Abstract

Bangladesh is a densely populated agricultural country. As the allocated forestland for pulpwood production is very limited and a substantial amount of crops residues are generated each year, the latter can substitute pulpwood. But it is hard to use crops residues as pulping raw materials in a conventional pulping process due to its high content of silica and fines. It was observed that formic acid (FA) pulping process can overcome these limitations. In this context, fourteen residues of crops produced in Bangladesh were evaluated by FA pulping with varying FA charge for 4 h at the boiling temperature followed by peroxyformic acid (PFA) treatment under constant conditions. It was observed that pulp yield and delignification degree decreased with FA charge. Also, PFA treatment further reduced the kappa number of pulps. Final pulp yields were 39–51% with the kappa number of 12–28 depending on crops residues. Holocellulose and α-cellulose content in crops residues were positively correlated (R2 = 0.95) with pulp yield at 0% level of significance. Pulps were bleached by alkaline peroxide bleaching and brightness reached to about 80% with acceptable papermaking properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The source of pulping raw materials is the forests, the total area of which is very small in number for a small country like Bangladesh. Therefore, interest in using straw and different crops residues for papermaking were observed for a long time in countries with little or no wood reserves. Bangladesh as an agricultural country generates a substantial amount of crops residues [1]. According to the World Bank report, annual growth in the agricultural sector of Bangladesh was reported at 2.7863% in 2016, thus it consequently increased crops residues over the years [2].

Conventionally, agricultural residues are pulped by alkaline processes. But most of the crops residues are high in ash content. In alkali processes, pulp yield and properties are good, but the main drawback is the dissolution of silica in the black liquor, which causes problem during recovery of the cooking reagents. A pulp mill cannot be environmentally friendly without chemical recovery system. Another factor for consideration is that the crops residues are bulky in nature, making transportation of these types of raw materials difficult. Therefore, organic solvent-based delignification has been exhaustively studied in recent years as an alternative to the traditional processes of chemical pulp production because of strict regulations on environmental discharges. In the solvent pulping, the major portion of silica remains on the fiber [3,4,5,6]. Formic acid (FA)/peroxyformic acid (PFA) treatment produced pulp yield of 43.4% with kappa number 15.5 from rice straw [3]. Jiménez et al. [7] used a central composite design to investigate the influence of the cooking conditions (time, temperature, and acid concentration) for wheat straw with organic acid-water mixtures on the properties of the pulp obtained (yield and holocellulose, α-cellulose and lignin contents). A second-order polynomial model, consisting of three independent process variables, was found to accurately describe the organosolv pulping of wheat straw. Delignification from rice straw by FA of approximately 85% with a pulp yield of 44.4% was obtained at the cooking conditions of, temperature, 100 °C; cooking time, 60 min; formic acid concentration, 90%. Pulp chemical and mechanical properties were comparable with those found for pulp obtained in basic environments [8].

Dissolved lignin and hemicelluloses in the spent liquor of organic acid pulping can be separated easily [3, 7,8,9], and organic acid can be recovered by distillation and reused in the process [10]. The detail organic acid fractionation of crops residues are shown in Fig. 1 [11]. Organic acid lignin is characterized a by higher phenolic group [12, 13], consequently improved reactivity in using resins [14]. This lignin can also be used for many value-added products due to its lower molecular weight and higher reactivity [15,16,17]. The spent liquor lignin can also be used for producing carbon fibers [18], activated carbon [19], etc.

Flow diagram of lignocellulosic biomass fractionation in organic acid process in biorefinery concept [11]

In this study, 14 important crops residues in Bangladesh were chemically characterized. These crops are native and available in Bangladesh. Both acetic acid (AA) and formic acid effectively delignify lignocellulose, but AA needs mineral acid as catalyst, which is corrosive for the digester [3, 13]. Therefore, in the present study, formic acid (FA) delignification of these crops residues were carried out with varying FA charge at boiling temperature followed by peroxyformic acid (PFA) pulping at 80 °C for 120 min. PFA activate the pulp in alkaline peroxide bleaching [3]. Produced pulps were bleached by two stages alkaline peroxide bleaching and evaluated the papermaking properties.

2 Materials and methods

2.1 Materials

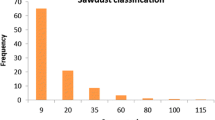

Wheat straw, corn stalks, mustard stalks, eggplant stalks, chia plant, banana pseudo stem, banana leaf, banana peduncle, bagasse, bamboo, kash (kans grass), okra plant, and kaun (millet) plant were collected from Katiadi, Kishoreganj, and rice straw was collected from Trishal, Mymensingh.

2.2 Chemical analysis

The chemical compositions of these crops residues were carried out by following Technical Association of Pulp and Paper Industries (Tappi) test methods: the extractive (T204 om88), Klason lignin (T211 om83), ash content (T211 om93), and pentosan (T223). The holocellulose was prepared by treating extractive-free wood meal with NaClO2 solution [20]. The pH of the solution was maintained at 4 by adding CH3COOH–CH3COONa buffer, and α-cellulose was determined by treating holocellulose with 17.5% NaOH (T203 om93).

2.3 Formic acid (FA) treatment

The crops residues were refluxed with formic acid in a hotplate under the following different conditions:

Formic acid concentration was 70, 80, and 90% (v/v)

Reaction time: 4 h at boiling temperature.

Liquor ratio 10.

After desired reaction time, pulp was filtered in a Buchner funnel and washed with fresh formic acid followed by distilled water. Then the pulp yield was determined gravimetrically. The lignin content in pulp was determined by Tappi test methods (T 222 om-98).

2.4 Peroxyformic acid treatment

FA-treated pulp was further delignified with peroxyformic acid (PFA) at 80 °C. The reaction was carried out in a thermostatic water bath. The PFA was prepared by adding 90% formic acid with 4% H2O2 (on o.d. FA pulp). The time was kept constant for 120 min. After completion of the pulping, a pulp was filtered off and washed with 80% fresh formic acid and finally with water. Pulp yield was determined gravimetrically on raw material. The kappa number of the resulting pulp was determined in accordance with Tappi test methods (T 236 om-99). All experiments were carried out thrice and average reading was taken.

2.5 Bleaching

Bleaching experiments of unbleached pulp (50 g) were carried out at 10% pulp concentration. The pH was adjusted to 11 by adding NaOH. The hydrogen peroxide was varied to 4% on o.d. pulp. The bleaching temperature was 80 °C for 1 h. A similar procedure was followed in the 2nd stage of peroxide bleaching.

2.6 Evaluation of formic acid pulp

Bleached pulp was blended in wearing blender for 10 min, and handsheets were prepared for tensile (T 494 om-96), tear (T 414 om-98), and burst (T 403 om-97) tests. All characteristics were determined according to Tappi standard methods given in the parenthesis.

3 Results and discussion

3.1 Chemical characteristics

Table 1 shows the chemical characteristics of different crops residues in Bangladesh. Lignin is undesirable polymer for pulp production. Lower lignin content of raw materials makes them suitable for delignification at milder pulping conditions (lower temperatures and chemical charges) to reach a desirable kappa number. It is clearly seen from Table 1 that lignin contents were varied from 18.1% in mustard stalks to 28.4% in eggplant stalks. Lignin content in wheat straw and rice straw was relatively higher as compared with other studies [21, 22]. This was because of high ash content, which was not corrected in this experiment. No reports have been found on the chemical characteristics of eggplant stalks, kaun plant, and chia plant. Lignin content in chia plant was 23.2%. The lignin content in corn stalks was very close to the result obtained by Ates et al. [23]. But the lignin content in different portions of banana fiber was much higher than the result obtained in previously published data [24]. This can be explained by the variation of banana species. Klason lignin content in these raw materials was close to hardwood lignin content [25]. Finally, it can be said that these crops residues are characterized by relatively moderate amounts of Klason lignin.

Total carbohydrate content is defined as holocellulose. Therefore, high holocellulose content is desirable for better pulp yield and papermaking properties [26]. The holocellulose content of these crops residues were very close (57–66%) except banana peduncle, which was 73.7%. The α-cellulose contents in lignocellulosic positively influence pulp yield during chemical pulping [27, 28]. The cellulose content also determines the physical strength properties of paper [1, 27]. As shown in Table 1, the highest α-cellulose content in banana peduncle was 45.2%, while the lowest α-cellulose content in okra plant was 29.6%, which was close to the α-cellulose in chia plant (30.5%). According to the Nieschlag et al. [29] rating system, lignocellulosics with 34%, and over α-cellulose content were characterized as promising for pulp and paper manufacture from a chemical composition point of view. The α-cellulose content in these crops residues was above 34% except for the chia plant.

Pentosan content in these crops residues varied from 13 to 22%. The highest amount of pentosan was found in kash. Pentosan is an important characteristic of papermaking pulp, which facilitates H-bonding during sheet formation. Bai et al. [30] showed that the addition of hemicelluloses increased tensile index, burst index, tear index, and folding endurance of paper sheet. The results were attributed to the role of hydroxyl group (OH–) in hemicelluloses molecular which brought about more H-bond formation between cellulose and hemicelluloses and benefited the bonding between the fibers.

The mineral components of lignocellulosic biomass represented as ash content. Ash content in these crops residues found to be 1.7% in eggplant stalks to 15.1% in rice straw, which was much higher compared with the wood [25]. Higher ash content is undesirable during chemical recovery in the process. Presence of transition metals such as Mn, Fe, and Cu negatively affects pulp bleachability in peroxide and oxygen bleaching [31].

As shown in Table 1, acetone solubility in these crops residues was much lower than the reported data [32]. Acetone soluble content also adversely affects the paper machine run ability. High extractive contents in lignocelluloses are undesirable for pulping, bleaching, and papermaking. It also affects the quality of paper because of shadow marking and paper manufactured from such type of fibrous material might show reduced water absorbency [33].

3.2 Formic acid treatment

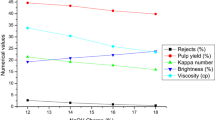

Delignification of chopped crops residues was carried out by varying formic acid charge and results of yield and residual lignin after formic acid treatment are shown in Figs. 2 and 3. From our previous studies, it was observed that organic acid deligninfication needs 4 h to get desirable deligninfication degree, where raw materials were defibrated [4]. Therefore, formic acid treatment was kept constant at 4 h in this investigation. Yield and residual lignin decreased with increasing formic acid charge. Residual lignin did not reach the desired level until the formic acid charge was 90%. Complete defibration of crops residues was considered as the desired level of residual lignin. Residual lignin content in mustard stalks was 11.0%, while the same in the banana pseudostem was 13.7%. There was no correlation found between lignin content in the raw materials and delignification degree with formic acid. The difference in lignin structure of the raw material was mainly responsible for deligninfication degree in formic acid treatment. [34] showed that the higher syringyl unit indicates higher delignification rate. [35] studied the organic acid delignification mechanism by using model lignin. The α-aryl ether bonds of arylglycerol-1, 3-aryl ethers were ruptured by acid treatment and generated carbonium ions in the first steps. Most of the carbonium ions immediately lose three protons to form vinyl ether which is then hydrolyzed, but some undergo intra- or intermolecular nucleophilic attack by aromatic rings to produce condensation products.

The highest yield after 90% formic acid treatment was 81.3% in banana peduncle, and the lowest yield was 41.2% in chia plant. This can be explained by α-cellulose content in the original raw materials. Eggplant stalks showed 68.6% yield after 90% formic acid treatment, which was not consistent with the α-cellulose content in the original raw materials. The higher residual lignin can be explained by a higher yield.

3.3 Peroxyformic acid treatment

Formic acid treated crops residues were cooked with peroxyformic acid (formed by 90% formic acid and 4% hydrogen peroxide) for 2 h at 80 °C. Longer cooking time in PFA pulping resulted in lignin condensation reaction, which increased kappa number [6]. Therefore, in this study, PFA treatment time was kept constant for 2 h. Pulp yield and kappa number of PFA treated pulp decreased accordingly as the yield and residual lignin content decreased in 70, 80, and 90% treatment of FA (Figs. 2, 3 and 4). Ninety percent of FA-treated crops residues produced pulps of almost similar kappa number than the conventional alkaline pulping process. As shown in Fig. 5, a kappa number of PFA banana leaf pulp was only 10.9, while the same raw material produced pulp with kappa number 23–17 in the kraft process [24]. A higher kappa number was observed for the banana pseudostem, which is still better or equal kappa number as compared with conventional pulping [24]. The kappa number of mustard stalks was 21.9 which is very close to the kappa number obtained by organic acid mixture treatment followed by peroxy acid pulping [36]. A very high pulp yield of 60.7% was obtained from banana peduncle after PFA cooking with kappa number 19.1. This higher pulp yield can be explained by higher α-cellulose content in banana peduncle (Table 1). The lowest pulp yield (39.9%) was obtained from the chia plant as its α-cellulose content was lower. Pulp yield from corn stalks was 41.1%, which was much lower than the other studies in conventional pulping processes [24, 37, 38]. This can be explained by different variety and location of raw material, which differentiate the chemical characteristics of the corn stalks. Pulp yield from kash was 54.0% with kappa number 17.8, which was very close to soda-AQ pulping [39]. Crops residues with high ash content such as rice straw and wheat straw showed higher pulp yield as compared with conventional pulping. This can be explained by the retention of silica on pulp during organic acid pulping [3]. There are no reports found on pulping of eggplant plant, chia plant, and kaun plant. Therefore, these raw materials for conventional pulping need to be studied further.

3.4 Bleaching and papermaking properties

PFA-treated pulps were bleached by two stages of alkaline peroxide bleaching. Pulp bleachability was improved with increasing FA charge during FA treatment (data are not shown). Organic acid pulps from bagasse (85.0%) and rice straw (81.3%) showed the best bleachability among these 14 crops residues. Cornstalks, wheat straw, and banana peduncle pulps reached to above 75% brightness in two stages alkaline peroxide bleaching, while mustard stalks and banana pseudo stem pulps did not show good bleachability. In another study of organic acid pulping, kash pulp reached to 83% brightness at 4% peroxide charge, while the brightness of banana stem and dhaincha pulps were 79 and 75%, respectively at the same peroxide charge [13].

Brightness can be increased to above 80% by increasing peroxide charge by 2% in each stage (data are not shown).

Bleached pulps were blended in warring bender for 5 min and handsheets were prepared for determining papermaking properties. As shown in Table 2, cornstalks pulp showed the highest tensile index (66.9 N.m/g) followed by chia plant (60.0 N.m/g), wheat straw (59.9 N.m/g), and kash (55.0 N.m/g) pulps. Longer fiber length, lower coarseness, higher fines, and degree of external fibrillation may explain higher tensile index (Table 3). The coarse fibers have a greater tendency to flocculate during sheet making that is detrimental to formation [40], which consequently produced the lower tensile index. The fines of chemical pulps have a strong tendency to intensify the interaction between fibers. Retulainen et al. and Kang and Paulapuro [41, 42] showed that external fibrillation, increased tensile index about 20%. But Hartman [43] showed that external fibrillation resulted in increased density without affecting tensile strength. Tear index and burst index of these pulps did not reach the desired level except wheat straw and chia plant pulps. This may be attributed by the poorly bonded fibers with fines [44]. Similar behavior of low tear and burst index of organic acid pulps were observed in elsewhere [45, 46].

3.5 Correlation

There is a strong positive correlation between holocellulose (%) and pulp yield (r = 0.891), and this relationship is significant (p = 0.002 < 0.05) at 5% level of significance. The correlation between α-cellulose (%) and pulp yield is positive and moderately strong (r = 0.717), and the association between these two parameters of pulp is significant as well (p = 0.004 < 0.05) at 5% level of significance.

3.6 Regression model

For predicting the percentage of pulp yield on the basis of lignin, holocellulose, α-cellulose, and pentosal, the fitted linear regression model is given in Eq. 1. Pulp yield and kappa number of crops residues treated with 90% FA followed by PFA treatment were considered for developing the model.

The model is significant (p = 0.002) at 5% level of significance with R2 = 0.95 and adjusted R2 = 0.91.

In this model, only two parameters, holocellulose, and α-cellulose are significant. If we consider these two parameters, only then the model becomes significant at 0% level of significance.

In case of predicting kappa number on the basis of these parameters, the model becomes

This model is not significant (p = 0.52) at 5% level of significance with R2 = 0.91 and adjusted R2 = 0.40. Neither of the parameters is individually significant for predicting kappa number. It was expected that the amount of lignin in raw material will be positively correlated with kappa number. But this model did not show this hypothesis. This can be explained by the syringyl to guaiacyl ratio of lignin present in the raw material. Nimz [47] reported that β-O-4 linkages in guaiacyl units are hydrolyzed at a slower rate than syringyl units.

4 Conclusion

In this study, 14 crops residues were evaluated in organic acid pulping. The α-cellulose contents in these samples are quite acceptable to consider as pulping raw materials. Most of these residues are high in ash content, which is challenging. Therefore, formic acid pulping was assessed in this study. The formic acid concentration had a remarkable effect on the delignification of crops residues. Peroxyformic acid treatment reduced the residual lignin remarkably. Pulp yield after peroxyformic acid treatment was better than the conventional pulp. Holocellulose and α-cellulose were positively correlated (R2 = 0.95) with pulp yield at 0% level of significance, but kappa number did not show good correlation with lignin. Organic acid pulps from bagasse, bamboo, rice straw, wheat straw, banana peduncle, okra plant, and corn stalks showed comparatively good bleachability in two stages alkaline peroxide bleaching. Crops residues generated a very high amount of fines in organic pulping. A good tensile index of most of the bleached pulp was observed, while tear and burst index suffered. Considering all parameters, especially pulp yield, delignification, papermaking properties, and bleachability, kash and banana peduncle showed the best raw materials for pulping.

References

Jahan MS, Uddin MN, Akhtaruzzaman AF (2016) An approach for the use of agricultural by-products through a biorefinery in Bangladesh. Forest Chron 92:447–452

Anon (2019) https://tradingeconomics.com/bangladesh/agriculture-value-added-annual-percent-growth-wb-data.html (accessed on 24 Jan 2019)

Jahan MS, Lee ZZ, Jin Y (2006) Organic acid pulping of rice straw. I: cooking. Turk J Agric For 30:231–239

Jahan MS, Rahman MM, Sutradhar S, Quaiyyum MA (2015) Fractionation of rice straw for producing dissolving pulp in biorefinery concept. Nord Pulp Paper Res 30:562–567. https://doi.org/10.3183/npprj-2015-30-04-p562-567

Pan XJ, Sano Y, Ito T (1999) Atmospheric acetic acid pulping of rice straw II: behavior of ash and silica in rice straw during atmospheric acetic acid pulping and bleaching. Holzforschung 53:49–55. https://doi.org/10.1515/HF.1999.009

Seisto A, Poppius-Levlin K (1997) Peroxyformic acid pulping of nonwood plants by the MILOX method. 1. Pulping and bleaching. TAPPI J 80:215–221

Jiménez L, De la Torre MJ, Maestre F, Ferrer JL, Pérez I (1998) Delignification of wheat straw by use of low-molecular-weight organic acids. Holzforschung 52:191–196. https://doi.org/10.1515/hfsg.1998.52.2.191

Lam HQ, Le Bigot Y, Delmas M (2001) Formic acid pulping of rice straw. Ind Crop Prod 14:65–71. https://doi.org/10.1016/S0926-6690(00)00089-3

Poppius-Levlin K, Mustonen R, Huovila T, Sundquist J (1991) Milox pulping with acetic acid/peroxyacetic acid. Pap Puu-Pap Tim 73:154–158

Muurinen E (2000) Organosolv pulping--a review and distillation study related to peroxyacid pulping. Dissertation, University Oulu, Finland

Jahan MS, Rukhsana B, Baktash MM, Ahsan L, Fatehi P, Ni Y (2013) Pulping of non-wood and its related biorefinery potential in Bangladesh: a review. Curr Org Chem 17:1570–1576

Tachon N, Benjelloun-Mlayah B, Delmas M (2016) Organosolv wheat straw lignin as a phenol substitute for green phenolic resins. BioResources 11:5797–5815

Jahan MS, Chowdhury DN, Islam MK, Islam MS (2007) Organic acid pulping of jute and its mechanism. Cellul Chem Technol 41:137–147

Watkins D, Nuruddin M, Hosur M, Tcherbi-Narteh A, Jeelani S (2015) Extraction and characterization of lignin from different biomass resources. J Mater Res Technol 4:26–32. https://doi.org/10.1016/j.jmrt.2014.10.009

Kubo S, Uraki Y, Sano Y (1998) Preparation of carbon fibers from softwood lignin by atmospheric acetic acid pulping. Carbon 36:1119–1124. https://doi.org/10.1016/S0008-6223(98)00086-4

Cetin NS, Özmen N (2002) Use of organosolv lignin in phenol–formaldehyde resins for particleboard production: I Organosolv lignin modified resins. Int J Adhes Adhes 22:477–480. https://doi.org/10.1016/S0143-7496(02)00058-1

Podschun J, Saake B, Lehnen R (2015) Reactivity enhancement of organosolv lignin by phenolation for improved bio-based thermosets. Eur Polym J 67:1–11. https://doi.org/10.1016/j.eurpolymj.2015.03.029

Kadla JF, Kubo S, Venditti RA, Gilbert RD, Compere AL, Griffith W (2002) Lignin-based carbon fibers for composite fiber applications. Carbon 40:2913–2920. https://doi.org/10.1016/S0008-6223(02)00248-8

Sarkar M, Tian C, Jahan MS (2018) Activated carbon from potassium hydroxide spent liquor lignin using phosphoric acid. TAPPI J 17:63–69

Browning BL (1967) Methods of wood chemistry, vol I & II. Wiley, New York

Tutuş AH, Eroğlu HÜ (2003) A practical solution to silica problem in straw pulping. Appita J 56:111–115

Rodríguez A, Moral A, Serrano L, Labidi J, Jiménez L (2008) Rice straw pulp obtained by using various methods. BioresourceTechnol 99:2881–2886. https://doi.org/10.1016/j.biortech.2007.06.003

Ateş S, Deniz I, kirci H, Atik C, Okan OT (2015) Comparison of pulping and bleaching behaviors of some agricultural residues. Turk J Agric For 39:144–153

Rahman MM, Islam T, Nayeem J, Jahan M (2014) Variation of chemical and morphological properties of different parts of banana plant (Musa paradisica) and their effects on pulping. Int J Lignocellul Prod 1:93–103

Jahan MS, Chowdhury N, Ni Y (2010) Effect of different locations on the morphological, chemical, pulping and papermaking properties of Trema orientalis (Nalita). Bioresour Technol 101:1892–1898. https://doi.org/10.1016/j.biortech.2009.10.024

Shakhes J, Marandi MA, Zeinaly F, Saraian A, Saghafi T (2011) Tobacco residuals as promising lignocellulosic materials for pulp and paper industry. BioResources 6:4481–4493

Clark TF, Cunningham RL, Wolff IA (1971) A search for new fiber crops. Tappi 54:63–65

Jahan MS, Uddin MN, Rahman A, Rahman MM, Aminb MN (2016) Soda pulping of umbrella palm grass (cyperusflabettiformic). J Bioresour Bioprod 1:85–91

Nieschlag HJ (1960) A search for new fibre crops. Tappi 43:193–201

Bai L, Hu H, Xu J (2012) Influences of configuration and molecular weight of hemicelluloses on their paper-strengthening effects. CarbohydPolym 88:1258–1263. https://doi.org/10.1016/j.carbpol.2012.02.002

Cao S, Ma X, Lin L, Huang F, Huang L, Chen L (2014) Morphological and chemical characterization of green bamboo (Dendrocalamopsis oldhami (Munro) Keng f.) for dissolving pulp production. BioResources 9:4528–4539

Alcaide LJ, Parra IS, Baldovin FL (1990) Characterization of Spanish agricultural residues with a view to obtaining cellulose pulp. TAPPI J 73:173–176

Sharma AK, Dutt D, Upadhyaya JS, Roy TK (2011) Anatomical, morphological, and chemical characterization of Bambusatulda, Dendrocalamushamiltonii, Bambusabalcooa, Malocanabaccifera, Bambusaarundinacea and Eucalyptus tereticornis. BioResources 6:5062–5073

Lourenço A, Gominho J, Marques AV, Pereira H (2012) Reactivity of syringyl and guaiacyl lignin units and delignification kinetics in the kraft pulping of Eucalyptus globulus wood using Py-GC–MS/FID. Bioresour Technol 123:296–302. https://doi.org/10.1016/j.biortech.2012.07.092

Yasuda S, Abe Y, Hirokaga Y (1991) Behavior of lignin in organic acid pulping. Part III. Additive effects of potassium and sodium halides on delignification. Holzforschung 45:79–82. https://doi.org/10.1515/hfsg.1991.45.s1.79

Jahan MS, Rumee JN, Rahman MM, Quaiyyum A (2014) Formic acid/acetic acid/water pulping of agricultural wastes. Cellul Chem Technol 48:111–118

Behin J, Zeyghami M (2009) Dissolving pulp from corn stalk residue and waste water of Merox unit. ChemEng J 152:26–35. https://doi.org/10.1016/j.cej.2009.03.024

Jahan MS, Rahman MM (2012) Effect of pre-hydrolysis on the soda-anthraquinone pulping of corn stalks and Saccharum spontaneum (kash). Carbohydr Polym 88:583–588. https://doi.org/10.1016/j.carbpol.2012.01.005

Jahan MS, Islam MK, Hasan AM, Chowdhury DN (2002) Investigation on soda and soda-anthraquinone (AQ) pulping of Saccharumsp ontaneum. Tappsa J 26:27–33

Scott WE, Abbott JC (1995) Properties of paper: an introduction, 2nd edn. TAPPI PRESS, Atlanta

Retulainen E, Luukko K, Nieminen K, Pere J, Laine J Paulapuro H (2001) papermaking quality of fines from different pulps-the effect of size, shape and chemical composition. In: 55th Appita annual conference. Proceedings Appita Inc, Hobart, p 291

Kang TA, Paulapuro H (2006) Effect of external fibrillation on paper strength. Pulp Pap-Canada 107:51

Hartman RR (1984) Mechanical treatment of pulp fibers for property development. Dissertation, Lawrence University

Seisto A, Poppius-Levlin K, Jousimaa T (1997) Peroxyformic acid pulping of nonwood plants by the MILOX method. Part 2: reed pulp for wood free fine papers. TAPPI J 80:235–240

Jahan MS, Chowdhury DN, Islam MK (2007) Atmospheric formic acid pulping and TCF bleaching of dhaincha (Sesbaniaaculeata), kash (Saccharumspontaneum) and banana stem (Musa Cavendish). Ind Crop Prod 26:324–331

Sahin HT, Young RA (2008) Auto-catalyzed acetic acid pulping of jute. Ind Crop Prod 28:24–28. https://doi.org/10.1016/j.indcrop.2007.12.008

Nimz HH, Tschivner V, Roth M (1983) Proceedings of the international symposium on wood and pulping chemistry, Japan TAPPI, 1: 90

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferdous, T., Jahan, M.S., Quaiyyum, M.A. et al. Formic acid pulping of crops residues available in Bangladesh. Biomass Conv. Bioref. 10, 289–297 (2020). https://doi.org/10.1007/s13399-019-00415-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00415-3