Abstract

As a biopolymer-modified building block, a poly-dopamine layer can be utilized with a wide range of inorganic and organic materials for an adsorptive and microbial remediation. In this study, dopamine (DOPA) was used as a structural platform to bind silver onto the surface of kapok fibers, and a composite of surface-modified kapok fibers coated with DOPA along with silver were successfully manufactured. After a silver-coating process, a very strong antibacterial property was exhibited against Staphylococcus aureus with a high antibacterial efficiency, over 99 %, which could last for 48 h in peptone water. Enumeration determination was carried out in a spread plate method. For a comparative study, the antibacterial activity of raw kapok fibers and chemically enhanced kapok fibers with DOPA and silver was also evaluated. The results indicated that the chemically enhanced kapok fibers were very useful in controlling a microbial activity on a surface environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The strong antimicrobial function of silver nanoparticles has been a major attention with their more advanced development in diverse applications such as disinfection in wastewater treatment, food, and textile businesses requiring for prevention from a bacterial colonization (Guzman et al. 2012). In a medical supply area, wound dressings, contraceptive devices, surgical instruments, and bone prostheses are also coated or embedded with silver nanoparticles (Ghafari-Nazari et al. 2012). They were applied onto fabrics for a garment business (Abdel-Mohsen et al. 2013; Rehan et al. 2013; Wang et al. 2011).

Several methods for the preparation of silver nanoparticles or their associated composites have been developed, such as photocatalytic reduction (Ghafari-Nazari et al. 2012; Rehan et al. 2013), chemical reduction (Abdel-Mohsen et al. 2013), plasma and enzyme treatments (Nithya et al. 2012), rapid thermal annealing (Hsieh et al. 2013), sol-gel (Chen et al. 2013), and sonication (Li et al. 2013). Also, many methods have been developed in order to extend the antibacterial activity of the surfaces using silver or silver derivatives. Most of the methods focused on pretreating the surface or coating the surface with a thin film of polymer containing silver nanoparticles or embedding silver nanoparticles on a fiber polymeric matrix. It was reported that, by using trimethylol melamine (TMM) to modify a cotton surface, the antibacterial activity was greatly enhanced even after regeneration or laundering (Ibrahim et al. 2008). Some researchers also used crosslinkable polysiloxane to pretreat a fabric surface, which was then covered with nanosized colloidal silver and silver-coated surface showed a high antibacterial efficiency against Klebsiella pneumoniae and Staphylococcus aureus (Dastjerdi et al. 2009). In a report, polyvinylpyrrolidone (PVP) was used to make silver nanoparticles stable during the synthesis and it was applied to a silk fabric surface using an exhaust method. A prominent antibacterial activity against the gram-positive bacterium, S. aureus, on silk fabrics, was introduced as well as the durability to washing (Gulrajani et al. 2008). Polystyrene-block-polyacrylic acid (PS-b-PAA) was used as a structural building block to stabilize silver nanoparticles with micelle cores, which was synthesized in an atom transfer free radical polymerization (ATRP) method (Budama et al. 2013). Others to enhance an antibacterial activity were associated with the surface modification of the fabrics and subsequent coating with silver nanoparticle sols, and their synthetic processes were the so-called sol-gel technique (Ilic et al. 2009; Tarimala et al. 2006; Xing et al. 2007).

It has also been reported that kapok fiber is in a distinct hollow structure with wax coated on the surface (Abdullah et al. 2010). Such wax structure, quite different from cotton fiber, makes it hydrophobic for the composition of cellulose (35 % for dry fiber), xylan (22 %), and lignin (21.5 %) (Keko et al. 2000). In this study, dopamine (DOPA) was used to modify the surface of kapok fibers. Its origin was from India and derived from the fruits of silk-cotton tree (Lim and Huang 2007). As a biopolymer-modified building block, the polymer layer using DOPA can be useful with a wide range of inorganic and organic materials (Lee et al. 2007). The poly-DOPA layer can play a structural platform in binding metals with chemical functional groups such as catechols in a poly-DOPA structure. With this poly-DOPA base, the efficiency of silver-coating kapok fibers can be highly enhanced with a functionalization of antibacterial activity against microorganisms including S. aureus. The role of kapok fibers is well mentioned in a study (Wang et al. 2014), describing that a kapok fiber is utterly building foundation for a three-dimensional structure with the help of chemical functional groups on its surface. A kapok fiber is well known for its application in oil removal (Wang et al. 2012) as well as wastewater treatment (Wang et al. 2014).

2 Materials and Methods

2.1 Materials

The kapok fibers were imported from Malaysia. Before using them, lumps and impurities found in the fiber products were completely removed. Then, the fibers were washed and dried at room temperature. DOPA was purchased from Sigma-Aldrich, Germany, and silver nitrate was purchased from Samchun Pure Chemical Co., Ltd., Korea. S. aureus (IFO 3060) was obtained from the Korean Culture Center of Microorganisms (KCCM).

For the polymerization of DOPA and the silver-coating process on the surface of kapok fibers, a DOPA solution (2 g/L) was prepared by dissolving DOPA completely into the Tis-HCl buffer solution (0.01 mol/L, pH = 8.0). Then, 0.2 g of kapok fiber was immersed in 100 mL of the DOPA solution, which was well mixed with a stirring bar for 24 h. A self-polymerization of DOPA was likely to gradually change the color of the prepared poly-DOPA-coated kapok fibers (KF-DOPA) from bright white to dark gray. Consequently, KF-DOPA was rinsed with deionized water and dried in a vacuum oven for a use. A silver-coating process was carried out under an UV irradiation. First, 0.2 g of KF-DOPA was immersed in 50 mL of silver nitrate solution at different concentrations of silver ions (5, 10, and 50 g/L) and subject to the UV irradiation while being stirred for 30 min. KF-DOPA deposited with silver (KF-DOPA/Ag) was washed thoroughly with distilled water and dried in the vacuum oven. All processes were conducted at room temperature under atmospheric condition. KF-DOPA coated with 5, 10, and 50 g/L of silver nitrate will be named as KF-DOPA/Ag-5, KF-DOPA/Ag-10, and KF- DOPA/Ag-50, respectively.

2.2 Microscopic Analysis

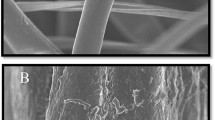

The surface morphology and elemental composition of the samples were analyzed using a field emission scanning electron microscope (FE-SEM, S-5500, Hitachi), equipped with an EDAX detector. The FE-SEM measurements were conducted at an accelerating voltage of 10 kV. The EDAX analysis was performed at 50 kV. In order to identify morphological differences of the bacteria cells before and after a chemical treatment, a biological scanning electron microscope (BIOSEM) was applied and the sample was required for a pretreatment as follows. Firstly, the inoculums were filtered and washed with phosphate buffer solution (PBS). The sample was washed with PBS two times after mixing with 1 % osmium tetroxide, and the mixture was kept at 4 °C for 1–2 h. Finally, a dehydration process was conducted using ethanol at a concentration range between 30 and 100 % in an increasing order and the sample was analyzed with BIOSEM.

2.3 Microbial Enumeration for the Antibacterial Efficiency of the KF-DOPA/Ag

S. aureus was cultured in 20 mL of broth containing 10 g/L of polypeptone, 2 g/L of yeast extract, and 1 g/L of MgSO4 · 7H2O at 30 °C. For an antibacterial assay, the direct contact method was used. After being cultured for 24 h, the bacteria-containing broth was centrifuged at 2500 rpm for 15 min, and 0.1 mL of the supernatant was removed and placed in 20 mL of peptone water containing 20 g/L of peptone and 5 g/L of NaCl. In order to enumerate the accurate number of the bacteria, colonies increased up to 106 forming units (CFU)/mL, the peptone water containing bacteria was also cultured for 1 h at favorable temperature, 30 °C. Then, 0.02 g of KF-DOPA/Ag was added to peptone water and the determination was made using a spread plate method, while the inoculums were diluted appropriately in sterile water and 0.05 mL of the diluted inoculum was spread evenly on the surface of the agar plate on a standard sized petri dish (Hyundai Micro Co., Ltd., Korea). The agar plate was cultured at 30 °C after the inoculum was dried during the spreading procedure. The colonies were observed on the surface of the plate after incubation for 24 h, and the counting was carried out to estimate the number of the live cells, when the number of the colonies ranged from 30 to 300 CFU on one agar plate. For a comparative study, the antibacterial efficiencies of the raw kapok fibers and the KF-DOPA/Ag were evaluated with a control in which bacteria had naturally grown in peptone water. Experiments were repeated three times and an average value was expressed in a mean ± standard deviation.

The antibacterial efficiency of the KF-DOPA/Ag was calculated in Eq. (1):

where C is the average number of bacteria colonies in the control and A is the average number of bacteria colonies in peptone water containing KF-DOPA/Ag (Arian et al. 2013).

3 Results and Discussion

3.1 DOPA Polymerization on the Surface of Kapok Fibers

The SEM images in Fig. 1 show the surface modification of the kapok fiber with and without a chemical treatment with a DOPA solution. For raw kapok fibers, the surface was seen smooth without any ripples because of the thick wax structure on the surface (Wang et al. 2012). However, the surface of the treated kapok fiber with DOPA was rough, and different degrees of wrinkles and grooves were observed. This result indicates that DOPA was successfully coated on the surface of the kapok fibers after a self-polymerization process in solution. After treated with DOPA, the color of the kapok fibers changed to dark brown as shown in Fig. 2. Similar observation was identified with a study (Xu et al. 2011); reportedly, a quinone structure was formed by oxidizing catechol groups under alkaline conditions, which was caused by the redox activity of functional groups of catechol in DOPA. These quinone structures could react further with amines and other catechol or quinone in order to form an adherent poly-DOPA film (Xu et al. 2011).

The process and mechanism of a DOPA polymerization is shown in Fig. 3. The entire process is based on the oxidative self-polymerization of dopamine (2-(3,4-dihydroxy-phenyl)ethylamine) onto surfaces with an intermediate step that formed 5,6-dihydroxyindole after oxidation and structural rearrangement (Lee et al. 2008; Postma et al. 2009; Zhang et al. 2013). The formation of poly-DOPA was reduced dramatically by purging a DOPA solution with argon, suggesting that both DOPA and oxygen were preconditioned (Lee et al. 2007). However, unlike the previous open system, some reported that the dissolved oxygen in the capillary sealing solution could not completely oxidize all the DOPA in its solution. Only one fifth of DOPA could be deposited onto the surface of the materials in the solution because of the difference between the calculated content of DOPA deposited on the inner wall and that in filtered solution (Yin and Liu 2008).

On a comparative viewpoint, the bacterial properties of the raw kapok fibers and the KF-DOPA were also evaluated in Fig. 3; a very low antibacterial efficiency could be observed with the raw kapok fibers as a control. As with KF-DOPA, the number of bacteria was much higher than that of the control, since DOPA on the kapok fibers serve as a substrate to microorganism. DOPA was also a good medium compound to cause microorganism to be attracted in a favorable environment. Five mechanisms of antibacterial action have been reported: (1) interference with a cell wall synthesis, (2) inhibition of protein synthesis, (3) interference with a nucleic acid synthesis, (4) inhibition of a metabolic pathway, and (5) direct destruction on a bacterial membrane structure (Tenover 2006). Those antibacterial actions are closely related with a metal coating on a surface mechanism.

3.2 Silver Coating on the Surface of Kapok Fibers after DOPA Functionalization

The entire process including the silver-coating step is shown in Fig. 4. The surface topography of the chemically enhanced kapok fibers was analyzed using FE-SEM. The elemental composition of the chemically modified kapok fibers (KF-DOPA/Ag) was also exhibited by EDAX. Figure 5a shows the FE-SEM image of the silver-coated kapok fibers right after coated with silver ions. The silver particles were clearly observed with the EDAX analysis (Fig. 5b) and the elemental composition (Table 1). The EDAX spectrum showed that the content of Ag was 2.54 wt.% and the quantitative signals for C and O were 61.47 and 35.99 wt.%, respectively.

Process of DOPA and silver coating on the surface of kapok fibers (a) and mechanism of a DOPA self-polymerization (b) (Wang et al. 2011)

Similarly, the surface of the cotton fabrics was successfully coated with poly-DOPA and silver nanoparticles (Xu et al. 2011). Some of the catechol groups chelated with Ag+ and in situ Ag+ were reduced to zero-valent silver (Ag0) without adding further reduction agents (Xu et al. 2011). In addition, a sol-gel method was improved for the formation of silver clusters by incorporating AgNO3 into the organic-inorganic hybrid sols derived from methacryloxypropyl trimethoxy-silane and vinyltriethoxysilane (VTES) (Lee et al. 2010). It was proven that the mean size and the number of Ag clusters could possibly be controlled by adjusting the initial AgNO3 concentrations in the precursor solutions. In other words, with increasing AgNO3 concentrations, the Ag loading amounts on the coating films increased, resulting in the increase of the mean diameter of the Ag colloids through more agglomeration between the Ag clusters (Jeon et al. 2003; Lee et al. 2010).

3.3 Antibacterial Properties of KF-DOPA/Ag

The antibacterial efficiency of the chemically enhanced kapok fibers (KF-DOPA/Ag) was evaluated using a direct contact method. It was observed that the number of S. aureus was considerably reduced after a direct contact of KF-DOPA/Ag for 1 h, comparing between KF-DOPA/Ag and the control. After 2 h, all the bacteria were deactivated, as shown in Fig. 6. As earlier mentioned, the initial concentration of AgNO3 in a precursor solution could affect the Ag loading amounts on the surface of the fibers coated with DOPA. By increasing the initial AgNO3 concentration, the number of Ag0 and the mean size of the Ag clusters increased, indicating that more Ag+ could possibly be released from these clusters into the medium. There was no significant difference observed in the first hour between the three different samples (Fig. 6). However, after 2 h, an obvious decrease in the number of bacteria was seen with KF-DOPA/Ag-50 that was greater than KF-DOPA/Ag-5 and Ag-10, although the KF-DOPA/Ag-5 and Ag-10 also showed good antibacterial properties. The antibacterial assay was carried out for 48 h (Table 2). For KF-DOPA/Ag-5, the number of bacteria increased after being incubated for 30 h and the increased number of bacteria was also observed for KF-DOPA/Ag-10 after 48 h. It can be said that the concentration of Ag+ released from the Ag clusters in the medium were not enough to inhibit the proliferation of the residual colonies in the medium. For the three samples, an antibacterial efficiency increased up to 99 % after 2 h and this high efficiency could last for 48 h, as shown in Table 3.

As for S. aureus, gram-positive bacteria, in Fig. 7, the shape of the cells was changed after a direct contact with KF-DOPA/Ag for 24 h (Fig. 7b), as compared to the control (Fig. 7a). The fact was that a cell wall synthesis was greatly inhibited the moment the Ag particles made contact with the surface of the cell membrane, resulting in the destruction on a cell membrane structure (Guzman et al. 2012).

4 Conclusions

A silver coating on the surface of kapok fibers was successfully fabricated though a DOPA functionalization. The antibacterial properties of this chemically enhanced composite, KF-DOPA/Ag, were evaluated. After a direct contact with it for 2 h, a high efficiency against S. aureus was shown with over 99 %. This high efficiency lasted for 48 h with the help of the coating of silver nanoparticles. This method envisions to be utilized in a number of areas including pharmaceutical, medical, and wastewater treatment.

References

Abdel-Mohsen, A. M., Hrdina, R., Burgert, L., Abdel-Rahman, R. M., Hasova, M., Smejkalova, D., Kolar, M., Pekar, M., & Aly, A. S. (2013). Antibacterial activity and cell viability of hyaluronan fiber with silver nanoparticles. Carbohydrate Polymers, 92, 1177–1187.

Abdullah, M. A., Rahmah A. U., Man Z. (2010). Physicochemical and sorption characteristics of Malaysian Ceiba pentandra (L.) Gaertn as a natural oil sorbent. J Hazardon Materials, 177, 683–691.

Arian, R. A., Khatri, Z., Memon, M. H., & Kim, I. S. (2013). Antibacterial property and characterization of cotton fabric treated with chitosan/AgCl-TiO(2) colloid. Carbohydrate Polymers, 96, 326–331.

Budama, L., Cakir, B. A., Topel, O., & Hoda, N. (2013). A new strategy for producing antibacterial textile surfaces using silver nanoparticles. Chemical Engineering Journal, 228, 489–495.

Chen, K. T., Ray, D., Peng, Y. H., & Hsu, Y. C. (2013). Preparation of Cu–Ag core–shell particles with their anti-oxidation and antibacterial properties. Current Applied Physics, 13, 1496–1501.

Dastjerdi, R., Montazer, M., & Shahsavan, S. (2009). A new method to stabilize nanoparticles on textile surfaces. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 345, 202–210.

Ghafari-Nazari, A., Moztarzadeh, F., Rabiee, S. M., Rajabloo, T., Mozafari, M., & Tayebi, L. (2012). Antibacterial activity of silver photodeposited nepheline thin film coatings. Ceramics International, 38, 5445–5451.

Gulrajani, M. L., Gupta, D., Periyasamy, S., & Muthu, S. G. (2008). Preparation and application of silver nanoparticles on silk for imparting antimicrobial properties. Journal of Applied Polymer Science, 108, 614–623.

Guzman, M., Dille, J., & Stephane Godet, S. (2012). Synthesis and antibacterial activity of silver nanoparticles against gram-positive and gram-negative bacteria. Nanomedicine: Nanotechnology, Biology and Medicine, 8, 37–45.

Hsieh, J. H., Chiu, C. H., Li, C., Wu, W., & Chang, S. Y. (2013). Development of anti-wear and anti-bacteria TaN-(Ag, Cu) thin films—a review. Surface and Coatings Technology, 233, 159–168.

Ibrahim, N. A., Aly, A. A., & Gouda, M. (2008). Enhancing the antibacterial properties of cotton fabric. Journal of Industrial Textiles, 37, 203–212.

Ilic, V., Saponjic, Z., Vodnik, V., Molina, R., Dimitrijevic, S., Jovancic, P., Nedeljkovic, J., & Radetic, M. (2009). Antifungal efficiency of corona pretreated polyester and polyamide fabrics loaded with Ag nanoparticles. Journal of Materials Science, 44, 3983–3990.

Jeon, H. J., Yi, S. C., & Oh, S. G. (2003). Preparation and antibacterial effects of Ag–SiO2 thin films by sol–gel method. Biomaterials, 24, 4921–4928.

Keko, H., Maxima, E. F., Shigenori, K., Thi, B. T. L., & Kenji, L. (2000). Exellent oil absorbant kapok [Ceiba pentandra (L.) Gaertn.] fiber structure, chemical characteristics, and application. Journal of Wood Science, 46, 401–404.

Lee, H., Dellatore, S. M., Miller, W. M., & Messersmith, P. B. (2007). Mussel-inspired surface chemistry for multifunctional coatings. Science, 318, 426–430.

Lee, H., Lee, Y., Statz, A. R., Rho, J., Park, T. G., & Messersmith, P. B. (2008). Substrate-independent layer-by-layer assembly by using mussel-adhesive-inspired polymers. Advanced Materials, 20, 1619–1623.

Lee, S. M., Lee, B. S., Byun, T. G., & Song, K. C. (2010). Preparation and antibacterial activity of silver-doped organic–inorganic hybrid coatings on glass substrates. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 355, 167–171.

Li, C., Wang, X., Chen, F., Zhang, C., Zhi, X., Wang, K., & Cui, D. (2013). The antifungal activity of graphene oxide–silver nanocomposites. Biomaterials, 34, 3882–3890.

Lim, T. T., & Huang, X. (2007). Evaluation of hydrophobicity/oleophilicity of kapok and its performance in oily water filtration: comparison of raw and solvent-treated fibers. Industrial Crops and Products, 26, 125–134.

Nithya, E., Radhai, R., Rajendran, R., Jayakumar, S., & Vaideki, K. (2012). Enhancement of the antimicrobial property of cotton fabric using plasma and enzyme pre-treatments. Carbohydrate Polymers, 88, 986–991.

Postma, A., Yan, Y., Wang, Y., Zelikin, A. N., Tjipto, E., & Caruso, F. (2009). Self-polymerization of dopamine as a versatile and robust technique to prepare polymer capsules. Chemistry of Materials, 21, 3042–3044.

Rehan, M., Hartwig, A., Ott, M., Gätjen, L., & Wilken, R. (2013). Enhancement of photocatalytic self-cleaning activity and antimicrobial properties of poly(ethylene terephthalate) fabrics. Surface and Coatings Technology, 219, 50–58.

Tarimala, S., Kothari, N., Abidi, N., Hequet, E., Fralick, J., & Dai, L. L. (2006). New approach to antibacterial treatment of cotton fabric with silver nanoparticle-doped silica using sol–gel process. Journal of Applied Polymer Science, 101, 2938–2943.

Tenover, F. C. (2006). Mechanisms of antimicrobial resistance in bacteria. The American Journal of Medicine, 119, S3–10; discussion S62–70.

Wang, W., Jiang, Y., Liao, Y., Tian, M., Zou, H., & Zhang, L. (2011). Fabrication of silver-coated silica microspheres through mussel-inspired surface functionalization. Journal of Colloid and Interface Science, 358, 567–574.

Wang, J., Zheng, Y., & Wang, A. (2012). Effect of kapok fiber treated with various solvents on oil absorbency. Industrial Crops and Products, 40, 178–184.

Wang, R., Shin, C. H., Park, S., Park, J. S., Kim, D. I., Cui, L. Z., & Ryu, M. H. (2014). Removal of lead (II) from aqueous stream by chemically-enhanced kapok fiber adsorption. Journal of Environmental Earth Sciences, 72, 5221–5227.

Xing, Y., Yang, X., & Dai, J. (2007). Antimicrobial finishing of cotton textile based on water glass by sol–gel method. Journal of Sol–gel Science and Technology, 43, 187–192.

Xu, H., Shi, X., Ma, H., Lv, Y., Zhang, L., & Mao, Z. (2011). The preparation and antibacterial effects of dopa-cotton/AgNPs. Applied Surface Science, 257, 6799–6803.

Yin, X. B., & Liu, D. Y. (2008). Polydopamine-based permanent coating capillary electrochromatography for auxin determination. Journal of Chromatography A, 1212, 130–136.

Zhang, R. X., Braeken, L., Luis, P., Wang, X. L., & Van der Bruggen, B. (2013). Novel binding procedure of TiO2 nanoparticles to thin film composite membranes via self-polymerized polydopamine. Journal of Membrane Science, 437, 179–188.

Acknowledgments

The authors would like to thank Dr. Tae-Sung Bae and his laboratory staff members at the Korean Basic Science Institute (KBSI) for the instrumental analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, R., Shin, C.h., Park, S. et al. Enhanced Antibacterial Activity of Silver-Coated Kapok Fibers Through Dopamine Functionalization. Water Air Soil Pollut 226, 2241 (2015). https://doi.org/10.1007/s11270-014-2241-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-014-2241-1