Abstract

This research aims to investigate the effect of integrating a simple solar collector, floatable black wicks, and orientation as modified double-slope solar still (MDSSS), and to compare its performance with conventional double-slope solar still (CDSSS). Costs of the developed desalination system were estimated, and its performance was compared with the previous literatures. A black hose was coiled and used as simple solar collector for preheating the saline water that is fed to the solar still. The floatable black wicks were used to increase the evaporation surface area and cause a localization of absorbed insolation at the evaporation surface of saline water. The longitudinal axis of solar still was oriented to north-south and east-west, the and productivity from each side was quantified. The northern side of MDSSS has more yield than the southern side by 33.98% for the east-west orientation and preheating. For the east-west orientation, preheating, and floatable black wicks, the total yield of MDSSS exceeded the CDSSS by 45.65%. And at the same conditions, the daily average efficiency of southern and northern sides of MDSSS was 25.33 and 37.25%, while for CDSSS, it was 13.87 and 30.73%, respectively. Estimated costs revealed that cost per liter water was about 0.062 and 0.059 $ for CDSSS and MDSSS, respectively. Solar still can provide a reasonable amount of water for irrigation based on daily production by installing the MDSSS in furrow, but keeping the longitudinal axis to east-west can secure more amount of water. The used modifications improved the solar still productivity and efficiency.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The solar desalination technology presents an alternative method than can be used to partially provide fresh water to humanity with simple technology, costless energy, and friendly to the environment. Solar desalination is an effective technique and renewable source of water in rural or remote areas, especially when the water demand is not too much. However, there are some drawback that offset these features and affect applications of these technologies such as low productivity and it requires large flat area of land for construction. Therefore, several researches were carried out in order to enhance the productivity of solar still.

The solar still productivity are affected by several factors like basin area, evaporation surface area, depth of water in the basin, temperature of feed water, and difference between evaporation surface temperature and top glass cover temperature. Tripathi and Tiwari (2006), Phadatare and Verma (2007), and Eltawil and Zhengming (2009) pointed out that increasing water depth in the basin led to decrease the solar still productivity and vice versa. Keeping water depth at minimum level in the solar still is very difficult; therefore, Velmurugan et al. (2009) used stepped solar still, Ward (2003) used plastic water purifier, and Kalidasa and Srithar (2011) used wicks to improve the solar still output. The previous literatures pointed out that a reduction of the saline depth in the solar still basin enhances the yield, and this may be attributed to the increase of water temperature in the basin.

The advantage of the wick is to keep the brine as shallow as possible while avoiding dry spots (Omara et al. 2013). Using the wick led to increase the evaporating surface area of the saline water through base and vertical walls of the basin. Also, it provides the solar still with a low thermal capacity and consequently faster response to insolation and higher evaporation rate.

Kalidasa et al. (2008) used mild steel plate to made a double-slope solar still (DSSS). Also, they used several wick materials in the basin like “light cotton cloth, sponge sheet, coir mate, and waste cotton pieces” in order to reduce the water flow rate. Results pointed out that the best wick material was “light black cotton cloth.”

Sakthivel et al. (2010) modified the solar still by attaching the jute cloth to the wall of solar still and fixed another layer of jute cloth in vertical position in the basin water at the middle. Results indicated that the efficiency was increased by about 8%, while the cumulative yield by using jute cloth was enhanced by about 20%. Kabeel (2009) formed a concave-wick surface for evaporation that is covered by a pyramid glass cover. The condensation takes place on four sides of a pyramid-shaped solar still. The distillate yield in the day time was about 4.1 l/m2 which attributed to the wick capillary effect and increased the evaporation surface due to using a concave shape. Tanaka (2011) tried to enhance the solar still productivity by using a flat plate reflector and analyzed the system performance numerically.

Omara et al. (2013) studied the integration of wicks and evacuated solar water heater with solar still. Omara and Eltawil (2013) used a simple solar collector, small L-shaped solar still as new boiler, and solar dish concentrator for water desalination. The plastic hose is a low-cost material that could be easily assembled in a simple home-made collector, hence avoiding expensive solutions like selective paints, inner-gas arc welding, and vacuum tubes (Juanicó and Di Lalla 2013).

Several researchers such as Eltawil et al. (2009), Kalidasa et al. (2008), Sampathkumar et al. (2010), Velmurugan and Srithar (2011), and Gnanaraj and Velmurugan (2019) have investigated experimentally and reviewed, thoroughly, the work on integration of renewable energy sources with desalination systems. They have investigated different designs of solar stills and their performance. Nazari et al. (2019) conducted an experimental study to improve the performance of single-slope solar still by using the “thermoelectric cooling channel and copper oxide nanofluid,” which improved the productivity by 81%.

El-Maghlany et al. (2020) studied the effect of continuous and discrete makeup water on the productivity of conventional solar still. Two scenarios were compared, the first one was continues makeup water (heat load penalty) to keep the thickness of water in the basin constant at 0.5 to 20 cm with each thickness as an individual case study. The second scenario was with water thickness reduction with time from initial maximum thickness of 20 cm and 1 cm to minimum level up to 0.5 cm.

Kabeel et al. (2019) conducted a comparative analysis on freshwater yield from conventional basin-type single-slope solar still with cement-coated red bricks. The exposure area of water was increased in modified solar still (MSS) by keeping the cement-coated red bricks in the absorber. Results indicated an improvement of about 34% in the water temperature, which acted as the driving force for evaporation of water inside the closed chamber.

Balachandran et al. (2019) improved the efficiency of single-sloped solar still using thermally conductive nano-ferric oxide. The cumulative yield for microabsorbent layer solar still and nanoabsorbent layer solar still was 3.23 and 4.39 kg/m2, respectively.

Sharshir et al. (2020c) improved the solar still performance by using three types of heat localization materials (HSHLM) such as “carbon foam with wick, exfoliated graphite flakes with wick, and exfoliated graphite flakes with wick and carbon foam,” which were floated on the water surface. Results revealed that the daily yield was improved by 34.5% for exfoliated graphite flakes with wick, 28.6% for carbon foam with wick, and 51.8% for exfoliated graphite flakes with wick and carbon foam, compared with traditional solar still.

Bixio et al. (2006) mentioned that “about half of the European countries are under water stress.” Therefore, to meet the increasing water demands of the society, it is necessary to develop strategies but which do not further degrade or damage the environment integrity.

Various techniques were investigated to improve the solar still performance through modifying designs or operating variables such as inclined wick still (Sharshir et al. 2020b, additional condenser (Feilizadeh et al. 2019), double slope connected to heat exchanger (Sahota et al. 2017), nanoparticles (Sharshir et al. 2020a), and nanofluids (Sahota and Tiwari 2016a, b; Sharshir et al. 2018). Rahbar et al. (2017) performed an exergy analysis for a double-slope solar still equipped with thermoelectric heating modules in order to improve the solar still performance. Water temperature was increased by using thermoelectric modules as a water heater. Results revealed that the maximum exergy efficiency of the system was about 25%, and cost of productivity during day and night was 0.1422 and 0.237 $/l/m2, respectively.

The daily yield of a solar still can be increased by changing orientation and glass cover inclination. The inclination and direction of the glass cover depend on the latitude. Meanwhile, optimizing the glass cover inclination leads to the optimization of the solar still yield area as well (Singh et al. 1995; Tiwari et al. 1994). Abderachid and Abdenacer (2013) studied the effect of orientation on the performance of a symmetric solar still with a double-effect solar still through a computer program. Results indicated that a 10° cover tilt and 0.02-m water depth were the optimum design for both stills at south-north and east-west orientations. Altarawneh et al. (2017) investigated the annual performance of single-basin single-slope, double-slope, and pyramidal-shaped solar stills experimentally and theoretically. On a seasonal basis, a south-oriented double-slope solar still with tilt angle of 35° was performed slightly better than the other stills in summer.

This research intended to enhance the distillate productivity of single-basin and double-slope solar still by integration with a simple solar collector and floatable black wicks at different orientations. The performance of the modified double-slope solar still (MDSSS) was compared with conventional double-slope solar still (CDSSS). The longitudinal axis of solar still was oriented to either north-south or east-west, and consequently, the fresh water production from each side was quantified and their performance was analyzed. The effect of individual parameters and their combined effect on the performance and productivity of the double-slope solar still were investigated. Performance and costs of the developed desalination system were compared with the previous literatures. This study suggested an alternative irrigation method for future work, where the basin of MDSSS can be installed in furrow between ridges, hence saline water evaporates and condensates on both sides for irrigation of agricultural plants growing on ridges.

Materials and methods

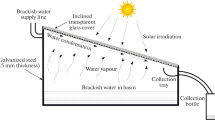

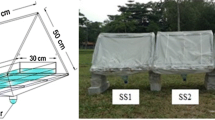

Two similar DSSSs of 2-m length, 1-m width, and 0.20-m height of sidewalls were designed and installed outdoor for performance evaluation as shown in Figs. 1 and 2. Basins of the two solar stills were made from galvanized sheets and painted from inside with a matte black paint to enhance the absorptivity of insolation. The basin was covered with double-slope glass sheets of 4-mm thick. The top cover was inclined with 30o horizontally at both sides (nearly latitude of the location). The experiments were carried out at the College of Agricultural and Food Sciences, King Faisal University, Al-Ahsa (25° 18′ N latitude, 49° 29′ E longitude), Saudi Arabia.

To minimize heat loss to the ambient, bottom and sidewalls of the basin were insulated by foam of 2-cm thick. The density of the foam is about 30 kg/m3, while its thermal conductivity is about 0.0246 W/m °C. The main saline water tank was kept at 1-m height, while the height of water in the constant head tank was about 0.20 m. The saline water was supplied to the basins continuously through a float bulb, which is used to keep a constant volume of water in the basins. One solar still was used as control (CDSSS), while the other still was modified by adding a simple preheating technique and floating wick to enhance the solar still performance.

The wick material was blackened by using standard dye bathes in order to avoid fading of black color. Inner base and vertical walls of the basin were covered by double layers of blackened wick. There were 5 wooden blocks, each one had dimensions of 0.98-m length × 0.05-m height × 0.04-m width, which kept in between the basin base metal and the double layers of wicks. The wooden blocks were used to keep the wicks floating above the base as shown in Figs. 3 and 4.

Covering the wooden blocks and sidewalls of the basin with blackened wicks led to increase the evaporation surface area and cause a localization of absorbed solar radiation at the evaporation surface of saline water. It should be noted that the double layers of blackened wicks created a thin film of water above the basin base, and water raised up by capillarity along the wooden blocks and basin sidewalls that are exposed to solar radiation, hence increasing the distillate productivity.

A 10-m-long black hose with diameter of 0.0254 m was coiled and used to preheat the saline water that is coming from constant water head tank before feeding to the basins. The coiled hose was placed on a black asbestos sheet to enhance absorbability of insolation. The preheating unit was laid horizontally between the constant water head tank (float bulb) and the solar still basin.

The constant head tank of 0.40-m length × 0.25-m depth × 0.17-m width was used to control the feeding rate of saline water to the DSSS.

The performance of the developed desalination system was evaluated in the case with and without preheating of feed saline water, with and without floating wicks, and two orientations of the double-slope solar still (north-south or east-west). For easy movement of the DSSS, each still was provided with 4 wheels. For testing the effect of orientation on the productivity, the longitudinal axes of the DSSS were oriented to either north-south or east-west. The saline water depth in both the basins was kept constant at about 0.03 m. Each experiment was carried out for almost three sunny days during summer (July to September) 2018, and average data was considered.

Measurements and uncertainty analysis

To study the double-slope solar still performance, the temperatures of different components were measured by using a AT4532 Multi-channel meter with the help of calibrated K-type thermocouples. The thermocouples sensors were used to measure temperatures of saline water, basin water, water vapor, glass cover, surrounding air, and preheating collector. The insolation was measured by using a pyranometer model of LP02-LI19 on the top glass cover of the right and left sides in order to study the effect of insolation. A digital anemometer model of AM-4201 was used to measure surrounding wind speed. The distillate water that was collected from right and left sides were quantified using scaled cylinder for each side separately. A pH meter and total dissolved solids (TDS) meter were used to identify the water quality. The experimental data were measured every hour from early morning to late afternoon (8 am to 4 pm). The performance of the MDSSS was evaluated and compared with CDSSS to qualify the modification that was made.

Uncertainties associated with the experimental measurement apparatus are given in Table 1. When the experiments were conducted, physical quantities were measured by using instruments that have inherent uncertainty, which is represented by the accuracy of instruments. Uncertainty of instruments is associated with the systematic errors and can be obtained from the calibration report or data book of the instrument. Also, the standard uncertainty “U” for the measuring instruments can be calculated by using the following equation (Kirkup and Frenkel 2006; Lira 2002):

where ac is the accuracy of the instrument.

Solar still efficiency

To assess the thermal performance for both MDSSS and CDSSS, the diurnal efficiency (ηd) was calculated by using the following equation:

where, mp is the hourly distillate water (kg) for each side of the solar still, hl is the water evaporative latent heat which is equal to 2335 kJ/kg, Ins is the hourly insolation (kW/m2) on each side of the glass cover, and A is the surface area of each side of the glass cover as well as area of simple solar collector.

Results and discussion

Effect of preheating of saline water when the longitudinal axis was due east-west

Figure 5a shows the variation of insolation received by the solar still on three levels (northern glass cover (Ins_N), southern glass cover (Ins_S), and horizontal level (Ins_H)) when the longitudinal axis was due east-west. It is clear that the southern side of the glass cover receives greater insolation than the northern side throughout the day. During the forenoon, the measured insolation on the southern side was more than that on the horizontal level till noon; thereafter, the horizontal insolation became more than that on the southern side till the end of the day. Due to tilt angle of the glass cover and inclination angle of the sun, the higher solar radiation of 1015 W/m2 was recorded on the southern glass cover at 11 am. The average measured insolation on the southern side, northern side, and horizontal levels were 718.33, 500.56, and 726.33 W/m2, respectively. The measured wind speed varied from time to time and reached 0 m/s at 2 pm, thereafter increased. The average wind speed throughout the day was 0.28 m/s.

The variation of temperatures for different components of MDSSS, CDSSS, and ambient temperature (Tamb) is shown in Fig. 5b (with preheating) and Fig. 5c (without preheating). Generally, the temperature increased with time of the day, and the highest temperatures were recorded at noon and afternoon.

The daily average ambient temperature was 41.5 °C. The daily average feed water temperature was 40 °C, while the average water temperature in the collector was 56.2 °C. The daily average temperatures of the basin water for MDSSS and CDSSS were 67.2 and 62.8 °C, respectively (i.e., MDSSS over the CDSSS by 7%). As shown in Fig. 5b and c, the highest temperature was recorded for basin water in the MDSSS (about 75.2 °C) compared with CDSSS, and this is due to the cumulative effect of heat by insolation and feeding hot water from the preheating simple solar collector. For the same reason, the daily average vapor temperature for MDSSS (66.5 °C) was higher than that for CDSSS (64.1 °C). The southern side of the top glass cover showed a little bit higher temperature compared with the northern side for both solar stills. This result attributed to the higher insolation that is received by the southern side of the top glass cover compared with that of the northern side. In addition to the cooling effect of wind speed for northern side, which is below from the north- west direction. The daily average of southern and northern sides of the glass cover temperature for MDSSS was 58.5 and 58.3 °C, respectively, while the daily average temperature of southern and northern glass cover for CDSSS was 56.6 and 56.0 °C, respectively.

Figure 6 shows the hourly variation of productivity for both MDSSS and CDSSS when the longitudinal axis was directed to east-west and using the preheating collector with the MDSSS. The difference between basin water and top glass cover temperature plays an important role in increasing the distillate productivity (Gnanaraj and Velmurugan 2019). For the same solar still, the northern side produced more fresh water than the southern side. This result is attributed to that the northern glass cover was cooler than the southern one. In addition, the solar still has one basin and the inner part of the northern side wall is exposed to insolation more than the southern side; therefore, the northern side tends to produce water more than the southern one. The productivity of the southern side in the MDSSS varied from 20 to 380 ml with an average of 228.89 ml and total amount of 2060 ml, while the productivity of the northern side for the same solar still varied from 30 to 450 ml with an average of 306.67 ml and total amount of 2760 ml. For MDSSS, the northern side produced more fresh water than the southern side by 33.98%.

The minimum productivity was recorded in the morning, when water has not yet been heated up, while maximum distillate output was recorded in the afternoon (13 h), as expected. This increase of productivity would arise due to high insolation heating and high surrounding temperature. In addition, the fed saline water to the solar still needs time to warm up.

During night time, the production of fresh water from solar stills continued due to heat storage in water. Also, for the same solar still, the productivity of the northern side was more than the southern side. For MDSSS, the productivity from southern and northern sides was 500 and 610 ml, respectively, and the total yield of solar still during day and night was 5930 ml, while for CDSSS, the productivity from southern and northern sides was 180 and 200 ml, respectively, and the total yield of solar still during day and night was 4110 ml.

Also, as shown in Fig. 6, the productivity of CDSSS followed the same trend like the modified solar still. The southern side in the CDSSS varied from 15 to 280 ml with an average of 148.89 ml and total amount of 1340 ml, while the productivity of the northern side for the same solar still varied from 25 to 405 ml with an average of 265.56 ml and total amount of 2390 ml. For CDSSS, the productivity of the northern side over the southern side is 78.36%.

The total fresh water yield from the MDSSS during day time only was more than that of CDSSS by 29.22%, which is attributed to using the preheating simple solar collector with the modified solar still. The total yield from the MDSSS during day and night was better than that from the CDSSS by 44.28%, which is attributed to feeding hot water using simple solar collector and better heat storage for the MDSSS.

Figure 7 shows the hourly variation of efficiency for both MDSSS and CDSSS with time of the day when the longitudinal axis was due to east-west and using preheating for MDSSS. For the same solar still, it was found that the efficiency for the northern side was higher than that for the southern side during day time. This result may be due to that the temperature of northern glass cover was lower than the southern one, in addition to the southern side that received more insolation compared with the northern side. The daily average efficiency for MDSSS was 24.56 and 31.9% for southern and northern sides, respectively, while for CDSSS, the daily average efficiency was 14.92 and 27.46% for southern and northern sides, respectively. The daily average efficiency of the southern side in MDSSS was higher than that of the CDSSS by 64.61%, while for the northern side, the daily average efficiency of MDSSS was higher than that of the CDSSS by 16.16%. The reason for that may be attributed to the preheating unit that was used with the MDSSS in addition to the northern side that receive lower insolation compared with the southern side. It is obvious that the instantaneous thermal efficiency for the studied solar stills was increased so fast at the end of the process (at 16:00 pm). The reason for that may be attributed to the lower rate of solar radiation at that time of the day, while the evaporation process continued under these conditions with a good rate due to thermal effect of localization heat on the surface of floatable black wicks.

Effect of preheating of saline water when the longitudinal axis was due to north-south

Figure 8a shows the variation of receipt insolation on eastern glass cover, western glass cover, and horizontal level when the longitudinal axis was oriented to north-south. It is clear that the western glass cover receives greater insolation than the eastern side throughout the day. Insolation on horizontal plane followed the common trend, since it increased from morning till it reached the peak value at 11 am, thereafter deceased at the end of the day. The daily average recorded insolation on horizontal plane was more on the eastern and western sides. The daily average measured insolation on eastern side, western side, and horizontal level was 574.44, 671.33, and 711.89 W/m2, respectively. The western glass cover received more insolation in the afternoon compared with before noon. The measured wind speed varied with time, where it was 0 at 8 am and reached 1.5 m/s at 3 pm, thereafter increased. The average ambient wind speed throughout the day was about 0.51 m/s.

The variation of temperatures for different components of MDSSS with preheating is shown in Fig. 8b, while variation of temperature for CDSSS without preheating and ambient temperature (Tamb) is shown in Fig. 8c.

The daily average ambient temperature was 41.2 °C. The daily average feed water temperature was 40.4 °C, while the average water temperature in the collector was 56.9 °C (in the case of MDSSS). The daily average temperatures of the basin water for MDSSS and CDSSS were 63.5 and 60.2 °C, respectively (i.e., MDSSS over the CDSSS by 5.48%). As shown in Fig. 8b and c, the basin water temperature of 74.3 °C in the MDSSS was the highest temperature overall the two studied solar still, and this referred to the cumulative effect of heat by insolation and feeding hot water using simple preheating collector. For the same reason, the daily average vapor temperature for MDSSS (62.8 °C) was higher than that for CDSSS (61.1 °C). The eastern glass cover showed a little bit higher temperature compared with the western glass cover for both solar stills. This result may be attributed to the cooling effect of ambient wind speed for the western side, which is below from the north- west direction. For MDSSS, the daily average of eastern and western glass cover temperatures was 53.4 and 52.4 °C, respectively, while, the daily average of eastern and western glass cover temperatures was 51.7 and 51.3 °C, respectively, for CDSSS. For both solar stills, the eastern glass cover showed higher temperature compared with the western side during the forenoon; thereafter, the western side showed higher temperature compared with the eastern side from noon to the end of the day.

The hourly variation of productivity for both MDSSS and CDSSS when the longitudinal axis was due to north-south and using the preheating collector with the MDSSS is shown in Fig. 9. The western side produced more water than the eastern side for both solar stills except at 9 am, where the eastern side produced more water. This result may be attributed to that the eastern glass cover was exposed to more insolation before noon, while during after noon, the western side received more insolation. At noon (1 pm), there was a little drop in the productivity because the coming solar radiation diverted between both sides (eastern and western glass covers). The yield of the eastern side in the MDSSS varied from 35 to 400 ml with an average of 220.56 ml and total amount of 1985 ml, while the yield of the western side for the same solar still varied from 15 to 420 ml with an average of 240.0 ml and total amount of 2160 ml. For MDSSS, the western side produced more fresh water than the eastern side by 8.82%.

During night time, the production of fresh water from solar stills continued due to heat storage in water. For MDSSS, the fresh water yields from eastern and western sides were 240 and 560 ml, respectively, and the total yield of solar still during day and night was 4945 ml, while for CDSSS, the yields from eastern and western sides were 225 and 60 ml, respectively, and the total yield of solar still during day and night was 3025 ml.

Also, as shown in Fig. 9, the productivity of CDSSS followed the same trend as the modified solar still. The eastern side in the CDSSS varied from 25 to 250 ml with an average of 132.22 ml and total amount of 1190 ml, while the distillate yield of the western side for the same solar still varied from 10 to 320 ml with an average of 172.22 ml and total amount of 1550 ml. For CDSSS, the productivity of western side was over the eastern side by 30.25%.

The total distillate productivity of the MDSSS during day time only was more than that of CDSSS by 51.28%, which is attributed to using the preheating simple solar collector with the modified solar still. The total distillate productivity of the MDSSS during day and night was better than that of the CDSSS by 63.47%, which referred to feeding hot water using simple solar collector and better heat storage for the MDSSS.

The performance efficiency for both MDSSS and CDSSS with time of the day when the longitudinal axis was directed to north-south and using preheating for MDSSS is presented in Fig. 10. For the same solar still, it was found that the efficiency for the western side was higher than that for the eastern side from morning till after 11:00 am; thereafter, the efficiency of eastern side became more than that for the western side till the end of the day. The reason for that may be because the produced amount of water by eastern side was not big enough before noon, while the received insolation was high compared with the western side, and vice versa in the afternoon.

The daily average efficiency for MDSSS was 38.51 and 16.02% for eastern and western sides, respectively, while for CDSSS, the daily average efficiency was 20.99 and 11.50% for eastern and western sides, respectively. The daily average efficiency of the eastern side in MDSSS was higher than that of the CDSSS by 82.83%, while for western side, the hourly average efficiency of MDSSS was higher than that of the CDSSS by 47.10%. This may be because of using the preheating collector with the MDSSS and thermal effect of glass house, in addition to the western side that received higher insolation compared with the eastern side.

Based on the abovementioned results, Table 2 summarizes the total productivity (day and night) from each side of solar still and daily average efficiency for MDSSS in the case of preheating process at different orientations. The obtained results were compared with the CDSSS at the same orientations.

Effect of preheating of saline water, floatable black wicks when the longitudinal axis was due east-west

Figure 11a shows the variation of insolation receipt by solar still on northern glass cover, southern glass cover, and horizontal plane when the longitudinal axis was oriented to east-west. As shown in the figure, the solar stills received solar radiation with similar trend as mentioned before, where the insolation fall on the southern side of the glass cover was greater than on the northern side throughout the day. During the forenoon, the southern side received insolation more than the horizontal plane and vice versa after that, at the end of the day. The daily average insolation was 710.11, 470.56, and 692.78 W/m2 for the southern side, northern side, and horizontal plane, respectively. The measured wind speed varied from 0.8 to 2.3 m/s with a daily average of about 1.51 m/s.

Figure 11b and c show the temperatures of different components of MDSSS (with preheating and floating wicks) and CDSSS (without any modification) in addition to ambient temperature (Tamb). The daily average ambient temperature, feed water temperature, and collector water temperature was 40.9, 37.6, and 53.4 °C, respectively. The daily average temperatures of the basin water for MDSSS and CDSSS were 61.9 and 57.1 °C, respectively (i.e., MDSSS over the CDSSS by 8.4%). As shown in Fig. 11b and c, the highest temperature was recorded for basin water in the MDSSS (about 72.5 °C) compared with CDSSS (67.05 °C), and this may be attributed to the combined effect of insolation heat, preheating of feed water, and floating wicks. Also, for the same reason, the daily average vapor temperature of 58.6 °C which is recorded inside the MDSSS was higher than that inside the CDSSS (57.1 °C). The daily average of southern and northern sides of the glass cover temperature for MDSSS was 52.0 and 51.2 °C, respectively, while the daily average of southern and northern sides of the glass cover temperature for CDSSS was 51.5 and 50.7 °C, respectively. The daily average temperature of the glass cover for MDSSS was a little bit higher than that for CDSSS, and this may be referred to the higher basin water temperature and vapor temperature which was higher in the MDSSS compared with CDSSS. It should be noted that the higher ambient wind speed caused a reduction in the measured temperature for different components of both solar stills compared with the previous case of using preheating only. Also, the northern glass cover showed a little bit lower temperature compared with the southern one for both solar stills because of the cooling effect of the wind that is below the north-west direction.

The productivity based on hourly interval for both MDSSS and CDSSS when the longitudinal axis was due to east-west and using both of preheating collector and floating wicks with the MDSSS is shown in Fig. 12. The measured data followed the same trend as mentioned before in the case of using preheating only. For both solar stills, the productivity of the northern side was more than that of the southern side. This result is attributed to that the northern glass cover was cooler than the southern one. In addition, the solar still has one basin and the inner part of the northern side wall was exposed to insolation more than the southern side; therefore, the northern side tends to produce water more than the southern one. The daily average productivity of the southern side in the MDSSS was 256.67 ml with a total amount of 2310 ml, while the daily average productivity of the northern side for the same solar still was 321.11 ml with a total amount of 2890 ml. For MDSSS, the productivity of the northern side was greater than that of the southern side by 25.11%.

The productivity of solar stills continued during night time because of heat storage in water, and for the same solar still, the northern side produced fresh water more than the southern side. The productivity from southern and northern sides of MDSSS during night was 410 and 500 ml, respectively, and the total fresh water produced from both sides during day and night was 6110 ml.

The productivity of CDSSS followed the similar trend as the modified one (Fig. 12). The daily average yield of the southern side was 151.11 ml with a total amount of 1360 ml, while the daily average yield of the northern side was 267.22 ml with a total amount of 2405 ml. For CDSSS, the productivity of northern side was more than that of the southern side by 76.84%. During night, the productivity of CDSSS from southern and northern sides was 200 and 230 ml, respectively, and the total fresh water produced from both sides of solar still during day and night was 4195 ml.

During day time only, the productivity of MDSSS was greater than that of CDSSS by 38.11%, while during day and night time, the total yield of the MDSSS was better than the CDSSS by 45.65%. The reason for that is attributed to using the preheating simple solar collector and floating wicks with the modified solar still, whereas feeding hot water to the MDSSS raised the basin water temperature and shorten the time that is required to heat up water, hence it evaporates fast, while using floatable black wicks that have low thermal conductivity led to localizing the absorbed insolation at the evaporation surface and increased the evaporation surface area, hence the temperature of water nearby the evaporation surface reaches a relatively high level and evaporates fast (Ghasemi et al. 2014).

Figure 13 shows the variation of efficiency for both MDSSS and CDSSS with time of the day when the longitudinal axis was directed to east-west and the MDSSS was integrated with preheating solar collector and floatable black wicks. The measured data followed the same trend as mentioned before in the case of the longitudinal axis that was oriented to east-west and using preheating only with the MDSSS. The efficiency of the northern side was higher than that of the southern side for both solar stills during day time. The reason for that may be because the northern glass cover was a little bit cooler than the southern side; in addition during day time, the southern side received higher insolation compared with the northern side. The daily average efficiencies for southern and northern sides were 25.33 and 37.25%, respectively, in the case of MDSSS, while for CDSSS, the daily average efficiencies were 13.87 and 30.73% for southern and northern side, respectively. The daily average efficiency of the southern side in MDSSS was greater than that of the CDSSS by 82.66%, while for northern side, the daily average efficiency of MDSSS was greater than that of the CDSSS by 21.62%. The reason for that may be referred to the integration of preheating solar collector and floatable black wicks with the MDSSS in addition to the southern glass cover that received higher insolation compared with the northern side.

Feeding hot water to the MDSSS raised the basin water temperature, and using floatable black wicks caused a localization of absorbed insolation at the evaporation surface in addition to increased evaporation surface area, hence increasing the productivity. Therefore, the fresh water yield from the MDSSS was greater than that from the CDSSS.

Effect of preheating of saline water, floatable black wicks when the longitudinal axis was oriented to north-south

The variation of solar radiation falls on the three surfaces (eastern glass cover, western glass cover, and horizontal plane) when the longitudinal axis was directed to north-south, which is presented in Fig. 14. As shown in the figure, the solar stills received solar radiation with similar trend as mentioned before, whereas the average solar radiation fall on the eastern side of the glass cover was smaller than that on the western side throughout the day. Solar radiation falls on horizontal plane followed the common trend, since it increased from morning till it reached the peak value at noon, thereafter deceased at the end of the day. The daily average solar radiation on horizontal plane was more than on the eastern and western sides. The daily average measured insolation on eastern side, western side, and horizontal plane was 622.22, 635.11, and 706.11 W/m2, respectively. The western glass cover received more solar radiation in the afternoon compared with before noon. The measured wind speed varied with time, where it was 1.2 m/s at 9 am and reached 0 m/s at 4 pm. The average ambient wind speed throughout the day was about 0.42 m/s.

Fig. 14b and c show the temperatures of different components of MDSSS (with preheating and floatable wicks) and CDSSS (without any modification) in addition to ambient temperature (Tamb) when the longitudinal axis was due to north-south. The daily average ambient temperature, feed water temperature, and collector water temperature were 40.4, 39.2, and 52.2 °C, respectively. The daily average temperatures of the basin water for MDSSS and CDSSS were 60.8 and 54.5 °C, respectively (i.e., MDSSS over the CDSSS by 11.77%). The reason may be attributed to the combined effect of solar radiation heat, preheating of feed water by simple solar collector, and floating wicks. For the same reason, the daily average vapor temperature for MDSSS (58 °C) was higher than that for CDSSS (53.1 °C) by 9.24%. The eastern side of the top glass cover showed a little bit higher temperature compared with the western side for both solar stills. This result may be attributed to the cooling effect of ambient wind speed for the western side, which is below the north-west direction. For MDSSS, the daily average temperature of eastern and western glass cover temperature was 52.7 and 51.8 °C, respectively, while the daily average temperature of eastern and western glass cover was 49.7 and 49.5 °C, respectively, for CDSSS.

The productivity based on hourly interval for both MDSSS and CDSSS when the longitudinal axis was due to north-south and integration of preheating collector and floatable black wicks with the MDSSS are shown in Fig. 15. The western side produced more water than the eastern side for both of solar stills, except from 8 am to 10:30 am, where the eastern side produced more water. The reason may be attributed to that the eastern glass cover is exposed to more insolation before noon, while during afternoon, the western side received more insolation. The average yield of the eastern side in the MDSSS was 235 ml with a total amount of 2115 ml, while the average yield of the western side for the same solar still was 272.8 ml with a total amount of 2445 ml. For MDSSS, the western side produced more pure water than the eastern side by 13.85%.

During night time, the production of fresh water from solar stills continued due to heat storage in water. For MDSSS, the fresh water yields from eastern and western sides were 745 and 680 ml, respectively, and the total yield of solar still during day and night was 5595 ml.

The productivity of CDSSS followed the similar trend as the modified one (Fig. 15). The daily average yield of the eastern side was 146.11 ml with a total amount of 1315 ml, while the daily average yield of the western side was 175.6 ml with a total amount of 1580 ml. For CDSSS, the productivity of the western side was more than the eastern side by 20.15%. During night, the productivity of CDSSS from eastern and western sides was 240 and 90 ml, respectively, and the total fresh water produced from both sides of the solar still during day and night was 3225 ml.

During day time only, the fresh water yield from MDSSS was greater than that from CDSSS by 57.86%, while during day and night time, the total yield of the MDSSS was better than that of the CDSSS by 85.9%. The reason for that is attributed to feeding hot water by using the preheating simple solar collector and floatable black wicks with the modified solar still, whereas feeding hot water to the MDSSS raised the basin water temperature and shorten the time that is required to heat up the water, hence it evaporates fast, while using floatable black wicks that have low thermal conductivity led to localizing the absorbed insolation at the evaporation surface, increased the evaporation surface area, and sped up the evaporation rate.

The hourly performance efficiency for both MDSSS and CDSSS with time of the day when the longitudinal axis was directed to north-south and integration of preheating simple solar collector and floatable black wicks with MDSSS is presented in Fig. 16. For the same solar still, it was found that the efficiency for the western side was higher than that for the eastern side during the forenoon; thereafter, the efficiency of the eastern side became more than the western side till the end of the day. The reason for that (as mentioned before) may be because the produced amount of fresh water by the eastern side was not big enough before noon, while the received solar radiation was high compared with the western side, and vice versa in the afternoon.

For MDSSS, the daily average efficiency was 28.47 and 19.69% for eastern and western sides, respectively, while for CDSSS, the daily average efficiency was 13.40 and 12.50% for eastern and western sides, respectively. The daily average efficiency of eastern side in MDSSS was higher than that of the CDSSS by 112.52%, while for western side, the daily average efficiency of MDSSS was higher than that of the CDSSS by 57.51%. This may be because of the integration of preheating solar collector and floatable black wicks with the MDSSS and thermal effect of glass house, in addition to the western side that received higher solar radiation compared with the eastern side, whereas preheating of water that fed to the MDSSS raised the basin water temperature, while using floatable black wicks caused a localization of absorbed insolation at the evaporation surface (Ghasemi et al. 2014), in addition to increase the evaporation surface area, hence increasing the productivity. Therefore, the fresh water yield from the MDSSS was greater than that from the CDSSS.

Table 3 summarizes the total productivity (day and night) from each side of solar still and daily average efficiency for MDSSS in the case of preheating process and floatable black wicks at different orientations. The obtained results were compared with the CDSSS at the same orientations.

Cost estimation and comparison with previous literatures

The total cost of the solar distillation system depends on capital and maintenance costs. To ensure continuous production from the desalination system, the maintenance is assumed to be carried out 1 day per month. The maintenance should be carried out frequently for cleaning solar stills, replacing of broken or damaged parts, and ensuring continuous water supply into solar stills.

The total fixed costs (Fc) per 1 m2 for CDSSS and MDSSS were about 195 $ and 250 $, respectively. The variable cost (Vc) is considered equal to 0.3 × Fc per year as reported by Kabeel (2009). The total cost (Tc) is equal to total fixed and variable costs (i.e., Tc = Fc + Vc = Fc + 0.3 × Fc). Assume the annual variable cost includes the maintenance cost and the expected life span for solar still is about 10 years, then:

For MDSSS, the wick material may be replaced every 2 years due to fading of blackened color and salt accumulation, which may block the pores of the wick. Also, the simple solar collector (preheating unit) may be replaced two times during the solar still life span. The cost of replacing wicks and hose of solar collector for four times (excluding the cost of initial instillation) during the expected life of the system should be considered. Assuming that the cost of wicks is about 12 $, while the cost of hose is about 15 $, then the total costs of replacing wicks and hose are equal to 78 $ (i.e., 4 × 12 + 2 × 15 = 78 $).

It was found that the annual distillate productivity (day and night) was about 1258.5 l/m2 and 1833 l/m2 for CDSSS and MDSSS (preheating and floatable wicks) when the longitudinal axis was due to east-west. To determine the annual cost of 1-l freshwater, it is assumed that the solar still operates for 300 days in a year.

It should be noted that the CDSSS and MDSSS here were for research purpose and not for commercial use. It is expected that the cost would significantly decrease if a large number of solar stills are fabricated for commercial purpose. Also, for application in the agricultural field, there are some other cheap materials such as black polyethylene sheets, which can be used as basin, while transparent sheets can be used as cover. In addition, it is assumed that the system would operate for about 300 days per year, hence increasing the number of days will cut down costs.

For this investigation, the water was collected from a water well at Al-Hassa, Saudi Arabia. The quality of water that was fed to the desalination system and resultant water after desalination process was tested, and the results indicated that the TDS value was about 1427 ppm and 60 ppm before and after the experiment, respectively, whereas the PH value was 8.1 and 7.2 before and after the experiment.

The present work was compared with the previous literature which was carried out to enhance conventional double-slope solar stills by adding wicks and nanoparticles, thermoelectric heating, or modifying solar still (Table 4).

Suggestion for the future work

Scarcity of fresh water in semi-arid and arid regions has led to increase utilization of low-quality, recycled wastewater and brackish groundwater for irrigation (Drechsel et al. 2015; Schacht et al. 2016). The agronomic, economic, and environmental costs of irrigation with low-quality water have been created a need for the desalination long-term strategy that required sustainable irrigated crop production in dry areas (Ben-Gal et al. 2009). In principle, substituting desalination water for irrigation can improve crop yields without local negative environmental effects. Many agricultural crops and vegetables can be planted in ridges, whereas furrows that are made between ridges are used for irrigation. Furrow is a shallow trench or narrow groove made in the soil surface. Due to water shortage, the saline or waste water can be used for irrigation by using the simple technique of solar stills that can be installed in furrows between ridges (Fig. 17). Using solar stills for irrigation can stimulate a reduction irrigation erosion and reduce the required irrigation water and reuse the waste or saline water. Based on the results obtained in this study, even though the orientation of the longitudinal axis of solar stills towards east-west or north-south can provide a reasonable amount of water for irrigation based on daily production, keeping the longitudinal axis to east-west can secure more amount of water. Also, the integration of simple solar collector and floatable black wicks improved the solar still productivity and efficiency. The technology of installing solar stills in furrows for irrigation of crops that are planted in ridges will be discussed in detail in another paper.

Conclusion

This study was conducted to improve the productivity of the double-slope solar still by using simple solar collector and floatable black wicks. The performance was investigated for individual parameters and their combined effect under different orientations of the longitudinal axis, either north-south or east-west. Also, the performance was compared with the conventional double-slope solar still. Costs of the developed desalination system were estimated, and outcomes were compared with previous studies. Results revealed that for both solar stills (MDSSS and CDSSS), the productivity of the northern side was more than that of the southern side. In the case of preheating of saline water, the total yield (day and night) of MDSSS and CDSSS was 5.93 and 4.11 l, respectively for the east-west, while it was 4.945 and 3.025 l, respectively for the north-south orientation. In the case of preheating of saline water and floatable black wicks, the total yield (day and night) of MDSSS and CDSSS was 6.11 and 4.195 l, respectively for the east-west, while it was 5.995 and 3.325 l, respectively for the north-south orientation. In the case of preheating of saline water and floatable black wicks, the daily average efficiency of southern and northern sides of MDSSS was 25.33 and 37.25%, respectively, while for CDSSS, it was 13.87 and 30.73%, respectively at the east-west orientation.

Due to water shortage, the saline or waste water can be used for irrigation by using the simple technique of solar stills that can be installed in furrows between ridges. Even though the orientation of the longitudinal axis of solar stills towards east-west or north-south can provide a reasonable amount of water for irrigation based on daily production, keeping the longitudinal axis towards east-west can secure more amount of water. In addition, the integration of simple solar collector and floatable black wicks improved the solar still productivity and efficiency.

Abbreviations

- MDSSS:

-

Modified double-slope solar still

- CDSSS:

-

Conventional double-slope solar still

- T_fw :

-

Temp. of feed water tank, °C

- T_W_coll :

-

Temp. of water after preheating collector, °C

- T_bw.MDSSS :

-

Temp. of basin water in the MDSSS, °C

- T_vapor_MDSSS :

-

Temp. of vapor in the MDSSS, °C

- T_gS_MDSSS :

-

Temp. of glass cover in the southern side of MDSSS, °C

- T_gN_MDSSS :

-

Temp. of glass cover in the northern side of MDSSS, °C

- T_gE_MDSSS :

-

Temp. of glass cover in the eastern side of MDSSS, °C

- T_gW_MDSSS :

-

Temp. of glass cover in the western side of MDSSS, °C

- T_gS_CDSSS :

-

Temp. of glass cover in the southern side of CDSSS, °C

- T_gN_ CDSSS :

-

Temp. of glass cover in the northern side of CDSSS, °C

- T_gE_ CDSSS :

-

Temp. of glass cover in the eastern side of CDSSS, °C

- T_gW_ CDSSS :

-

Temp. of glass cover in the western side of CDSSS, °C

- T_vapor_CDSSS :

-

Temp. of vapor in the CDSSS, °C

- T_bw.CDSSS :

-

Temp. of basin water in the conventional solar still, °C

- Insolation:

-

Incident solar radiation

- Ins_S :

-

Insolation on the southern glass cover, W/m2

- Ins_N :

-

Insolation on the northern glass cover, W/m2

- Ins_E :

-

Insolation on the eastern glass cover, W/m2

- Ins_W :

-

Insolation on the western glass cover, W/m2

- Ins_H :

-

Insolation on the horizontal level, W/m2

- T_amb :

-

Ambient air temperature, °C

- WS:

-

Wind speed, m/s

- W_MDSSS_S :

-

Water productivity from southern side of MDSSS, ml

- W_MDSSS_N :

-

Water productivity from northern side of MDSSS, ml

- W_MDSSS_E :

-

Water productivity from eastern side of MDSSS, ml

- W_MDSSS_W :

-

Water productivity from western side of MDSSS, ml

- W_CDSSS_S :

-

Water productivity from southern side of CDSSS, ml

- W_CDSSS_N :

-

Water productivity from northern side of CDSSS, ml

- W_CDSSS_E :

-

Water productivity from eastern side of CDSSS, ml

- W_CDSSS_W :

-

Water productivity from western side of CDSSS, ml

- Effi_S_MDSSS :

-

Efficiency of southern side of MDSSS, %

- Effi_N_MDSSS :

-

Efficiency of northern side of MDSSS, %

- Effi_E_MDSSS :

-

Efficiency of eastern side of MDSSS, %

- Effi_W_MDSSS :

-

Efficiency of western side of MDSSS, %

- Effi_S_CDSSS :

-

Efficiency of southern side of CDSSS, %

- Effi_N_CDSSS :

-

Efficiency of northern side of CDSSS, %

- Effi_E_CDSSS :

-

Efficiency of eastern side of CDSSS, %

- Effi_W_CDSSS :

-

Efficiency of western side of CDSSS, %

References

Abderachid T, Abdenacer K (2013) Effect of orientation on the performance of a symmetric solar still with a double effect solar still (comparison study). Desalination 329:68–77

Altarawneh I, Rawadieh S, Batiha M, Al-Makhadmeh L, Alrowwad S, Tarawneh M (2017) Experimental and numerical performance analysis and optimization of single slope, double slope and pyramidal shaped solar stills. Desalination 423:124–134

Balachandran GB, David PW, Mariappan RK, Kabeel AE, Athikesavan MM, Sathyamurthy R (2019) Improvising the efficiency of single-sloped solar still using thermally conductive nano-ferric oxide. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-019-06661-2

Ben-Gal A, Yermiyahu U, Cohen S (2009) Fertilization and blending alternatives for irrigation with desalinated water. J Environ Qual 38:529–536

Bixio D, Thoeye C, De Koning J, Joksimovic D, Savic D, Wintgens T, Melin.T. (2006) Wastewater reuse in Europe. Desalination 187:89–101

Drechsel P, Danso G, Qadir M (2015) Wastewater use in agriculture: challenges in assessing costs and benefits. Springer, Wastewater, pp 139–152

El-Maghlany WM, Abdelaziz AH, Hanafy AA, Kabeel AE (2020) Effect of continuous and discrete makeup water on the productivity of conventional solar still. J Energy Storage 28:101223

Eltawil MA, Zhengming Z, Liqiang Y (2009) A review of renewable energy technologies integrated with desalination systems. Renew Sust Energ Rev 13(9):2245–2262

Feilizadeh M, Estahbanati MRK, Khorram M, Rahimpour MR (2019) Experimental investigation of an active thermosyphon solar still with enhanced condenser. Renew Energy 143:328–334

Ghasemi H, Ni G, Marconnet AM, Loomis J, Yerci S, Miljkovic N, Chen G (2014) Solar steam generation by heat localization. Nat Commun 2014(5):4449

Gnanaraj SJP, Velmurugan V (2019) An experimental study on the efficacy of modifications in enhancing the performance of single basin double slope solar still. Desalination 467:12–28

Juanicó LE, Di Lalla N (2013) A new low-cost plastic solar collector. ISRN Renew Energy 2013:102947, 10 pages. https://doi.org/10.1155/2013/102947

Kabeel AE (2009) Performance of solar stills with a concave wick evaporation surface. Energy 34:1504–1509

Kabeel AE, El-Sayed E-A, Athikesavan MM, Ramalingam RD, Sathyamurthy R, Prakash N, Prasad C (2019) Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: an experimental approach. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-019-07288-z

Kalidasa MK, Srithar K (2011) Performance study on basin type double slope solar still with different wick materials and minimum mass of water, Renew. Energy 36:612–620

Kalidasa MK, Chockalingam K, Srithar K (2008) Progresses in improving the effectiveness of the single basin passive solar still. Desalination 220:677–686

Kirkup L, Frenkel R (2006) An introduction to uncertainty in measurement using the GUM (guide to the expression of uncertainty in measurement), First. Cambridge University Press, Cambridge

Lira I (2002) Evaluation the measurement uncertainty fundamental and practical guidance. Institute of Physics Publishing

Modi KV, Modi JG (2019) Performance of single-slope double-basin solar stills with small pile of wick materials. Appl Therm Eng 149:723–730

Nazari S, Safarzadeh H, Bahiraei M (2019) Performance improvement of a single slope solar still by employing thermoelectric cooling channel and copper oxide nanofluid: an experimental study. J Clean Prod 208:1041–1052

Omara ZM, Eltawil MA (2013) Hybrid of solar dish concentrator, new boiler and simple solar collector for brackish water desalination. Desalination 326(1 October):62–68

Omara ZM, Eltawil MA, Elnashar EA (2013) A new hybrid desalination system using wicks/solar still and evacuated solar water heater. Desalination 325(16 september):56–64

Pal PP, Yadav RD, Singh D (2017) Performance analysis of modified basin type double slope multi–wick solar still. Desalination 422:68–82

Phadatare MK, Verma SK (2007) Influence of water depth on internal heat and mass transfer in a plastic solar still. Desalination 217:267–275

Rahbar N, Gharaiian A, Rashidi S (2017) Exergy and economic analysis for a double slope solar still equipped by thermoelectric heating modules-an experimental investigation. Desalination 420:106–113

Rajaseenivasan T, Murugavel KK (2013) Theoretical and experimental investigation on double basin double slope solar still. Desalination 319:25–32

Sahota L, Tiwari GN (2016a) Effect of Al2O3 nanoparticles on the performance of passive double slope solar still. Sol Energy 130:260–272

Sahota, L., Tiwari, G.N. (2016b) Effect of nanofluids on the performance of passive double slope solar still: a comparative study using characteristic curve, Desalination, 388 (2016b) 9-21.

Sahota L, Shyam, Tiwari GN (2017) Analytical characteristic equation of nanofluid loaded active double slope solar still coupled with helically coiled heat exchanger. Energy Convers Manag 135:308–326

Sakthivel M, Shanmugasundaram S, Alwarsamy T (2010) An experimental study on a regenerative solar still with energy storage medium-jute cloth. Desalination 264:24–31

Sampathkumar K, Arjunan TV, Pitchandi P, Senthilkumar P (2010) Active solar distillation-a detailed review. Renew Sust Energ Rev 14(14):1503–1526

Schacht K, Chen Y, Tarchitzky J, Marschner B (2016) The use of treated wastewater for irrigation as a component of integrated water resources management: reducing environmental implications on soil and groundwater by evaluating site-specific soil sensitivities. In: Integrated Water Resources Management: Concept, Research and Implementation. Springer, Berlin, pp 459–470

Sharshir SW, Peng G, Elsheikh AH, Edreis EMA, Eltawil MA, Abdelhamid T, Kabeel AE, Zang J, Yang N (2018) Energy and exergy analysis of solar stills with micro/nano particles: a comparative study. Energy Convers Manag 177:363–375

Sharshir SW, Ellakany YM, Eltawil MA (2020a, 248) Exergoeconomic and environmental analysis of seawater desalination system augmented with nanoparticles and cotton hung pad. J Clean Prod:119180

Sharshir SW, Peng G, Elsheikh AH, Eltawil MA, Elkadeem, Dai MR, Zang HJ, Yang N (2020b, 248) Influence of basin metals and novel wick-metal chips pad on the thermal performance of solar desalination process. J Clean Prod:119224

Sharshir SW, Elsheikh AH, Ellakany YM, Kandeal AW, Edreis EMA, Sathyamurthy R, Thakur AK, Eltawil MA, Hamed MH, Kabeel AE (2020c) Improving the performance of solar still using different heat localization materials. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-07800-w

Singh AK, Tiwari GN, Sharma PB, Khan E (1995) Optimization of orientation for higher yield of solar still for a given location. Energy Convers Manag 36:175–187

Tanaka H (2011) Tilted wick solar still with flat plate bottom reflector. Desalination 273:405–413

Tiwari GN, Thomas JM, Khan E (1994) Optimisation of glass cover inclination for maximum yield in a solar still. Heat Recover Syst CHP 14:447–455

Tripathi R, Tiwari GN (2006) Thermal modeling of passive and active solar stills for different depths of water by using the concept of solar fraction, Sol. Energy 80:956–967

Velmurugan VKJ, Kumar N, Noorul Haq T, Srithar K (2009) Performance analysis in stepped solar still for effluent desalination. Energy 34:1179–1186

Velmurugan V, Srithar K (2011) Performance analysis of solar stills based on various factors affecting the productivity-A review. Renewable and Sustainable Energy Reviews, Elsevier, 15(2):1294–1304

Ward J (2003) A plastic solar water purifier with high output. Sol Energy 75:433–437

Funding

The authors express their sincere appreciation to deanship of scientific research, King Faisal University, for moral support and financial funding for this project (150036).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Molhem, Y.A., Eltawil, M.A. Enhancing the double-slope solar still performance using simple solar collector and floatable black wicks. Environ Sci Pollut Res 27, 35078–35098 (2020). https://doi.org/10.1007/s11356-020-09509-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09509-2