Abstract

The aim of this paper is to propose three predictive models namely empirical, artificial neural network (ANN), and adaptive neuro-fuzzy inference system (ANFIS) for prediction of ground vibration produced by blasting operations conducted in Gol-E-Gohar Iron mine, Iran. In this way, 115 operations were precisely monitored and related parameters of blasting were measured. Furthermore, maximum charge per delay and the distance from the blast-face were set and applied to construct the ground vibration predictive models. By assigning all data sets into training and testing, many ANFIS and ANN models were constructed. The results revealed that the proposed ANFIS model can estimate ground vibrations more accurately than other developed models. Root-mean-square error value of 4.644, for testing data set, shows superiority of the ANFIS predictive system in predicting ground vibration while they were achieved as 7.522 and 10.689 for ANN and empirical models, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In blasting operations, a large amount of explosive energy is wasted to create environmental impacts like air-overpressure, flyrock, ground vibration (GV), and back-break (Khandelwal and Singh 2006, 2007; Khandelwal and Kankar 2011; Ghasemi et al. 2012, 2013, 2014; Sari et al. 2014; Raina et al. 2014; Ebrahimi et al. 2015; Faradonbeh et al. 2016). Among these environmental issues, GV is considered as one of the most important blasting effects (Mohamed 2011; Monjezi et al. 2011). High GVs produced by blasting have unwanted effects on the structural integrity and groundwater of the nearby area (Singh and Singh 2005; Ozer et al. 2008). Hence, suitable estimation of GV may minimize/reduce the blasting environmental problems.

Peak particle velocity (PPV) is considered as one of the components of GV. According to Bureau of Indian Standard (1973), Kahriman (2002), and Singh and Singh (2005), PPV is an important factor/index to measure GVs for controlling the structural damage criteria. During the past few decades, several vibration empirical predictors have been developed, but their performance predictions are not reliable enough for engineering practice. In addition to empirical models, the use of statistical approaches for PPV prediction is addressed by some other researchers like Verma and Singh (2011) and Hudaverdi (2012). As a result, their capacity in predicting PPV is similar to empirical approaches. Therefore, there is a need to develop more accurate models for estimation of PPV in engineering practice.

During the recent years, intelligent techniques have been widely utilized and developed to predict PPV. ANN as a common intelligent method has been used by many scholars in the field of GV and PPV (e.g. Khandelwal and Singh 2006; Mohamad et al. 2012). Fuzzy inference system (FIS) was also examined and proposed for approximating PPVs resulting from blasting operations (e.g. Fisne et al. 2011; Ghasemi et al. 2013). Generally, the obtained results by previous researchers show that intelligent techniques are able to predict PPV with higher level of accuracy compared to empirical and statistical techniques.

In the current study, blasting results have been gathered form Gol-E-Gohar iron mine, Iran. Using the two models: ANN and ANFIS, PPV values are predicted. Moreover, to indicate the ability of the proposed predictive models, one of the most in demand empirical equations in the PPV prediction field is performed and the obtained results are compared.

Predictive techniques

ANN

In solving complex engineering problems, artificial neural networks (ANN) are mainly utilized and developed. When the connections between independent and dependent variables are extremely nonlinear, the problems are considered as complex. In this condition, finding a convenient solution to solve the problems would be a difficult task. Many researchers addressed the efficiency of the ANN technique by approximating complicated problems.

The most commonly used neural networks are the feed-forward (FF) neural networks. Several scholars such as Shahin et al. (2002) recommended that when there is no time-dependent variable in defining ANNs, FF would be applied. As highlighted in the study conducted by Haykin (1999), multilayer perceptron (MLP) neural network can be considered as one of the most popular FF ANNs. In MLP, there are at least three layers defined as input, hidden, and output layers. Each layer has a weight (w) matrix, a bias (b) vector, and an output vector. Each layer can possess different number of neurons. Within these types of networks, the output of each intermediate layer is used as the input of the next one. A three-layer feed-forward MLP network is depicted in Fig. 1.

Three-layer sample of feed-forward MLP network (Demuth and Beale 2000)

Among various algorithms to train ANNs, back-propagation (BP) is the most widely utilized one (Dreyfus 2005; Laman and Uncuoglu 2009; Khandelwal and Singh 2006, 2007, 2009). BP learning is composed of a forward pass and a backward pass through various layers of network. More details about application/procedure of BP algorithm can be found in some other studies (e.g. Dreyfus 2005; Khandelwal and Singh 2009).

ANFIS

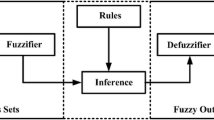

Adaptive neuro-fuzzy inference system (also known as ANFIS) introduced by Jang (1993) is a soft computation technique used for solving highly nonlinear problems. The ANFIS objective is used to find a predictive model/solution which correctly associates the input parameters with the values of output (Yilmaz and Yuksek 2009). By using ANFIS, which is a specific ANN type, advantages of the fuzzy inference system (FIS) and ANN can be performed simultaneously. In FIS rule base, each fuzzy rule defines a local behaviour of the system (Gokceoglu et al. 2004). ANFIS is implemented to increase the generalization capability of an ANN system through providing more reliable data when extrapolation is required beyond the range of training data.

As mentioned in the studies carried out by many researchers (e.g. Iphar et al. 2008; Sezer et al. 2014; Armaghani et al. 2015a), a typical ANFIS structure consists of one input layer, one output layer, and four hidden layers. It is worth mentioning that ANFIS regularly generates a single output. In ANFIS, the number of hidden node (N h) reflects the rule number(s). It also should be noted that rule type of Takagi and Sugeno is applied by ANFIS system (Jang 1993). As reported by Jin and Jiang (1999), the mentioned type of rules is suppler to solve complicated problems in general. A typical ANFIS structure for two-input Sugeno model with four rules is presented in Fig. 2. More details regarding the ANFIS structure and application can be found in other alternative studies (e.g. Jang 1993; Grima et al. 2000; Iphar et al. 2008; Armaghani et al. 2015b).

Site location and data collection

Gol-E-Gohar iron ore mine is located in the south of Iran. The site lies geographically in latitude 29°7′N and longitude 55°19′E, surrounded by mountains with height of 2500 m. There are six separate ore bodies in the Gol-E-Gohar mines over an area of 40 km2. In particular, about 1.135 billion tons can be estimated for total deposits of iron ore in this area. Figure 3 shows the location of Gol-E-Gohar iron ore mine.

Blasting operations in Gol-E-Gohar mine were conducted using hole diameters of 152, 165, and 250 mm. Hole depths in the blasted area were in the range of 5–19 m. ANFO was utilized as the main explosive material, while for initiation purpose dynamite was considered. Additionally, the designed blast-holes were stemmed by fine gravel.

In this study, a total of 115 blast vibrations and related parameters were measured in the Gol-E-Gohar iron ore mine site. During these operations, several blast design parameters such as spacing, burden, stemming, hole depth, hole diameter, distance from the blast-face, number of blasting series, specific charge, maximum charge per delay, and specific drilling were measured in each blasting operation. In addition, in each blasting operation, ground vibration values were monitored using the seismograph (Blastmate III) manufactured by M/s Instantel, Canada. This equipment records PPV values in three different directions with a geophone. Dynamic range of this seismograph is more than 2 mm/s, and the sampling rates are 1024 samples per second. Figure 4 illustrates the blast vibration monitoring in the mentioned site. In addition, Fig. 5 demonstrates the general terminology used in the blasting operations.

Preparing a proper database with the most effective inputs is considered as the first stage of the simulation investigations. In order to propose an accurate predictive PPV model, the most influential factors on PPV should be determined. Maximum charge per delay (MC) and distance from the blast-face (DI) have been applied to develop new PPV predictive simulations by many researchers such as Iphar et al. (2008), Khandelwal et al. (2011), Mohamed (2011), Fisne et al. (2011), and Hasanipanah et al. (2015). Hence, in this research, the mentioned factors were chosen as the inputs of the proposed models. Table 1 tabulates the input and output parameters used in this study and their ranges.

Prediction of PPV caused by blasting

ANN predictive model

The present section is about modelling procedure of the proposed ANN model. All data sets were normalized in the first stage of ANN modelling as suggested by Khamesi et al. (2015) using the following equation:

where X and X norm are respectively, the measured and normalized values. X max and X min are the maximum and minimum values of X.

Then, for training and testing purposes, the established database is divided into two groups. Previous researchers have suggested various percentages for testing data sets. Amounts of 20, 25 %, and a range of 20–30 % whole data sets were suggested for testing data sets in the studies carried out by Swingler (1996), Looney (1996) and Nelson and Illingworth (1990). Hence, respectively, in the present study, 80 and 20 % of all 115 data sets were performed to develop and examine the PPV predictive models.

Levenberg–Marquardt (LM) algorithm was used for training the ANN models. On the other hand, the prediction performance of ANNs is closely related to the architecture of the selected network. Therefore, defining the optimum network architecture is crucial in designing ANN models. As mentioned by many scholars (e.g. Hornik et al. 1989), an ANN network with only one hidden layer can estimate essentially all of the problems. Therefore, one hidden layer was used to design the ANN models of this study.

Table 2 presents some of the previous equations in determining number of hidden nodes (N h). Sonmez et al. (2006) mentioned that N h has a deep impact in designing the ANN models. Based on Table 2, a range of (1–5) for the N h can solve PPV problem. A series of ANN models were constructed using the mentioned N h range, and their obtained performance predictions are shown in Table 3. As a result, run number 4 of the ANN model number 4 with N h = 4 shows lower RMSE value for both training and testing data sets and its architecture (2 × 4 × 1) was used in approximating PPV values.

ANFIS predictive model

In this section, ANFIS modelling procedure for PPV prediction is described. Here, in order to have a fair comparison, the best data set of the ANN part (run 4 of model No. 4) has only been utilized. To find the optimum number of fuzzy rules, numerous models with different rules were examined using the trial-and-error method. In the ANFIS analysis, RMSE results of both training and testing data sets were considered. In addition, as a well-known membership function (MF), the Gaussian MF was performed in the analysis of this study. This type of MF was extensively used in many ANFIS studies (e.g. Iphar et al. 2008; Singh et al. 2012; Ataei and Kamali 2012). Moreover, as recommended by several scholars (e.g. Ataei and Kamali 2012; Armaghani et al. 2015a), a linear MF type was applied for the output (PPV) of the system.

After performing a series of models and analysis, it was found that the best ANFIS predictive model is obtained when five fuzzy rules are utilized for each model input. Therefore, it can be concluded that the number of fuzzy rules =25 leads to a good enough performance in predicting PPVs produced by blasting. Details of the parameters used in modelling procedures are presented in Table 4. Figures 6 and 7 illustrate the shapes and different categories (low, medium, high) of MFs used for model inputs. It should be stated that these MFs are assigned after the training phase. Evaluation of the developed ANFIS predictive model will be discussed later. In modelling of the ANFIS and ANN, in this study, MATLAB version 7.14.0.739 was utilized (Demuth et al. 2009).

Empirical predictive model

As mentioned earlier, many empirical PPV predictors are proposed by the previous investigators. In this study, one of the most popular PPV predictors (Duvall and Petkof 1959) has been selected to develop empirical model for PPV prediction. In this model, based on scaled distance factor (SD) which is presented in a form where DI is distance from the blast-face (m) and MC is the maximum charge per delay (kg), PPV values can be estimated using the following equation:

where K and B are site constants. Considering the same training data sets of ANN and ANFIS parts and using Eq. (2), a new PPV empirical model for the collected data from Gol-E-Gohar iron mine is developed as demonstrated below:

Figure 8 displays the PPV values, measured in the mine against SDs together with developed equation and the obtained R 2. R 2 of 0.721 acknowledges that the developed PPV model can estimate PPVs with only a suitable degree of accuracy. Evaluating the developed models for training and testing data sets will be discussed later. Empirical analysis was conducted considering the statistical software package of SPSS version 16 (SPSS 2007).

Results and discussion

Two AI-based models, i.e. ANN and ANFIS as well as an empirical model were applied and developed to estimate PPV produced by blasting. For evaluating the accuracy of the mentioned approaches, some performance indices, i.e. RMSE, variance account for (VAF), and R 2 were selected and computed. Their equations can be seen as follows:

where x i is the measured value, x p is the predicted value, x mean is mean of the measured value, and ‘var’ is the sign for the variance. The n is the number of data sets. Note that, if RMSE is 0, VAF is 100 (%) and R 2 is 1, the predictive model will be excellent in terms of predicting the performance levels. Results of models’ performance indices (only based on R 2) for the developed PPV models are shown in Table 5. Moreover, Fig. 9 illustrates the obtained results of VAF and RMSE for all of the models proposed. According to Table 5 and Fig. 9, the highest values of VAF and R 2 and the lowest values of RMSE are obtained from the ANFIS predictive model. For instance, RMSE equal to 5.283 and 4.644, for training and testing data sets, respectively, reveals that the ANFIS predictive model can perform much better in estimating PPV compared to the two other developed models.

Conclusions

In order to propose new equations for indirect determination of PPV, a total number of 115 blasting events have been identified in Gol-E-Gohar iron mine, Iran. By reviewing previous investigations, the most influential parameters on PPV, i.e. the maximum charge per delay and distance from the blast-face were set as model inputs. Two AI-based models (ANFIS and ANN) and an empirical equation were applied and proposed in this study in order to estimate PPVs produced by blasting. In order to have a fair comparison, all analysis has been conducted on a set of training and testing data set. To evaluate the authenticity and accuracy of the developed models, three performance indices namely RMSE, VAF, and R 2 were applied and computed. As a result, ANFIS predictive model provides a more accurate prediction capacity in comparison with the ANN and empirical models. R 2 equal to 0.952 for testing data sets recommends the superiority of the ANFIS predictive model in estimation of PPV, while for ANN and empirical models, these values are obtained as 0.888 and 0.749, respectively. It can be concluded that ANFIS, by incorporating the advantages of both ANN and FIS models in a hybrid system, can predict PPV values with a higher degree of accuracy.

References

Armaghani DJ, Mohamad ET, Hajihassani M, Yagiz S, Motaghedi H (2015a) Application of several non-linear prediction tools for estimating uniaxial compressive strength of granitic rocks and comparison of their performances. Eng Comput. doi:10.1007/s00366-015-0410-5

Armaghani DJ, Hajihassani M, Sohaei H, Mohamad ET, Marto A, Motaghedi H, Moghaddam MR (2015b) Neuro-fuzzy technique to predict air-overpressure induced by blasting. Arab J Geosci. doi:10.1007/s12517-015-1984-3

Ataei M, Kamali M (2012) Prediction of blast-induced vibration by adaptive neuro-fuzzy inference system in Karoun 3 power plant and dam. J Vib Control. doi:10.1177/1077546312444769

Bureau of Indian Standard (1973) Criteria for safety and design of structures subjected to underground blast. ISI Bull IS-6922

Demuth H, Beale M (2000) Neural network toolbox user’s guide version 4. The Math Works, USA

Demuth H, Beale M, Hagan M (2009) MATLAB version 7.14.0.739; neural network toolbox for use with Matlab. The Mathworks

Dreyfus G (2005) Neural networks: methodology and application. Springer, Berlin

Duvall WI, Petkof B (1959) Spherical propagation of explosion-generated strain pulses in rock. U.S. Dept. of the Interior, Bureau of Mines, Washington

Ebrahimi E, Monjezi M, Khalesi MR, Armaghani DJ (2015) Prediction and optimization of back-break and rock fragmentation using an artificial neural network and a bee colony algorithm. Bull Eng Geol Environ. doi:10.1007/s10064-015-0720-2

Faradonbeh RS, Armaghani DJ, Majid MA, Tahir MM, Murlidhar BR, Monjezi M, Wong HM (2016) Prediction of ground vibration due to quarry blasting based on gene expression programming: a new model for peak particle velocity prediction. Int J Environ Sci Technol. doi:10.1007/s13762-016-0979-2

Fisne A, Kuzu C, Hüdaverdi T (2011) Prediction of environmental impacts of quarry blasting operation using fuzzy logic. Environ Monit Assess 174:461–470

Ghasemi E, Sari M, Ataei M (2012) Development of an empirical model for predicting the effects of controllable blasting parameters on flyrock distance in surface mines. Int J Rock Mech Min Sci 52:163–170

Ghasemi E, Ataei M, Hashemolhosseini H (2013) Development of a fuzzy model for predicting ground vibration caused by rock blasting in surface mining. J Vib Control 19(5):755–770

Ghasemi E, Amini H, Ataei M, Khalokakaei R (2014) Application of artificial intelligence techniques for predicting the flyrock distance caused by blasting operation. Arab J Geosci 7(1):193–202

Gokceoglu C, Yesilnacar E, Sonmez H, Kayabasi A (2004) A neuro-fuzzy model for modulus of deformation of jointed rock masses. Comput Geotech 31:375–383

Grima MA, Bruines PA, Verhoef PNW (2000) Modeling tunnel boring machine performance by neuro-fuzzy methods. Tunn Undergr Sp Technol 15(3):259–269

Hasanipanah M, Monjezi M, Shahnazar A, Armaghani DJ, Farazmand A (2015) Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 75:289–297

Haykin S (1999) Neural networks, 2nd edn. Prentice-Hall, Englewood Cliffs

Hecht-Nielsen R (1987) Kolmogorov’s mapping neural network existence theorem. In: Proceedings of the first IEEE international conference on neural networks, San Diego, CA, USA, pp 11–14

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2:359–366

Hudaverdi T (2012) Application of multivariate analysis for prediction of blast-induced ground vibrations. Soil Dyn Earthq Eng 43:300–308

Inc SPSS (2007) SPSS for windows (version 160). SPSS Inc, Chicago

Iphar M, Yavuz M, Ak H (2008) Prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neurofuzzy inference system. Environ Geol 56:97–107

Jang RJS (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23:665–685

Jin Y, Jiang J (1999) Techniques in neural-network based fuzzy system identification and their application to control of complex systems. In: Leondes CT (ed) Fuzzy theory systems, techniques and applications, vol 1, chap 5. Academic Press, San Diego, CA, pp 112–128

Kaastra I, Boyd M (1996) Designing a neural network for forecasting financial and economic time series. Neurocomputing 10:215–236

Kahriman A (2002) Analysis of ground vibrations caused by bench blasting at can open-pit lignite mine in Turkey. Environ Earth Sci 41:653–661

Kanellopoulas I, Wilkinson GG (1997) Strategies and best practice for neural network image classification. Int J Remote Sens 18:711–725

Khamesi H, Torabi S, Mirzaei-Nasirabad H, Ghadiri Z (2015) Improving the performance of intelligent back analysis for tunneling using optimized fuzzy systems: case study of the Karaj Subway Line 2 in Iran. J Comput Civ Eng 29(6):05014010

Khandelwal M, Kankar PK (2011) Prediction of blast-induced air overpressure using support vector machine. Arab J Geosci 4:427–433

Khandelwal M, Singh TN (2006) Prediction of blast induced ground vibrations and frequency in opencast mine: a neural network approach. J Sound Vib 289:711–725

Khandelwal M, Singh TN (2007) Evaluation of blasting induced ground vibration predictors. Soil Dyn Earthq Eng 27:116–125

Khandelwal M, Singh TN (2009) Prediction of blast-induced ground vibration using artificial neural network. Int J Rock Mech Min Sci 46:1214–1222

Khandelwal M, Kumar DL, Yellishetty M (2011) Application of soft computing to predict blast-induced ground vibration. Eng Comput 27(2):117–125

Laman M, Uncuoglu E (2009) Prediction of the moment capacity of short pier foundations in clay using the neural networks. Kuwait J Sci Eng 36:1–20

Looney CG (1996) Advances in feed-forward neural networks: demystifying knowledge acquiring black boxes. IEEE Trans Knowl Data Eng 8(2):211–226

Masters T (1994) Practical neural network recipes in C++. Academic Press, Boston

Mohamad ET, Noorani SA, Armaghani DJ, Saad R (2012) Simulation of blasting induced ground vibration by using artificial neural network. Electron J Geotech Eng 17:2571–2584

Mohamed MT (2011) Performance of fuzzy logic and artificial neural network in prediction of ground and air vibrations. Int J Rock Mech Min Sci 48(5):845–851

Monjezi M, Ghafurikalajahi M, Bahrami A (2011) Prediction of blastinduced ground vibration using artificial neural networks. Tunn Undergr Sp Technol 26:46–50

Nelson M, Illingworth WT (1990) A practical guide to neural nets. Addison-Wesley, Reading

Ozer U, Kahriman A, Aksoy M, Adiguzel D, Karadogan A (2008) The analysis of ground vibrations induced by bench blasting at Akyol quarry and practical blasting charts. Environ Geol 54:737–743

Paola JD (1994) Neural network classification of multispectral imagery. M.Sc. thesis, The University of Arizona, USA

Raina AK, Murthy VMSR, Soni AK (2014) Flyrock in bench blasting: a comprehensive review. Bull Eng Geol Environ. doi:10.1007/s10064-014-0588-6

Ripley BD (1993) Statistical aspects of neural networks. In: Barndoff-Neilsen OE, Jensen JL, Kendall WS (eds) Networks and chaos-statistical and probabilistic aspects. Chapman & Hall, London, pp 40–123

Sari M, Ghasemi E, Ataei M (2014) Stochastic modeling approach for the evaluation of backbreak due to blasting operations in open pit mines. Rock Mech Rock Eng 47(2):771–783

Sezer EA, Nefeslioglu HA, Gokceoglu C (2014) An assessment on producing synthetic samples by fuzzy C-means for limited number of data in prediction models. Appl Soft Comput 24:126–134

Shahin MA, Maier HR, Jaksa MB (2002) Predicting settlement of shallow foundations using neural networks. J Geotech Geoenviron Eng 128:785–793

Singh TN, Singh V (2005) An intelligent approach to prediction and control ground vibration in mines. Geotech Geol Eng 23:249–262

Singh R, Kainthola A, Singh TN (2012) Estimation of elastic constant of rocks using an ANFIS approach. Appl Soft Comput 12(1):40–45

Sonmez H, Gokceoglu C, Nefeslioglu HA, Kayabasi A (2006) Estimation of rock modulus: for intact rocks with an artificial neural network and for rock masses with a new empirical equation. Int J Rock Mech Min Sci 43:224–235

Swingler K (1996) Applying neural networks: a practical guide. Academic Press, New York

Verma AK, Singh TN (2011) Intelligent systems for ground vibration measurement: a comparative study. Eng Comput 27:225–233

Wang C (1994) A theory of generalization in learning machines with neural application. Ph.D. thesis, The University of Pennsylvania, USA

Yilmaz I, Yuksek G (2009) Prediction of the strength and elasticity modulus of gypsum using multiple regression, ANN, and ANFIS models. Int J Rock Mech Min Sci 46(4):803–810

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghoraba, S., Monjezi, M., Talebi, N. et al. Estimation of ground vibration produced by blasting operations through intelligent and empirical models. Environ Earth Sci 75, 1137 (2016). https://doi.org/10.1007/s12665-016-5961-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-5961-2