Abstract

The efficacy of acidic electrolyzed water (AEW) for reducing total bacteria, coliforms, yeast and mold counts on commercial mung bean sprouts was investigated. The impact of pH, available chlorine concentration (ACC) and the cleaning method on antimicrobial efficacy of AEW was studied. AEW with a pH of 4.47 reduced the total bacterial, coliform, and yeast and mold counts on mung bean sprouts by 1.23, 1.42 and 1.25 log CFU/g, respectively. The efficacy of AEW increased with increasing ACC, and further studies showed that its antimicrobial ability was based on a combination of pH and ACC values. Cleaning using ultrasonic waves enhanced the antimicrobial activity of electrolyzed water, achieving reduction of 2.46, 2.13 and 2.92 log CFU/g for total bacterial, yeast and mold, and coliform counts, respectively. These results have indicated that using ultrasonic waves as a cleaning method, combined with AEW, could be a promising way to reduce the microbial populations on mung bean sprouts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mung bean sprouts have become a popular food item, but like other sprouted seed products, they can potentially become contaminated with human pathogens. Contamination can occur before and after harvesting the seeds and during their germination to produce sprouts when the conditions are optimal for the growth of many types of microorganism (Yang et al. 2013b). As raw sprouts have become more popular, so have outbreaks of foodborne illnesses which present significant challenges to the sprout industry (Hagger and Morawicki 2013). Therefore, measures must be taken during processing to eliminate populations of pathogenic microorganisms from sprouts.

Of the methods explored for pathogen reduction, hot water treatment at 90 °C for 90 s has been shown to be effective for eliminating pathogens from artificially-inoculated mung bean seeds. However, their germination yield decreased significantly (Bari et al. 2011). Using gamma irradiation combined with dry heat treatments eliminated E. coli O157:H7 from mung bean seeds. The combined treatments did not affect the percentage germination, but the sprout length decreased (Bari et al. 2003). In another study, a high dose of gamma irradiation had adverse effects on the rate of germination, and the length and thickness of the sprouts (Yang et al. 2013b). Immersing alfalfa sprouts inoculated with E. coli O157:H7 in 21 mg/L ozonated water did not significantly reduce the cell counts compared with the control treatment (Sharma et al. 2003).

Electrolyzed water (EW) has also been used in mung bean sprout production during the rinsing and soaking procedures, resulting in a reduction in the number of microorganisms and an increase in their growth rate (Rui et al. 2011; Liu et al. 2013, 2014). EW is usually generated by electrolyzing a dilute salt solution, which produces acidic electrolyzed water (AEW) and alkaline electrolyzed water (AlEW). As a non-thermal method, EW causes no changes in the ingredients, texture, aroma, or flavor of foods which can often occur after heat-treatment (Al-Haq et al. 2005). However, commercial mung bean sprouts are usually produced using tap water (TW), which has no disinfection effect, and as a result, foodborne illnesses related to sprouts have been reported worldwide in recent years (Rimhanen-Finne et al. 2011; Yang et al. 2013b). To improve the safety of commercial mung bean sprouts intended for immediate human consumption, the present study aims to investigate the microbial populations in these food products and how electrolyzed water can be used for disinfecting and cleaning during sprout processing.

Materials and methods

Experimental design

In this research, four experiments were designed to investigated the antimicrobial effects of EW on commercially-produced mung bean sprouts. In the first experiment, the impact of the pH of the AEW on the number of microbes of samples was evaluated compared with the untreated samples (CK). In the second experiment, the effect of the ACC value of the AEW on the number of microbes on the mung bean sprouts samples was evaluated compared with the CK. In the third experiment, the factors influencing the disinfection efficacy of EW were studied compared with acetate buffer solution (ABS), NaClO solution and CK. The fourth experiment was based on the enhanced bactericidal effect of EW reported by Liu et al. (2013) achieved when using ultrasonic waves for cleaning germinated brown rice. In this case, the effects of 10 min of ultrasound in AEW, and 10 min ultrasound in AlEW followed by soaking in AEW were compared with the effect of soaking in AEW, rinsing with AEW and CK. The total numbers of aerobic bacteria, coliform bacteria, and molds and yeasts in fresh mung bean sprouts were enumerated as indices of the efficacy of disinfection.

Materials

The fresh mung bean sprouts used in the experiments were purchased from local market and kept at 4 °C and used within 6 h.

Preparation of treatment solutions

The EW was prepared using an electrolyzed water generator (model XY-L-150, Xinu Optics-Mechanics-Electricity Co. Ltd., Baoji, China). It was collected from the outlet in polypropylene containers and used immediately. A range of AEW with the same ACC value but different pH levels was prepared by adding AlEW and distilled water to AEW to obtain about 45 mg/L available chlorine. EW with approximately the same pH value but with different ACC values was prepared by adding distilled water to AEW. The NaClO solution was prepared by adding concentrated sodium hypochlorite solution to distilled water to obtain about 45 mg/L available chlorine. ABS was prepared by adding acetic acid and sodium acetate to distilled water then adjusting the pH to about 4.5. The pH values of the electrolyzed water were measured using a PHB-1 electrode (Ao Li Long Instrument Co. Ltd., Hangzhou, China). The ACC of the EW was determined using iodometry (Block 1983). The physicochemical parameters of all treatment solutions used in the study are shown in Table 1.

Treatment of the mung bean sprouts

For EW treatment by immersion, 25 g of mung bean sprouts were immersed in 200 mL of treatment solution in a sterile beaker for 10 min at room temperature. The solutions were then decanted and the number of microorganisms on the sprouts enumerated.

For EW treatment by rinsing, 25 g of mung bean sprouts were rinsed with 200 mL AEW 8 (Table 1) for 1 min at room temperature. The solutions were then decanted and the number of microorganisms on the sprouts enumerated.

For ultrasonic waves AEW (UAEW) treatment, 25 g of mung bean sprouts were soaked in 200 mL AEW 8 (Table 1) then treated ultrasonically (model KQ-500DE, 500 W, 40 kHz, Kun Shan Ultrasonic Instrument, China) for 10 min. After treatment, the solutions were decanted and the number of microorganisms on the sprouts enumerated. The procedure for ultrasonic waves AlEW cleaning before AEW soaking (UAlEW) was almost the same as that for UAEW, except that the sprouts were soaked in AlEW during ultrasonic treatment, then in AEW 8 (Table 1) for 10 min after ultrasonic treatment.

Microbial analysis

After soaking, the mung bean sprouts were collected aseptically then immediately microbially analyzed as described by Hao et al. (2011), with modifications. To enumerate the microorganisms, 25 g of each mung bean sprouts sample were immersed in 225 mL of sterile physiological saline solution then homogenized for 2 min at normal speed in a Stomacher (Model YM-08X, Shanghai Yuming Instrument, China). Then 1 mL of the solution was diluted to 10 mL with sterile physiological saline solution, and 1 mL of the appropriate dilutions pour plated onto Plate Count Agar (PCA) (AOBOX Biotechnology Co. Ltd., Beijing, China) for the total bacterial counts, Rose Bengal Medium (RBM) (AOBOX Biotechnology Co. Ltd.) for the yeast and mold counts, and Violet Red Bile Agar (VRBA) (AOBOX Biotechnology Co. Ltd.) for the coliform counts. The PCA and VRBA plates were incubated at 37 °C for 48 h, while RBM plates were incubated at 28 °C for 48 h. Each microbial count was recorded as the mean of triplicate determinations and expressed as log colony forming units per gram (log CFU/g).

Statistical analysis

Different batches of sprouts from the same source were used for each experiment, and data from independent replicate trials were pooled and the means calculated. A one-way analysis of variance (ANOVA) was used to determine the significance of differences between treatments (SPSS 16.0, Chicago, IL, USA) and the level of statistical significance was set at a p value of ≤0.05.

Results and discussion

Effect of pH of electrolyzed water on microbial population of mung bean sprouts

The effect of EW with different pH values on reductions in the microbial populations of commercial mung bean sprouts is illustrated in Fig. 1. The initial microbial populations of total bacteria, yeasts and molds, and coliforms in the untreated group were 4.91, 3.53 and 4.99 log CFU/g, respectively. Compared with the untreated group, soaking in AEW with pH values of 3.02, 4.47, 5.58, and 6.51, for 10 min significantly decreased (p < 0.05) the microbial populations of total bacteria, yeasts and molds, and coliforms by 1.06, 1.23, 0.85, and 0.95 log CFU/g, respectively.

Effect of pH values of electrolyzed water on the reduction of microorganism populations of commercial mung bean sprouts. CK untreated group, AEW acidic electrolyzed water, AEW1 with pH 3.02 and available chlorine concentration (ACC) 46.09 mg/L, AEW2 with pH 4.47 and ACC 46.09 mg/L, AEW3 with pH 5.58 and ACC 46.09 mg/L, AEW4 with pH 6.51 and ACC 47.86 mg/L. The different letters on the error bar indicate significant differences (p < 0.05)

There were no significant differences in the population of total bacteria between samples treated with AEW 3 and AEW 4 (Table 1). However, the results demonstrated that the populations of total bacterial counts of mung bean sprouts disinfected with AEW 1 and AEW 2 (Table 1) were significantly lower compared with the other treatments (p < 0.05).

Similar results were obtained for the disinfection efficacy of electrolyzed water with different pH values on the coliform counts of mung bean sprouts. When compared with the population of coliforms in the control, acidic electrolyzed water with pH values of 3.02, 4.47, 5.58 and 6.51 decreased the counts by 1.24, 1.25, 0.96 and 0.94 log CFU/g, respectively. There were no significant differences in the population of coliforms between AEW 1 and AEW 2 or between AEW 3 and AEW 4. However, the coliform counts after AEW 1 and AEW 2 treatments were significantly lower than for the other treatment (p < 0.05).

More reductions were observed in the yeast and mold counts. Compared with the untreated group, treatment using AEW with pH values of 3.02, 4.47, 5.58 and 6.51 decreased counts by 1.21, 1.42, 1.29 and 1.04 log CFU/g, respectively. There were no significant differences between AEW 1 and AEW 3 treatments, with the largest reductions in the yeast and mold counts observed after AEW 2 treatment.

These results demonstrated that AEW with different pH values can reduce the populations of microorganisms on mung bean sprouts. AEW contains a mixture of inorganic oxidants, HClO, ClO− and Cl2, which effectively inactivate a variety of microorganisms (Yang et al. 2003). The results of the present study have shown that treatment using AEW with a pH of 4.47 can reduce the counts of total bacteria, yeasts and molds, and coliforms significantly, compared with using AEW with pH values of 3.02, 5.58 and 6.51. Previous studies have indicated that the disinfection depends on the form of available chlorine, which is strongly influenced by the pH value (Xiong et al. 2012). When the pH was less than 2, Cl2 gas and HOCl were the main forms of available chlorine. As the pH increased, Cl2 gas reacted with H2O to form HOCl, reaching a maximum percentage at a pH of approximately 4. Between pH values of 3 and 6, HClO was the main form of available chlorine. As the pH increased further, to between 8 and 10, the primary form of available chlorine was ClO− (Xiong et al. 2012). These results were verified by ultraviolet spectroscopy, which showed that at around a pH of 4, the absorption peak measured at 232 nm, regarded as the characteristic absorption peak for HClO, reached a maximum. Thus available chlorine in the form of HClO was considered to produce the antimicrobial activity of AEW (Xiong et al. 2014). These results coincided with their previous study, indicating that AEW with a pH of 4.47 provided the best antimicrobial ability for treating mung bean sprouts.

Effect of available chlorine concentration of electrolyzed water of microorganism populations of mung bean sprouts

The effect of the ACC of EW on reducing microbial populations on commercial mung bean sprouts is shown in Fig. 2. The initial microbial populations of total bacteria, molds and yeasts, and coliforms in the untreated group were 5.12, 3.66 and 4.76 log CFU/g, respectively. Compared with the untreated group, soaking in AEW with different values of ACC for 10 min decreased the microbial populations of total bacteria, molds and yeasts, and coliforms.

Effect of available chlorine concentration of electrolyzed water on the reduction of microorganism populations of commercial mung bean sprouts. CK untreated group, AEW acidic electrolyzed water, AEW5 with pH 3.87 and available chlorine concentration (ACC) 7.81 mg/L, AEW6 with pH 3.27 and ACC 27.48 mg/L, AEW 7 with pH 2.88 and ACC 44.32 mg/L, AEW 8 with pH 2.76 and ACC 69.14 mg/L. The different letters on the error bar indicate significant differences (p < 0.05)

A similar trend was observed for EW with different ACCvalues on disinfection efficacy. Compared with the untreated group, AEW with ACC values of 7.81, 27.48, 44.32 and 69.14 mg/L decreased the total bacterial count on commercial mung bean sprouts by 0.46, 0.83, 1.27, and 2.20 log CFU/g, respectively, the yeast and mold counts by 0.24, 1.06, 1.42, and 1.93 log CFU/g, respectively, and the coliforms count by 0.30, 0.46, 1.08, and 1.92 log CFU/g, respectively.

AEW contains available chlorine in the form of HClO, ClO−, and Cl2. It has been shown that the form of ACC present can alter as the pH changes, which is highly related to the antimicrobial activity of AEW (Xiong et al. 2012, 2014). However, even at approximately the same pH value, AEW with different ACC values can also exhibit different disinfection abilities (Yang et al. 2013a). A previous study has also shown a high level of correlation (r = 0.95) between HOCl concentration and the bactericidal effectiveness of AEW (Len et al. 2000). Zhang et al. (2016a) have reported that the log CFU/g reduction in the counts of the natural microbiota on celery and cilantro increased significantly with increasing ACC values. Zhang et al. (2016b) have also demonstrated that the population of the natural microbiota on radish seeds decreased using AEW with increasing ACC values. This phenomenon has also been demonstrated in the present study. Our results have shown that the log CFU/g reduction in the counts of total bacteria, molds and yeasts, and coliforms increased with increasing ACC values of AEW. Furthermore, AEW with ACC values varying from 7.81 to 69.14 mg/L did not adversely alter the visual appearance of mung bean sprouts (data not shown).

Factors influencing the disinfection efficacy of electrolyzed water

The factors influencing the disinfection efficacy of EW were studied (Fig. 3). The initial total bacterial count of the untreated group was 5.19 log CFU/g. Treatment with tap water only decreased this value by 0.18 log CFU/g, an insignificant difference compared with CK. No significant differences were observed between treatments by ABS and NaClO solution, which decreased the total bacterial count by 1.05 and 1.12 log CFU/g, respectively. While AEW achieved the greatest reduction, 1.62 log CFU/g, this difference was insignificant compared with the other treatments.

The factors influencing disinfection efficacy of electrolyzed water. CK untreated group, TW tap water with pH 7.23 and available chlorine concentration (ACC) was not detected, ABS acetate buffer solution with pH 4.81 and ACC was not detected, AEW9 acidic electrolyzed water with pH 4.73 and ACC 46.87 mg/L, NaClO solution with pH 10.17 and ACC 47.13 mg/L. The different letters on the error bar indicate significant differences (p < 0.05)

Similar results were observed for disinfection efficacy on the mold and yeast counts from commercial mung bean sprouts. The initial mold and yeast count of the untreated group was 3.77 log CFU/g. TW treatment reduced this by 0.07 log CFU/g, which was insignificant compared with CK. Meanwhile, no significant differences in the mold and yeast counts were observed between the ABS and NaClO treatments, which decreased by 1.45 and 1.63 log CFU/g, respectively. AEW treatment reduced the mold and yeast counts by 2.14 log CFU/g, which was significant (p < 0.05) compared with the other treatments.

TW, ABS, and NaClO solution all decreased the coliform count on commercial mung bean sprouts by 0.18, 1.03, and 0.95 log CFU/g, respectively. While AEW treatment decreased the coliform count significantly by 1.54 log CFU/g, no significant differences were observed between the ABS and NaClO solution treatments.

The results have shown that TW treatment, often used for cleaning by consumers, cannot effectively control the naturally-occurring populations of microorganisms on mung bean sprouts. Therefore, to improve safety, effective disinfection measures must be taken. The bactericidal activity of AEW has previously been confirmed (Huang et al. 2008) but its antimicrobial mechanism has not yet been fully clarified. The disinfection efficacies of ABS and NaClO solution have also been studied on the basis of the physicochemical properties of AEW. The ABS and NaClO solution used in the present study had approximately the same values of pH and ACC, respectively, as AEW. However, the ABS and NaClO solution did not show the same disinfection abilities as AEW. Although ABS had the same pH as AEW, it contained no chlorine species, and the available chlorine is considered as the main factor contributing to the disinfecting potential of AEW (Koseki and Itoh 2000). The pH of the AEW used in the present study was 4.73. At this pH value, the main form of chlorine in AEW is hypochlorous acid, which has a strong antimicrobial activity (Al-Haq et al. 2005). However, for the NaClO solution the main factor contributing to the disinfection ability is the hypochlorite ion. The present study has indicated that even though AEW and NaClO solution have approximately the same ACC, their disinfection abilities were significantly different. This is because hypochlorous acid and hypochlorite ions have different disinfection abilities, hypochlorous acid being 80 times more effective as a sanitizing agent than an equivalent concentration of hypochlorite ions (Rahman et al. 2010).

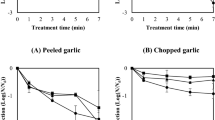

Effect of cleaning methods on the disinfection efficacy of acidic electrolyzed water

The effects of different modes of washing on disinfection efficacy are shown in Fig. 4. The total bacterial count of the untreated group of mung bean sprouts was 4.99 log CFU/g, whereas those treated by soaking, rinsing, ultrasonic assisted AEW cleaning, and ultrasonic assisted AlEW cleaning before AEW soaking decreased the total bacterial counts by 2.08, 0.92, 2.46 and 2.26 log CFU/g, respectively. No significant differences were observed between soaking in AEW and ultrasonic assisted AlEW cleaning before AEW soaking, while the total bacterial count of ultrasonic assisted AEW cleaning was significantly lower compared with the other treatments.

The effect of cleaning methods on the disinfection efficacy of acidic electrolyzed water. CK untreated group, UAEW ultrasound in acidic electrolyzed water with pH 2.76 and available chlorine concentration (ACC) 69.14 mg/L, UAlEW ultrasound in alkaline electrolyzed water with pH 11.28 followed by ultrasound in acidic electrolyzed water with pH 2.76 and ACC 69.14 mg/L. The different letters on the error bar indicate significant differences (p < 0.05)

The initial yeast and mold counts of the untreated group was 3.63 log CFU/g, while mung bean sprouts treated by soaking, rinsing, UAEW, and UAlEW before AEW soaking decreased yeast and mold counts by 1.93, 1.25, 2.13 and 2.29 log CFU/g, respectively. UAlEW treatment before AEW soaking decreased the yeast and mold counts by the greatest amount, but the differences were not significant compared with UAEW cleaning alone.

The initial coliform count of mung bean sprouts was 4.78 log CFU/g. After soaking, rinsing, UAEW cleaning, and UAlEW cleaning before AEW soaking, this value decreased by 1.91, 0.93, 2.92, and 2.12 log CFU/g, respectively. The coliform count after UAEW cleaning was significantly lower compared with the other treatments (p < 0.05).

This work indicated that soaking was more effective than rinsing for decreasing the counts of all the naturally-occurring microorganisms tested, agreeing with previous research by Lu et al. (2010). One possible explanation could be that during rinsing, no effective contact can be achieved between the mung bean sprouts and the AEW, but soaking can guarantee a much more effective contact between them. Meanwhile, our results have shown that ultrasound-assisted cleaning significantly reduced the counts of the microorganisms naturally occurring on mung bean sprouts. Ultrasound has been found to generate a powerful cavitation effect which can detach and destroy microorganisms from the surfaces of fresh produce (Ding et al. 2015). The smooth surface of mung bean sprouts would provide easier access for ultrasonic waves to facilitate the contact between AEW and the microflora. Therefore, ultrasonic treatment achieved a greater reduction in the log CFU/g of naturally-occurring microorganisms. Our results have also shown that UAEW has an equivalent (for the mold and yeast counts), or high (for the total bacterial and coliform counts) disinfectant efficacy on mung bean sprouts compared with the UAlEW treatment. This may have been because AlEW was less effective than AEW (Ovissipour et al. 2015). Therefore, with the assistance of ultrasonic waves, the natural-occurring microorganisms were removed from the surface of the mung bean sprouts then destroyed by contact with AEW during the UAEW treatment. However, in the UAlEW treatment, the log CFU/g reduction was less than UAEW (especially for the total bacterial and coliform counts), even after soaking in AEW.

Conclusion

To improve the safety of commercial mung bean sprouts for consumers, the efficacy of using electrolyzed water for reducing the microbial populations on mung bean sprouts has been investigated. The study has shown that between pH values of 3.0 and 6.5, the disinfection ability of AEW increased with increasing ACC, and that ultrasonic-assisted AEW cleaning could be a promising method for reducing the microbial populations on mung bean sprouts.

References

Al-Haq MI, Sugiyama J, Isobe S (2005) Applications of electrolyzed water in agriculture and food industries. Food Sci Technol Res 11(2):135–150. doi:10.3136/fstr.11.135

Bari ML, Nazuka E, Sabina Y, Todoriki S, Ishiki K (2003) Chemical and irradiation treatments for killing Escherichia coli O157: H7 on alfalfa, radish, and mung bean seeds. J Food Prot 66(5):767–774

Bari ML, Enomoto K, Nei D, Kawamoto S (2011) Development of effective seed decontamination technology to inactivate pathogens on mung bean seeds and its practical application in Japan. Jpn Agric Res Q 45(2):153–161. doi:10.6090/jarq.45.153

Block SS (1983) Sterilants, disinfectants and antiseptics. In: Block SS (ed) Disinfection, sterilization, and preservation. Lea and Febiger, Philadelphia, pp 157–160

Ding T, Ge Z, Shi J, Xu YT, Jones CL, Liu DH (2015) Impact of slightly acidic electrolyzed water (SAEW) and ultrasound on microbial loads and quality of fresh fruits. LWT Food Sci Technol 60(2):1195–1199. doi:10.1016/j.lwt.2014.09.012

Hagger T, Morawicki R (2013) Potential for dry thermal treatments to eliminate foodborne pathogens on sprout seeds. Agric Food Anal Bacteriol 3(3):218–229

Hao JX, Liu HJ, Liu R, Dalai WY, Zhao RP, Chen TP, Li TL (2011) Efficacy of slightly acidic electrolyzed water (SAEW) for reducing microbial contamination on fresh-cut cilantro. J Food Saf 31(1):28–34. doi:10.1111/j.1745-4565.2010.00261.x

Huang YR, Hung YC, Hsu SY, Huang YW, Hwang DF (2008) Application of electrolyzed water in the food industry. Food Control 19(4):329–345. doi:10.1016/j.foodcont.2007.08.012

Koseki S, Itoh K (2000) The effect of available chlorine concentration of the disinfecting potential of acidic electrolyzed water for shredded vegetables. J Jpn Soc Food Sci Technol 47(12):888–898

Len SV, Hung YC, Erickson M, Kim C (2000) Ultraviolet spectrophotometric characterization and bactericidal properties of electrolyzed oxidizing water as influenced by amperage and pH. J Food Prot 63(11):1534–1537

Liu R, He X, Shi J, Nirasawa S, Tatsumi E, Li L, Liu HJ (2013) The effect of electrolyzed water on decontamination, germination and γ-aminobutyric acid accumulation of brown rice. Food Control 33(1):1–5. doi:10.1016/j.foodcont.2013.02.008

Liu R, Shi JQ, He XL, Nirasawa S, Tatsumi E, Liu HJ (2014) Effect of slightly acidic electrolyzed water on germination and sprouts growth of soybean seeds. Int Agric Eng J 23(3):50–56

Lu ZH, Zhang Y, Li LT, Curtis RB, Kong XL, Fulcher RG, Zhang G, Cao W (2010) Inhibition of microbial growth and enrichment of γ-aminobutyric acid during germination of brown rice by electrolyzed oxidizing water. J Food Prot 73(3):483–487

Ovissipour M, Al-Qadiri HM, Sablani SS, Govindan BN, Al-Alami N, Rasco B (2015) Efficacy of acidic and alkaline electrolyzed water for inactivating Escherichia coli O104: H4, Listeria monocytogenes, Campylobacter jejuni, Aeromonas hydrophila, and Vibrio parahaemolyticus in cell suspensions. Food Control 53:117–123. doi:10.1016/j.foodcont.2015.01.006

Rahman SME, Ding T, Oh DH (2010) Effectiveness of low concentration electrolyzed water to inactivate foodborne pathogens under different environmental conditions. Int J Food Microbiol 139(3):147–153. doi:10.1016/j.ijfoodmicro.2010.03.020

Rimhanen-Finne R, Niskanen T, Lienemann T et al (2011) A nationwide outbreak of Salmonella Bovismorbificans associated with sprouted alfalfa seeds in Finland, 2009. Zoonoses Public Health 58(8):589–596. doi:10.1111/j.1863-2378.2011.01408.x

Rui L, Jianxiong H, Haijie L, Lite L (2011) Application of electrolyzed functional water on producing mung bean sprouts. Food Control 22(8):1311–1315. doi:10.1016/j.foodcont.2011.02.005

Sharma RR, Demirci A, Beuchat LR, Fett WF (2003) Application of ozone for inactivation of Escherichia coli O157: H7 on inoculated alfalfa sprouts. J Food Process Preserv 27(1):51–64. doi:10.1111/j.1745-4549.2003.tb00500.x

Xiong K, Liu H, Li L (2012) Product identification and safety evaluation of aflatoxin B1 decontaminated by electrolyzed oxidizing water. J Agric Food Chem 60(38):9770–9778. doi:10.1021/jf303478y

Xiong K, Li X, Guo S, Li L, Liu H (2014) The antifungal mechanism of electrolyzed oxidizing water against Aspergillus flavus. Food Sci Biotechnol 23(2):661–669. doi:10.1007/s10068-014-0090-8

Yang H, Swem BL, Li Y (2003) The effect of pH on inactivation of pathogenic bacteria on fresh-cut lettuce by dipping treatment with electrolyzed water. J Food Sci 68(3):1013–1017. doi:10.1111/j.1365-2621.2003.tb08280.x

Yang H, Feirtag J, Diez-Gonzalez F (2013a) Sanitizing effectiveness of commercial “active water” technologies on Escherichia coli O157: H7, Salmonella enterica and Listeria monocytogenes. Food Control 33(1):232–238. doi:10.1016/j.foodcont.2013.03.007

Yang Y, Meier F, Ann Lo J et al (2013b) Overview of recent events in the microbiological safety of sprouts and new intervention technologies. Compr Rev Food Sci Food Saf 12(3):265–280. doi:10.1111/1541-4337.12010

Zhang C, Cao W, Hung YC, Li B (2016a) Disinfection effect of slightly acidic electrolyzed water on celery and cilantro. Food Control 69:147–152. doi:10.1016/j.foodcont.2016.04.039

Zhang C, Cao W, Hung YC, Li B (2016b) Application of electrolyzed oxidizing water in production of radish sprouts to reduce natural microbiota. Food Control 67:177–182. doi:10.1016/j.foodcont.2016.02.045

Acknowledgements

This work was supported by the Startup Project of Doctor Scientific Research of Yuncheng University (Grant No. YQ-2014026); the “131” Talents Funded Projects (Grant No. XK-2015019); and the Subject Cluster Project (Grant No. XK-2015010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Rui Liu and Zhang-Long Yu contributed equally to this work.

Rights and permissions

About this article

Cite this article

Liu, R., Yu, ZL. Application of electrolyzed water on reducing the microbial populations on commercial mung bean sprouts. J Food Sci Technol 54, 995–1001 (2017). https://doi.org/10.1007/s13197-016-2445-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2445-z