Abstract

Affected by various uncertain factors, the critical chain is random. The article studies the critical chain and its randomness, and points out that when there is no buffer, the critical chain method and the critical path method have the same identity, and the central limit law of the same distribution can solve the randomness of the critical chain. This conclusion is mainly based on the following research: (1) The paper analyze the technical points of the critical chain, and points out that the setting of the buffer can be replaced by the operation time of the process; (2) The principles and expressions are proposed for determining the critical chain; (3) The influence factors of the randomness of the critical chain are analyzed; (4) The randomness of the random critical chain is determined based on the central limit law of the same distribution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The traditional critical path methodology (CPM) is a tool for planning, scheduling, and coordinating complex engineering projects, but CPM is particularly limited in resolving resource conflicts. In order to solve the problem of limit resources in the construction project, Dr. Goldratt proposed the Critical Chain Method (CCM) (Taghipour et al. 2020). Once proposed, this method has aroused great interest and extensive researches in academia. CCM has been widely accepted to be superior to the traditional Critical Path Method (CPM) (Taghipour et al. 2020). However, through a comparative study by the authors, it is concluded that there is no essential distinction between the two, and the only difference between those two is about the method of determining the priority of resource allocation and the buffer zone (Goto 2017).

The critical chain proposed based on the constraint theory has significant advantages in solving resource constraints and construction time waste caused by inefficiency of workers. The critical chain has two technical points when solving the problem, the identification of the critical chain and the setting buffer zone (Yang et al. 2014).

Adopting a heuristic algorithm determine the start sequence, adjust the logical relationship between the work predecessors and successors, and obtain the longest chain in time that meets the resource limit requirements which is the critical chain identified. However, the heuristic algorithm can only solve the problem of determining the operation time of the sequence.

In the middle of construction process, affected by various uncertain factors, the time factors such as the earliest start time and the latest finish time of the activity are uncertain. It also leads to uncertainties in construction sequence variance and activity duration. The randomness of sequence duration leads to the uncertainty of the total construction duration after the project logical sequence change. The \(ACTIM\) algorithm cannot identify critical chains with uncertain sequence duration and total duration. When there is more than one critical chain, the variance of different critical chain sequences’ duration is different, and there are differences between the critical chains. The uncertainty of the sequence duration of the critical chains, the uncertainty of the total construction duration, and the differences between the critical chains lead to the randomness of the critical chains.

The purpose of the buffer zone is to absorb the risks caused by reducing the duration of critical chain processes. However, the setting of buffer zone is not scientific and reasonable, and there exists a problem that the buffer zone may be set too large or too small.

The traditional method is not applicable to the identification of critical chains with random characteristics and the problem of unreasonable buffer settings. Based on this, the article studied the randomness of critical chains and the problem of buffer setting. This paper solves the problem of randomness in scheduling.

2 Literature review

On solving the problem of limited resources, CCM has two technical key points of critical chain identification and buffer zone setting. Research the critical chain through these two technical points. Qian et al. (2009) improved the critical chain buffer by integrating resource supply, network complexity and project manager risk appetite. Zhao et al. (2010) improved the genetic algorithm and inserted the feed buffer to deal with the uncertainty problem, and innovated the critical chain method. Ma et al. (2014) proposed an improved framework based on the multi-mode activity execution structure to solve the buffer size and multi-resource balance problems. Lucko et al. (2016) put forward the concept of risk management and control of the critical chain, but still retains the buffer zone. Ciarapica et al. (2017) considered the impact of human factors on the project in the project. Goto (2017) pointed out the problem of uncertain project duration with limited resources, and the MPL (Maximum Plus Linearity) method can be used. She et al. (2020) proposed a buffer sizing method based on network decomposition. Aramesh et al. (2020) proposed a new soft computing framework that improved the buffer. Dong et al. (2021) proposed a workflow scheduling based on deep reinforcement learning in the cloud environment, and the result showed that the workflow scheduling by the deep reinforcement learning is more effective comparing with other four single objective heuristic algorithms. Modieginyane et al. (2019) implemented a Software Defined Wireless Sensor Network (SDWSN) approach coupled with Discrete Event Simulation (DES) and a highly extensible and scalable Software Defined Networking (SDN) controller–OpenDayLight (ODL), to implement a software-oriented network environment to increase network service adaptability and simplify network management. An inversion procedure based on an Artificial Neural Network (ANN) approach is proposed in order to determine the moisture content of the felts. Measurements on several reference felts, with different density, thickness, and moisture content levels, ranging from dry to waterlogged state, proved the effectiveness of the proposed sensor architecture and the ANN-based inversion procedure (Gentili et al. 2006). To handle the uncertainty of the blood supply chain environment, a robust optimization approach is devised to tackle the uncertainty of parameters, and the TH method is utilized to make the bi-objective model solvable (Hosseini-Motlagh et al. 2020). Han et al. (2021b, a) proposed a reasoning model for emergency measures that can be applied in the scheduling control of industrial projects, which is an excellent way to provide effective case support and decision data for the improvement of early warning and feedback tracking theory in project scheduling control. Han (2021) proposed a WBS-free scheduling method based on database relational model, which solved the problem of diversity in scheduling form and implement the innovation of scheduling method. The repair process to improve the virtual age of used products was investigated and integrated to forward flow as a closed-loop supply chain (CLSC), and the proposed mixed-integer non-linear model has been solved by three metaheuristic algorithms: Particle Swarm Optimization Algorithm (PSO), Genetic Algorithm (GA), Invasive Weeds Optimization algorithm (IWO) (Keshavarz-Ghorbani et al. 2021). Han (2021) proposed an improved ant colony algorithm to determine the critical path by setting the path distance and time as negative, while the transition probability remains unchanged. Han et al. (2021c) analyzed the complex network comprising different models of industrial projects, and it has been concluded that the characteristics of the agent maintain an advantage in competition.

2.1 Identification of critical chain

The identification of critical chain is an algorithm that allocates resources reasonably under the resource constraints. There are quite a few methods for identifying, the most commonly used is a heuristic algorithm based on priority rules proposed by (Goldratt 1977a, b), also known as \(ACTIM\) value method.

In this formula,\(T\)- Total Duration,\({LS}_{i-j}\)-Latest Start Time of an activity.

When resource conflicts occur between activities, the priority of resource allocation can be determined by the \(ACTIM\) value: the activity with larger \(ACTIM\) value has higher priority over the activity with smaller \(ACTIM\) value on resource allocation (Goldratt, 1977a, b). This may cause changes in the logical relationships between related activities in the original network diagram and delays in the total construction duration, and there will be multiple critical chains. However, there has not been sufficiently studied regarding this issue up to present, and neither on how to represent the critical chains under the resource constraints (Mckay and Morton 1998).

2.2 Setting buffer zone and its problems

In the execution of a project, at the beginning people are more tend not to hurry to work at full strength until it’s getting closer to the project finish phase. It's like students tend to waste most of their time outside of studying, whereas study is extremely hard right before the exam coming. This phenomenon is called “Student Syndrome”, which is expressed in Parkinson's Law- How much time left will automatically become the time needed to complete that work, that is, the work will always be dragged down to be completed to the last minute, and never be completed ahead of time.

To mitigate the impact of “Student Syndrome” or Parkinson's Law on the project duration, the critical chain technology proposed a method of setting a buffer zone. The essence of it is to reduce the working time of each process and gather the reduced time together for setting up a buffer area for use. Common buffer setting methods are 50% clipping method and root variance method (Zhang et al. 2020).

No matter which method is used to set the buffer zone, it is a subjective method and lacks scientific basis. The purpose of setting up the buffer zone is to solve the problem of “Student Syndrome”, but this is not the only solution. It is entirely possible to make a scientific and reasonable estimate of the activity duration by studying various uncertain factors affecting the activity duration, including “Student Syndrome” that may occur. Therefore, it is not necessary to set the buffer zone (Goldratt, 1977a).

3 Methodology

3.1 Determination and representation of critical chains

3.1.1 Rules for determining critical chains

According to the \(ACTIM\) value method proposed by Goldrat (1977a, b), it mainly solves the issue of resource allocating priority when the resource is limited, and meets the constraint condition of resource priority allocation order, which may change the logical relationships between some activities s in the original network and form new paths. It increases the difficulty of identifying critical chains, for which the following basic rules must be followed:

-

1)

Meet the constraints of resource limits.

-

2)

New paths formed after changes in the logical relationships between certain activities must be considered.

-

3)

The sum of the durations of all activities on the same path is the longest.

This often leads to multiple critical chains. How to present the critical chain clearly and intuitively is a problem to be solved.

3.1.2 Representation of critical chains

There are many researches on the critical chain, but there is still no consensus has been reached on the representation of the critical chain, and the problem that the critical chain representation is unclear still exists. The key to solving this problem is to clearly show the change in the logical relationships between some activities after meeting the resource constraints. This paper proposed two representations of critical chains.

Taking Fig. 1 as an example, assuming that all activities use the same resource and the buffer zone setting is not considered, the numbers in parentheses on the arrow line indicate the resource requirements (cubic meters / week), and the numbers below the arrow line indicate the duration of activity (week). The maximum resource limit is 20 cubic meters per week.

3.1.2.1 Representation 1

According to the resource constraints and critical chain determination rules, determine the new logical relationships and critical chains between the activities, and use the double solid line or thick solid line to directly mark out on the network diagram. The double solid lines in Fig. 2 represent two critical chains: A–C–F–G and B–D–F–G. If the work in the network diagram has no logical relationship, after adjusting the resources, it becomes a Finish-Start relationship, and it is located on the critical chain, and the operations are still marked with double solid lines. For example, activity A and activity C originally had a parallel relationship, and after adjustment of resources, there was a Finish-Start relationship, and a double solid line was artificially added to form a complete critical chain. In this way, the critical chain and the change in the logical relationships between the activities that meet the resource limit can be seen intuitively and clearly from the figure. The wavy line in the figure indicates the float time.

3.1.2.2 Representation 2

Add nodes and activities to annotate the changes of critical chains and relevant activity logic relationships.

The first representation method is relatively simple and easy to operate, but there will arrow line crosses that do not meet the drawing rules of the network diagram. If the work in the network graph originally had no logical relationships, after the resource adjustment, the logical relationship of Finish-Start can be represented by adding nodes and dummy activities. The critical chain is still represented by double solid line or thick solid line. As shown in Fig. 3, node 3 and dummy activity 2–3 are added between activities A and C. Similarly, nodes 8 and 9 are new nodes. Other places are exactly the same as Fig. 2.The critical chains are still A–C–F–G and B–D–F–G. The expression is clearer, especially when there are multiple key chains, which is more advantageous.

3.2 Comparison of CCM and CPM

A comparative study of the Critical Chain Method and Critical Path Method using the network plan shown in Fig. 4 is based on the following assumptions:

-

1)

The duration of every activity is a fixed value and does not change;

-

2)

Do not consider the buffer zone setting for the critical chain;

-

3)

Once an activity is started, it must not be interrupted to ensure the integrity of the construction process;

-

4)

The resource allocation intensity of each activity is balanced and reasonable, and will not be changed during the optimization process.

-

5)

All activities use the same resource, and the resource limit is \({R}_{max}=12\) (cubic meters / week)

The meanings of the parameters in Fig. 4 are consistent with those in Fig. 1. For example, the parentheses above the arrow of the process A indicate its resource requirements (cubic meters/week), and the part below the arrow indicates its duration (weeks).

3.2.1 CPM solution process

3.2.1.1 CPM optimization fundamentals

Using the peak-cutting method in CPM (Zhang et al. 2020), assuming that the total resource demand exceeds the resource limit at a certain time period, there are several activities being performed at the same time, and any two activities A and B are changed from the original parallel operation to A being performed before B (Olivieri et al. 2019), as shown in Fig. 5. Process A and B are transformed from the original parallel relationship to process B, which is an immediate post-work of process A.

Then proceed with the new sequence, the extended construction duration is:

where,\(\Delta {T}_{a,b}\)—when activity A is arranged before activity B, the corresponding duration is extended. \(\Delta {T}_{a,b}\)—The smallest one will get the top priority on resource allocation.

\({EF}_{a}\)—Early Finish time of activity A.

\({LS}_{b}\)—Late Start Time for activity B.

Similarly, we can get \(\Delta {T}_{a,b}\), compare \(\Delta {T}_{a,b}\) and \(\Delta {T}_{b,a}\), and choose the smallest one as the optimization solution.

3.2.1.2 Main optimization steps

During the period (3,4), A and C are running simultaneously (Burns and Cao 2011).

\({R}_{(\mathrm{3,4})}\)—The consumption of resources in the period (3,4).

\({R}_{a}\)—Resource requirements required for process A.

\({R}_{c}\)—Resource requirements required for process B.

\({R}_{max}\)—Maximum limit of resources.

Priority of resource allocating of resources is required (Kim et al. 2005). There are two possible solutions: activity A is performed before activity C and the duration is not extended; Activity C is performed before activity A and the duration is extended by 2 days. So, choose activity A before C. As shown in Table 1.

During the period of (7, 9), there are D, E, and F working simultaneously.

\({R}_{(\mathrm{7,9})}\)—The consumption of resources in the period (7,9).

Priority of resource allocation is required. There are 6 possible solutions. Activity D is performed before activity E and the duration is extended by 1 day. Activity D is performed before activity F and the duration is not extended. Activity E is performed before activity F and the duration is extended by 1 day; Activity E is performed before activity D and the duration is extended by 2 days; Activity F is performed before activity D and the duration is extended by 5 days; Activity F is performed before activity E and the duration is extended by 1 day. So select activity D before activity F, as shown in Table 2.

3.2.1.3 CPM-based determination and representation of critical chain

As shown in Fig. 6, the logical relationship between steps A and C and steps D and F in Fig. 4 is changed. When considering resource constraints, using the peak cutting method, processes A and C, processes D and F change from a parallel relationship to a cohesive relationship. Activities A and C and activities D and F are new logical relationships.

3.2.1.4 CCM solution process

To solve the network plan resource constraint issue shown in Fig. 6 by applying critical chain method, the main steps are indicated as the following:

3.2.1.5 Calculate the late start time (LS) of each activity and the total duration of the project.

The total duration of the network plan was determined to be 13 weeks by the CPM method. The latest start time of each activity is shown in the second row of Table 3.

3.2.1.6 Calculate the priority of resource allocation for each activity

Adopt the heuristic algorithm and obtain the \(ACTIM\) value of each activity according to formula (1), see the third row of Table 3.

3.2.1.7 Determine the start time and end time of the activity

For allocating resources based on the \(ACTIM\) value and constraints, if the amount of simultaneous resources demand in a certain period exceeds the maximum resource limit. The resource with the highest \(ACTIM\) value is allocated first, and the smaller one is pushed backward. According to this method, until all the activities meet the resource limit requirements, the start time and finish time of each activity are re-determined. The specific results are shown in rows 6 and 7 of Table 1.

3.2.1.8 Identify critical chains

In order to meet the resource limit requirements, activities A and C, and activities D and F are transformed from the original parallel relationship to the immediately Finish-Start relationship. At this time, the length of the line formed by steps A, D, and F is the longest, so the critical chain is A-D-F, as shown in Table 3.

3.2.1.9 Comparison of CCM and CPM results

Based on the above research, we analyze the similarities and differences between CCM and CPM, as shown in Table 4.

From the above results, there is no difference between CCM and CPM when the buffer zone setting is not considered.

The article compared the Critical Chain Method and Critical Path Method through case studies, and drew the following conclusions:

-

1)

The buffer zone setting in the Critical Chain Method is a subjective method and lacks scientificity. To solve the problem of “Student Syndrome”, other methods can be adopted;

-

2)

Two representation methods of the critical chain were proposed to make the expression of the critical chain clearer and more intuitive;

-

3)

If the buffer zone setting is not considered, there is essentially no difference between Critical Chain Method and Critical Path Method; the only difference is about the method of determining the priority of resource allocation.

Therefore, the comparative study of this article enriches and improves the Critical Chain Method and opens up the connections between CCM and CPM.

3.3 Uncertainty factor analysis

The randomness of the critical chain is mainly caused by the uncertainty of the total duration of the construction sequence (Mckay and Morton 1998) The critical chain projects with large time span and complicated procedures are affected by various uncertain factors such as the local economy, politics, and technics, resulting in turbulence of the durations of activities, which ultimately affect the total duration of the project. The critical chain sequence duration is determined by four factors: construction quantity, planned productivity rate, manpower and equipment manhour invested, and the number of shifts in work (Mckay and Morton 1998, Olivieri et al. 2019).

3.3.1 Construction quantity

Uncertain factors affect the construction sequence duration by affecting the construction quantity. Once the construction drawings are determined, the project's quantity will usually not change, but design drawings’ defects, construction problems and other factors can cause the project's quantity to change, and the activity duration and the total construction duration would change consequently (Hegazy et al. 2010).

3.3.2 Productivity rate

Uncertainty affects the duration of a sequence by affecting the planned productivity rate. Although the planned productivity rate is reasonable and scientific, deviation always exists between the plan and the actual productivity. In fact, unexpected situations happen in real-world construction jobs. For example, the impact of bad weather on workers’ efficiency makes the critical chain impossible to be implemented with the planned productivity rate, which affects the construction sequence duration.

3.3.3 Manpower and manhours

During project implementation, in the manpower and equipment manhours are maintained in a constant state. Therefore, once personnel and work shift change would affect the construction sequence duration and project duration.

3.3.4 Working shifts

To complete the work as soon as possible, the construction shift change causes the actual progress to be inconsistent with the planned progress, which affects the activity duration.

Therefore, the activity duration is affected by construction quantity, planned productivity rate, manpower and equipment manhours, and work shifts. Any change in any single factor would affect the construction sequence duration of the critical chain, and the duration of the construction sequence is random.

3.4 Estimation of an activity duration

Due to the existence of many uncertain factors mentioned above, the duration of an activity is uncertain, which makes the start and finish time of each activity and the total construction duration uncertain. For this reason, it is necessary to make a scientific and reasonable estimation of the activity duration. Commonly used approaches are theoretical calculation, three-point estimation and two-point probability estimation, etc.

Theoretical calculation refers to the estimation about activity duration based on construction quantity, productivity rate, manpower and equipment manhours, and work shifts, but the theoretical calculation does not take into account the impact of uncertain factors on the project activity duration, and the estimation results are not accurate. In order to make the activity duration estimation as scientific and accurate as possible, the most optimistic time, common time and most pessimistic time of the activity duration are estimated under the influence of uncertain factors, and the three estimated times are used as the process under uncertainty basic data for working hours (Goto 2017).

Assume that the activity duration follows the \(\upbeta \) distribution, and estimate the expectation of each activity duration. The calculation formula is as follows:

Among them, \(a\) is the most optimistic operation time of process \(i\);

\(b\) is the most probable operating time of process \(i\);

\(c\) is the most pessimistic operation time of process \(i\).

The corresponding variance of operation time is:

3.5 Probability estimation and determination of critical chains

3.5.1 Estimate of total construction period and completion probability

In order to solve the problem of the randomness and the irrational buffer setting of the critical chain, it is proposed to use the completion probability of the critical chain to control the time limit of the critical chain to ensure that the efficiency of the project can be effectively solved. It also avoids the problem that the buffer is too large or too small due to the irrational buffer settings. Fundamentally, the points that are prone to problems in the critical chain are deeply controlled to achieve the purpose of scientific and reasonable management and control of the project.

The expected value of the operation time of each process on the key chain is \(\mu_{i}\), and the variance is \(\sigma_{i}^{2}\). According to the nature of the expectation and variance, the total duration expectation and variance can be obtained:

Assume that the operating time of each process of the engineering project follows the same distribution. According to the limit theorem of the same distribution center, it can be known that when there are enough processes on the critical chain, the total construction period follows the normal distribution. Its completion probability function at a specific time is:

Under certain conditions, the completion probability of a project's total duration is:

Among them: \({T}_{r}\) is the designated duration or contract duration;

\(\mu \) is the expected duration of the critical chain, that is, the expected value of the total duration;

\({\sigma }^{2}\) is the variance of the total duration on the critical chain;

\(n\) is the nth critical chain.

3.5.2 Identification and representation of critical chains

When the activity duration is uncertain, the critical chain is random. At this time, the determination of the critical chain must also meet the following conditions:

-

1)

Meet the constraints of resource limits;

-

2)

The sum of the duration of various activities on the critical chain is the longest;

-

3)

The probability of completion is the lowest. When there are multiple critical chains, the total completion probability of the network plan is the product of the completion probability of each critical chain.

When the operation time of the process is uncertain, the specific steps of the critical chain representation based on the double-coded time-scale network diagram are as follows:

-

4)

Based on the determined duration of each activity, it is expected to obtain the start time and finish time of each activity that meets the resource limit conditions based on the ACTIM value;

-

5)

Draw a time-scaled network diagram based on the start time and finish time, and draw double solid lines for the sequence in which the time on the critical chain is sequentially connected, and at the same time, add nodes manually for the node-free time sequence transfer. As shown in Fig. 2, when there are multiple key chains, all can be represented by one icon.

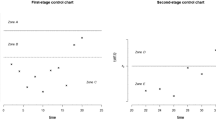

3.5.3 Examples

-

1)

Known conditions: The relevant information of the project is shown in Table 5. The resource limit is \(Ra=12\) units, and the specified construction period is \(Tr=14\mathrm{d}\).

-

2)

Draw network diagram. Based on the known conditions shown in Table 5, the network is drawn as shown in Fig. 7. The numbers above the arrows indicate the resource intensity of the activity, and the numbers below the arrow indicate the expected activity duration.

-

3)

Identify critical chains. \(ACTIM\) heuristic algorithm is adopted to identify the critical chain, determine the \(\mathrm{ACTIM}\) value, and the expected start time and finish time of each activity.

According to the above method, two critical chains A–C–E–G and A–D–F can be obtained, and the expected construction duration is 13d.

-

4)

According to the data in Table 6, draw the diagram of the critical chain representation in the network diagram, as shown in Fig. 8 below.

-

5)

There are two critical chains. The completion probability of different critical chains in the specified construction duration are:

3.5.3.1 For the critical chain A–D–F

Variance:\({\sigma }_{1}^{2}={\sigma }_{A}^{2}+{\sigma }_{D}^{2}+{\sigma }_{F}^{2}\),\({\sigma }_{1}^{2}=1.2\),When the specific duration is 14d, according to formula (6), \(P_{1} = 0.8\) can be obtained.

3.5.3.2 For the critical chain A–C–E–G

Variance:\({\sigma }_{2}^{2}={\sigma }_{A}^{2}+{\sigma }_{C}^{2}+{\sigma }_{E}^{2}+{\sigma }_{G}^{2}. {\sigma }_{2}^{2}=2.6\), when the specific duration is 14d, \(P_{2} = 0.7\) can be obtained.

At 14d, the total completion probability of the critical chain is \(P=0.56\), and critical chain A–C–E–G need to be controlled well to ensure completion on time.

4 Results

By analyzing the uncertain factors of the critical chain, the article has made the following conclusions:

-

(1)

The uncertainty of the activity duration of the critical chain sequence can be confirmed by the expectation of the activity duration;

-

(2)

Using fixed probability to determine the completion probability at a specific time can achieve the purpose of determining which critical chain to direct the construction;

-

(3)

The critical chain representation method based on the time-scaled network graph is used to make the critical chain representation more intuitive and clearer.

5 Discussion

The article studies the critical chain and the significance of its randomness problem in three aspects:

-

(1)

Analyze the technical points of the critical chain, determine the principles and expression methods followed by the critical chain, and propose for the first time that the scientific evaluation of the process operation time can replace the setting of the buffer zone.

-

(2)

Comparing the critical chain method and the critical path method, the gap between the two methods is broken. When guiding the actual construction, the two methods can also be converted to verify the accuracy of the construction organization plan and reduce mistakes.

-

(3)

Based on the randomness of the critical chain, the probability of completion of the random critical chain and the determination method of the total construction period were proposed, which improved the theoretical system of the critical chain.

6 Conclusions and future research

The main conclusions of the article on the critical chain and its randomness are as follows:

-

(1)

The setting of the critical chain buffer is not necessary, and it can be realized through scientific evaluation of process operation time;

-

(2)

The critical chain method and the critical route method have the same identity except for the algorithm gap when solving resource constraint problems;

-

(3)

The main influencing factors of the randomness of the critical chain can be determined by analyzing the uncertain factors that affect the operation time of the process;

-

(4)

The central limit theorem of the same distribution can determine the probability of completion of the random critical chain and the total construction period;

-

(5)

The identification of multiple critical chains and the determination of the probability of completion can be achieved through the central limit law of the same distribution.

The main defect of this research is the lack of a large amount of practical verification. In the future, relevant staff can closely integrate the research conclusions of the paper with practice to verify the general applicability of the conclusions of the paper.

Data availability

The data used to support the findings of this study are included within this article. Requests for more details should be made to the corresponding author.

Abbreviations

- CPM:

-

Critical Path Methodology

- CCM:

-

Critical Chain Method

- ACTIM:

-

Activity Time(Heuristic Algorithm)

- T:

-

Total Time

- LF:

-

Late Fnish Date

- EF:

-

Early Fnish Date

- LS:

-

Late Start Date

- R:

-

Resource

- P:

-

Probability

References

Aramesh S, Mousavi SM, Mohagheghi V, Zavadskas EK, Antucheviciene J (2020) A soft computing approach based on critical chain for project planning and control in real-world applications with interval data. Appl Soft Comput 98(6):106915. https://doi.org/10.1016/J.ASOC.2020.106915

Burns J, Cao Q (2011) Deterministic, path-sensitive heuristics for project earned value management. Int J Proj Org Manag 3(1):1–21. https://doi.org/10.1504/IJPOM.2011.038861

Ciarapica FE, Mazzuto G, Bevilacqua M (2017) A heuristic scheduling algorithm based on fuzzy logic and critical chain project management. Int J Proj Org Manag 9(4):303. https://doi.org/10.1504/IJPOM.2017.088244

Dong T, Xue F, Xiao C, Zhang J (2021) Workflow scheduling based on deep reinforcement learning in the cloud environment. J Ambient Intell Human Comput. https://doi.org/10.1007/s12652-020-02884-1

Gentili GB, Riminesi C, Tesi V (2006) Low cost microwave sensor for moisture content measurement in paper milling industry. Sens Imaging 7:155–173. https://doi.org/10.1007/s11220-006-0027-2

Goldratt E.M (1997a) Critical chain. The North River Press, Great Barrington

Goldratt E.M.(1997b) Critical chain. The North River Press, Great Barrington

Goto H (2017) Forward-compatible framework with critical-chain project management using a max-plus linear representation. Opsearch 54:201–216. https://doi.org/10.1007/s12597-016-0276-3

Han XK (2021) WBS-free scheduling method based on database relational model. Int J Syst Assur Eng Manag. https://doi.org/10.1007/s13198-021-01106-x

Han XK, Yan WZ, Lu M (2021a) Research on reasoning concerning emergency measures for industrial project scheduling control. Adv Civil Eng. https://doi.org/10.1155/2021/5595354

Han XK, Yan WZ, Lu M (2021b) Intelligent critical path computation algorithm utilising ant colony optimisation for complex project scheduling. Complexity. https://doi.org/10.1155/2021/9930113

Han X, Yan W, Lu M (2021c) Research on the coordination mechanism of major industrial project engineering and construction multi-agents based on structural holes theory. PLOS ONE 16(8): e0255858. https://doi.org/10.1371/journal.pone.0255858

Hegazy T, Menesi R (2010) Critical path segments scheduling technique. J Constr Eng Manag 136(10):1078–1085. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000212

Hosseini-Motlagh SM, Samani MRG, Homaei S (2020) Blood supply chain management: robust optimization, disruption risk, and blood group compatibility (a real-life case). J Ambient Intell Human Comput 11:1085–1104. https://doi.org/10.1007/s12652-019-01315-0

Keshavarz-Ghorbani F, Khamseh A (2021) A Modeling and optimizing a multi-period closed-loop supply chain for pricing, warranty period, and quality management. J Ambient Intell Human Comput. https://doi.org/10.1007/s12652-021-02971-x

Kim K, Garza JMDL (2005) Evaluation of the resource-constrained critical path method algorithms. J Constr Eng Manag 131(5):522–532. https://doi.org/10.1061/(ASCE)0733-9364(2005)131:5(522)

Lucko G, Thompson RC, Yi S (2016) Simulating the balanced allocation of project float to the critical path in network schedules. Construct Res Congress. https://doi.org/10.1061/9780784479827.076

Ma G, Wang A, Nan L, Gu L, Qi A (2014) Improved critical chain project management framework for scheduling construction projects. J Const Eng Manag. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000908

Modieginyane KM, Malekian R, Letswamotse BB (2019) Flexible network management and application service adaptability in software defined wireless sensor networks. J Ambient Intell Human Comput. https://doi.org/10.1007/s12652-018-0766-7

Mckay K N & Morton T E (1998) Review of: “Critical Chain” Eliyahu M. Goldratt The North River Press Publishing Corporation, Great Barrington, MA, 1997. ISBN 0–88427–153–6. IIE Transactions 30(8): 759–762. https://doi.org/10.1080/07408179808966521

Olivieri H, Seppänen O, Thais A (2019) Survey comparing critical path method, last planner system, and location-based techniques. J Construct Eng Manag. https://doi.org/10.1061/(ASCE)CO.1943-7862.0001644

Qian S, Gong T (2009) An improved project buffer sizing approach to critical chain management under resources constraints and fuzzy uncertainty. Int Conf Artif Intell Comput Intell IEEE Comput Soc. https://doi.org/10.1109/AICI.2009.192

She B, Chen B, Hall NG (2020) Buffer sizing in critical chain project management by network decomposition. Omega 102:102382. https://doi.org/10.1016/j.omega.2020.102382

Taghipour M, Seraj F, Amin M, Delivand MC (2020) Evaluating CCPM method versus CPM in multiple petrochemical projects. Management. https://doi.org/10.31058/j.mana.2020.32004

Yang S, Lei F (2014) Critical chain and evidence reasoning applied to multi-project resource schedule in automobile r&d process. Int J Project Manage 32(1):166–177. https://doi.org/10.1016/j.ijproman.2013.01.010

Zhang R, Zhu Y, Xu S (2020) Scheduling risk evaluation for the integrated design of blanket system project for CFETR based on fuzzy PRET method. J Fusion Energy 39:156–162. https://doi.org/10.1007/s10894-020-00246-5

Zhao ZY, You WY, Zuo J (2010) Application of innovative critical chain method for project planning and control under resource constraints and uncertainty. J Constr Eng Manag 136(9):1056–1060. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000209

Acknowledgements

The authors thank the Editor, Associate Editor, and referees for their comments on the initial version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (51478384) and the Industrial Building Environment and Energy Conservation Innovation Team of China (2017KCT-14).

Author information

Authors and Affiliations

Contributions

XH and WY conceptualized the main idea of this research project; WY and TL designed and conducted the experiments; WY checked the results; XH wrote the whole paper. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

Any submission that has data collected from human subjects requires ethics approval.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, X., Yan, W. & Liu, T. Critical chains and its randomness study for scheduling optimization. Int J Syst Assur Eng Manag 13, 844–854 (2022). https://doi.org/10.1007/s13198-021-01345-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01345-y