Abstract

In recent years, chromium water pollution has become a serious problem for aquatic environments as rivers and wetlands, and for human health. Many researchers are working on finding economic and efficient ways to solve this issue, with the objective of mitigating the damaging effluents of the industries, as in the case of the dumping of chromium. In this study, the removal of chromium (VI) by plant cellulose and bacterial cellulose was evaluated. An experiment was carried out with different initial concentrations of chromium, evaluating the ability to eliminate and adsorb this contaminant by means of biomass of E crassipes, bacterial cellulose, and the union of these two biomasses, determining which is the best biomass. Different design variables such as characterizations of biomasses, adsorption kinetics, adsorption capacities through Langmuir isotherms, pH influence, and desorption-adsorption capacities of each of these biomasses were evaluated. Concluding that the capacity of bacterial cellulose (BC) is 47 mg/g, the capacity between bacterial cellulose and E crassipes cellulose (EC + BC) is 28 mg/g and the cellulose of E crassipes (EC) is 10 mg/g. However, with the biomass of EC was given five processes of treatment more due to the power of elution that had the HCl about the Cr (VI) adhered in this biomass. But with the biomass of BC, the HCl had not the same result of elutions and alone had one treatment of Cr (VI).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conventional industrial wastewater treatments, such as activated sludge, oxidation ditches, and membrane filtration, among others, are usually very expensive for industries that contaminate with heavy metals the water resources. For this reason, new and economical treatments for proper management must be investigated and implemented in these industries, to avoid the serious environmental and social pollution consequences (Gong et al. 2017; Huang et al. 2019).

A form to treat the water could be through the adsorption of pollutants by cellulose. Different types of cellulose-based biomass have been identified with the capacity to adsorb heavy metals. Some of them are chitosan (Zhou et al. 2014), Coco residues (Pillai et al. 2013); (Kobielska et al. 2018) Banana (Saman et al. 2017), vegetable cellulose from camphor leaf (Cinnamomum camphora) (Wang et al. 2018), bacterial cellulose (Baldikova et al. 2017; Jin et al. 2017), Biochar of banana (Gazi et al. 2018) and cellulose from E crassipes (Gupta and Balomajumder 2015; Sayago et al. 2020).

Therefore, an alternative is needed for the proper treatment of industrial wastewater; this alternative could be bacterial cellulose as a heavy metal removal agent in water. Bacterial cellulose has been used to remove chromium (Stoica-Guzun et al. 2016), lead (Jin et al. 2017; Huang et al. 2018); Cobalt (Jin et al. 2017), Copper (Wang et al. 2015), Cadmium (Min et al. 2014). Bacterial cellulose (BC) is synthesized by the fermentation of the bacterium present in the genus Acetobacter reclassified as Gluconacetobacter. The bacterium that produces cellulose more efficiently is the Gram-Negative bacteria of the genus Gluconacetobacter xylinus sucrofermentans (Carreño Pineda 2011). Its morphology is bacillus, stick-shaped, with a length of 2–10 microns and a width of 0.5–1 microns. (Kamarudin et al. 2018). It produces cellulose from a carbon source such as glucose, sucrose, mannitol, or arabitol among other polysaccharides. This type of cellulose is extracellular produced mainly in vitro by the bacterium Acetobacter (Sulaiman et al. 2018; De Souza et al. 2019; Phruksaphithak et al. 2019; Mohammed et al. 2018; Kumar et al. 2019; Xiang et al. 2017; Xiang et al. 2016; Cheng et al. 2017; Huang et al. 2018).

It has also been experienced on the use of vegetable cellulose in the removal of heavy metals, as in the case of E crassipes, Arsenic (Lin et al. 2018; Dyes (El-Zawahry et al. 2016), Lead (Zhou et al. 2011) (Ammar et al. 2014) (Tan et al. 2014); Uranium (Yi et al. 2016). E crassipes is an invasive aquatic plant present in wetlands contaminated by organic matter. Its abundant biomass and its great capacity to retain heavy metals make it a promising source of biomass for the construction of water treatment systems (Sayago, 2019, 2021; Carreño Sayago & Granada, 2017; Tabinda et al. 2019; Shalaby et al. 2019).

In adsorbent treatment processes, desorption is an important design parameter, due to the recyclability of this material in the treatment of water contaminated with heavy metals. Hydrochloric acid (HCl) has been used in many investigations with important results in the desorption of heavy metals in different types of biomasses (Lin et al. 2018; Pillai et al. 2013) due to the fact that this reagent attracts the heavy metals adhered to the biomass (Hokkanen et al. 2013; Hokkanen et al. 2014a, b).

In the present investigation, the ability to remove and absorb chromium (VI) by the biomass of E crassipes (EC), bacterial cellulose (BC), and the union of the two biomasses EC + BC were evaluated, determining which is the best combination, through of the characterizations of biomasses, adsorption kinetics, isotherms, the influence of pH, and desorption-adsorption capacities of each of these biomasses.

Materials and methods

Preparation of bacterial cellulose BC

Bacterial Cellulose BC films were produced in the culture medium of a ripe pineapple, using Kombucha, obtained in the bioprocess laboratory of the Jorge Tadeo Lozano University. It was washed with distilled water and all kinds of impurities were separated. The initial weight of the pineapple (Ananas comosus) was taken, the proportion was 65% distilled water and 35% pineapple. The juices were sterilized in an autoclave at 121 °C for two hours (Sulaiman et al. 2018).

500 ml media were prepared in previously sterilized glass containers. In each culture, 450 ml pineapple juice and 50 ml Kombucha liquid were added, then 0.5 g yeast extract and 2 g Kombucha fungus were added. pH and temperature measurements were taken periodically. Bacterial cellulose film was obtained. The BC membranes were cut into pieces with a dimension of 20 mm × 20 mm × 5 mm. Then dried at 70 °C for 48 h to remove moisture and grind to a 0.216 mm diameter. There was a production of 18 g in 6 h, this process was adapted (Carreño Pineda 2011).

Utilization of the E crassipes (EC)

E. crassipes plants were collected in a wetland located in the municipality of Mosquera, outsides Bogotá D.C.; subsequently washed EC with distilled water, separating the stem from the stem and leaves. Then dryed at 70 °C for 48 h to remove moisture and grind to 0.212 mm diameter. The pulverized biomass was screened through Blade Mill to obtain different particle sizes.

Creation of bacterial cellulose biomass and plant cell EC + BC

Three different types of biomass were evaluated: E crassipes cellulose (0.3 g); Bacterial cellulose (0.3 g) and Combined cellulose of EC (0.15 g) and BC (0.15 g).

The parameters of the investigation consisted on the following

Initial chromium concentrations: 20, 50, 100, 200, 300 and 600 mg (chromium/L). Samples were taken in the flask at each time interval, analyzing the residual chromium concentration. Samples of 20 µL were obtained and subsequently taken to the Centrifuge (KASAI MIKRO 200).

Rice et al (2017) To determine Chromium (VI), a UV84 spectrophotometer was used, where it monitored the changes in absorbance. According to the norm (standard methods for the examination of water and wastewater).

Adsorption experiment

The batch adsorption experiments were carried out in a 10-ml glass vessel with a stirring (IKA Ks 4000 equipment stirrer) at a constant temperature of 20 °C, 250 rpm. Data were taken every 20 min to complete the 180 min. By better results statistics everything, the experiments were made in triplicate, the average was the result end.

The stock solution of 1000 (mg/L) of Cr (VI) was prepared with distilled water using potassium dichromate. This stock solution was used to prepare the test solutions of: 20; 100; 200; 300 and 600. mg/L Cr (VI). The batch adsorption study was taken at a temperature of 24 °C. The adsorption capacity was determined with the suspension of 0.3 g of biomass in 100 ml of Cr (VI) solution for 140 min at 200 rpm, taking samples every 20 min, before determining the residue, discarding the sediment.

FTIR

The Materials were characterized by Fourier Transform infrared spectroscopy (79 Jasco FTIR 430) to measure IR spectra in a spectral range of 4000–400 cm−1; a resolution of 4 cm−1, and a scanning speed of 2 mm s−1.

pH influence

Three pH scenarios (pH 3, pH Neutral and pH 10) adjustments were made to the pH to bring it to acidic and basic conditions, with 100 mg/L of Cr (VI).

Desorption-adsorption

After the Cr (VI) adsorption processes, it was arranged to take this chromium-loaded biomass to carry out the elution process. At the end of the adsorption process by each of the biomasses were washed with distilled water and posteriorly, the process of elution with HCl in an Erlenmeyer flask at 25 °C for 24 h with constant agitation. 20 ml HCl was used; then the biomass was separated through a filter and the pH was adjusted through distilled water (Hokkanen et al. 2014a, b).

g of BC and EC were eluted with 10 ml HCl 0.1 mol/L, then subjected to Cr (VI) g again, until saturation or wear of cellulose (Pillai et al. 2013).

Chromium Determination

The amount of Cr (VI) residue was estimated by means of the diphenylcarbazide method. For this the phosphate buffer solution was prepared by adjusting it to a pH equal to 2 with (H3PO4) to 90%. In an eppendorf tube 200 µl of 0.5% diphenylcarbazide (P/V acetone) is added, 900 µl of phosphate buffer and 100 µl of residual sample. The absorbance is measured at 540 nm, where it was transferred from an adsorption cell.

Adsorption isotherm

There were 6 different initial concentrations, where it was 20, 50, 100, 200, 300 and 600 mg/L Cr (VI). Each process yielded 6 final concentrations (Ce), which could be defined as the equilibrium concentration and 6 final capacities (q), it could be called equilibrium capacity with these clear parameters: The Langmuir, Freundlich isotherms, Tenkim and Dubinin R, and the second-order adsorption kinetics. These results were plotted. To obtain Langmuir isotherm, Ce/q versus Ce was graphed, for the Freundlich isotherm ln (q) versus Ln (Ce), Kf and n were graphed, the Temkin isotherm was graphed Ln (Ce) versus (q), obtaining the parameters Kt and B. The Dubinin R isotherm was graphed Ln (q) versus (ʓ). obtaining the parameters: qm and b. The representative graphs of each isotherm represent the values of these constants.

Results and discussion

Results

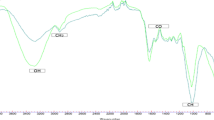

FTIR analysis

The spectra were measured on the Fourier transform spectrophotometer FTIR, EC, BC, and EC + BC, with and without attached Cr (VI) were measured.

Characterizations through FTIR the spectrum (light green) shows the characteristics of biomass of EC bands of hydroxyl (OH) groups, due to the existence of cellulose and lignin, this is shows in the prolonged stretching in 3280.

Also, different sections can be seen of hydrogen bonds due to (COOH) groups 1632 and amino groups; amides are masked by broad bands (OH) (Wei et al. 2017).

These hydrogen bonds are useful tools for the interaction with heavy metals. This is evidenced in the spectrum color (dark green) which represents a sample of EC with Cr (VI) adhered after the adsorption process, where the stretching of the group (OH) lost part of its extension (Fig. 1).

The change in peak 3280, after the adsorption of Cr (VI), indicates that EC removed Cr (VI) as a function of interaction with (OH), part of (OH) was lost due to the formation of vibrations of ascension O-Cr. (Wang et al. 2018).

In Fig. 2, is shown the characteristic spectra of BC before and after the adsorption of Cr (VI). Hydroxyl (OH) groups can be seen in bands 3400 and 580, you can also see the characteristic band of bacterial cellulose 1650 of the amine group, unlike vegetable cellulose of EC. Also in Fig. 2, different stretches can be seen as in the case of (CH) with 1032.

After the experimental process of adsorption of Cr (VI), pink spectrum, significant changes were observed in its stretch levels during the tests FTIR. An important change in the hydroxyl group (OH) can be observed after the chemisorption process, like the vegetable cellulose of the group (OH) (Muhamad et al. 2020), part of the hydroxyl groups was lost in the characterization due to the presence in the biomass of Cr (VI) who is largely responsible for the adsorption of this heavy metal, due to the strong vibrations of O-Cr. In Fig. 2, can also be identified a loss in vibration expansion of (NH2), at the peak of 1632, because this amino group contributed to the adsorption of Cr (VI) and is much greater than vegetable cellulose. Concluding that this biomass incorporated Cr (VI) through two functional groups such as (OH) and (NH2).

BET

The specific surface area, pore volumes and pore types were the basic units of EC and BC are characterized, where the density of the biomass (ρb), its porosity (ε), mass (m) and the volume of the adsorbent (V) are stipulated.

A special concept in this article is the density particle (ρp), this density is defined as the diminute mass of the particle (mp) over the small volume of the particle (Vp) occupied in a space.

The volume of each particle, assuming they are spherical, was calculated through the following Eq. (3).

where (r) is the radius of the particle. The parameter (ε) was calculated with the relationship between the density of particle and density of the biomass of EC and BC.

According to Iváñez (2017), the density of the particle must be higher than the density of the biomass, in order to guarantee the diffusion of the pollutant in the pores of the adsorbent material. Worch (2012) concludes that, in treatment system designs, porosity values must be above 0.5.

Adsorption results

Figure 3, 4 and 5 show three adsorption processes, where 6 initial Cr (VI) concentrations were used, evaluating in the case of Fig. 3 only the biomass of EC, Fig. 4 BC, and in Fig. 5, 0.15 g of BC and 0.15 of EC cellulose were evaluated.

In the percentage of Cr (VI) elimination, the higher the concentration, the lower the percentage of removal due to the high Cr (VI) load that the fluid with 600 mg/L of this contaminant possessed. The biomass saturation of EC was evident in the removals, with to efficiency of 10% at the initial concentrations of 600 mg/L and also saturating with initial concentrations of 300 mg/L, with to efficiency of 40%. With the initial 200 mg/L concentrations of Cr (VI), an interesting efficiency of around 60% could be observed. The initial concentration of 100 mg/L, had an efficiency of 80% of the Cr (VI) present in the water and the removal at 50 and 20 mg/L met the expectations for removal. Lin et al. (2015) also achieved significant As (V) removals with this biomass without chemical modifications. In Fig. 4, it shows the removals of BC.

Removals of Cr (VI) with BC were significant within first the 60 min the initial concentrations of 20, 50 and 100 mg /L were already above 80% of Cr (VI) removed, and efficiencies around 98% at the finish of the process experiment. For 200 mg /L got the removals around of 65% in the first minutes, posteriorly it reaches removals for above of 95%. The concentration initial of 300 mg/L was under 50% in the first minutes but finish with an efficiency meaningful of 92% and the concentration initial of 600 mg/L was under 30% the initial process, however, reach an efficiency of 88% of the Cr (VI) present.

This biomass shared between EC + BC also performed interesting removing Cr (VI). The initial concentrations of 20 and 50 mg/L started with efficiency 70 and 65%, respectively, reaching an equilibrium toward the end of the process with efficiencies around 97% of Cr (VI). The initial concentrations of 100 mg/L were similar to the initial concentrations of 20 and 50 mg/L. The difference was that this concentration began with less than 30% in removal efficiency. The initial concentrations of 200 and 300 mg/L of Cr (VI) had low efficiencies in the first minutes, however reach a removal interesting of above 90%. The initial concentration of 600 mg/L of Cr (VI), had an efficiency was around 10% in the first minutes, however, reach the removal of 78% of Cr (VI) at the finished of the process experiment.

Adsorption isotherms

The adsorption Isotherms of Langmuir are shown in Fig. 6, 7, and 8, (Ce/q) vs. (Ce) for the adsorption of Cr (VI), representing the Langmuir equation. All the data obtained in the experimental process of each biomass and each different initial concentration were taken for the case of EC biomass, BC, and the combination of the biomass, with this graph the maximum adsorption capacity of this biomass could be obtained. Figure 6 shows the Langmuir isotherms of the EC biomass experiment removing Cr (VI).

A representative adjustment of 0.992 R2 can be observed. Taking as reference the Langmuir equation (Jin et al.2017), which is Eq. (5).

The maximum capacity variable (qm) is obtained by clearing the expression observed in Fig. 6: y = 0.1306x + 0.677. The expression 0.1306 × resembles 1/(qm) Ce.

Where (qm) is cleared and the maximum retention capacity of on the part of the vegetable cellulose EC, was 10 mg/g, concluding that this biomass could retain per gram 10 mg of Cr (VI). Similar results were seen in the experiments reported by Li et al. (2013), Lin et al. (2018) and Zhang et al. (2015), where they used biomass of EC without modification.

Figure 7, it shows the Langmuir isotherms of the BC biomass experiment removing Cr (VI).

Figure 7, it can be concluded that there is an important adjustment in this equation, due to this adjustment the maximum capacities that this biomass can be taken as a reference. The maximum capacity was obtained from the equation of the line, of the cellulose of BC of 47 mg/g of Cr (VI) for each gram of cellulose, an ideal result for design purposes of systems of treatment.

Figure 8, it shows the Langmuir isotherms of the experiment of the biomass of EC + BC removing Cr (VI).

Figure 8, the maximum adsorption capacity was obtained, with the equation of the line, clearing 0.0321, of EC + BC of 28 mg/g. This ability is interesting since it is much larger than EC alone and less than BC. Oladipo et al., (2019) experimented with biochar in the removal of Zn (II), finding that the isotherm of Langmuir is better adapted to the process of adsorption of heavy metals.

This combination has not been reported in the literature and is a possible solution to treat wastewater contaminated with heavy metals. BC removes heavy metals much more than EC cellulose, but the latter is much cheaper and easier to achieve, therefore they make an ideal combination in order to achieve an effective economic and viable treatment system.

The Temkin isotherm is used in the thermic process, due to this, it isotherm does not represent the adsorption process of Cr(VI) for the EC or BC. It was revised the adjust of the isotherm Dubinin–Radushkevich, where the (Ln) adsorption capacity (q) is obtained and the (ε2) is the Polanyi potential is obtained.

The Dubinin–Radushkevich isotherm establishes that the micropores of the adsorbed are filled through a physical adsorption process (c). Due to this, this isotherm does not represent the adsorption process of EC or BC toward Cr (VI). Table 1 resumes the parameters of each isotherm.

Table 2 shows a comparative between the researches with the biomasses of EC and BC, and with others biomasses.

Result BET

The theory BET is an extension of the Langmuir isotherm (Condon, 2019; Oladipo et al. 2019) and due to the adsorption adjustments of EC and BC removing Cr (VI) with this isotherm, it was characterized under this theory.

The biomass used in the adsorption process was 0.3 g, measuring the volume occupied by the amount of biomass used EC yields 0.35 ml and 0.40 ml for BC. With Eq. (1), the density of the biomass used in the present experiment was obtained, both for EC and BC.

The size of the diameter per particle for EC is 0.212 mm, similar observations have been reported (Song et al., 2021; Cao et al., 2019). With this value, the volume of each particle was calculated through Eq. (3).

For bacterial cellulose BC, the diameter of the particle was 0.216 mm, similar observations have been reported (Zhang et al. 2020). As well as the biomass of EC, the volume of the particle was obtained, yielding 0.006 mm3.

Taking the weight of the tiny particle of EC, with Eq. (2), the density of the particle is obtained:

Solving this equation, the volume occupied by the particle of EC of 0.005 mm3 that occupies the particle sphere of EC was obtained, taking the weight of the tiny particle of EC, yielding an approximate value of 0.01 mg, the density of the particle being 2 mg/mm3. Similar observations have been reported (Oladipo et al. 2017). For bacterial cellulose BC, the diameter of the particle was 0.216 mm, as was the biomass of EC, the volume of the particle was obtained, yielding 0.006 mm3, weighing 0.016 mg, being the density 1.6 mg/mm3.

Through Eq. (4) the porosity of the particle of the biomass pores of EC and BC was established.

The relationship between the density of the particle and the biomass establishes an important parameter of design in process of treatment with the column. Due to the porosity values above 0.5, is important this result of design (Ivañez 2017; Worch, 2012). A diameter under 0.212 mm is imperative in the design of this system of treatment with absorbent material (Sayago, 2021).

Second-order model

In the adjustment of a second-order adsorption process, it demonstrates that chemisorption was predominant in the process due to the high capacity of EC + BC to retain heavy metals, especially Cr (VI). The exchange occurs between the hydrogens of (OH) and the amine groups (NH2) that possesses these biomasses and the need of chromium to adjust and gain electrons that it needs.

The constant rates, equilibrium capacities and the corresponding correlation coefficients for all the concentrations tested have been calculated and summarized in Table 3.

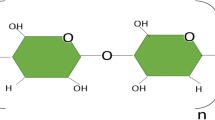

Adsorption process in bacterial cellulose and vegetable cellulose

In the biomass of EC + BC are find groups of hydroxyl (OH) and amines (NH2) where the ions of chromium are accommodated. Cr (VI) in the experimental process is adsorbed by EC + BC through two mechanisms. One is reduction (see Fig. 9), the reduction of Cr (VI) to Cr (III) by cellulose can be seen.

In the first mechanism, Cr (VI) is reduced to Cr (III), due to the interaction of this metal with the (OH) and (NH2) groups, which act as electron donors. The biomass is oxidized because the oxygen that has oxidized to Cr (VI) react with the hydrogenions of the biomass, generating (OH) and (H2O), going from dichromate (Cr2O7) or Cr (VI) to chromium oxide (Cr2O3) or Cr (III).

This reduction is very important for the adsorption process and therefore for the treatment process. When Cr (III), which at that time is chromium oxide (Cr2O3), is reduced and begins a process of chemical diffusivity with biomass, the electron-charged biomass reacts with the chromium adsorbing it while the oxygen reacts with the protons of (H+) in the biomass. Figure 10 shows the process of adsorption of Cr (III) to the bacterial biomass.

In Fig. 10, it can be seen that for every 4 glucose molecules that form the branching of the cellulose structure (n) two chromium molecules adhere due to the chemisorption supplied by the hydroxyl (OH) groups and amino groups (NH2).

This article wants to represent the biomass reduction-adsorption process in parts, but this is a continuous process. The chemical reaction is as follows:

where 24(COO−H +) represents the biomass of EC + BC, (Cr2+ 6O7−2) represents Cr (VI). It can be seen both in Fig. 9 and Fig. 10 that 4 parts of glucose (24 COO- H +) react with Cr (VI), forming for each 4 cellulose glucose adsorption 24 (COO) * Cr2.

pH influence

In Fig. 11, three proposed pH scenarios are shown, because pH has an important effect on the adsorption capacity in these processes. In the present work, adjustments were made to the pH to bring it to acidic and basic conditions, with EC + BC and with 100 mg/L of Cr (VI). Adsorption experiments with pH 3 were carried out in the contaminated water. When the pH is in the range of 2.0–5.0, there is competition between the (H+) and Cr (VI) for the active sites that the biomass has, which are (OH) and (NH2). These hydrogens, when they compete, avoid greater removals (Niu et al. 2017; Huang and Chen, 2009). For this reason, the elimination in this pH range was around 85%.

As the pH increases, the surface of EC + BC becomes more negative, stabilizing the (H+) and (OH) groups, compared to the low pH. For this reason, the (OH) and (NH2) groups Biomass attracts Cr (VI) metal ions favoring the adsorption process. In the present investigation, the tests were performed under a neutral pH.

However, experiments were carried out with a pH 10. When the liquid is above pH 8, it reaches removals 65% due to the large amount of anions (OH−) that water has. This can lead to the formation of hydroxides or metallic oxides, such as chromic oxide (CrO); Chromium oxide and chromic oxide (Cr2O3). The mechanism of adsorption of heavy metals at a high pH would be affected due to that could confuse between adsorption and precipitation of Cr (VI) ions (Jin et al., 2017).

Desorption-adsorption

In Fig. 12, it shows the elution process of BC with HCl.

After the adsorption process, where the biomass of removed 98% the initial concentration of 100 mg/L in 140 min, it removed about 55% in the second removal process, because this biomass is more sensitive to the eluent HCl, the same affected was seen in the second elution process, where it only reached 40% in Cr (VI) removal, later the other processes were also insignificant in removal. It could be concluded that for the eluent HCl, this biomass could be used once again. Also the research of Chen et al. (2020), the biomass of BC was affected in the processed of elution. In Fig. 13, it shows the elution process with HCl with EC.

The biomass of EC does not affect the process of elution with HCl. In the first process of adsorption of Cr (VI) got an efficiency of removal of 80% and the second process also got an efficiency of 80%. In the third treatment process, there was a 70% Cr (VI) removal and in the fourth process, there was a 60% yield. For the fifth process, the biomass was affected, removing around 40%. Concluding that this biomass can support up to four elution processes with HCl. This information is underlying for the design of the treatment system (Lin et al. 2018; Tan et al. 2014; Lin et al. 2020).

Conclusion

In experiments with low and high concentrations of Cr (VI), BC removed in the first 20 min about 95% of this heavy metal. These results show that this biomass is highly efficient when is used for treating water contaminated with Cr (VI). The removals of the mixture of EC + BC were also significant, removing about 90% in the first 100 min of treatment.

The mixture with the biomass of EC + BC has the objective of improving the treatment conditions. While the removals and capacities of the bacterial cellulose are superior to the cellulose of E crassipes, the latter is cheaper and easier to achieve.

The pH stabilization should be one of the design’s criteria of a large-scale treatment system due to the initial pH conditions. For the treatment of effluents loaded with heavy metals, it is recommended to stabilize bacterial biomass and E crassipes at a neutral pH and under.

Through experiments and different adsorption tests, the adjustment of the experiments to the Langmuir isotherm was verified, evidencing an adsorption monolayer and also obtaining the maximum capacity of each biomass. The capacity of BC is 47 mg/g, EC + BC is 28 mg/g and EC is 10 mg/g. An adjustment to second-order kinetics was also verified, evidencing chemisorption processes in Cr (VI) removal of the different processes. In the process of elution favored of biomass of EC with HCl due to that got high efficiency of removal of Cr (VI) after this process. Removing 80% in the first process and also 80% in the second process of elution, reaching to remove the 70% in the third process and the fourth process of 60% of Cr (VI). This parameter is imperative for the design of the process of treatment on large scale. However, the biomass of BC did not reach removal important after of process of elution.

Recommended beginning to use this biomass to scale to a bigger system, for example, designed treatment with column fixed, with elution of HCl for the biomass of EC + BC.

References

Ammar NS, Elhaes H, Ibrahim HS, Ibrahim MA (2014) A novel structure for removal of pollutants from wastewater. Spectrochim Acta Part A Mol Biomol Spectrosc 121:216–223

Baldikova E, Pospiskova K, Ladakis D, Kookos IK, Koutinas AA, Safarikova M, Safarik I (2017) Magnetically modified bacterial cellulose: a promising carrier for immobilization of affinity ligands, enzymes, and cells. Mater Sci Eng, C 71:214–221

Cao F, Lian C, Yu J, Yang H, Lin S (2019) Study on the adsorption performance and competitive mechanism for heavy metal contaminants removal using novel multi-pore activated carbons derived from recyclable long-root Eichhornia crassipes. Biores Technol 276:211–218

Carreño Pineda LD (2011) Efecto de las Condiciones de Cultivo y Purificación sobre las Propiedades Fisicoquímicas y de Transporte en Membranas de Celulosa Bacteriana (Doctoral dissertation, Universidad Nacional de Colombia)

Carreño Sayago UF, Granada Torres CA (2017) Design, development, and evaluation of a laboratory-scale phytoremediation system using eichhornia crassipes for the treatment of chromium-contaminated waters. Tecciencia 12(22):7–14

Chen X, Cui J, Xu X, Sun B, Zhang L, Dong W, Sun D (2020) Bacterial cellulose/attapulgite magnetic composites as an efficient adsorbent for heavy metal ions and dye treatment. Carbohyd Polym 229:115512

Cheng Z, Yang R, Liu X, Liu X, Chen H (2017) Green synthesis of bacterial cellulose via acetic acid pre-hydrolysis liquor of agricultural corn stalk used as carbon source. Biores Technol 234:8–14

Condon JB (2019) Surface Area and Porosity Determinations by Physisorption: Measurement. Elsevier, Classical Theories and Quantum Theory

Dautoo UK, Shandil Y, Chauhan GS (2017) New crosslinked hydrazide–based polymers as Cr (VI) ions adsorbents. J Environ Chem Eng 5(6):5815–5826

de Souza SS, Berti FV, de Oliveira KP, Pittella CQ, de Castro JV, Pelissari C, Porto LM (2019) Nanocellulose biosynthesis by komagataeibacter hansenii in a defined minimal culture medium. Cellulose 26(3):1641–1655

El-Zawahry MM, Abdelghaffar F, Abdelghaffar RA, Hassabo AG (2016) Equilibrium and kinetic models on the adsorption of reactive black 5 from aqueous solution using Eichhornia crassipes/chitosan composite. Carbohyd Polym 136:507–515

Gazi M, Oladipo AA, Azalok KA (2018) Highly efficient and magnetically separable palm seed-based biochar for the removal of nickel. Sep Sci Technol 53(7):1124–1131

Gong X, Huang D, Liu Y, Zeng G, Wang R, Wan J, Xue W (2017) Stabilized nanoscale zerovalent iron mediated cadmium accumulation and oxidative damage of Boehmeria nivea (L.) Gaudich cultivated in cadmium contaminated sediments. Environ Sci Technol 51(19):11308–11316

Gupta A, Balomajumder C (2015) Removal of Cr (VI) and phenol using water hyacinth from single and binary solution in the artificial photosynthesis chamber. J Water Process Eng 7:74–82

Hokkanen S, Repo E, Sillanpää M (2013) Removal of heavy metals from aqueous solutions by succinic anhydride modified mercerized nanocellulose. Chem Eng J 223:40–47

Hokkanen S, Repo E, Suopajärvi T, Liimatainen H, Niinimaa J, Sillanpää M (2014a) Adsorption of Ni (II), Cu (II) and Cd (II) from aqueous solutions by amino modified nanostructured microfibrillated cellulose. Cellulose 21(3):1471–1487

Hokkanen S, Repo E, Westholm LJ, Lou S, Sainio T, Sillanpää M (2014b) Adsorption of Ni2+, Cd2+, PO43− and NO3− from aqueous solutions by nanostructured microfibrillated cellulose modified with carbonated hydroxyapatite. Chem Eng J 252:64–74

Hokkanen S, Bhatnagar A, Sillanpää M (2016) A review on modification methods to cellulose-based adsorbents to improve adsorption capacity. Water Res 91:156–173

Huang SH, Chen DH (2009) Rapid removal of heavy metal cations and anions from aqueous solutions by an amino-functionalized magnetic nano-adsorbent. J Hazard Mater 163(1):174–179

Huang X, Hu J, Qin F, Quan W, Cao R, Fan M, Wu X (2017) Heavy metal pollution and ecological assessment around the Jinsha coal-fired power plant (China). Int J Environ Res Publ Health 14(12):1589

Huang X, Zhan X, Wen C, Xu F, Luo L (2018) Amino-functionalized magnetic bacterial cellulose/activated carbon composite for Pb2+ and methyl orange sorption from aqueous solution. J Mater Sci Technol 34(5):855–863

Huang D, Liu C, Zhang C, Deng R, Wang R, Xue W, Guo X (2019) Cr (VI) removal from aqueous solution using biochar modified with Mg/Al-layered double hydroxide intercalated with ethylenediaminetetraacetic acid. Biores Technol 276:127–132

Iváñez M (2017) Diseño de un sistema de adsorción para la eliminación de fenol presente en disolución acuosa (Doctoral dissertation)

Jin X, Xiang Z, Liu Q, Chen Y, Lu F (2017) Polyethyleneimine-bacterial cellulose bioadsorbent for effective removal of copper and lead ions from aqueous solution. Biores Technol 244:844–849

Kamarudin NSB, Rahman NA, Kalil SM, Kamarudin SK (2018) Comparative study of bio-cellulose from Acetobacter Xylinum 0416 and commercial hard gelatine capsule. Int J Appl Eng Res 13(1):743–748

Kobielska PA, Howarth AJ, Farha OK, Nayak S (2018) Metal–organic frameworks for heavy metal removal from water. Coord Chem Rev 358:92–107

Komy ZR, Abdelraheem WH, Ismail NM (2013) Biosorption of Cu2+ by Eichhornia crassipes: physicochemical characterization, biosorption modeling and mechanism. J King Saud Univ Sci 25(1):47–56

Kumar V, Sharma DK, Bansal V, Mehta D, Sangwan RS, Yadav SK (2019) Efficient and economic process for the production of bacterial cellulose from isolated strain of Acetobacter pasteurianus of RSV-4 bacterium. Bioresource Technol 275:430–433

Li X, Liu S, Na Z, Lu D, Liu Z (2013) Adsorption, concentration, and recovery of aqueous heavy metal ions with the root powder of Eichhornia crassipes. Ecol Eng 60:160–166

Lin S, Yang H, Na Z, Lin K (2018) A novel biodegradable arsenic adsorbent by immobilization of iron oxyhydroxide (FeOOH) on the root powder of long-root Eichhornia crassipes. Chemosphere 192:258–266

Lin S, Huang W, Yang H, Sun S, Yu J (2020) Recycling application of waste long-root Eichhornia crassipes in the heavy metal removal using oxidized biochar derived as adsorbents. Bioresour Technol 314:123749

Min LU, Zhang YM, Guan XH, Xu XH, Gao TT (2014) Thermodynamics and kinetics of adsorption for heavy metal ions from aqueous solutions onto surface amino-bacterial cellulose. Trans Nonferrous Met Soc China 24(6):1912–1917

Mohammed N, Grishkewich N, Tam KC (2018) Cellulose nanomaterials: promising sustainable nanomaterials for application in water/wastewater treatment processes. Environ Sci Nano 5(3):623–658

Muhamad, I. I., Muhamad, S. N. H., Salehudin, M. H., Zahan, K. A., Tong, W. Y., & Pa'e, N. (2020). Effect of pandan extract concentration to chromium (IV) removal using bacterial cellulose-pandan composites prepared by in-situ modification technique. Materials Today: Proceedings.

Niu Y, Li K, Ying D, Wang Y, Jia J (2017) Novel recyclable adsorbent for the removal of copper (II) and lead (II) from aqueous solution. Biores Technol 229:63–68

Oladipo AA, Adeleye OJ, Oladipo AS, Aleshinloye AO (2017) Bio-derived MgO nanopowders for BOD and COD reduction from tannery wastewater. J Water Process Eng 16:142–148

Oladipo AA, Ahaka EO, Gazi M (2019) High adsorptive potential of calcined magnetic biochar derived from banana peels for Cu 2+, Hg 2+, and Zn 2+ ions removal in single and ternary systems. Environ Sci Pollut Res 26(31):31887–31899

Phruksaphithak, N., Kaewnun, C., & Sompong, O. (2019). Bacterial cellulose production and applications. Science, Engineering and Health Studies (FORMER NAME" SILPAKORN UNIVERSITY SCIENCE AND TECHNOLOGY JOURNAL"), 13(1), 1–7.

Pillai SS, Deepa B, Abraham E, Girija N, Geetha P, Jacob L, Koshy M (2013) Biosorption of Cd (II) from aqueous solution using xanthated nano banana cellulose: equilibrium and kinetic studies. Ecotoxicol Environ Saf 98:352–360

Rice, E. W., Baird, R. B., & Eaton, A. D. (2017). Standard Methods for the Examination of Water and Wastewater, 23rd Edition (23rd ed.). American Water Works Association.

Ruan C, Strømme M, Lindh J (2016) A green and simple method for preparation of an efficient palladium adsorbent based on cysteine functionalized 2, 3-dialdehyde cellulose. Cellulose 23(4):2627–2638

Saman N, Johari K, Song ST, Kong H, Cheu SC, Mat H (2017) High removal efficacy of Hg (II) and MeHg (II) ions from aqueous solution by organoalkoxysilane-grafted lignocellulosic waste biomass. Chemosphere 171:19–30

Sayago UFC (2019) Design of a sustainable development process between phytoremediation and production of bioethanol with Eichhornia crassipes. Environ Monit Assess 191(4):221

Sayago UFC, Castro YP, Rivera LRC et al (2020) Estimation of equilibrium times and maximum capacity of adsorption of heavy metals by E. crassipes (review). Environ Monit Assess 192:141 (2020). https://doi.org/10.1007/s10661-019-8032-9

Sayago UFC (2021) Design and development of a biotreatment of E. crassipes for the decontamination of water with Chromium (VI). Sci Rep 11:9326. https://doi.org/10.1038/s41598-021-88261-0

Shalaby, E. A., Ragab, A. A., Mahmoud, G. I., Shanab, S. M., Monsef, W. S., Fattah, O. A. E., & Ghoneim, A. E. (2019). Enhancement the removal capacity of heavy metals from aqueous solution using different aquatic organisms.

Song C, Zhao Y, Pan D, Wang S, Wu D, Wang L, Hao J, Wei Z (2021) Heavy metals passivation driven by the interaction of organic fractions and functional bacteria during biochar/montmorillonite-amended composting. Bioresource Technol 329:124923

Stoica-Guzun A, Stroescu M, Jinga SI, Mihalache N, Botez A, Matei C, Berger D, Damian CM, Ionita V (2016) Box-Behnken experimental design for chromium (VI) ions removal by bacterial cellulose-magnetite composites. Int J Biol Macromol 91:1062–1072

Sulaiman, N. N., Abd Rahman, N., & Esa, F. (2018). Monitoring Production of Bacterial Cellulose by Acetobacter xylinum 0416 with Fuzzy Logic via Simulation. Jurnal kejuruteraan, 1(7).

Tabinda, A. B., Arif, R. A., Yasar, A., Baqir, M., Rasheed, R., Mahmood, A., & Iqbal, A. (2019). Treatment of textile effluents with Pistia stratiotes, Eichhornia crassipes and Oedogonium sp. International journal of phytoremediation, 1–5.

Tan J, Yang G, Mao J, Dai H (2014) Laboratory study on high-temperature adsorption of HCl by dry-injection of Ca (OH)2 in a dual-layer granular bed filter. Front Environ Sci Eng 8(6):863-870

Wang J, Lu X, Ng PF, Lee KI, Fei B, Xin JH, Wu JY (2015) Polyethylenimine coated bacterial cellulose nanofiber membrane and application as adsorbent and catalyst. J Colloid Interface Sci 440:32–38

Wang C, Wang H, Gu G (2018) Ultrasound-assisted xanthation of cellulose from lignocellulosic biomass optimized by response surface methodology for Pb (II) sorption. Carbohyd Polym 182:21–28

Wei Y, Fang Z, Zheng L, Tsang EP (2017) Biosynthesized iron nanoparticles in aqueous extracts of Eichhornia crassipes and its mechanism in the hexavalent chromium removal. Appl Surf Sci 399:322–329

Worch E (2012) Adsorption technology in water treatment: fundamentals, processes, and modeling. Walter de Gruyter

Xiang Z, Gao W, Chen L, Lan W, Zhu JY, Runge T (2016) A comparison of cellulose nanofibrils produced from Cladophora glomerata algae and bleached eucalyptus pulp. Cellulose 23(1):493–503

Xiang Z, Liu Q, Chen Y, Lu F (2017) Effects of physical and chemical structures of bacterial cellulose on its enhancement to paper physical properties. Cellulose 24(8):3513–3523

Yi ZJ, Yao J, Chen HL, Wang F, Yuan ZM, Liu X (2016) Uranium biosorption from aqueous solution onto Eichhornia crassipes. J Environ Radioact 154:43–51

Yu X, Tong S, Ge M, Wu L, Zuo J, Cao C, Song W (2013) Adsorption of heavy metal ions from aqueous solution by carboxylated cellulose nanocrystals. J Environ Sci 25(5):933–943

Zhang W, Wang XC, Li XY, Jiang F (2020) A 3D porous microsphere with multistage structure and component based on bacterial cellulose and collagen for bone tissue engineering. Carbohydr Poly 236:116043

Zhou W, Ge X, Zhu D, Langdon A, Deng L, Hua Y, Zhao J (2011) Metal adsorption by quasi cellulose xanthogenates derived from aquatic and terrestrial plant materials. Biores Technol 102(3):3629–3631

Zhou Y, Fu S, Zhang L, Zhan H, Levit MV (2014) Use of carboxylated cellulose nanofibrils-filled magnetic chitosan hydrogel beads as adsorbents for Pb (II). Carbohyd Polym 101:75–82

Acknowledgements

To the Fundation University Libertadores.

Funding

About of researcher project, the university “Los Libertadores” is the company that contribute to development of this article and other process.

Author information

Authors and Affiliations

Contributions

UC analyzed and interpreted the used of FTIR and also the process of adsorptions with the design of composites of biomass. YP Evaluated the result of adsorptions and design the experiment of the projects. “All authors read and approved the final manuscript."

Corresponding author

Ethics declarations

Conflict of interest

"The authors declare that they have no competing interests".

Additional information

Editorial responsibility: Samareh Mirkia.

Rights and permissions

About this article

Cite this article

Sayago, U.F.C., Castro, Y.P. Development of a composite material between bacterial cellulose and E crassipes, for the treatment of water contaminated by chromium (VI). Int. J. Environ. Sci. Technol. 19, 6285–6298 (2022). https://doi.org/10.1007/s13762-021-03581-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03581-y