Abstract

Environmentally friendly natural deep eutectic solvents (NADES) have been shown to efficiently extract a wide range of phenolic compounds from virgin olive oil (VOO). The objective of this work was to optimize the yield of olive oil phenols extracted by NADES based on xylitol/choline choride (Xyl/ChCl). Different extraction and recovery conditions were investigated, including the effect of different extraction operating parameters (temperature, time, VOO:NADES ratio) and subsequent recovery conditions (XAD resin height, wash-water and eluent volume and pH). The highest concentration of phenols (555.36 mg/kg VOO) was obtained from extraction at 40 °C for 1 h, with a 1:1 ratio, using an adsorption resin XAD-16 with bed height of 10 cm, 250 mL acidified wash-water and 300 mL EtOH 100% as eluent. No statistically significant loss of the sum of phenolic compounds was observed when compared with the concentration values obtained by direct analysis in HPLC without the elimination of NADES. Additionally, a sequential desorption with different concentration of ethanol was used to determine the effect of the solvent concentration on polyphenol yield. Polar compounds, such as hydroxytyrosol and tyrosol, were recovered at 81.7% and 83.6%, respectively with 50 and 80% ethanol; however, 100% ethanol was required for the complete elution of oleacein (3,4-DHPEA-EDA) and oleocanthal (p-HPEA-EDA). In this paper we present an effective process for the extraction of polyphenols from VOO by NADES for direct analysis in HPLC and for the recovery and concentration of polyphenols by removing the solvent (NADES) with no losses of yield and solvent recycling.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural deep eutectic solvents (NADES) are currently an alternative to conventional solvents for the extraction of phytochemicals, such as phenolic compounds, from diverse sources, among them olive fruits and derived products including olive oil (Ferrone et al. 2018; García et al. 2016). In the present day, consumers demand natural bioactive products for multiple purposes, which have been obtained using sustainable production techniques, challenging many conventional procedures. Many organic solvents, e.g., alcohols, chloroform, and ethyl acetate, are still extensively employed for extraction of biologically active compounds (Gavahian et al. 2019; Mark et al. 2019; Francisco et al. 2019), although they contribute to environmental pollution and leave undesirable solvent deposits in the extracts. This is the reason why significant progress has recently been made in the development of new extraction methods for substances of interest, such as phenolic compounds, that avoid or minimize the use of organic solvents, and that allow obtaining extracts or purified compounds, useful both in research and in the food, pharmaceutical or cosmetic industries.

An alternative to these solvents are the so-called NADES (Dai et al. 2013a, b), a group of eco-friendly solvents (Jiang et al. 2019; Athanasiadis et al. 2018), with properties such as low volatility at room temperature, non-flammability, a wide range of polarity, and high biodegradability. Dai et al. (2014) included the term NADES to define liquids obtained from natural products as primary metabolites, including organic acids, amino acids, sugars, alcohol or amines with a wide variety of applications (Dai et al 2013a). NADES are considered to form an ionic bond to give a liquid crystal at room temperature whose melting temperature is much lower than that of the starting components. Such interactions are formed by the combination of compounds of high melting point, generally solid to form a liquid due to the delocalization of the charge, caused by hydrogen bonding, generating a eutectic point whose melting temperature is much lower than the starting compounds. Since NADES are constituted by natural and innocuous substances, they are very interesting for the extraction of bioactive compounds from different matrices (Dai et al. 2013b).

Phenolic compounds are a group of structurally diverse secondary metabolites in plants that are essential for plant growth, development, stress adaptation, and defense and exhibit numerous beneficial properties for health (Villard et al. 2019; Gutierrez-Albanchez et al. 2019). They have attracted a large amount of interest in recent years due to their antioxidant capacity (Franco et al. 2014; Fuentes et al. 2018), which has been associated with beneficial effects for health, such as a reduced risk of coronary heart disease, prevention of several types of cancers (Reboredo-Rodríguez et al. 2018), modification of immune and inflammatory responses, antihypertension, antimicrobial and cholesterol-lowering properties (Hounsome et al. 2008).

Virgin olive oil (VOO) contains at least 30 phenolic compounds, whose main classes are secoiridoids aglycons such as the dialdehydics forms of elenolic acid linked to hydroxytyrosol (3,4-DHPEA-EDA) or tyrosol (p-HPEA-EDA), oleuropein and ligtroside aglycons (3,4-DHPEA-EA, p-HPEA-EA) respectively, phenolic alcohols such as hydroxytyrosol (Hy) and tyrosol (Ty), the lignans acetoxypynoresinol and pinoresinol, and flavonoids such as luteolin and apigenin. Most phenolic compounds present a broad spectrum of antioxidant, free radical scavenger and anti-inflammatory effects and their biological properties have been wide investigated (Serreli and Deiana 2018). Among them, secoiridoid derivatives of oleuropein and ligstroside are considered bioactive compounds because they can be hydrolyzed to Hy before reaching human plasma (Fitó et al. 2007). In addition, p-HPEA-EDA (oleocanthal) has demonstrated anti-inflammatory activity with the ability to inhibit COX-1 and COX-2 enzymes similar to ibuprofen (Beauchamp et al. 2005). Furthermore, this phenolic compound is able to inhibit the phosphorylation of c-Met kinase in vitro, a proto-oncogene receptor with a significant oncogenic role in many tumors, (Akl et al. 2014) and suppress the growth of luminal breast cancer cells, in part, by reducing total levels of ERα in cell culture and animal studies (Ayoub et al. 2017). The antibacterial effect of 3,4-DHPEA-EDA (oleacein) against a broad spectrum of bacteria is also well described, together with its antioxidant and antiproliferative properties (de Castro et al. 2007). Lignans such as acetoxypinoresinol and pinoresinol possess antioxidant activity and they have been associated with antitumor effects. Pinoresinol exerts anti-inflamatory activity and antifungal activity against several human pathogen fungi, neuroprotective and hypoglycaemis actions (López-Biedma et al. 2016). Flavonoids like apigenin and luteolin showed effect in suppressing colorectal cancer cell by slowing their growth by cell cycle arrest. (Borzi et al. 2019). Phenolic compounds in olive oil have been traditionally extracted by means of organic solvents such as methanol, ethanol, their aqueous mixtures or others solvents such as N,N-dimethylformamide, with liquid–liquid or solid-phase extraction (Brenes et al. 2000). In the organic solvent extraction, parameters such as the ratio VOO:solvent, temperature or the extraction time are slightly variable. Phenolic compounds in oil such as secoiridoids derivatives can be hydrolyzed with high temperature when extracted and concentrated with organic solvents or their aqueous mixtures, for that reason, temperatures below 35 °C are used to obtain a phenolic extract without hydrolyzing. The official method for extraction of phenolic compounds from VOO by the International Olive Council Testing Method uses 80% (v/v) methanol at room temperature. However, Garcia et al. (2016) demonstrated that extraction of phenolic compounds from the VOO by eutectic solvents was more effective than extraction by methanol 50% or 80% (v/v) at temperature of 40 °C The removal of organic solvent for the concentration of polyphenols from the extracts is done by low temperature evaporation. For the removal of eutectic solvents from phenolic extracts, resin adsorption was used, it is not known how different parameters of this process affect the phenolic content of the extracts.

However, different factors can affect the extraction and recovery of phenolic compounds from VOO. The objective of this work was to determine the optimal conditions for the extraction and recovery of phenolic compounds from VOO using an NADES-based method.

Materials and methods

Samples, standards, and reagents

VOO of the Hojiblanca variety was purchased from commercial suppliers and preserved at − 20 °C until its use. The standard compounds tyrosol, luteolin, apigenin and pinoresinol were purchased from Sigma-Aldrich (St. Louis, MO). Hydroxytyrosol was obtained by the method described by Fernández-Bolaños et al. (2004). Oleacin, oleocanthal, oleuropein aglycone, ligstroside aglycone and 1-acetoxypinoresinol were obtained from VOO separated in an analytic C-18 column and eluted with MeOH:H2O, as described by García et al. (2001). HPLC grade methanol was purchased from Panreac-Applichem. Milli-Q water was used acidified with 6 N TFA.

Xylitol, and 1,2-choline chloride were obtained from Sigma Aldrich. Resin Amberlite XAD-16 was purchased from Vivaqua, Spain.

Preparation of natural deep eutectic solvent (NADES)

Natural deep eutectic solvent (NADES) was prepared according to the evaporating method described by Dai et al. (2013b). Briefly, a choline chloride, xylitol and water mixture (ChCl:Xyl:Water) with a ratio (2:1:3) was heated with a rotary evaporator in a round-bottomed flask until a homogeneous colorless liquid was formed.

Extraction of phenolic compounds

The control extraction procedure was performed by mixing 14 g VOO with 14 g of NADES with agitation in a water bath at 40 ºC for 1 h. The 1:1 VOO: NADES mixture was centrifuged at 1200 g during 10 min and the NADES-phase was recovered. This procedure was repeated and the extracts pooled. The extract was analyzed by direct injection in HPLC without elimination of NADES. The NADES phase was washed four times with hexane to eliminate residual oil and bubbled with nitrogen to eliminate residual hexane.

In order to evaluate the effect of different conditions on the extraction of polyphenols, the procedure described above was modified. To investigate the effect of extraction time, extraction times of 0.5 h, 2 h and 6 h were used and compared to the control time of 1 h at a temperature of 30 and 40 ºC and with a 1:1 VOO: NADES ratio. The effect of temperature on the extraction was analyzed at 30, 60 and 90 °C and compared to the control temperature of 40 °C, with extraction time 1 h and 1:1 VOO: NADES ratio. Finally, the effect of the VOO: NADES ratio was determined applying the ratios 1:3, 1:4, 1:7, and compared to the 1:1 control ratio with an extraction time of 1 h and temperature of 40 °C.

Recovery of phenolic compounds

NADES extracts (20 mL) were passed through an amberlite XAD-16 adsorbent filled column with 2.3 cm inside diameter to give a bed height of 10 cm. The adsorbent was pre-treated with 50 mL of ethanol and washed with 50 mL of MQ water prior to loading of the phenolic extracts. Extracts were washed with 250 mL of MQ water and the captured phenols eluted from the resin with 300 mL of ethanol 100%. Eluted samples were dried under vacuum at 30 ºC, dissolved in 1 mL of MeOH and filtered through a 0.45 µm nylon filter for analysis by HPLC–DAD. This procedure was considered the control recovery protocol.

The control conditions that had been used in the recovery of phenols were modified to determine their possible effect on the final concentration. For this, the effect of column bed height on the adsorption of phenolic compounds from the NADES extract was analyzed, using 10 cm, control height, and doubling it to 20 cm. In the processes of pre-treatment of the column and elution of the phenols, all volumes were doubled with respect to the control. Thus, 100 mL of ethanol followed by 100 mL of MQ water were used in the pre-treatment of the adsorbent, then 20 mL of NADES extract was loaded, it was washed with 500 mL of MQ water, and then eluted with 600 mL of 100% ethanol.

The possible effect of pH on the recovery of phenolic compounds from the extract was studied. Thus, the washing water used during the pretreatment of the column and in the phenol elution process, was adjusted to pH 4 with acetic acid. The possible effect of the type of solvent, ethanol or methanol used in the column pre-treatment and phenol recovery processes was also determined.

Finally, the effect of the aqueous solvent mixtures on the desorption of the polyphenols was assayed using a column bed of 20 cm, with sequential elution performed with 100 mL of 50, 80 and 100% ethanol.

HPLC–DAD analysis of phenolic compounds

The chromatographic system consisted of a HP 1100 Series gradient HPLC (Agilent Technologies, Santa Clara, California). A Mediterranea SEA 18 column (250 mm 4.6 mm i.d. 5 µm, Teknokroma, Barcelona, Spain) was used for the separation. Detection was performed with a HP diode array detector (DAD): the wavelength used for the quantification of luteolin and apigenin was 340 nm, and 280 nm for the rest of the compounds. The mobile phases used to perform the separation consisted of methanol and water. Elution was achieved using an elution gradient with an initial composition of 90% water (with pH adjusted to 2.5 with 6 N trifluoroacetic acid) and 10% methanol. The concentration of methanol was increased to 30% in 10 min and maintained for 10 min. Then, the methanol percentage was raised to 40% in 10 min and maintained for 5 min. Finally, the methanol percentage was increased to 60%, 70%, and 100% in 5-min periods. The initial conditions were reached in 15 min. The flow rate used was 1 mL/min. Quantification of phenolic compounds was performed using the reference compounds obtained from commercial suppliers or preparative HPLC, as previously described (Sect. 2.1). The concentration of polyphenols was expressed in mg/kg of VOO.

Statistical analysis

All studies were performed in duplicate and means and standard deviations were calculated. One-way and two-way statistical analyses were completed by ANOVA test using IBM.SPSS Statistics (Version 25). The significance of the results was compared using p < 0.05.

Results and discussion

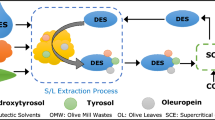

NADES are solvents that allow the efficient extraction of molecules, including polyphenols, from different matrices such as olive oil. In this work, we performed the extraction of polyphenols from VOO using a NADES formulation based on Xyl/ChCl that was chosen for its high extractive efficiency compared to other NADES formulations and conventional solvents (García et al. 2016). The most favorable conditions for obtaining phenolic compounds and eliminating the solvent from the extracts by means of adsorption resins were studied. This method permits the concentration of polyphenols for later use.

The content of the phenolic compounds obtained from NADES extracts was determined by quantitative analysis by HPLC–UV, the results are shown in Fig. 1. A direct injection analysis of the phenolic extract obtained without solvent removal was performed by the control extraction procedure (Fig. 1a). The results were compared with those obtained from the extract after solvent removal using the control recovery protocol (Fig. 1b). Direct injection of the extract is a useful analysis when no concentration of the phenolic compounds in the extract is required. However, the use of concentrated solvent-free phenolic extracts is useful in many analytical and industrial applications. Results showed that chromatographic profiles of the two analytical determinations are similar. The sum of all the polyphenols is also statistically similar. When analyzing the compounds individually, the concentrations of secoiridoid aglycones were higher in the concentrated extract while the alcohols hydroxytyrosol and tyrosol showed higher amounts in the extract analyzed by direct injection, the differences were not statistically significant except for hydroxytyrosol. These losses could have been produced by the washing during the recovery stage of these highly water-soluble phenols. NADES have low volatility, hence it was difficult to eliminate the solvent from the extracts obtained and therefore the yield for downstream analytical applications is somewhat limited. In order to concentrate the phenolic extracts obtained by NADES, methods such as the adsorption of polyphenols to resins followed by elution with organic solvent can be used. The effect of parameters—including time, temperature and ratio—on the capacity of NADES to extract polyphenols from VOO were analyzed sequentially, and the optimal extraction conditions for each parameter were defined. Figure 1b shows the chromatogram of the phenolic compounds concentrated and obtained under optimal extraction conditions.

HPLC chromatogram of phenolic compounds in virgin olive oil and their concentrations extracted by NADES using a time of extraction of 1 h, ratio of virgin olive oil: NADES (1:1), temperature 40 °C. Direct injection of the NADES extract (a), concentration of the extract and solvent removal with 10 cm of XAD-resin bed height, washing with acidified water, and desorption with 300 ml of ethanol 100% (b). The concentrations are expressed as mg/kg of VOO ± SD (n = 2)

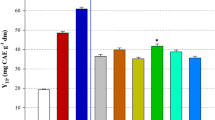

Effect of temperature

The effect of different temperatures (30, 40, 60 and 90 °C) on the extraction efficiency of the phenolic compounds from VOO obtained with Xylitol-Choline Chloride based NADES (Xyl/ChCl-NADES) (g/g) in a 1:1 ratio during 1 h of extraction was evaluated. The solvent exhibited a higher extractive capacity at 30 and 40 °C for the four most abundant secoiridoid derivatives in VOO (Fig. 2a), with the most favorable temperature being 40 °C for the extraction of 3,4-DHPEA-EDA (oleacein) and p-HPEA-EDA (oleocanthal), followed by oleuropein aglycon (3,4-DHPEA-EA) and ligstroside aglycon (p-HPEA-EA). The simple phenols hydroxytyrosol (Hy) and tyrosol (Ty) were extracted in the highest concentrations at 30 and 40 ºC for Hy and at 40 °C for Ty (Fig. 2b). The extractability of these compounds decreased significantly (p < 0.05) with the increase of temperature from 40 to 60 and 90 °C. The increase in temperature may reduce the viscosity of NADES and thus improve its extraction efficiency (Dai et al. 2013a; Moghimi and Roosta 2019; Lapeña et al. 2019) and/or it could degrade secoiridoid aglycons (Brenes et al. 2002; Lee et al. 2007). However, no increase was detected in the simple molecules derived from hydrolysis, hence the increase in temperature decreased the overall extraction capacity. For the rest of the phenolic compounds analyzed, the lignans 1-acetoxypinoresinol and pinoresinol were stable at high temperatures (Brenes et al. 2002), and neither significant differences in concentration of the flavonoids luteolin and apigenin, which remained stable even at 60 and 90 °C, nor improvements in the extraction of phenols by NADES were observed. Therefore, temperatures of 30º and 40 °C were selected to perform the next experiment.

Effect of temperature on the concentration of phenolic compounds in virgin olive oil (VOO). (a) oleacein (3,4-DHPEA-EDA); oleocanthal (p-HPEA-EDA); oleuropein aglycon (3,4-DHPEA-EA) and ligstroside aglicon (p-HPEA-EA). (b) hydroxytyrosol (Hy), tyrosol (Ty), 1-acetoxypinoresinol, pinoresinol, luteolin, apigenin. The results are expressed as mg/kg of VOO ± SD (n = 2). The letters represent significant differences, absence of letters indicate non-significant differences according to Duncan´s test (p < 0.05)

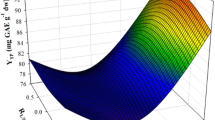

Effect of extraction time

The effect of extraction time at two different temperatures 30 and 40 °C was conducted for the extraction of phenols during 0.5, 1, 2 and 6 h, with a 1:1 ratio of VOO: Xyl/ChCl-NADES (g/g) (Table 1). The extract obtained with NADES at 40 ºC for 1 h had the highest concentration of the four secoiridoids, followed by the extraction at 0.5 h, which yielded 10%, 17% and 43% lower amounts of 3,4-DHPEA-EDA, p-HPEA-EDA and 3,4-DHPEA-EA, respectively (Fig. 3c). The amount of secoiridoids decreased significantly with longer extraction times, with lowest yields at 6 h. This may reflect the degradation of these compounds with longer extraction times, which occurred even at 30 ºC. However, a slight but significant increase of Hy and Ty was observed after 6 h of treatment at 40 °C, which could be related to the decrease in their secoiridoids derivatives by hydrolysis and release of the phenolic alcohols, highest concentration of lignan 1-acetoxipinoresinol was obtained for 6 h of extraction at 40 °C; this increase was also detected after 6 h at 30 °C which would correspond with the greater stability of the lignans. The rest of the phenolic compounds analyzed showed similar recovery yields at 30 and 40 ºC and were stable during all extraction times.

Effect of the extraction time on the concentration of the phenolic compounds in virgin olive oil (VOO). At 30 °C and 40 °C. a, c oleacein (3, 4-DHPEA-EDA); oleocanthal (p-HPEA-EDA); oleuropein aglycon (3, 4-DHPEA-EA) and ligstroside aglicon (p-HPEA-EA). b, d hydroxytyrosol (Hy), tyrosol (Ty), 1-acetoxypinoresinol, pinoresinol, luteolin, apigenin. The results are expressed as mg/kg of VOO ± SD (n = 2). The letters represent significant differences, absence of letters indicate non-significant differences according to Duncan´s test (p < 0.05)

Effect of the oil/solvent ratio

Different ratios of VOO: Xyl/ChCl-NADES (1:1, 1:3, 1:4 and 1:7) were used in order to determine the influence of the oil/solvent ratio on the yield of phenolic compounds extracted using the control conditions of 1 h at 40 °C. The 1:1 ratio extracted significantly higher concentrations of the secoiridoids 3,4-DHPEA-EDA, p-HPEA-EDA and 3,4-DHPEA-EA (Fig. 4a), yielding 22.5%, 31.7% and 46% higher mean concentrations than for ratios of 1:3, 1:4 and 1:7, respectively. The alcohols Hy and Ty showed similar behavior, with the 1:1 ratio producing the most efficient extraction (Fig. 4b). However, no significant differences (p < 0.05) were found for the extraction of lignans and the flavonoids between the different ratios assessed.

Effect of ratio virgin olive oil (VOO): Xyl/ChCl-DES on the concentration of phenolic compounds in VOO. a oleacein (3, 4-DHPEA-EDA); oleocanthal (p-HPEA-EDA); oleuropein aglycon (3,4-DHPEA-EA) and ligstroside aglicon (p-HPEA-EA). b hydroxytyrosol (Hy), tyrosol (Ty), 1-acetoxypinoresinol, pinoresinol, luteolin, apigenin. The results are expressed as mg/kg of VOO ± SD (n = 2). The lowercase letters represent significant differences, absence of letters indicate non-significant differences according to Duncan´s test (p < 0.05)

The highest phenolic extractive yields were obtained using the control conditions, 40 °C during 1 h with a 1:1 VOO: Xyl/ChCl-NADES ratio (Table 1), with which a concentration of 555.36 mg/kg VOO was obtained.

Removal of solvent from the NADES extract

To remove the solvent, the NADES extracts were passed through a column filled with XAD-16 resin, the solvent was washed with deionized water with no acidification, and the adsorbed phenols were eluted by organic solvent. The influence of the bed height, acidity of the wash water and the solvent used for the desorption of phenols and its concentration were analyzed.

In order to recover and concentrate the phenols from the NADES extracts, a macrophorous adsorbent resin XAD-16 was used. To study the effect of height on the adsorption capacity of the phenolic compounds from the NADES extract on the resin, 2 beds heights were assayed, 10 and 20 cm. Following adsorption, the adsorbate-laden column was washed first by acidified and then non-acidified desionized water with the objective of protecting the phenolic compounds until all the NADES was eluted (Mylonaki et al. 2008). The effect of wash-water acidity on the recovery of phenolic compounds was studied by washing a 10 cm and 20 cm bed height with acidified and non-acidified wash water. Results showed no significant differences due to the 2 beds heights of resin analyzed or to the wash-water acidity on the recovery of phenolics (data not shown).

Significant difference were only found in the sum of phenolic compound recovery from these extracts after washing with acidified water at a bed height of 10 cm, obtaining 555.36 mg/kg of phenols in these conditions and 447.08 mg/kg of phenols desorpting with non-acidified wash water. A bed height of 10 cm and acidified water were used in the following desorption assay.

Then a 100 mL sequential desorption with different concentrations of ethanol (50, 80 and 100%) was used in order to determine the effect of solvent concentration on the polyphenol extraction yield. Table 2 shows the concentration of simple phenols, secoiridoids, lignans and flavonoids recovered at the different ethanol concentrations. It should be noted that the most polar compounds, the simple phenols Hy and Ty, were recovered in higher proportions (81.7% and 83.6%), with the lowest concentrations of ethanol, 50% and 80%, respectively. The most abundant compounds present in the olive oil studied, 3,4-DHPEA-EDA and p-HPEA-EDA, remained in the resin in high proportions (26.8–31.5% of the total amount recovered) after elutions with 50% and 80% ethanol; it was necessary to increase the ethanol concentration to 100% for their complete recovery. Less polar compounds 3,4-DHPEA-EA, p-HPEA-EA, luteolin and apigenin were recovered in high proportions 93.4%, 69%, 96% and 98%, respectively after elution with 80% and 100% ethanol. However, the desorption of lignans, 1-acetoxypinoresinol and pinoresinol, with a similar polarity according to their behavior in HPLC under the conditions of this study, showed a similar trend and reached maximum values at an ethanol concentration of 100%. The content of lignan remained low even at high ethanol concentrations, with a concentration of 100% ethanol necessary to recover 74.9% and 78.3% of 1-acetoxypinoresinol and pinoresinol, respectively. Therefore, 100% ethanol was selected as the appropriate desorption solution for all the phenolic compounds extracted with NADES from VOO. When 100% methanol was used as elution solvent, the amounts of recovered phenolic compounds were statistically similar (p < 0.05) to those eluted with 100% ethanol, except for 3,4-DHPEA-EDA (data not shown). Bertin et al. (2011) found the highest desorption rates were obtained with ethanol, which mobilized almost all polyphenols adsorbed onto XAD-16 resins. Thus, all the solvents used in this extraction process are “green” solvents, such as water and ethanol. Moreover, the NADES could be reused several times, reducing the associated cost of the extraction process.

Conclusion

The present work reports an effective method for the extraction of phenolic compounds from VOO using NADES based on xylitol and ChCl, as well as the recovery of the phenolic compounds and the removal of NADES from a macroporous resin was developed. The most effective extraction conditions were 1 h at 40 °C with a VOO: Xyl/ChCl ratio of 1:1 for the highest percentage extraction of all the phenolic compounds without degradation. The most efficient conditions for the recovery of phenolic compounds and removal of NADES-based Xyl/ChCl was a column bed height of 10 cm, 250 mL of acidified wash water and 300 mL of ethanol as eluent, which allowed the recovery of a total of 555.36 mg/kg phenolic compounds. These results are comparable to those obtained by direct analysis of phenols without removal of NADES whose sum was 527.36 mg/kg of phenols. This indicates that no phenols were significantly lost in the solvent removal process under these conditions. This work presents an eco-friendly and highly efficient method for the extraction of phenolic compounds from VOO, and their recovery and concentration from NADES.

References

Akl MR, Ayoub NM, Mohyeldin MM, Busnena BA, Foudah AI, Liu YY, Ei Sayed KA (2014) Olive phenolics as c-Met inhibitors:(−)-Oleocanthal attenuates cell proliferation, invasiveness, and tumor growth in breast cancer models. PLoS One 9(5):1–15

Athanasiadis V, Grigorakis S, Lalas S, Makris DP (2018) Highly efficient extraction of antioxidant polyphenols from Olea europaea leaves using an eco-friendly glycerol/glycine deep eutectic solvent. Waste Biomass Valorizat 9(11):1985–1992

Ayoub NM, Siddique AB, Ebrahim HY, Mohyeldin MM, El Sayed KA (2017) The olive oil phenolic (−)-oleocanthal modulates estrogen receptor expression in luminal breast cancer in vitro and in vivo and synergizes with tamoxifen treatment. Eur J Pharmacol 810:100–111

Beauchamp GK, Keast RSJ, Morel D, Lin J, Pika J, Han Q, Breslin PAS (2005) Ibuprofen-like activity in extra-virgin olive oil. Nature 437:45–46

Bertin L, Ferri F, Scoma A, Marchetti L, Fava F (2011) Recovery of high added value natural polyphenols from actual olive mill wastewater through solid phase extraction. Chem Eng J 171:1287–1293

Borzi AM, Biondi A, Basile F, Luca S, Vicari ESD, Vacante M (2019) Olive oil effects on colorectal cancer. Nutrients 11(1):1–16

Brenes M, Garcia A, Garcia P, Garrido A (2000) Rapid and complete extraction of phenols from olive oil and determination by means of a coulometric electrode array system. J Agric Food Chem 48:5178–5183

Brenes M, García A, Dobarganes MC, Velasco J, Romero C (2002) Influence of thermal treatments simulating cooking processes on the polyphenol content in virgin olive oil. J Agric Food Chem 50(21):5962–5967

Dai Y, Witkamp GJ, Verpoorte R, Choi YH (2013a) Natural deep eutectic solvents as new extraction media for phenolic metabolites in Carthamus tinctotius L. Anal Chem 85(13):6272–6278

Dai Y, van Spronsen J, Witkamp GJ, Verpoorte R, Choi YH (2013b) Natural deep eutectic solvents as a new potential media for green technology. Anal Chim Acta 766:61–68

Dai Y, Verpoorte R, Choi YH (2014) Natural deep eutectic solvents providing enhanced stability of natural colorants from safflower (Carthamus tinctorius L). Food Chem 159:116–121

de Castro A, Romero C, García A, Medina E, Brenes M (2007) Main antimicrobial compounds in table olives. J Agric Food Chem 55(24):9817–9823

Fernández-Bolaños J, Rodríguez G, Gómez E, Guillén R, Jiménez A, Heredia A, Rodríguez R (2004) Total recovery of the waste of two-phase olive oil processing: isolation of added-value compounds. J Agric Food Chem 52(19):5849–5855

Ferrone V, Genovese S, Carlucci M, Tiecco M, Germani R, Preziuso F, Epifano F, Carlucci G, Taddeo VA (2018) A green deep eutectic solvent dispersive liquid-liquid micro-extraction (DES-DLLME) for the UHPLC-PDA determination of oxyprenylated phenylpropanoids in olive, soy, peanuts, corn, and sunflower oil. Food Chem 245:578–585

Fitó M, De La Torre R, Covas MI (2007) Olive oil and oxidative stress. Mol Nutr Food Res 51(10):1215–1224

Francisco V, Ruiz-Fernandez C, Lahera V, Lago F, Pino J, Skaltsounis L, Gonzalez-Gay MA, Mobosheri A, Gómez R, Scotece M, Gualillo O (2019) Natural molecules for healthy lifestyles: oleocanthal from extra virgin olive oil. J Agric Food Chem 67:3845–3853

Franco MN, Galeano-Díaz T, López Ó, Fernández-Bolaños JG, Sánchez J, De Miguel C, Gil MV, Martin-Vertedor D (2014) Phenolic compounds and antioxidant capacity of virgin olive oil. Food Chem 163:289–298

Fuentes E, Paucar F, Tapia F, Ortiz J, Jimenez P, Romero N (2018) Effect of the composition of extra virgin olive oils on the differentiation and antioxidant capacities of twelve monovarietals. Food Chem 243:285–294

García A, Brenes M, Martínez F, Alba J, García P, Garrido A (2001) High-performance liquid chromatography evaluation of phenols in virgin olive oil during extraction at laboratory and industrial scale. J Am Oil Chem Soc 78(6):625–629

García A, Rodríguez-Juan E, Rodríguez-Gutiérrez G, Rios JJ, Fernández-Bolaños J (2016) Extraction of phenolic compounds from virgin olive oil by deep eutectic solvents (DESs). Food Chem 197:554–561

Gavahian M, Mousavi Khaneghah A, Lorenzo JM, Munekata PES, Garcia-Mantrana I, Collado M, Meléndez-Martínez A, Barba F (2019) Health benefits of olive oil and its components: Impacts on gut microbiota antioxidant activities, and prevention of noncommunicable diseases. Trends Food Sci Technol 88:220–227

Gutierrez-Albanchez E, Kirakosyan A, Bolling SF, García-Villaraco A, Gutierrez-Mañero J, Ramos-Solano B (2019) Biotic elicitation as a tool to improve strawberry and raspberry extract potential on metabolic syndrome-related enzymes in vitro. J Sci Food Agric 99:2939–2946

Hounsome N, Hounsome B, Tomos D, Edwards-Jones G (2008) Plant metabolites and nutritional quality of vegetables. J Food Sci 73:48–65

Jiang ZM, Wang LJ, Gao Z, Zhuang B, Yin Q, Liu EH (2019) Green and efficient extraction of different types of bioactive alkaloids using deep eutectic solvents. Microchem J 145:345–353

Lapeña D, Lomba L, Artal M, Lafuente C, Giner B (2019) The NADES glyceline as a potential Green Solvent: A comprehensive study of its thermophysical properties and effect of water inclusion. J Chem Thermodyn 128:164–172

Lee J, Lee Y, Choe E (2007) Temperature dependence of the autoxidation and antioxidants of soybean, sunflower, and olive oil. Eur Food Res Technol 226:239–246

López-Biedma A, Sánchez QC, Delgado-Rodríguez M, Gaforio JJ (2016) The biological activities of natural lignans from olive and virgin olove oils: a review. J Funct Foods 26:36–47

Mark R, Lyu X, Lee JJL, Parra-Saldívar R, Chen WN (2019) Sustainable production of natural phenolics for functional food applications. J Funct Foods 57:233–254

Moghimi M, Roosta A (2019) Physical properties of aqueous mixtures of (choline chloride + glucose) deep eutectic solvents. J Chem Thermodyn 129:159–165

Mylonaki S, Kiassos E, Makris DP, Kefalas P (2008) Optimisation of the extraction of olive (Olea europaea) leaf phenolics using water/ethanol-based solvent systems and response surface methodology. Anal Bioanal Chem 392:977–985

Reboredo-Rodríguez P, Varela-López A, Forbes-Hernández TY, Gasparrini M, Afrin S, Cianciosi D, Zhan J, Manna PP, Bompadre S, Quilles JL, Battino M (2018) Phenolic compounds isolated from olive oil as nutraceutical tools for the prevention and management of cancer and cardiovascular diseases. Int J Mol Sci 19:2305

Serreli G, Deiana M (2018) Biological relevance of extra virgin olive oil polyphenols metabolites. Antioxidants 7(170):1–19

Villard C, Larbat R, Munakata R, Hehn A (2019) Defence mechanisms of ficus: pyramiding strategies to cope with pests and pathogens. Planta 249:617–633

Acknowledgements

This work was supported by the Spanish Government (Project AGL2016-76820-R) AEI/FEDER, UE) and by the Spanish FPI funding program (MEIC) (BES-2017–079648).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rodríguez-Juan, E., Rodríguez-Romero, C., Fernández-Bolaños, J. et al. Phenolic compounds from virgin olive oil obtained by natural deep eutectic solvent (NADES): effect of the extraction and recovery conditions. J Food Sci Technol 58, 552–561 (2021). https://doi.org/10.1007/s13197-020-04567-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04567-3