Abstract

The behaviour of granular columns as soil reinforcement under compressive axial loading is well documented. However, the different forms of lateral soil movements occurring in soft soil cause lateral force on granular columns, resulting in shear deformations. Minimal comprehensive direct laboratory research in this area forms the motivation behind this work. This experimental study is focused on the contribution of granular column reinforcement to the shear strength of the soft ground. For this purpose, a series of large-scale direct shear tests with 300 × 300 mm sample dimensions were performed in the laboratory. Effect of variables like normal stress, characteristics of granular column infill material, and column configurations (single, triangular, and square) was studied. Test results obtained from this experimental study are presented in terms of the increase in the overall shear resistance of the soil-column matrix and increase in the shear strength parameters. The experimental test results showed higher values than the values predicted from analytical equations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

India is on the cusp of frenetic development in infrastructure to catch up with the developed world and to achieve a better level of living. Civil engineering projects and development will play a vital part in transforming the look of Indian panorama. However, this threshold and the decreasing availability of stable construction sites have put pressure on geotechnical engineers. Depending on the economic feasibility and limited or constrained lead time available, granular column techniques are considered effective solutions. Stone column techniques are used widely in various construction activities because of their multipurpose behavior. The ground-column composite possesses improved stiffness and strength with a significant reduction in settlement by accelerating the rate of consolidation as the column has an efficient permeability and can act as drains [1,2,3,4,5,6,7]. Many researchers have also reported that due to installation process, the soil immediately surrounding the granular column is highly remolded, leading to the development of a smear zone [8,9,10]. The use of the stone column technique also causes a reduction in the liquefaction potential of the ground [11,12,13,14]. The potential applications of this technique include supporting the foundation on weak strata, supporting embankments and retaining structures, a solution to landslide and liquefaction problems, etc. [13, 15,16,17,18].

Various researches are available in the literature on the engineering behavior of a stone column reinforced soil, including laboratory studies, field experiments, analytical and numerical analysis. Most of these studies evaluate the behavior of the soil-column composite to vertical loading. The failures due to the vertical loading are well documented in the literature [19,20,21,22,23,24,25,26,27,28,29,30,31]. However, when we talk about the granular columns provided in soft soils or loose grounds, the lateral flow of ground can result in a lateral force acting on granular inclusions [18, 32, 33]. This lateral flow of soil may cause failures like shear and bending of columns, especially in case of the columns present at the toe of embankments. Earthquake-induced ground motions or liquefaction-induced soil movements may also result in such failures. Mohapatra [18] conducted a study to evaluate the response of granular columns placed in dry sand subjected to lateral loads by performing large-scale direct shear tests. The study was conducted on two different column diameters. As per their study increasing the replacement ratio increases shear resistance, and higher shear resistance was seen by group action of columns. Cengiz [34, 35] highlighted in his research the lateral shear and bending problems faced by granular columns when subjected to lateral loadings. Rezaei-Hosseinabadi [36] conducted direct shear test on sand reinforced with steel slag columns and reported that the utilization of steel slag in the form of granular column infill could improve the lateral load capacity of the ground. However, this condition needs to be studied, explored, and well documented. The lack of comprehensive direct laboratory research in this area forms the motivation behind this experimental testing. The lateral shear resistance of soft soil reinforced by columnar inclusions was evaluated by performing large-scale direct shear tests in a laboratory. The contribution of various controlling variables like granular column arrangement, varying granular infill material, and normal stresses on shear resistance were investigated. The experimental shear parameters are compared with the analytical equivalent shear strength parameters available in the literature.

Description of the Experiment

Material

The soil used to simulate soft soil condition in this experimental program was collected from the Bemina area of Srinagar City, Jammu and Kashmir, India, with GPS marking: N 34° 05′ 24″, E 74° 45′ 44″ shown in Fig. 1. The proposed site is predominantly a part of flood outwash/alluvial deposit. The location has a recent history of being a marshy/swampy area. The properties of the soil sample obtained from the laboratory testing are summarized in Table 1.

For the column infill material, two different types of granular material used were river aggregates (RA) with a smooth/sub-round texture and crushed aggregates (CA) with a rough/angular texture shown in Fig. 2. The range of the particle size distribution of granular infill material was selected, keeping in view the size of the model sample tested. The column diameter in this study varies from 50 to 100 mm. In this study, the ratio of column diameter to the maximum size of column infill material was selected to be around 6 as suggested by Nayak [37] and Fattah [38] to reduce the particle size by appropriate scaling factor. Therefore, the chosen granular infill material has a particle size ranging from 8 mm (passing) to 1.18 mm (retained). The selected particle distribution of granular materials also satisfies the requirements for a sample to be tested by direct shear apparatus as per ASTM standards (the maximum particle size should be less than 1/10 of width of specimen or 1/6 of thickness of specimen) [39]. Table 2 summarizes the properties of the two infill materials.

Test Setup and Experimental Procedure

Direct Shear Test

The 300 × 300 × 220 mm large-scale direct shear box, consisting of two halves shown in Fig. 3, was used. The bottom half slides horizontally while the top half is restrained from movement. The setup can provide the maximum shear displacement of 60 mm with 50 kN shear capacity. For all the tests, the height of the sample was maintained as 150 mm. Three series of direct shear tests were carried out, first on soft soil alone, second on column infill aggregates alone, and final on soft soil-column composite. Normal stress levels were selected based on the actual stress levels experienced by the granular columns (in a typical embankment) in the field. As per previous studies, for such tests to be conducted in the laboratory, normal stress should be selected on the prototype granular column to avoid the discrepancy between the prototype behavior and scaled model response [18]. The area replacement ratio for all the tests conducted on soil-column composites was kept constant at 8.7%. To calculate the radius of columns for different configurations, the equation used was:

where \(a_{r}\) is area replacement ratio, n is number of columns,\(A_{C}\) is cross-sectional area of granular column, \(A_{S}\) is cross-sectional area of the reinforced sample, \(D_{c}\) is diameter of column, a is the internal dimension of the shear box. The description of the test series is given in Table 3.

Sample Preparation

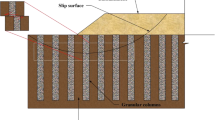

A series of direct shear tests were conducted on the selected soil with varying water content and densities in accordance with compaction curve obtained from the standard proctor test. To simulate the soft soil condition around the stone column in the laboratory, a soil sample with cohesion less than 12 kPa was selected. The necessary condition of shear strength parameters was satisfied at a water content of 35% (which was on the wet-side of optimum) and a dry unit weight of 13.4 kN/m3. The shear strength parameters of the soil at 35% water content were found to be c = 10.6 kPa and ϕ = 2°. The soil used in the experimental work was air-dried and the required amount of water for the moisture content to reach 35% was added to the sample. The sample was appropriately kneaded and put into airtight plastic bags for about 24 h. to achieve moisture content equilibrium. The shear box was graduated along the height and silicon grease was applied to the bottom and sides of the shear box. With a moisture content of 35%, pre-weighed amount of soil in three layers of 50 mm thickness was placed into the shear box. Each layer was compacted to achieve the wet unit weight of 18.09 ± 0.3 kN/m3. After preparing the complete soil sample, a cylindrical cavity was cored in the sample using a thin, smooth hollow steel pipe with 2 mm thickness and an outer diameter equal to the diameter of the columns. These pipes were lubricated by applying a thin coat of oil before insertion into the soil sample to avoid friction effects. The custom-designed plates with collars were fabricated to insert the pipes vertically into the soil sample. The picture of the fabricated plate-pipe collar set-up is shown in Fig. 4.

The soil inside the pipes was removed with the help of hand augers. After the soil was removed, the pipes were pulled out in three steps during the granular column construction. The space created by the pipes in each step was filled with premeasured amount of granular material. The granular material was dropped in the cavity from 250 mm height and then compacted with a tamping rod to attain the density corresponding to the relative density of 80% in both types of granular materials. The observations during trial testing for all configurations ensured that this process provides the required density with no lateral spread-out of column material. Figure 5a shows the detailed schematic diagram of granular column arrangements in this experimental study. The final reinforced samples are presented in Fig. 5b and c. All the tests were performed in undrained condition. The normal stress for the tests ranged from 25 to 75 kPa to develop the Mohr-Column failure envelopes. The samples were sheared at a horizontal displacement rate of 1% per min. All the tests were terminated at the horizontal shear displacement of 60 mm which is 20% of sample length. Granular columns were positioned such that minimum clear distance from the inner face of the shear box along the direction of shear was greater than 60 mm in all cases in order to avoid boundary effect during shearing.

a Schematic diagrams of granular columns installed in different configurations during experimental testing, b Plan view of large direct shear box with crushed aggregate granular columns in different configurations, c Plan view of large direct shear box with river aggregate granular columns in different configuration

Results and Interpretation

Effect of the Granular Column on Shear Stress

The shear behavior of the untreated soil is shown in Fig. 6, and that of the soil reinforced with the different configurations of CA granular columns is shown in Figs. 7, 8, and 9. It is clear from the shear behavior that the shear stress corresponding to 60 mm horizontal displacement increases on reinforcing the soft soil with granular columns. This behavior can be attributed to the soil-column system’s combined stiffness, thus reflecting higher shear resistance than untreated soft soil samples. Also, it is evident that as the normal stress applied increases, so does the shear resistance.

The shear behavior of the soil reinforced with RA granular columns is shown in Figs. 10, 11, and 12. The difference between shear stress values using two different granular infill materials is clear from the stress-displacement plots. Comparing the response of the two types of columns, the soil-column composite with the columns of CA infill mobilizes higher shear stress compared to the columns of RA infill. Based on this observation, the infill characteristics are believed to play a key role in enhancing the shear behaviour of the whole soft soil-column composite. Thus, higher the shear strength characteristics of the granular particles, the higher will be the shear resistance of the soil-column composite ground.

The improvement in stiffness of the soil sample by reinforcing with the granular columns is also evident from the increased slope of stress-displacement curves, with the highest in the case of square pattern. The shear resistance is more for smaller diameter granular columns installed in a group as compared to that of a single large diameter granular column, although area replacement ratio is same for all cases. Figure 13a and b show the variation of normalised shear strength ratio versus number of columns installed. Normalised shear strength ratio is given by Eq. 2:

where τc is strength of different reinforced samples, τs is strength of unreinforced soft soil sample.

The value of the normalised shear strength ratio increases with increase in the number of columns. The highest value is found in the sample with four columns of 50 mm diameter, placed in a square arrangement. This response of the soil-column system can be attributed to the increased lateral surface area of granular columns. Also, the soil within the columns mobilizes high shear resistance because of additional confinement provided by surrounding columns.

Effect of the Granular Column Installation on Shear Strength Parameters

Figure 14a and b illustrate the effect of the column installation on strength parameters of the soft soil-column composite in terms of the Mohr-Column failure envelopes for different column arrangements.

An increasing trend was observed in the angle of internal friction with the inclusion of the granular columns. However, a negligible effect on the cohesion parameter was seen. The friction angle increased by a maximum of about 400% in the samples with CA columns. The maximum increase in friction angle is seen in soil-column composite with square configuration columns. The minimum value pertains to soil-column composite with a single column of RA infill. Also, it is clear from Fig. 14 that CA columns reflect higher angle of internal friction than RA columns. The reason for such a response is the morphology/angularity of the infill material used for the construction of columns.

The analytical approach presented in the literature for calculating the soil-column composite characteristics are based on the average of soil and column parameters contributed by their corresponding areas [38]. Therefore, the shear parameters of the soil-column composite are based on the soil’s shear parameters, shear parameters of column infill material, and area replacement ratio. The shear strength can be calculated by an analytical equation given as:

where τ is shear strength of composite, \(\tau_{{{\text{cm}}}}\) is shear strength of column infill, \(\tau_{s}\) is shear strength of surrounding soil, and ar is area replacement ratio [38, 40]

Figure 15a and b illustrate the shear strength values acquired from the experiments and those estimated using an analytical relationship given by Eq. 3. The difference between the experimental and analytical results is important to be noted. The value of maximum shear stress values from experimental study for a single column reinforced soil are almost congruent with calculated shear stress values from Eq. 3. However, the effect of group action is neglected in analytical approach.

Christoulas [41] suggested equation for calculating the equivalent friction angle using the law of mixtures (or equivalent area method) which is

where ϕeq = equivalent angle of internal friction, ϕcm = angle of internal friction of column infill material, ar is area replacement ratio, ϕs = angle of internal friction of surrounding soil. The calculated values of the friction angle are shown in Table 4.

The above analytical approaches are based on unit cell homogenization method (or equivalent area method) in which the heterogeneous geometry problem of soil-column matrix is replaced with an equivalent homogeneous soil with improved properties. This concept of unit cell homogenisation model is used widely in analytical and numerical approaches. Using Eq. 4 the equivalent angle of internal friction, ϕeq for the soil-column composite is 7° for crushed aggregate columns and 6° for river aggregate columns. However, on comparing the experimental results with the calculated values (Eq. 4), it is seen that values of angle of internal friction from experimental results are higher than those calculated from the analytical relationship. One of the reasons for this disagreement is increased lateral surface area as the number of columns increases for the same area replacement ratio. The increase in the contact surface between the surrounding soil and the granular columns results in increased shear strength and strength parameters [29]. The analytical equations neglect the soil-column interaction and the effect of the group action. Thus, using these analytical relationships is conservative.

To take into account increased soil-column interaction due to group action for different column configurations, contact coefficient χ derived from the surface area of the columns given by Eq. 5 was applied [29].

where LSg is the lateral contact surface of one column belonging to a group of n number of columns, and LS is the lateral contact surface of a single column having the same area replacement ratio as of group.

Figure 16 shows the variation of \({{{\text{tan}}\phi_{g} } \mathord{\left/ {\vphantom {{{\text{tan}}\phi_{g} } {{\text{tan}}\phi_{s} }}} \right. \kern-\nulldelimiterspace} {{\text{tan}}\phi_{s} }}\) vs contact coefficient χ given by Eq. 5. where ϕg is the angle of internal friction of soil-column composite reinforced by a group of columns (triangle or square), ϕs is the angle of internal friction of soil-column composite reinforced by a single column of same area replacement ratio as that of a group, coefficient χ represents the variation of the contact surface between column, and soil.

For this experimental study, the value of χ varies between 1 (for composite reinforced with the single column) to 2 (for the composite reinforced by the group of 4 columns). The value of normalized friction angle ratio increases with an increase in contact coefficient for both types of granular columns, with the maximum value of 1.29 for soil reinforced by four columns in a square pattern. Therefore, when the number of granular columns is increased despite the fixed area replacement ratio, the soil-column interaction in terms of lateral contact surface area increases resulting in improved strength properties of the soil-column eco-composite.

Conclusions

This study was aimed at analyzing the lateral shear behavior of stone column-treated soft soils by carrying out large-scale direct shear tests. Various parameters were changed to study their effect on the shear strength of soft soils. The key findings of this study are:

-

1.

The inclusion of granular column in soft soil increased the overall stiffness of the soil-column composite and consequently, the shear strength increased by about 70–80% due to a mere replacement of 8.72% area of soft soil. The increase in the initial slope of the stress-displacement curves is indicative of improved stiffness of the soil-column eco-composite.

-

2.

The particle morphology of column infill material was found to play a vital role in the response of the soil-column composite to shear loading. The normalized shear strength ratio of the composite increased by 82% in the case of rough angular aggregate infill, while for smooth sub-round aggregate infill, the value increases by only 68%.

-

3.

While there was a negligible effect on the cohesion property of the soft soil due to column reinforcement, the angle of internal friction increased up to 5 times using crushed aggregate columns and 4.5 times using river aggregate columns in the soft soil.

-

4.

For the same area replacement ratio, the number of columns installed proves to be an influential factor in defining the shear behavior of the eco-composite. In case of both RA and CA columns, the highest shear resistance pertains to four-column configuration of 50 mm diameter, while the lowest is in case of single column of 100 mm diameter, although the values are lesser for RA columns. This is because of the increased soil-column interaction in terms of lateral contact surface area which was taken into consideration by introducing surface contact coefficient χ. As the value of χ increased from 1(single column) to 2 (four columns), the value of normalized friction angle ratios increased by about 30%.

-

5.

Compared to the experimental results, the analytical relationships available in the literature were found to underestimate the strength parameters of the soil column composite. The analytical equations neglect the soil-column interaction and the effect of the group action. So, it is conservative to calculate the shear resistance of soil-column composites using such relationships.

Availability of Data and Materials

All the data was generated by experimental tests performed in the Geotechnical laboratory of NIT Srinagar by the first author.

References

Greenwood DA (1970) Mechanical improvement of soils below ground surface. In the Proceeding of Ground Engineering Conference, Institute of Civil Engineering: 9–20

Hughes JMO, Withers NJ (1974) Reinforcing of soft cohesive soils with stone columns. Ground Eng 7:42–49

Priebe HJ (1995) The design of vibro replacement. Ground Eng 28(10):31

Han J, Ye SL (2001) Simplified method for consolidation rate of stone column reinforced foundations. J Geotech Geoenviron Eng 127(7):597–603

Kempfert H G (2003) Ground improvement methods with special emphasis on column-type techniques. International Workshop on Geotechnics of Soft Soils-Theory and Practice VGE: 1–12

Mir B A, Juneja A (2012) Consolidation behaviour of composite ground reinforced with sand columns. International Conference on Ground Improvement and Ground Control, University of Wollongong Australia (ICGI 2012) 1: 431–437

Castro J, Sagaseta C (2011) Deformation and consolidation around encased stone columns. Geotext Geomembr 29(3):268–276

Mir BA (2010) Study of the influence of smear zone around sand compaction pile on properties of composite ground. Ph.D. Thesis, IIT Bombay

Juneja A, Mir BA, Parihar A (2011) Effects of sand compaction pile installation in model clay beds. Int J Geotech Eng 5(2):199–209. https://doi.org/10.3328/IJGE.2011.05.02.199-209

Juneja A, Mir BA, Roshan NS (2013) Effect of the smear zone around SCP improved composite samples tested in the laboratory. Int J Geomech 13(1):16–25. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000169

Debnath P, Dey AK (2017) Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay. Geotext Geomembr 45:653–664

Alamgir M, Miura N, Poorooshasb HB, Madhav MR (1996) Deformation analysis of soft ground columnar inclusions. Comput Geotech 18(4):261–290

Rajagopal K, Mohapatra S R (2016) Behaviour of geosynthetic encased granular columns under vertical and lateral loading. 6th Asian Regional Conference on Geosynthetics-Geosynthetics for Infrastructure Development New Delhi, India, 8–11

Hung WY, Lee CJ, Tran PD (2017) Centrifuge shaking table tests on effect of vertical drain systems for liquefied soil. J Vibro Eng 19(1):458–467

Gniel J, Bouazza A (2009) Improvement of soft soils using geogrid encased stone columns. Geotext Geomembr 27(3):167–175

Murugesan S, Rajagopal K (2010) Studies on the behavior of single and group of geosynthetic encased stone column. J Geotech Geoenviron Eng 136:129–139

Almeida MS, Hosseinpour I, Riccio M, Alexiew D (2015) Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J Geotech Geoenviron Eng 141(3):04014116

Mohapatra SR, Rajagopal K, Sharma J (2016) Direct shear test on geosynthetic-encased granular columns. Geotext Geomembr 44:396–405

McKelvey D, Sivakumar V, Bell A, Graham J (2004) Modelling vibrated stone columns in soft clay. Proc Inst Civil Eng Geotech Eng 157(3):137–149

Ambily AP, Gandhi SR (2004) Experimental and theoretical evaluation of stone column in soft clay. ICGGE, 2004(1): 201–206

Sivakumar V, McKelvey D, Graham J, Hughes D (2004) Triaxial tests on model sand columns in clay. Can Geotech J 41(2):299–312

Black J, Sivakumar V, McKinley JD (2007) Performance of clay samples reinforced with vertical granular columns. Can Geotech J 44(1):89–95

Murugesan S, Rajagopal K (2006) Geosynthetic-encased stone columns: numerical evaluation. Geotext Geomembr 24:349–358

Malarvizhi SN, Ilamparuthi K (2007) Comparative study on the behavior of encased stone column and conventional stone column. Soils Found 47:873–885

Andreou P, Frikha W, Frank R, Canou J, Papadopoulos V, Dupla JC (2008) Experimental study on sand and gravel columns in clay. Proc ICE–Ground Improv 161:189–198

Najjar SS, Sadek S, Maakaroun T (2010) Effect of sand columns on the undrained load response of soft clays. J Geotech Geoenviron Eng 136:1263–1277

Ghazavi M, Afshar JN (2013) Bearing capacity of geosynthetic encased stone columns. Geotext Geomembr 38:26–36

Schnaid F, Winter D, Silva AEF, Alexiew D, Kuster V, Hebmuller A (2014) Geotextile encased columns (GEC) under bridge approaches as a pressure-relief system: concept, experience and measurements. In: 10th International Conference on Geosynthetics, Berlin, Germany

Frikha W, Taunekti F, Kaffel W, Bouassida M (2015) Experimental study for the mechanical characterization of Tunis soft soil reinforced by a group of sand column. Soils Found 65:181–191

Chen JF, Wang XT, Xue JF, Zeng Y, Feng SZ (2018) Uniaxial compression behavior of geotextile encased stone columns. Geotext Geomembr 46(3):277–283

Farah RE, Nalbantoglu Z (2020) Behaviour of geotextile encased single stone column in soft soils. Arab J Sci Eng 45:3877–3890

Barksdale RD, Bachus CR (1983) Design and construction of stone columns. vol I. FHWA/RD-83/026; SCEGIT-83–104. Turner-Fairbank Highway Research Center

Rashma RSV, Shivashankar R, Jayalekshmi BR (2018) Behaviour of reinforced stone columns subjected to static shear loading conditions. Int J Eng Technol 7(4):6928–6933

Cengiz C, Guler E (2018) Seismic behavior of geosynthetic encased columns and ordinary stone columns. Geotext Geomembr 46(1):40–51

Cengiz C, Kilic IE, Guler E (2019) On the shear failure mode of granular column embedded unit cells subjected to static and cyclic shear loads. Geotext Geomembr 47(2):193–202

Rezaei-Hosseinabadi M J, Bayat M, Nadi B, Rahimi A (2021) Utilisation of steel slag as a granular column to enhance the lateral load capacity of soil. Geomech Geoeng, 1–11. https://doi.org/10.1080/17486025.2021.1940315

Nayak NV (1983) Recent advances in ground improvements by stone column. In Proceedings of Indian geotechnical conference, Madras India IGC-83

Fattah MY, Shlash KT, Al-Waily MJ (2013) Experimental evaluation of stress concentration ratio of model stone columns strengthened by additives. Int J Phys Model Geotech 13(3):79–98

ASTM D (2011) Standard test method for direct shear test of soils under consolidated drained conditions. D3080/D3080M 3: 9

Nazariafshar J, Aslani M, Mehrannia N (2020) Experimental study on equivalent shear strength of cohesive soils improved with stone columns by triaxial testing. Amirkabir J Civil Eng 52(9):2191–2210

Christoulas ST, Giannaros CH, Tsiambaos G (1997) Stabilization of embankment foundation by using stone columns. Geotech Geol Eng 15(3):247–258

Acknowledgements

The authors express the heartfelt gratitude towards the authorities of NIT Srinagar, notably the Department of Civil Engineering, for helping us in the execution of this work at the institute.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

First author: Testing, data analysis, and drafting of paper. Second author: Supervising, reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohammad, S., Mir, B.A. Strength Behaviour of Granular Column-Reinforced Soft Soil Subjected to Lateral Shear Loading. Indian Geotech J 52, 1450–1463 (2022). https://doi.org/10.1007/s40098-022-00652-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-022-00652-w