Abstract

This research was performed with the goal of using neutral sulfite semi chemical pulp (NSSC) from populous instead of all or part of MWPI’s NSSC pulp for producing fluting paper. Firstly, NSSC pulp was prepared from populous species and hardwood sawdust under the mill’s cooking conditions. Then, the two mentioned pulp samples were replaced with the mill’s NSSC pulp in a variety of mixing ratios. Next, handsheets with 120 g/m2 were produced of mixed pulps and the properties were measured. The results showed that both raw materials could supply the pulp properties in acceptable way in comparison with control pulp (NSSC pulp of Mazandaran mill).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fluting paper is one of the most useful productions of the paper and board industry that use in packing industry. So for providing some parts of country’s need, Mazandaran wood and paper industries in north of Iran was stablished with capacity of 85,000 tons per year for producing of fluting paper with 113 or 127 g/m2 by Neutral sulfite semi chemical (NSSC) process. In this mill, required raw materials were a mixture of different species of hardwoods that grow in northern forests of Iran. But accompanying with an increment in fluting Paper consumption in recent years, non-forest species were introduced as an alternative to suffice some parts of raw material shortage in Mazandaran wood and paper industries. For this purpose, populous as a fast growing species was used in this study. Besides, a great deal of hardwood sawdust could be used as another alternative in reply to the shortage of raw material. Therefore, these two alternatives were pulped in the way of mill condition. Similar studies about the producing paper from populous were including: Gergely (1973) studied on the comparative investigation of different hardwood’s semi chemical pulps in Hungary. This study showed that populous robusta and marilandica, Betula verrecusa, Salix alba and Alnus glutinosa were recognized as the better species for producing NSSC pulp in comparison to Beech, hornbeam, robinia and oak species (5). Dix (1989) studied on investigation of heart and sapwood effect on properties of NSSC Populous pulp and compared them with the results of producing NSSC pulp from Beech. In comparison to Beech, NSSC populous pulp showed the better strength properties. Also existence of populous bark up to 15 % had no reductive effect on mechanical properties (4). Naraghi (1997) studied on the investigation of juvenile & late wood effect on properties of NSSC pulp from populous deltoids and compared them together. Populous deltoids with 0.95 mil length and 0.41 g/m3 density was belong to hardwoods with medium length of fiber and very light woods (3). Afra (2003) evaluated the paper properties obtained from mixture of populous deltoids and paulownia species by NSSC method. The results showed it is possible to increase the portion of paulownia to populous pulp up to 10 % without any decrease in strength properties. Finally, the main goals of this research were investigation on the possibility of producing NSSC populous pulp with MWPI, s cooking conditions (75 % yield) in first step and investigation on the possibility of replacing NSSC populous pulp instead of all or part of MWPI, s NSSC pulp for producing fluting paper with grammage 127.

Materials and methods

Raw materials

Mazandaran wood and paper industry (MWPI), is one of the paper producing companies of Iran which produces fluting paper of hardwoods mixing using by NSSC pulping method (MWPI pulp). In recent decades, in order to compensate the lack of the forest species, a few ways have been investigated; i.e. replacement of some parts of wood pulps with recycled paper (Ghasemian et al. 2004; Ghaffari et al. 2012; Soltani et al. 2013), nonwood (Hammett et al. 2005; Kissinger et al. 2007; Ghafarzade Mollabashi et al. 2011). In this paper, two other samples have been considered as a raw material for pulping. Actually, firstly, usage of populous chips as a fast growing and non-forest species were considered. The produced pulp was named pulp 1. Besides, hardwood sawdust has been used for pulping, too. The produced pulp was named pulp 2. Both populous chips and sawdust were prepared from Mazandaran pulp and paper factory. In this case, a combination of populous over American and populous deltoids were used as a sample for pulp 1. In contrary, in producing of MWPI pulp, not just one sample, but a variety of hardwood species had been used as a pulping sample.

Before starting pulping tests, sawdust was screened to evaluate size distribution of the pieces. For this purpose, screens with 115, 100, 80, 60, 40, 20 and 9 mesh were settled on each other so that least 9 meshes was the lowest and 115 mesh was the highest screen.

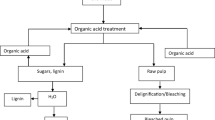

Pulping

Both mentioned pulp samples were pulped using by NSSC cooking liquor of MWPI. The characteristics of the cooking liquor have been illustrated in the Table 1 below:

The time at temperature was variable (from 60 to 200 min) in order to reach yield of 75 %. The selected treatment was chosen based as yield value. Afterwards, the selected pulp samples namely pulp 1 and pulp 2 were defiberated using by laboratory defiberator. Then, the pulp samples were refined (based as T 248 om–88 of TAPPI standard test methods) up to 7000 RMP in a laboratory PFI mill to achieve the freeness of 410 CSF. Afterwards, both pulp samples classified using a Mc-net classifier. For this purpose, screen with 14- 30, 50, 100 and 200 were used.

Mixing of the pulps

In this step, the two refined pulp samples (pulp1 and pulp 2) were separately replaced with MWPI pulp in a variety of ratios; Table 2 shows the replacement ratios of the two selected pulp with MWPI pulp sample.

Next, in order to realize the best mixture ratio, standard handsheets with grammage of 120 were made based as T 205 om–88 of the TAPPI standard test methods. Also, based as the TAPPI test methods, the pulp properties including: stiffness, breaking length, burst, tear, corrugating medium test (CMT), ring crush test (RCT), gurley were measured and were analyzed by using one way Anova and Duncan’s multiple comparison test at 95 % confidence level.

Results and discussion

Sawdust classification

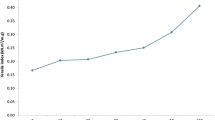

The classification results of hardwoods sawdust have been brought in Fig. 1. As seen, the highest amount related to sawdust with 9 mesh screen and lowest one contributes to group of 115 mesh screen (the pieces which not pass from screen with mesh 115).

Shive amount of pulp

After ending pulping tests and selection of the favorite treatment (for mixing in next step), uncooked parts of the pulp have been evaluated. As indicated in Fig. 2, the shive amount of sawdust pulp is much more than the two other pulp samples. In adition, there is not a siginificant difference between the shive amounts of pulp 1 and MWPI pulp and they are in a same group from statistical point of view.

Fiber classification

The results of fiber classification for each three pulp samples have been shown in Fig. 3.

As seen in Fig. 2, the amount of fibers with class 14–28, for populous pulp is higher than MWPI one and meanwhile it is more than sawdust pulp. In the higher mesh screen, the trend is completely different. As indicated in the each four mesh screen, populous pulp values is less than two other one. It could be support the higher values of tear strength for the pulp 1 compared to pup 2 and MWPI pulp. In fact, the average size of the fibers of populous pulp is more than the two other pulp sample. This fact is in consistent with the values of strength for the all three pulp samples.

Pulp properties

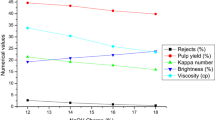

The replacement of populous pulp (pulp 1) has a different effect on the final mixed pulp in comparison of sawdust pulp (pulp 2). In total, usage of pulp 1 as an alternative of MWPI has a positive effect on the properties of final mixed pulp. Figures 4, 5, 6, 7, 8, 9, 10, 11 and 12 have been illustrated the effect of populous replacement with MWPI pulp sample. Totally, investigation of physical and strength properties showed that there was a similar trend about the factors i.e. burst, stiffness, breaking length, tear, and Gurley. As seen, in level of 5 % probability, significant difference was observed among the results of 7 treatments. Also, the most value for all above mentioned parameters belong to treatment 7 (100 % populous) and the least one belong to treatment 1 (100 % MWPI pulp). As a matter of fact, it could be concluded that, with an increase in amount of populous pulp addition, an increase has been observed in the value of mentioned parameters. About CMT and RCT, the trend was approximately similar; in fact, usage of populous pulp has increased the values and the treatment with 100 % populous showed the highest value; but the least value related to treatment with 20 % populous. Also, usage of populous pulp, has a reverse effect on optical properties i.e. yellowness and opacity; so that, treatment with no usage (0 percent) of populous produced yellowest and most opaque paper and treatment 7 with highest usage of populous pulp has caused to produce paper with least amount of the yellowness and opacity. As expected, in a reverse way, brightness value has been increased. Figures 13, 14 and 15 show the optical properties of the pulps.

In evaluation of sawdust potential as an alternative, a similar trend has been observed. It has been found that with an increment in the value of sawdust pulp ratio in final mixed pulp, strength properties have been increased and highest value depended to 10 percent ratio (Figs. 16, 17, 18, 19, 20, 21, 22, 23, 24). Noted that there was not significant difference between 10 and 100 percent and the both ratio were in a same statistical group. As mentioned, sawdust replacement ratio was 0, 5, 10 and 100. Also, usage of sawdust has a reverse effect on optical properties i.e. yellowness and opacity; so that, with an increment in the ratio of sawdust pulp 1 final mixed pulp, both mentioned parameters have been decreased and 5 percent ratio showed highest value. But, in a different way, brightness value has been increased. Figures 25, 26 and 27 show the effect of sawdust replacement with MWPI pulp on optical properties. It could be concluded that usage of sawdust pulp has resulted to produce relative brighter and more transparent paper.

According to the results, utility of NSSC populous pulp as an alternative of MWPI, s NSSC pulp has improved the strength properties of the pulp. The most probable reason could be the structure of populous species means less lignin amount and more carbohydrate amount in comparison of a blend of hardwoods. The direct relationship between bonding strength properties such as burst, tensile and tear support this idea. Besides, low ratio of cell wall thickness to cell wall diameter and less density, results to cook more uniformly which produces least amount of shive and fine contents. It means that the pulp will refined with a lower intensity and average length of fibers will be rather high. This idea will confirm the effect of populous structure on higher strength properties.

Conclusion

The amount of fibers with class 14–28, for populous pulp is higher than MWPI one and meanwhile it is more than sawdust pulp. It could be support the results of tear strength thatrepresent higher value for the pulp 1 compared to pulp 2 and MWPI pulp.

With a usage of populous pulp as an alternative of MWPI’s NSSC pulp, it is possible to produce NSSC pulp with the relative better strength properties. Moreover, sawdust pulp usage could increase the value of pulp properties, too. It will be valuable alternative for hardwood species in MWPI pulp. In addition, it has been observed that both alternatives resulted to produce brighter and less opaque paper compared to MWPI pulp.

References

Afra E (2003) Comparative investigation on paper properties produced from combination of populous deltoids and paulownia in NSSC method. Master of Science thesis, Gorgan University of Agriculture and Natural Resources (in Persian)

Gergely I (1973) Comparative investigation of different hardwood semi chemical pulps. Abstract bulletin of the institute of paper chemistry, p 44

Ghafarzade Mollabashi O, Saraeian AR, Resalati H (2011) The effect of surfactants application on soda pulping of wheat straw. BioResour 6(3):2711–2718

Ghaffari M, Ghasemian A, Resalati H, Asadpour Gh (2012) Determination of the optimum use of cationic starch on the basis of the mechanical strengths of mixed OCC and virgin NSSC pulps. Iran J Wood Paper Ind 2(2):121–133

Ghasemian A, Enayati A, Resalati H, Pinder KL (2004) A study on the properties of local ONP/OMG deinked pulp in comparison with local CMP pulp. Iran J Nat Resour 57(3):537–550

Hammett AL, Youngs RL, Sun X, Chandra M (2005) Non-wood fiber as an alternative to wood fiber in chinas pulp and paper industry. Holzforschung 55(2):219–224

Kissinger M, Fix J, Rees WE (2007) Wood and non-wood pulp production: comparative ecological footprinting on the canadian prairies. Ecol Econ 62(3–4):552–558

Naraghi MA (1997) Comparison of paper strength produced from populous deltoids wood in NSSC method. MSc thesis, Gorgan University of Agricultural Sciences and Natural Resources, 120 p (in Persian)

Soltani F, Ghasemian A, Saraeeyan AR, Resalati H (2013) The effect of old magazine (OMG) deinked pulp on the properties of populus deltoides CMP pulp. J Wood For Sci Technol 20(1):91–97

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Forouzanfar, R., Sukhtesaraie, A., Ahmadi, M. et al. NSSC pulp from planted populus and hardwood sawdust for flutting production. J Indian Acad Wood Sci 13, 73–81 (2016). https://doi.org/10.1007/s13196-016-0168-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-016-0168-4