [211] on Ti–5Zr–3Sn–5Mo–15Nb alloy using MAO where better osteoblasts adhesion, spread, viability, and differentiation were observed. However, by increasing the applied voltage of MAO treatment, better cell spread and viability was observed. The authors stated that this behaviour might be explained by the increased roughness together with an increased Ca/P ratio obtained at the highest voltage. On the other hand, Yu et al. [212] used similar alloy and MAO treatment conditions but performed further activation in an aminated solution. Results showed that MC3T3-E1 cell proliferation was favoured and hard tissue implantation indicated that the activated surfaces exhibited good biocompatibility and better osteointegration than the untreated alloy. Chen et al. [217] bio-functionalized Ti–13Cr–3Al–1Fe alloy using MAO in NaH2PO4 electrolyte. In vitro tests using MC3T3-E1 cell line and in vivo tests in distal femora of Japanese white rabbits showed that the rutile-rich TiO2 layer gave better biocompatibility and osteointegration performance than anatase rich phase, suggesting that MAO-treated implant may achieve better bone formation and on growth.

In addition to their increased bioactivity, anodic layers on Ti-based alloy created by MAO can also increase the corrosion resistance of the base alloys. Kazek-Kesik et al. [197, 201, 202, 219] reported the corrosion behaviour of different low Young’s modulus alloys modified by MAO. The corrosion behaviour of Ti–6Al–7Nb, Ti–13Nb–13Zr, and Ti15Mo MAO-treated alloys was studied in Ringer’s solution [202]. Surface modification caused an increase in the corrosion resistance for all substrates. However, the highest differences in the electrochemical parameters were found between treated and untreated Ti–15Mo alloy.

It has been reported [201] that MAO treatment in TCP, wollastonite or silica particle-containing electrolytes improved the corrosion resistance of Ti–15Mo alloy due to the barrier-type oxide layer formed on the alloy surface. The highest corrosion resistance was recorded for the electrolyte containing TCP particles owing to the thicker and more compact oxide layer. Similar MAO treatment was performed on Ti–13Nb–13Zr by Kazek-Kesik et al. [197, 219]. Results showed that the OCP values in Ringer’s solution were much nobler on the treated samples, showing a lower tendency to corrosion when compared with the untreated alloy. Furthermore, the polarization resistance increased and current density decreased, independently of the incorporated particles, as compared to the untreated alloy [197]. By immersing the treated alloy in Ringer’s solution for 5 months, the authors could observe the degradation of the anodic layers due to the dissolution of Ti, Nb, and Zr phases [219]. The concentration of dissolved Ti ions in electrolyte was found to be influenced by the applied voltage during MAO treatment as a consequence of increased surface roughness with increasing applied potential. Apart from Ti ions, Nb and Zr ions were also detected but their amounts were very small.

2.4.2 Nanotubular Structures

TiO2 nanotubular surface structures have been widely reported for biomedical applications since protective stable oxides on Ti-base surfaces lead to a favourable osteointegration [201, 224]. TiO2 nanotube growth is obtained by anodic treatment using F− containing electrolytes. The nanotube growth has been reported on binary, ternary and quaternary β-Ti alloys such as Ti–Nb [220, 224], Ti–13Zr–13Nb [225, 226], Ti–25Ta–xZr [227], Ti–35Nb–xZr [228, 229], Ti–29Nb–13Ta–4.6Zr [230], and Ti–24Nb–4Zr–7.9Sn [231, 232].

Gebert et al. [220] compared the growth of the nanotubes on Ti–40Nb and cp-Ti (grade 2) in fluoride-containing solutions and observed a similar growth. Moreover, the oxide nanotubes presented amorphous structures and mixed compositions as (TixNb1−x)O2. On the other hand, Jang et al. [224] produced nanotubular surfaces on Ti–xNb (x = 10, 20, 30 and 40 wt%) alloys using 1.0 M H3PO4 electrolyte containing 0.8 wt% NaF. The nanotubes formed on the Ti–xNb alloy surface presented a wide range of diameters (55–220 nm). More specifically, as Nb content increased, the length of the nanotubes increased from 730 nm to 2 µm. The authors also reported that the initial structure of the nanotubes was an amorphous TiO2–Nb2O5 layer. After annealing at 300 and 450 °C, the formation of crystalline anatase, and after annealing at 600 °C, in addition to anatase, the formation of rutile was detected.

Ossowska et al. [225] and Hernández-López et al. [226] performed anodic treatment to obtain nanotubes on Ti–13Zr–13Nb alloy using a mixture of 1 M H2SO4 and 0.035 M HF. Hernández-López et al. [226] stated that shorter anodizing times resulted in nanostructured layers with a porous morphology, whereas after longer anodizing times, the anodic film showed a nanotubular structure. Moreover, the average molecular composition given by Rutherford backscattering spectroscopy (RBS) analysis was (TiNbZrO)0.450.081TiF40.102NbF50.081ZrF4 for the nanoporous layers while the nanotubular layers presented a molecular composition as (TiNbZrO)0.610.078TiF40.098NbF50.078ZrF4. On the other hand, Ossowska et al. [225] compared the nanotube growth on dense and porous Ti–13Zr–13Nb alloy. Results showed a fine nanotubular structure with long nanotubes, moreover, the nanotubular structure is formed also inside the pores in the case of the porous alloy. However, the nanotube dimension was smaller on the porous alloy when compared to the dense alloy.

Li et al. [231] and Hao et al. [232] modified the surface of Ti–24Nb–4Zr–8Sn by anodic treatment. Both authors performed the anodic treatment in a neutral electrolyte with 1 M (NH4)2SO4 and 0.15 M NH4F. Hao et al. [232] stated that the outer diameter of the nanotubes increased from 30 to 90 nm as the treatment voltage increased from 10 to 25 V. Results showed that the contact angle decreased sharply with increased nanotube diameters from 30 to 70 nm and then was constant with the further increase of diameter to 90 nm. The authors suggested that the surface energy increases with an increase of nanotube diameter up to 70 nm, which was explained by the formation of surface oxides and their contribution to surface roughness. XPS analysis showed that the outmost nanotubular layer consisted of amorphous mixed oxides of TiO2, Nb2O5, SnO2, and ZrO2. Similar results regarding the chemical composition of the oxides were also reported by Li et al. [231].

Similar to MAO-treated β-Ti alloys, studies investigating the corrosion behaviour of nanostructured surfaces on β-Ti alloys are scarce. Jang et al. [224] performed potentiodynamic polarization tests in 9 g/L NaCl at 36.5 ± 1 °C for nanotubes formed on Ti–xNb alloys and found that the corrosion resistance of nanotubular structured alloys was lower as compared to the untreated alloys. The authors explained this behaviour by the defected structure of the nanotubular surfaces that may promote the current transport. However, the anodic treated samples presented a wider range of a passive region when compared with the untreated alloys, suggesting that the mixture of TiO2 and Nb2O5 film was more stable. On the other hand, Ossowska et al. [225] and Hernández-López et al. [226] reported that the proper formation of nanotubular structures by anodic treatment resulted with a better corrosion behaviour as compared to the bare alloy.

Nanotubular structures on ternary and quaternary β-Ti alloys have been reported to stimulate rapid cell proliferation and osteoblast differentiation as well as to accelerate osteointegration and facilitate the transport of nutrients and bone ingrowth [231, 232]. It has been shown that the formation of ordered nanotubes on Ti–24Nb–4Zr–7.9Sn alloy via anodic treatment improved cytocompatibility, as well, enhanced bone implant integration in vitro and in vivo [231]. Hao et al. [232] obtained nanotubular surfaces with mixed oxides (TiO2, Nb2O5, SnO2, and ZrO2) and reported after biological studies with osteoblast-like MG-63 cells that smaller nanotube diameter was beneficial for the cell adhesion, proliferation, and differentiation. Also, the antibacterial behaviour of Ti–35Nb alloy was improved with the corporation of Sn as an alloying element [233].

2.4.3 HA Electrochemical Deposition

HA and calcium phosphate ceramic coatings are widely used in the biomedical field due to their excellent response to cell adhesion and proliferation, as well as their ability to enhance bone ingrowth and osteointegration processes. The deposition conditions have a great effect on the structure and biofunctionality of HA coatings. The electrochemical deposition of HA coatings on metallic biomaterials has unique advantages and it is an attractive technique because highly complex structures can be coated quickly at low temperatures. Moreover, the coating morphology and chemical composition of HA can be well controlled by varying the electrochemical potential, current, electrolyte concentration, and temperature.

Several studies reported the electrochemical deposition of HA [180, 210, 234,235,236,237]. Schmidt et al. [180] studied the influence of electrolyte temperature and different chemical pre-treatments on Ti–40Nb alloy for the deposition of the HA layer. The authors performed potentiostatic deposition of HA using a mixture of Ca(NO3)2 and NH4H2PO4 on grounded surfaces, etched surfaces with piranha solution, and alkali-treated surfaces. The morphology of the HA deposit was dependent on the electrolyte temperature. When the electrolyte temperature increased from 60 to 80 °C, the morphology of HA passed from plate-like to needle-like shape. However, the use of different pre-treatments did not have a significant effect on HA layer morphology. On the other hand, Byeon et al. [237] performed HA deposition on Ti–xNb alloy by cyclic voltammetry in two different electrolytes (CaP—a mixture of Ca(NO3)24H2O and NH4PO4; and Zn–CaP—a mixture of Ca(NO3)24H2O, NH4PO4 and Zn(NO3)24H2O). Although different Ca- and P- rich electrolytes were used, the Ca/P ratio kept constant, and the HA layer presented a nanoscale rod-like HA for CaP electrolyte, while the Zn–CaP electrolyte led to a nanoscale network-like Zn–HA layer. Although the authors reported successful Zn–HA layer deposition, further studies are needed to get a better understanding of the formation and properties of these layers on Ti–Nb alloys.

Kim et al. [234] used a mixture of Ca(NO3)2 and NH4PO4 as an electrolyte to deposit HA by cyclic voltammetry over nanotubular structured anodic layer on Ti–25Ta–xZr alloy. Although all the deposited surfaces showed a Ca/P ratio lower than 1.68, a successful HA layer was deposited on its surfaces. The HA precipitate morphology was influenced by the Zr content of the alloy; as the Zr content increased, HA precipitates morphology changed from plate-like or leaf-like shape to needle-like or flower-like shape. A similar electrolyte was used by Kim et al. [235] to deposit HA layers on highly ordered nanotubular surfaces of Ti–25Nb–xHf alloys. The authors observed that the needle-like nucleation and growth of the HA particles were promoted on the increased number of cyclic voltammetry cycles. However, the morphology of HA precipitates was influenced by Nb and Hf contents.

A study on the electrochemical deposition of HA on nanotube-formed Ti–Nb–Zr alloys was reported by Jeong et al. [236]. The authors studied deposition protocols using 5, 10, and 30 cycles of the pulsed current method and two electrolytes based on a mixture of Ca(NO3)4H2O and NH4PO4. The HA layer morphologies changed from a mixture of rough particles and plate-like shape particles to entirely plate-like shapes depending on the number of deposition cycles and the Ca and P concentrations in the electrolyte.

2.5 Laser Surface Treatments

Most of the laser surface treatments for β-Ti alloys were performed in a nitrogen-rich environment resulted in the nitrided surface. Laser nitrided Ti–20Nb–13Zr alloy presented significantly higher hardness, hydrophilicity, coefficient of friction, and corrosion resistance in artificial saliva and SBF compared to the untreated alloy, cp-Ti, and Ti–6Al–4V alloy due to formation of a uniform 9 μm thick nitrided layer [238, 239]. Similar behaviour was reported for different β-Ti alloys namely Ti–35Nb–7Zr–5Ta [240], Ti–45Nb [241], Ti–13Nb–13Zr [242], Ti–35Nb–2Ta–3Zr [243], Ti–35Nb–7Zr–5Ta [244], and Ti–35.3Nb–7.3Zr–5.7Ta [245]. Femtosecond lasers are being used to increase the surface roughness and reported to provide significant advantages for hole formation compared to nanosecond lasers. Its advantages are negligible heat transfer and the absence of a liquid phase since the vapor and plasma phase are formed very quickly. In addition to these advantages, the periodic nanostructures are self-organized in the laser-irradiated field. Jeong et al. [229] evaluated the nanotubular surfaces formed on the femtosecond laser-treated Ti–35Nb–xZr (x = 3 and 15 wt%) and reported an extensive proliferation and spreading of the MG 63 cells. Similarly, laser treatment was reported as a sufficient pre-treatment for HA and β-TCP bio-ceramic coatings associated with the formation of oxides diversity and irregular morphology on Ti–15Nb alloy.

Saud et al. [246] investigated the microstructure, corrosion behaviour, bioactivity, and antibacterial activity of graphene oxide (GO) coated by dip coating on femtosecond laser surface modified Ti–30Nb alloy. The authors reported that laser-treated and GO-coated samples displayed higher corrosion resistance than the GO-coated and uncoated samples in SBF at 37 °C. Moreover, the GO coating on Ti–30Nb alloy led to a superior antibacterial activity against Gram-negative bacteria as compared with the uncoated samples. Similarly, fibre laser nitrided Ti–35Nb–7Zr–6Ta alloy drastically improved the mesenchymal stem cell attachment, proliferation and differentiation, and also led to a reduction on staphylococcus aureus bacterial attachment due to formation of a hard rough surface with low hydrophobicity [247, 248].

2.6 Immobilization of Biomolecules

Bioactive molecules are also used to enhance the soft tissue compatibility on metallic biomaterials. Many studies investigated the biopolymer coated cp-Ti and Ti–6Al–4V alloy, however, a very limited number of studies are available on biopolymer coated β-Ti alloys [188, 249,250,251,252,253]. The schematic diagram for the immobilization process is presented in Fig. 9. Biochemical modification of the Ti–25Nb–16Hf alloy with elastin-like polymers (ELPs) was performed, and their influence on the cell response was analyzed by González et al. [249]. ELPs presented remarkable biocompatibility and one of these polymers contains the well-known cell adhesion amino acid sequence, arginine-glycine-aspartic (RGD). It was found that the RGD interface presented enhanced results in terms of cell adhesion and spreading but no improvement was observed on the numbers and differentiation of the cultured cells. Hsu et al. [250] investigated the biocompatibility of NaOH treated Ti–25Nb–8Sn alloy surface and found that the RGD peptide grafted Ti–25Nb–8Sn alloy significantly enhanced the cell adhesion, proliferation, and differentiation.

Adhesiveness to metallic materials is an important issue for biomedical polymer coatings from the viewpoint of long-term durability. Silane-coupling treatment is a traditionally popular route for increasing the adhesive strength between metallic materials and polymers. Hieda et al. [251] investigated the effect of terminal functional groups and silane layer thickness on the adhesive strength of Ti–29Nb–13Ta–4.6Zr alloy to segment polyurethane (SPU) and reported that silane-coupling treatment led to a significant increase on the shear bond strength for all tested types of terminal functional groups and the silane layers thickness. Moreover, an immobilized 3-aminopropyltriethoxysilane-reduced graphene oxide (APTES-RGO) nano-layer coated on Ti–29Nb–13Ta–4.6Zr alloy presented better tribological behaviour as compared to the uncoated alloy [188].

2.7 Hybrid/Multi-layered Treatments

The hybrid treatments have been aimed to effectively enhance the mechanical and biological properties, and also reduce the interfacial failure. Bio-functionalization of β-Ti alloys by combining different techniques are studied in the literature. Choe [254] developed a double-layered surface on Ti–30Nb–xZr (x = 3 and 15 wt%) having a nanotubular inner layer formed by anodic treatment and a HA outer layer formed by electron beam-physical vapor deposition (EB-PVD). The author investigated the corrosion behaviour of the functionalized surfaces in 9 g/L NaCl solution at body temperature and reported the spalling of the HA layer on the samples only coated with a single HA layer, and cracking of the HA layer on the double-layered surfaces due to the differences on the size of the nanotubes affected the corrosion behaviour mainly leading to the appearance of a breakdown potential on the passive region, which was not observed on the bare alloy. A similar double-layered structure was also developed by Jeong et al. [228] on Ti–35Nb–10Zr alloy having a femtosecond laser-treated surface to increase the roughness. The authors stated that the application of femtosecond laser-treated created microscale features can be beneficial for mechanical interlocking with bone. Moreover, based on the SEM observations, the authors reported a higher trend on the attachment and spreading of MG-63 cells on the double-layered surfaces developed on the femtosecond laser-treated alloy. Similar hybrid structure (NT + HA) was developed on Ti–25Nb–xHf (x = 0 and 7) [235], Ti–29Nb–xZr (x = 3 and 15) [236], Ti–25Ta–xZr (x = 0, 3, 7 and 15) [234], Ti–13Ta–2Mo–6Zr [255], and Ti–20Ta–1Mo–8Zr [255]. The authors reported that the HA structure was significantly influenced by morphology, diameter of tubes, and distribution of nanotubular layer, which were changing by microstructure and composition of the alloy. Apatite precipitation was also affected by nanotubes diameter, where the largest diameter presented better apatite formation for Ti–35Nb–2Zr–0.2O alloy [256]. In addition to biological improvement observed by in vitro studies, membranes treated by this hybrid structure on Ti–20Ta–1Mo–8Zr alloy were covered on rat calvarial defects, and tomography, histologic and fluorescent analysis indicated higher bone mineral density and a contact osseointegration, suggesting durable osteogenesis at the early stage of bone defect repair [255].

RF sputtered TiN coatings on nanotubular Ti–25Ta–xZr alloys (x = 0, 3, 7, and 15 wt%) were studied by Kim et al. [227]. The authors reported that as the Zr content in the alloys increased, the average thickness of the nanotubular layer increased. For the alloy with the highest Zr content, the nanotubular surfaces were covered entirely with the RF-sputtered TiN film. The authors concluded that the Zr content affected roughness and wettability, leading to highly hydrophilic properties on the nanotubular surfaces. As discussed in Sect. 2.6, the immobilization of bio-functional polymers is important for improving the tissue compatibility. A poly(sodium styrene sulfonate) (PNaSS) biopolymer grafted with nanotubular layer grown on Ti–15Mo and a significant improvement of bioactivity and decrease of bacterial adhesion was reported [257]. However, these polymers may not sufficiently adhere to metallic materials. Nanostructures (nanopores and nanotubes) were formed on Ti–29Nb–13Ta–4.6Zr surfaces through anodic treatment to improve the adhesive strength of SPU [230]. It was found that the anchor effect given by the nanostructures increased the adhesive strength of SPU.

The MAO/HA structure is another commonly studied hybrid treatments for β-Ti alloys [210, 258,259,260,261]. Park et al. [258] electrochemically deposited HA on MAO layer grown on Ti–3Ta–xNb (x = 0 and 10), and it was found that the particle size and morphology of HA was affected by the composition of the alloy and alkaline treatment. Also, a biodegradable poly(lactide-co-glycolide) (PLGA) polymer was deposited on the MAO layer formed on the Ti–15Mo alloy [203]. Additionally, the PLGA loaded with the drug of amoxicillin layer was coated on MAO layer of Ti–15Mo using a dip coating technique, and it was reported an improvement on corrosion and bacterial resistance of substrate [261]. The main goal of the polymer-oxide layer was to explore the active substance to be released after implantation.

2.8 Other Methods