Abstract

The present study presents an enhancement in wick solar stills performance depending on using different aspect ratios with the same project area and wick materials, glass cover cooling, and external reflectors after practical knowledge of the best wick material type and dimensions. The proposed three stills (A), (B), and (C) have evaporation area dimensions of 1 × 0.85, 1.5 × 0.57, and 2 × 0.425 m2, with an aspect ratio of 1.18, 2.63, and 4.71, respectively. The results revealed that the solar still with medium dimensions set has the best performance. Also, adding a top and bottom reflector to type (B) solar still with cotton cloth wicks increased the freshwater productivity and energy efficiency by 37.99 and 39.96%, respectively, compared to type (A) solar still with cotton cloth wicks. Moreover, the cost of one liter of freshwater distillate was decreased by 1.82%. Applying glass cover cooling on type (B) solar still with cotton cloth wicks increased the freshwater productivity and energy efficiency by 30.59 and 33.13%, respectively, compared to type (A) solar still with cotton cloth wicks. Furthermore, we have a decrement in the cost of one liter of freshwater distillate by 7.69%. Moreover, adding reflectors and cover cooling together to wick solar still increased the freshwater productivity and energy efficiency by 52.36 and 58.5%, respectively. On the other hand, the cost per liter of freshwater was reduced by 9.8%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The rapid worldwide industry and population growth lead to a massive increment in freshwater demand [1]. On the other hand, water which covers two-thirds of the earth's area is not sufficient to supply this required freshwater. In many countries, fresh water shortage is a serious problem so much so that two million people lose their lives yearly due to this problem [2]. Water desalination is the right solution for the freshter shortage problem, but it depends on fossil fuels and requires high expenses [3]. To overcome the dependence of the desalination process on a non-renewable fuel source and reduce the process cost, solar stills are a perfect alternative. The solar still consists of a water basin that stagnates the brackish water, tilted glass cover over the basin, and insulation around the still body [4]. When the still is exposed to the solar radiation, the water evaporates and condenses over the tilted glass cover. Then, the condensate is collected as the produced freshwater from the still. Solar stills are an inexpensive, simple, and reliable method to convert brackish water to potable water, especially in arid and semiarid areas. The most remarkable limitation associated with solar stills is their low freshwater productivity, so research presents a lot of studies and attempts to increase freshwater productivity.

Ongoing to the studies carried out to enhance solar still freshwater productivity, Sharshir et al. [5] concluded that freshwater output from solar stills depends on some un-controlled metrological and some other controlled parameters. Solar radiation intensity, wind speed, and ambient temperature are metrological parameters which are positively proportional to the freshwater yield from the solar still. Increasing the temperature difference between water and glass cover, decreasing water thickness, and improving insulation thickness are controlled actions that can enhance solar still freshwater yield. The glass cover inclination angle is a controllable parameter that affects the solar still freshwater yield. The best results are obtained by using a glass cover inclination angle equal to the latitude angle of the experiment location [6]. As attempts to enhance the performance of the solar still, a lot of design changes were presented and investigated, such as tubular solar stills [7, 8], double-slope solar stills [9, 10], pyramid solar still coated with TiO2 nano black paint [11], pyramid solar still with evacuated tubes [12], pyramid solar still with nanofluid [13], adding internal or external condensers [14], adding internal or external reflectors, applying to cool on glass cover[15], fumed silica nanoparticle in black paint [16], activated carbon as a porous absorber [17], using wick materials[18], using hydrogel materials[19], using nanofluids/nanoparticles [20, 21], using gravels or phase change materials [22], solar still with humidification–dehumidification [23, 24], ultrasound waves atomizer [25], thin film evaporation [26, 27], using airing multi-functional textile [28], wick-metal chips [29], and graphene oxide-based absorber [30].

Literature review

The present study presents an enhancement in solar stills performance depending on using different wick materials, glass cover cooling, and external reflectors after practical knowledge of the best wick material type and dimensions. So, the literature review will include a summary of some previous studies which apply wick materials, glass cover cooling, and reflectors techniques to improve solar stills performance. Every technique of the mentioned techniques will be individually discussed in the following subsections.

Improving solar still performance by wick materials

Applying wick materials in solar stills is a very simple and effective modification that directly enhances the freshwater productivity as it increases the solar radiation absorption and evaporation areas. The core idea of using these materials is to transport a little quantity of brackish water from its basin to the evaporation area by capillary action. So, it is easy to evaporate this small quantity of water. After evaporation, new brackish water comes again to the evaporation area. Many investigations depended on using wick materials to enhance solar stills performance, and they are reviewed and discussed in [31].

Ongoing to studies that applied different wick materials configurations on solar stills, Alaian et al. [32] installed vertical finned wicks with pin shape on the basin of conventional solar still by aid of steel wires. An experimental comparison between the modified and traditional solar still was carried out. The results revealed that using this proposed wick material configuration can increase freshwater productivity of conventional solar still by 23%. On the other way, Abdullah et al. [33] experimentally investigated the performance of the conventional solar still with vertically and horizontally rotating jute wick belt under different operating conditions. A 300% augmentation in freshwater productivity compared with traditional solar still was recorded by applying continuous turning the rotating wick on and off for 5 and 30 min, respectively. Kabeel [34] carried out an experimental study on pyramid solar still after changing its basin surface to a concave geometry and adding wick materials on it. The results showed an increment in freshwater productivity of 95.24% compared to conventional solar still reported in [35].

Improving solar still performance by reflectors

Adding reflectors to solar stills is a simple, cheap, and effective modification that increases the solar radiation directed to the basin water leading to enhancement in solar still freshwater productivity and energy efficiency. Omara et al. [36] presented a survey and discussion about studies associated with solar stills integrated into diverse designs of reflectors.

Tanaka [37] utilized internal and external reflectors to enhance conventional solar still performance. An experimental study was carried out under outdoor winter conditions in Kurume, Japan. The results illustrated that using reflectors in traditional solar stills leads to an increment in freshter productivity by 70–100%. Omara et al. [38] carried out a comprehensive study between conventional solar still and stepped single-slope solar still integrated with top and bottom reflectors. The stepped still with reflectors produced freshwater higher than conventional still by 125%. Furthermore, El-Samadony et al. [39] experimentally investigated the modified stepped single-slope solar still with top and bottom reflectors and external condenser. The comparison between the modified solar still and the conventional solar still revealed that the modified one has higher freshter productivity by 165%.

Improving solar still performance by cover cooling

The higher the difference between evaporating and condensing areas in the solar still, the greater the distillate output will be collected. So, the researchers presented various glass cover cooling techniques to enhance the performance of the solar still. Also, glass cover cooling gives another advantage of cleaning the cover from dirt and filth which inversely affects the still energy efficiency. Omara et al. [40] presented a detailed review of various cooling methods of solar still covers.

Depending on enhancing the solar still performance by increasing the temperature difference between the glass cover and the basin, Somwanshi and Tiwari [41] applied water flow on the glass cover of the conventional solar still, collected this water, refresh it through a desert cooler and reapply it on the cover. The effect of this closed-loop cooling system on the still was studied under climatic conditions of different four locations in India. The results showed that the annual freshter productivity of conventional solar still can be augmented by 41.3–56.5% by adding this proposed cooling system. Also, Abdullah [42] cooled the glass cover of the single-slope stepped solar still by water flow and heated the stepped basin by a hot air obtained by a solar air heater. This combination of modification maximizes the temperature difference between the water basin and the glass cover, accelerating water evaporation and condensation processes. The comparison between the modified still and the conventional solar still highlighted a 112% increment in freshwater productivity for the proposed modification. Moreover, Dhiman and Tiwari [43] theoretically investigated a multi-wick solar still with cooling water flow on its cover. The freshwater output was increased by 10%.

Researchers still search for successful ways to enhance the performance of solar still at a low cost and eco-friendly. From the literature review above, various types and shapes of solar stills are available: for example, single slope, double slope, pyramid, stepped, inclined wick, and so on. All these types have various output freshwater productions and different thermal efficiencies. Additionally, to improve the performance of a solar still, some designs need external areas such as condensers, collectors, and so on to improve productivity and efficiency. But unfortunately, their investment needs a power source, and the cost of freshwater will be high as well as the thermal efficiency will be low.

This work innovatively proposed the combination of different various wick materials to get the best performance of the wick solar still, and using different aspect ratios (ARs) (1.18, 2.63, and 4.71 at the same projected area 1 m2) to get the best performance of the wick solar still. Furthermore, after we select the best wick material with the best aspect ratio a combination between reflectors and glass cooling is utilized to increase the thermal performance. Top and bottom reflectors are utilized to increase the amount of solar radiation to the wick solar still. Also, using glass cover cooling decreases glass temperature and increases the temperature difference between the glass and the wick surface, which improves water evaporation and water productivity. In addition, a cost analysis of the modified wick solar still is determined.

Test-rig and measurement devices

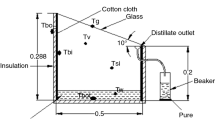

All experiments were carried out in Shebin ElKom, Egypt (latitude 30.55° N, longitude 31.01° E) during August and September 2019. The experiment day starts at 7:00 am and ends at 5:00 pm (lasts for 10 h). Figure 1 shows a schematic illustration for the test-rig and its details and Fig. 2 illustrates pictorial photographs for the test-rig during experiments. Also, the experimental setup contains three-wick solar stills with back saline water basins. The three stills have the same evaporation area and water basin volume of 0.85 m2 and 0.03 m3, respectively.

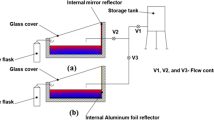

On the other hand, they vary in dimensions. Types (A), (B), and (C) have evaporation area dimensions of 1 × 0.85, 1.5 × 0.57, and 2 × 0.425 m2, respectively, while their water basin dimensions are 1 × 0.15, 1.5 × 0.1, and 2 × 0.075 m2, respectively, with a common height dimension of 0.2 m for all of them. All stills were fabricated from 1-mm-thickness galvanized steel, painted to prevent rust, insulated well with 5 cm thermal insulation, and covered with 4 mm transparent glass. The interior of the stills was painted in black to absorb the maximum possible solar radiation. Glass cover area of stills (A), (B), and (C) is 1 × 1.02, 1.5 × 0.685, and 2 × 0.51 m2, respectively, with absorptivity 0.05, emissivity 0.88, and specific heat 800 J/m °C [44]. All glass covers are installed and sealed by using silicon sealant at an inclination angle of ~ 30° which approximately equals the latitude angle of the location of the experiment. In some conducted experiments, we utilized top and bottom reflectors to increase the amount of solar radiation to the wick solar still, also using glass cover cooling to decrease the glass temperature and increase the temperature difference between the glass and wick surface which improve water evaporation and water productivity.

Experimental procedure

To the best of our knowledge, no one has studied the effect of changing the dimensional set off a constant evaporation area on the performance of solar stills integrated with wick materials. This study was carried out to study the effect of this parameter by using three types of solar stills with the same evaporation area but with different area dimensions. After that, the experiments were carried out to study the effects of adding reflectors, glass cover cooling, and both of them on the best dimensional set of solar stills integrated with the best wick material out of cotton cloth, cotton towel, and jute cloth.

Herein, the sequence of experiments will explain in detail. Firstly, the three solar stills were examined with the use of cotton cloth wicks. This experiment was carried out to know the best dimensional set for the solar still with wick materials. Secondly, the best solar still in the first experiment was tested under three different wick materials: cotton cloth, cotton towel, and jute wicks. After that, the top and bottom reflectors were integrated to the first best solar still type with the best wick material and compared with the second-best solar still type with the same wick material. Then, the previous experiment was repeated but with water flow for cooling of glass cover of the first best solar still, type in the state of integrating reflectors. Finally, the last experiment was repeated with both reflectors and cooling water flow with the first best solar still.

The top and bottom reflectors were installed at inclination angles recommended by [38]. The top and bottom reflectors inclination angles were 15° and 50° in the clockwise direction according to the vertical and horizontal directions, respectively. Water flow for glass cover cooling was carried out by using nozzles connected to the saline water feed tank, flowing 6 L of water on the cover per hour. The wick materials used in the experiments are cotton cloth, cotton towel, and jute cloth. To compare the capillary effect of the wick materials, specimens of them are sub-immersed in water mixed with red dye for 15 min. As shown in Fig. 3, the liquid reached heights of 21, 15, and 11 cm for cotton cloth, cotton towel, an1d jute cloth wicks, respectively.

The test-rig was suitably equipped with measuring devices to record the continuous variations of the different parameters in the tested solar stills. All measuring instruments were calibrated before utilization. K-type thermocouples were utilized to measure the temperature with an operating range of − 50 to 180 °C and accuracy of ± 1 °C. Solar radiation intensity was measured by TES-1333R solar meter with an operating range of 0 to 2000 W/m2 and accuracy of ± 10 W/m2. Wind speed was measured by GM816 digital vane-type anemometer with an operating range of 0.1 to 30 m/s and an accuracy of ± 0.1 m/s. All dimensional measurements were conducted with an accuracy of ± 0.5 mm. The freshwater distillate was measured by a cylindrical graduated tube with an accuracy of ± 2 ml. The following equation was used to calculate the uncertainty of an estimated value obtained from the measured parameters uncertainties such as calculation of energy efficiency uncertainty [45]:

where \(U_{x}\) is the uncertainty propagation of value \(X\) and \(U_{n}\) are uncertainties values of independent variables \(x_{n}\).

Thermal performance calculation

Energy efficiency

The energy efficiency of every solar still was calculated to evaluate, analyze, and assess the performance of each still. Solar still efficiency can be calculated by dividing the latent heat of the freshwater distillate (FWD) on the harvested solar energy. The following equation has been used to calculate the daily energy efficiencies of the tested solar stills during the experiment time (ET) [20]:

where \(\eta\) is daily energy efficiency, \(\dot{m}_{t,FWD}\) is mass of freshwater distillate per hour (kg/h), \(h_{fg}\) is the latent heat of vaporization (J/kg) which may be calculated by using Eq. (3) according to [46], \(I\left( t \right)\) is solar radiation intensity (W/m2), and \(A_{G}\) is glass cover area (m2).

where \(T_{w}\) is the average water temperature (°C).

Exergy efficiency calculation

Exergy analysis can be performed by applying the second law of thermodynamics, as exergy efficiency (\(\eta {}_{{{\text{EX}}}}\)) represents the ratio of harvested exergy of evaporated water to input solar exergy. And that can be achieved by applying the following expressions [47].

In an MSSS and CSS, harvested exergy is an outcome of water evaporation, and therefore, the condensation of freshwater.

where \(T_{a}\) is the temperature of air (K) and \(T_{w}\) is the temperature of water (K).

The exergy input to SS (\(E_{{x_{{{\text{sun}}}} }}\)) can be estimated as coming from the sun through the solar radiation as follows:

where \(T_{s}\) is the temperature of the sun (6000 K).

Observation and results

Effect of different dimension on wick solar still performance with cotton cloth wicks

Variations in ambient parameters such as solar radiation intensity, ambient temperature, and wind speed according to time were recorded and are plotted in Fig. 4a. Solar radiation intensity and ambient temperatures were 185 W/m2 and 25 °C, respectively, at the beginning of the experiment day (at 7:00 am). Then, solar radiation intensity and ambient temperature were continuously increasing until their maximum values at 12:30 pm. After that, these values were continuously decreasing until the end of the experiment day (at 5:00 pm). The maximum and last recorded solar radiation intensity values were 850 and 280 W/m2, while the maximum and last recorded ambient temperature values were 33 and 30 °C. The wind speed was varying during all the experiment days within the range of 0.1–1.5 m/s. Wicks and glass cover temperature variations of all tested solar stills types were recorded and are plotted in Fig. 4b and c. All temperature variation curves look like an inverted bell with a maximum value at 12:30 pm. The maximum wicks temperature for type (B) was 73 °C, which was higher than type (C) by 2.82% and lower than type (A) by 2.74%, while type (B) maximum glass cover temperature was 58 °C, which was higher than type (C) by 1.75% and lower than type (A) by 3.45%.

Hourly freshwater distillate of studied different solar stills is illustrated in Fig. 5a. Type (B) solar still has the highest productivity as its dimensional set maintains the water existence at the right amount in the wick materials without dry spots or excess water. At the beginning of the experiment day (at 7:00 am), the freshwater distillate of all stills was still zero, but it was increasing till its maximum value at 12:30 a.m., and then, it was decreasing till the end of the experiment day. The maximum value of type (B) freshwater distillate was higher than types (A) and (C) by 13.92 and 16.88%, respectively. As shown in Fig. 5b, the accumulated freshwater distillate of type (B) solar still was higher than types (A) and (C) by 16.31 and 22.41%, respectively. Moreover, energy efficiency calculations revealed that types (A), (B), and (C) solar stills with cotton cloth wicks have an efficiency of 39.81, 47.38, and 38.14%, respectively.

Effect of different wick materials on wick solar still performance

Hitherto, the dimensional combination of type (B) solar still showed the best results, so it was tested under different capillary materials: black cotton cloth, black cotton towel, and black jute cloth wicks. In this section, the results of testing these materials with type (B) solar still will be presented. The hourly and accumulated freshwater distillate is shown in Fig. 6a and b, respectively. Using black cotton cloth gave the highest reshwater distillate, which led the distillate obtained from using a black cotton towel and black jute cloth by 19.17 and 24.14%, respectively.

Effect of cotton cloth and reflectors on the wick solar still performance

Figure 7a shows the variations of metrological conditions during the experiment day. At the beginning of the experiment (at 7:00 am), the solar radiation intensity and ambient temperatures were 195 W/m2 and 28 °C, respectively. At 12.30 pm, the solar radiation and ambient temperature reached their maximum values which were 890 W/m2 and 34 °C, respectively. At the end of the experiment day (at 5:00 pm), the solar radiation intensity was 270 W/m2, while the ambient temperature was 31 °C. Wind speed was randomly changing during all the experiment day within the range of 0.78 and 1.5 m/s. Figure 7b shows the variations of wicks and glass cover temperatures concerning time for types (A) and (B) solar stills. Adding reflectors to type (B) solar still led to a maximum wick temperature of 78 °C at 12:30 pm which was higher than type (A) solar still by 4% at this time. The beginning, maximum, and end recorded values for the type (B) glass cover temperature were 27, 61, and 38.5 °C, respectively, while these values for type (A) glass cover changed to 26, 58, and 37 °C, respectively. Depending on hourly and accumulated freshwater distillate shown in Fig. 7c and d, respectively, adding a top and bottom reflector to type (B) solar still with cotton cloth wicks increases the productivity by 37.99% compared to type (A) solar still with cotton cloth wicks. According to energy efficiency calculations, the efficiency of type (B) solar still with cotton cloth wicks and reflectors was 55.72% which was higher than type (A) solar still with cotton cloth wicks by 39.96%.

Effect of cotton cloth and cover cooling on the wick solar still performance

The beginning values of solar radiation intensity and ambient temperature at 7:00 am were 175 W/m2 and 26 oC, respectively, thereafter these values were increasing till reaching their maximum values; 885 W /m2 and 34 °C, respectively, at 12:30 pm. After that, they were decreasing until the end of the experiment day at 5:00 PM. At that time, solar radiation intensity and ambient temperature recorded 265 W/m2 and 29 °C, respectively. Wind speed was changing randomly within a range of 0.2–1.5 m/s. Figure 8a shows variations in measured metrological parameters with respect to time during the experiment day. Variations in wicks, glass cover, and cooling water temperatures were measured and recorded in Fig. 8b. The cooling water temperature ranged between 25 and 33 °C. At noon (12:00 pm), the temperature difference between wicks and glass cover for type (B) solar still with cotton cloth wicks and glass cover cooling was 25 °C, while type (A) solar still with cotton cloth wicks recorded only 11 °C. So, the freshwater productivity of type (B) solar still was higher than type (A) solar still as shown in Fig. 9c and d. For example, type (B) solar still was higher than type (A) solar still by 20.78% in hourly freshter distillate at 12:30 PM. Moreover, the accumulated freshter distillate of type (B) solar still was higher than type (A) solar still by 30.59%. Energy efficiency calculations showed that type (B) solar still with cotton cloth wicks and glass cover cooling has an energy efficiency of 53% which was higher than type (A) solar still with cotton cloth wicks by 33.13%.

Effect of cotton cloth wicks, reflectors, and cover cooling on the wick solar still performance

At 7:00 am, the solar radiation intensity was 200 W/m2, while the ambient temperature was 26 °C. Then, they were increasing to their maximum values at 12:30 pm. The maximum values of solar radiation intensity and ambient temperature were 900 W/m2 and 34 °C, respectively. At the end of the experiment day (at 5:00 pm), the solar radiation intensity recorded 250 W/m2. At the same time, the ambient temperature was 31 °C. Wind speed was changing randomly between maximum and minimum levels of 0.8 and 2.2 m/s. Figure 9a illustrates variations in ambient conditions during the experiment day. Variations in wicks, glass cover, and cooling water temperatures were recorded and are plotted in Fig. 9b. The cooling water temperature ranged between 24 and 33 °C. In the afternoon (at 1:00 PM), the temperature difference between wicks and glass cover for type (B) solar still with cotton cloth wicks, reflectors, and glass cover cooling was 26.5 °C. In contrast, type (A) solar still with cotton cloth wicks recorded only 14 °C. This increment in temperature difference between evaporation and condensation areas in type (B) solar still is a result of using reflectors and glass cover cooling and led to an increment in freshwater productivity as shown in Fig. 9 (c) and (d). For example, type (B) solar still freshter distillate was higher than type (A) solar still by 66.67 and 77.78% at 10:00 am and 3:00 pm, respectively. Furthermore, accumulated freshter distillate of type (B) solar still was higher than type (A) solar still by 52.36%. According to energy efficiency calculations, type (B) solar still with cotton cloth wicks, reflectors, and glass cover cooling had an efficiency of 63.1% which was higher than type (A) solar still with only cotton cloth wicks by 58.5%.

Finally, the average daily exergy efficiency of type A, type B, and type C wick solar still with different aspect ratio was 3.65%, 4.05%, and 3.11%, respectively, as illustrated in Fig. 10. Furthermore, the average daily exergy efficiency of type B with cooling, type B with reflectors, and type B wick solar still with cooling and reflectors was found to be 4.55%, 4.9%, and 5.36%, respectively. The combined effect of type B with cooling and reflectors coating increased the exergy efficiency of wick solar still by 46.84%, compared to conventional wick solar still type A, and 32.34% compared to conventional wick solar still type B without any modifications, respectively. This was due to cooling and reflectors activated carbon with high energy storage capacity, which leads to significantly augmented exergy.

Comparison between present work and previous literature

Herein, a comparison between the present work and previous literature depending on the cost of produced freshter and augmentation in freshwater productivity was carried out. Table 1 summarizes this comparison.

Cost analysis

To assess the proposed solar stills from a financial point of view, a cost analysis was carried out as illustrated in Table 2. In this section, the accomplished cost analysis was described. The total number of configurations in all experiments is eight. These eight configurations are type (A) with cotton cloth wicks, type (B) with cotton cloth wicks, cotton towel wicks, jute cloth wicks, cotton cloth wicks and reflectors, cotton cloth wicks and glass cover cooling, cotton cloth wicks, and both of reflectors and glass cover cooling, and type (C) with cotton cloth wicks. To get the annual freshwater output from the accumulated daily freshwater distillate, multiply it by only 270 days. However, the sun rises almost all days of the year in Egypt so that the obtained results are reliable and true although the experiments were not carried out over all the year [48]. By the aid of the following equations which were described by [10], Table 2 is established to evaluate the total cost of one liter of produced freshwater for every configuration.

where \(L_{{{\text{TC}}}}\) is the total cost of one liter of freshwater, \(C_{{{\text{TA}}}}\) is a total annual cost which can be calculated by Eq. (8), and \({\text{FWD}}_{{{\text{TA}}}}\) is total annual freshter distillate.

where \(C_{{{\text{AF}}}}\) is an annual fixed cost, \(C_{{{\text{AOM}}}}\) is annual operating and maintenance cost, and \(V_{{{\text{AS}}}}\) is annual salvage value. All of these values were calculated by Eq. (9).

where \(C_{{\text{F}}}\) is fixed cost and \(F_{{\text{R}}}\) is a recovery factor which is calculated by knowing annual interest value (\(i = 12\%\)) and life years of the system (\(n = 10\)).

where \(S\) is salvage value and equal to \(20\% C_{{\text{F}}}\) and \(F_{{{\text{SF}}}}\) can be calculated as follows:

Conclusions

In this paper, three-wick solar stills with different aspect ratios but with the same evaporation and condensation areas were experimentally investigated. The first best solar still was type (B), and it was tested with three different wick materials: cotton cloth, cotton towel, and jute cloth. Cotton cloth wicks showed the best results as it has the best capillary action out of all these wicks. Then, top and bottom reflectors were added to type (B) solar still with cotton cloth wicks and compared with type (A) solar still with cotton cloth wicks. The previous experiment was repeated twice but one time was with glass cover cooling in state of reflectors and the other time was with both reflectors and glass cover cooling. On the light of the discussed results and cost analysis, we can conclude as follows:

-

Type (B) solar still with its medium dimensions showed higher freshwater productivity than type (A) and type (C) solar stills by 16.31 and 22.41%, respectively.

-

Using cotton cloth wicks with type (B) solar still gave higher freshter productivity than using a cotton towel and jute cloth wicks by 19.17 and 24.14%, respectively.

-

Adding top and bottom reflectors to type (B) solar still with cotton cloth wicks increased the freshter productivity and energy efficiency by 37.99 and 39.96%, respectively, compared to type (A) solar still with cotton cloth wicks. Moreover, the cost of one liter of fresh water distillate was decreased by 1.82%.

-

Applying glass cover cooling on type (B) solar still with cotton cloth wicks increased the freshwater productivity and energy efficiency by 30.59 and 33.13%, respectively, compared to type (A) solar still with cotton cloth wicks. Furthermore, the cost of one liter of freshwater distillate was reduced by 7.69%.

-

Adding reflectors and glass cover cooling for type (B) solar still with cotton cloth wicks increased the freshwater productivity and energy efficiency by 52.36 and 58.5%, respectively. On the other hand, the cost per liter of freshwater was reduced by 9.8%.

References

Holdren, J.P., Ehrlich, P.R.: Human population and the global environment: population growth, rising per capita material consumption, and disruptive technologies have made civilization a global ecological force. Am. Sci. 62, 282–292 (1974)

Nisan, S., Benzarti, N.: A comprehensive economic evaluation of integrated desalination systems using fossil fuelled and nuclear energies and including their environmental costs. Desalination 229, 125–146 (2008)

Al-Karaghouli, A., Kazmerski, L.L.: Energy consumption and water production cost of conventional and renewable-energy-powered desalination processes. Renew. Sustain. Energy Rev. 24, 343–356 (2013)

Katekar, V.P., Deshmukh, S.S.: A review on research trends in solar still designs for domestic and industrial applications. J. Clean. Prod. 257, 120544 (2020)

Sharshir, S.W., Yang, N., Peng, G., Kabeel, A.E.: Factors affecting solar stills productivity and improvement techniques: a detailed review. Appl. Therm. Eng. 100, 267–284 (2016)

Singh, H.N., Tiwari, G.N.: Monthly performance of passive and active solar stills for different Indian climatic conditions. Desalination 168, 145–150 (2004)

Wang, Y., Kandeal, A.W., Swidan, A., Sharshir, S.W., Abdelaziz, G.B., Halim, M.A., Kabeel, A.E., Yang, N.: Prediction of tubular solar still performance by machine learning integrated with Bayesian optimization algorithm. Appl. Therm. Eng. 184, 116233 (2021)

Kabeel, A.E., Sharshir, S.W., Abdelaziz, G.B., Halim, M.A., Swidan, A.: Improving performance of tubular solar still by controlling the water depth and cover cooling. J. Clean. Prod. 233, 848–856 (2019)

Elmaadawy, K., Kandeal, A.W., Khalil, A., Elkadeem, M.R., Liu, B., Sharshir, S.W.: Performance improvement of double slope solar still via combinations of low cost materials integrated with glass cooling. Desalination 500, 114856 (2021)

Sharshir, S.W., Eltawil, M.A., Algazzar, A.M., Sathyamurthy, R., Kandeal, A.W.: Performance enhancement of stepped double slope solar still by using nanoparticles and linen wicks: energy, exergy and economic analysis. Appl. Therm. Eng. 174, 115278 (2020)

Kabeel, A.E., Sathyamurthy, R., Sharshir, S.W., Muthumanokar, A., Panchal, H., Prakash, N., Prasad, C., Nandakumar, S., El Kady, M.S.: Effect of water depth on a novel absorber plate of pyramid solar still coated with TiO2 nano black paint. J. Clean. Prod. 213, 185–191 (2019)

Sharshir, S.W., Kandeal, A.W., Ismail, M., Abdelaziz, G.B., Kabeel, A.E., Yang, N.: Augmentation of a pyramid solar still performance using evacuated tubes and nanofluid: experimental approach. Appl. Therm. Eng. 160, 113997 (2019)

Sharshir, S.W., Elkadeem, M.R., Meng, A.: Performance enhancement of pyramid solar distiller using nanofluid integrated with v-corrugated absorber and wick: an experimental study. Appl. Therm. Eng. 168, 114848 (2020)

El-Bahi, A., Inan, D.: A solar still with minimum inclination, coupled to an outside condenser. Desalination 123, 79–83 (1999)

Sharshir, S.W., Peng, G., Wu, L., Yang, N., Essa, F.A., Elsheikh, A.H., Mohamed, S.I.T., Kabeel, A.E.: Enhancing the solar still performance using nanofluids and glass cover cooling: experimental study. Appl. Therm. Eng. 113, 684–693 (2017)

Sathyamurthy, R., Kabeel, A.E., Balasubramanian, M., Devarajan, M., Sharshir, S.W., Manokar, A.M.: Experimental study on enhancing the yield from stepped solar still coated using fumed silica nanoparticle in black paint. Mater. Lett. 272, 127873 (2020)

Abdelaziz, G.B., El-Said, E.M.S., Bedair, A.G., Sharshir, S.W., Kabeel, A.B., Elsaid, A.M.: Experimental study of activated carbon as a porous absorber in solar desalination with environmental, exergy, and economic analysis, process safety and environmental Protection, (2021)

Sharshir, S.W., El-Samadony, M.O.A., Peng, G., Yang, N., Essa, F.A., Hamed, M.H., Kabeel, A.E.: Performance enhancement of wick solar still using rejected water from humidification-dehumidification unit and film cooling. Appl. Therm. Eng. 108, 1268–1278 (2016)

Sharshir, S.W., Algazzar, A.M., Elmaadawy, K.A., Kandeal, A.W., Elkadeem, M.R., Arunkumar, T., Zang, J., Yang, N.: New hydrogel materials for improving solar water evaporation, desalination and wastewater treatment: a review. Desalination 491, 114564 (2020)

Sharshir, S.W., Peng, G., Elsheikh, A.H., Edreis, E.M.A., Eltawil, M.A., Abdelhamid, T., Kabeel, A.E., Zang, J., Yang, N.: Energy and exergy analysis of solar stills with micro/nano particles: a comparative study. Energy Convers. Manag. 177, 363–375 (2018)

Sharshir, S.W., Ellakany, Y.M., Eltawil, M.A.: Exergoeconomic and environmental analysis of seawater desalination system augmented with nanoparticles and cotton hung pad. J. Clean. Prod. 248, 119180 (2020)

Sharshir, S.W., Peng, G., Wu, L., Essa, F.A., Kabeel, A.E., Yang, N.: The effects of flake graphite nanoparticles, phase change material, and film cooling on the solar still performance. Appl. Energy 191, 358–366 (2017)

Sharshir, S.W., Peng, G., Yang, N., Eltawil, M.A., Ali, M.K.A., Kabeel, A.E.: A hybrid desalination system using humidification-dehumidification and solar stills integrated with evacuated solar water heater. Energy Convers. Manag. 124, 287–296 (2016)

Sharshir, S.W., Peng, G., Yang, N., El-Samadony, M.O.A., Kabeel, A.E.: A continuous desalination system using humidification—dehumidification and a solar still with an evacuated solar water heater. Appl. Therm. Eng. 104, 734–742 (2016)

El-Said, E.M.S., Abdelaziz, G.B.: Experimental investigation and economic assessment of a solar still performance using high-frequency ultrasound waves atomizer. J. Clean. Prod. 256, 120609 (2020)

Peng, G., Ding, H., Sharshir, S.W., Li, X., Liu, H., Ma, D., Wu, L., Zang, J., Liu, H., Yu, W., Xie, H., Yang, N.: Low-cost high-efficiency solar steam generator by combining thin film evaporation and heat localization: both experimental and theoretical study. Appl. Therm. Eng. 143, 1079–1084 (2018)

Elsheikh, A.H., Sharshir, S.W., Ahmed Ali, M.K., Shaibo, J., Edreis, E.M.A., Abdelhamid, T., Du, C., Haiou, Z.: Thin film technology for solar steam generation: a new dawn. Sol. Energy 177, 561–575 (2019)

Peng, G., Deng, S., Sharshir, S.W., Ma, D., Kabeel, A.E., Yang, N.: High efficient solar evaporation by airing multifunctional textile. Int. J. Heat Mass Transf. 147, 118866 (2020)

Sharshir, S.W., Peng, G., Elsheikh, A.H., Eltawil, M.A., Elkadeem, M.R., Dai, H., Zang, J., Yang, N.: Influence of basin metals and novel wick-metal chips pad on the thermal performance of solar desalination process. J. Clean. Prod. 248, 119224 (2020)

Thakur, A.K., Sathyamurthy, R., Sharshir, S.W., Elnaby Kabeel, A., Shamsuddin Ahmed, M., Hwang, J.-Y.: A novel reduced graphene oxide based absorber for augmenting the water yield and thermal performance of solar desalination unit. Mater. Lett. 286, 128867 (2021)

Manikandan, V., Shanmugasundaram, K., Shanmugan, S., Janarthanan, B., Chandrasekaran, J.: Wick type solar stills: a review. Renew. Sustain. Energy Rev. 20, 322–335 (2013)

Alaian, W.M., Elnegiry, E.A., Hamed, A.M.: Experimental investigation on the performance of solar still augmented with pin-finned wick. Desalination 379, 10–15 (2016)

Abdullah, A.S., Alarjani, A., Abou Al-sood, M.M., Omara, Z.M., Kabeel, A.E., Essa, F.A.: Rotating-wick solar still with mended evaporation technics: Experimental approach. Alex. Eng. J. 58, 1449–1459 (2019)

Kabeel, A.E.: Performance of solar still with a concave wick evaporation surface. Energy 34, 1504–1509 (2009)

Abdel-Rehim, Z.S., Lasheen, A.: Experimental and theoretical study of a solar desalination system located in Cairo, Egypt. Desalination 217, 52–64 (2007)

Omara, Z.M., Kabeel, A.E., Abdullah, A.S.: A review of solar still performance with reflectors. Renew. Sustain. Energy Rev. 68, 638–649 (2017)

Tanaka, H.: Experimental study of a basin type solar still with internal and external reflectors in winter. Desalination 249, 130–134 (2009)

Omara, Z.M., Kabeel, A.E., Younes, M.M.: Enhancing the stepped solar still performance using internal and external reflectors. Energy Convers. Manage. 78, 876–881 (2014)

El-Samadony, Y.A.F., Abdullah, A.S., Omara, Z.M.: Experimental study of stepped solar still integrated with reflectors and external condenser. Exp. Heat Transf. 28, 392–404 (2015)

Omara, Z.M., Abdullah, A.S., Kabeel, A.E., Essa, F.A.: The cooling techniques of the solar stills’ glass covers—a review. Renew. Sustain. Energy Rev. 78, 176–193 (2017)

Somwanshi, A., Tiwari, A.K.: Performance enhancement of a single basin solar still with flow of water from an air cooler on the cover. Desalination 352, 92–102 (2014)

Abdullah, A.S.: Improving the performance of stepped solar still. Desalination 319, 60–65 (2013)

Dhiman, N.K., Tiwari, G.N.: Effect of water flowing over the glass cover of a multi-wick solar still. Energy Convers. Manag. 30, 245–250 (1990)

Zurigat, Y.H., Abu-Arabi, M.K.: Modelling and performance analysis of a regenerative solar desalination unit. Appl. Therm. Eng. 24, 1061–1072 (2004)

Holman, J., Gajda, W.J.N.Y. : Experimental Methods for Engineers. McGraw-Hill Book Company, (1978)

Kabeel, A.E., Abdelgaied, M., Eisa, A.: Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J. Clean. Prod. 183, 20–25 (2018)

Sharshir, S., Elsheikh, A., Peng, G., Yang, N., El-Samadony, M., Kabeel, A.: Thermal performance and exergy analysis of solar stills–A review. Renew. Sustain. Energy Rev. 73, 521–544 (2017)

Kabeel, A., Abdelgaied, M.J.J.O.C.P.: Performance enhancement of a photovoltaic panel with reflectors and cooling coupled to a solar still with air injection, 224, 40–49 (2019)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharshir, S.W., Salman, M., El-Behery, S.M. et al. Enhancement of solar still performance via wet wick, different aspect ratios, cover cooling, and reflectors. Int J Energy Environ Eng 12, 517–530 (2021). https://doi.org/10.1007/s40095-021-00386-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-021-00386-0