Abstract

Municipal sewage triggers a stress prone environment to accumulate polyhydroxyalkanoates (PHAs) in the cytosol of bacteria. In view of that, different Bacillus species were isolated from municipal sewage and screened for evaluating their efficacy of PHA production. Growth parameters such as temperature, pH, glucose concentration and carbon nitrogen combinations were optimized with respect to higher biomass production as it is analogous to PHA accumulation. Under optimized conditions, the Bacillus species produced 3.09 g/L of PHAs which was estimated as a higher yield in comparison to other similar strains. Fourier transform infrared spectroscopic analysis of the extracted polyhydroxybutyrate confirmed the distinct peak corresponding to C=O group, whereas proton nuclear magnetic resonance (1H NMR) and differential scanning colorimetric analysis exhibited detailed insight of its chemical structure and properties by reflecting monomeric unit. The high yielding bacterial isolate was identified by 16S rDNA sequencing and the sequence was confirmed as Bacillus subtilis with an accession no. KP172548 after submission to NCBI data base. The potential bacterium may be further exploited for cost effective and mass scale production of biopolymer.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Synthetic polymers create environmental hazards because of their inherent toxicity, petrochemical origin and non-biodegradable nature. These plastic products cause significant problems on solid waste management while dumping in the ecosystem [1]. However, it is very difficult to reduce the consumption of plastic products due to their versatile and wide spread applications, but it is possible to replace conventional petrochemical based plastics with alternative bio-materials that are biodegradable. The reusable grafted biopolymer can also permit temperature-swing adsorption and provide an eco-friendly metal separation process [2]. Among the various types of biodegradable plastics, polyhydroxyalkanoates (PHAs) are the most recognized, biodegradable polymers synthesized by microbes and decomposed to carbon-di-oxide and water. More than 90 hydroxyalkanoic acids have been reported as constituents of PHAs [3] and among these, polyhydroxybutyrate (PHB) represents a common type synthesized by different microbes. Microbes are primary member of ecological niches and are generally influenced by biotic-abiotic factors. Microbes derive their energy through diverse adaptation in environment to sustain successful existence. PHA accumulation is one of the stress-driven responses experienced by microbes residing at different ecological niches such as estuarine sediments, marine habitat, rhizospheric soil, groundwater sediments and sewage. These environments are frequently rich in organic contents and possess minimum nutrients for supporting PHB accumulation and metabolic energy requirements during starvation period [4]. More specifically, waste and wastewaters has high BOD and COD values as compared to other ecological niches to support growth of these microbes by utilizing the nutrients present in wastewater and converting them into valuable PHAs that can be used as polymers [5].

Polyhydroxyalkanoates are reported to be produced by a wide range of bacteria in response to stress conditions and in the presence of excess carbon source [6]. Among all, Bacillus species produces several derivatives of PHAs especially PHB with diverse properties and significant applications [7]. Nevertheless, the most attractive feature of PHAs is its eco-friendliness and documented as a noble candidate to replace conventional plastics, but higher production cost has restricted its broader application as a commodity plastic [8]. Genus Bacillus has been widely used in industry and academia due to the stability of its replication and maintenance of plasmids [9] and also exhibited significance and predominance in PHA production. In addition to that, use of Bacillus species has much advantage over other bacterial species for the production of PHAs due to the absence of lipopolysaccharide layer making the extraction easier, its capability to grow in cheap raw materials and high growth rate in comparison to other bacteria [10]. Thus vigorous screening of potential Bacillus strains from stress prone environment, improvement in PHA production strategies and supplementation of inexpensive carbon sources may lead to make the complete process cost-effective. Therefore, the goal of this study was to isolate and identify gram positive Bacillus from municipal wastewater having high PHA productivity under optimized conditions and to characterize these extracted monomers for future mass scale application.

Material and Methods

Isolation and Screening of PHAs Producing Bacteria

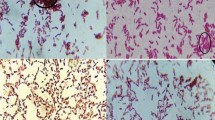

Municipal wastewater samples were collected aseptically in sterile container from Taladanda canal, Cuttack, Odisha for cultivation of potential aerobic heterotrophic bacterial isolates. Then, the samples were transported to the laboratory for bacteriological analysis using standard procedures of tenfold serial dilution followed by spread plating. Colonies of notable morphologies were individually picked, sub-cultured and preserved in glycerol stock at −80 °C for further use. Before screening, the isolates were induced to accumulate PHA granules in their cytosol using nitrogen limiting medium and incubated at 37 °C for 48 h. The nitrogen limiting medium contained the following ingredients such as NaCl 3.0 g/L, KH2PO4 1.5 g/L, K2HPO4 1.5 g/L, MgSO4·5H2O 1.0 g/L, glucose 10.0 g/L, ammonium nitrate 0.5 g/L and agar agar 15.0 g/L. Smear was made using these bacterial isolates on a clean grease free glass slide. After drying, 3 % of Sudan black in 70 % ethanol was added. The slide was immersed in xylene for few seconds followed with 5 % Safranin for 20 s. It was then washed gently and observed under light microscope for detection of PHA granules in the cytosol of bacteria [11].

Morphological and Biochemical Characterization

The morphological and physiological properties of PHA accumulating bacterial isolates were investigated on the basis of their colony characteristics and gram’s variability reactions with microscopic examination. Then, the bacterial isolates were also processed for identification by the standard methods of biochemical, enzymatic, sugar utilization and antibiogram profile as prescribed by Bergey’s manual of determinative bacteriology [12].

Optimization of Growth Parameters for Biomass Production

Ecological deviation is one of the vital factors that determine the growth patterns of an organism [13]. Thus, various parameters such as pH, temperature, sugar concentration, combination of different carbon and nitrogen sources were evaluated using marginally modified growth medium (composition data not shown) for biomass production. Moreover, some microbial strains have PHA accumulation which are parallel to biomass production [14]. Thus, 24 h fresh culture was cast-off to study the effect of parameters on PHA accumulating bacterial biomass production. The parameters include pH (6–10), temperature (16–51 °C), glucose concentration (5–25 g/L), combination of different carbon (glucose, sucrose, fructose and lactose) and nitrogen sources (beef extract, urea, peptone and yeast extract) in a constant ratio (6:1).

To find out the optimum pH for biomass production, 100 ml of growth medium was taken in different test tubes and pH was adjusted from 6 to 10 by keeping glucose concentration at 5 g/L where glucose and yeast extract were functioned as combination of carbon and nitrogen source respectively. 1 ml of 24 h fresh culture was dispensed and incubated at 37 °C for 24 h at 120 rpm. Then comparative bacterial biomass production was evaluated by measuring the OD600 in UV–Vis spectrophotometer (λ35, Perkin-Elmer) and the optimum pH was determined. Similarly, other parameters were also standardized following the mentioned methods.

Extraction and Quantitative Analysis of PHAs

Owing to the above optimized growth parameters, bacterial isolates were grown in 1000 ml of modified growth medium for 72 h at 37 °C with 120 rpm rotation. Then cell pellet was harvested by centrifugation at 6500 g rotation for 10 min and kept for drying. The dried weight of the pellet was taken as biomass weight. Subsequently, the cell pellet was re-suspended with sodium hypochlorite followed by incubation at 37 °C for 2 h to digest the non PHA materials. The mixture of sodium hypochlorite and bacterial biomass was centrifuged to harvest the PHA pellets which was washed twice with acetone, methanol and diethyl ether (1:1:1) to remove sodium hypochlorite. Finally, the PHAs were dissolved in boiling chloroform to remove all the remaining organic solvents present with PHA pellets and subsequent evaporation by air drying to yield dried form of extracted PHAs [15]. PHA production was also quantified using the following formula:

Characterization of Biopolymer PHAs

FTIR Analysis

The functional groups present in the extracted PHAs were determined by FTIR spectroscopy. PHAs sample was mixed with 2 % KBr and compressed into translucent sample discs and fixed in the FTIR spectrometer (Perkin-Elmer RX I). Scans were performed under the following conditions: spectral range, 4000–400 cm−1; window material, CsI; 16 scans; resolution 4 cm−1. The detection was conducted with a temperature stabilized, coated FR-DTGS detector [16].

1H NMR Analysis

Extracted PHAs were characterized by spectroscopic analysis. The composition and sequence distribution of the other groups were determined by 1H NMR spectra (JEOL JNM-LA). The 500 MHz 1H NMR spectra were recorded at 27 °C in CDCl3 solution of PHA (10 mg/mL) with 5 ms pulse width, 32,000 data points and 32 accumulations [17].

Differential Scanning Colorimetry

Differential Scanning Colorimetry analysis was carried out to define the thermal properties of the PHAs and the experiment was performed on a Perkin-Elmer instrument with a dry nitrogen gas flow of 50 ml/min. After calibration, 5 mg of the sample was sealed in an aluminium plate and analysed. The melting temperature (Tm) and glass transition temperature (Tg) were determined by the endothermic peaks [18]. Scans were initiated at −50 °C and were ramped at 50 °C per minute to 200 °C.

Molecular Identification of Bacterial Isolates

The molecular identification of high yielding bacterial isolate was carried out at Xcelris Labs Ltd., Ahmedabad, India. Genomic DNA was extracted and its quality was evaluated on 1.2 % agarose gel using 1 kb Xcelgen ladder (Xcelris Labs Ltd). Fragment of 16S rDNA gene was amplified and a single discrete PCR amplicon band resolved on agarose gel. Then, the amplified product was purified to remove contaminants. Forward and reverse DNA sequencing reaction of PCR amplicon was carried out with 27F (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1542R (5′-AAAGGAGGTGATCCA-3′) primers using BDT v3.1 Cycle sequencing kit on ABI 3730xl Genetic Analyzer. Consensus sequence of 16S rDNA was analysed by Bio-Edit software v7.0.5.3 and submitted to http://blast.ncbi.nlm.nih.gov/blast.cgi.

Methodology for Molecular Phylogeny

The submitted 16S rDNA consensus sequence of Bacillus subtilis (Acc. No: KP172548) was searched for sequence homology using BLAST algorithm (http://blast.ncbi.nlm.nih.gov/blast.cgi) against NCBI database. From the resulted hits, top 10 sequences were chosen on the basis of 99 % sequence identity with 100 % query coverage and subjected for multiple sequence analysis using ClustalW v1.6 followed by phylogenetic tree construction for twelve 16S rDNA sequences using UPGMA method [19] of MEGA v6.0 (Molecular Evolutionary Genetics Analysis) software [20]. Here UPGMA method was employed as best similar eleven 16S rDNA sequences of Bacillus species are closely similar and have shown strong similarity among them. Thus, during phylogenetic tree construction Pseudomonas chlororaphis strain DR2 (HG796168) was taken as an out group for the analysis. The tree evaluation was done by considering the bootstrap method for 1000 replica.

Statistical Analysis

The results obtained were analysed using SPSS 20.0 software, where p < 0.05 was considered to be statistically significant.

Results and Discussion

Isolation and Screening of PHAs Producing Bacteria

In the present study, eighteen different bacterial strains were isolated from municipal wastewater samples. Among these, four isolates accumulated PHAs in their cytosol effectively as confirmed by Sudan black staining method. Based on the gram’s reaction, morphological features and corresponding biochemical tests, the isolated bacterial strains belonged to the genus Bacillus. The PHAs producing different species of Bacillus have been reported from various environments such as wastewater, sewage and sludge ecosystems [8, 21–24]. Moreover, Bacillus is the predominant genus in soil and water and capable of growing in cheap raw materials than other bacterial isolates [10]. Waste and wastewaters has high BOD and COD values as compared to other ecological niches [5] and mostly rich in organic contents and less in nitrogen and phosphorus [25]. These unbalanced nutrient statuses (especially carbon to nitrogen) create selective pressures [26, 27] which may play a major role for accumulation of PHA granules in the cytosol of the microbes.

Extraction and Quantitative Analysis of PHAs

The parameters play a key role for the biomass production and synthesis of PHAs in vitro. Thus, biomass production of all the isolates was standardized and observed that pH 7.0, temperature 37 °C, glucose concentration of 10 g/L and combination of different carbon and nitrogen sources (glucose and yeast extract) were optimum at significance (P < 0.05) level (Fig. 1). Subsequently all the four isolates were subjected for PHA production under optimized condition, B. subtilis (KP172548) was found to produce maximum amount of PHAs (3.09 g/L) in modified growth medium. Such PHA production rate appears to be the highest as recorded for all isolated bacteria so far. This result is similar with early reporting of PHA production using different species of Bacillus and its possible applications [28–30]. In addition to that, 70.5 % PHA production was observed [10] using Bacillus sp. in the presence of 0.5 g/L of nitrogen source which is also in accordance to the findings of the present study. The combination of different carbon and nitrogen source ratio was constant at 6:1 during the study, as reports suggested highest dry cell weight at this ratio for many bacterial species [31]. The optimized data revealed that pH 7.0 and temperature 37 °C is pre-eminent for PHA production, as these bacteria were isolated from environmental samples. Moreover, glucose is a simple and most easily assimilable sugar, as compared to others. Similarly yeast extract also resulted in higher PHA accumulation in a short time, due to low nitrogen content and presence of vitamin B complex and growth factor as compared to other nitrogen sources used in the study.

Characterization of PHAs by FTIR Analysis

Figure 2 represents the functional groups of extracted PHA polymers from B. subtilis (KP172548) showing the characteristic peaks at 2953 cm−1 (C–H methylene group), 2766 cm−1 (C–H stretch), 2349 cm−1 (–C≡C–stretch), 1711 cm−1 (C=O stretch), 1679 cm−1 (–C=C–stretch), 1531 cm−1 (N–O asymmetric stretch), 1046 cm−1 (C–O stretch) and 500–1000 cm−1 (OH) respectively. However high intense peak was obtained at 1711 cm−1 corresponding to ester carbonyl (C=O) stretching vibration of PHB. The spectroscopic analysis presented a correct insight for the chemical structure of PHB by reflecting the monomeric units which are predominantly present in the PHA polymers. This result is also similar to the IR spectrum strong absorption band obtained at 1714 cm−1 corresponding to (C=O) ester carbonyl group, characteristics of PHB [32–34].

Characterization of the Extracted PHB by H1 NMR Analysis

Figure 3 describes the 1H NMR spectral data of the extracted PHB showing characteristics signals; (CDCl3, 300 MHz): δ (ppm): 0.85-1.06 (m, –CH3, HV side group), 1.26–1.29 (m, –CH3, HB side group), 1.59 (m, –CH2, HV side group), 2.45–2.64 (m, –CH2, HV and HB bulk structure), 5.26–5.27 (m, –CH, HV and HB bulk structure) respectively. The 1H NMR spectra of the PHA samples conferred that extracted intracellular compounds are similar with PHBs [35]. However, analysis of 13C NMR and other characterizations are essential for complete elucidation of structure of the extracted biopolymer.

Differential Scanning Colorimetry

Figure 4 shows DSC analysis exhibiting thermal properties of biopolymer PHB. Generally it is crystalline in nature, but amorphous within bacterial cell. Moreover its rapid crystallization takes place after being extracted from bacterial cells. The extracted PHB is having Tg almost −11 °C and Tm about 99 °C respectively. This result corresponds to the thermal properties of the biopolymer reported earlier, where the Tg and Tm values were reported as −11, −11 and 161, 88 °C, respectively [18, 36]. The low thermal properties revealed, an increase in the side chain length resulting in the decrease of the Tg value.

Molecular Identification of the Isolates

The sequencing of 16S rDNA confirmed the molecular identification of the highest PHB producing bacterial isolate and identified bacteria as B. subtilis (accession no. KP172548). In this regard, many research investigations have been documented to use B. subtillis for economic production of PHB, which represents the most common PHA [24, 37–39]. This may be due to predominant nature of Bacillus in nature, absence of lipopolysaccharide layer, its high growth proficiency even at cheap raw materials in comparison to other bacteria [10]. Additionally, these isolates have the efficacy to produce a variety of hydrolytic enzymes for cost-effective production of PHB using agro-industrial wastes [40].

Design and Analysis of Evolutionary Tree

Figure 5 demonstrates the evolutionary history of gram positive Bacillus species for cost effective PHA production by using UPGMA method [19]. The optimal tree with the sum of branch length = 3.10134744 is shown in the UPGMA tree. The percentage of replicate trees in which the associated taxa clustered together in the bootstrap test (1000 replicates) was shown next to the branches. The evolutionary distances were computed using the Maximum Composite Likelihood method [41] which are in the units of the number of base substitutions per site. The analysis involved 12 nucleotide sequences of bacterial isolates. From the constructed phylogenetic tree it is inferred that top 10 maximum similar gram positive Bacillus chosen sequences are distributed in two branches with 63 and 65 % bootstrap accuracy, whereas the 16S rDNA sequence of Pseudomonas chlororaphis strain DR2 (HG796168) is distantly related from them as an out group of the tree.

Conclusion

Although PHB production is a costly affair but it can compensate the major health and environmental problems created by the synthetic polymer. In current investigation, factors for stimulating higher PHB production were evaluated using a modified growth medium. The application of statistical optimization was applied to determine the process conditions responsible for PHB production collectively. However, the researchers have not yet achieved the strategic protocol to decrease its production cost in mainstream application. The isolate characterized was B. subtilis (KP172548) which can potentiate higher production of PHB in vitro. The potential of this Bacillus subtilis strain will be further investigated to increase the PHB productivity by supplementing other raw materials to make the whole process cost-effective.

References

Chanprateep S (2010) Current trends in biodegradable polyhydroxyalkanoates. J Biosci Bioeng 110(6):621–632

Mani D, Kumar C (2014) Biotechnological advances in bioremediation of heavy metals contaminated ecosystems: an overview with special reference to phytoremediation. Int J Environ Sci Technol 11(3):843–872

Braunegg G, Lefebvre G, Genser KF (1998) Polyhydroxyalkanoates, biopolyesters from renewable resources: physiological and engineering aspects. J of Biotechnol 65:127–161

Koller M, Gasser I, Schmid F, Berg G (2011) Linking ecology with economy: insights into polyhydroxyalkanoate-producing microorganisms. Eng Life Sci 11(3):222–237

Bhuwal AK, Singh G, Aggarwal NK, Goyal V, Yadav A (2013) Isolation and screening of polyhydroxyalkanoates producing bacteria from pulp, paper, and cardboard industry wastes. J of Biomat. 10.1155/2013/752821

Khanna S, Srivastava AK (2005) Recent advances in microbial polyhydroxyalkanoates. Proc Biochem 40(2):607–619

Kulpreecha S, Boonruangthavorn A, Meksiriporn B, Thongchul N (2009) Inexpensive fed-batch cultivation for high poly (3-hydroxybutyrate) production by a new isolate of Bacillus megaterium. J Biosci Bioeng 107(3):240–245

Pandian SRK, Deepak V, Kalishwaralal K, Rameshkumar N, Jeyaraj M, Gurunathan S (2010) Optimization and fed-batch production of PHB utilizing dairy waste and sea water as nutrient sources by Bacillus megaterium SRKP-3. Bioresource Technol 101:705–711

Biedendieck R, Gamer M, Jaensch L, Meyer S, Rohde M, Deckwer WD, Jahn DA (2007) Sucrose inducible promoter system for the intra- and extracellular protein production in B. megaterium. J Biotechnol 132:426–430

Khiyami MA, Al Fadual SM, Bahklia AH (2011) Polyhydroxyalkanoates production via Bacillus plastic composite support (PCS) biofilm and date palm syrup. J Med Plants Res 5(14):3312–3320

Schlegel HG, Latterty R, Krauss I (1970) Isolation of mutants not accumulating polyhydroxybutyric acid. Arch Microbiol 71:283–294

Holt JG, Krieg NR, Sneath PHA, Staley JT, Williams ST (1994) Bergey’s manual of determinative bacteriology. Williamsons and Wilkins, Baltimore

Shah JA, Pandit AK, Shah GM (2015) A research on rotifers of aquatic ecosystems of kashmir himalaya for documentation and authentication. Proc Natl Acad Sci India Sect B BiolSci 85(1):13–19

Koller M, Atlic A, Dias M, Reiterer A, Braunegg G (2010) Microbial PHA Production from waste raw materials. Chen GQ (eds) Plastics from bacteria: Natural functions and applications, Microbiology monographs. Springer Verlag Berlin Heidelberg, pp 85-119

Dash S, Mohapatra S, Samantaray DP, Sethi AK (2014) Production of polyhydroxyalkanoates by sugar cane rhizospheric soil bacterial isolates. J Pure Appl Microbiol 8(6):4889–4895

Preethi R, Sasikala P, Aravind J (2012) Microbial production of polyhydroxyalkanoate (PHAs) utilizing fruit waste as a substrate. Res in Biotech 3(1):61–69

Chuah J, Yamada M, Taguchi S, Sudesh K, Doi Y, Numata K (2013) Biosynthesis and characterization of polyhydroxyalkanoate containing 5-hydroxyvalerate units: effects of 5HV units on biodegradability, cytotoxicity, mechanical and thermal properties. Polym Degrad Stab 98:331–338

Contreras AR, Koller M, Dias MMS, Monfort MC, Braunegg G, Calvo MSM (2013) High production of poly (3-hydroxybutyrate) from a wild Bacillus megaterium bolivian strain. J Appl Microbiol 114(5):1378–1387

Sneath PHA, Sokal RR (1973) Numerical taxonomy. Freeman, San Francisco

Tamura K, Stecher G, Peterson D, Filipski A, Kumar S (2013) MEGA6: molecular evolutionary genetics analysis version 6.0. Mol Biol Evol 30:2725–2729

Sangkharak K, Prasertsan P (2012) Screening and identification of polyhydroxyalkanoates producing bacteria and biochemical characterization of their possible application. J Gen Appl Microbiol 58:173–182

Soam A, Singh AK, Singh R, Shahi SK (2012) Optimization of culture conditions for bio-polymer producing Bacillus mycoides (WSS2) bacteria from sewage. Int J curr discover innov 1(1):27–32

Reddy SV, Thirumala M, Mahmood SK (2009) Production of PHB and P (3HB-co-3HV) biopolymers by Bacillus megaterium strain OU303A isolated from municipal sewage sludge. World J Microbiol Biotechnol 25(3):391–397

Wang Y, Ruan L, Cjua H, Yu PFH (2006) Cloning and expression of the PHA synthase genes phaC1 and phaC1AB into Bacillus subtilis. World J Microbiol Biotechnol 22(6):559–563

Dircks K, Beun JJ, Van LM, Heijnen JJ, Henze M (2001) Glycogen metabolism in aerobic mixed cultures. Biotechnol Bioeng 73:85–94

De LT, Breno M, Christina B (1999) Bacteria isolated from sugarcane agro ecosystem: their potential production of polyhydroxyalkanoates and resistance to antibiotics. Rev Microbiol 30:214–224

Wang J, Bakken LR (1998) Screening of soil bacteria for poly-β-hydroxybutyric acid production and its role in the survival of starvation. Microb Ecol 35:94–101

Hungund B, Shyama VS, Patwardhan P, Saleh AM (2013) Production of polyhydroxyalkanoate from Paenibacillus durus BV-1 isolated from oil mill soil. J Microb Biochem Technol 5:013–017

Reddy SV, Tirumala M (2012) Isolation of polyhydroxyalkanoates (PHAs) producing bacteria from contaminated soils. Int J Environ Biol 2(3):104–107

Boyandin AN, Prudnikova SV, Filipenko ML, Khrapov EA, Vasil’ev AD, Volovo TG (2012) Biodegradation of polyhydroxyalkanoates by soil microbial communities of different structures and detection of PHA degrading microorganisms. Appl Biochem Microbiol 48:28–36

Sangkharak K, Prasertsan P (2008) Nutrient optimization for production of polyhydroxybutyrate from halotolerant photosynthetic bacteria cultivated under aerobic-dark condition. Electron J Biotechnol 11(3):1–12

Shah KR (2012) FTIR analysis of polyhydroxyalkanoates by novel Bacillus sp. AS 3-2 from soil of kadi region. J Biochem Technol 3(4):380–383

Jeyaseelan A, Pandiyan S, Ravi P (2012) Production of polyhydroxyalkanoate (PHAs) using hydrolyzed grass and Syzygium cumini seed as low cost substrates. J Microbiol 2(3):970–982

Otari SV, Ghosh JS (2009) Production and characterization of the polymer polyhydroxy butyrate-co-polyhydroxy valerate by Bacillus megaterium NCIM 2475. Curr Res J Biol Sci 1:23–26

Bhattacharyya A, Pramanik A, Maji SK, Haldar S, Mukhopadhyay UK, Mukherjee J (2012) Utilization of vinasse for production of poly-3-(hydroxybutyrate-co-hydroxyvalerate) by Haloferax mediterranei. AMB Express 2:34

Wonga YM, Brigham CJ, Rha CK, Sinskey AJ, Sudesh K (2012) Biosynthesis and characterization of polyhydroxyalkanoate containing high 3-hydroxyhexanoate monomer fraction from crude palm kernel oil by recombinant Cupriavidus necator. Bioresour Technol 121:320–327

Singh M, Patel KSS, Kalia CP (2009) Bacillus subtilis as potential producer for polyhydroxyalkanoates. Microb Cell Fact 8(38):1–11

Reddy SV, Thirumala M, Reddy TVK, Mahmood SK (2008) Isolation of bacteria producing polyhydroxyalkanoates (PHA) from municipal sewage sludge. World J Microbiol Biotechnol 24(12):2949–2955

Mishra S, Ojha SK, Goswami AD (2013) Microbial biopolymer technology. In: Thatoi HN, Mishra BB (eds) Advances in biotechnology. Studium Press LLC, New Delhi, pp 241–272

Israni N, Shivakumar S (2013) Combinatorial screening of hydrolytic enzymes and PHA producing Bacillus sp. for cost effective production of PHAs. Int J Pharm Bio Sci 4(3):934–945

Tamura K, Nei M, Kumar S (2004) Prospects for inferring very large phylogenies by using the neighbor-joining method. Proc Nat Acad Sci (USA) 101(30):11030–11035

Acknowledgments

The authors are thankful to Dr. B. B. Mishra (HOD, Microbiology), Dr. N. Sahoo, Dr. S. Acharya (In-charge of Central laboratory, OUAT) and Dr. G. S. Acharya for providing laboratory facilities during the period of study. They are also thankful to S. Basu and H. R. Dash of NIT, Rourkela, India for their support during the study. The authors have no conflict of interest to declare.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mohapatra, S., Mohanta, P.R., Sarkar, B. et al. Production of Polyhydroxyalkanoates (PHAs) by Bacillus Strain Isolated from Waste Water and Its Biochemical Characterization. Proc. Natl. Acad. Sci., India, Sect. B Biol. Sci. 87, 459–466 (2017). https://doi.org/10.1007/s40011-015-0626-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40011-015-0626-6