Abstract

Geosynthetic encapsulation of granular columns has proven to be an effective ground improvement solution. The behavior of this innovative eco-composite under vertical loading is well documented in the literature. Granular columns, however, also endure significant lateral shear stress, particularly when located at the toes of embankments or retaining walls and due to stresses brought on by earthquakes. This study experimentally investigated lateral shear loading on ordinary and granular columns encapsulated by geosynthetic material. The experimental tests were performed using the large-scale direct shear testing machine. Based on the findings of this experimental investigation, extra confining forces provided to columns by geosynthetic encapsulation led to the development of apparent cohesion within the column, increasing the lateral shear resistance of the composite. The effect of critical factors like the morphology of column infill material and column configurations on the shear strength parameters of soil-column composites has been highlighted. Also, it was observed that ordinary granular columns undergo complete shear failure along the shear plane; however, for the geosynthetic-encased columns, the failure mechanism was bending rather than complete shear failure, preventing catastrophic failure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

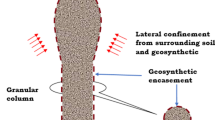

For geotechnical engineers, coping with soft soils is a severe difficulty. Economic feasibility and environmental concerns limit the foundation options in construction over soft soil. Recent advancements in the field of ground improvement by inclusions include prefabricated vertical drains (Chu et al. 2006; Sakleshpur et al. 2018), deep soil mixing columns or grids (Bruce and Geosystems 2000; Rahmani et al. 2022), controlled modulus columns, and encased columns. These techniques play many critical roles in construction projects on soft soils or liquefiable grounds. Ground improvement by encased granular columns (EGC) has been widely adopted to ameliorate weak soils because of its multitude of applications. Insufficient lateral reaction from the surrounding soft soil and clogging of voids within the column can lead to the insignificant contribution of ordinary granular columns (OGC) (Hughes and Withers 1974; Raithel et al. 2002; Almeida et al. 2015; Deb and Shiyamalaa 2016; Pal and Deb 2020). This drawback of a granular column can be overcome by encasing the granular column within the geosynthetic sleeve, thus providing extra lateral support to the column (Raithel and Kempfert 2000; Kempfert 2003; Raithel and Kirchner 2008; Almeida et al. 2013; Jayarajan and Karpurapu 2020). Although this technique is successfully used in several applications like providing vertical support to the embankment, accelerating the consolidation, and mitigating the liquefaction hazards (Alexiew and Raithel 2015; Pal and Deb 2021), the general understanding of the modes of failure of the columnar technique rarely extends beyond the ones caused by vertical loading. The column installed in soft soil is subjected to combined action loads. A great deal of previous research in this area was done with a primary focus on bulging and punching failure (Ambily and Gandhi 2004; Murugesan and Rajagopal 2006, 2007, 2010; Malarvizhi and Ilamparuthi 2007; Gniel and Bouazza 2009; Gneil and Bouazza 2010; Najjar et al. 2010; Frikha et al. 2015; Fattah et al. 2011, 2017; Castro and Sagaseta 2011; Miranda and Costa 2016). Shear failures initiated by soft soil lateral flow, earthquake-induced lateral forces, or column position near the toe of the embankment (shown in Fig. 1) are equally essential to be addressed (Cengiz and Guler 2018).

The available literature provides a concise discussion on the performance of EGCs under lateral shear loading. Murugesan and Rajagopal (2009) carried out a plate-strain laboratory experiment to comprehend the behavior of OGC and ECG under shear loading. This study manifests that encapsulation of the column resulted in improved shear strength. In 2016, Mohapatra et al. (2016) investigated the performance of granular columns with geosynthetic encapsulation under a large-scale direct shear test. In his research, sandy soil was used instead of the surrounding soft soil. As per this work, encapsulation enhances the resistance of columns to lateral loads, but the resistance declines after encasement ruptures. Aslani et al. (2019) conducted direct shear tests on soft soil treated with stone columns. The load-displacement response of the composite showed higher stiffness than soft clay. Cengiz et al. (2019) studied the behavior of granular columns under static and cyclic loading using a unit cell shear device. It was seen that the geosynthetic encasement of the columns led to a marked increase in the shear resistance of the unit cell under both loading conditions. Rezaei-Hosseinabadi et al. (2022) studied the response of sand treated with granular columns using direct shear tests. As per this study, apparent cohesion developed in the columns by geosynthetic encapsulation. Mohammad and Mir (2022) conducted shear testing on soil reinforced by OGCs. As per the study, the inclusion of granular columns increases the shear resistance of the composite. The positive contribution of the group action of columns was evident in this experimental program. Hosseinpour et al. (2022) conducted direct shear experimental testing to study the effect of the undrained shear strength of soil, the diameter of granular columns, and aggregate density on the stone column’s behavior. Installing granular columns has increased shear resistance substantially at the lower undrained shear strength of the surrounding soil. As per the study conducted by Zaini et al. (2023), the granular bottom ash column bound by the geotextile functions as a semi-rigid pile, increasing the cutting strength of the granular column composite. The tensile forces in the geotextile were highlighted as the reason for the rise in the critical shear strength. Jasim and Tonaroglu (2023) conducted slope stability analysis to study the response of embankments over the geogrid-EGC-reinforced ground. By this analysis, it was concluded that the failure mechanism of the embankment, which was deep-seated slope failure prior to reinforcement, was shifted to shallow slope failures with higher safety factors after reinforcing the foundation of the embankment with EGCs. Some of the recent numerical studies (Zhang et al. 2022; Ji et al. 2023) highlighted factors like vertical stress, replacement ratio, column diameters, spacing of columns, and the stiffness of the encasing material that affect the lateral shear-resisting capacity of EGCs.

Most of the previous studies reported are on the lateral load response of column-sand composites. Limited, extensive laboratory research is available on the lateral shear behavior of soft soils/wet clays treated with granular columns, mainly with lower values of area replacement ratio (Ar). The impact of critical factors like column infill characteristics/morphology and column configuration/group action on lateral shear response has not received adequate attention. It is imperative to quantify these effects to attain comprehension of the behavior of OGCs and EGCs. Therefore, this experimental study was undertaken with the following objectives:

-

1.

To investigate the lateral shear response of soft soil bed reinforced with granular columns with and without geosynthetic encasement.

-

2.

To study the effect of column infill morphology on the shear response of soil-column composites.

-

3.

To investigate the group action of the columns under lateral shear loading.

The present study uses the data obtained from large-scale direct shear tests to accomplish the objectives mentioned above. The study also provides insight into the types of failures seen in OGC and EGC.

2 Testing Methodology

2.1 Test Setup-Large-Scale Direct Shear Test

The equipment used in this study was a large-scale direct shear test apparatus with plan dimensions of 30 cm × 30 cm × 22 cm. The whole shear assembly, shown in Fig. 2, moves horizontally on smooth rollers. The shear box was made in two halves. The sample’s thickness was kept constant at 150 mm throughout all experiments. While the shear box’s top half was immobile, the lower half glided horizontally with the rest of the assembly.

2.2 Material Properties

2.2.1 Soil and Column Material

The soil used in the experimental tests was sourced from Srinagar, J&K, India (N 34° 05′ 24″, E 74° 45′ 44″). The physical properties of the soil determined from the tests performed in the laboratory are displayed in Table 1. Since this research focused on determining the lateral shear response of soft soils reinforced with columns, the bed material was chosen to be a cohesive soil with an undrained cohesion value of less than 12 kPa. Direct shear tests were conducted on samples at various water contents and unit weights based on the IS-light compaction curve to obtain the requisite cohesion. The required condition of shear strength requirements for the surrounding soil was achieved at a moisture content equal to 35% by the dry weight of soil and a wet unit weight of 18.09 ± 0.3 kN/m3. This experimental work considered the variability of the granular column fill material based on shape and angularity. Two fill materials are angular-crushed aggregate (CA) from the stone crusher plant and sub-round–smooth aggregates (RA) from the river. The properties of granular material are given in Table 1. The diameters of the granular columns used in the model were smaller than those in the field. So, it was necessary to lower the particle size by an adequate scale factor to approximate the actual behavior of granular columns. As recommended by Aslani et al. (2019), Nayak (1983), and Fattah et al. (2013), the ratio of column diameter to the maximum size of column infill material was chosen to be around 6, which scaled down the particle size by the proper factor. The chosen granular material’s particle distribution also complies with the standards of ASTM, which require that the largest particle size be smaller than 1/10 of the specimen’s width or 1/6 of its thickness (ASTM, D. 2011) when tested using a direct shear instrument. The particle distribution curves for granular materials and clay are shown in Fig. 3a.

2.2.2 Encasement

The nonwoven geotextile supplied by HUESKER Synthetic GmbH, shown in Fig. 3b, was used to encapsulate the columns.

The tensile strength of the geotextile, given in Table 1 (provided by the manufacturer) was determined using the wide-width tensile test following DIN EN ISO 10319 (2015).

2.3 Sample Preparation and Methodology

2.3.1 Soft Soil Bed Preparation

After collecting soil from the site, the sample was air-dried. Air-dried soil was sieved through a 2-mm sieve and appropriately mixed with the specific water content. After proper mixing, the wet soil sample was placed in sealed plastic bags for 24 hrs to achieve moisture equilibrium. The shear box was graduated along the height for sample preparation. All the tests were conducted in undrained conditions. In addition to using plain gripper plates at the top and bottom of the specimen, silicon grease was applied to seal the shear box gaps from water loss. The pre-weighed quantity of wet soil sample was placed in three layers. Each layer was kneaded by hand and then compacted with a hammer (2 kg) to the required density. Hallow steel tubes of 2-mm wall thickness were then pushed into the soil sample prepared. The customized plates with collar attachments ensure the vertical alignment of the steel tubes. A small-scale hand auger was used to remove soil inside the tubes. The tubes were pulled out in steps, followed by column construction. The column infill material required to construct each portion with an 80% relative density was weighed and poured into the space created by the tube. A chain of trials with different heights of pulviation and compaction efforts was conducted. It was found that granular material, when allowed to fall from 250-mm height followed by uniform compaction using a steel tamping rod of 1-kg weight, results in the desired density without lateral column material spread. The compactive effort of 74.7 kJ/m3 was used in all the tests for all configurations. Figure 4a shows the complete, stepwise construction of the model. In the case of encased granular columns (EGC), geosynthetic encasements were pushed into the cavity after the soil was discharged from the steel tubes. Then the column infill material was poured and compacted similarly as in the case of an ordinary column construction. The final plan view of the OGC and EGC reinforced soft soil for testing is shown in Fig. 4b respectively.

2.3.2 Testing Program

Experiments were performed on ordinary and encased columns to quantify the effect of the encapsulation. Three different types of column configurations were used to evaluate the impact of the installation pattern or group action of columns at a constant area replacement ratio (Ar). For Mohr failure envelope construction, the tests were done on three different normal stresses of 25 kPa, 50 kPa, and 75 kPa. According to the earlier study, to avoid discrepancies between prototype behavior and model response, the normal stress applied during such testing in the laboratory should be in the same range as on the prototype granular column (Mohapatra et al. 2016; Aslani et al. 2019). All experiments were stopped at a horizontal relative displacement of 60 mm. In each test, there was enough clearance of more than 60 mm to avoid the boundary effect. A detailed summary of the testing program is given in Table 2.

3 Test results and Discussions

The behavior of soil-column composites is examined in terms of increased shear strength with respect to that of unreinforced soil. The test results in this section are analyzed to understand the impact of pertinent factors like the encapsulation of columns, normal stress, column granular material characteristics, and group action of the columns on the improvement in shear strength and the shear strength parameters of the soil-column composite.

3.1 Effect of Geosynthetic Encapsulation

Figures 5 and 6 display the results of direct shear tests conducted at different levels of normal stress in the form of stress-displacement curves. On observing the curves, the partial replacement of soft soil with granular columns resulted in an enhanced stress-displacement response. Compared to the untreated soil sample, the maximum shear stress of the sample containing encased granular columns of crushed aggregate increased by 179%. Soil samples reinforced with encased granular columns (EGC) exhibit higher shear resistance than those reinforced with ordinary granular columns (OGC). The mobilization of higher shear stresses in the case of EGC could be due to the development of extra-resisting forces within the granular columns due to geosynthetic straining during shear. Also, it was seen that the stress-displacement graph of ordinary columns under the normal stress of 75 kPa almost coincides with the stress-displacement graph of encased columns under the normal stress of 25 kPa. Therefore, it can be inferred from this result that the encased columns show higher shear stress resistance even in low-confining surrounding soil conditions. The tensile forces developed in the geosynthetic encasement add extra confinement to the column, thus reducing the dependability of the granular column’s performance on the surrounding soil support. Therefore, encasing the granular columns can widen the application of this technique to soft soil/very soft soil.

On comparing the stress-displacement curves of samples with and without geosynthetic encasement, the soil-column composite with EGC experienced significant shear strain hardening at higher shear displacement levels, which are in good agreement with results reported in the literature Mohapatra et al. (2016) and Rezaei-Hosseinabadi et al. (2022). The column initially deriving its support from surrounding soil will behave as a semi-rigid pile now, thus leading to increased shear strength (Rezaei-Hosseinabadi et al. 2022).

From the results, the shear strength was found to be directly proportional to the normal stress applied, but the contribution of geotextile confinement was found to be inversely proportional to applied normal pressures. The contribution of the encasement in terms of percentage increase in the shear strength (Δτ) was calculated using Eq. 1.

where τEGC is the maximum shear stress of a specimen with EGC, τOGC is the maximum shear stress of a specimen with OGC

For example, for the specimens with four CA columns in a square configuration, the values of Δτ are 81%, 58%, and 53% at normal pressures of 25 kPa, 50 kPa, and 75 kPa, respectively. Therefore, the contribution of geotextile encapsulation was seen maximum at a lower normal stress of 25 kPa. A similar trend of results was reported by Mohapatra et al. (2016) in his study.

3.2 Effect of Granular Column Infill Characteristics

Tests were conducted on soft soil reinforced with granular columns of two different infills (CA-crushed aggregate and RA-river aggregate) with different morphology and friction angles to assess the impact of column infill characteristics on the shear behavior of treated soil. Comparing the plots from Figs. 5 and 6, in all cases, soft soil treated with OGCs and EGCs of crushed aggregate reflects greater shear strength than river aggregate columns. The reason for this response could be the angularity and roughness of the material, which cause more aggregate-to-aggregate friction. The experimental results are in good agreement with the observations of Siahaan et al. (2018). Siahaan et al. (2018) postulated that the particle angularity of the column particles appears to influence the mechanical behavior much more than the particle gradation. After the tests were completed, the surrounding soil was removed carefully to observe the mode of failure in the encased granular columns. The picture of the column post-shear test is shown in Fig. 7a. The post-shear visuals showed predominantly bending. The encasement deforms due to the lateral stress, thus interlocking the granular particles. As the morphology of the particles is different, the particle-geotextile interaction would be different. For EGC with crushed aggregate infill, there is efficient interaction in the form of friction and interlocking between geosynthetic sleeves and granular infill compared to river aggregate infill, where frictional resistance comes due to the rolling/sliding of aggregates. The pictorial representation of granular fill material and geotextile interaction is shown in Fig. 7b. There was a maximum of almost a threefold increase in the shear resistance of the composite with CA columns, while in the case of RA columns, a maximum of a twofold increase was observed. Therefore, it is evident that the mechanical behavior of granular columns, whether encased or non-encased, becomes highly dependent on the characteristics of the fill material.

3.3 Effect of Column Configuration

It can be inferred from stress-displacement curves that the four columns in a square configuration showed an enhanced shear response compared to a single column and three columns in a triangular configuration with the same area replacement ratio (Ar). This is because of the group action of granular columns. Granular columns and the intervening soft soil between columns work as a composite when OGCs or EGCs are used in a group. In the case of EGCs, the percentage increase in shear strength with an increase in the number of columns is more significant than that of OGCs, irrespective of the same Ar. The normalized strength ratio (\({\tau }_{c}/{\tau }_{s}\)) versus the number of columns relation is shown in Figs. 8 and 9. Where τc is the maximum shear stress of the soil-column composite and τs is the maximum shear stress of the soil. From Figs. 8 and 9, the beneficial impact of increasing the number of granular columns on shear strength is evident ((\({\tau }_{c}/{\tau }_{s}\)) > 1 and goes on increasing as the number of columns increases) in all curves. A similar trend in results was reported by Aslani et al. (2019) in his study. This behavior can be attributed to the higher confining pressure on the soil between columns in square and triangular layouts. As a result, the soil between stone columns mobilizes more shear strength than the soil around a single column. Another cause Aslani et al. (2019) highlighted was the increase in column lateral surface area brought about by changing from single-column arrangements to square and triangular layouts. The increase in lateral contact surface area of columns increases the contribution of columns towards lateral force resistance.

3.4 Improvement in the Shear Strength Parameters

The shear strength envelopes of the samples reinforced with OGC and EGC are shown in Figs. 10 and 11. The results are shown in the form of linear Mohr-Coulomb failure envelopes corresponding to maximum shear stress (τ) and applied normal stress (σ). The slope of the envelope is referred to as the coefficient of internal friction of the soil-column composite (tanϕ), and the vertical intercept of the linear envelope is referred to as the apparent cohesion of the soil-column composite/cohesion intercept (c). Figures illustrate that adding granular columns (OGC or EGC) to soft soil significantly increased the angle of internal friction of the composite (ϕ). This is because the higher stiffness of the granular column compared to the surrounding soil attracts a major portion of the applied normal stress. A substantial portion of the shear strength of the soil-column composite will be offered by granular columns, thus significantly contributing to the improvement in frictional resistance. Also, during soil-column composite testing, the granular column’s ability to drain radially creates semi-drained conditions, increasing the equivalent friction angle of the composite soil (Mohapatra et al. 2016). For OGC, the values of apparent cohesion are more or less the same as that of the cohesion intercept in the case of unreinforced soft soil (i.e., around 10–11 kPa). However, the encapsulation of the granular column by the geosynthetic sleeves increases the apparent cohesion of the composite. The values of the apparent cohesion increase from 11 to 22.4 kPa when EGCs are used to reinforce the soft soil. A similar trend of results was postulated by Mohapatra et al. (2016) and Rezaei-Hosseinabadi et al. (2022). Comparing the friction angles of OGC and EGC, the values are almost the same but greatly enhanced compared to unreinforced soft soil. The particle morphology influences the shear strength parameters of the soil-column composite. Higher shear strength parameters are seen for columns with angular particles as infill. The composite with CA columns has a maximum apparent cohesion of 22.4 kPa and a friction angle of 11°, whereas the composite with RA columns reflects lesser shear strength parameters. The angle of shearing resistance of the granular infill, which is influenced by particle morphology, impacts the performance of reinforced soft soil (Siahaan et al. 2018).

The effect of the number of columns (group action) is displayed in Fig. 12. Figure 12 illustrates the variation of Δϕ (Eq. 2) and Δ\({c}\) (Eq. 3) for different soil-column composites were as follows:

For the present study, a constant Ar value of 8.77% was provided in three different forms: a single column, a group of three columns, and a group of four columns with a diameter of 100 mm, 57.7 mm, and 50 mm, respectively. From Fig. 12, it is evident that, with an increase in column number, the angle of internal friction of soil reinforced with OGC increases with an insignificant improvement in the value of apparent cohesion. However, in the case of the EGC, as the number of columns increased from 1 to 4 under a fixed Ar, the angle of internal friction and the apparent cohesion of the composite increased. With an increase in the number of columns, the lateral surface area of the column also increases. This causes higher shear stress mobilization of granular column materials, thus leading to improved shear strength parameters (Aslani et al. 2019).

3.5 Comparison of Results of the Present Study with Previous Studies

A comparison of the change in shear strength parameters of different soil-column composites tested in our research with the previous key findings (Mohapatra et al. 2016; Rezaei-Hosseinabadi et al. 2022) available in the literature was made to validate the experimental findings of this study. As can be seen from Fig. 12, the trend of the results of this study is in good agreement with the trend reported by other researchers previously. For OGC, the values of apparent cohesion are the same as those of the cohesion intercept in the case of unreinforced soft soil. However, as shown in Fig. 12, the encapsulation of the granular column by the geosynthetic sleeves increased the apparent cohesion of the composite, which is well supported by prior studies. The quantitative variation in the comparison is due to the different material properties used in the above studies. However, from the quantitative comparison, it can be inferred that the increase in the apparent cohesion of the composite is directly proportional to the strength characteristics of the geosynthetic encasement. It is clear from the comparison that encasement with a higher strength modulus, as used in the study of Rezaei-Hosseinabadi et al. (2022), imparts maximum apparent cohesion to the composite. The variation of OGC and EGC’s friction angles is in close agreement with the previous studies. One of the critical conclusions of the present study was that, with constant Ar, both the shear parameters friction angle and cohesion intercept increased with an increase in the number of columns. The same trend of results was postulated in the previous studies. This overall increase in apparent cohesion and angle of internal friction with an increase in column number in the case of EGCs can be attributed to the increased geosynthetic shearing surface and the increase in the interlocking of the granular material with the geosynthetic surface (Rezaei-Hosseinabadi et al. 2022).

3.6 Modes of Failure of Granular Columns

The soil around the columns was carefully removed after the shear test was completed to observe the failure modes of the granular columns. On removing the soil, it was observed that the mode of failure of this reinforcement technique entirely changed due to the encasement of the column. The pictorial representation of the modes of failure is shown in Fig. 13. In the case of OGCs, complete horizontal shear along the shear plane was observed. However, in the case of the EGCs, the columns showed predominant bending without complete shear along the predefined shear plane. The geosynthetic encasing restricts the free movement of column aggregates at the shear surface. Therefore, the capacity of EGC to avoid complete shear failure of granular columns is crucial, thus averting total structural collapse. Recently, several researchers have become interested in using geosynthetic-encased granular columns to prevent the course of the slip surface and reduce the probability of failures like deep-seated failures in the case of embankments due to this intact behavior of EGC even at higher shear deformations (Jasim and Tonaroglu 2023; Dar and Shah 2021).

The ability of geosynthetic encasement to prevent the shear failure of granular columns can be important in the event of liquefaction, which may cause the foundation soil to endure substantial deformation. EGCs will continue to drain the extra pore pressure in these circumstances, allowing foundation soil to restore effective stresses swiftly (Mohapatra et al. 2016).

4 Conclusions

This experimental work aims to advance comprehension of the behavior of granular columns under lateral shear loading. The results of direct shear tests were analyzed to highlight the enhancement in lateral shear resistance of the soil-column composite by encapsulating the column with geotextile. The following conclusions are drawn from the observed results:

-

1.

The inclusion of granular columns with and without encasement resulted in higher shear-resisting capacity. Due to encasement, the normalized stress ratio increases from 1.8 to 2.8 for CA columns and from 1.68 to 2.3 for RA columns. Moreover, the contribution of geotextile encapsulation was significant at a lower normal stress of 25 kPa.

-

2.

For soil reinforced with ordinary granular columns, the friction angle increased from 2˚ to 11° while the apparent cohesion values remained almost unaffected. However, the geosynthetic encasement of the granular columns imparted an additional apparent cohesion to the composite. The apparent cohesion of the soil-column composite increased twofold due to geosynthetic encasement, while the friction angle remained the same as that of ordinary granular columns.

-

3.

For OGC and EGC, a group arrangement mobilizes higher shear resistance than a single column of the same area replacement ratio (Ar = 8.77% in this study). The friction angle and apparent cohesion of the sample with a group of four EGCs were calculated as 11° and 22.4 kPa, respectively, compared to 8° and 18.6 kPa for a sample with a single EGC of crushed aggregate (CA) infill. Therefore, with constant Ar, a group of smaller-diameter columns yields better results than a single column of a larger diameter.

-

4.

It was evident from the results that the morphological features of column infill have a considerable impact on the mechanical response of granular columns, whether the columns are encased or not. In encased columns, the shear strength of soil with crushed aggregate columns was almost 3-times that of unreinforced soil, while it was 2-times for soil with river aggregate columns. This may be attributed to the effective interaction between the crushed aggregate infill and the geosynthetic sleeve in the form of friction and interlocking.

-

5.

Ordinary granular columns exhibited a distinct horizontal shear failure along the predefined shear plane, while the encased granular columns demonstrated a bending-type deformation without an apparent shear failure plane. In this way, the integrity of the column remains intact to a great extent, even at large deformations for encased columns.

-

6.

The experimental results of the current study, when compared with the previous studies, showed good agreement regarding the effect of ordinary or encased columns on the shear strength properties of soft soil.

The scope of the present research is limited to the laboratory response of soil-column composites under static lateral shear loading. For researchers in the future, it is recommended to work on large-scale field testing for specific field applications like slope stability of embankments. The cyclic/dynamic response of the OGC and EGC reinforced soil with a focus on the mitigation of liquefaction is also recommended as a research gap for the future. Moreover, there is a dire need to use numerical and analytical approaches for better understanding and application of this ground improvement in complex geotechnical problems.

Data Availability

All the data was generated by experimental tests performed in the geotechnical laboratory of NIT Srinagar by the first author.

Abbreviations

- A r :

-

Area replacement ratio

- CA:

-

Crushed aggregate column material

- RA:

-

River aggregate column material

- OGC:

-

Ordinary granular column

- EGC:

-

Encased granular column

- γ max :

-

Maximum dry unit weight

- γ min :

-

Minimum dry unit weight

- γ 80 :

-

Dry unit weight at 80% relative density

- τ :

-

Maximum shear stress

- σ :

-

Normal stress

- ϕ :

-

Angle of internal friction

- c :

-

Cohesion intercept/apparent cohesion

References

Alexiew, D., Raithel, M.: Geotextile-encased columns. Embankments with special reference to consolidation and other physical methods, pp. 451–477. Butterworth-Heinemann, Oxford (2015)

Almeida, M.S., Hosseinpour, I., Riccio, M., Alexiew, D.: Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J. Geotech. Geoenviron. Eng. 141(3), 04014116 (2015). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001256

Almeida, M. S., Hosseinpour, I., Riccio, M.: Performance of a geosynthetic-encased column (GEC) in soft ground: Numerical and analytical studies. Geosynth. Int. 20(4), 252–262 (2013). https://doi.org/10.1680/gein.13.00015

Ambily, A. P., Gandhi, S. R.: Experimental and theoretical evaluation of stone column in soft clay. In Proc., Int. Conf. on Geosynthetics and Geoenvironmental Engineering (ICGGE-2004), Bombay. 201–206 (2004)

Aslani, M., Nazariafshar, J., Ganjian, N.: Experimental study on shear strength of cohesive soils reinforced with stone columns. Geotech. Geol. Eng. 37(3), 2165–2188 (2019). https://doi.org/10.1007/s10706-018-0752-z

ASTM D3080/D3080M: Standard test method for direct shear test of soils under consolidated drained conditions. Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA. 3(9) (2011)

Bruce, D. A., Geosystems, E. C. O.: An introduction to the deep soil mixing methods as used in geotechnical applications (No. FHWA-RD-99–138). United States. Federal Highway Administration. Office of Infrastructure Research and Development. (2000). https://rosap.ntl.bts.gov/view/dot/40947

Castro, J., Sagaseta, C.: Deformation and consolidation around encased stone columns. Geotext. Geomembr. 29(3), 268–276 (2011). https://doi.org/10.1016/j.geotexmem.2010.12.001

Cengiz, C., Guler, E.: Seismic behavior of geosynthetic encased columns and ordinary stone columns. Geotext. Geomembr. 46(1), 40–51 (2018). https://doi.org/10.1016/j.geotexmem.2017.10.001

Cengiz, C., Kilic, I.E., Guler, E.: On the shear failure mode of granular column embedded unit cells subjected to static and cyclic shear loads. Geotext. Geomembr. 47(2), 193–202 (2019). https://doi.org/10.1016/j.geotexmem.2018.12.011

Chu, J., Bo, M.W., Choa, V.: Improvement of ultra-soft soil using prefabricated vertical drains. Geotext. Geomembr. 24(6), 339–348 (2006). https://doi.org/10.1016/j.geotexmem.2006.04.004

Dar, L.A., Shah, M.Y.: Deep-seated slope stability analysis and development of simplistic FOS evaluation models for stone column-supported embankments. Transp. Infrastruct. Geotech. 8, 203–227 (2021). https://doi.org/10.1007/s40515-020-00134-7

Deb, K., Shiyamalaa, S.: Effect of clogging on rate of consolidation of stone column–improved ground by considering particle migration. Int. J. Geomech. 16(1), 04015017 (2016). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000492

DIN EN ISO 10319, 2015–09: Geosynthetic-wide width tensile test. (2015). https://doi.org/10.31030/2273622

Fattah, M.Y., Shlash, K.T., Al-Waily, M.J.M.: Stress concentration ratio of model stone columns in soft clays. Geotech. Test. J. 34(1), 1–11 (2011)

Fattah, M.Y., Shlash, K.T., Al-Waily, M.J.: Experimental evaluation of stress concentration ratio of model stone columns strengthened by additives. Int. J. Phys. Modell. Geotech. 13(3), 79–98 (2013). https://doi.org/10.1680/ijpmg.12.00006

Fattah, M.Y., Al-Neami, M.A., Al-Suhaily, A.S.: Estimation of bearing capacity of floating group of stone columns. Eng. Sci. Technol. Int. J. 20(3), 1166–1172 (2017). https://doi.org/10.1016/j.jestch.2017.03.005

Frikha, W., Taunekti, F., Kaffel, W., Bouassida, M.: Experimental study for the mechanical characterization of Tunis soft soil reinforced by a group of sand column. Soils Found. 65, 181–191 (2015). https://doi.org/10.1016/j.sandf.2014.12.014

Gneil, J., Bouazza, A.: Construction of geogrid encased stone columns—a new proposal based on laboratory testing. Geotext. Geomembr. 28, 108–118 (2010). https://doi.org/10.1016/j.geotexmem.2009.12.012

Gniel, J., Bouazza, A.: Improvement of soft soils using geogrid encased stone columns. Geotext. Geomembr. 27(3), 167–175 (2009). https://doi.org/10.1016/j.geotexmem.2008.11.001

Hosseinpour, I., Ghorbani, A., Zarei, J., Mohapatra, S.R.: Experimental study on the behaviour of granular column-treated soft clay under shear loading. Geomech. Geoeng. 18(2), 121–132 (2022). https://doi.org/10.1080/17486025.2021.2015977

Hughes, J.M.O., Withers, N.J.: Reinforcing of soft cohesive soils with stone columns. Ground Eng. 7, 42–49 (1974)

Jasim, O.H., Tonaroglu, M.: Using geogrid encased granular columns for embankment’s slope protection: 3D-finite difference analysis. Appl. Sci. 13(4), 2448 (2023). https://doi.org/10.3390/app13042448

Jayarajan, J., Karpurapu, R.: Settlement analysis of geosynthetic encased granular column treated soft clay deposits. Int. J. Geotech. Eng. 14, 473–489 (2020). https://doi.org/10.1080/19386362.2019.1698218

Ji, M., Wang, J., Zheng, J. J., Zheng, Y.: Contribution of geosynthetic on the shear strength of geosynthetic encased stone columns. Geosynth. Int. (2023). https://doi.org/10.1680/jgein.22.00384

Kempfert, H. G.: Ground improvement methods with special emphasis on column-type techniques. In Proc., Int. Workshop on Geotechnics of Soft Soils-Theory and Practice. 101–112 (2003)

Malarvizhi, S.N., Ilamparuthi, K.: Comparative study on the behavior of encased stone column and conventional stone column. Soils Found. 47, 873–885 (2007). https://doi.org/10.3208/sandf.47.873

Miranda, M., Da Costa, A.: Laboratory analysis of encased stone columns. Geotext. Geomembr. 44(3), 269–277 (2016). https://doi.org/10.1016/j.geotexmem.2015.12.001

Mohammad, S., Mir, B.A.: Strength behaviour of granular column-reinforced soft soil subjected to lateral shear loading. Indian Geotech. J. 52(6), 1450–1463 (2022). https://doi.org/10.1007/s40098-022-00652-w

Mohapatra, S.R., Rajagopal, K., Sharma, J.: Direct shear test on geosynthetic-encased granular columns. Geotext. Geomembr. 44, 396–405 (2016). https://doi.org/10.1016/j.geotexmem.2016.01.002

Murugesan, S., Rajagopal, K.: Geosynthetic-encased stone columns: Numerical evaluation. Geotext. Geomembr. 24, 349–358 (2006). https://doi.org/10.1016/j.geotexmem.2006.05.001

Murugesan, S., Rajagopal, K.: Model tests on geosynthetic-encased stone columns. Geosynth. Int. 14(6), 346–354 (2007). https://doi.org/10.1680/gein.2007.14.6.346

Murugesan, S., Rajagopal, K.: Shear load tests on stone columns with and without geosynthetic encasement. Geotech. Test. J. 32(1), 76–85 (2009)

Murugesan, S., Rajagopal, K.: Studies on the behavior of single and group of geosynthetic encased stone column. J. Geotech. Geo-Environ. Eng. 136, 129–139 (2010). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000187

Najjar, S.S., Sadek, S., Maakaroun, T.: Effect of sand columns on the undrained load response of soft clays. J. Geotech. Geo-Environ. Eng. 136, 1263–1277 (2010). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000328

Nayak, N. V.: Recent advances in ground improvements by stone column. In Proc., Indian geotechnical conference. Madras India IGC-83. 1, V-19 (1983)

Pal, S., Deb, K.: Post earthquake reconsolidation settlement of stone column-treated liquefiable sand. Int. J. Geomech. 20(10), 04020183 (2020). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001818

Pal, S., Deb, K.: Filtration performance of geotextile encasement to minimize the clogging of stone column during soil liquefaction. Geotext. Geomembr. 49(3), 771–788 (2021). https://doi.org/10.1016/j.geotexmem.2020.12.008

Rahmani, F., Hosseini, S.M., Khezri, A., Maleki, M.: Effect of grid-form deep soil mixing on the liquefaction-induced foundation settlement, using numerical approach. Arab. J. Geosci. 15(12), 1112 (2022). https://doi.org/10.1007/s12517-022-10340-x

Raithel, M., Kempfert, H. G.: Calculation model for dam foundations with geotextile coated sand columns. In Proc., Int. Conf. on Geotechnical and Geological Engineering, Melbourne. 347–352 (2000)

Raithel, M., Kirchner, A.: Calculation techniques and dimensioning of encased columns-design and state of the art. In: Li, G., Chen, Y., Tang, X. (eds) Geosynth. Civil Environ. Eng, pp. 718–723. Springer, Berlin, Heidelberg (2008). https://doi.org/10.1007/978-3-540-69313-0_131

Raithel, M., Kempfert, H. G., Kirchner, A.: Geotextile-encased columns (GEC) for foundation of a dike on very soft soils. In Proc., 7th Int. Conf. on Geosynthetics, Nice. 1025–1028 (2002)

Rezaei-Hosseinabadi, M. J., Bayat, M., Nadi, B., Rahimi, A.: Utilisation of steel slag as a granular column to enhance the lateral load capacity of soil. Geomech. Geoeng. 17(5),1406–1416 (2022). https://doi.org/10.1080/17486025.2021.1940315

Sakleshpur, V.A., Prezzi, M., Salgado, R.: Ground engineering using prefabricated vertical drains: a review. Geotech. Eng. J. SEAGS AGSSEA 49(1), 45–64 (2018)

Siahaan, F., Indraratna, B., Ngo, N., Rujikiatkamjorn, C., Heitor, A.: Influence of particle gradation and shape on the performance of stone columns in soft clay. Geotech. Test. J. 41(6), 1–16 (2018). https://doi.org/10.1520/GTJ20160234

Zaini, M. S. I., Hasan, M., Jusoh, W. N. B. W.: Utilization of bottom ash waste as a granular column to enhance the lateral load capacity of soft kaolin clay soil. Environ. Sci. Pollut. Res. (2023) https://doi.org/10.1007/s11356-023-25966-x

Zhang, L., Peng, B., Xu, Z., Zhou, S.: Shear performance of geosynthetic-encased stone column based on 3D-DEM simulation. Comput. Geotech. 151, 104952 (2022). https://doi.org/10.1016/j.compgeo.2022.104952

Acknowledgements

The authors express the heartfelt gratitude towards the authorities of NIT Srinagar, notably the Department of Civil Engineering, for helping us in the execution of this work at the institute.

Author information

Authors and Affiliations

Contributions

First author: testing, data analysis, and drafting of paper. Second author: supervising, reviewing, and editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammad, S., Mir, B.A. Comparative Performance Evaluation of Ordinary and Encased Granular Columns Subjected to Lateral Shear. Transp. Infrastruct. Geotech. 11, 956–977 (2024). https://doi.org/10.1007/s40515-023-00310-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-023-00310-5