Abstract

Disinfection after harvest is an essential step to maintain commodities and facilities free of fungal and bacterial postharvest pathogens, responsible of storage decay and economic losses. Electrolyzed water (EW) has gained considerable interest over the last decades as a novel broad-spectrum sanitizer. EW is sustainable and cost effective since it can be produced on-site utilizing tap water and different inexpensive salts and is healthy for both the environment and human beings. Its effectiveness in controlling fungi, yeasts, and bacteria within a wide range of pH is due to multiple mode of actions. Furthermore, its strong oxidizing potential is capable to reduce the amount of pesticide residues on fruit and vegetable surfaces and to avoid pathogen resistance. Properties of EW are related to salts employed for production, being those with low chlorine content preferable. Lastly, EW has no negative effect on the organoleptic properties and features of treated commodities. The present chapter highlights recent developments in EW generation, factors affecting its effectiveness for controlling postharvest decay of fruits and vegetables, mechanism of action on microbes and hosts, and advantages and disadvantages on its use.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Physical means

- Electrolyzed water

- Sodium bicarbonate

- Sodium chloride

- Fruits and vegetables

- Decontamination

Introduction

Postharvest decay of fruits and vegetables is often a direct result of poor handling practices in the packinghouse environment. The wash water used in dump tanks for processing is among the various sources of pathogen contamination; thus, its proper sanitation is extremely important for delivering healthy products to the consumer and minimizing postharvest losses. Indeed, sanitation after harvest can reduce spoilage by 50% or more (Sargent et al. 2000). The most popular disinfecting agent is chlorine (hypochlorite) applied as spray or dip, but several alternative sanitizers of minor use during washing or storage of fresh produce are available, such as chlorine dioxide, ozone, ethanol, hydrogen peroxide, organic acids, and electrolyzed water (EW). This latter has gained importance in the food industry, representing a relevant technical advancement (Buck et al. 2002; Hricova et al. 2008; Feliziani et al. 2016; Rahman et al. 2016). It was firstly developed in Russia for water decontamination and regeneration (Kunina 1967), then it gained great interest for sterilization of utensils, meats, cutting boards, and, more recently, in livestock management and for the sanitation of the washing waters of fresh and minimally processed fruit and vegetables (Lee et al. 2004; Guentzel et al. 2010; Fallanaj et al. 2013; Gómez-López et al. 2013). This chapter will address EW generation, factors affecting its effectiveness, mechanism of action on microbes and hosts, and advantage and disadvantage on its use.

Generation of EW

In chemistry, the electrolysis is the process by which electrical energy is transformed into chemical energy, where an electric current passes through an electrolyte with subsequent migration of positive and negatively charged ions towards the negative and positive electrodes, respectively. EW is typically produced by electrolysis of dilute solutions of sodium chloride (NaCl) in an electrolysis cell with or without a diaphragm, which separates the anode (+) and cathode (−). Salts such as potassium chloride (KCl), magnesium chloride (MgCl2), sodium sulfite (Na2SO3), sodium hydrogen carbonate (NaHCO3) and many others (Table 12.1) can also be used (Buck et al. 2002; Fallanaj et al. 2013; Feliziani et al. 2016; Youssef and Hussien 2020). However, since a certain amount of chloride is contained in tap water, it would be possible to reactivate its free chlorine by electrolysis, although obtained amount is usually too low to be effective against pathogenic microorganisms (Nakajima et al. 2004). Recently a PE-1 water ionizer machine (Shenzhen, Guangdong, China) that use only naturally present salts in tap water allowed to obtain good results by selecting different levels of electrolyzing potentials (Hussien et al. 2017).

In an electrolysis cell divided by a membrane, two types of EW are produced: the acidic electrolyzed water (AEW) and the basic electrolyzed water (BEW), as displayed in Fig. 12.1. During electrolysis, the dissociated Cl− together with OH− move to the anode donating electrons to generate oxygen (O2), chlorine gas (Cl2), hypochlorite ions (ClO−), and hydrochloric acid (HCl), whereas positively charged ions, such as H+ and Na+, move to the cathode to accept electrons to generate hydrogen gas (H2) and sodium hydroxide (NaOH) (Siddiqui 2018). When the electrolysis cell is separated by a septum, species produced on the anode stream result in an acidic solution of pH 2–3, an oxidation-reduction potential (ORP) higher than 1100 mV, and an active chlorine content (ACC) of 10–90 ppm. Species produced on the cathode stream result in a basic solution of pH 10–13 and an ORP of −800 to −900 mV. When the electrolysis cell is not separated by a septum, neutral electrolyzed water (NEW), with a ORP of 750–900 mV and pH of about 7 is produced, because hydroxide ions (OH−) formed at the anode neutralizes the protons (H+) produced at the cathode (Deza et al. 2007). Compared to other types of EW, NEW has a longer shelf-life under certain circumstances (Rahman et al. 2010a, b).

Schematic representation of AEW and BEW generation using NaCl solution. (Hricova et al. 2008)

Indeed, EW is usually prepared on site just before use, but Len et al. (2002) demonstrated that AEW stored in a closed and dark environment remains stable. In particular, AEW rapidly decreased ORP releasing Cl2 through the evolution of chlorine gas, thus rapidly reducing the biocidal effectiveness of the solutions. Len et al. (2002) observed a 100% loss of active chlorine and a 10% loss of ORP within a 4-day period for AEW stored in an open dark container at 25 °C. In contrast, loss of chlorine oxidants and ORP of NEW was substantially lower, with only 5% decrease of active chlorine and no significant loss of ORP after 4 days in a closed dark container at 25 °C (Guentzel et al. 2010). Another way to preserve the effectiveness of EW is to convert it into ice cubes for later use (Koseki et al. 2002). Finally, slightly acidic electrolyzed water (SAEW) with a pH of 5.0–6.5 (Fig. 12.2) and an ORP of 800–900 mV is produced by electrolysis of diluted solution of HCl alone or in combination with NaCl in an EW generation equipment using an electrolysis chamber without the membrane (Forghani et al. 2015). SAEW usually has high ACC (up to 200 ppm) and for this reason can be used in a diluted form; its main free chlorine is HOCl (Fig. 12.3). The bactericidal activity of hypochlorous acid was 80 times greater than that of hypochlorite ion (ClO−) for inactivating Escherichia coli at the same chlorine concentration and treatment time (Anonymous 1997). Therefore, SAEW may improve the bactericidal activity through maximizing the use of hypochlorous acid, thus reducing corrosion of surfaces and minimizing human health and safety issues side effects from off-gassing of Cl2 (Guentzel et al. 2008).

Schematic representation of SAEW generation using diluted solution of HCl. (From Xuan and Ling 2019)

Chlorine profile change with pH. The activities of Cl2, HOCl, and OCl− produced during the electrolysis process are pH dependent, being Cl2 present at low pH, HOCl active at pH around 4.0–5.0, and OCl− effective at high pH. (From Al-Haq et al. 2005)

EW is generally considered safer and less expensive than most traditional preservation methods. Various machines are manufactured around the world. The most common equipment used in published reports are ROX-20TA-U and ROX-10 WBE (Hoshizaki Electric Inc., Toyoake, Aichi, Japan), Remotex (Remote Co., Toshima-ku, Tokyo), model IKS 1005 (Mitsubishi Electric Engineering Co., Japan) (Al-Haq and Gómez-López 2012), and HRW-1500 (HuoRen-Jing-Chuang Medical Equipment Co., Ltd., Beijing) (Chen et al. 2020). In Europe the most common equipment in published reports producing NEW are manufactured by Adamant Technology (SA, Switzerland) (López-Gálvez et al. 2012; Fallanaj et al. 2013, 2016, 2015), Denora Next (Milan, Italy), Best Life (China), ATS unique technologies BV (The Netherlands), ATS (Holambra, SP, Brasil) and more recently by Aqanat Limited (Coxwold, York, UK).

Factors Influencing the Effectiveness of EW

The electrode materials play an important role in the production of oxidant species in relation to the current, temperature, salt, and type of electrolysis (Martínez-Huitle and Brillas 2008). Traditionally, platinum is used as the anode in the EW generator. A descending order of electrode materials in terms of efficiency in producing active free chlorine was proposed by Rahman et al. (2016): Ti/IrO2 > Ti/RuO2 > Ti/Pt–IrO2 > BDD (Boron-Doped Diamond) > Pt.

The influence of water hardness on the basic properties of EW has been reported by a few researchers (Pangloli and Hung 2013; Forghani et al. 2015). The authors reported that water hardness from 0 to 50 mg/L CaCO3 increases the ACC and ORP levels of EW, while decreasing the pH; however, water hardness higher than 50 mg/L was observed to inhibit the inactivation of E. coli O157:H7 by EW. The mechanisms of how water hardness changes the bactericidal efficacy of EW still remains unclear and requires more investigations. Moreover, Forghani et al. (2015) highlighted that pre-heating water before EW generation allowed to increase the ACC and the biocide activity.

In a fresh produce processing plant, sanitizers generally are used in the presence of organic matter, such as produce debris, soils, and microorganisms present on fruit and vegetable surfaces, all of which reduce sanitizer efficacy. Oomori et al. (2000) reported that organic matter, including amino acids and proteins, potentially react with ACC and change it into the combined form. For instance, Li et al. (1996) observed that the reduction rate of Bacillus subtilis var. niger by EW exposure for 20 min decreased from 100 to 19.5% after adding 10% bovine serum albumin (BSA) to AEW. Indeed, organic matters might wrap target microorganisms and protect the outer structures of microbial cells from the attack of EW (Park et al. 2009; Virto et al. 2005).

In addition, the bactericidal effect of EW is thought to be better on smooth surfaces than on rough ones (Koseki et al. 2004; Park et al. 2009). For instance, Park et al. (2009) observed that the reduction of E. coli O157:H7, Salmonella typhimurium, and Listeria monocytogenes on the surface of a tomato by AEW exposure was higher than that on the surface of green onions. The authors explained that the smoother surface of tomatoes accelerated the activity of chlorine species in EW to better contact with microorganisms.

Effect on Plant Pathogens

The modes of action of electrochemical treatment of water are still not completely understood. Evidences suggest that a direct oxidation at the anode surface and indirect oxidation in the bulk solution by oxidants produced from the substances present in the water are responsible for the inactivation of microorganisms (Anglada et al. 2009). In Aspergillus flavus morphological changes occurred both in the conidia and mycelia, such as cell wall shrinkage, partial cracking, chipping, and holes (Fig. 12.4, Xiong et al. 2014). Chlorine compounds, pH, ORP, and their combination are considered the main factors involved in the antimicrobial activity (Al-Haq et al. 2005) and these are reported as the mode of action of many gaseous and aqueous oxidizing agents (Finnegan et al. 2010). However, since EW is active in a wide range of ORP and pH values and in some cases free chlorine is not generated, it is conceivable that its activity is related but not limited to these three factors. EW seems to induce higher sensitivity to active chlorine by sensitizing the outer membrane to the entry of HOCl (Park et al. 2004a). HOCl is considered the most active of the chlorine compounds (Mahmoud 2007) produced during electrolysis, penetrating cell membranes and producing hydroxyl radicals, which exert the antimicrobial activity through the oxidation of key metabolic compounds (Albrich et al. 1986; Barrette et al. 1989; Hurst et al. 1991; Hricova et al. 2008). HOCl can change bacterial respiration destroying the electron transport chains and affecting adenine nucleotide pool (Albrich et al. 1981). Chlorine is considered responsible of: (a) disruption of protein synthesis; (b) oxidative decarboxylation of amino acids to nitrites and aldehydes; (c) reactions with nucleic acids, purines, and pyrimidines; (d) unbalanced metabolism after the destruction of key enzymes; (e) induction of DNA lesions with the accompanying loss of DNA-transforming ability; (f) inhibition of oxygen uptake and oxidative phosphorylation, coupled with leakage of some macromolecules; (g) formation of toxic N-chlorine derivatives of cytosine; and (h) creation of chromosomal aberrations (Feliziani et al. 2016).

Scanning electron photomicrographs of Aspergillus flavus conidia and mycelia. (a), normal mycelium; (b), mycelia treated with AEW; (c), mycelium treated with NEW; (d), normal conidia; (e), conidia treated with AEW; (f), conidia treated with NEW. Arrows show morphological changes in the conidia and mycelia, including cell wall shrinkage, partial cracking, chipping, and holes. Scale bars = (a and c), 30 μm; (b), 50 μm; (d–f), 5 μm. (From Xiong et al. 2014)

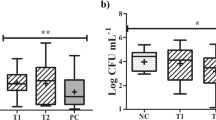

ORP is also involved in the mode of action of EW but its effect on the deactivation of microbes is controversial (McPherson 1993; Venkitanarayanan et al. 1999; Kim et al. 2000, 2001; Al-Haq et al. 2002; Liao et al. 2007). Aerobic bacteria grow mostly at ORP range + 200 to +800 mV, while anaerobic bacteria grow well at −700 to +200 mV (Jay 1996). The high ORP in the EW could cause the modification of metabolic fluxes and ATP production (Fig. 12.5), probably due to the change in the electron flow in cells (Huang et al. 2008).

Effect of electrolyzed water (ew), sodium bicarbonate (NaHCO3) and electrolyzed NaHCO3 (eNaHCO3) on mitochondrial membrane potential of Penicillium digitatum spores represented as red/green florescence ratio (a), and on ATP content (b). For each treatment representative images of stained spores under fluorescence microscopy are showed (c). Water was used as a control. (From Fallanaj et al. 2016)

Some authors suggested that the bacterial inactivation is primarily related to ORP and not to residual chlorine (Kim et al. 2000; Al-Haq et al. 2005). The high ORP of the solution affected fungi disrupting the outer membrane and facilitating the transfer of HOCl across the cell membrane, interfering on respiratory pathways (Liao et al. 2007). For example, it could cause damage to E. coli O157:H7, and attacked inner and outer membranes, causing necrosis of cells (Liao et al. 2007), with damage verified by microscopy (Feliciano et al. 2012). In case of NEW, produced by using diamond electrode and NaHCO3 as electrolyte, the activity of free chlorine was negligible and the pH little above the neutral value (Fallanaj et al. 2013); as reported also by Jeong et al. (2009), Fallanaj et al. (2013, 2016) ascribed the observed inactivation of Penicillium spp. population to electrochemical production of non-chlorine-based oxidants, such as hydrogen peroxide (H2O2), peroxymonocarbonate (HCO4−), and reactive oxygen species (ROS). In addition, the thin film-coated diamond electrode is known to produce by itself active oxygen species in a higher amount as compared to other anodes and, in presence of carbonate/bicarbonate-containing solutions, it can produce peroxycarbonate and derivatives, acting as strong disinfectants (Furuta et al. 2004). In addition, a paper by Fallanaj et al. (2016) demonstrated that electrolyzed NaHCO3 solution, when applied in wounds nearby the ones inoculated with the pathogen, was able to control P. digitatum infections in citrus fruit and a significant up-regulation of defense-related genes coding the enzymes chitinase, peroxidase, and phenylalanine ammonia-lyase was observed in treated tissues. Differences in mycelia micromorphology of Penicillium species treated with various EW and untreated were displayed in Fig. 12.6 and Fig. 12.7 employing scanned electron microscopy (Youssef and Hussien 2020). Based on above results on the mode of action of EW, its antimicrobial effect derives from the combined action of pH, ORP, free chlorine, and other still unknown active substances (Huang et al. 2008); in addition, the induction of tissue resistance should be considered as another important aspect of the multiple mechanism of action of this technology (Fallanaj et al. 2016).

Scanning electron microscope images of Penicillium digitatum-mycelium with free and linearly shaped hyphae (controls a and e). P. digitatum-mycelium in the presence of BEW generated by sodium metabisulphite (b), potassium sorbate (c) or potassium carbonate (d). P. digitatum-mycelium in the presence of AEW generated by sodium metabisulphite (f), potassium sorbate (g) or potassium carbonate (h). (From Youssef and Hussien 2020)

Scanning electron microscope images of Penicillium italicum-mycelium with free and linearly shaped hyphae (controls a and e). P. italicum-mycelium in the presence of BEW generated by sodium metabisulphite (b), potassium sorbate (c) or potassium carbonate (d). P. italicum-mycelium in the presence of AEW generated by sodium metabisulphite (f), potassium sorbate (g) or potassium carbonate (h). (From Youssef and Hussien 2020)

The pH also has its role in limiting the microbial growth; therefore, scientists also include it as one of the factors. Each microorganism has its own optimal growth range of pH; a low pH tends to destroy cell wall compounds (e.g. polysaccharides) and increase the permeability, resulting in the death of cell (McPherson 1993). Nevertheless, a low pH might not be sufficient to kill microbes, especially spores. Li et al. (1996) reported that the reduction level of B. subtilis var. niger can reach 100% after a 10-min AEW treatment, whereas it was only 1.06% for an HCl solution with the same pH. Therefore, most likely, the differences in effectiveness at different pHs is due to the high or low abundance of HOCl. In particular, at high pHs, the concentration of HOCl decreased, reflecting its dissociation to H+ and OCl− (Johnson and Melbourne 1996; White 1998).

Based on above literature there is no a consensus about EW mode of action against microorganisms (Table 12.2), but a lot of theories exist. Likely, multiple mechanisms are responsible of EW biocidal activity and this is theoretically confirmed by the absence of pathogen resistance.

Effect on Microbial Toxins

A study conducted by Audenaert et al. (2012) demonstrated that EW has potential to control Fusarium spp. in wheat grains during transport and storage although sub-lethal concentrations can result in increased deoxynivalenol (DON) biosynthesis. According to Zhang et al. (2012), soaking contaminated peanuts in an EW solution, the content of aflatoxin B1 (AFB1) decreased of about 85%. Moreover, they reported better results with AEW, suggesting a stronger decontamination effect of HClO than ClO−. On the same line, Suzuki et al. (2002) reported a strong reduction of the mutagenesis effect of AFB1 against Salmonella typhimurium TA-98 and TA-100 strains after the exposure of the toxin to the AEW.

Effect on Plants

Considering a holistic approach to the crop protection, it should be taken into account the effect of EW not only against the pathogens, but also on the crop. It has been demonstrated that SAEW inhibited the growth of broccoli sprouts, but increased sulforaphane content (Li et al. 2018). Another study conducted on Chinese cabbage highlighted that foliar application of EW solution could enhance the photosynthetic rate, leaf number, and yield; instead, root applications could increase the content of vitamin C (Hou et al. 2011). The application of EW on harvested sugarcane during summer months showed relatively less decline in Commercial Cane Sugar (CCS), sucrose, and purity of juice compared to untreated and water-treated control (Solomon and Singh 2009).

The effect of EW water on respiration rate is variable; it can increase, decrease, or remain unchanged. After AEW treatment, it has been reported that the respiration rate increased in lettuce and cabbage (Koseki and Itoh 2002). In contrast, an EW treatment on leek, white cabbage, and mizuna baby leaf, reduced the respiration rate significantly (Vandekinderen et al. 2009a, b). Finally, a NEW treatment on grated carrots and iceberg lettuce did not influence the respiration rate (Vandekinderen et al. 2008; Vandekinderen et al. 2009c). Moreover, depending on the fruits or vegetables and especially for “minimally processed” produce, the treatment with EW could have some effects on the nutritional and phytochemical composition, due to the oxidation nature of the EW and/or by leaching of substances from vegetable tissue due to water-vegetable surface contact (Al-Haq and Gómez-López 2012). Other researchers showed that changes in respiration rate during cold storage of cabbages and broccoli could be avoided by EW (Gómez-López et al. 2007; Navarro-Rico et al. 2014).

Electrolyzed Water and Quality of Produce

It is well known that fruit and vegetable quality is becoming more relevant than market price to most of the consumers. Unfortunately, most of research accounts have tested the effect of treatment on pathogens, while any possible negative consequence on fruit quality is not often acknowledged. Few studies were performed to investigate the effect of EW on produce quality. Youssef and Hussien (2020) summarized that neither BEW nor AEW have any harmful effect in terms of citrus quality including weight loss, total soluble solids, citric acid, ascorbic acid, pH and color index. Some scientists found no statistical difference in color index of lettuce, broccoli, strawberry, and date palm before and after EW treatment (Park et al. 2001; Hung et al. 2010a, b; Jemni et al. 2014). Also, EW application proved to have no harmful effect on iceberg lettuce and white cabbage quality with regard to vitamin C loss (Vandekinderen et al. 2009a, b). In addition, the use of EW had no obvious effect on both titratable acidity and pH in the case of date fruit and strawberry (Hung et al. 2010a, b; Bessi et al. 2014).

Effect on Removing Pesticide Residues

To ensure a sustainable production of fruits, vegetables, and grains, the farmers use a variety of pesticides to protect the crops from insects, mites, fungi, bacteria, weeds, etc. However, when humans and animals consume foods with pesticide residues, they can cause cumulative poisoning effects. Several physical, chemical, and biological methods including adsorption, oxidation, catalytic degradation, membrane filtration, and biological treatment have been developed in order to remove/inactivate pesticide residues. The use of EW as potential tool to remove pesticide residues, has been evaluated during the last years (Hao et al. 2011b; Sung et al. 2011, 2012; Wuyun 2011; Hao and Li 2006; Luo et al. 2014; Liu et al. 2015; Hu et al. 2016; Han et al. 2017; Qi et al. 2018), as shown in Table 12.3.

They showed that a higher ACC and a longer treatment time leaded to greater reductions of pesticide residues. Moreover, the effectiveness was dependent on the chemical proprieties of the pesticides. For example, organophosphorus pesticides (e.g. dimethoate, chlorpyrifos, etc.), containing P=S double bonds and P–S or P–O single bonds, are easily attacked by chlorin (Deborde and von Gunten 2008) and hence can be degraded by the available chlorine in EW (Qi et al. 2018). In addition, a nucleophilic reaction has been reported to occur under acidic or alkaline conditions with the break of the double bond because of AEW low pH and high ORP value, whereas BEW with its high pH has proved to have a good emulsifying property (Wang and Han 2019). In summary, the EW has an obvious effect on the removal of pesticide residues on food without a significant decrease in quality (Wang and Han 2019).

Advantages of EW

The on-site production of the EW, whatever the use, represents a great advantage because there are no chemicals to purchase or store, except for an inexpensive salt (NaCl or others), eliminating the need for purchasing, transporting, storing, preparing and using traditional chemicals. EW has minimal impact on the environment (Koseki et al. 2002); particularly, NEW and BEW are safe for the environment and the operators since little chlorine is released to the air. If non-chlorine salts (e.g. NaHCO3) are used as electrolytes, health concerns with regard to chlorine in the air and in water are avoided and, consequently, the formation of chlorinated organic compounds including chloramines (NH2Cl), dichloramines (NHCl2), and trichloromethanes (HCCl3). These are respiratory irritants suspected to be carcinogenic (Roberts and Reymond 1994; Fallanaj et al. 2013; Citizens Concerned About Chloramine 2019. EW reverts to normal water after use, and its effectiveness has been verified within a large pH range (Park et al. 2004b). Since EW has multiple mechanisms of action, it is quite unlikely that resistance in target microorganisms will develop (Al-Haq et al. 2005).

After the initial cost of the apparatus for electrolysis, operational expenses become minimal (Bonde et al. 1999) and the capital cost of the on-site apparatus can often be recovered in less than a few years.

Indeed, in USA the unit cost per kilogram of electronically generated chlorine is significantly cheaper than liquefied chlorine gas, sodium hypochlorite solution, dry calcium hypochlorite, and cyanurate-based (TCIA) tablets (Grech and Rijkenberg 1992). The raw materials, water and sodium chloride, are found virtually everywhere (Venczel et al. 1997). Its use reduces the hazards associated with handling, transportation, and storage of concentrated chlorine solution (Nakagawara et al. 1998). The biocidal capacity of EW as compared to traditional chemical solutions permits the use of low dose rates, reducing the risk for environmental impact and the solutions should be less corrosive than alternate products. Lastly, the use of EW on various food commodities did not negatively affect the organoleptic properties, color, scent, flavor, or texture (Al-Haq et al. 2005; Hricova et al. 2008; Huang et al. 2008).

Disadvantages of EW

Strongly acidic EW and free chlorine content may be corrosive to some metals and may induce synthetic resin degradation (Tanaka et al. 1999), and hazardous chlorinated by-products can be produced. Its effectiveness may be hindered by the presence of organic substances (Oomori et al. 2000); its antimicrobial potential could be loosed quickly, once the apparatus is switched-off (Kiura et al. 2002). Depending on the electrolyte used and the pH (e.g. in AEW), pungent chlorine gas is formed that can cause discomfort to operators (Al-Haq et al. 2005). Excessive chlorine can be potentially toxic for plant produce (Grech and Rijkenberg 1992). AEW can induce phytotoxicity; for example, white spots and slight necrosis were observed on flowers and leaf edges of some ornamental bedding plants following an AEW foliar spray (Buck et al. 2003). A drawback could be also the need to switch-on the apparatus one or few hours before utilization to allow the bulk of water to become rich in antimicrobial oxidizing species (Fallanaj et al. 2013).

Conclusion

Disinfection of fresh produce and storage facilities is generally an important requirement for postharvest decay management. The applicability of disinfectants to control postharvest fruit decay depends on many aspects, i.e. on the fresh produce, the orientation towards organic or conventional agriculture, the time of the produce storage, the characteristics of the postharvest facilities, the possibilities to integrate the disinfection operations with other technologies and the know-how of the staff. In general, EW is characterized by a low impact on the environment and the operators, leaving no toxic residues or eliminating them on the food matrix. Because EW have multiple mechanisms of action it is quite unlikely that resistance in target microorganisms could develop. In view of the potential benefits to extend the storage period of fruit provided by the disinfectant agents, further studies could optimize their integration into current practices of postharvest manipulation.

References

Albrich JM, McCarthy CA, Hurs JK (1981) Biological reactivity of hypochlorous acid: implications for microbicidal mechanisms of leukocyte myeloperoxidase. Proc Natl Acad Sci U S A 78(1):210–214

Albrich JM, Gilbaugh JH, Callahan KB et al (1986) Effects of the putritive neutrophil– generated toxin, hypochlorous acid, on membrane permeability and transport systems of Escherichia coli. J Clin Invest 78:177–184

Al-Haq MI, Gómez-López VM (2012) Electrolyzed oxidizing water. In: Gómez-López VM (ed) Decontamination of fresh and minimally processed produce, 1st edn. Wiley-Blackwell, Hoboken, pp 135–164

Al-Haq MI, Seo Y, Oshita S et al (2001) Fungicidal effectiveness of electrolyzed oxidizing water on post harvest brown rot of peach. Hortic Sci 36:1310–1314

Al-Haq MI, Seo Y, Oshita S et al (2002) Disinfection effects of electrolyzed oxidizing water on suppressing fruit rot of pear caused by Botryosphaeria berengeriana. Food Res Int 35:657–664

Al-Haq MI, Sugiyama J, Isobe S (2005) Applications of electrolyzed water in agriculture and food industries. Food Sci Technol Res 11:135–150

Anglada A, Urtiaga A, Ortiz I (2009) Contributions of electrochemical oxidation to waste-water treatment: fundamentals and review of applications. J Chem Technol Biotechnol 84:1747–1755

Anonymous (1997) Principle of formation of electrolytic water. Hoshizaki Electic Co., Ltd., Sakae, Toyoake

Audenaert K, Monbaliu S, Deschuyffeleer N et al (2012) Neutralized electrolyzed water efficiently reduces Fusarium spp. in vitro and on wheat kernels but can trigger deoxynivalenol (DON) biosynthesis. Food Control 23(2):515–521

Barrette WCJ, Hannum DM, Wheeler WD et al (1989) General mechanism for the bacterial toxicity of hypochlorous acid: abolition of ATP production. Biochemistry-US 28:9172–9178

Bessi H, Debbabi H, Grissa K et al (2014) Microbial reduction and quality of stored date fruits treated by electrolyzed water. J Food Qual 37:42–49

Bonde MR, Nester SE, Khayat A et al (1999) Comparison of effects of acidic electrolyzed water and NaOCl on Tilletia indica teliospore germination. Plant Dis 83:627–632

Buck JW, Van Iersel MW, Oetting RD et al (2002) In vitro fungicidal activity of acidic electrolyzed oxidizing water. Plant Dis 86(3):278–281

Buck JW, Van Iersel MW, Oetting RD et al (2003) Evaluation of acidic electrolyzed water for phytotoxic symptoms on foliage and flowers of bedding plants. Crop Prot 22:73–77

Chen Y, Xie H, Tang J et al (2020) Effects of acidic electrolyzed water treatment on storability, quality attributes and nutritive properties of longan fruit during storage. Food Chem 320:126641

Citizens Concerned About Chloramine (2019) http://www.chloramine.org/. Accessed 15 Jan 2020

Deborde M, Von Gunten URS (2008) Reactions of chlorine with inorganic and organic compounds during water treatment kinetics and mechanisms: a critical review. Water Res 42:13–51

Deza M, Araujo M, Garrido M (2007) Efficacy of neutral electrolyzed water to inactivate Escherichia coli, Listeria monocytogenes, Pseudomonas aeruginosa, and Staphylococcus aureus on plastic and wooden kitchen cutting boards. J Food Prot 70(1):102–108

Ding T, Ge Z, Shi J et al (2015) Impact of slightly acidic electrolyzed water (SAEW) and ultrasound on microbial loads and quality of fresh fruits. Food Sci Technol 60(2):1195–1199

Fallanaj F, Sanzani SM, Zavanella C et al (2013) Salt addition improves the control of citrus postharvest diseases using electrolysis with conductive diamond electrodes. J Plant Pathol 95(2):373–383

Fallanaj F, Sanzani SM, Youssef K et al (2015) A new perspective in controlling postharvest citrus rots: the use of electrolyzed water. Acta Hortic 1065:1599–1605

Fallanaj F, Ippolito A, Ligorio A et al (2016) Electrolyzed sodium bicarbonate inhibits Penicillium digitatum and induces defence responses against green mould in citrus fruit. Postharvest Biol Technol 115:18–29

Feliciano L, Lee J, Pascall MA (2012) Transmission electron microscopic analysis showing structural changes to bacterial cells treated with electrolyzed water and an acidic sanitizer. J Food Sci 77(4):M182–M187

Feliziani E, Lichter A, Smilanick JL et al (2016) Disinfecting agents for controlling fruit and vegetable diseases after harvest. Postharvest Biol Techol 122:53–69

Finnegan M, Linley E, Denyer SP et al (2010) Mode of action of hydrogen peroxide and other oxidizing agents: differences between liquid and gas forms. J Antimicrob Chemoth 65:2108–2115

Forghani F, Park JH, Oh DH (2015) Effect of water hardness on the production and microbicidal efficacy of slightly acidic electrolyzed water. Food Microbiol 48:28–34

Fujiwara K, Fujii T, Park JS (2009) Comparison of foliar spray efficacy of electrolytically ozonated water and acidic electrolyzed oxidizing water for controlling powdery mildew infection on cucumber leaves. Ozone Sci Eng 31:10–14

Furuta T, Tanaka H, Nishiki Y et al (2004) Legionella inactivation with diamond electrodes. Diam Relat Mater 13:2016–2019

Gómez-López VM, Ragaert P, Ryckeboer J et al (2007) Shelf-life of minimally processed cabbage treated with neutral electrolysed oxidising water and stored under equilibrium modified atmosphere. Int J Food Microbiol 117(1):91–98

Gómez-López VM, Marín A, Medina-Martínez MS et al (2013) Generation of trihalomethanes with chlorine-based sanitizers and impact on microbial, nutritional and sensory quality of baby spinach. Postharvest Biol Technol 85:210–217

Grech NM, Rijkenberg FHJ (1992) Injection of electronically generated chlorine into citrus micro-irrigation systems for the control of certain waterborne root pathogens. Plant Dis 76:446–457

Guentzel JL, Lam KL, Callan MA et al (2008) Reduction of bacteria on spinach, lettuce, and surfaces in food service areas using neutral electrolyzed oxidizing water. Food Microbiol 25:36–41

Guentzel JL, Lam KL, Callan MA et al (2010) Postharvest management of gray mould and brown rot on surfaces of peaches and grapes using electrolyzed oxidizing water. Int J Food Microbiol 143:54–60

Guentzel JL, Callan MA, Emmons SA et al (2011) Evaluation of electrolyzed oxidizing water for phytotoxic effects and pre-harvest management of gray mold disease on strawberry plants. Crop Prot 30:1274–1279

Han YT, Song L, An QS et al (2017) Removal of six pesticide residues in cowpea with alkaline electrolysed water. J Sci Food Agric 97:2333–2338

Hao JX, Li LT (2006) Study on the removal of pesticide residue of vegetables by electrolyzed functional water. Sci Technol Food Ind 5:164–166

Hao J, Liu H, Liu R et al (2011a) Efficacy of slightly acidic electrolyzed water (SAEW) for reducing microbial contamination on fresh-cut Cilantro. J Food Saf 31(1):28–34

Hao J, Liu H, Chen T et al (2011b) Reduction of pesticide residues on fresh vegetables with electrolyzed water treatment. J Food Sci 76(4):C520–C524

Hao J, Li H, Wan Y et al (2015a) Combined effect of acidic electrolyzed water (AcEW) and alkaline electrolyzed water (AlEW) on the microbial reduction of fresh-cut cilantro. Food Control 50:699–704

Hao J, Li H, Wan Y et al (2015b) Effect of slightly acidic electrolyzed water (SAEW) treatment on the microbial reduction and storage quality of fresh-cut Cilantro. J Food Process Pres 39(6):559–566

Hirayama Y, Asano S, Watanabe K et al (2016) Control of Colletotrichum fructicola on strawberry with a foliar spray of neutral electrolyzed water through an overhead irrigation system. J Gen Plant Pathol 82:186–189

Hou M, Gao J, Deng L et al (2011) Effect of electrolyzed water on growth and development, nutritional quality of Chinese cabbage. Hubei Agric Sci 7(50):1342–1346

Hricova D, Stephan R, Zweifel C (2008) Electrolyzed water and its application in the food industry. J Food Prot 71(9):1934–1947

Hu ZH, Wu TJ, Wan YF et al (2016) Study on the removal of dimethoate and chlorpyrifos in leek by slightly acidic electrolyzed water. Sci Technol Food Ind 37(01):49–52

Huang YR, Hung YC, Hsu SY et al (2008) Application of electrolyzed water in the food industry. Food Control 19:329–345

Hung YC, Bailly D, Kim C et al (2010a) Effect of electrolyzed oxidizing water and chlorinated water treatments on strawberry and broccoli quality. J Food Qual 33(5):578–598

Hung YC, Tilly P, Kim C (2010b) Efficacy of electrolyzed oxidizing (Eo) water and chlorinated water for inactivation of Escherichia coli O157:H7 on strawberries and broccoli. J Food Qual 33(5):559–577

Hurst JK, Barrette WCJ, Michel BR et al (1991) Hypochlorous acid and myeleperoxidasecatalyzed oxidation of iron-sulfur clusters in bacterial respiratory dehydrogenase. Eur J Biochem 202:1275–1282

Hussien A, Al-Essawy A, Rehab A et al (2017) Preliminary investigation of alkaline and acidic electrolysed water to control Penicillium species of citrus. Citrus Res Technol 38(2):175–183

Hussien A, Ahmed Y, Al-Essawy AH et al (2018) Evaluation of different salt-amended electrolysed water to control postharvest moulds of citrus. Trop Plant Pathol 43(1):10–20

Jay JM (1996) Modern food microbiology, 5th edn. Aspen Pub, Frederick, pp 48–49

Jemni M, Gomez P, Souza M et al (2014) Combined effect of UV-C, ozone and electrolyzed water for keeping overall quality of date palm. Food Sci Technol 59(2):649–655

Jeong J, Kim C, Yoon J (2009) The effect of electrode material on the generation of oxidants and microbial inactivation in the electrochemical disinfection processes. Water Res 43:895–901

Johnson M, Melbourne P (1996) Photolytic spectroscopic quantification of residual chlorine in potable waters. Analyst 121:1075–1078

Kim C, Hung Y, Brackett RE (2000) Roles of oxidation-reduction potential in electrolyzed oxidizing and chemically modified water for the inactivation of food-related pathogens. J Food Prot 63:19–24

Kim C, Hung Y-C, Brackett RE et al (2001) Inactivation of Listeria monocytogenes biofilms by electrolyzed oxidizing water. J Food Process Preserv 25:91–100

Kiura H, Sano K, Morimatsu S et al (2002) Bactericidal activity of electrolyzed acid water from solution containing sodium chloride at low concentration, in comparison with that at high concentration. J Microbiol Meth 49(3):285–293

Koide S, Takeda J, Shi J et al (2009) Disinfection efficacy of slightly acidic electrolyzed water on fresh cut cabbage. Food Control 20(3):294–297

Koseki S, Itoh K (2002) Effect of nitrogen gas packaging on the quality and microbial growth of freshcut vegetables under low temperature. J Food Prot 65(2):326–332

Koseki S, Fujiwara K, Itoh K (2002) Decontamination effect of frozen acidic electrolyzed water on lettuce. J Food Prot 65:411–414

Koseki S, Yoshida K, Isobe S et al (2004) Efficacy of acidic electrolyzed water for microbial decontamination of cucumbers and strawberries. J Food Prot 67(6):1247–1251

Kunina LA (1967) From experience in the electrolytic decontamination of drinking water. Gig Sanit 32:100–101

Lee JH, Rhee P, Kim JH et al (2004) Efficacy of electrolyzed acid water in reprocessing patient-used flexible upper endoscopes: comparison with 2% alkaline glutaraldehyde. J Gastroenterol Hepatol 19:897–903

Len SV, Hung YC, Chung D et al (2002) Effects of storage conditions and pH on chlorine loss in electrolyzed oxidizing (EO) water. J Agric Food Chem 50(1):209–212

Li XW, Sun SH, Li T (1996) Preliminary study of microbiocide effect and its mechanism of electrolyzed oxidizing water. Zhonghua liu xing bing xue za zhi = Zhonghua liuxingbingxue zazhi 17(2):95

Li J, Ding T, Liao X et al (2017) Synergetic effects of ultrasound and slightly acidic electrolyzed water against Staphylococcus aureus evaluated by flow cytometry and electron microscopy. Ultrason Sonochem 38:711–719

Li L, Hao J, Song S et al (2018) Effect of slightly acidic electrolyzed water on bioactive compounds and morphology of broccoli sprouts. Food Res Int 105:102–109

Liao LB, Chen WM, Xiao XM (2007) The generation and inactivation mechanism of oxidationreduction potential of electrolyzed oxidizing water. J Food Eng 78:1326–1332

Liu HJ, Li RZ, Su DH et al (2015) Degradation of Lambda-cyhalothrin in fruits and vegetable by alkaline electrolyzed water. Food Sci Technol 40(2):123–127

López-Gálvez F, Posada-Izquierdo GD, Selma MV et al (2012) Electrochemical disinfection: an efficient treatment to inactivate Escherichia coli O157: H7 in process wash water containing organic matter. Food Microbiol 30(1):146–156

Luo Q, Zu YH, Shi KQ et al (2014) Study on the reduction effect of pesticide residues of vegetables with slightly acidic electrolyzed water. J Food Saf Qual 5(11):3657–3663

Mahmoud BS (2007) Electrolyzed water: a new technology for food decontamination - a review. Dtsch Lebensmitt Rundsch 103(5):212–221

Martínez-Huitle CA, Brillas E (2008) Electrochemical alternatives for drinking water disinfection. Angew Chem Int Edit 47(11):1998–2005

McPherson LL (1993) Understanding ORP’s in the disinfection process. Water Eng Manage 140:29–31

Nakagawara S, Goto T, Nara M et al (1998) Spectroscopic characterization and the pH dependence of bactericidal activity of the aqueous chlorine solution. Anal Sci 14:691–698

Nakajima N, Nakano T, Harada F et al (2004) Evaluation of disinfective potential of reactivated free chlorine in pooled tap water by electrolysis. J Microbiol Meth 57(2):163–173

Navarro-Rico J, Artes-Hernandez F, Gomez PA et al (2014) Neutral and acidic electrolysed water kept microbial quality and health promoting compounds of fresh-cut broccoli throughout shelf life. Innov Food Sci Emerg Technol 21:74–81

Okull DO, Laborde LF (2004) Activity of electrolyzed oxidizing water against Penicillium expansum on suspension and on wounded apples. J Food Sci 69:23–27

Oomori T, Oka T, Inuta T et al (2000) The efficiency of disinfection of acidic electrolyzed water in the presence of organic materials. Anal Sci 16:465–469

Pangloli P, Hung YC (2013) Effects of water hardness and pH on efficacy of chlorine-based sanitizers for inactivating Escherichia coli O157:H7 and Listeria monocytogenes. Food Control 32(2):626–631

Park CM, Hung YC, Doyle MP et al (2001) Pathogen reduction and quality of lettuce treated with electrolyzed oxidizing and acidified chlorinated water. J Food Sci 66:1368–1372

Park SG, Lim HJ, Kim JK et al (2004a) Microbiocidal effect of E. coli with ozone solution generated by BDD electrode. http://www.electrochem.org/dl/ma/206/pdfs/2185.pdf. Accessed 24 Jan 2020

Park H, Hung YC, Chung D (2004b) Effects of chlorine and pH on efficacy of electrolyzed water for inactivating Escherichia coli 157:H7 and Listeria monocytogenes. Int J Food Microbiol 91:13–18

Park EJ, Alexander E, Taylor GA et al (2009) The decontaminative effects of acidic electrolyzed water for Escherichia coli O157:H7, Salmonella typhimurium, and Listeria monocytogenes on green onions and tomatoes with differing organic demands. Food Microbiol 26:386–390

Pinto L, Ippolito A, Baruzzi F (2015) Control of spoiler Pseudomonas spp. on fresh cut vegetables by neutral electrolyzed water. Food Microbiol 50:102–108

Qi H, Huang Q, Hung YC (2018) Effectiveness of electrolyzed oxidizing water treatment in removing pesticide residues and its effect on produce quality. Food Chem 239:561–568

Rahman SME, Ding T, Oh DW (2010a) Inactivation effect of newly developed low concentration electrolyzed water and other sanitizers against microorganisms on spinach. Food Control 21(10):1383–1387

Rahman SME, Jin YG, Oh DW (2010b) Combined effects of alkaline electrolyzed water and citric acid with mild heat to control microorganisms on cabbage. J Food Sci 75:M111–M115

Rahman SME, Khan I, Oh DH (2016) Electrolyzed water as a novel sanitizer in the food industry: current trends and future perspectives. Compr Rev Food Sci Food Saf 15:471–490

Roberts RG, Reymond ST (1994) Chlorine dioxide for reduction of postharvest pathogen inoculum during handling of tree fruits. Appl Environ Microbiol 60:2864–2868

Sargent SA, Ritenour MA, Brecht JK (2000) Handling, cooling and sanitation techniques for maintaining postharvest quality. University of Florida Cooperative Extension Service, Institute of Food and Agriculture Sciences, EDIS

Siddiqui MW (2018) Postharvest disinfection of fruits and vegetables. Academic, Elsevier

Solomon S, Singh P (2009) Efficacy of electrolyzed water to minimize postharvest sucrose losses in sugarcane. Sugar Tech 11(2):228–230

Sung JM, Kwon KH, Kim JH et al (2011) Effect of washing treatments on pesticide residues and antioxidant compounds in Yuja (Citrus junos Sieb ex Tanaka). Food Sci Biotechnol 20(3):767–773

Sung JM, Park KJ, Lim JH et al (2012) Removal effects of microorganism and pesticide residues on Chinese cabbages by electrolyzed water washing. Korean J Food Sci Technol 44(5):628–633

Suzuki T, Noro T, Kawamura Y et al (2002) Decontamination of aflatoxin-forming fungus and elimination of aflatoxin mutagenicity with electrolyzed NaCl anode solution. J Agric Food Chem 50:633–641

Tanaka N, Fujisawa T, Daimon T et al (1999) The effect of electrolyzed strong acid aqueous solution on hemodialysis equipment. Artif Organs 23:1055–1062

Tango C, Khan I, Ngnitcho K et al (2017) Slightly acidic electrolyzed water combined with chemical and physical treatments to decontaminate bacteria on fresh fruits. Food Microbiol 67: 97–105

Vandekinderen I, Van Camp J, Devlieghere F et al (2008) Effect of decontamination agents on the microbial population, sensory quality, and nutrient content of grated carrots (Daucus carota L.). J Agric Food Chem 56:5723–5731

Vandekinderen I, Van Camp J, Devlieghere F et al (2009a) Evaluation of the use of decontamination agents during fresh-cut leek processing and quantification of their effect on its quality by means of multidisciplinary approach. Innov Food Sci Emerg Technol 10:363–373

Vandekinderen I, Van Camp J, Devlieghere F et al (2009b) Effect of decontamination on the microbial load, the sensory quality and the nutrient retention of ready-to-eat white cabbage. Eur Food Res Technol 229:443–455

Vandekinderen I, Van Camp J, De Meulenaer B et al (2009c) Moderate and high doses of sodium hypochlorite, neutral electrolyzed oxidizing water, peroxyacetic acid, and gaseous chlorine dioxide did not affect the nutritional and sensory quality of fresh-cut iceberg lettuce (Lactuca sativa var. capitata L.) after washing. J Agric Food Chem 57:4195–4203

Venczel LV, Arrowood M, Hurd M et al (1997) Inactivation of Cryptosporidium parvum and Clostridium perfringens spores by a mixed-oxidant disinfectant and by free chlorine. Appl Environ Microbiol 63(4):1598–1601

Venkitanarayanan KS, Ezeike OI, Hung Y et al (1999) Efficacy of electrolyzed oxidizing water for inactivating Escherichia coli O157:H7, Salmonella enteritidis, and Listeria monocytogenes. Appl Environ Microbiol 65:4276–4279

Virto R, Manas P, Alvarez I et al (2005) Membrane damage and microbial inactivation by chlorine in the absence and presence of a chlorine-demanding substrate. Appl Environ Microbiol 71:5022–5028

Wang J, Han R (2019) Removal of pesticide on food by electrolyzed water. In: Electrolyzed water in food: fundamentals and applications. Springer, Singapore, pp 39–65

Whangchai K, Saengnil K, Singkamanee C et al (2010) Effect of electrolyzed oxidizing water and continuous ozone exposure on the control of Penicillium digitatum on tangerine cv ‘Sai Nam Pung’ during storage. Crop Prot 29:386–389

White GC (1998) Handbook of chlorination and alternative disinfectants, 4th edn. Wiley, New York, pp 212–287

Wuyun DL (2011) Mechanism and application of slightly acid electrolyzed functional water degradation of organophosphorus pesticide residues. China Agricultural University

Xiong K, Li XT, Guo S et al (2014) The antifungal mechanism of electrolyzed oxidizing water against Aspergillus flavus. Food Sci Biotechnol 23(2):661–669

Xuan X, Ling J (2019) Generation of electrolyzed water. In: Electrolyzed water in food: fundamentals and applications. Springer/Zhejiang University Press, Hangzhou

Youssef K, Hussien A (2020) Electrolysed water and salt solutions can reduce green and blue molds while maintain the quality properties of ‘Valencia late’ oranges. Postharvest Biol Technol 159:111025

Youssef K, Mustafa ZMM, Al-Essawy A (2018) Efficacy of alkaline and acidic electrolysed water generated by some salt solutions against gray mold of table grape: pre and postharvest applications. J Phytopathol Pest Manag 5(1):1–21

Zhang Q, Xiong K, Tatsumi E et al (2012) Elimination of aflatoxin B1 in peanuts by acidic electrolyzed oxidizing water. Food Control 27(1):16–20

Zhang C, Cao W, Hung Y et al (2016a) Application of electrolyzed oxidizing water in production of radish sprouts to reduce natural microbiota. Food Control 67:177–182

Zhang C, Cao W, Hung Y et al (2016b) Disinfection effect of slightly acidic electrolyzed water on celery and cilantro. Food Control 69:147–152

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Ippolito, A., Mincuzzi, A., Surano, A., Youssef, K., Sanzani, S.M. (2021). Electrolyzed Water as a Potential Agent for Controlling Postharvest Decay of Fruits and Vegetables. In: Spadaro, D., Droby, S., Gullino, M.L. (eds) Postharvest Pathology. Plant Pathology in the 21st Century, vol 11. Springer, Cham. https://doi.org/10.1007/978-3-030-56530-5_12

Download citation

DOI: https://doi.org/10.1007/978-3-030-56530-5_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-56529-9

Online ISBN: 978-3-030-56530-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)