Abstract

Granular columns are commonly used to support flexible structures over soft clay soils. The installation of such columns increases both the strength and stiffness of the ground. However, constructing these columns in clay soils having low cohesive strength of about 15 kPa is a challenge due to inadequate confinement. The columns may be encapsulated in geosynthetic tubes to enhance their constructability, strength and drainage properties. The geosynthetic encasement is also known to improve their performance under shear loading. This paper reviews the application of geosynthetic-encased granular columns for treatment of soft grounds. The design of these systems under vertical loads by two different methods is described in this paper. The performance of geosynthetic-encased granular columns under shear loads and the influence of geosynthetic encasement on the factor of safety of embankments supported on soft clay soils is discussed. The use of geosynthetic encasement of granular columns is seen to change the deep-seated foundation failure mechanism to toe failure mechanism.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

India has a long coast line of almost 6000 km. Most of the coastal regions are covered with soft and weak clay deposits. The depth of these deposits varies between 10 and 30 m, IRC- 113 [1]. The need for utilization of these weak soil deposits along the coastal regions for construction activities poses various geotechnical challenges due to their low bearing strength coupled with high compressibility. Various ground improvement techniques such as preloading using PVD’s, granular columns, lime and cement columns, grouting and vacuum preloading can be used to improve the engineering behaviour of these soft deposits. Among all these ground improvement techniques, granular column technique is a simple and economical method that has been adopted for several decades along the coastal regions of India and other countries. The granular column technique in infrastructure projects has become popular as majority of these projects are time sensitive. Hence, a technique which accounts for considerable savings in the cost and the time required for installation over other ground improvement solutions is a target for design engineers. Apart from all other techniques mentioned above, granular columns are chosen as they offer two important functions unlike other methods. They act as strong and stiff load bearing members and also help in dissipating the excess pore pressures generated.

Need for Geosynthetic-Encased Granular Columns

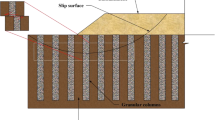

Ordinary granular columns (OGC) have been used in weak deposits mainly to improve the bearing capacity, to reduce the total and differential settlements, to increase the stability of embankments and to improve the resistance to liquefaction in loose sands. Nevertheless, the granular columns have some limitations. The formation of granular columns is a difficult task due to inadequate confinement when they are installed in soft clays having undrained cohesive strength less than about 15 kPa. Besides this, the aggregate particles may get contaminated by the soft clay hindering the drainage function of granular columns. The frictional strength of the aggregates may also reduce due to the intrusion of clay soil. The limitations listed above were reported from the field studies conducted by McKenna et al. [2], Chummar [3], etc., and can be generally avoided by encapsulating the granular column with appropriate geosynthetics. A typical geosynthetic-encased granular column (EGC) is shown in Fig. 1.

Geosynthetic-encased granular column—schematic, Murugesan and Rajagopal [7]

The surface load on the ground generates bulging in the granular column. This bulging provokes a counter pressure from the surrounding soft clay. The soft clay passively resists the bulging of granular column if it has sufficient shear strength. If the soil does not have adequate strength, the support can be offered by encapsulating the granular column with a geosynthetic tube. This is the key difference between OGC and EGC.

Studies on EGC’s were initiated by Van Impe and Silence [4]. Subsequently, other researchers Raithel and Kempfert [5], Malarvizhi and Ilamparuthi [6], Murugesan and Rajagopal [7] and several other researchers [8,9,10,11,12,13,14,15,16] have worked on the analytical, numerical, experimental and field studies on encased granular columns. A detailed literature review on the mechanism and the factors influencing the behaviour of EGC’s in soft clays is reported by Jayapal and Rajagopal [17]. Nevertheless, research work on the practical design methodologies for EGC’s in soft clays is limited. This manuscript discusses the design of encased granular columns in two parts: first one by Raithel and Kempfert [5] method which is popular and accepted by the German design guidelines EBGEO [18] and the second by modified IS code method based on findings from Murugesan and Rajagopal [7].

Part A: Design Procedure by Raithel and Kempfert [5]

The recently published German design guidelines are based on the work of Raithel and Kempfert [5]. The design procedure is based on unit cell approach with the contribution of the geosynthetic encasement. The fundamental assumptions involved are listed below followed by a brief description of the method in simple steps. Detailed description of the procedure and the method for arriving at the settlement improvement factor can be found in Raithel and Kempfert [5], EBGEO [18] and Jayapal and Rajagopal [15].

Assumptions in Raithel and Kempfert [5] are:

-

The soft clay is in at-rest earth pressure condition before the application of loads.

-

The granular column rests on a competent stratum.

-

The settlements on the top of the granular column and the soft soil are the same.

-

The granular column is incompressible.

-

The granular column is in active earth pressure state.

-

The applied additional stress does not decrease with depth as the plan size of the loaded area is much greater than the depth of soft soil deposit.

-

The design procedure is based on drained condition (long term behaviour).

Unit cell representation of granular column encased with geosynthetic by Raithel and Kempfert [5] is shown in Fig. 2.

Unit cell model of granular column encased with geosynthetics [5]

Step 1: The radial stresses generated in the EGC (σr,c) and the soft soil (σr,s) are calculated as,

where \(\sigma_{zo,c} =\) overburden stress of the granular column; \(\sigma_{{zo,{\text{s}}}} =\) overburden stress of the soft clay deposit; \(\Delta \sigma_{{\text{c}}} = \) additional vertical stress in the granular column; \(\Delta \sigma_{{\text{s}}} =\) additional vertical stress in the soft clay soil; \(K_{{o,{\text{s}}}}\) = at-rest earth pressure co-efficient in the soft clay soil; \(K_{{\text{a,c}}} = {\text{active }}\,{\text{earth }}\,{\text{pressure }}\,{\text{coefficient }}\,{\text{in }}\,{\text{the }}\,{\text{granular }}\,{\text{column}}\).

Step 2: Computation of the radial stress difference between the EGC and soft clay soil,

where σr,g is the radial stress due to geosynthetic and Tg is the hoop tensile force in the geosynthetic encasement. The change in the radius of the column, Δrc is,

where \(\Delta r_{{\text{g}}}\) is the increase in radius of the geosynthetic encasement, rg and rc are the radii of the geosynthetic encasement and granular column.

\(\sigma_{{\text{r,g}}}\) is the radial stress on the geosynthetic encasement equivalent to the hoop tension force, and J is the tensile modulus of the geosynthetic encasement.

Step 3: Calculation of the radial displacement of the EGC and settlement of the soft soil,

\(E^{*} \,{\text{ and}}\, E_{{\text{s}}}\) are the modulus of the soft clay and composite of granular column and virgin soft clay.

Step 4: Calculation of the settlement of the EGC (Scl) and the soft soil (Ssl).

Step 5: Equate the settlement of the EGC and the soft clay soil to obtain the additional vertical stress on the soil.

\(\vartheta_{{\text{s}}}\) is the Poisson’s ratio of the soft clay.

Step 6: Evaluate the settlement improvement factor (SIF)

The design of EGC by [5] described in the above steps is used to estimate the settlement improvement factor (SIF).

The term area replacement ratio (as) is an indication of the volume percentage by which the granular material is used to replace the soft soil within a single unit cell. The same is computed using the equation suggested by Balaam and Booker [19] for different installation patterns, namely triangle, square and hexagon.

where D and S are the diameter and c/c spacing of the granular columns. The constant C is 0.907, 0.785 and 0.592 to account for the shape of the three unit cell patterns, viz. triangular, square and hexagonal, respectively. The three different plan arrangements are shown in Fig. 3.

Different plan arrangements of granular column—Balaam and Booker [19]

Methodology and Evaluation of Settlement Improvement Factor (SIF):

The design of a real-time soft clay improvement using ordinary and geosynthetic-encased granular columns was worked out based on the input values suggested in [18]. Equations (1)–(13) were implemented in an EXCEL spread sheet program. The settlement improvement factor (SIF) which is defined as the ratio of the settlement of soft ground with and without granular columns was computed for various ranges of influencing parameters based on a trial and error procedure. The problems due to bearing failure of granular columns is rarely accounted. Hence, this procedure focuses on the settlement behaviour which is often the main limiting criteria in practice. The final aim of this study is to develop a comprehensive design chart for encased granular columns arranged in various patterns. In order to achieve the aim, comprehensive parametric studies were conducted based on a real time field problem described below to understand the influence of various parameters on SIF.

Problem Statement

A normally consolidated soft clay deposit of 10 m depth with ground water level at the ground surface is proposed to be improved with ordinary and encased granular columns. The soil properties are assumed as per those given in [18]. The input data corresponding to the soft clay, granular column, embankment and geosynthetic encasement are shown in Table 1. The granular columns were arranged in triangular pattern. The hand calculations of the problem statement can be seen in [15].

Parametric Evaluation

The parameters varied include diameter, spacing and friction angle of the granular column followed by constrained modulus, at-rest earth pressure, thickness of the soft clay deposit, height of the embankment and the tensile modulus (J) of the geosynthetic encasement. The values listed in Table 1 correspond to the baseline case, and the individual parameters are varied on one factor at a time basis. The performance of OGC was investigated by assigning zero (0) value to the tensile modulus of the geosynthetic (J). The pattern of arrangement of granular columns is indicated by the markers in all the figures for granular columns with and without encasement. Dotted lines and continuous lines are used to indicate the response of OGC’s and EGC’s as indicated in the legends.

Diameter of the Granular Column

The variation of SIF with granular column diameters of 0.6 m, 0.75 m and 1 m is shown in Fig. 4. The S/D ratio for all these analyses is 2.50. A decrease in SIF is observed with increase in the diameter of the encased granular columns (EGCs) for all the plan patterns, while the same for ordinary granular columns (OGCs) had remained nearly constant. The reason for the decrease of SIF for the EGCs is the development of lesser hoop tension forces for larger diameters of encased columns at the same axial strains. The triangular pattern gives the best performance due to its larger area replacement ratio (as) for the same S/D ratio. The constant value of SIF with OGCs shows that the area replacement ratio plays an important role for the OGCs and not the diameter of columns. The SIF for the EGCs is higher compared to that of OGCs due to the additional contribution of geosynthetic encasement.

Friction Angle of Granular Column (ϕ c′)

The settlement behaviour of granular columns is also influenced by the properties of the infill materials used to form the granular column. In the case of EGC’s, the guidelines in [18] recommend granular material having friction angles greater than 30°. As presented in Fig. 5, the friction angle of the infill material was varied from 34° to 42° with an increment of 2° to investigate its influence on the SIF. The diameter of columns was assumed to be 600 mm, and S/D ratio was 2.50 for these analyses. Larger SIF’s are observed for granular columns with and without geosynthetic encasement as the friction angle is higher. The triangular pattern showed the highest performance when compared to other plan arrangements. The OGC treatment was not much affected by the arrangement pattern of columns, while the EGC treatment was found to be affected by the plan arrangement. On an average, the improvement in SIF is 2.4 times higher for EGC’s when compared to OGC’s. The improvement for EGCs varied exponentially with the friction angle due to larger increase in confinement at higher friction angles.

Spacing-to-Diameter Ratio (S/D)

The variation of SIF with S/D ratio is shown in Fig. 6 with constant column diameter of 600 mm. Beyond 3D spacing, the group effect of granular columns is found to reduce significantly. At very large spacings, the columns tend to behave as isolated columns due to lack of adequate confinement from soil. The studies conducted by [20] revealed that the optimum spacing for OGC’s ranges between 2 and 3 times the diameter. In the present analysis, the variation is extended up to S/D of 4 to assess the performance of EGC’s over OGC’s. The study reveals that beyond S/D ratio of 2.5, the SIF for OGC’s remained nearly constant irrespective of the plan pattern. In the case of EGC treatment, considerable variation in SIF is seen until a larger spacing-to-diameter ratio of 3.5. This shows that the EGC treatment leads to lesser area replacement ratio (as), i.e. they enable large spacings between the columns. For a given diameter and installation pattern, the (as) value reduces by 50% upon increasing the S/D ratio from 2.5 to 3.5. The results from Fig. 6 also reveal that the influence of plan arrangement is significant only with closer spacings and sufficient lateral support from the soft clay soil. The geosynthetic encapsulation can be used for substantially improving the performance of the foundation system with reduced use of stone aggregates.

Depth of Soft Deposit

Deep deposits of soft clays of about 30 m are observed in the coastal areas of Cochin [1]. Figure 7 presents the variation of SIF with depth of soft clays ranging between 10 and 30 m. The diameter of columns was 600 mm, and S/D was 2.5 for these analyses with different depths of soil. Irrespective of the plan arrangement of granular columns, a gradual increase in SIF is observed with depth for both types of treatments. However, the level of increase in the case of OGC is found to be minimal. The recommendations of [5] are strictly for columns which are resting on hard strata and are not applicable for floating columns. The design considerations by [5] did not take into account the length-to-diameter (L/D) ratio which is one of the important factors which influences the behaviour of granular columns.

Constrained Modulus (D s) of the Soft Clay

According to [18], the soft clays having constrained modulus in the range of 500–3000 kPa are ideal candidates for EGC treatment as they do not possess adequate strength to confine the granular column. Figure 8 displays the variation of SIF values with constrained or (oedometer) modulus. The constrained modulus is obtained as the inverse of the coefficient of volume compressibility (mv). The constrained modulus is related to the cohesive strength of the clay soil. As shown in the figure, the SIF values decrease with increasing constrained modulus. The reason for this is that the increase in constrained modulus refers to stronger soils which do not require as much ground improvement compared to that in softer soils.

At-Rest Earth Pressure Coefficient (K o)

The variation of SIF with at-rest earth pressure coefficient Ko of the foundation soil is shown in Fig. 9 for both ordinary and encased granular columns and different installation patterns. These Ko values refer to those expected in typical normally consolidated (NC) clays [21]. With increase in Ko, the SIF value increases for both OGC’s and EGC’s. The increase is more noticeable for EGC’s compared to the OGC’s. This is because of higher confining pressures exerted on the granular columns due to higher Ko values. The influence of increasing confining pressures is more apparent on the EGCs than on the OGCs.

Height of Embankment (H)

The embankment heights were varied between 2 and 6 m in the present analyses. The variation of the SIF with the height of the embankment fill for different plan arrangements with regard to OGC’s and EGC’s is displayed in Fig. 10. It can be observed that the SIF’s remain nearly the same at all the heights. The influence of installation pattern is clearly seen only in the case of EGC unlike OGC where there is not much of influence. The higher values of SIF reported for EGC’s reveal the efficacy of improvement offered by granular columns with encasement in soft deposits when compared to OGC’s.

Modulus of the Geosynthetic Encasement (J)

With continuous increase in the tensile modulus of the geosynthetic encasement, the SIF was found to increase linearly (Fig. 11). This result clearly shows the influence of geosynthetic modulus (J) on the performance of the EGC’s. The higher the (J) value, the higher the level of confinement offered to the granular aggregates and consequently the higher the SIF. The secant modulus values ranging between 1500 and 6500 kN/m are usually adopted in the field practices with 5–10% permissible strains [22]. Further, it can be seen from Fig. 11 that the effect of installation pattern with respect to SIF is noticeable only for (J) values greater than 3500 kN/m. When compared to other parameters discussed above, the secant modulus of the geosynthetic encasement is the key parameter which strongly influences the SIF.

Design Chart for Geosynthetic-Encased Granular Column

The design chart presented in Fig. 12 shows the relation between the SIF and the area ratio for different plan arrangements pertaining to 750-mm-diameter granular columns. The particular markers used are as relevant to the three different plan patterns, viz. triangular, square and hexagonal. The analyses were performed with spacing ratios (S/D) ranging between 2 and 4. The friction angle of the granular aggregate was varied between 35° and 45°.The term “area ratio” is the inverse of area replacement ratio \(\left( {a_{{\text{s}}} } \right)\) [23]. This terminology was used to compare the present results with previously published design charts by [23]. It can be observed from Fig. 12 that the present results are in good agreement with the results reported by [23] for the case of ordinary granular columns (OGC). In Fig. 12, the trends of the settlement improvement factors (SIF) computed for EGC’s are similar to that of OGC’s but with higher values, which adds confidence to the results obtained.

The design charts in Fig. 12 are quite comprehensive when compared to the ones published by [24]. The SIF can be quickly obtained for a given plan arrangement, diameter, c/c spacing, friction angle and the secant modulus of the geosynthetic encasement for both ordinary and encased granular columns.

Part B: Design of EGC’s Using Modified IS 15284 Part I [25]

The design method for EGC’s by Raithel and Kempfert [5] involves in several parameters and could be cumbersome as a trial and error procedure is involved. The procedure described in this section is a straightforward method to calculate the SIF’s by modifying the Indian Standard Code IS 15284 [25] for the design of ordinary granular columns.

Estimation of the Load-Carrying Capacity of Granular Columns

The load-carrying capacity of ordinary granular column-treated ground to support flexible structures (e.g. oil storage tanks, embankments) may be obtained by summing up the contribution of the following as given in IS 15284 [25]:

-

1.

Capacity of the granular column resulting from the passive resistance offered by the surrounding soft clay against its bulging under axial load.

-

2.

Capacity of the granular column resulting from increase in resistance offered by the surcharge acting on the surrounding soil.

-

3.

Bearing support provided by the intervening soil between the columns.

Suggested Modification

Murugesan and Rajagopal [8] have used the following equation proposed by Henkel and Gilbert [26] to estimate the increase in the additional confining pressure (\(\Delta \sigma_{3}\)) in the granular columns in terms of the geosynthetic tensile modulus (J), diameter of the column (D) and the allowable axial strain (\(\varepsilon_{{\text{a}}}\)),

This additional confining pressure offered by the geosynthetic encasement can be added to the confining pressure offered by the surrounding soil as discussed in [25] to extend the design procedure of OGC to EGC.

Parametric Evaluation

A wide variety of parameters influencing the behaviour of granular columns were varied to understand the response of OGC and EGC in soft clay soils. The parameters varied are diameter of granular column, friction angle of the aggregates, plan arrangement, c/c spacing, undrained shear strength of soft clay, tensile modulus of the geosynthetic encasement. The equations provided in [25] along with the suggested modification Eq. (15) and Ref. [8] were implemented in an EXCEL spread sheet program to evaluate the settlement response of granular columns with and without ground improvement to obtain the SIF’s. The aim of this parametric evaluation was to develop a design chart for the use of EGC treatment of soft clays.

It is to be noted that among various methods reported in the literature pertaining to the design of ordinary granular columns, the method by [23] is the most popular and widely adopted in various field projects around the world. The comparison in Fig. 13 shows the SIF’s for two different diameters, namely 600 mm and 1500 mm which may be lower and upper limits of the normal range of granular column diameters adopted in the field. The tensile modulus values of the geosynthetic encasement were varied between 50 and 5000 kN/m. Similar to the method discussed in [5], the friction angles were deliberately chosen as 35° and 45° to compare the present results with those in [23]. When a lower degree of geosynthetic confinement was offered to the granular columns, say (J = 50 kN/m), the EGC’s tend to behave like ordinary granular columns with low SIF as depicted in Fig. 13a. However, with increase in degree of confinement (i.e. for J = 500 and 5000 kN/m) and with better quality infill material (ϕ = 45°) the EGC-treated system showed remarkable performance indicating higher SIF’s (Fig. 13b, c). The design chart shown in Fig. 13a also indicates a better performance with increase in diameter for EGC’s with low confinement similar to the concept of OGC’s. In spite of higher degree of confinements (J = 500 and 5000 kN/m) offered by the geosynthetic encasements, the SIF values for 1.5-m-diameter granular column tend to be lower due to the reduced hoop confinement in larger diameter granular columns. This is again in line with the well-established concept as evident from Eq. (15).

Comparison of Predictions with Field Data

In order to verify the reliability of the present results, the results from EBGEO and modified IS code methods are compared with comprehensive field and laboratory test data compiled by Raithel et al. [24] for both OGC’s and EGC’s as shown in Fig. 14. The results from the modified IS code method were obtained with 2% axial compression in these comparisons.

Comparison of the present settlement improvement factors with that of Raithel et al. [24] for ordinary and geosynthetic-encased granular columns (J = 1500 kN/m and 2500 kN/m)

The comparisons were made with two geosynthetic modulus values of 1500 kN/m and 2500 kN/m and three area replacement ratios of 10%, 15% and 20% and triangular installation pattern. These two modulus values are averages of the two ranges shown in the figure. It is interesting to note that the comparison with reported data is excellent at lower area replacement ratios of 10% and 15%. Typically, the area replacement ratio does not exceed beyond 15% for the EGCs, especially for high-strength geosynthetics as illustrated in Fig. 14. The difference between the predictions and the reported data is higher for 20% area replacement ratio for both EBGEO and modified IS code methods.

The advantage with the modified IS code method is its simplicity and use of lesser number of parameters in the calculations. It is interesting that the predictions by the simple IS code method compare with the more rigorous EBGEO method and field data.

PART-C: Granular Columns Subjected to Vertical and Shear Loads

The granular columns installed near the toe of embankments may be subjected to both vertical and shear loads due to embankment loading and lateral deformations in the foundation soil as illustrated in Fig. 15. The columns near the mid-section of the embankment are subjected to predominantly compressive loading. The strength of granular columns subjected to shear loading was studied by Mohapatra et al. [27] through large-scale direct shear tests. They have reported that the geosynthetic encasement increases the shear strength of the columns and the integrity of the encased columns was found to be preserved even at large lateral deformations.

The behaviour of granular columns subjected to combined vertical and shear loading under an embankment was investigated through three-dimensional numerical analyses. The influence of geosynthetic encasement on the response of granular columns was studied through the factor of safety analysis of the embankments supported on granular-column-treated foundation soil. All the analyses were performed using FLAC3D program which is based on finite difference method. This program has capability to capture the nonlinear behaviour of soils, incremental geotechnical constructions and the interaction between different materials like geosynthetic and granular material.

An embankment of height 5 m with side slope of 26.6° (2H:1 V) resting on 10-m-thick soft clay layer was considered for all the analyses. The side slope of the embankment was kept low to promote deep seated failure to bring out the contribution of granular column treatment of the soft foundation soil. The crest width and base of the embankment were fixed as 20 m and 40 m, respectively (Fig. 16). Only half section of the embankment with single row of granular columns was considered for numerical analyses in the present study as illustrated in Fig. 17. All the nodes on the vertical boundaries are prescribed with zero displacement in the normal direction to simulate smooth rigid vertical boundaries. The nodes on the bottom boundary were fixed in all directions to represent rough rigid boundary.

The single row of granular columns represents the square arrangement of granular columns in the field. The centre-to-centre spacing of the granular columns varies between 2 and 3 times the diameter of the column. The influence of the area replacement ratio (as) was studied by performing the analyses with different column diameters of 0.8 m, 1.0 m, 1.2 m and 1.4 m while keeping the centre-to-centre spacing of columns constant at 2.5 m. These diameters correspond to area replacement ratios of 8.04%, 12.56%, 18.09% and 24.62%, respectively.

The vertical boundary beyond the toe was fixed at twice the depth of soft clay layer such that the most critical slip surface is contained within the analysis domain. The generated mesh for the numerical analyses is shown in Fig. 17. The perspective view of the mesh is shown in Fig. 17a, and the plan view is shown in Fig. 17b. The generated mesh was chosen after several trials with finer meshes until the results did not change any further. Very fine meshing was provided in the regions with large shear strains, e.g. near the toe, while coarser mesh was provided at the mid-section where the strains are predominantly compressive normal strains. The water table was fixed at the ground level to simulate soft clay conditions.

The granular columns were generated using cylindrical-shaped mesh, and the soft soil was generated using radially graded mesh. The geosynthetic-soil interface parameters were calculated based on the size of the grid around the interface and the modulus of the soil, Itasca Consulting Group, Inc. [28] and Mohapatra and Rajagopal [29]. The initial values of normal and shear stiffnesses (kn and ks) were set as high values for perfect bond between the different surfaces as shown in Table 2. After the shear stresses on the interface reach the limit values as defined by Coulomb’s criteria, the shear separation is allowed to happen between the different surfaces.

The constitutive behaviour of different materials like embankment soil, soft clay and stone aggregates in columns was simulated using Mohr–Coulomb model. The interface between the geosynthetic and soil was modelled using frictional based Coulomb’s law. The properties of different materials are listed in Table 2.

The factor of safety of the embankment was determined using strength reduction technique as proposed by Dawson et al. [30]. The program estimates the factor of safety by gradually bringing the slope to a state of limit equilibrium by reducing the shear strength of the materials as given below:

In the above equations, the \(c\) and ϕ are the actual cohesion and friction angle of the soil, respectively, while \(\overline{c} \) and \(\overline{\phi }\) are the corresponding reduced strength values which bring the slope to the verge of limit state. If the slope is initially unstable, the value of \(\overline{c}\) and \(\overline{\phi }\) are increased progressively to reach a state of limit equilibrium (i.e. the FS value is decreased).

As the strength of the materials is gradually reduced, the system will reach a limit state with large deformations and formation of continuous rupture surface for the formation of a failure mechanism. When the ground was treated with ordinary granular columns (or with low area replacement ratios with EGCs), the embankments failed by deep seated failure with shear movements through the granular columns as shown in Fig. 18. When the columns were encased with strong geosynthetics, the failure mechanism changed from deep seated failure to toe failure mode as illustrated in Fig. 19.

The factors of safety values with different configurations are reported in Table 3. The factor of safety of embankment for the OGC-treated ground has increased from 0.83 at 8.04% area replacement ratio to 1.02 at 24.62% area replacement ratio. These low factor of safety values are due to the low shear strength of foundation soil. On the other hand, the geosynthetic encasement has enabled the development of higher factors of safety by increasing the modulus of the geosynthetic at the same area replacement ratio. Even with low area replacement ratio of 12.56%, the factor of safety has increased to 1.29 for higher geosynthetic modulus values. Beyond a certain limit of geosynthetic modulus and area replacement ratio, the factor of safety did not increase any further as the failure mechanism has changed from deep seated to toe failure mode. The factor of safety with toe failure mode is dependent on the strength of the embankment soil rather than on the strength of the granular columns.

Another advantage with geosynthetic encasement is in the transfer of lower embankment stresses to the foundation soil. This will in turn result in lower total and differential settlements. The use of geogrid encasement of granular columns has resulted in increase of loads transferred to the columns and reduction of pressures transferred into the foundation soil as illustrated in Fig. 20. It is clearly seen that the pressures on the encased columns are higher by about 20% to nearly 100% compared to those on the ordinary columns. The pressures on the foundation soil have reduced by almost 50% with ESC as compared to those with OSC. These comparisons are made based on the observations within the embankment portion of central 10 m width. The higher loads on the columns and lower pressures on the foundation soil are due to the arching taking place around the rigid elements. Due to higher rigidity of the geosynthetic-encased columns, there is further change in pressures in the case of encased columns.

Conclusions

A series of parametric investigations were performed to understand the response of geosynthetic-encased granular columns. The present study limits the discussions on the EGC-treated soft clays with very low cohesive strength in the range of 5–10 kPa and the influence of the installation patterns. The behaviour of embankments supported on stone-column-treated soft foundation soil was investigated through three-dimensional numerical modelling. Some of the major conclusions from this study are as follows:

-

1.

The predictions by both EBGEO and modified IS Code method compare well with the field and laboratory test data. Compared to EBGEO method, IS code method uses lesser number of parameters for design calculations.

-

2.

The settlement reduction factor is higher with EGC treatment when compared to OGC treatment. For a fixed area replacement ratio, the improvement with EGC treatment is dependent on the diameter of columns and the modulus of geosynthetic encasement.

-

3.

The settlement improvement factor for OGC increases with increase in diameter of the granular column (for the same spacing-to-diameter (S/D) ratio), while the EGC’s show better performance with smaller diameters due to larger hoop confinement in smaller diameter columns.

-

4.

The granular material with higher friction angles results in higher settlement improvement factors for both OGC’s and EGC’s.

-

5.

The effect of installation pattern on the SIF was significant only with encased granular columns and not so considerable in the case of OGC treatment.

-

6.

The role of the geosynthetic encasement on the settlement improvement factor is more prominent in the case of softer soils as they cannot provide adequate lateral support to the granular columns.

-

7.

The geosynthetic encasement of granular columns leads to as much as 50% reduction in foundation stresses and also settlements with proper choice of geosynthetic modulus. This is due to increased soil arching owing to stiffer granular columns.

-

8.

For geosynthetic modulus larger than about 2500 kN/m, the failure mechanism with EGC treatment changes from deep seated failure to shallow toe failure even with very soft foundation soils.

Abbreviations

- OGC:

-

Ordinary granular column

- EGC:

-

Encased granular column

- SIF:

-

Settlement improvement factor

- \(a_{s}\) :

-

Area replacement ratio

- \(h \) :

-

Thickness of the soil

- \(C\) :

-

Constant applied for a given granular column arrangement

- \(D\) :

-

Diameter of the granular column

- \(D_{{\text{s}}}\) :

-

Constrained modulus of the soil

- \(E_{{\text{s}}}\) :

-

Elastic modulus of the soil

- \(E^{*}\) :

-

Elastic modulus of the soft clay–granular column composite

- \(S\) :

-

Spacing of the granular column at c/c

- H :

-

Height of the Embankment

- \( J\) :

-

Modulus of the geosynthetic encasement

- \(K_{{0,{\text{s}}}}\) :

-

At-rest earth pressure coefficient in the soft clay soil

- \(S_{{\text{u}}}\) :

-

Undrained shear strength of the soft clay

- \(S_{{{\text{sl}}}}\) :

-

Settlement of the soft soil

- \(S_{{{\text{cl}}}}\) :

-

Settlement of the improved ground with granular column with or without encasement

- \(T_{{\text{g}}}\) :

-

Hoop tensile force in the geosynthetic encasement

- \(r_{{\text{g}}}\) :

-

Radius of the geosynthetic element

- \(r_{{\text{c}}}\) :

-

Radius of the granular column

- \(\varphi_{{\text{c}}}^{^{\prime}}\) :

-

Effective friction angle of the granular column

- \(\varphi_{{\text{s}}}^{^{\prime}}\) :

-

Effective friction angle of the soft soil

- \(\vartheta_{{\text{s}}}\) :

-

Poisson’s ratio of the soil

- \(\sigma_{{z0,{\text{c}}}} \) :

-

Overburden stress of the granular column

- \(\sigma_{{z0,{\text{s}}}}\) :

-

Overburden stress of the soft clay soil

- \(\Delta \sigma_{{\text{c}}}\) :

-

Additional vertical stress in the column

- \(\Delta \sigma_{{\text{s}}}\) :

-

Additional vertical stress in the soft clay soil

- \(\Delta \sigma_{{\text{r}}}\) :

-

Radial stress difference between column and soil

- \(\sigma r_{{\text{g}}}\) :

-

Radial stress in the geosynthetic element

- \(\sigma r_{{\text{c}}}\) :

-

Radial stress in the granular column

- \(\gamma_{{\text{s}}}\) :

-

Unit weight of soil

- \(\gamma_{{\text{w}}}\) :

-

Unit weight of water

- \(\gamma_{{\text{e}}}\) :

-

Unit weight of embankment or fill

References

IRC 113-(2013) Indian Standard- Guidelines for the design and construction of geosynthetic reinforced embankments on soft subsoils

McKenna JM, Eyre WA, Wolstenholme DR (1975) Performance of an embankment supported by stone columns in soft ground. Geotechnique 25(1):51–59

Chummar AV (2000) Ground improvement using stone columns: problems encountered. In: An international conference on geotechnical and geological engineering, GeoEng2000, Melbourne, Australia

Van Impe W, Silence P (1986) Improving of bearing capacity of weak hydraulic fills by means of geotextiles. In: Proceedings of the 3rd international conference on geotextiles, Vienna, Austria, pp 1411–1416

Raithel M, Kempfert HG (2000) Calculation models for dam foundations with geotextile coated sand columns. In: International conference on geotechnical and geological engineering, GeoEng2000, Melbourne

Malarvizhi SN, lamparuthi K (2004) Load versus settlement of claybed stabilized with stone and reinforced stone columns. In: Asian regional conference on geosynthetics, Geo-Asia, pp 322–329

Murugesan S, Rajagopal K (2006) Geosynthetic encased stone columns: numerical evaluation. GeotextGeomembr 24(6):349–358

Murugesan S, Rajagopal K (2010) Studies on the behavior of single and group of geosynthetic encased stone columns. J GeotechnGeoenvironEng 136(1):129–139

Pulko B, Majes B, Logar J (2011) Geosynthetic-encased stone columns: analytical calculation model. GeotextGeomembr 29(1):29–39

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. GeosynthInt 19(4):292–305

Almeida MSS, Hosseinpour I, Riccio M (2013) Performance of a geosynthetic-encased column (GEC) in soft ground: numerical and analytical studies. GeosynthInt 20(4):252–262

Zhang L, Zhao M (2014) Deformation analysis of geotextile-encased stone columns. ASCE Int J Geomech 15(3):1–10

Rajesh S (2016) Time-dependent behaviour of fully and partially penetrated geosynthetic encased stone columns. GeosynthInt 24(1):60–71

Hasan M, Samadhiya NK (2016) Soft soils improvement by granular piles reinforced with horizontal geogrid strips. Int J GeotechEng. https://doi.org/10.1080/19386362.2016.1252139

JayapalJayarajan and RajagopalKarpurapu (2019) Settlement analysis of geosynthetic encased granular column treated soft clay deposits. Int J GeotechEng. https://doi.org/10.1080/19386362.2019.1698218

Jayarajan J, Karpurapu R (2020) Bearing capacity and settlement response of ordinary and geosynthetic encased granular columns in soft clay soils: analysis and design charts. Indian Geotechn J. https://doi.org/10.1007/s40098-020-00457-9

Jayapal J, Rajagopal K (2018) Encased columnar inclusions in soft grounds—a review. GeotechnEng 49(1):106–118

EBGEO (2011) Recommendations for design and analysis of earth structures using geosynthetic reinforcements. Essen-Berlin: German Geotechnical Society (DGGT), Ernst & Sohn

Balaam NP, Booker JR (1981) Analysis of rigid rafts supported by granular piles. Int J Numer Anal Meth Geomech 5:379–403

Rao L, Madhav MR (2010) Evaluation of optimum spacing of stone columns. Geotrendz, Proceedings of the indian geotechnical conference, Bombay.

AS 4678-2002, Earth retaining structures, Australian Standard

Alexiew D, Thomson G (2013) Foundations on geotextile encased granular columns: overview, experience, and perspectives. In: Phoon KK, Chua TS (eds) Proceedings of international symposium on advances in foundation engineering (ISAFE 2013)

Priebe HJ (1995) The design of vibro replacement. Ground Engineering, December 21–27

Raithel M, Kirchner A, Schade C, Leusink E (2005) Foundation of constructions on very soft soils with geotextile encased columns—state of the art. In: Schaefer VR, Bruce DA, Byle MJ (eds) Innovations in grouting and soil improvement, geotechnical special publication, No. 136, ASCE, Reston, VA, pp 1–11

IS 15284-Part1 (2003) Indian standard—design and construction for ground improvement—guidelines. Part—1 Stone columns

Henkel DJ, Gilbert GD (1952) The effect measured of the rubber membrane on the triaxial compression strength of clay samples. Geotechnique 3(1):20–29

Mohapatra SR, Rajagopal K, Sharma JS (2016) Large direct shear load test on geosynthetic encased granular columns. GeotextGeomembr 44(3):396–405

Mohapatra SR, Rajagopal K, Sharma JS (2017) 3-Dimensional numerical modeling of geosynthetic-encased granular columns. GeotextGeomembr. https://doi.org/10.1016/j.geotexmem.2017.01.004

Itasca (2005) Fast Lagrangian analysis of continua (FLAC3D 5.00). Itasca Consulting Group Inc, Minneapolis, USA

Dawson EM, Roth WH, Drescher A (1999) Slope stability analysis by strength reduction. Geotechnique 49(6):835–840

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Karpurapu, R., Jayarajan, J. & Mohapatra, S.R. Geosynthetic-Encased Granular Columns Subjected to Vertical and Shear Loads. Indian Geotech J 51, 137–153 (2021). https://doi.org/10.1007/s40098-020-00486-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-020-00486-4