Abstract

With the rapid development of the economy, increasingly large, complex, and systematic projects put forward new requirements to project scheduling management, which make the methods and technology innovation of project scheduling management to meet the diversified needs of different users. This paper proposed a WBS-free scheduling method, which separates scheduling activities and WBS. The novel method establishes a data set scheduling model based on database relational model, extracts the database schedule data through P6, and applies P6 activity code to implement scheduling method innovation through initialization, screening, classification, and composition function of P6. The case study on Pakistan NRL-ISBL national refinery project scheduling management proved that the combination of traditional scheduling methods and WBS-free scheduling method is feasible in project scheduling execution and that WBS-free scheduling method can reduce the work load greatly and optimize the workload of progress planning, so WBS-free scheduling method is able to simplify the scheduling, solve the problem of diversity in scheduling form and implement the innovation of scheduling method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

If there are many kinds of subsystems with hierarchical structure, and the relationship between them is very complex, this is a complex giant system (Qian et al. 1993). The process management of industrial projects involves many parts, such as process, package design, basic design, detailed design, procurement, construction, commissioning, etc., and each part is closely connected, complicated, and hierarchical, so it can be called a complex giant system. Especially large petrochemical EPC project is a typical complex giant system.

Project scheduling management focuses on the processes to ensure the timely completion of the project (Ashtiani and Aryanezhad 2011), which is one of the nine functions of project management (project integration management, project scope management, project scheduling management, project cost management, project quality management, project resource management, project communication management, project risk management, project procurement Management). Especially in the process of project execution, it is the key link to balance the project constraints of competition and restrict resources, and plays an essential role in management and control.

The project scheduling problem was first proposed in the 1960s, and the scheduling problem is usually regarded as the formal beginning of scheduling theory research (Conway et al. 1967). Subsequently, a resource-constrained project scheduling problem is proposed (Pritsker and Wolfe 1969).

A two-phase local search algorithm is proposed to optimize the class, and the results indicated that the optimality gap even within the larger class of elementary policies is very small (Rostami et al. 2017). A two-stage coupled algorithm is proposed for an integrated maintenance planning and flowshop scheduling problem with deteriorating machines (Bajestani and Beck 2015). A single-machine multiple-job-types makespan problem with APC constraints is proved to be NP-hard, an efficient heuristic algorithm based on these structural results is proposed and compared with an integer programming approach (Cai et al. 2012). A method is proposed to use the work breakdown structure (WBS) concept to improve work interface management (Chua and Godinot 2006).

In recent years, the rapid development of economy drives the scale of the project investment scale to be larger and larger, the technology to be increasingly complex, and the large, complex and systematic project to be increasingly, which puts forward new requirements for project scheduling management. In the large, complex, and systematic project management, there are many project stakeholders. In the process of project execution, the owner, the contractor, and the subcontractor put forward different requirements for the form and content of project scheduling management from different user perspectives, which promotes the continuous innovation of the technology and methods of project scheduling management to meet the diversified needs of different users.

Tools and techniques for scheduling preparation methods:

-

(1)

Gantt chart: Gantt chart, which is also called bar chart, is a traditional scheduling tool, which displays the project progress with a bar chart and intuitively represents the project implementation progress information.

-

(2)

Critical path method (CPM): it is the most commonly used scheduling preparation technology at present. It is a project scheduling preparation method based on mathematical calculation of network diagram. The critical path method breaks down the work of the project, establishes the work breakdown structure and the activities of the lower level, determines the duration of the activities under the work breakdown structure, and connects the logical relationship between predecessor and successors, to calculate the duration characteristics in the planning network and get the optimal project scheduling (PMI 2017).

-

(3)

Program/project evaluation and review technology (PERT): it is a scheduling method that analyzes the progress of each activity and the relationship between them on the basis of the network diagram of the progress plan. It controls the scheduling on the time axis and around the critical path method.

-

(4)

Critical chain method: To solve the problem of limit resources in the construction project, Goldratt proposed the Critical Chain Method (CCM). Once proposed, this method has aroused great interest and extensive researches in academia (Goldratt 1997b, a). CCM has been widely accepted to be superior to the traditional Critical Path Method (CPM). It is a method of planning and scheduling. Based on the critical path method and planning review technology, resources are introduced to calculate the optimal project scheduling according to the limited resources.

-

(5)

Graphic evaluation and review technology (GERT), also known as decision network technology or graphic review technology, is a network analysis technology that can deal with the conditions and probability of logical relations. Compared to CPM, GERT allows a certain probability description in terms of network logic and work duration. GERT uses computer simulation technology to simulate the progress of the project.

Among the above five scheduling tools and technologies, the first three are widely used in traditional scheduling.

The traditional scheduling preparation method is based on the critical path method and project or P6 (Oracle Primavera) software. The steps are as follows:

-

(1)

Create projects in the enterprise project structure (EPS);

-

(2)

Create a work breakdown structure (WBS) in the project;

-

(3)

Under the work breakdown structure (WBS), activities are established, classified, and defined, and the logical relationship between activities is established to achieve the calculation and update of the scheduling.

The WBS is created by breaking down the scope of work of the project through the work breakdown structure. The WBS and activity code are defined, respectively. The project deliverables (design finished products) and engineering entities are decomposed into each kind of drawing documents, or the minimum inspection lot. The project work is decomposed into smaller and easier to manage components, and activities are added under the WBS, and then the logical relationship can be set between activities (Oracle Primavera 2009).

The traditional method of scheduling preparation only has a unique WBS, which can not meet the diversified needs of large, complex, and systematic project management WBS.

2 Database relational model

Database management system is composed of a collection of interrelated data and a set of programs to access these data, which is usually called database.

The basis of database structure is the data model. Data model is a collection of conceptual tools that describe data, data relations, data semantics, and consistency constraints. Data models can be divided into three types: Object-based logical model, record-based logical model, and physical model (O'Neil 1994).

The record-based logical model is used to describe data in the logical layer and the attempt layer. Unlike the object-based database model, the record-based logical model is used to define the global logical structure of the database and has a high-level description for implementation.

Relational models, mesh model, and hierarchical models are commonly used in record-based logic models. The relational model uses a set of tables to represent the relationship between data and data. Each table has multiple columns and each column has a unique column name. The following will build a database without the main elements of WBS scheduling based on the database relational model.

To define the activity code, it is necessary to define the relationship between elements related to scheduling. With the help of database relation model, the relation of scheduling elements related to activity code is established. The relation model is established by seven main scheduling elements: project organization breakdown structure (OBS), work breakdown structure (WBS), task, task activity (taskactv), activity code (actvcode) and activity type (actvtype), to achieve WBS-free scheduling.

The data set model of scheduling is established as follows:

Database Model = {PROJECT, OBS, WBS, TASK, TASKACTV, ACTVCODE, ACTVTYPE}

Define the data header in the collection, which is represented by the database head function as follows:

Head(PROJECT) = {proj_id,proj_short_name,plan_start_date,plan_end_date,critical_path_type,create_user……}

Head(OBS) = {obs_id,obs_name,parent_obs_id,obs_descr,guid,create_user……}

Head(WBS) = {wbs_id,proj_id,wbs_id,wbs_short_name,wbs_name,parent_wbs_id……}

Head(TASK) = {task_id,proj_id,wbs_id,task_type,task_code,task_name……}

Head(TASKACTV) = {task_id,actv_code_type_id,actv_code_id,proj_id,update_user,create_user……}

Head(ACTVCODE) = {actv_code_id,actv_code_type_id,actv_code_short_name,actv_code_name,parent_actv_code_id,create_user……}

Head(ACTVTYPE) = {actv_code_type_id,actv_code_type,proj_id,actv_code_type_scope,actv_short_len,create_user……}

Taskactv is the Cartesian product of project, task, actvcode and actvtype, which is expressed as follows:

TASKACTV = PROJECT X TASK X ACTVCODE X ACTVTYPE

The detailed definitions of the data tables and columns of the collection are shown in Table 1.

3 WBS-free scheduling method based on database relation model

The data set model of scheduling compilation is set up in the SQL Server database, and the WBS-free scheduling method is realized by an external program reference.

The WBS-free scheduling method is to establish a method of scheduling compilation separate from WBS, not without WBS, but with multiple WBS, and can flexibly call applicable WBS to realize the diversity of scheduling forms and meet the needs of different users.

The WBS-free scheduling method is different from the traditional scheduling. The compilation method is as follows.

3.1 Initialization work

Define the activity code of the proposed scheduling, establish the required WBS activity code of each layer, and establish the minimum deliverables or minimum inspection lot level according to the requirements of the scheduling deepening and levels.

3.2 Task settings

Establish the activities (including activity ID, activity name, activity duration, activity weight, etc.) required for the preparation of the project scheduling, and assign the corresponding activity code and activity code value to the activities.

3.3 Other property settings

Set logical relationship, load resources, perform progress calculation, and generate scheduling.

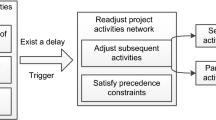

The following Fig. 1 is the SQL Server database relation diagram of seven main planning elements: project, OBS, WBS, task, taskactv, actvcode, and actvtype (Oracle Primavera 2009).

4 WBS-free scheduling method based on activity code

The scheduling data set model of database relation model is applied in P6 software to form a WBS-free scheduling method with P6 activity code.

The WBS-free scheduling method of P6 activity code is a scheduling preparation method which relies on P6 activity code function to realize diversified scheduling forms. P6 activity code is composed of one or several numbers or letters, which is used to identify task characteristics, or to classify process activities in some way, to filter and arrange the activities in the report.

The key to the WBS-free scheduling method of P6 activity code is initialization, that is, the definition of project activity code and the definition of classification code value. It is necessary to complete the definition of the project, plan level, devices, units, stages, specialties, work package, and tasks. The initialization work is very heavy, but it can be reused repeatedly afterward. In the process of scheduling, only adding tasks and setting the required activity codes of each layer can produce the scheduling of WBS required.

The steps of preparation of WBS-free scheduling method for P6 activity code are as follows:

4.1 Building project

Establish the proposed project in EPS and set the project parameters.

4.2 Definition of activity code and activity code value

The definition of activity code is slightly different for different projects, generally including the definition of scheduling project, level-1, schedule, level-2 schedule, level-3 schedule, schedule device or area, main item or unit of schedule, stage of scheduling, discipline of schedule and work package of scheduling, scheduling activity definition, etc., and increase or decrease the activity code according to different project requirements.

The definition of activity code value is to set the corresponding activity code value under each activity code, which is prepared according to different company systems and standards. The definition of activity code and activity code value are shown in Table 2.

4.3 Create a new activity and assign an activity code

To create a new activity under a project and assign a code to an activity is to assign the corresponding activity code attribute to the activity, and the activity code attribute of the activity is to be called grouping. As shown in Fig. 2, the assignment of activity code of new activity A1000 New Activity is assigned to schedule item, level-1 schedule level-2 schedule, level-3 schedule, schedule device or area, schedule main item or unit, schedule stage, schedule discipline, schedule work package and schedule task definition activity code.

4.4 Group method setting

The grouping method set is to sort the assigned activity codes. Through grouping settings, the same method can have multiple WBS. The sorting of activity codes is a virtual WBS, that is, the order of WBS. Table 3 below is a way of grouping activity codes, that is, a WBS. If you adjust the way of grouping activity codes, the WBS will also be adjusted to meet the requirements of method preparation.

4.5 Generating scheduling

Through the above five steps of establishing project activity code and code value definition, creating new activities and assigning activity code, setting, grouping method, and generating scheduling, we can realize the WBS-free scheduling of P6 activity code and realize the diversified WBS scheduling preparation. As shown in Fig. 3, a WBS scheduling is generated.

5 Empirical analysis of WBS-free scheduling method

There is a certain difference between the WBS-free scheduling method of P6 activity code and the traditional method in the preparation concept, a scheduling engineer may not be able to quickly apply the practice and apply to the current project. Therefore, whether the WBS-free scheduling method can be combined with the traditional method is going to be studied.

Through the case study of Pakistan NRL-ISBL national oil refining project scheduling management, this paper analyzed whether the traditional scheduling preparation method and the WBS-free scheduling method of P6 activity code can be used in the scheduling preparation work synchronously. The original plan of Pakistan NRL-ISBL national oil refining project is divided into the unique WBS form according to the WBS plant area and process system MS Critical Milestone/PM Project Management/ 01 Heavy Oil Block/ 02 Naphtha Block/ 03 Sulfer Block. P6 activity code of the WBS-free scheduling is divided, based on the initial WBS project phase MS Critical Milestone/ PM Project Management/ H1 Engineering/ D1 Equipment Procurement/ D2 Bulk Material Procurement/ S1 Construction / T1 Pre-Com. and Commissioning. The WBS of WBS-free scheduling can be adjusted by the activity code function according to the needs of the owner, contractor, and other users. The above two WBS are different in form and characteristics. WBS according to the plant area or process system can reflect the engineering, procurement, construction, and commissioning of the plant as a whole, with the integrity of a single project, WBS according to the project stage reflects the work of the whole project in an independent stage, with the integrity of the process in an independent stage.

In the process of industrial project implementation, it is difficult or impossible to combine the two kinds of WBS, but different users or project executors have different needs, some tend to divide WBS by plant area or process system, some tend to divide WBS by project stage, which forces project managers to prepare project scheduling with multiple WBS.

The following are the specific steps for the WBS-free scheduling.

5.1 Creating an activity code: project

The project activity code is shown in Figure 4.

5.2 Assign activity codes to activities in the original plan: project

The activity code for scheduling of NRL-ISBL national refining project: The project is shown in Figure 5.

5.3 Setting the original scheduling grouping method

The NRL-ISBL national refining project scheduling grouping is shown in Figure 6.

5.4 Folded scheduling of NRL-ISBL national oil refining project in Pakistan

The folded scheduling of the original Pakistan NRL-ISBL national oil refining project is shown in Fig. 7.

5.5 Folded scheduling of NRL-ISBL national oil refining project scheduling based on activity code project

The folded scheduling of NRL-ISBL national refining project scheduling generated by the activity code project is shown in Figure 8.

In P6, the original scheduling activity is initialized with activity code definition (project), activity code definition (project), assignment, activity code grouping method setting, and task setting, and the scheduling based on the activity code project is generated through scheduling calculation. It is concluded that P6 can well realize the WBS-free scheduling, and it is proved by empirical analysis that it is clear that the traditional scheduling method and the WBS-free scheduling method using activity code can be well combined in the preparation and implementation of the scheduling, which shows that the WBS-free scheduling method can be widely used in large, complex and systematic engineering projects.

In the case study on the WBS-free scheduling method of P6 activity code, it is found that the WBS-free scheduling method greatly reduced the scheduling preparation workload, optimized the scheduling preparation work, saved a lot of time and improved work efficiency in the scheduling preparation, and made the scheduling preparation work fast and effective.

6 Conclusions

WBS-free scheduling method is based on the database relation model, and it can be used in the design of SQL server database, through the application of P6 to extract the data of database scheduling. By using the function of activity code, what can be implemented includes: the steps of setting up the project, defining activity code, defining activity code value, creating new activities, and assigning activity code, grouping method definition, scheduling generation, etc.. Thus, WBS-free scheduling is achieved. Through the case study on NRL-ISBL refinery project scheduling management in Pakistan, it is proved that the traditional scheduling method can be well combined with the WBS-free scheduling method, and that the WBS-free scheduling can greatly reduce the scheduling preparation workload and optimize the scheduling preparation work. The WBS-free scheduling method is fast and effective, because it not only benefits scheduling engineers’ scheduling work, but also meets the requirements put forward by different users with different perspectives in the implementation of the EPC project. It is capable of simplifing the preparation of scheduling, solving the diversity of scheduling forms, and realizing the innovation of the preparation method of scheduling.

Data availability

The data used to support the findings of this study are included within this article. Requests for more details should be made to the corresponding author.

References

Ashtiani B, Aryanezhad L (2011) New competitive results for the stochastic resource-constrained project scheduling problem: exploring the benefits of pre-processing. J Sched 14(2):157–171. https://doi.org/10.1007/s10951-009-0143-7

Bajestani MA, Beck JC (2015) A two-stage coupled algorithm for an integrated maintenance planning and flowshop scheduling problem with deteriorating machines. J Sched 18(5):471–486. https://doi.org/10.1007/s10951-015-0416-2

Cai Y, Kutanoglu E, Qin HJ (2012) Single-machine scheduling with advanced process control constraints. J Sched 15(2):165–179. https://doi.org/10.1007/s10951-010-0215-8

Chua DK, Godinot M (2006) Use of a wbs matrix to improve interface management in projects. J Const Eng Manag 132(1):67–79. https://doi.org/10.1061/(ASCE)0733-9364(2006)132:1(67)

Conway RW, Maxwell WL, Miller A (1967) Theory of scheduling. Addison-Wesley Publishing Co., London

Goldratt EM (1997a) Critical chain. The North River Press, Great Barrington

Goldratt EM (1997b) It’s not luck. The North River Press, Great Barrington

O'Neil PE (1994) Database : principles programming performance. DBLP.

PMI (2017) A guide to the project management body of knowledge (PMBOK® Guide), 6th edn. Project Management Institute Inc., Pennsylvania

Primavera O (2009) Oracle primavera® P6 project management reference manual. Oracle, Redwood City

Pritsker A, Wolfe WPM (1969) Multiproject scheduling with limited resources: a zero-one programming approach. Manag Sci 16:93–108. https://doi.org/10.2307/2628369

Qian X, Yu J, Dai R (1993) A new discipline of science-the study of open complex giant system and its methodology. Chin J Syst Eng Elect 4(2): 2–12. https://www.cnki.net/kcms/doi/CNKI:SUN:XTGJ.0.1993-02-000

Rostami S, Creemers S, Leus R (2017) New strategies for stochastic resource-constrained project scheduling. J Sched 21(3):349–365. https://doi.org/10.1007/s10951-016-0505-x

Acknowledgments

The authors thank the Editor, Associate Editor, and referees for their comments on the initial version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (51808424 and 51478384) and the Industrial Building Environment and Energy Conservation Innovation Team of China (2017KCT-14).

Author information

Authors and Affiliations

Contributions

X.H. conceptualized the main idea of this research project; X.H. designed and conducted the experiments; X.H. wrote the whole paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

Any submission that has data collected from human subjects requires ethics approval.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, X. WBS-free scheduling method based on database relational model. Int J Syst Assur Eng Manag 12, 509–519 (2021). https://doi.org/10.1007/s13198-021-01106-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01106-x