Abstract

A hydrophilic kapok fiber was prepared by a chemical process of the Fenton reaction and used as an adsorbent to remove Pb(II) from aqueous solution. The effects of experimental parameters including pH, contact time, Pb(II) concentration, and coexisting heavy metals were estimated as well as evaluated. The optimum concentrations of FeSO4 and H2O2 for the Fenton reaction-modified kapok fiber (FRKF) were 0.5 mol L−1 and 1 mol L−1, respectively. The adsorption kinetic models and isotherm equations of Langmuir and Freundlich were conducted to identify the most optimum adsorption rate and adsorption capacity of Pb(II) on FRKF. The FRKF displayed an excellent adsorption rate for Pb(II) in single metal solution with the maximum adsorption capacity of 94.41 ± 7.56 mg g−1 at pH 6.0. Moreover, the FRKE still maintained its adsorption advantage of Pb(II) in the mixed metal solution. The FRKF exhibited a considerable potential in removal of metal content in wastewater streams.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As industrial sectors have rapidly developed and extensively grown, the environmental pollution issues caused by wastewater streams including heavy metals such as lead, chromium, and mercury have become more serious. Such issues have been increasingly harmful to public health (Li et al. 2002). Heavy metals, unlike organic matters, cannot be completely converted to harmless substances by the biochemical process and rather accumulate in organisms (Witek-Krowiak et al. 2011). Particularly, wastewater containing lead is one of the major environmental pollutants, mainly stemming from the wastewater discharges from battery manufacturing, metallurgy, electroplating industry, and coating and painting (Li et al. 2002). Lead is also well known to accumulate in human body system, and excessive exposure can significantly damage the tissues and organs; this situation is so-called lead poisoning. For example, it can damage mental and central nerve functions, blood composition, enzyme inhibitor, lungs, kidneys, liver, male fertility (Kim et al. 2009), pregnancy (Rothenberg et al. 2001), and other vital organs (Needleman 1991). A recent study (Shiue 2017) mentioned on the link to the adult sleep problem. Thus, the removal of toxic metallic ions including lead and its associated compounds before being discharged into the environment has become a global demand. In terms of control methods, chemical precipitation, electrochemical treatment, adsorption, filtration, ion exchange, and membrane separation were widely used for wastewater treatment (Bediako et al. 2015; Sotto et al. 2014; Torres-Blancas et al. 2013). Among them, adsorption was considered because of its various options of adsorbents, relatively economical method, and high removal efficiency.

Kapok fiber, a natural product, is derived from the seeds of kapok trees, which mainly grow in Asia, Africa, and South America, and is structurally made from cellulose, lignin, polysaccharide, and wax (Zheng et al. 2015). Traditionally, because of its hollow structure (Veerakumar and Selvakumar 2012; Xiang et al. 2013), buoyancy (Zhang et al. 2013), and warming performance (Hong et al. 2012), kapok fiber has been used as a filler for sound and heat proof insulation, bedding, upholstery, and apparel textiles via blended with other fibers. By nature, kapok fiber, enwrapped by wax layers, is hydrophobic (Duan et al. 2013; Huang and Lim 2006). In recent years, kapok fiber has attracted more attention for its special structure of high surface area and hydrophobic characteristics, which allow it to be used in a wide range of applications such as oil adsorbent and water treatment material (Rengasamy et al. 2011). And it also exhibits excellent performance in other fields, for instance, antibacterial and dye adsorption (Wang et al. 2014, 2015, 2016). However, the characteristics of hydrophobicity, although it has hollow lumen with large surface area, limit its usage in water treatment. Thus, when used in water-related field, kapok fiber might need pretreatment to convert it from hydrophobic to hydrophilic. Zhang et al. prepared a novel dicarboxylatic kapok fiber (DC-KF) by mild surface oxidation treatment with NaClO2 and NaIO4, and the adsorption capacities for natural red, methylene blue, and rhodamine 6G were as high as 816.4, 524.4, and 613.4 mg g−1, respectively (Zhang et al. 2016). Besides, after hydrophilic treatment with dichloromethane and NaOH solution, and reaction with diethylenetriamine pentaacetic acid (DTPA), the kapok-DTPA showed high affinity for metal ions with the adsorption capacity of 310.6, 163.7, and 101.0 mg g−1 for Pb(II), Cd(II), and Cu(II), respectively (Duan et al. 2013).

Recently, because of the refractory contaminants in wastewater streams, the advanced oxidation processes (AOPs) are often applied in the removal of such organic contaminants. The Fenton reaction, which could produce hydroxyl (∙OH) radicals in the reaction solution, is one of the most common AOPs. With the strong oxidized characteristics of hydroxyl radicals, Fenton reaction can oxidize most organic compounds quickly (Zhang et al. 2008). Zhou et al. (2014) reported that magnetic porous carbon microspheres were used as catalysts in heterogeneous Fenton reactions to remove methylene blue (MB) from wastewater, and the results indicated a good performance in removal of MB. Furthermore, Fenton reaction is also used in biological researches. Martin et al. (2010) modified the diamond nanoparticles with Fenton reaction and used these functionalized materials in gene delivery. As a result, the treated materials became free of amorphous soot matter and the particle size was decreased, but the surface hydroxyl number and water solubility were increased. In current work, the raw kapok fiber (RFK) was chemically modified with Fenton reaction, whose waxy layer was removed thus making more available binding sites underneath the surface for lead uptake. Following this context, therefore, the objectives of the study were to evaluate the Pb(II) adsorption performance of FRKF, and to compare with the RFK, in terms of kinetic reaction, isotherm models, and surface chemistry. Finally, this work may help to determine the commercial feasibility of taking advantage of chemically modified kapok fiber when treating toxic metal wastewater.

Materials and methods

Materials

In this work, the raw kapok fibers (RKF) were obtained from Indonesia, washed by deionized water, and dried in an oven at 60 °C for 24 h before being used for experiments. The solutions of Pb(II), Ni(II), Cu(II), Zn(II), Cd(II), and Hg(II) were prepared by using nitrate complex purchased from Junsei Chemical Co., Ltd, Japan. The chemicals of FeSO4∙7H2O and H2O2 were obtained from Showa Chemical Co., Ltd, Japan. The pH was adjusted by adding 0.1 or 1.0 mol L−1 of HCl and NaOH solutions. All the reagents were of analytical grade and deionized water was used for the whole experimental process.

Preparation of kapok fiber

The RKF was modified by the Fenton reaction at different ratios of FeSO4 and H2O2. The process was carried out as follows: 150 mL of FeSO4 solution at pH of 3.0 was prepared in a 500-mL beaker, then 5 g of RKF was added and immersed in the solution. Hydrogen peroxide was slowly poured into the beaker while stirring, and the total volume of mixed solution was set to 250 mL. Afterwards, the beaker was shaken in an incubator at 120 rpm and 25 °C for 24 h. The chemically modified fibers were washed several times with deionized water and dried using a freeze dryer (TFD Series, Ilshinbiobase, Korea) for 24 h.

To select the most optimum variables such as FeSO4 and H2O2 concentrations, a number of combinations of FeSO4 (0.1–0.5 mol L−1) and H2O2 (0.5–3 mol L−1) were experimented on the RKF. Thus, 0.03 g of Fenton reaction modified kapok fiber (FRKF) and 30 mL of 100 mg L−1 Pb(II) solution were prepared in 50-mL falcon tubes, and shaken at 25 °C for 3 h, and the adsorption capacity of the FRKF for the removal of Pb(II) was estimated. Finally, the most optimum FRKF which had the maximum adsorption capacity for Pb(II) was selected for the following experiments.

Adsorption experiment

A series of experiments were conducted in conical flasks, which contained 0.1 g of fiber and 100 mL of Pb(II) solution (100 mg L−1) and were shaken in a temperature-controlled orbital shaker at 120 rpm and 25 °C. The pH-dependence of the FRKF in the Pb(II) adsorption reaction was evaluated at a pH range of 3.0–6.0 with contact time of 3 h. The kinetic study was accomplished at different contact times ranging from 0 to 240 min at pH 6.0. The isotherm study was carried out by varying initial Pb(II) concentrations ranging from 25 to 300 mg L−1 at pH 6.0 for 3 h. In order to evaluate the feasibility of the FRKF application to the industrial wastewater stream, the FRKF was tested in multicomponent system, namely 0.1 g of the FRKF was reacted with 100 mL of the mixed metal solution containing 100 mg L−1 of Pb(II), 100 mg L−1 of Ni(II), 100 mg L−1 of Cu(II), 100 mg L−1 of Zn(II), 100 mg L−1 of Cd(II), and 100 mg L−1 of Hg(II) at pH 6.0 for 3 h.

The effect of light precipitation phenomena was eliminated by calculating the difference in Pb(II) concentration before and after pH was adjusted. The concentrations of Pb(II) were determined by an inductively coupled plasma atomic emission spectrometer (ICP-AES, iCAP-7000, Thermo Scientific, USA). The adsorption capacity was calculated using the following equation:

where qe is the adsorption capacity of an adsorbent (mg g−1), Co and Ce are the initial and equilibrium metal concentrations (mg L−1), respectively, V is a working volume (L), and m is the dried mass of an adsorbent (g).

Biomass characterization

The functional groups, surface morphology, wettability, and elemental composition of the RKF and FRKF fibers were characterized by Fourier transform infrared spectroscopy (FTIR) (100 FR-IR, PerkinElmer, MA, USA), scanning electron microscopy (SEM) (SU8200, Hitachi, Japan), contact angle analyzer (Phoenix 300, SEO, Korea), and energy-dispersive spectroscopy (EDS) (JEOL, JSM-6000 series WDS/EDS system, Japan). The infrared spectrum of the RKF and the FRKF fibers were recorded to analyze the structure of the fiber, while the surface morphologies and element information were enlightened by a combined equipment of SEM-EDS. Prior to contact angle measurements, which were carried out at ambient temperature with a 50-µL water droplet, kapok fiber assembly was flattened with a tablet machine. The surface wettability of FRKF was performed with a digital camera after nearly 50 µL of water droplet (dyed with methylene blue) was dripped on the surface of fiber from a syringe.

Results and discussion

Preparation of hydrophilic kapok fiber

The novel hydrophilic kapok fiber (FRKF) fabricated by the Fenton reaction is shown in Fig. 1b, comparing to the raw fibers (RKF) in Fig. 1a. The color changed from its original white to yellow, but the appearance still remained fiber-like even after the chemical modification. The surface wettability of water on the surface of the RKF and the FRKF was observed in Fig. 1c, d, respectively. The water contact angle of the RKF was 138.7°. On the contrary, the water droplet dyed with methylene blue was fleetly then completely adsorbed by the interstice of the as-prepared fiber (FRKF) so that there was no contact angle measured. According to these results, the surface wettability of water on the RKF became hydrophilic after the treatment of the Fenton reaction.

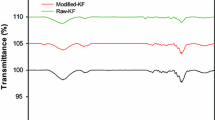

FTIR spectra

The infrared spectra of the RKF and the FRKF are shown in Fig. 2. For RKF, the peak at 3343 cm−1 was due to the stretching vibration of the hydroxyl (–OH) group, while the peak at 2917 cm−1 was the adsorption bond of CH2 and CH3 stretching. The enhancement of both such two peaks was concerned with the removal of surface wax (Lim and Huang 2007; Wang and Wang 2013). The three peaks at 1737 cm−1, 1371 cm−1, and 1239 cm−1 occurred by the adsorption of C=O stretching vibration, C–H stretching (–C–CH3), and C–O stretching (–O–C–CH3) in lignin and acetyl ester groups in xylan, respectively (Sun 2003). Other weak bands such as 1595 cm−1, 1504 cm−1, and 1425 cm−1 were known to relate to the aromatic skeleton vibration and ring breathing with C–O stretching in lignin (Sun et al. 2001). The peak at 1035 cm−1 was attributed to the C–O–C stretching because of the existence of cellulose, hemicellulose, and lignin (Rengasamy et al. 2011). Compared with RKF, the intensity of the characteristic peaks in FRKF enhanced considerably. In other words, the amount of the functional groups might increase on FRKF. The results indicated that the oxidation of the Fenton reaction altered the surface structure of the fiber by decomposing the lignin, wax, pectin, and natural oils that covered the surface of the fiber, and exposed more functional groups such as hydroxyl group, even oxidized the hydroxyl group into carboxyl group (Wahi et al. 2013).

SEM and EDS analyses

The SEM spectrograms of the RKF and the FRKF are displayed in Fig. 3a–d. The images exhibited that the outer surface of the RKF was relatively smooth, compared to the uneven rather rough surface topography of the FRKF. The latter is due to the fact that lignin, pectin, waxy substances, and natural oils enwrapping the fiber were destabilized, removed, and finally left with a rough surface by the application of the Fenton reaction (Mwaikambo and Ansell 2002).

The characteristic peaks matching with EDS spectrograms are presented in Fig. 4a, b, and the peaks provided an evidence for the actual elemental compositions in the fiber samples. For the RKF, C and O were the primary elements, whereas S and Fe were introduced into the FRKF after the Fenton reaction was applied, specifying that the redox reaction had an impact on the structure of the fiber.

Response surface methodology

In this work, the amounts of FeSO4 and H2O2 for the Fenton reaction were important variables affecting the adsorption capacity of the FRKF. The 3-D response surface plots, reported in the previous reference (Zinatizadeh et al. 2006), were used to understand the main effects of the two factors and their relationship with other factors. Hence, in order to determine the optimized concentrations of FeSO4 and H2O2 in Fenton reaction, the surface pattern of adsorption performance, in response to the Pb(II) uptake, is built and presented in Fig. 5. The results exhibited that, if the concentration of H2O2 was below 1 mol L−1, the Pb(II) uptake was susceptible to enhancement as the FeSO4 dosage was increased. Therefore, when the concentration of FeSO4 was 0.5 mol L−1 and H2O2 was 1 mol L−1, the Pb(II) uptake was maximized with the capacity of 82.8 mg g−1. The fiber modified with this optimum ratio of FeSO4 and H2O2 concentrations was used as a benchmark reference for the following experiments.

Effects of pH on adsorption of Pb(II)

pH is one of the most influencing parameters for the metal uptake in aqueous solution because of the influence on the existing form of the metallic species (Kuo and Lin 2009). In previous studies, seven kinds of lead species in water at different pH values, and polynuclear or complex species containing Pb2OH3+, Pb3(OH)42+, Pb4(OH)44+, and Pb6(OH)84+ were experimented when Pb(II) concentration was higher than 0.01 mmol L−1 (Charles et al. 1976; Wang et al. 2014). In addition, Qiu also reported that there were almost no species of Pb(OH)2, Pb(OH)3−, Pb2OH3+, Pb3(OH)42+, and Pb4(OH)44+ existing in the acidic solution in the pH range of 2.85–6.01, except Pb2+ which existed as the major components of total Pb(II) (Qiu et al. 2008). In the present study, to avoid the formation of precipitation, the pH was deliberately controlled in the range of 3.0–6.0 at 100 mg L−1 of Pb(II) solution and was kept constant throughout the experiments. Owing to the modification of the fiber which was carried out at pH 3.0, the H+ could be released from the modified fiber in solution, and caused a decrease of pH value, which might have helped prevent the precipitation of Pb(II). Accordingly, there was almost no precipitation formed when reactions were implemented at pH 6.0. The results are presented in Fig. 6. The Pb(II) uptake increased as the pH values increased up to 6.0. At a lower or up to pH of 6.0, Pb(II) was the primary specie of lead, and its removal was mostly dependent on the competition between H+ and Pb2+ ions on the surface sites (Yu et al. 2011; Weng and Huang 2004). In this work, a dynamic process may exist in the solution where the added hydroxyl ions were preferentially neutralized by the continually released hydrogen ions. Because of such reason, the precipitation of Pb(OH)2 would not be generated at the beginning and the Pb(II) could replace the H+ and bond with the sites on the surface of the fiber. Hence, the sites on the surface of the modified fiber complexed with H+ instead of binding with Pb2+ at a lower pH, which led to the relatively lower rate of Pb(II) uptake. But with the increased pH, the H+ released by FRKF would combine with the increased OH−; so that more Pb(II) could bind with the active sites on fiber. Thus, the Pb(II) uptake increased.

Kinetic study

In order to better understand the adsorption reactions of the RKF and the FRKF, the adsorption efficiency and reaction dynamics of adsorbents were kinetically studied. The experiments of the Pb(II) uptake with the contact time for 240 min were conducted at pH 6.0, and the results were shown in Fig. 7. There was a distinctive difference between the RKF and the FRKF with respect of the adsorption capacity. For the FRKF, the equilibrium was reached within 90 min. The experimental data were to fit with the two kinetic equations of pseudo-first-order (Largegren 1898) and pseudo-second-order (Ho and Mckay 1999), and the non-linear equations were presented as follows:

where qt (mg g−1) and qe (mg g−1) are the adsorption capacity at time t (min) and at equilibrium, respectively; k1 (min−1) and k2 (g mg−1 min) are the kinetic rate constants for the pseudo-first-order and the pseudo-second-order reactions, respectively (Mao et al. 2010).

The kinetic parameters of the Pb(II) adsorption on the RKF and the FRKF are summarized in Table 1. The correlation coefficient (R2) values of the two models for the RKF were 0.649 and 0.709, indicating that the adsorption process of Pb(II) was not well explained by the two models. For the FRKF, the adsorption reaction of Pb(II) was well represented by both models of the pseudo-first-order (R2 = 0.982) and the pseudo-second-order (R2 = 0.998).

The adsorption capacity (qe) was calculated from the pseudo-second-order reaction, which was quite close to the experimental value. It could be induced that the pseudo-second-order was a good representation for better describing the mechanism of the adsorption in this study. According to the pseudo-second-order model, the adsorption rate of Pb(II) on the FRKF was influenced by a chemisorption process, and the adsorption rate constant was found, 7 × 10−4 ± 3 × 10−5 g −1 (mg min).

Adsorption isotherms

Based on the kinetic parameters determined by pseudo second-order model, adsorption isotherms including Langmuir and Freundlich models could be established. Both of them are non-ideal (or non-linear) adsorption model, and are describing the equilibrium of metal ion adsorption on solid adsorbents (Freundlich 1906; Langmuir 1918). The Langmuir model is used with the assumptions that binding sites on the adsorbents are homogeneous, and monolayer adsorption occurs with no interaction between adsorbed species. However, the Freundlich represents a multilayer adsorption onto heterogeneous surfaces with exponential distribution of adsorption sites. The latter is more similar to the linear adsorption with the empirical constant. The formulas of the Langmuir and Freundlich isotherm models were shown as follows:

where qe (mg g−1) is the equilibrium of the Pb(II) uptake, Ce (mg L−1) is the concentration of metal ion at equilibrium, qm (mg g−1) and Ka (L mg−1) are the Langmuir constants, representing the maximum adsorption capacity and the constant related to the heat of adsorption, respectively. KF (L g−1) and n are the Freundlich constants related to the adsorption capacity and the intensity of adsorption, respectively (Zhao et al. 2015).

The plotted curves for the experimental data fit with the two models are shown in Fig. 8, and the equilibrium adsorption constants are listed in Table 2. The surface of the RKF was hydrophobic, which made binding sites on raw fibers difficult to connect with Pb(II). In consequence, the Pb(II) uptake on the RKF was negligible, compared with that of the FRKF. As for the FRKF, qm and Ka calculated by the Langmuir model were 94.41 ± 7.56 mg g−1 and 0.082 ± 0.033 L mg−1, respectively. Furthermore, the correlation coefficient of the Langmuir and Freundlich models were 0.901 and 0.993, respectively, meaning that the Freundlich model imitated the experimental data better than the Langmuir model in this study.

It is well known that oxygen-containing functional groups such as –OH, –COOH, –COO− and –O−, play a significant role in the Pb(II) uptake in aqueous solution (Wang et al. 2014; Xu et al. 2008). As previous research summarized, many scholars altered the hydrophobicity of kapok fiber to hydrophilicity by introducing hydroxyl, carboxyl, and aldehyde etc. groups to enhance the adsorption capacity for metal ions (Zheng et al. 2015). With the carboxyl groups generated by an oxidation process of chlorite-periodate, Chung et al. (2008) enhanced the adsorption capacity of kapok fiber for Pb(II) to 38.46 mg g−1. For the same purpose, Xiong et al. (2014) prepared an amphiprotic cotton with the Pb(II) adsorption capacity of 70.6 mg g−1 by using a cationic monomer and anionic monomer. Compared with these studies, although some of the oxygen-containing functional groups in cellulose, hemicellulose, and lignin were destroyed by the Fenton reaction in present work, there were still considerable functional groups, which were reserved and newly formed on the fibers, that could be used in adsorbing Pb(II). These chemical groups in multitude numbers play a role in providing more adsorption sites for the uptake of Pb(II). At last, this re-stabilized structure of kapok fiber will eventually result in a very robust crosslinked fishnet (Kim et al. 2009, 2012; Wang et al. 2016a, b, c). The adsorption mechanism of Pb(II) on the FRKF is well illustrated in Fig. 9.

Competitive adsorptions

Wastewater stream from industrial pipelines usually involves multi-metal conditions (multicomponent). Thus, the FRKF was challenged to remove many different metals with bi-valent in a complex solution. Figure 10 demonstrated the adsorption of coexisting metal ions including Pb(II), Ni(II), Cu(II), Zn(II), Cd(II), and Hg(II) onto the FRKF. Under the same initial concentration, Pb(II) showed the highest uptake by the FRKF and Cu(II) also had a good affinity for the adsorbent compared to other metals. However, the adsorption in the multi-metal solution for Ni(II), Zn(II), Cd(II) and Hg(II) was nearly negligible, and the maximum uptake for Pb(II) was also reduced to 51.46 mg g−1. The results showed that the Pb(II) uptake was dependent on the presence of other metal ions, especially by Cu(II) in the mixed solution. Apparently, the competition among coexisting metal ions occurred, which might be due to bigger ionic radius and higher electronegativity to attract more binding sites (Bediako et al. 2015).

Conclusions

A hydrophilic kapok fiber was prepared, using the Fenton reaction. According to the response surface methodology, the optimum concentrations of FeSO4 and H2O2 for FRKF preparation were 0.5 and 1.0 mol L−1 respectively. With the support of analytical methods including FTIR, contact angle analyzer, SEM, and EDS, the chemically enhanced fibers (FRKF) were evaluated in terms of the Pb(II) uptake. In kinetic study, the adsorption equilibrium could reach within 90 min, and the pseudo-second-order was fitted better to describe the adsorption process. As adsorption isotherm study showed, the new FRKF displayed an excellent adsorption capacity for Pb(II) in single metal solution with the maximum adsorption capacity, which was calculated by Langmuir isotherm model, of 94.41 ± 7.56 mg g−1 at pH 6.0. In the bi-valent metal ions system, although the Pb(II) uptake was relatively reduced by the competition of coexisting metal ions such as Cu(II), and there was also a limitation that industrial wastewater usually contains multi-valent metal ions while this work only studied the bi-valent metal ions, the FRKF still could be used for removing toxic metal ions in wastewater stream, especially well suitable for a pretreatment medium to industrial wastewater. Finally, compared with previously reported, this work provided a new method for the modification of kapok fiber, and confirmed that Fenton reaction was a feasible approach to enhance the Pb(II) adsorption capacity of kapok fiber.

References

Bediako JK, Wei W, Kim S (2015) Removal of heavy metals from aqueous phases using chemically modified waste Lyocell fiber. J Hazard Mater 299:550–561

Charles F, Baes J, Mesmer RE (1976) The hydrolysis of cations. Wiley, New York

Chung BY, Cho JY, Lee MH, Wi SG, Kim JH, Kim JS, Kang PH, Nho YC (2008) Adsorption of heavy metal ions onto chemically oxidized Ceiba pentandra (L.) Gaertn. (Kapok) Fiber. J Appl Biol Chem 51(1):28–35

Duan C, Zhao N, Yu X (2013) Chemically modified kapok fiber for fast adsorption of Pb2+, Cd2+, Cu2+ from aqueous solution. J Cellul 20(2):849–860

Freundlich HMF (1906) Over the adsorption in solution. J Phys Chem 57:385–470

Ho YS, Mckay G (1999) Pseudo second order model for sorption. J Process Biochem 34:451–465

Hong J, Liu MC, Mo JY, Wu PY, Chen D (2012) Wearability test and anlaysis of kapok-containing fabrics. J Text Res 33(8):46–49

Huang X, Lim TT (2006) Performance and mechanism of a hydrophobic–oleophilic kapok filter for oil/water separation. Desalination 190(1–3):295–307

Kim D, Quinlan M, Yen TF (2009) Encapsulation of lead from hazardous CRT glass wastes using biopolymer cross-linked concrete systems. Waste Manag 29:321–328

Kim D, Park JS, Yen TF (2012) Feasibility study on cross-linked biopolymeric concrete encapsulating selenium glass wastes. J Air Waste Manag Assoc 62(8):898–904

Kuo CY, Lin HY (2009) Adsorption of aqueous cadmium (II) onto modified multi-walled carbon nanotubes following microwave/chemical treatment. Desalination 249(2):792–796

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40(9):1361–1403

Largegren S (1898) About the theory of so-called adsorption of soluble substances. J Kungliga Svenska Vetenskapsakademiens Handlingar 24(4):1–39

Li YH, Wang S, Wei J, Zhang X, Xu C, Luan Z, Wu D, Wei B (2002) Lead adsorption on carbon nanotubes. Chem Phys Lett 357:263–266

Lim TT, Huang X (2007) Evaluation of hydrophobicity/oleophilicity of kapok and its performance in oily water filtration: comparison of raw and solvent-treated fibers. Ind Crops Prod 26(2):125–134

Mao J, Lee SY, Won SW, Yun YS (2010) Surface modified bacterial biosorbent with poly(allylamine hydrochloride): development using response surface methodology and use for recovery of hexachloroplatinate(IV) from aqueous solution. Water Res 44(20):5919–5928

Martin R, Alvaro M, Herance JR, Garcia H (2010) Fenton-treated functionalized diamond nanoparticles as gene delivery system. ACS Nano 4(1):65–74

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84(12):2222–2234

Needleman HL (1991) The health effects of low level exposure to lead. Annu Rev Public Health 12(1):111–140

Qiu Y, Cheng H, Xu C, Sheng GD (2008) Surface characteristics of crop-residue-derived black carbon and lead(II) adsorption. Water Res 42(3):567–574

Rengasamy RS, Das D, Karan CP (2011) Study of oil sorption behavior of filled and structured fiber assemblies made from polypropylene, kapok and milkweed fibers. J Hazard Mater 186(1):526–532

Rothenberg SJ, Kondrashov V, Manalo M, Manton WI, Khan F, Todd AC, Johnson C (2001) Seasonal variation in bone lead contribution to blood lead during pregnancy. Epidemiol Stud 85:191–194

Shiue I (2017) Urinary arsenic, pesticides, heavy metals, phthalates, polyaromatic hydrocarbons, and polyfluoroalkyl compounds are associated with sleep troubles in adults: USA NHANES, 2005–2006. Environ Sci Pollut Res 24(3):3108–3116

Sotto A, Kim J, Arsuaga JM, del Rosario G, Martinez A, Nam D (2014) Binary metal oxides for composite ultrafiltration membranes. J Mater Chem A 2(19):7054–7064

Sun XF (2003) A convenient acetylation of sugarcane bagasse using NBS as a catalyst for the preparation of oil sorption-active materials. J Mater Sci 38:3915–3923

Sun RC, Lu Q, Sun XF (2001) Psycho-chemical and thermal characterization of lignins from Caligonum monogoliacum and Tamarix spp. Polym Degrad Stab 72:229–238

Torres-Blancas T, Roa-Morales G, Fall C, Barrera-Diaz C, Urena-Nunez F, Silva P (2013) Improving lead sorption through chemical modification of de-oiled allspice husk by xanthate. Fuel 110:4–11

Veerakumar A, Selvakumar N (2012) A preliminary investigation on kapok/polypropylene nonwoven composite for sound absorption. Indian J Fiber Text Res 37(4):385–388

Wahi R, Chuah LA, Choong TSY, Ngaini Z, Nourouzi MM (2013) Oil removal from aqueous state by natural fibrous sorbent: an overview. Sep Purif Technol 113:51–63

Wang J, Wang A (2013) Acetylated modification of kapok fiber and application for oil absorption. Fibers Polym 14(11):1834–1840

Wang R, Shin CH, Park SH, Park JS, Kim D, Cui LZ, Ryu MH (2014) Removal of lead (II) from aqueous stream by chemically enhanced kapok fiber adsorption. Environ Earth Sci 72(12):5221–5227

Wang R, Shin CH, Park SH, Cui LZ, Kim D, Park JS, Ryu MH (2015) Enhanced antibacterial activity of silver-coated kapok fibers through dopamine functionalization. Water Air Soil Pollut 226:2241 pg 1–9

Wang JT, Zheng YA, Wang AQ (2016a) Superhydrophobic kapok fiber oil-absorbent: preparation and high oil absorbency. Chem Eng J 213:1–7

Wang R, Shin CH, Chang YG, Kim D, Park JS (2016b) Aqueous antibacterial enhancement using kapok fibers chemically modified in 3-D crosslinked structure. Water Environ Res 88(7):611–616

Wang R, Shin CH, Kim D, Ryu MH, Park JS (2016c) Adsorption of heavy metals and organic contaminants from aqueous stream with chemically enhanced kapok fibers. Environ Earth Sci 75(4):1–6

Weng CH, Huang CP (2004) Adsorption characteristics of Zn(II) from dilute aqueous solution by fly ash. Colloids Surf A Physicochem Eng Aspects 247(1–3):137–143

Witek-Krowiak A, Szafran RG, Modelski S (2011) Biosorption of heavy metals from aqueous solutions onto peanut shell as a low-cost biosorbent. Desalination 265(1):126–134

Xiang HF, Wang D, Liu HC, Zhao N, Xu J (2013) Invesigation on sound absorption properties of kapok fibers. Chin J Polym Sci 31(3):521–529

Xiong J, Jiao C, Li C, Zhang D, Lin H, Chen Y (2014) A versatile amphiprotic cotton fiber for the removal of dyes and metal ions. Cellulose 21:3073–3087

Xu D, Tan X, Chen C, Wang X (2008) Removal of Pb(II) from aqueous solution by oxidized multiwalled carbon nanotubes. J Hazard Mater 154(1–3):407–416

Yu XY, Luo T, Zhang YX, Jia Y, Zhu BJ, Fu XC, Liu JH, Huang XJ (2011) Adsorption of lead(II) on O2-plasma-oxidized multiwalled carbon nanotubes: thermodynamics, kinetics, and desorption. ACS Appl Mater Interfaces 3(7):2585–2593

Zhang GQ, Yang FL, Gao MM, Liu LF (2008) Electrocatalytic behavior of the bare and the anthraquinonedisulfonate/polypyrrole composite film modified graphite cathodes in the electro-Fenton system. J Phys Chem C 112(24):8957–8962

Zhang XY, Fu WY, Duan CT, Xiao H, Shi MW, Zhao N, Xu J (2013) Superhydrophobicity determines the buoyancy performance of kapok fiber aggregates. Appl Surf Sci 266:225–229

Zhang XL, Duan CT, Jia X, Dai B (2016) Carboxylation kapok fiber as a low-cost, environmentally friendly adsorbent with remarkably enhanced adsorption capacity for cationic dyes. Res Chem Intermed 42:5069–5085

Zhao YF, Wang DF, Xie HZ, Won SW, Cui LZ, Wu GP (2015) Adsorption of Ag (I) from aqueous solution by waste yeast: kinetic, equilibrium and mechanism studies. Bioprocess Biosyst Eng 38(1):69–77

Zheng YA, Wang JT, Zhu YF, Wang AQ (2015) Research and application of kapok fiber as an absorbing material: a mini review. J Environ Sci 27:21–32

Zhou LC, Shao YM, Liu JR, Ye ZF, Zhang H, Ma JJ, Jia Y, Gao WJ, Li YF (2014) Precipitation and characterization of magnetic porous carbon microspheres for removal of methylene blue by a heterogeneous Fenton reaction. ACS Appl Mater Interfaces 6(10):7275–7285

Zinatizadeh AAL, Mohamed AR, Abdullah AZ, Mashitah MD, Isa MH, Najafpour GD (2006) Process modeling and analysis of palm oil mill effluent treatment in an up-flow anaerobic sludge fixed film bioreactor using response surface methodology. Water Res 40(17):3193–3208

Author information

Authors and Affiliations

Corresponding authors

Additional information

This article is a part of Topical Collection in Environmental Earth Sciences on Water Sustainability: A Spectrum of Innovative Technology and Remediation Methods, edited by Dr. Derek Kim, Dr. Kwang-Ho Choo, and Dr. Jeonghwan Kim.

Rights and permissions

About this article

Cite this article

Wang, D., Kim, D., Shin, CH. et al. Removal of lead(II) from aqueous stream by hydrophilic modified kapok fiber using the Fenton reaction. Environ Earth Sci 77, 653 (2018). https://doi.org/10.1007/s12665-018-7824-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-018-7824-5