Abstract

Integrations of two-phase culture for cell growth and lipid accumulation using mixed LED and green LED wavelengths were evaluated with the microalgae, Phaeodactylum tricornutum, Isochrysis galbana, Nannochloropsis salina, and Nannochloropsis oceanica. Among the single and mixed LED wavelengths, mixed LED produced higher biomass of the four microalgae, reaching 1.03 g DCW/L I. galbana, followed by 0.95 g DCW/L P. tricornutum, 0.85 g DCW/L N. salina, and 0.62 g DCW/L N. oceanica than single LED or fluorescent lights at day 10. Binary combination of blue and red LEDs could produce the high biomass and photosynthetic pigments in the four microalgae. The highest lipid accumulation during second phase with the exposure to green LED wavelengths was 56.0% for P. tricornutum, 55.2% for I. galbana, 53.0% for N. salina, and 51.0% for N. oceanica. The major fatty acid in the four microalgae was palmitic acid (C16:0) accounting for 38.3–47.3% (w/w) of the total fatty acid content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgal biomass is used as a feedstock for food or feed supplements, nutraceuticals, and cosmetics, and has been considered as a promising feedstock for aquaculture [1]. Microalgae play a vital role in aquatic food chain and are popularly used in rearing aquatic animals like mollusks, shrimps, and fishes at different growth stages [2]. In addition, microalgal photosynthesis has been recognized as one of the most cost-effective ways to solve global warning [3]. The four microalgae Phaeodactylum tricornutum, Isochrysis galbana, Nannochloropsis salina, and Nannochloropsis oceanica have desirable merits to contribute to environmental and economic issues such as their carbon fixation, high biomass productivity, and lipid synthesis [4,5,6].

Photoautotrophic microalgae absorb light energy (photons) and convert it into chemical energy, such as in the form of ATP and NADPH. These reactions occur in the microalgal photosystems and the absorption of light energy occurs via chlorophyll pigments and carotenoids [7]. Thus, the wavelength and intensity of light play key roles in the process of photosynthesis for photoautotrophic microalgal growth and also affect lipid production by microalgae [8]. The wavelengths absorbed by microalgae differ depending on the species.

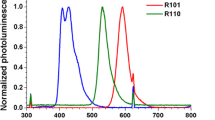

Chlorophylls and carotenoids are the two major classes of photosynthetic pigments found in plants and algae. Chlorophyll a (Chl a) is the primary molecule responsible for photosynthesis, while chlorophyll b (Chl b) is an accessory pigment, the level of which increases upon exposure to a broad spectrum of light that transfers the energy to Chl a. Carotenoids as photosynthetic pigments play a role of excess energy disposal. The absorbance maxima of chlorophylls and carotenoids are in the red and blue wavelength regions of the light spectrum [7].

The use of specific narrow bands of light using light-emitting diode (LED) is more economical than using ordinary light sources with cost-effective low-wattage irradiance. Indeed, the light absorption ability of photosystem II was improved by red light, while that of photosystem I was improved by blue light [9]. Thus, mixed LED lights with red (660 nm) and blue (465 nm) wavelengths are more suitable for microalgal growth than other wavelengths and promote microalgal photosynthesis [10].

One of the most effective methods of improving microalgae lipid accumulation is nutrition stress [11]. However, higher lipid contents by nutrition stress conditions were accompanied by lower growth rates, which lead to decreased biomass and lipid productivity [12]. Gao et al. [13] studied the effect of nitrogen limitation on lipid accumulation of Chaetoceros muelleri. Under nitrogen-limited conditions, the lipid accumulation was increased to 23–46% and decreased in biomass productivity from 19.0 to 12 mg/L. On the other hand, little data of green LED wavelength stresses are available in the literature on lipid accumulation influence on microalgae. Thus, a two-phase culture was carried out to enhance the biomass and lipid productivities in the one photobioreactor. In the first phase, the microalgae are grown under mixed LED lights with red (660 nm) and blue (465 nm) wavelengths to obtain maximum biomass production. Then, lipid accumulation was performed with green (520 nm) wavelength at 10 days of culture as second phase.

The aim of this study was to use LED lights with a mixture of red and blue wavelengths, and green wavelength as two-phase culture process to enhance the production of components such as biomass, carotenoids, and lipids in four marine microalgae: P. tricornutum, I. galbana, N. salina, and N. oceanica.

Materials and methods

Microalgal strains and culture conditions

Four microalgae, Phaeodactylum tricornutum, Isochrysis galbana, Nannochloropsis salina, and Nannochloropsis oceanica, were obtained from the Korea Marine Microalgae Culture Center (Busan, Korea). They were cultured in sterilized seawater with modified f/2 medium [14]. Four microalgae species were cultured in 2 L flasks with a 1.5 L working volume at 20 ± 1 °C, an aeration rate of 2.5 L/min, nitrate concentration of 16 mg/L, and a 12/12-h light/dark cycle under a light intensity of 100 µmol/m2/s for 10 days. After the culture reached to stationary phase at 10 days, the second phase culture was carried out to accumulate lipid in microalgae until 13 days.

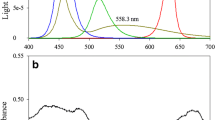

The two-phase culture process was employed to elucidate the link between mixed blue and red LED wavelengths for the biomass production and green LED wavelength stress condition for lipid accumulation as an energy storage product. This strategy included first phase allowing high biomass production without stress using blue LED (465 nm), red LED (660 nm), or mixed LED (blue:red = 1:1) in 10 days. Then, green LED (520 nm) wavelength stress in the second phase culture was carried out for 3 days to find the optimum culture time to accumulate high lipid contents.

A control experiment was carried out using fluorescent light at the same light intensity and operating conditions. The initial cell density was determined using the standard curve of OD680 versus dry cell weight (DCW) using a UV spectrophotometer (Ultrospec 6300 Pro; Biochrom Ltd., Cambridge, UK). Aeration with filtered air was provided through an air stone at a rate of 2.5 L/min. Each of the flasks was then exposed to light with the mixture of red (660 nm) and blue (465 nm) wavelengths under a 12-h:12-h light–dark cycle for 10 days and green (520 nm) wavelength for day 10 to day 13.

Light source for microalgal culture

LED square panel lights (28.5 × 38.6 × 4.4 cm3; LUXPIA Co., Ltd., Suwon, Korea) were used as the light source for the photoautotrophic growth of microalgae, as shown in Fig. 1. Thirty blue (465 nm), green (520 nm), and red (660 nm) diodes were each spaced alternately in six strips at 1-cm intervals in both rows and columns. LED light at 100 µmol/m2/s with a mixture of blue (465 nm) and red (660 nm) wavelengths at a 1:1 ratio and green (520 nm) were used for cell biomass and lipid production, respectively. The LED square panel lights were placed in parallel to illuminate the 2-L flask culture at a distance of 15 and 7 cm for cell mass (first phase) and lipid (second phase) production, respectively. The light intensity was measured with a light sensor (TES-1339; UINS Inc., Busan, Korea) as the photon flux at the center line of the flask filled with culture medium. A control experiment was conducted under the same intensity of fluorescent light and operating conditions for 13 days.

Lipid extraction and transesterification

The numbers of inoculated microalgal cells were determined by counting using a hemocytometer and a microscope (CK40-SLP; Olympus, Tokyo, Japan). The cultures were sampled at 24-h intervals. Based on the standard curve of OD680 and DCW, one unit of OD680 corresponded to 0.42-, 0.42-, 0.27-, and 0.22-g DCW/L dry biomass weights of P. tricornutum, I. galbana, N. salina, and N. oceanica, respectively. The specific growth rate (μ) of microalgae was calculated using the following equation:

where μ is the specific growth rate (h−1), and DCW1 and DCW2 are the dry cell weights at times T 1 and T 2, respectively. Nitrate concentration was determined according to the standard methods using an ultraviolet–visible (UV–Vis) spectrophotometer (Ultrospec™ 6300 Pro; Biochrom Ltd.) [15]. Determination of chlorophyll a, chlorophyll b, and total carotenoid contents has been well established [16]. The determination of levels in whole pigment extract of microalgae using a UV–Vis spectrophotometer was performed using the following equations:

Lipid extraction and transesterification

After cell growth and lipid accumulation, suspended cells were harvested by centrifugation (994×g, 10 min) and lyophilized using freeze drier (SFDSM-24L; SamWon Industry, Seoul, Korea). Total lipids were extracted with chloroform/methanol (2:1, v/v) and quantified gravimetrically [17]. The lipid content in dry weight was calculated using the following equation:

where lipid content is the cellular lipid content of the microalgae (% of DCW), W 1 (g) is the weight of the empty 20 mL glass tube, W 2 (g) is the weight of the lipid extracting 20 mL glass tube, and DCW (g) is the dry cell weight of the microalgae.

The lipid composition was determined as fatty acid methyl esters (FAMEs) via the direct transesterification method [18]. FAME profiling was performed by gas chromatography (GC; YL 6100; YoungLin Inc., Anyang, Korea) with a flame ionization detector (FID) and a silica capillary column (HP-INNOWAX; 30 m × 0.32 mm × 0.5 μm; Agilent Technologies, Santa Clara, CA, USA). The column temperatures and holding times were set as follows: 140 °C for 5 min, followed by a temperature increase to 240 °C at a rate of 5 °C/min; this temperature was maintained for 5 min. Both injector and FID detector temperatures were set to 250 °C. The FAMEs were identified by comparing their retention times to those of authentic standards.

Statistical analysis

Each experiment was carried out in triplicate. The statistical significance of differences in biomass and lipid contents was evaluated by one-way analysis of variance and Duncan’s multiple range test (P < 0.05) using SPSS Software (ver. 23; SPSS Inc., Chicago, IL, USA)

Results and discussion

Effects of LED light with a mixture of wavelengths on the growth of microalgae

P. tricornutum, I. galbana, N. salina, and N. oceanica cultures under mixed LED lights of blue:red wavelengths at a ratio of 1:1 were carried out for four microalgae. The cell growth with mixed LED lights was compared to those with blue LED (465 nm), red LED (660 nm), or conventional fluorescent lights for 13 days, as shown in Fig. 2.

Among those wavelengths, mixed LED produced the highest biomass among the four microalgae, achieving 1.03 g DCW/L I. galbana, followed by 0.95 g DCW/L P. tricornutum, 0.85 g DCW/L N. salina, and 0.62 g DCW/L N. oceanica at day 10. This suggests that mixture of blue and red LEDs can be suitable light source for microalgae culture, because microalgal plastids are related to those of terrestrial plants in terms of structure, metabolism, and biochemical composition [19]. The specific growth rates were calculated from the growth curve in Fig. 2 a–d. Specific growth rates (μ) of P. tricornutum, I. galbana, N. salina, and N. oceanica with mixed LED were 0.037, 0.042, 0.029, and 0.025 h−1, respectively. However, four microalgae with the blue, red LEDs, and fluorescent light resulted in decrease of the specific growth rates such as 0.029, 0.030, and 0.025 h−1 for P. tricornutum; 0.025, 0.025 and 0.022 h−1 for I. galbana; 0.021, 0.024 and 0.021 h−1 for N. salina; and 0.019, 0.025 and 0.018 h−1 for N. oceanica, respectively. These results were consistent with those from Chen et al. [20]. The illumination with mixed blue (465 nm) and red LED (660 nm) wavelengths at 1:1 ratio led to higher microalgae biomass production than those of single LED wavelengths and fluorescent light. Similar results were obtained previously for the culture of Chlorella sp., which showed maximum biomass production of 0.49 g DCW/L using a mixture of red (660 nm) and blue (460 nm) LEDs at 1:1 ratio [21]. As shown in Fig. 3, the four microalgae reached the stationary phase of growth at 10 days and reached to the stage of depleted nitrate concentrations at 10–11 days. Overall, mixed blue (465 nm) and red LED (660 nm) wavelengths at 1:1 ratio consumed higher nitrate than those of single LED wavelengths and fluorescent light. Using mixed LED lights, four microalgae showed the high and fast cell growth with 16.0 mg/L nitrate concentration.

Furthermore, several studies have applied LED with a mixture of wavelengths to promote microalgal photosynthesis [10, 20, 22, 23]. The biomass upon the treatment with red:blue light at a ratio of 1:1 was higher than those of the other treatments, such as at red:blue light ratios of 1:9, 3:7, 7:3, and 9:1 [10]. In addition, the opposite effect was observed in Nannochloropsis sp., which grew better under blue LED comparing to multi-chromatic white LED exposure [5]. This preference showed a correlation with the evolutionary pigment composition of the light-harvesting complexes in the chloroplasts of each microalgae [19]. In this present study, mixed LED was selected for biomass production of four microalgae.

Effects of LED light with a mixture of wavelengths on Chl a, Chl b, and carotenoids

As shown in Fig. 4, higher concentrations of biomass and photosynthetic pigments (Chl a, Chl b, and carotenoids) were obtained with mixed red (660 nm) and blue (460 nm) LED at a 1:1 ratio cultivation than those with the conventional fluorescent light at 10 days in four microalgae. As shown in Fig. 4a, the growth of four microalgae was improved using a mixture of red and blue LEDs at a ratio of 1:1 comparing to those of single LED wavelengths and fluorescent light (Fig. 2).

Effects of mixed LED wavelengths on the growth and chlorophylls of microalgae during 10 days of culture. a Growth of four microalgae, b chlorophyll a, c chlorophyll b, and d carotenoids in four microalgae. The vertical line in a indicates the start of second phase in microalgae cultures. Different capital and small letters indicate significant differences (P < 0.05, Duncan’s test)

Figure 4b, c shows that the pigment concentrations upon exposure to mixed LED wavelengths were as follows: P. tricornutum (Chl a: 9.91 mg/g, Chl b: 0.92 mg/g), I. galbana (Chl a: 11.38 mg/g, Chl b: 1.48 mg/g), N. salina (Chl a: 9.95 mg/g, Chl b: 2.06 mg/g), and N. oceanica (Chl a: 5.64 mg/g, Chl b: 0.66 mg/g). These results indicate that Chl a and Chl b contents of four microalgae cultured under mixed LED were higher than those cultured under the conventional fluorescent light. Koller et al. [24] reported that the chlorophyll a, b and carotenoid contents in biomass for the photosynthesis reaction. Because chlorophyll a is the core of reaction pigment, while accessory pigments chlorophyll b, c, and d extend the range of wavelengths [7]. Thus, spectral quality is defined by the adsorption spectrum (light wavelengths) of the chlorophyll and other photosynthetically active pigments in microalgae such as carotenoids [25]. Figure 4d shows that the highest carotenoid content of 6.30 mg/g was obtained with I. galbana exposed to mixed LED wavelengths. P. tricornutum, N. salina, and N. oceanica showed carotenoid concentrations of 4.70, 3.12, and 2.54 mg/g, respectively. These results indicate that combination of blue and red LEDs is critical for the syntheses of photosynthetic pigments.

In addition, most photosynthetic pigments (Chl a, Chl b, and carotenoids) have two major wavelengths: blue wavelength range of 450–475 nm or the red wavelength range of 630–675 nm [23]. Due to the specific wavelength, microalgae require optimum light conditions within the narrow band of spectrum. However, the ordinary fluorescent light for microalgae culture contains a wide range of wavelengths and consists of a combination of growth-efficient and growthinefficient wavelengths [26]. Therefore, the production of two essential chlorophylls and carotenoids was sufficiently stimulated to achieve the highest growth rate of microalgae, especially upon exposure to mixed red (660 nm) and blue (465 nm) wavelengths.

Effect of lipid accumulation using two-phase culture process

Two-phase culture processes were carried out for high biomass production using mixed LED in 10 days, and then, stress condition with green (520 nm) LED wavelength in the second phase at day 10 was applied for following 3 days, as shown in Figs. 4a and 5. The effects of fluorescent light, mixed LED (blue:red = 1:1) and green LED wavelengths on lipid accumulation were evaluated with four species of microalgae, as shown in Fig. 5.

As shown in Fig. 5a–d, the high lipid accumulations at day 3 of second phase under fluorescent light were 45.0% for P. tricornutum, 41.4% for I. galbana, 32.0% for N. salina, and 32.0% for N. oceanica. The high lipid accumulations at day 2 of exposure to mixed LED wavelengths were 53.0% for P. tricornutum, 51.4% for I. galbana, 48.6% for N. salina, and 47.6% for N. oceanica. The highest lipid accumulation was achieved under green LED, reaching 56.0% of the dry cell weight by P. tricornutum in day 2, followed by I. galbana (55.2%) in day 3, N. salina (53.0%) in day 2, and N. oceanica (51.0%) in day 2. There were significant differences in lipid contents under fluorescent light, mixed LED, and green LED wavelength stresses.

In general, a number of researchers have reported on lipid content improvement using physical or chemical stresses, such as nitrogen starvation [27], high light intensity [28], high temperature [29], and salinity [30]. However, higher lipid contents by physical or chemical stress conditions were accompanied by lower growth rates, which lead to decreased biomass and lipid productivity [11, 12]. These reports indicated that it is mainly due to reduced rate of metabolism under stress, the excess carbon generated is channeled towards as storage molecules predominantly triacylglycerol (TAG) or starch depending upon the microalgae species [26]. Therefore, the green LED as a light wavelength stress in the second phase could enhance the performance of lipid accumulation comparing to other stress factors. As observed in the previous report [6], the lipid accumulation by green LED wavelength was higher than those of different LED wavelengths. This may be due to the reason that green LED was not absorbed but reflected. Similar results were obtained for Nannochloropsis sp [23]. It was also observed that green microalgae species did not grow well under green LEDs. Whereas the culture was under dark period (100% dark phase) in the second phase, microalgae did not show cell growth or carbon dioxide consumption [31]. Thus, green LED wavelength stress could be used as the simple and convenient lipid accumulation method without changing culture medium from one photobioreactor. Figure 5.

Fatty acid composition

The lipids extracted from four microalgae, P. tricornutum, I. galbana, N. salina, and N. oceanica, were converted to FAMEs and their compositions are shown in Table 1. Through the analysis of the fatty acid methyl esters (FAMEs) composition, a useful comparison of four microalgae lipids with respect to the saturated (SFAs; C14:0, C16:0, C18:0, C20:0, and C22:0) and unsaturated (UFAs; C18:1, C18:2, C18:3, C20:5, and C22:6) fatty acids is provided in the present study.

Four species of microalgae were enriched in the common C14–C22 fatty acids such as myristic (C14:0), palmitic (C16:0), stearic (C18:0), oleic (C18:1), linoleic (C18:2), linolenic (C18:3), arachidic (C20:0), eicosapentaenoic (C20:5, EPA), behenic (C22:0), and docosahexaenoic (C22:6, DHA) acids. Those indicated fatty acids of four microalgae varied significantly. Among these FAMEs, 38.3–47.3% (w/w) palmitic acid (C16:0) was predominant form observed for four microalgae in the lipid accumulation. These results are similar to those reported by Converti et al. [32]. They reported that the palmitic acid (C16:0) found in C. vulgaris and N. oculata represented 47–66% (w/w) and 58–62% (w/w) of the total fatty acids, respectively. Green LED wavelength stress in the cultivation of the four microalgae induced a cascade of reactions leading to the formation of acetyl-CoA, which induced more synthesis of palmitic acid (C16:0). Thus, more syntheses of palmitic acid (C16:0) have been occurred due to palmitic acid (C16:0) acting as a precursor of fatty acids synthesis.

Furthermore, the palmitic acid (C16:0) level decreased from 51.01 to 38.34% (w/w) for P. tricornutum, 43.90–39.63% (w/w) for I. galbana, 65.08–47.33% (w/w) for N. salina, and 55.39–46.52% (w/w) for N. oceanica from control to green LED stress, respectively, as shown in Table 1. Overall, the synthesis pathway of fatty acids in microalgae starts from SFAs like palmitic acid (C16:0), which undergoes subsequent desaturation and elongation reactions leading to decrease in SFAs and increase in UFAs. The UFA component increased from 19.49 to 33.19% (w/w) for P. tricornutum, 14.34–23.38% (w/w) for I. galbana, 19.57–37.86% (w/w) for N. salina, and 21.62–38.13% (w/w) for N. oceanica (Table 1). Based on UFAs to SFAs fraction, the quality and usage of microalgae oil for aquaculture can be determined. High levels of UFAs and low levels of SFAs increase the quality of fish feed [1].

Conclusion

Two-phase culture processes of four microalgae species were carried out under mixed LED of red and blue wavelengths for biomass production, and green LED wavelength for lipid accumulation. Among the four strains with high growth and lipid production, the two species, P. tricornutum and I. galbana, can be used for aquaculture feedstock. The highest lipid contents of four microalgae in the two-phase culture increased from 38.8 to 56.0% (w/w) for P. tricornutum, 36.0–55.2% (w/w) for I. galbana, 31.5–53.0% (w/w) for N. salina, and 28.5–51.0% (w/w) for N. oceanica under green LED wavelength stresses. These results indicate that lipid accumulation under green LED wavelength had significant effects on lipid productivity in the second phase. Thus, two-phase culture process could enhance to accumulate lipid in the microalgae.

References

Roy SS, Pal R (2015) Microalgae in aquaculture: a review with special references to nutritional value and fish dietetics. Proc Zool Soc 68:1–8

Borowitzka MA. Microbiology of fermented foods. 2, Wood BJB (1998) Algae as food Blackie Academic and Professional, London 585–602

Kumar K, Dasgupta CN, Nayak B, Lindblad P, Das D (2011) Development of suitable photobioreactors for CO2 sequestration addressing global warming using green algae and cyanobacteria. Bioresour Technol 102:4945–4953

Song MM, Pei HY, Hu WR, Ma GX (2013) Evaluation of the potential of 10 microalgal strains for biodiesel production. Bioresour Technol 141:245–251

Das P, Lei W, Aziz SS, Obbard JP (2011) Enhanced algae growth in both phototrophic and mixotrophic culture under blue light. Bioresour Technol 102:3883–3887

Ra CH, Kang CH, Jung JH, Jeong GT, Kim SK (2016) Effects of light-emitting diodes (LEDs) on the accumulation of lipid content using a two-phase culture process with three microalgae. Bioresour Technol 212:254–261

Richmond A (2003) Handbook of microalgal culture: biotechnology and applied phycology. In: Masojídek J, Koblížek M, Torzillo G (eds) Photosynthesis in microalgae. Blackwell, Hoboken 20–39

Ugwu CU, Aoyagi H, Uchiyama H (2008) Photobioreactors for mass cultivation of algae. Bioresour Technol 110:4021–4028

You T, Barnett SM (2004) Effect of light quality on production of extracellular polysacchariedes and growth rate of Porphyridium cruentum. Biochem Eng J 19:251–258

Kim TH, Lee YH, Han SH, Hwang SJ (2013) The effects of wavelength and wavelength mixing ratios on microalgae growth and nitrogen, phosphorus removal using Scenedesmus sp. for wastewater treatment. Bioresour Technol 130:75–80

Minhas AK, Hodgson P, Barrow CJ, Adholeya A (2016) A review on the assessment of stress conditions for simultaneous production of microalgal lipids and carotenoids. Front Microbiol 7:546

Huerlimann R, de Nys R, Heimann K (2010) Growth, lipid content, productivity, and fatty acid composition of tropical microalgae for scale-up production. Biotechnol Bioeng 107:245–257

Cao J, Yuan H, Li B, Yang J (2014) Significance evaluation of the effects of environmental factors on the lipid accumulation of Chlorella minutissima UTEX 2341 under low-nutrition heterotrophic condition. Bioresour Technol 152:177–184

Guillard RR, Ryther JH (1962) Studies of marine planktonic diatoms. I. cyclotellanana Hustedt and Detonula confervacea (cleve) Gran. Can J Microbiol 8:229–239

Collos YF, Mornet A, Sciandra N, Waser AL, Harrison PJ (1999) An optical method for the rapid measurement of micromolar concentrations of nitrate in marine phytoplankton cultures. J Appl Phycol 11:179–184

Lichtenthaler HK (1987) Chlorophylls and carotenoids: pigments of photosynthetic biomembranes. Methods Enzymol 148:350–382

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Dhup S, Dhawan V (2014) Effect of nitrogen concentration on lipid productivity and fatty acid composition of Monoraphidium sp. Bioresour Technol 152:572–575

Schulze PSC, Barreira LA, Pereira HGC, Perales JA, Varela JCS (2014) Light emitting diodes (LEDs) applied to microalgal production. Trends Biotechnol 32:422–430

Chen CY, Chen YC, Huang HC, Ho SH, Chang JS (2015) Enhancing the production of eicosapentaenoic acid (EPA) from Nannochoropsis oceanica CY2 using innovative photobioreactors with optimal light source arrangements. Bioresour Technol 191:407–413

Yan C, Zheng Z (2014) Performace of mixed LED light wavelengths on biogas upgrade and biogas fluid removal by microalga Chlorella sp. Appl Energy 113:1008–1014

Zhao YG, Wang J, Zhang H, Yan C, Zhang YJ (2013) Effects of various LED light wavelengths and intensities on microalgae-based simultaneous biogas upgrading and digestate nutrient reduction process. Bioresour Technol 136:461–468

Teo CL, Atta M, Bukhari A, Taisir M, Yusuf AM, Idris A (2014) Enhancing growth and lipid production of marine microalgae for biodiesel production via the use of different LED wavelengths. Bioresour Technol 162:38–44

Koller M, Muhr A, Braunegg G (2014) Microalgae as versatile cellular factories for valued products. Algal Res 6:52–63

Lee CG (1999) Calculation of light penetration depth in photobioreactors. Biotechnol Bioprocess Eng 4:78–81

Cheirsilp B, Torpee S (2012) Enhanced growth and lipid production of microalgae under mixotrophic culture condition: effect of light intensity, glucose concentration and fed- batch cultivation. Bioresour Technol 110:510–516

Mujtaba G, Choi WJ, Lee CG, Lee KS (2012) Lipid production by Chlorella vulgaris after a shift from nutrient-rich to nitrogen starvation conditions. Bioresour Technol 123:279–283

Liu Y, Yuan C, Hu G, Li F (2012) Effects of light intensity on the growth and lipid accumulation of microalga Scenedesmus sp. 11–1 under nitrogen limitation. Appl Biochem Biotechnol 166:2127–2137

Ho SH, Chen CNN, Lai YY, Lu WB, Chang JS (2014) Exploring the high lipid production potential of a thermotolerant microalga using statistical optimization and semi-continuous cultivation. Bioresour Technol 163:128–135

Arroussi HE, Benhima R, Bennis I, Mernissi NE, Wahby I (2015) Improvement of the potential of Dunaliella tertiolecta as a source of biodiesel by auxin treatment coupled to salt stress. Renew Energy 77:15–19

Sasi D, Mitra P, Vigueras A, Hill GA (2011) Growth kinetics and lipid production using Chlorella vulgaris in a circulating loop photobioreactor. J Chem Technol Biotechnol 86:875–880

Converti A, Casazza AA, Ortiz EY, Perego P, Borghi MD (2009) Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process 48:1146–1151

Acknowledgements

This research was a part of the project titled ‘Innovative marine production technology driven by LED-ICT convergence photo-biology (D11514915H480000110)’, funded by the Ministry of Oceans and Fisheries, Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ra, C.H., Sirisuk, P., Jung, JH. et al. Effects of light-emitting diode (LED) with a mixture of wavelengths on the growth and lipid content of microalgae. Bioprocess Biosyst Eng 41, 457–465 (2018). https://doi.org/10.1007/s00449-017-1880-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1880-1