Abstract

This work describes preparation of bacterial cellulose membranes and their use as filters for water remediation. The samples were tested as filters using natural specimens that were extracted from the Igarassu River basin in Pernambuco, Brazil, and using suspensions with a high load of Escherichia coli and raw industrial effluents from the dairy and textile industries. The bacterial cellulose membrane performance was compared with commercial membranes that are used in sterile environments with better results. The membranes were shown to be effective for removing E. coli and dye effluent for up to ten cycles. When the samples that were extracted from the river were studied, no microorganisms were detected after the filtrate was inoculated into a culture medium. The results reported here show that the bacterial cellulose membranes are effective for the remediation of samples with different compositions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

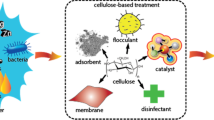

Introduction

Water contamination remains a critical issue mainly in developing countries. The United Nations has identified improving water quality as one of the eight Millennium Development Goals (MDGs) (Pandey et al. 2014). According to the World Health Organization (WHO), 2 billion people consume drinking water that is contaminated with feces, and polluted drinking water causes nearly 502,000 diarrheal deaths each year worldwide. In 2015, 2.3 billion people did not have access to essential sanitation services (WHO 2018). This is a consequence of unplanned urbanization and inadequate disposal of domestic and industrial waste, leading to water contamination, which mainly occurs in rivers and lakes (Schwarzenbach et al. 2006; Franco et al. 2018).

For industrial wastewater, effluents from both textile and dairy activities are especially concerning because factories consume enormous amounts of water, and the resulting effluents must be treated appropriately so that they can be reused or released into the environment (Dasgupta et al. 2015; Yaseen and Scholz 2019; Wang and Serventi 2019).

In Pernambuco State in the Northeast Region of Brazil, the textile and dairy industries play a significant role in the economy. Most activity occurs in small and medium factories where a high amount of effluent is frequently discarded directly into nearby rivers. According to the Pernambuco’s State Environmental Agency (Lima et al. 2005), in the textile sector, nearly 70% of the effluents are directly disposed into the environment. It is estimated that 32 million liters of water is consumed daily. The dairy industry processes 1.8 million liters of milk each day, and 10 L of milk is needed to make 1 kg of cheese.

Several different approaches are currently used for water remediation, such as ozonation, chlorination, and UV radiation. These technologies usually require a high investment, sophisticated equipment, and skilled labor with the use of large quantities of chemical reagents that are harmful to the environment (Caslake et al. 2004).

Membrane-based processes, however, are intrinsically simpler than competing technologies, and they are scalable, do not generate secondary pollutants, and are accepted as environmentally friendly technologies (Dasgupta et al. 2015). They are also widely used in water purification and effluent treatment because of their lower energy consumption and efficiency (Ulbricht 2006; Collivignarelli et al. 2018). Moreover, membranes can also be combined with biological treatments using membrane bioreactor technologies, which have been successfully employed to treat both dairy and textile effluents (López et al. 2004; Andrade et al. 2014).

Microporous membranes were first used for water quality control during World War II (Baker 2004). In 1953, cellulose acetate membranes were reported to be a highly efficient material for saline solution retention in reverse osmosis systems, increasing researchers’ interest in developing new products with an efficient filtering capability and low cost (Matsuura 2001). Currently, polymer membranes based on cellulose acetate, cellulose nitrate, polyethylene terephthalate, polyethylene, polyvinylidene fluoride, polyethersulfones, poly(vinyl alcohol), polyacrylonitrile, and activated carbon have been extensively used to purify contaminated water (Zaini et al. 2010; Pendergast and Hoek 2011; Carpenter et al. 2015).

Bacterial cellulose or biocellulose (BC) membranes, which are formed directly as a result of metabolism of several types of bacteria (Sulaeva et al. 2015), can be an attractive, sustainable alternative to synthetic polymer-based membranes, aiming to develop bio-based and environmentally friendly new filters that are suitable for water treatment. BC membranes result from sugar fermentation processes; thus, their production is compatible with the perspectives of a bio-based economy where chemicals are fabricated using renewable carbon sources (Koutinas et al. 2014). BC production can be scaled up using agro-industrial wastes as raw materials, as recently reviewed by Hussain et al. (2019).

Gluconacetobacter xylinum is the most widely used microorganism for BC production, and it is able to produce up to 200,000 molecules of glucose per second (Hestrin and Schramm 1954). The biopolymer comprises glucose monomers that are linked by glycosidic β-1,4 bonds with a three-dimensional arrangement of nanofibrils (6–10 nm thick and 30–50 nm wide) where inter- and intramolecular hydrogen bonds provide excellent mechanical and thermal stability, and high tensile strength compared to plant cellulose (Moon et al. 2011). It is also non-toxic, hypoallergenic, biodegradable, and has a high capacity to absorb up to 100 times its weight in water (Huang et al. 2013; Çakar et al. 2014; Napavichayanun et al. 2015).

Because of the high number of surface hydroxyl groups, BC can readily undergo chemical modification, thereby expanding its potential applications. Taha et al. (2012) developed an NH2-functionalized cellulose acetate/silica composites for Cr(VI) removal. Sai et al. (2015) produced aerogels of modified BCs using trimethylchlorosilane to remove oils and organic solvents from the environment, and it had a capacity to remove up to 185 times its own weight in oils and solvents. Hassan et al. (2017) studied the utilization of BC to remove oil from oil-in-water emulsions. Liu et al. (2017) produced a filter for particulate removal from the air that was composed of BC modified with an isolated soy protein.

The most investigated BC applications, however, are in the field of biomedicine. For example, it has been used as artificial skin, wound dressings (commercial applications are already available), antimicrobial materials, artificial blood vessels, scaffolds for tissue regeneration (bone and cartilage), and artificial dura mater membrane (Czaja et al. 2006; Lin et al. 2013; Sulaeva et al. 2015; Kwak et al. 2015). This topic has been reviewed by several authors (Petersen and Gatenholm 2011; Fu et al. 2013; Torgobo and Sukay 2018; Wang et al. 2018).

Applications of BC as separation membranes have been reported by Takai et al. (1991), who investigated their use in separating polyethylene glycol (PEG), and Wanichapichart et al. (2002) used BC to filter Chlorella sp. and bovine serum albumin efficiently. BC modification with acrylic acid was shown to be useful in the removal of metallic ions, including heavy metals (Choi et al. 2004).

There are no reports that investigated BC applications as filters that aimed to remove pathogenic microorganisms. Additionally, to the best of our knowledge, no real wastewater samples from domestic or industrial effluents have been tested with BC membranes. Ideally, the filters should be capable of concurrently eliminating the pathogenic microorganisms, toxic organic compounds, and heavy metal ions (Mohmood et al. 2013). To achieve the desired performance, the membrane pore size should be smaller than the typical size of bacteria, which ranges from 0.3 to 3.0 µm (Baker 2004), and must have chemical functionalities that allow them to react with organic radicals and metallic cations.

The BC pore size reported in the literature has a vast range, as follows: 45–800 Å (N2 adsorption method, BET) (Phisalaphong and Jatupaiboon 2008); 12–24 nm (BET) (Guo and Catchmark 2012); 240–430 nm (scanning electron microscopy, SEM) (Li et al. 2015); and 10–20 µm (SEM) (Yin et al. 2012). The resulting pore size is dependent on the experimental parameters, and even a single membrane will present different pore sizes when examined under the electron microscope from its bottom and upper sides, as reported by Li et al. (2015). The pore sizes are convenient for the retention of bacteria that are commonly detected in water, such as Escherichia coli, Shigella spp., Salmonella spp., Pseudomonas, and Enterobacter.

In this work, we report the preparation of BC membranes and their use as filters for water decontamination. The membranes were tested against samples with a high concentration of E. coli (108 cells mL−1) that simulates a sanitary effluent (Payment et al. 2001), and they were also tested against textile and dairy industry effluents and natural samples collected from different points in the hydrographic basin of the Igarassu River, in Pernambuco State, Brazil, that receives daily effluents from textile, food, metallurgical, sugar, and alcohol industries and also domestic effluents (State Agency for the Environment 2016). The samples were collected between October 2018 and January 2019. The dairy and textile effluents were collected in Garanhus and Caruaru, which are located in Pernambuco State, Brazil.

Materials and methods

Reagents and solutions

All of the following reagents were of analytical grade: agar Mueller–Hinton, nutrient agar, potato dextrose agar, lactose broth, and brilliant green bile broth 2% (Kasvi). EC medium (Acumedia), succinic acid 99% (Moderna), absolute ethanol (Neon), yeast extract (Micro-Med), sodium phosphate 98% (Dynamics), and glycerol (Alphatec) were all used as received.

Production of BC membranes

BC membranes were produced in a culture medium containing 30.00 g L−1 glycerol, 16.00 g L−1 yeast extract, 4.00 g L−1 sodium phosphate, and 3.50 g L−1 succinic acid. The resulting solutions were autoclaved at 121 °C for 20 min. Gluconacetobacter xylinus (ATCC 23769), which was acquired from the André Tosello Foundation, Campinas, SP, Brazil, was used to prepare the membranes. For microorganism activation, the inoculum was incubated in culture medium at 10% (v/v) and 30 °C for 24 h, and this process was repeated three times. BC membranes were then produced at 30 °C for 72 h. The resulting samples (6.0 cm in diameter, 0.15 mm thick) were washed with hot water (80 °C), 0.10 mol L−1 NaOH aqueous solution, and deionized water up to pH 7.00.

Characterization

SEM images were acquired using a FEI Quanta 200F electron microscope. The samples were previously lyophilized, and a thin gold layer was sputtered before the analysis. The Fourier transform infrared spectroscopy (FT-IR) spectra were collected using a Bruker model IF66, within the 4000–400 cm−1 spectral range, from milled samples that were dispersed in KBr pellets.

BC membrane performance for water remediation

The performance of the BC membrane filtration was tested against four different samples: (1) an E. coli suspension that simulated a sanitary effluent; (2) natural water samples collected from a river; (3) dairy industry effluents collected from a cheese factory; and (4) textile industry effluents with two different pigments.

-

1.

E. coli suspension: the bacteria were cultured in Mueller–Hinton agar medium and incubated at 35 °C for 24 h. An initial absorbance of 0.66 was standardized for all suspensions, which corresponds to 108 cells mL−1, according to the measurements performed in a Neubauer chamber. The absorbance was measured in a Thermo Biomate spectrophotometer at 660 nm, using sterile distilled water as the blank. The cell counts were performed using a Leica CME optical microscope. E. coli was provided by the Department of Antibiotics of the Federal University of Pernambuco (UFPEDA 224). Cellulose acetate commercial membranes (CM) with an average pore size of 0.22 µm were also tested for comparison.

-

2.

Samples collected from the Igarassu River, in Pernambuco State, Brazil: the samples were collected by the State Environmental Agency (CPRH) during the dry season. The sampling points are shown in Fig. 1. The quantification of E. coli was performed using the most probable number (MPN), according to the standard methods procedure (APHA 2012) before and after filtrations. The methodology was used to evaluate the mean density of viable coliform bacteria in the samples, which is related to the sanitary quality of water. The filtrates (100 μL) were inoculated into Mueller–Hinton agar medium and incubated at 35 °C for 24 h (Bartram et al. 2004).

-

3.

Effluents from the dairy industry (cheese factory) collected in Garanhuns, Pernambuco, Brazil: raw samples (100 μL) and filtrates (100 μL) were inoculated into Petri dishes containing the nutrient agar medium, potato dextrose agar, and Mueller–Hinton agar, and they were incubated at 35 °C for 24 h. The absorbance was measured in a Thermo Biomate spectrophotometer at 660 nm, using sterile distilled water as the blank.

-

4.

Effluents from a textile industry collected in Caruaru, Pernambuco, Brazil: the samples present a high load of red and blue pigments. The absorption spectra were acquired before and after each filtration using an Agilent 8453 spectrophotometer in the 200 to 800 nm range against distilled water.

Results and discussion

BC membrane characterization

The membranes are strong enough not to tear during manual manipulation, which is a result of the entanglement of the fibers. The typical Young’s modulus and tensile strength of the BCs are in the range of 15 to 45 GPa and 200 to 300 MPa, respectively, according to Vitta and Thiruvengadam (2012). The BC membranes show that the nanofibrilar morphology is composed of a three-dimensional network, as shown in the SEM image in Fig. 2 and as described previously in the literature (Sulaeva et al. 2015; Stumpf et al. 2018). The fiber diameters ranged from 50 to 100 nm, which was similar to those reported by He et al. (2018).

The FT-IR spectrum of a BC membrane is presented in Fig. 2. All the following features, which were reported previously, can be observed: (1) 3410 cm−1 attributed to OH stretching and hydrogen bonds; (2) 2896 cm−1 corresponding to C–H stretching of CH2 groups; (3) 1643 cm−1 referring to water OH bending mode; (4) 1427 cm−1 corresponding to CH2 symmetric bending; (5) 1369 cm−1 from the C–H bending; (6) at 1338 cm−1 attributed to O–H in-plane bending; (7) at 1315 cm−1 corresponding to CH2 wagging; (8) at 1155 cm−1 from antisymmetric bridging C–O–C stretching mode; (9) 1111 cm−1 and 1032 cm−1 attributed to C–O; and (10) stretching at 667 cm−1 and 617 cm−1 corresponding to OH out-of-phase bending (Barud et al. 2008; Castro et al. 2011; Figueiredo et al. 2015; Qiu et al. 2016).

BC membrane performance for water remediation

Escherichia coli suspensions

Figure 3 shows a BC membrane and the E. coli suspension before and after ten filtration cycles. A clear transparent liquid was collected from the initially turbid sample. The part of the membrane that was exposed to the E. coli suspension was opaque because of bacteria accumulation in the membrane, while the outer part that was not exposed to the suspension retained the typical transparency of a wet membrane.

Figure 4a shows the output count and the output absorbance (at 660 nm) for the filtrates that were obtained using the BC and CM membranes to filter the E. coli suspension. The output count and the output absorbance (at 660 nm) were nearly zero for the BC membrane. The CM, however, presented an output that is related to the presence of microorganisms in all measurements. The CM is frequently used to produce sterile water with excellent results. However, the bacteria amount in the samples that were investigated here is similar to what is found in sanitary effluents.

The hydrophilic nature of cellulose acetate membranes makes them suitable for several laboratory applications such as protein separation, which is compatible to automated processes under pressure conditions at reasonable flow rates. However, these membranes are not used to filter effluents. There are some reports about membranes that are based on cellulose nanofibers or activated carbon that were effectively used to remove E. coli from water, as reported by Hassan et al. (2017).

BC-based membranes modified using polymers such as chitosan (Yin et al. 2020) and polyethyleneimine (Wahid et al. 2020) or nanoparticles (ZnO, CuO, and Ag) have been recently shown to have interesting antibacterial properties against E. coli (Mohammadalinejhad et al. 2019). The results described above show, for the first time, that BC membranes are promising for such highly contaminated samples.

Igarassu river samples

Quantification of E. coli in the samples that were collected from the Igarassu River basin before and after the filtration is presented in Table 1. The presence of such bacteria is the primary indicator of fecal contamination, which can cause severe gastrointestinal diseases that can lead to death (Khan et al. 2018). Both BC and CM were efficient for E. coli retention with an undetectable bacterial count after filtration.

As expected, all the inocula from the four samples collected from the Igarassu River showed positive results for heterotrophic bacteria (Fig. 5a, d, g, j). After filtration through BC membranes, no microorganisms were observed up to the detection limit (10 CFU/mL). When the CM membrane was used, the filtrates from samples IG03 and IG04, which had higher contamination levels, showed positive results (Fig. 5k, l).

This result is consistent with the use of the CM in samples with moderate microorganism concentrations, and it demonstrates that BC membranes are also efficient for real samples that present a much more complex composition compared to the suspensions that were prepared in the laboratory environment.

Dairy effluent

Figure 6 (left) presents inocula of the dairy effluent in agar Mueller–Hinton nutrient agar and potato dextrose agar before filtration. These culture media allow for the identification of bacteria, yeast, and molds, and fungi, respectively (Babu et al. 2006; Shivsharan et al. 2013). A colorless filtrate was collected after filtration through the BC membrane (Fig. 6, center), the absorbance at 660 nm decreased from 0.655 to 0.004, and no microorganisms growth was observed in any of the three the culture media after filtration (Fig. 6, right).

Raw effluents from the dairy industry showed high loads of microorganisms, including Bacillus subtilis, Staphylococcus aureus, E. coli, Lactobacillus sp., Candida, Cryptococcus, and Streptococcus faecalis (Babu et al. 2006; Porwalet al. 2015; Garcha et al. 2016), and high concentration of lipids, carbohydrates, and organic materials (Wang and Serventi 2019).

Several methodologies have been used to treat dairy industry wastewater, including photocatalysis (Abreu et al. 2013), aerobic or anaerobic digestion (Dabrowski et al. 2017), and physicochemical treatments (Wang and Serventi 2019). These technologies are complex and require professional equipment that has a high operating cost. Sarkar et al. (2006) used a cellulose acetate membrane and coagulants to treat dairy effluent. The use of these two techniques proved to be efficient for removing the color and odor from the sample. Hatimi et al. (2020) reported the use of inorganic membranes that were composed of clay to treat dairy effluent, and they reported that this method showed efficiency in removing turbidity, conductivity, and oil and grease index. Bortoluzzi et al. (2017) used an integrated membrane system that was composed of a hollow fiber-type polymeric membrane, poly(ether sulfonate)/poly(vinyl pyrrolidone) membrane, and polyamide membrane showing efficiency in reducing the sample color and turbidity. No study showed a microbiological evaluation of these samples, based on filtration with BC membranes. None of the studies described above presented information about a microbiological evaluation of the filtrates.

Textile effluents

Figure 7 shows the blue textile effluent before and after filtration and the membrane after ten filtration cycles. The effluent was also filtered in its raw form. The BC membranes were shown to have the capability to retain most of dyes and solids. The UV–Vis absorption spectra from red and blue effluents before and after filtration are shown in Fig. 8. In both cases, the absorbance decreased in the entire 200 to 800 nm range. The blue sample spectrum shows presents maxima at 242 and 624 nm, and there was a 67.8 and 100% decrease, respectively, after filtration, while in the red sample, the decrease was about 67.1%. The filtrates collected from the blue effluent were transparent to the naked eye even after ten filtration cycles. The membrane was not washed between two successive cycles.

According to Neamtum et al. (2002), textile industry effluents present a complex composition with a high concentration of dissolved salts, surfactants, solids in suspension, and organics with high potential to harm the environment if not correctly handled. The results presented here demonstrate that the BC membranes are capable of efficiently retaining dye contaminants.

Cellulose-based compounds are efficient in removing contaminants from the textile industry, as reported by Li et al. (2019), who used carboxylated cellulose fabricated with 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) to remove dyes from simulated wastewater. Saranya et al. (2015) used zero-valent iron-impregnated cellulose acetate mixed-matrix membranes for remediation of textile industry effluent. Goel et al. (2015) reported the use of cotton cellulose for the treatment of textile dye wastewater.

The in situ reduction of cationic polyethyleneimine combined with platinum nanomaterials that are placed onto the BC membrane was recently shown to be effective for adsorbing anionic dyes (Huang et al. 2020). BC/TiO2 nanocomposites showed almost 90% removal of methylene blue in aqueous solution by photocatalysis (Brandes et al. 2018).

To the best of our knowledge, there is no published article that investigated a membrane that had a filtering capacity that was as efficient as reported here. This is the first report that investigated BC membranes as filters for treating samples of different natures; the BC membranes were shown to be efficient in removing microorganisms from natural water and industrial wastewater sources.

These applications require development for large-scale BC membrane production. Thus, the use of effluents as raw materials for the BC membrane production has been pursued, and some successful attempts have already been reported in the literature. BC has been produced using distillery effluents (Gayathri and Srinikethan 2010; Jahan et al. 2018) or corinthian currant finishing side-stream and cheese whey (Bekatorou et al. 2019). The production of BC membranes using industrial waste (from agriculture, food, brewery, sugar industries, lignocellulosic biorefineries, textile, and pulp mills) was reviewed recently by Hussain et al. (2019), and there is a good potential for large-scale production BC membranes in the near future.

Conclusion

The BC membranes were shown to be efficient as filters for microorganism removal from natural and industrial samples and from a simulated effluent with a high E. coli load. The membranes retained their efficiency even after ten filtration cycles for the E. coli suspensions and the blue pigmented textile effluent, which makes them good candidates for water treatment. The excellent performance of the BC membranes in retaining contaminants from E. coli suspensions, natural samples extracted from a river, and textile and dairy wastewater demonstrated their versatility for a wide range of applications. The use of industrial wastes to fabricate BC membranes and their use for wastewater remediation can potentially be an essential contribution of bio-based technological development in the circular economy.

References

Abreu P, Pereira EL, Campos CMM, Naves FL (2013) Photocatalytic Oxidation Process (UV/H2O2/ZnO) in the treatment and sterilization of dairy wastewater. Acta Sci 35:75–81

Andrade LH, Mendes FDS, Espindola JC, Amaral MCS (2014) Nanofiltration as tertiary treatment for the reuse of dairy wastewater treated by membrane bioreactor. Sep Purif Technol 126:21–29

APHA (2012) Standard methods for the examination of water and wastewater. American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC

Babu RB, Maruthamuthu S, Rajasekar A, Muthukumar PN (2006) Microbiologically influenced corrosion in dairy effluent. Int J Environ Sci Technol 3:159–166

Baker RW (2004) Membrane technology and applications. Wiley, California

Bartram J, Cotruvo J, Exner M, Fricker C, Glasmacher A (2004) Heterotrophic plate count measurement in drinking water safety management: Report of an Expert Meeting Geneva. Int J Food Microbiol 92:241–247

Barud HS, Assunção RMN, Martinez MAU, Ghys JD, Marques RFC, Messaddeq Y, Ribeiro SJL (2008) Bacterial cellulose–silica organic–inorganic hybrids. J Sol-Gel Sci Technol 46:363–367

Bekatorou A, Plioni I, Sparou K, Maroutsiou R, Tsafrakidou P, Petsi T, Kordouli E (2019) Bacterial cellulose production using the corinthian currant finishing side-stream and cheese whey: process optimization and textural characterization. Foods 8:193

Bortoluzzi AC, Faitão JA, Luccio M, Dallago RM, Steffens J, Zabot GL, Tres MV (2017) Dairy wastewater treatment using integrated membrane systems. J Environ Chem Eng 5:4819–4827

Brandes R, Trindade ECA, Vanin DF, Vargas VMM, Carminatti CA, Hazin A, Al-Qureshi R (2018) DOS Spherical bacterial cellulose/TiO2 nanocomposite with potential application in contaminants removal from wastewater by photocatalysis. Fiber Polym 19:1861–1868

Ҫakar F, Ozer I, Aytekin AO, Sahin F (2014) Improvement production of bacterial cellulose by a semi-continuous process in molasses medium. Carbohydr Polym 106:7–13

Carpenter AW, Lannoy CF, Wisner MR (2015) Cellulose nanomaterials in water treatment technologies. Environ Sci Technol 49:5277–5287

Caslake LF, Connolly DJ, Menon V, Duncanson CM, Rojas R, Tavakoli J (2004) Disinfection of contaminated water by using solar irradiation. Appl Environ Microbiol 70:1145–1150

Castro C, Zuluaga R, Putaux JL, Caro G (2011) Mondragin, I., Gañán, P. Structural characterization of bacterial cellulose produced by Gluconacetobacterswingsii sp. From Colombian agroindustrial wastes. Carbohydr Polym 84:96–102

Choi YJ, Ahn Y, Kang MS, Jun HK, Kim IS, Moon SH (2004) Preparation and characterization of acrylic acid-treated bacterial cellulose cation-exchange membrane. J Chem Technol Biotechnol 79:79–84

Collivignarelli MC, Abbà A, Benigna I, Sorlini S, Torretta V (2018) Overview of the main disinfection processes for wastewater and drinking water treatment plants. Sustainability. https://doi.org/10.3390/su10010086

Czaja W, Krystynowicz A, Bielecki B, Brown RM Jr (2006) Microbial cellulose-the natural power to heal wounds. Biomaterials 27:145–151

Dabrowski W, Zylka R, Malinowski P (2017) Evaluation of energy consumption during aerobic sewage sludge treatment in dairy wastewater treatment plant. Environ Res 153:135–139

Dasgupta J, Silkder J, Chakraborty S, Curcio S, Drioli E (2015) Remediation of textile effluents by membrane based treatment techniques: a state of the art review. J Environ Manage 147:55–72

Figueiredo ARP, Silvestre AJD, Neto CP, Freire CSR (2015) In situ synthesis of bacterial cellulose/polycaprolactone blends for hot pressing nanocomposite films production. Carbohydr Polym 132:400–408

Franco S, Gaetano V, Gianni T (2018) Urbanization and climate change impacts on surface water quality: enhancing the resilience by reducing impervious surfaces. Water Res 144:491–502

Fu L, Zhang J, Yang G (2013) Present status and applications of bacterial cellulose-based materials for skin tissue repair Carbohydr. Polym. 92:1432–1442

Garcha S, Verma N, Brar SK (2016) Isolation, characterization and identification of microorganisms from unorganized dairy sector wastewater and sludge samples and evaluation of their biodegradability.Water Resour. Ind. 16:19–28

Gayathri G, Srinikethan G (2010) Bacterial cellulose production by K. saccharivorans BC1 strain using crude distillery effluent as cheap and cost effective nutrient medium. Int J Biol Macromol 138:950–957

Goel NK, Kumar V, Misra N, Varshney L (2015) Cellulose based cationic adsorbent fabricated via radiation grafting process for treatment of dyes waste water. Carbohydr Polym 132:444–451

Guo J, Catchmark JM (2012) Surface area and porosity of acid hydrolyzed cellulose nanowhiskers and cellulose produced by Gluconacetobacter xylinus. Carbohydr Polym 87:1026–1037

Hassan E, Hassan M, Abouzeid R, Berglund L, Oksman K (2017) Use of bacterial cellulose and crosslinked cellulose nanofibers membranes for removal of oil from oil-in-water emulsions. Polymers 9:388–4012

Hatimi B, Mouldar K, Loudiki A, Hafdi H, Joudi M, Daoudi EM, Nasrellah H, Lançar T, El Mhammedi MA, Bakasse M (2020) Low cost pyrrhotite ash/clay-based inorganic membrane for industrial wastewaters treatment. J Environ Chem Eng 8:103646

He J, Zhao H, Li X, Su D, Zhang F, Ji H, Liu R (2018) Superelastic and superhydrophobic bacterial cellulose/silica aerogels with a hierarchical cellular structure for oil absorption and recovery. J Hazard Mater 346:199–207

Hestrin S, Schramm M (1954) Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Huang Y, Zhu C, Yang J, Nie Y, Chen C, Sun D (2013) Recent advances in bacterial cellulose. Cellulose 21:1–30

Huang X, Li B, Wang S, Yue X, Yu Z, Deng X, Ma J (2020) Facile in-situsynthesis of PEI-Pt modified bacterial cellulose bio-adsorbent and its distinctly selective adsorption of anionic dyes. Colloids Surf 586:124163

Hussain Z, Sajjad W, Khan T, Wahid F (2019) Production of bacterial cellulose from industrial wastes: a review. Cellulose 26:2895–2911

Jahan F, Kumar V, Saxena RK (2018) Distillery effluent as a potential medium for bacterial cellulose production: a biopolymer of great commercial importance. Bioresour Technol 250:922–926

Khan K, Lu Y, Saeed MA, Bilal H, Sher H, Khan H, Ali J, Wang P, Uwizeyimana H, Baninla Y, Li Q, Liu Z, Nawab J, Zhou Y, Su C, Liang R (2018) Prevalent fecal contamination in drinking water resources and potential health risks in Swat Pakistan. J Environ Sci 71:1–12

Koutinas AA, Vlysidis A, Pleissner D, Kopsahelis N, Garcia IL, Kookos LK, Papanikolaou S, Kwan TH, Lin CSK (2014) Valorization of industrial waste and by-product streams via fermentation for the production of chemicals and biopolymers. Chem Soc Rev 43:2587–2627

Kwak MH, Kim JE, Go J, Koh EK, Sung HS, Son HJ, Kim HS, Yun YH, Jung YJ, Hwang DY (2015) Bacterial cellulose membrane produced by Acetobacter sp. A10 for burn wound dressing applications. Carbohydr Polym 122:387–398

Li Y, Wang S, Huang R, Huang Z, Hu B, Zheng W, Yang G, Jiang X (2015) Evaluation of the effect of the structure of bacterial cellulose on full-thickness skin wound repair on a microfluidic chip. Biomacromol 16:780–789

Li C, Ma H, Venkateswaran S, Hsiao BJ (2019) Highly efficient and sustainable carboxylated cellulose filters for removal of cationic dyes/heavy metals ions. Chem, Eng, p 123458

Lima G, Souza R, Barros Ch, Rezende R, Custódio L, Cavalcante G M (2005) Diagnóstico ambiental das lavanderias de Toritama. Agência estadual de meio ambiente e recursos hídricos–CPRH, pp 1–48. http://www.cprh.pe.gov.br/downloads/toritama.pdf

Lin WC, Lien CC, Yeh HJ, Yu CM, Hsu SH (2013) Bacterial cellulose and bacterial cellulose-chitosan membranes for wound dressing applications. Carbohydr Polym 15:603–611

Liu X, Souzandeh H, Zheng Y, Xie Y, Zhong WH, Wang C (2017) Soy protein isolate/bacterial cellulose composite membranes for high-efficiency particulate air filtration. Compos Sci Technol 138:124–133

López C, Moreira MT, Feijoo G, Lema JM (2004) Dye decolorization by manganese peroxidase in an enzymatic membrane bioreactor. Biotechnol 20:74–81

Matsuura T (2001) Progress in membrane science and technology for seawater desalination a review. Desalination 134:47–54

Mohammadalinejhad S, Almasi H, Esmaili M (2019) Simultaneous green synthesis and in situ impregnation of silver nanoparticles into organic nanofibers by Lythrum salicaria extract: morphological, thermal, antimicrobial and release properties. Mater Sci Eng C 105:110115

Mohmood I, Lopes CB, Lopes I, Ahmad I, Duarte AC, Pereira E (2013) Nanoscale materials and their use in water contaminants removal: a review. Environ Sci Pollut Res 20:1239–1260

Moon RJ, Martini A, Naim J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Napavichayanun S, Amomsudthiwat P, Pienpinijtham P, Aramwit P (2015) Interaction and effectiveness of antimicrobials along with healing-promoting agents in a novel biocellulose wound dressing. Mater Sci Eng, C 55:95–104

Neamtum M, Siminiceanu I, Yediler A, Kettrup A (2002) Kinetics of decolorization and mineralization of reactive azo dyes in aqueous solution by the UV/H2O2 oxidation. Dyes Pigm 53:93–99

Pandey PK, Kass PH, Soupir ML, Biswas S, Singh VP (2014) Contamination of water resources by pathogenic bacteria. AMB Express. https://doi.org/10.1186/s13568-014-0051-x

Payment P, Plante R, Cejka P (2001) Removal of indicator bacteria, human enteric viruses, Giardia cysts, and Cryptosporidium oocysts at a large wastewater primary treatment facility. Can J Microbiol 47:188–193

Pendergast MTM, Hoek EMV (2011) A review of water treatment membrane nanotechnologies. Energy Environ Sci 4:1946–1971

Petersen N, Gatenholm P (2011) Bacterial cellulose-based materials and medical devices: current state and perspectives. Appl Microbiol Biotechnol 91:1277–1286

Phisalaphong M, Jatupaiboon N (2008) Biosynthesis and characterization of bacteria cellulose–chitosan film. Carbohydr Polym 74:482–488

Porwal HJ, Mane AV, Velhal SG (2015) Biodegradation of dairy effluent by using microbial isolates obtained from activated sludge. Water Resour. Ind. 9:1–15

Qiu Y, Qiu L, Cui J, Wei Q (2016) Bacterial cellulose and bacterial cellulose-vaccarin membranes for wound healing. Mater Sci Eng C 59:303–309

Sai H, Fu R, Xing L, Xiang J, Li Z, Li F, Zhang T (2015) Surface modification of bacterial cellulose aerogels’ web-like skeleton for oil/water separation. Appl Mater Interfaces 13:7373–7381

Saranya R, Arthanareeswaran A, Ismail AF, Dionysiou DD, Paul D (2015) Zero-valent iron impregnated cellulose acetate mixed matrix membranes for the treatment of textile industry effluent. RCS Adv 5:62477–62485

Sarkar B, Chakrabarti PP, Vijaykumar A, Kale V (2006) Wastewater treatment in dairy industries: possibility of reuse. Desalination 195:141–152

Schwarzenbach RP, Escher BI, Fenner K, Hosfstetter TB, Johnson AC, Gunten UV, Wehrli B (2006) The challenge of micropollutants in aquatic systems. Science 313:1072–1077

Shivsharan VS, Wani M, Khetmalas MB (2013) Isolation of microorganisms from dairy effluent. Microbiol Res 3:346–354

State Agency for the Environment (2016) Monitoring report of the hydrographic basin State of Pernambuco. http://www.cprh.pe.gov.br/ARQUIVOS_ANEXO/bacias2014/G_Relat16-IG.pdf. Accessed 01 Dec 2018

Stumpf TR, Yang X, Zhang J, Cao X (2018) In situ and exsitu modifications of bacterial cellulose for applications in tissue engineering. Mater Sci Eng C 82:372–383

Sulaeva I, Henniges U, Rosenau T, Potthast A (2015) Bacterial cellulose as a material for wound treatment: Properties and modifications: A review. Biotechnol Adv 33:1547–1571

Taha AA, Wu Y, Wang H, Li F (2012) Preparation and application of functionalized cellulose acetate/silica composite nanofibrous membrane via electrospinning for Cr(VI) ion removal from aqueous solution. J Environ Manage 112:10–16

Takai M, Nonomura F, Inukai T, Fujiwara M, Hayashi J (1991) Filtration and permeation characteristics of bacterial cellulose composite. Transaction 47:119–129

Torgobo S, Sukay P (2018) Bacterial cellulose-based scaffold materials for bone tissue engineering. Appl Mater Today 11:34–49

Ulbricht M (2006) Advanced functional polymer membranes. Polymer 47(7):2217–2262. https://doi.org/10.1016/j.polymer.2006.01.084

Vitta S, Thiruvengadam V (2012) Multifunctional bacterial cellulose and nanoparticle-embedded composites. Curr Sci 102:1398–1405

Wahid F, Bai H, Wang FP, Xie YY, Zhang YW, Chu LQ, Jia SR, Zhong C (2020) Facile synthesis of bacterial cellulose and polyethyleneimine based hybrid hydrogels for antibacterial applications. Cellulose 27(369):383

Wang Y, Serventi L (2019) Sustainability of dairy and soy processing: a review on wastewater recycling. J Clean Prod 237:117821

Wang Y, Yuan X, Yu K, Meng H, Zheng Y, Peng J, Lu S, Liu X, Xie Y, Qiao K (2018) Fabrication of nanofibrous microcarriers mimicking extracellular matrix for functional microtissue formation and cartilage regeneration. Biomaterials 171:118–132

Wanichapichart P, Kaewnopparat S, Buaking K, Puthai W (2002) Characterization of cellulose membranes produced by Acetobacter xylinum. J Sci Technol 24:856–862

World Health Organization (2018) Drinking-water. http://www.who.int/news-room/fact-sheets/detail/drinking-water. Accessed 08 Nov 2018

Yaseen DA, Scholz M (2019) Textile dye wastewater characteristics and constituents of synthetic efuents: a critical review. Int J Environ Sci Technol 16:1193–1226

Yin N, Chen S, Li Z, Ouyang Y, Hu W, Tang L, Zhang W, Zhou B, Yang J, Xu Q, Wang H (2012) Porous bacterial cellulose prepared by a facile surfactant-assisted foaming method in azodicarbonamide-NaOH aqueous solution. Mater Lett 81:131–134

Yin N, Du R, Zhao F, Han Y, Zhou Z (2020) Characterization of antibacterial bacterial cellulose composite membranes modified with chitosan or chitooligosaccharide. Carbohydr Polym 229:115520

Zaini MAA, Amano Y, Machida M (2010) Adsorption of heavy metals onto active carbons derived from polyacrylonitrile fiber. J Hazard Mater 180:552–560

Acknowledgements

The authors acknowledge the Research Support Center/UFRPE (CENAPESQ), Center for Strategic Technologies of the Northeast (CETENE), Pernambuco State Environment Agency (CPRH), and the Analytical Center of the Department of Fundamental Chemistry/UFPE. A.A. Alves acknowledges for the doctoral scholarship from FACEPE, Grant No. APQ-0994-1.06/15. M.F. The research was funded by CNPq (Universal Project 14/2014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Editorial responsibility: Ta Yeong Wu.

Rights and permissions

About this article

Cite this article

Alves, A.A., Silva, W.E., Belian, M.F. et al. Bacterial cellulose membranes for environmental water remediation and industrial wastewater treatment. Int. J. Environ. Sci. Technol. 17, 3997–4008 (2020). https://doi.org/10.1007/s13762-020-02746-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-020-02746-5