Abstract

Microalga would be the paramount resource of biodiesel able of satisfying the world requirements for transportation fuels, which could fully replace the petrodiesel. Therefore, the research studies focus on developing novel biodiesel production methods. The present study investigates the effect of monochromatic light such as red light-emitting diodes (LEDs) and He–Ne red laser radiation on the accumulated lipid and the growth of the green microalgae Chlorella sorokiniana. The irradiation of microalgal cells with He–Ne red laser source which has a wavelength of 632.8 nm was hypothesized to enhance the accumulation of lipid inside the algal cells, which ultimately increases the biodiesel production. The photobiostimulating effects of laser irradiation on biodiesel was investigated by irradiating the microalga for a duration of 2 h with 632.8 nm He–Ne red laser source compared with 2 h irradiation with red LEDs and 2 h irradiation with white light (the control). The results showed that the oil content inside the algal cells irradiated with He–Ne red laser was 3.1 times the algal cells irradiated with white light (the control). Similarly, the biodiesel yielded from the algal cells irradiated with He–Ne red laser was 3.1 times the biodiesel yielded from the algal cells irradiated with white light (the control). However, the oil content and the biodiesel yield from algal cells irradiated with red LEDs were only 0.82 times those of the control. Therefore, it was concluded that the irradiation of microalga with red laser increases the biodiesel yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Algal biofuels are renewable fuels produced from algal biomass through diverse bioconversion processes; this is owing to the fact that algae have a high reproduction rate and the aptitude to accumulate a large amount of high-energy lipids due to their photosynthetic activity [1, 2]. Besides, algae have several advantages like simple life cycle and resource availability for large-scale production [3, 4]. Additional benefits of algae are fixing CO2 from the atmosphere and generating oxygen [5], as well as having large oil yield which can be extracted by breaking down their cell structure [6, 7]. The major advantage of algae is the possibility to convert the produced biomass into a wide range of biofuels [3]. The most important factor that stimulates microalgae to accumulate oil is the light which is easy to control. Therefore, it is practicable to enhance the lipid content by light using laser radiation [8]. Biodiesel is the most promising alternative for conventional diesel. According to literature, biodiesel was identified as one of the potential resources that fulfill the world’s energy demand whereas it can be used in diesel engines without requiring any amendments to the engine as their combustion characteristics are almost similar to the petrodiesel [9,10,11,12].

The effects of light-emitting diodes (LEDs) on green microalgae were investigated in some literature. The light intensity ranging 1000–10,000 lx and the optimum ranging 2500–5000 lx [13], where the different colors of LEDs led to different effects on dry weight (DW) of microalgal biomass, lipid content and yield of biodiesel [14]. Blue light LED illumination (wavelength: 430–465 nm) leads to increased cell size of some microalgae strains, while red light LED illumination (wavelength: 630–665 nm) leads to small-sized cell with active divisions [15, 16]. The photobiostimulation of green microalgae using green LEDs is not effective because the green light cannot be reflected, therefore can be said green microalgae cannot not absorbed the green light [17]. Advanced research investigated the following: (1) effect of ultrasound algae treatment [18], (2) oil extraction processes [19], (3) life cycle assessment on microalgal biodiesel production [20], (4) light–dark cycle [21, 22], and (5) screening procedure of microalgae.

The problem being addressed by this study is that outdoor cultures are subjected to daily and diurnal cyclic changes in weather conditions and dramatic fluctuations of light intensity. Additionally, there are limited capabilities of harvesting light because of the self-shading of microalgae and the photobioreactor translucent properties which ultimately have negative impacts on lipid accumulation in microalgae [18]. Culture productivity is invariably controlled by the availability of light, particularly when the scale of photobioreactor increases. Investigating the influence of natural light fluctuating intensity on the cultivation of microalgae is rarely tested outdoors with photobioreactors; thus, it is still exceedingly relevant to be thoroughly explored [19].

The hypotheses being addressed by this study is that algae exposure to laser radiation, for short duration before exposure to natural sunlight, to photobiostimulate algal cells and make algae able to cope with the daily and diurnal cyclic changes in weather conditions and the fluctuations of natural light intensity. Additionally, the photobiostimulated algae using laser radiation are able to create more lipids which results in increasing oil production and, therefore, increasing biodiesel production. Furthermore, photobiostimulation of algal cells using laser radiation with different wavelengths in a range of 400–700 nm and with different colors (green, blue, yellow and red) to increase both the growth rate of algae and biomass (i.e. oil content) which in turn increases biodiesel production (L ha−1 year−1) from dry weight of algal biomass.

The objectives of this research are as follow: photobiostimulating algae using laser radiation (short duration exposure) for enhancing lipid accumulation of algae therefore increasing oil production; cultivating the algae in photobioreactors exposed to sunlight, after being irradiated with laser source; transesterification of the produced/extracted oil into biodiesel; and investigating several engineering and bioengineering parameters.

2 Materials and methods

2.1 Experimental setup

The experimental setup can be elaborated as follows: designing an array of photobioreactors, identifying the appropriate laser source, and selecting the microalgae strain.

2.1.1 Design of photobioreactors

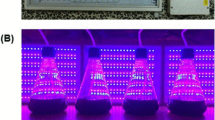

The design of the photobioreactors (Fig. 1) is based on the literature [20,21,22,23,24]. The implemented lab-scale model is a closed photobioreactor (PBR) which consists of a bottle with 34 cm height and 25.5 cm diameter with working volume of 15 L, an air pump (shengzhe Bs-410, China), sample pure filters (NY 0.45 µm, China) and tubes used for inlet and gas outlet.

2.1.2 Photobiostimulation

The biological response to alterations of light intensity is a crucial factor for finding out the optimal photosynthetic activity of microalgae [25]. The irradiation setup consists of light-emitting diode (LED) source (Alobeidi, China), laser source (Gas laser, He–Ne laser, Thorlabs, USA), magnetic hot plate stirrer (Wise Stir, Model: MSH-20A, Daihan Scientific Co., Ltd., Korea), and beam expander to expand the laser beam diameter to 10 cm.

Light-emitting diode

Algal culture was exposed to red light-emitting diode (LED) source (Alobeidi, China) for 2 h then cultivated in the photobioreactors and exposed to sunlight, i.e., white light (wavelength: 400–700 nm). This wavelength was determined according to the literature [26,27,28,29,30]. The photobiostimulation was conducted at the Department of Microbiology, Faculty of Agriculture at Cairo University. The specifications of red LED were as follows: wavelength of 635 nm, frequency of 4.7 × 1014 Hz, energy (3.11 × 10–19 J), light intensity of 600 lx, forward voltage of 1.8 V at 20 mA.

Laser type

Algal culture was exposed to Gas laser, He–Ne laser (632.8 nm, Red, Thorlabs, USA) for 2 h then cultivated in the photobioreactors (PBRs) and exposed to sunlight, i.e., white light (wavelength: 400–700 nm). This wavelength was determined according to the literature [9, 15]. A laser beam expander was implemented to expand the laser beam diameter from 0.8 to 10 cm.

Helium–Neon lasers are widely used in various applications and as alignment tools due to their excellent beam quality and gas discharge laser characteristics. The output beam is either linearly polarized or randomly polarized (unpolarized).

He–Ne laser (632.8 nm) features a tube design that makes them easy to mount in nearly any optical system with power of 10 mW output. These lasers are offered with either linear (500:1 polarization ratio) or random polarization.

The specifications of Helium–Neon lasers were Power supply of 100–240 VAC, Power of 10 mW, Divergence of 1.3 mrad, Longitudinal Mode Spacing (LMS) of 730 MHz, Noise as from 30 Hz to 10 MHz (RMS) of 0.1%, Operating voltage of 1800 VDC, Operating current of 6.5 mA.

2.1.3 Microalga and culture medium

Microalgal strain

The microalga used in this research were Chlorella sorokiniana SAG 211-8 k which was obtained from the Marine Toxin laboratory at the Egyptian Agriculture Research Institute. This oleaginous strain with low oil contents was selected to be exposed to red laser where the photobiostimulation could increase the lipid accumulation in algae which have medium oil contents (19–20%) and, therefore, increase biodiesel production.

Culture medium

The used transparent medium was (BG11-broth) Blue Green medium (Sigma-Aldrich, Germany). Trace metals for BG-11 were synthesized using standard protocols [31].

2.2 Experimental design and cultivation conditions

To investigate the effects of light-emitting diodes (LEDs) and laser radiation on biodiesel production, 750 mL algae were kept in 2L Erlenmeyer flask with continuous stirring and were irradiated by both of red LED source and red laser source (Fig. 2). Generally, the used LED radiation to continuously illuminate the photobioreactors through the whole hydraulic retention time (HRT) of 21 days is with a wavelength of 380–760 nm as it is a white light which represents the whole light spectrum from 380 to 760 nm including all colors: violet, blue, green, yellow and red. The photobiostimulating effects of laser irradiation on biodiesel were investigated by irradiating the microalgae for a duration of 2 h with 632.8 nm He–Ne red laser source compared with 2 h irradiation with red LEDs and 2 h irradiation with white light (the control).

The photobiostimulation using light-emitting diodes (LEDs) was conducted at the Department of Microbiology, Faculty of Agriculture, Cairo University. The photobiostimulation using laser radiation was conducted at the National Institute of Laser Enhanced Sciences (NILES), Cairo University. Generally, there are three stages to biodiesel production from algae as illustrated Fig. 3.

After the photobiostimulation process, 750 ml of microalgal inoculums (containing 5.15 Log10 cell ml−1) were inoculated aseptically into 15 L BG-11 medium, then incubated at 30 ± 5 °C with continuous stirring, pumping CO2 and pH adjusted at 7.4. The hydraulic retention time (HRT) of the microalga in the photobioreactor extended to 21 days. Experiments were carried out in triplicate.

By the end of cultivation period, harvesting of microalgae biomass was done by centrifugation at 5000 rpm for 15 min to remove water. Supernatants were decanted, and cell pellets were weighed (biomass fresh weight), washed with distilled water and then dried in an incubator (35 °C) to achieve a constant weight (biomass dry weight). Then, dried biomass was milled to fine powder.

2.3 Measurements

2.3.1 Light intensity

The light intensity was determined using light meter (LX-101, Lutron, Taiwan). This device provides readings in Klux (1 Klux = 19.5 μmol m−2 s−1). The light intensity of white LED was 1400 lx, red LED was 600 lx, and red laser was 1800 lx.

2.4 Calculations

2.4.1 Microalgal cell counts

Microalgal cell counts were determined by improved Neubauer counting chamber with 0.0025 mm2 as area and 0.1000 mm as depth. The initial microalgal load was 5.15 Log10 cell mL−1. Cell density was counted under the microscope by the Neubauer counting chamber, calculated according to the following formula [32] and then expressed as Log10 cell ml−1:

where D = cell concentration (cell/ml), A = total number of cells counted (cell), and X = Number of squares.

2.5 Analytical methods

All chemical analyses were carried out in Cairo University Research Park (CURP), Faculty of Agriculture.

2.5.1 Oil extraction

Oil (lipid) was extracted from the microalgae which were harvested after 21 days of cultivation by filtration. The total lipids were extracted by means of a Soxhlet Reflux Extractor with chloroform/methanol (2/1, v/v) from different samples of lyophilized (freeze-dry) microalgae and were further gravimetrically quantified as described in the literature [21, 30, 33,34,35].

2.5.2 Peroxide value and acid value

The peroxide value and the acid value were determined by applying the Association of Official Analytical Chemists (AOAC) method [36, 37].

2.5.3 Transesterification

The transesterification of extracted oils and characterization of resulting biodiesel were conducted in this research according to Onay et al. [38]. The transesterification of the extracted oils was conducted using methanol (CH3OH) and potassium hydroxide (KOH) and stirred for 3 h at 60 °C. The mixture was kept at room temperature for 18 h for separation of biodiesel and glycerol using a flask separator.

2.6 Statistical analysis

The statistical analysis aimed at evaluating the effects of LED and laser irradiance on microalgae growth. Each experiment was conducted in three replicates. The statistical significance of difference was evaluated by one-way analysis of variance and Kruskal‐Wallis Test (P ≤ 0.05) using the SPSS software (IBM, v. 20). The statistical analysis was conducted using the statistical package Origin (version 8, MA, USA). Data are represented as standard error (SE) of mean values. Analysis of variance (ANOVA) and Fisher test as a post hoc one were performed to compare the DW of biomass, total lipid and biodiesel produced after variable microalgae treatments by visible light. P value < 0.05 was set as the significant level. For all results of statistical analysis, Sig equals to 1 indicates that the mean difference is significant at the 0.05 level, and Sig equals to 0 indicates that the mean difference is not significant at the 0.05 level.

Principle component analysis (PCA) is nowadays a basic and powerful tool to monitor multivariate processes. This analytical methodology was successful in many cases in extracting the related data from various chemical and physical means along specific criteria for the assessment of a certain process. PCA was done by using the Unscrambler X 10.3 software (Camo, Norway). Prior to PCA analysis, pre-treatments of the selected data followed by baseline correction and normalization. PCA was done to visualize the different microalgae treatment with visible light and to correlate any possible relationships between such treatments in the production of FW, DW, of biomass, total lipid, yield of biodiesel, moisture percentage, peroxide, and acid value.

3 Results

3.1 Microalgal biomass

The effects of different wavelengths of monochromatic light on the growth of microalgae were evaluated by using He–Ne red laser (632.8 nm) and red LED (635 nm). As a control, white light was used under the same conditions required for the microalgal growth. The irradiation of microalgae using both red LED (653 nm) and He–Ne red laser (632.8 nm) for 2 h led to increase the microalgal biomass which were 1.156 g and 0.995 g, respectively; compared with the irradiation by the control (white light) which delivered only 0.397 g as illustrated Fig. 4, whereas the moisture (%) was 70.2% for white light followed by He–Ne red laser (61.6%) and red LED (45.1%) as shown Fig. 5.

The statistical analysis of the various exposed microalga groups revealed that all the employed treatments have resulted in significant higher production of dry weight (DW) of biomass in grams when compared to the group that just received white light (P < 0.005). Nevertheless, the red LED exposed microalgae group showed the highest DW of biomass, but this elevation of the DW of biomass was not of statistical significance when compared to the He–Ne laser, but that increase was of statistical significance when compared to all the other DW of biomass production by other groups (P < 0.05) as shown Table 1.

The red LED microalga treated group was found to significantly reduce the moisture percentage (P < 0.005) when compared to the white light-treated groups. Although the He–Ne laser has reduced the moisture percentage, but that reduction was not statistically significant when compared to the white treated group as shown Fig. 5 and Table 2.

3.2 Microalgal cell counts

Microalgal cell counts were determined by Neubauer counting chamber. As illustrated Fig. 6. The best treatment in terms of microalgal cell counts was found to be with the red LED (7.62 log10 cell ml−1), followed by He–Ne red laser where was 7.55 log10 cell ml−1, then white light (7.13 log10 cell ml−1).

3.3 Chemical analyses

3.3.1 Total lipid

The yield of extracted oil from microalgal biomass which had been irradiated with He–Ne red laser (632.8 nm) was the highest percentage ever, whereas red LED (653 nm) was less than the white light as a control (400–700 nm).

As a result of microalgae irradiation by He–Ne red laser and red LED, the total lipid extracted from 100 g of microalgae was 2.639% dry weight for the microalgae irradiated with He–Ne red laser, 0.944%for those irradiated with white light (control) and 0.905% for those irradiated with red LED, respectively (Fig. 7).

The oil content in the algae irradiated with He–Ne red laser for 2 h was three times the oil content in the algae irradiated with white light (the control) which yielded 1.2 g oil L−1 microalgae, 0.4 g oil L−1 microalgae.

The statistical analysis of the various exposed microalga groups showed that He–Ne red laser treatments have resulted in significant higher production of total lipids (g 100 g−1) when compared to the group that just received white light (P < 0.01 and 0.0001 respectively) as shown in Table 3.

Surprisingly, despite the He–Ne red laser group has produced the highest total lipids 0.87967 (g 100 g−1) from the treated microalga, the red LED which has the same wavelength range did not have the ability to change the total lipids significantly than the white light-exposed group. This suggests that the laser coherence, brightness, and monochromaticity are key factors in the influence of lipid production rather than the wavelength (Fig. 7).

3.3.2 Chemical properties of microalgae oil

The results of peroxide and acid values of microalgal oil are presented in Tables 4 and 5 respectively.

All the groups have almost the same peroxide value levels with the white light-treated microalgae as shown Fig. 8 and Table 4.

All the experimental groups were found to have no effect on the acid value as there is almost no change recorded in the acid value of all the treated groups as shown Fig. 9 and Table 5.

3.3.3 Biodiesel yield

As a result of microalgae irradiated by He–Ne red laser and red LED compared with white light as a control, the yield of biodiesel produced from algae irradiated by He–Ne red laser was the highest which was0.1321 g, whereas the yield of biodiesel produced from algae irradiated by red LED was the lowest which was 0.0349 g and the algae irradiated by white light (control) produced 0.0534 g as shown Fig. 10. The best treatment that led to increase the total lipid and biodiesel yield was He–Ne red laser irradiation, whereas the yield of biodiesel was three times the white light treatment (control) where the biodiesel yield was 0.06 g biodiesel L−1 microalgae, 0.02 g biodiesel L−1 microalgae, respectively. The statistical analysis was extended to investigate the differences of the biodiesel production by different microalgae light treatments. It was quite the same trend that has been seen in the total lipid production, where the He–Ne red laser-treated group yielded the highest biodiesel production. Those enhancements of the biodiesel production by those groups were statistically significant (P < 0.0001 and 0.001 respectively) as shown in Table 6. Figure 10 shows the same behavior that has been observed by the total lipid production where the red LED which has the same wavelength range of the He–Ne red laser, yet it did not change the biodiesel production by the treated microalgae when compared to the white light-treated group.

3.3.4 Statistical analysis of fresh weight of microalgal biomass

The statistical analysis of the various exposed microalgae groups revealed that all the employed treatments have resulted in significant (Table 7 and Fig. 11) higher production of fresh weight (FW) biomass in grams when compared to the group that just received white light (P < 0.001).

3.4 PCA results

Assessment of the microalgae treatments with different light wavelengths was done by PCA. The chemical variables included in the PCA plots are the values of FW and DW biomass, biodiesel production, total lipid, acid value, moisture percentage, and peroxide value. The PCA analysis for the different exposed microalgae was shown in Fig. 12.

Figure 12 clearly shows that the He–Ne laser exposed group is discriminated alone from red LED exposed group and white light. Surprisingly, this differentiation was even seen between the He–Ne laser and the red LED group (where the exposed wavelengths are near to each other). This suggests that the laser light has unique properties other than the wavelength like the collimating properties, monochromaticity, brightness, and directionality.

3.5 Energy balance assessment and cost analysis

To estimate the competence of the He–Ne red laser treatment in terms of the net energy production and the relevant costs, an energy balance assessment and cost analysis were performed where the outcomes are shown in Table 8.

The He–Ne red laser source requires a power of 35 W, and it was operated for 2 h which is the algae irradiation time which results in 0.07 kWh power requirements. This power can irradiate 1 L of algae which can be cultivated in a total volume of 20 L after the addition of water. Thus, in order to cultivate 1 m3 of algae, an amount of 50 L of irradiated algae is required and those require 3.5 kWh of power to be irradiated.

Generally, algae yielded an amount of oil equal to 97,800–1,36,900 L/ha/year [21] with an average of 117,350 L/ha/year, where 86% of the oil can be converted to biodiesel [39]. Noting that oil content is 50% of the algae, then it is required to cultivate 235 m3 of irradiated algae, where this amount requires a power of 822.5 kWh to be irradiated with a He–Ne red laser source. The world average price is 0.12 USD (US Dollar) per kWh for business users in 2019 (source: https://www.globalpetrolprices.com/). Therefore, the aforementioned amount costs 98.7 USD/ha/year.

According to our results, the amount of biodiesel produced using He–Ne laser source (with 2 h irradiation) is 3 times the control (traditional method without irradiation). Then, the expected amount of produced biodiesel is 303 m3/ha/year with irradiated algae compared to 101 m3/ha/year produced by the control. The increase in biodiesel production was 202 m3/ha/year, where McCormick [40] stated that the biodiesel density is 0.88 g/ml (g/ml = ton/m3), i.e. this amounts to 177.8 ton/ha/year. Taking into consideration that Sheehan et al. [41] stated that one metric ton of biodiesel contains an amount of energy equal to 37.8 GJ (33.3—35.7 MJ/liter) which are equal to 10,500 kWh/ton, then the net energy production is 1,866,900 kWh/ha/year. The international price of biodiesel is 836 USD/ton on December 31, 2019 (Source: https://www.neste.com/). Accordingly, the price of this increase is 148,607 USD. The benefit is equal to the deduction of the price of the laser device and the beam expander (taking into consideration that their lifetime is 5 years) and the power utilized to be deducted from the price of the increase. The total price of laser source and beam expander is equal to 6064 USD, i.e. 1,213 USD/ha/year. Then, the net profit of using laser radiation is equal to 147,295 USD over the net profit of the traditional plant (without laser irradiation), where these calculations are for an algal biodiesel plant which has an area of 1 ha cultivating 235 m3 of algae and produces an amount of oil equal to 97,800–1,36,900 L/ha/year and averaged as 117,350 L/ha/year.

4 Discussion

The results of this study showed that the cultivation of microalgae is highly depending on light, where the yield of biomass is dependent on light which is a crucial factor for the bioprocesses. The light intensity used to irradiate the microalgae influences the biomass production. These findings agree with the statements of Judd et al. [42] and they added that the microalgal growth increases with light intensity until it reaches a maximum value, i.e., the microalgae’s light saturation.

The results of the present study showed that the implementation of different lights can provide an advantageous microalgae production process. The application of specific wavelengths of laser is more feasible than applying ordinary lights with low-power irradiance, which can influence microalgae biomass. These statements agree with Dickinson et al. [43] and Duarte and Costa [27] who investigated LEDs only. However, the results of the present study showed superior advantages of laser radiation over LEDs.

The results of the present study showed that laser sources and LEDs can be used instead of conventional light lamps due to their low energy consumption, which makes them environmentally friendly. These results agree with Duarte and Costa [27] but they investigated LEDs only. Additionally, the application of laser radiation in microalgae cultivation directly influences the quantity and quality of biomass produced. This occurs mainly due to the light's mono-chromaticity. These statements agree with Schulze et al. [44], where their investigations focused on LEDs only.

This study found that the irradiations with red laser source accelerated the growth of microalgae. Additionally, visible light has been found to induce a large variety of bioresponses. These findings agree with Karu et al. [45] as they stated that the irradiation with red light enhanced the growth of Escherichia coli. The results of the present study showed that the red laser was advantageous for rising the dry weight of microalgal biomass in comparison with white light and therefore increasing the total lipids and biodiesel production.

The irradiance of microalgae was for 2 h. The highest dry weight of microalgal biomass was produced from microalgae irradiation with red LED, followed by He–Ne red laser and then white light LED, respectively. According to the results of dry weight of microalgal biomass, it was found that the best color is red which agrees with Kim et al. [46] who concluded that red LED illumination (wavelength: 630–665 nm) led to small-sized cell with active divisions.

The results of the present study indicated that the irradiation of microalgae with He–Ne red laser source increased the total lipids and the yield of biodiesel. The only exception was the red LED light as despite the dry weight of microalgal biomass was the highest one, but that increase not led to increasing in total lipids and biodiesel yield, this is due to that the red LED light led to small-sized cell with active divisions, which is in agreement with Kim et al. [46].

It was found that light stimulates the microalgae to accumulate lipids in form of oil, where the light is easy to control. Therefore, it is practicable to enhance the lipid accumulation and oil content using laser radiation which agrees with Zhang et al. [15]. It should be noted that the effects of laser radiation on microalgal cells have been investigated in a very few previous studies. The results of the present study indicated that the irradiation of microalgae with He–Ne red laser source led to increasing the weight of microalgal biomass, the total lipids and the biodiesel yield.

The findings of the present study can be further explained by the statements of Singh and Priyanka Singh [47] who reported that green algae comprise chlorophyll a and b, which are the main light harvesting pigments and are sensitive to the wavelengths of red light and, therefore, green algae grow well in red light which plays a substantial role in algae growth, lipid accumulation and biodiesel production.

The results of the present study showed that the peroxide value increased in the He–Ne red laser treatment compared to red LED and white light, where the oxidative stress resulted from laser treatment was reflected in an amount higher than red LED and white light treatments. Therefore, this is a response to oxidative stress that was generated through the irradiation of microalgae with He–Ne red laser source. The resulting induction of oxidative stress and reactive oxygen species (ROS) accumulation that suppress cell division and accumulate total lipids and in sequence biodiesel production. These findings are in accordance with Kushibiki et al. [48] who found that the laser irradiation creates intracellular ROS in numerous types of cells and reported that intracellular ROS created subsequent to a red or a near-infrared laser irradiation are considered to be important messengers modulate, specific functional regulation of cell division and lipid storage.

Yilancioglu et al. [49] indicated that oxidative stress is accompanied by increased lipid content in the green algae. The results of the present study support that oxidative stress and lipid overproduction are linked. Importantly, these results also suggest that oxidative stress mediates lipid accumulation. Understanding such relationships may provide guidance for efficient production of algal biodiesel.

The results of the present study showed that the red LED irradiation significantly reduced the lipid accumulation, while it showed a significant increase in cell growth and DW compared to laser and white LED treatments. This can be further elucidated by the findings of Fernandes et al. [50] that there is a negative correlation between algae growth and lipid accumulation when cell begins to grow and then divides while consuming energy reserves especially starch and lipids.

The results of the present study showed that the irradiation of green algae Chlorella sorokiniana with red laser source increased lipid accumulation. These findings agree with the findings of Zhang et al. [51] who found that lipid accumulation of microalgae Chlorella pacifica can be improved by laser irradiation. On the other hand, the results of the present study showed that the irradiation of green algae Chlorella sorokiniana with red laser source increased algae cell counts. These findings agree with the findings of Kuwahara et al. [52] who found that the algal cell counts of Chlamydomona sreinhardtii can be significantly increased by red laser irradiation.

The irradiation with laser accelerates the growth of several cell cultures. Laser radiation has been found to photobiostimulate a large variety of bioresponses [53]. Mitochondria are susceptible to irradiation with monochromatic visible light. The illumination of mitochondria raises the adenosine triphosphate (ATP) synthesis and the intake of oxygen. In this study, it was found that irradiation of algal cells with laser radiation boosts the ATP synthesis and accelerates the proliferation of cells, which agrees with Abdelsalam et al. [54]. At the same time, elevated activity of mitochondrial respiratory chain enzymes and ATP synthesis was revealed in irradiated cells using laser radiation which agrees with Abdelsalam et al. [55]. The photobiostimulation of algal cells using laser radiation increases the biodiesel production from algal biomass. Specifically, it was found that the laser radiation has photobiostimulating effects on the cell activity during the startup of the process and through the hydraulic retention time (HRT) to the end of the experiments, which agrees with the statements of Abdelsalam et al. [54].

Algae exposure to laser radiation, for short duration before exposure to natural sunlight, to photobiostimulate algal cells and make algae able to cope with the daily and diurnal cyclic changes in weather conditions and the fluctuations of natural light intensity. Additionally, the photobiostimulated algae using laser radiation can create more lipids which results in increasing oil production and, therefore, increasing biodiesel production. Furthermore, the photobiostimulation of algal cells using laser radiation with different wavelengths in a range of 400–700 nm increases both the growth rate of algae and biomass (i.e. oil content) which in turn increases biodiesel production from dry weight of algal biomass which agrees with the statements of the literature [53,54,55,56,57,58]. On the other hand, this technology [59, 60] was found to be environmentally friendly.

An important future application is to develop an air purification system using algae to purify the exhaust air from industries, factories, and agricultural systems [61,62,63,64] to replace current purification systems by an environmentally friendly algal purification system, where such technology developed in this research can be implemented to increase the algal purification system’s efficiency.

5 Conclusions

The general finding of this study is that the photobiostimulation of microalgae using He–Ne red laser radiation led to increasing the dry weight of algal biomass as well as increasing the total lipids and the biodiesel yield. The specific findings of this study can be elaborated as follows: (1) the oil content of the algae irradiated with He–Ne red laser for 2 h was three times the oil content in the algae irradiated with white light (the control), (2) the oil content of the algae irradiated with red LED was only 0.82 times the control, (3) the biodiesel yielded from the algae irradiated with He–Ne red laser for 2 h was three times the biodiesel yielded from the algae irradiated with white light (the control), (4) the biodiesel yielded from the algae irradiated with red LED were only 0.82 times the control, (5) the He–Ne red laser radiation and the red LED radiation increased the dry weight of the microalgae, where the highest significant growth and dry weight of the microalgae were attained when the algae were irradiated with red LED and He–Ne red laser compared to the control, respectively; (6) the highest significant total lipid and biodiesel yielded from microalgae were attained when the algae were irradiated with He–Ne red laser compared to the control; however, these values were the lowest when the algae were irradiated with red LED, and (7) the implementation of He–Ne red laser technology for irradiating microalgae for 2 h before cultivation could have a positive effect on the future of commercial biodiesel production from microalgae.

Abbreviations

- LEDs:

-

Light-emitting diodes

- DW:

-

Dry weight

- FW:

-

Fresh weight

- PBR:

-

Photobioreactor

- LMS:

-

Longitudinal mode spacing

- CURP:

-

Cairo University Research Park

- AOAC:

-

Association of Official Agricultural Chemists

- ANOVA:

-

Analysis of variance

- PCA:

-

Principle component analysis

- Mean diff:

-

Mean difference

- SEM:

-

Standard error of mean

- Prob:

-

Probability

- Sig:

-

Significance

- LCL:

-

Lower control limit

- UCL:

-

Upper control limit

References

Natarajan Y, Nabera A, Salike S, Tamilkkuricil VD, Pandian S, Karuppan M, Appusamy A (2019) An overview on the process intensifcation of microchannel reactors for biodiesel production. Chem Eng Process 136:163–176

Martínez VMO, Martínez PA, Martíneza NG, de los Ríos AP, Fernández FJH, Medina JQ (2019) Approach to biodieselproduction from microalgae under supercritical conditions by the PRISMA method. Fuel Process Technol 191:211–222

Fulke AB, Krishnamurthi K, Giripunje MD, Devi SS, Chakrabarti T (2015) Biosequestration of carbon dioxide, biomass, calorific value and biodiesel precursors production using a novel flask culture photobioreactor. Biomass Bioenergy 72:136–142

Faried M, Samer M, Abdelsalam E, Yousef RS, Attia YA, Ali AS (2017) Biodiesel production from microalgae: processes, technologies and recent advancements. Renew Sustain Energy Rev 79:893–913

Sun B, Fan X, Ye H, Fan H, Qian C, Driel WV, Zhang G (2017) A novel lifetime prediction for integrated LED lamps by electronic-thermal simulation. Reliab Eng Syst Saf 163:14–21

Budžaki S, Miljić G, Sundaram S, Tišma M, Hessel V (2018) Cost analysis of enzymatic biodiesel production in small-scaled packed-bed reactors. Appl Energy 210:268–278

Shah SH, Raja IA, Rizwan M, Rashid N, Mahmood Q, Shah FA, Pervez A (2018) Potential of microalgal biodiesel production and its sustainability perspectives in Pakistan. Renew Sustain Energy Rev 81:76–92

Adeniyi OM, Azimov U, Burluka A (2018) Algae biofuel: current status and future applications. Renew Sustain Energy Rev 90:316–335

Politaeva N, Smyatskaya Y, Slugin V, Toumi A, Bouabdelli M (2018) Microalgae as feedstock for biodiesel production under ultrasound treatment – a review. Earth Environ Sci 59:534–653

Suganya T, Varman M, Masjuki HH, Renganathan S (2016) Macroalgae and microalgae as a potential source for commercial applications along with biofuels production: a biorefinery approach. Renew Sustain Energy Rev 55:909–941

Thiruvenkadam S, Izhar S, Hiroyuki Y, Harun R (2019) One-step microalgal biodiesel production from Chlorellapyrenoidosa using subcritical methanol extraction (SCM) technology. Biomass Bioenergy 120:265–272

Laamanen CA, Ross GM, Scott JA (2016) Flotation harvesting of microalgae. Renew Sustain Energy Rev 58:75–86

Hallenbeck PC, Grogger M, Mraz M, Veverka D (2016) Solar biofuels production with microalgae. Appl Energy 179:136–145

Al-Ameri M, Al-Zuhair S (2019) Using switchable solvents for enhanced, simultaneous microalgae oil extraction-reaction for biodiesel production. Biochem Eng J 141:217–224

Zhang H, Gao Z, Li Z, Du H, Lin B, Cui M, Yin Y, Lei F, Yu C, Meng C (2017) Laser radiation induces growth and lipid accumulation in the seawater microalga Chlorella pacifica. Energies 10:1671–1684

Mohd-Noor CW, Noor MM, Mamat R (2018) Biodiesel as alternative fuel for marine diesel engine applications: a review. Renew Sustain Energy Rev 94:127–142

Lee J, Kim J, Sik Ok Y, Kwon EE (2017) Rapid biodiesel synthesis from waste pepper seeds without lipid isolation step. Biores Technol 239:17–20

Sivaramakrishnan R, Incharoensakdi A (2018) Microalgae as feedstock for biodiesel production under ultrasound treatment – a review. Biores Technol 250:877–887

Shomal R, Hisham H, Mlhem A, Hassan R, Al-Zuhair S (2019) Simultaneous extraction–reaction process for biodiesel production from microalgae. Energy Rep 5:37–40

Adesanya VO, Cadena E, Scott SA, Smith AG (2014) Life cycle assessment on microalgal biodiesel production using a hybrid cultivation system. Biores Technol 163:343–355

Kiran B, Kumar R, Deshmukh D (2014) Perspectives of microalgal biofuels as a renewable source of energy. Energy Convers Manag 88:1228–1244

Li M, Hu D, Liu H (2014) Photobioreactor with ideal light–dark cycle designed and built from mathematical modeling and CFD simulation. Ecol Eng 73:162–167

Taleb A, Pruvost J, Legrand J, Marec H, Le-Gouic B, Mirabella B, Legeret B, Bouvet S, Peltier G, Li-Beisson Y, Taha S, Takache H (2015) Development and validation of a screening procedure of microalgae for biodiesel production: application to the genus of marine microalgae Nannochloropsis. Biores Technol 177:224–232

Tercero EAR, Domenicali G, Bertucco A (2014) Autotrophic production of biodiesel from microalgae: an updated process and economic analysis. Energy 76:807–815

Ra CH, Kang CH, Jung JH, Jeong GT, Kim SK (2016) Effects of light-emitting diodes (LEDs) on the accumulation of lipid content using a two-phase culture process with three microalgae. Biores Technol 212:254–261

Severes A, Hegde S, D’Souza L, Hegde S (2017) Use of light emitting diodes (LEDs) for enhanced lipid production in microalgae based biofuels. J Photochem Photobiol B 170:235–240

Duarte JH, Costa JAV (2018) Blue light emitting diodes (LEDs) as an energy source in Chlorella fusca and Synechococcus nidulans cultures. Biores Technol 247:1242–1245

Hun-Ra C, Sirisuk P, Jung JH, Jeong GT, Kim SK (2018) Effects of light-emitting diode (LED) with a mixture of wavelengths on the growth and lipid content of microalgae. Bioprocess Biosyst Eng 41:457–465

Sirisuk P, Hun Ra C, Jeong GT, Kim SK (2018) Effects of wavelength mixing ratio and photoperiod on microalgal biomass and lipid production in a two-phase culture system using LED illumination. Biores Technol 253:175–181

Ma R, Hall SRT, Chua ET, Eltanahy E, Netzel ME, Netzel G, Lua Y, Schenk PM (2018) LED power efficiency of biomass, fatty acid, and carotenoid production in Nannochloropsis microalgae. Biores Technol 252:118–126

Stanier RY, Kunisawa R, Mandel M, Cohen-Bazire G (1971) Purification and properties of unicellular blue-green algae (order Chroococcales). Bacteriol Rev 35(2):171–205

Trinh DM, Nguyen TT, Nguyen PK, Tran NQA, Vo CT (2019) The effect of nutrients on the growth of microalgae Haematococcuslacustris (Girod-chantrans) Rostafinski 1875. Int J Curr Res Biosci Plant Biol 6(4):17–23

Ho SH, Chen CNN, Lai YY, Lu WB, Chang JS (2014) Exploring the high lipid production potential of a thermotolerant microalga using statistical optimization and semi-continuous cultivation. Biores Technol 163:128–135

Lam MK, Lee KT (2014) Cultivation of Chlorella vulgaris in a pilot-scale sequential-baffled column photobioreactor for biomass and biodiesel production. Energy Convers Manag 88:399–410

Santos CA, Nobre B, Lopes da Silva T, Pinheiro HM, Reis A (2014) Dual-mode cultivation of Chlorella protothecoides applying inter-reactors gas transfer improves microalgae biodiesel production. J Biotechnol 184:74–83

AOAC (1990) Method 988.05. In: Helrich, K., Ed., 15th Edition, Official Methods of Analysis, The Association of Official Analytical Chemists, Inc., Arlington, USA

AOAC (2000) Methods 925.10. 17th Edition, Official Methods of Analysis, The Association of Official Analytical Chemists, Gaithersburg, USA

Onay M, Sonmez C, Oktem HA, Yucel AM (2014) Thermo-resistant green microalgae for effective biodiesel production: isolation and characterization of unialgal species from geothermal flora of Central Anatolia. Biores Technol 169:62–71

Rahman MA, Aziz MA, Al-khulaidi RA, Sakib N, Islam M (2017) Biodiesel production from microalgae Spirulina maxima by two step process: optimization of process variable. J Radiat Res Appl Sci 10(2):140–147

Alleman TL, McCormick RL, Christensen ED, Fioroni G, Moriarty K, Yanowitz J (2016) Biodiesel handling and use guide (Fifth Edition), National renewable energy laboratory, United States. https://www.osti.gov/servlets/purl/1347103

Sheehan J, Camobreco V, Duffield J, Graboski M, Shapouri H (1998) An overview of biodiesel and petroleum diesel life cycles. Report of national renewable energy laboratory (NREL) and US Department of Energy (DOE), United States. https://doi.org/10.2172/1218368

Judd S, van den Broeke LJP, Shurair M, Kuti Y, Znad H (2015) Algal remediation of CO2 and nutrient discharges: a review. Water Res 87:356–366

Dickinson S, Mientus M, Frey D, Hajibashi AA, Ozturk S, Shaikh F, Sengupta D, El-Halwagi MM (2017) A review of biodiesel production from microalgae. Clean Technol Environ Policy 19:637–668

Schulze PSC, Barreira LA, Pereira HGC, Perales JA, Varela JCS (2014) Light emitting diodes (LEDs) applied to microalgal production. Trends Biotechnol 32:422–430

Karu T, Tiphlova OA, Letokhov VS, Lobko VV (1983) Stimulation of E. coli growth by laser and incoherent red light. NuovoCimento 2:1138–1144

Kim DG, Lee C, Park SM, Choi YE (2014) Manipulation of light wavelength at appropriate growth stage to enhance biomass productivity and fatty acid methyl ester yield using Chlorella vulgaris. Biores Technol 159:240–248

Singh SP, Singh P (2015) Effect of temperature and light on the growth of algae species: A review. Renew Sustain Energy Rev 50:431–444

Kushibiki T, Hirasawa T, Okawa S, Ishihara M (2013) Blue laser irradiation generates intracellular reactive oxygen species in various types of cells. Photomed Laser Surg 31(3):95–104

Yilancioglu K, Cokol M, Pastirmaci I, Erman B, Cetiner S (2014) Oxidative stress is a mediator for increased lipid accumulation in a newly isolated Dunaliellasalina strain. PLoS One 9(3):e91957. https://doi.org/10.1371/journal.pone.0091957

Fernandes B, Teixeira J, Dragone G, Vicente AA, Kawano S, Bišová K et al (2013) Relationship between starch and lipid accumulation induced by nutrient depletion and replenishment in the microalga Parachlorellakessleri. Biores Technol 144:268–274

Zhang H, Gao Z, Li Z, Du H, Lin B, Cui M, Yin Y, Lei F, Yu C, Meng C (2017) Laser radiation induces growth and lipid accumulation in the seawater microalga Chlorella pacifica. Energies 10(10):1671

Kuwahara SS, Cuello JL, Myhre G, Pau S (2011) Growth of the green algae Chlamydomonasreinhardtii under red and blue lasers. Opt Lasers Eng 49:434–438

Abdelsalam E, Samer M, Abdel-Hadi MA, Hassan HE, Badr Y (2018) Influence of laser irradiation on rumen fluid for biogas production from dairy manure. Energy 163:404–415

Abdelsalam E, Samer M, Attia Y, Abdel-Hadi MA, Hassan HE, Badr Y (2019) Effects of laser irradiation and Ni nanoparticles on biogas production from anaerobic digestion of slurry. Waste Biomass Valorization 10(11):3251–3262

Abdelsalam EM, El-Hussein A, Samer M (2021) Photobiostimulation of anaerobic digestion by laser irradiation and photocatalytic effects of trace metals and nanomaterials on biogas production. Int J Energy Res 45:141–150

Faried M, Ali AS, Ahmed RH, Moselhy MA, Abdelsalam E, Yousef RS, Marrez DA, Samer M (2021) Photobiostimulation of Chlorella sorokiniana using light emitting diodes (LEDs) for increasing lipid and biodiesel production. Egypt J Chem. https://doi.org/10.21608/EJCHEM.2021.75349.3696

Abdelqader A, Abdelsalam E, Attia YA, Moselhy MA, Ali AS, Arisha AH, Samer M (2021) Application of helium-neon red laser for increasing biohydrogen production from anaerobic digestion of biowastes. Egypt J Chem. https://doi.org/10.21608/EJCHEM.2021.65932.3423

Attia YA, Samer M, Moselhy MA, Arisha AH, Abdelqader AA, Abdelsalam E (2021) Influence of laser photoactivated graphitic carbon nitride nanosheets and nickel nanoparticles on purple non-sulfur bacteria for biohydrogen production from biomass. J Clean Prod 299:126898

Samer M, Hijazi O, Abdelsalam EM, El-Hussein A, Attia YA, Yacoub IH, Bernhardt H (2021) Life cycle assessment of using laser treatment and nanomaterials to produce biogas through anaerobic digestion of slurry. Environ Dev Sustain. https://doi.org/10.1007/s10668-021-01264-9

Abdelsalam E, Samer M, Moselhy MA, Arisha AH, Abdelqader AA, Attia YA (2021) Effects of He–Ne red and green laser irradiation on purple non-sulfur bacteria for biohydrogen production from food wastes. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-02084-7

Samer M, Abuarab ME (2014) Development of CO2 balance for estimation of ventilation rate in naturally cross-ventilated dairy barns. Trans ASABE 57(4):1255–1264

Samer M, Müller H-J, Fiedler M, Berg W, Brunsch R (2014) Measurement of ventilation rate in livestock buildings with radioactive tracer gas technique: theory and methodology. Indoor Built Environ 23(5):692–708

Samer M, Fiedler M, Müller H-J, Gläser M, Ammon C, Berg W, Sanftleben P, Brunsch R (2011) Winter measurements of air exchange rates using tracer gas technique and quantification of gaseous emissions from a naturally ventilated dairy barn. Appl Eng Agric 27(6):1015–1025

Samer M (2013) Emissions inventory of greenhouse gases and ammonia from livestock housing and manure management. Agric Eng Int CIGR J 15(3):29–54

Funding

This study is funded by the Science and Technology Development Fund (STDF) of Egypt through the research project number 26272.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Effects of He–Ne red laser on accumulated lipid and algae growth were studied

• Algae irradiation by red laser with a wavelength of 632.8 nm raises biodiesel yield

• Algae irradiation by He–Ne red laser raises oil content 3.1 times the control

• Algae irradiation by He–Ne red laser raises biodiesel yield 3.1 times the control

Rights and permissions

About this article

Cite this article

Faried, M., Samer, M., Moselhy, M.A. et al. Photobiostimulation of green microalga Chlorella sorokiniana using He–Ne red laser radiation for increasing biodiesel production. Biomass Conv. Bioref. 14, 117–131 (2024). https://doi.org/10.1007/s13399-021-02220-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02220-3