Abstract

In this paper, four crops residues such as eggplant, cassava, okra and mulberry plants were assessed as papermaking raw materials. These crops residues had lower α-cellulose and holocellulose and moderate lignin content with syringyl:guaiacyl range of 1.05–1.63. The fiber length of eggplant, cassava, and mulberry plants were shorter (0.58–0.65 mm), while the same for okra plant was medium (1.14 mm). The Runkle ratios of these plant fibers were low (0.208–0.678), and flexibility coefficient was low to medium (55–79). All these non-wood plants were difficult to cook except eggplant plant. Eggplant plant produced screened pulp yield of 33.21 with kappa number of 22.9 at the conditions 3 h cooking at 170 °C with 20 alkali charge. Cassava plant showed the lowest screened pulp yield of 17.7% with kappa number 30.3 at the conditions 2 h cooking at 170 °C with 20 alkali charge. The okra plant pulp showed the best papermaking properties among these crops residues. Eggplant and okra plants can be used for brown packaging grade pulp.

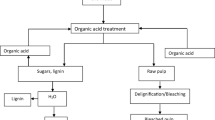

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

For the first time, chemical and morphological characteristics and pulpability of eggplant and cassava plants have been evaluated. Although a partial chemical analysis of okra and mulberry plants was done, but no reports available on alkaline nitrobenzene oxidation and fiber quality analysis. A complete chemical and morphological characteristics and pulping and papermaking potential of eggplant, cassava, okra and mulberry plants have been evaluated for the first time.

Introduction

GDP growth in Bangladesh has been above 7% for the last few years. Consequently, people’s living standard, as well as the demand for consumer products, has increased which has subsequently led to an increased demand for packaging paper, tissue paper etc. In this context, many paper mills have been set up based on imported pulp and recycled paper. The fluctuation of pulp price in the world market, however, have made many paper mills’ owners to consider constructing pulp mills based on local raw materials or imported wood chips.

Bangladesh is a forest deficient country, but self-sufficient in agriculture sector, which generates a large quantity of agricultural residues. After harvesting crops, most of the agricultural wastes are burned and incorporated into the soil for the following crop [1]. However, burning is becoming socially unacceptable because of its extensive atmospheric pollution [2], including greenhouse gas emissions [3] as well as smoke? (either add its demerits or delete it). Government policy is to increase income from agrarian products and by-products through value addition with minimum or no environmental damage. Therefore, utilization of agricultural waste will directly facilitate farmer’s economy, and consequently improve their livelihood. In this situation, screening of most of the non-wood plant available in Bangladesh for pulping raw material has been carried out. In this paper, four non-wood plants, namely- eggplant, cassava, okra and mulberry have been characterized for pulping.

Among these, the okra plant (Abelmoschus esculentus) had previously been evaluated as a pulping raw material [4, 5]. Chemical analysis of the mulberry plant was also done to evaluate the differences in its chemical composition in relation to plant age [6]. But no reports are available on Eggplant and cassava plant are however, yet to be evaluated as potential pulping raw material. For the first time, chemical and morphological characteristics of eggplant, cassava, okra and mulberry plants are presented in this paper along with the soda-anthraquinone (AQ) pulping of these four non-wood plants.

Materials and Methods

Raw Materials

The eggplant plant, cassava plant, okra plant and mulberry plant were collected from Mymensing region of Bangladesh. These non-wood plants were chopped to 2–3 cm size. Then they were ground in a Wiley mill to about 40–60 mesh size, which were used for chemical analysis.

Anatomical and Morphological Properties

For the measurements of fiber morphological properties, firstly, these samples were macerated in a solution containing 1:1 HNO3 and KClO3. A drop of the macerated sample was taken in a slide and fiber length and diameter were measured in image analyzer Euromex-Oxion using Image Focus Alpha software. For measuring fiber length and fiber width, 200 fibers were measured from the slides and average reading was taken.

For anatomical analysis, the three samples were sectioned with sliding microtome and transversal section slide was prepared and investigated under an image analyzer. SEM image of the cross-section was recorded using a scanning electron microscope (Model EV018, Carl Zeiss AG, Germany), which are shown in Fig. 1.

Chemical Analysis

The extractive (T204 om88), 1% alkali solubility (T 212 om98), water solubility (T207 cm99), Klason lignin (T222 om83), acid soluble lignin (TAPPI UM 250 1991) and ash content (T211 os76) were determined in accordance with Tappi Test Methods. Holocellulose was determined by treating extractive free wood meal with NaClO2 solution. The pH of the solution was maintained at 4 by adding CH3COOH-CH3COONa buffer and α-cellulose was determined by treating holocellulose with 17.5% NaOH.

Alkaline Nitrobenzene Oxidation (ANO)

Extractive free milled wood of bagasse, kash or corn stalk amounting to 10 mg was taken in a bomb and 4 ml of 2 M NaOH and 0.25 ml nitrobenzene were added, and the mixture was kept at 170 °C for 2 h. The detail method of ANO was carried out following method described in elsewhere [7].

Pulping

In order to find out pulpability of eggplant plant, cassava plant, okra plant and mulberry plant, these samples were cooked by soda-AQ process with varying alkali charge. The cooking time was fixed for 3 h at 170 °C for eggplant plant, okra plant and mulberry plant and 2 h at 170 °C for cassava plant. The liquor ratio was maintained at 6. After digestion, pulp was washed till free from residual chemicals, and screened by flat vibratory screener (Yasuda, Japan). The screened pulp yield, total pulp yield and screened reject were determined gravimetrically as percentage of o.d. raw material. The kappa number (T 236 om-99) of the resulting pulp was determined in accordance with Tappi Test Methods. Three replicates of all experiments were done and average reading was taken.

Evaluation of Pulps

Pulps from eggplant plant, cassava plant, okra plant and mulberry plant were beaten in a valley beater to different freeness (°SR) and hand sheets of about 60 g/m2 were made in a Rapid Kothen Sheet Making Machine. The sheets were tested for tensile (T 494 om-96), burst (T 403 om-97) and tear strength (T 414 om-98) according to TAPPI Standard Test Methods. Fiber quality of screened pulp samples were by Fiber Quality Analyzer – 360, OpTest, Canada.

Results and Discussion

Chemical Characteristics

As shown in Table 1, cold water solubility and hot water solubility of eggplant plant was lower than cassava plant and okra plant. The cold-water treatment removes a part of extraneous components like tannins, gums, sugars, inorganic matter and colored compounds present in lignocellulosic biomass whereas hot water treatment removes, in addition, starches. One percent NaOH solubility of cassava plant was very high (40.74%) followed by okra plant (37.98%), while mulberry plant showed the lowest amount of one percent NaOH solubility. The higher one NaOH solubility of cassava plant and okra plant can be explained by the presence of low molar mass of carbohydrates and other alkali soluble materials. A very high water and alkali solubility of cassava plant and okra plant indicated the lower pulp yield. Acetone extractives of mulberry plant were the highest (3.55%) and eggplant plant was the lowest (0.29%). Acetone extractives include waxes, fats, resins etc. Higher acetone extractives content adversely affects the runnability of paper machine.

Holocellulose and α-cellulose contents are the most important factors for pulping raw material. These parameters positively affect the pulp yield in chemical pulping process. The α-cellulose contents of eggplant plant, cassava plant, okra plant and mulberry plant were 35.0, 30.4. 29.6 and 38.8%, respectively. Cellulose content in a raw material also determines physical strength properties of paper [8]. Most of the non-wood hemicellulose contains mainly xylan, which is reflected by pentosan. The pentosan in these four non-wood plants ranged between 14 and 16%. Hemicellulose content affects pulp yield and especially papermaking properties. Sitch and Marshall [9] showed that the presence of hemicellulose reduced average fiber length during beating, thus indicating a correlation between fiber flexibility and hemicellulose content, thus pulps of high strength were prepared.

Lignin is undesirable polymer for paper production and the removal of lignin during pulping requires a high amount of energy and chemicals. Lower lignin content of raw materials makes them suitable for delignification at milder pulping conditions (lower temperatures and chemical charges) to reach a desirable kappa number. The highest total lignin content was in eggplant plant (30.44%) and lowest in okra plant (22.32%). The lignin content in eggplant plant was similar to that of Acacia hybrid [10].

Ash content represents inorganic minerals present in the raw materials. Ash content of these four non-wood plants was lower (0.77–3-15%) than other rice and wheat straws [8].

Alkaline Nitrobenzene Oxidation

Alkaline nitrobenzene oxidation (ANO) is a common technique for characterizing lignin’s constituent through the chemical degradative technique. In the ANO, the three constitutive monomeric lignin, p-hydroxyphenyl, guaiacyl and syringyl unit produce the corresponding p-hydroxybenzaldehyde, vanillin and syringaldehyde. Table 2 shows the yield of alkaline nitrobenzene oxidation products from the eggplant plant, cassava plant, okra plant and mulberry plant. The predominant product was identified to be syringaldehyde (S), which comprised 18.6% for eggplant plant lignin, 18.1% for cassava plant lignin, 17.9% for okra plant lignin and 14.8% for mulberry plant lignin. It was obtained from the degradation of noncondensed syringyl unit. Therefore, mulberry plant lignin contains more condensed structure than other plant lignins. Vanillin (V) appeared as the second major degradation products resulted from the noncondensed guaiacyl unit, which consisted of 11–17%. Okra plant lignin had the highest amount of vanillin, 17.1%. The presence of small quantities (2–9%) of p- hydroxybenzaldehyde from the noncondensed p-hydroxyphenyl unit (H) was found in all these non- plant lignin. Mulberry plant showed the highest amount of H unit, 9.1%. Similar results have been reported in abaca fibre, oil palm fibre Iignins [11, 12].

The molar ratio of S to V was 1.63 for eggplant plant lignin, 1.55 for cassava plant lignin, 1.05 for okra plant lignin and 1.14 for mulberry plant lignin. The results appeared to be in general agreement with the range of S to V ratios obtained from hardwood lignin [13].

Morphological Properties and its Derived Values

The role of morphological characteristics such as fiber length width, wall thickness, lumen diameter and their derived values such as flexibility coefficient, slender ratio and Runkel ratio of eggplant plant, cassava plant, okra plant and mulberry plant are given in Table 3. Fibre length of okra plant longer than that other plants (1.14 mm vs 0.58–0.65 mm). Okra plant consists of long fibre bast fibre and and short fibre stick, this bast fibre contributing to increase average fibre length. The fibre length of eggplant plant, cassava plant, and mulberry plant was shorter as compared to other grasses such as bamboo (1.91 mm), lemon grass (1.09 mm) and sofia grass (0.87 mm) [14, 15]. A higher fibre length contributes higher tearing strength of paper [15]. Fibre diameter eaggplant plant (13.2 μm) and mulberry plant was less than cassava plant (25.5 μm), okra plant (21.0 μm). The fiber wall thickness of these non-wood plant was thin (2.09–2.75 μm). Paper formed by thin-walled fibre would be dense, and well formed [16].

As shown in Table 3, cassava plant showed the lowest slender ratio (25.49). There is a positive correlation between slenderness ratio and folding endurance [17, 18]. Generally, it is considered that if the slenderness ratio for the fibre is less than 70, the pulp would have weak strength [18]. The highest and lowers Runkel ratios were found in eggplant plant (0.678) and cassava plant (0.208), respectively. Runkel ratio of these non-wood plants was very similar to A. auriculiformis fibers grown in Bangladesh (0.24 to 0.41) [20]. Fibers which have Runkel ratio less than 1.0 are considered as thin-walled fibers [21] and fibers having Runkel ratio above 1.0 are considered as thick-walled, stiffer and rigid in nature and form bulky and more opaque paper with lower bonded area [22]. Based on the results, these non-wood plants had comparatively thin walled fibres (Table 3).

The fibre diameter and cell wall thickness controlled the fibre flexibility. The flexibility coefficient of cassava and okra plant fibers was 79% and 77%, respectively, while it was 56% for eggplant plan fiber. Fibers of low flexibility coefficient do not collapse easily thus retain their tabular structure on pressing consequently lesser surface for bonding. Such type of fibers produces paper sheets of higher tear, bulk and opacity. The laboratory handsheets would be bulky, coarse-surfaced and had higher void volume, and between flexibility coefficient and burst [18], breaking length and tear resistance [23]. Fibre flexibility influences the number of interfibre bonds because more flexible fibres have more interfibre contact [24].

Pulping

Therefore, these three non-wood plants were cooked at 170 °C for 3 h and cassava plant were cooked at 170 °C for 2 h with varying alkali charge in soda-AQ process and results are shown in Table 4. As shown in Table 4, screened pulp yield increased and reject decreased with increasing alkali charge. All these four raw materials were difficult to cook even in drastic cooking conditions. At 20% alkali charge, screened rejects were 2.9%, 0.78%, 16.0% and 4.17% for eggplant, cassava plant, okra plant and mulberry plant, respectively, while screened pulp yield at this condition was 33.21%, 17.7%, 21.55% and 27.84%. Cassava plant has the lowest pulp yield due to high starch, tannin, extractive etc. as indicated by hot, cold and one percent alkali solubilities (Table 1). In an earlier study, it was also observed that mulberry plant was difficult to cook [6]. As shown in Fig. 2, the pulp yields from these non-wood plants were much lower than other crops residues [25,26,27]. This lower pulp yield can be explained by lower α-cellulose and holocellulose (Table 1). Mulberry plant had the highest pulp yield among these four non-wood plants due to higher α-cellulose content.

The delignification of these non-wood plants was very difficult. Eggplant plant showed comparatively better delignification as compare to cassava, okra and mulberry plant. The kappa number of eggplant plant pulp was 38.0 at 14% alkali charge, which decreased to 22.9 with the increase of alkali charge to 20% at 170° for 3 h of cooking. At 20% alkali charge for 3 h cooking at 170°, kappa numbers of okra plant and mulberry plants were 47.4 and 40.0, respectively. High delignification can be observed when S/V ratio is higher. Tsutsumi et al. [28] showed that ß-aryl ether of syringyl lignin model was cleaved much faster delignification than that of guaiacyl lignin model by soda and soda/anthraquinone treatment. The S/V eggplant plant was higher than other plants (Table 2). As shown in Fig. 2, kappa number of eggplant pulp was lower at any pulp yield than other plants (by extrapolation).

Fiber Quality of Pulps

Table 5 shows the average arithmetic, length and weighted length, average width, fine percentage curl, kink indexes, degree of fibrillation and coarseness of pulp samples from eggplant plant, cassava plant, okra plant and mulberry plant. Such measurements are essential since they directly impact the properties of the pulps and the quality of the produced papers. All these non-wood plant except eggplant plant contains many fines, generated from nonfibrous parenchymatic cells (Fig. 1). Cassava plant had the highest amount of fines 53.2% followed by mulberry plant, 36.7% and eggplant plant pulp showed the lowest amount of fines. The lowest amount of fines in eggplant plant pulp can be explained by wood like anatomical structure (sclerenchyma). The high fines content may correspond to the fibers that are more flexible. The length–weight fiber length of okra plant pulp was the longest. Okra plant consists of bast fiber and stick and the fiber length of bast fibre was more than 3 mm, which contributed to average longer fibre length [4]. Paper formation has a large effect on fines and fiber length. Reducing fibre length has a little direct impact on the sheet structural and optical properties but does reduce papermaking properties.[29]. The coarseness of these non-wood plants fibre had a lot of variation (3.4–14.3 mg/100 m). This parameter is related to the fiber wall thickness and influences the fiber collapse degree and development of bulk [30]. Curl and kinks index of okra plant pulp were higher. Curl and kinks are fiber deformations that contribute to a more developed network, generating less inter-fiber bonds and leading to a potential develop bulk, porosity, and smoothness in the final product.

Papermaking Properties

The papermaking properties were significantly improved by the refining operation. It is interesting to note that the unbleached okra plant pulp exhibited excellent properties in terms of tensile, bursting and tearing strengths. This can be explained by longer fiber length of okra plant pulp (Table 5).

Figures 3, 4 and 5 report the papermaking properties of the handsheets obtained from these four non-wood plants. From these data, it appears that the tensile and burst index of produced papers increased with increasing beating degree, while tear index decreased. Okra plant pulp exhibited the highest tensile index at any SR followed by mulberry plant pulp. At 41° SR, the tensile index of okra plant pulp was 68.7 N.m/g and tear index was 7.06 mN.m2/g.

Conclusion

Cassava and okra plants were characterized with lower α-cellulose and moderate lignin content, while eggplant and mulberry plants were characterized with moderate α-cellulose and higher lignin contents. Morphologically, these non-wood plants fibers have thinner cell wall and shorter fiber length except okra plant fiber, which can be considered as medium. Cooking of these non-wood plants was difficult to bleachable grade level. As compare to other non-wood plants, eggplant plant showed better pulp yield of 33.2% at kappa number 22.9 (at the conditions of 22% alkali charge, 3 h cooking at 170 °C). Okra plant pulp showed the best papermaking properties among these non-wood plants. Finally, it can be concluded that eggplant and okra plants can be used for board grade brown pulp.

References

Hanafi, E.M., El Khadrawy, H.H., Ahmed, W.M., et al.: Some observations on rice straw with emphasis on updates of its management. World Applied Sciences Journal 16, 354–361 (2012)

Kadam, L.K., Forrest, L.H., Jacobson, W.A.: Rice straw as a lignocellulosic resource: collection, processing, transportation and environmental aspects. Biomass Bioenerg. 18, 369–389 (2005)

Arai, H., Hosen, Y., Pham Hong, V.N., Thi, N.T., Huu, C.N., Inubushi, K.: Greenhouse gas emissions from rice straw burning and straw mushroom cultivation in a triple rice cropping system in the Mekong Delta. Soil Science and Plant Nutrition 61, 719–735 (2015)

Jahan, M.S., Rahman, M.M.: Characterization and evaluation of okra fibre (abelmoschus esculentus) as a pulping raw material. J-For, J Sci Technol Forest Prod Process 2(5), 1–17 (2012)

Omer, S.H., Khider, T.O., Elzaki, O.T., Mohieldin, S.D., Shomeina, S.K.: Application of soda-AQ pulping to agricultural waste (Okra Stalks) from Sudan. BMC Chemical Engineering 1(1), 6 (2019). https://doi.org/10.1186/s42480-019-0005-9

Rahman, M.M., Jahan, M.S.: Evaluation of mulberry plant as a pulping raw material. Biomass Conversion and Biorefinery 4(1), 53–58 (2014)

Chen, C. L.; Nitrobenzene and cupric oxide oxidations. In: Methods in lignin chemistry. Springer, Berlin, Heidelberg (1992). 301–321

Ferdous, T., Quaiyyum, M.A., Bashar, S., Jahan, M.S.: Anatomical, morphological and chemical characteristics of kaun straw (Seetaria-ltalika). Nord. Pulp Pap. Res. J. (2020). https://doi.org/10.1515/npprj-2019-0057

Sitch, D.A., Marshall, H.B.: The effect of hemicelluloses on the papermaking properties of white birch. Canadian Journal of Research 28(10), 376–389 (1950)

Haque, M.M., Aziz, M.I., Hossain, M.S., Quaiyyum, M.A., Alam, M.Z., Jahan, M.S.: Pulping of hybrid acacia planted in a social forestry program in Bangladesh. Cellul. Chem. Technol. 53(7–8), 739–745 (2019)

Sun, R., Mott, L., Bolton, J.: Isolation and fractional characterization of ball-milled and enzyme lignins from oil palm trunk. Journal of agricultural and food chemistry 46(2), 718–723 (1998)

Sun, R.C., Fang, J.M., Goodwin, A., Lawther, J.M., Bolton, A.J.: Physico-chemical and structural characterization of alkali lignins from abaca fibre. J. Wood Chem. Technol. 18(3), 313–331 (1998)

Creighton, R.H.J., Gibbs, R.B., Hibbert, H.: Studies on lignin and related compounds LXXV: Alkaline nitrobenzene oxidation of plant materials and application to Taxonomic Classification. J. Amer. Chem. Soc. 66, 32–37 (1944)

Sharma, A.K., Dutt, D., Upadhyaya, J.S., Roy, T.K.: Anatomical, morphological, and chemical characterization of Bambusa tulda, Dendrocalamus hamiltonii, Bambusa balcooa, Malocana baccifera. Bambusa arundinacea and Eucalyptus tereticornis. Bioresources 6(4), 5062–5073 (2011)

Kaur, H., Dutt, D.: Anatomical, morphological and chemical characterization of lignocellulosic by-products of lemon and sofia grasses obtained after recuperation of essential oils by steam distillation. Cellul. Chem. Technol. 47(1–2), 83–94 (2013)

Horn, R. A.;. Morphology of Pulp Fiber from Hardwoods and Influence on Paper Strength (No. FSRP-FPL-312). Forest Products Lab Madison Wis. (1978)

Dinwoodie, Jm: The relationship between fibre morphology and paper properties: a review of literature. Tappi J. 48, 440–447 (1965)

Ona, T., Sonoda, T., Ito, K., Shibata, M., Tama, Y., Kojim, Y., Ohshima, J., Yokota, S., Yoshizawa, N.: Investigation of relationship between cell and pulp properties in Eucalyptus by examination of within-tree property variations. Wood Sci. Technol. 35, 363–375 (2001)

Ververis, C., Georghiou, K., Christodoulakis, N., Santas, P., Santas, R.: Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 19, 245–254 (2004)

Jahan, M.S., Haque, M.M., Quaiyyum, M.A., Nayeem, J., Bashar, M.S.: Radial variation of anatomical, morphological and chemical characteristics of Acacia auriculiformis in evaluating pulping raw material. Journal of the Indian Academy of Wood Science 16(2), 118–124 (2019)

Granholm, K., Harju, L., Ivaska, A.: Desorption of metal ions from kraft pulps, part 1, chelation of hard wood and softwood kraft pulp with EDTA. BioResources 5, 206–226 (2010)

Colodette, J.L.; Highlights of the 5th colloquium on eucalyptus pulp proceeding peers conference, Portland-OR,

Mabilanganm, L., Estudillo, C.: Philippines woods suitable for kraft pulping process. Trade Bulletin Series 5, 1–9 (1996)

Amidon, T.E., Te, A.: Effect of the wood properties of hardwoods on kraft paper properties. Tappi J. 64, 123–126 (1981)

Khiari, R., Mhenni, M.F., Belgacem, M.N., Mauret, E.: Chemical composition and pulping of date palm rachis and Posidonia oceanica–A comparison with other wood and non-wood fibre sources. Biores. Technol. 101(2), 775–780 (2010)

Jahan, M.S., Kanna, G.H., Mun, S.P., Chowdhury, D.N.: Variations in chemical characteristics and pulpability within jute plant (Chorcorus capsularis). Ind. Crops Prod. 28(2), 199–205 (2008)

Jahan, M.S., Chowdhury, D.N., Islam, M.K.: Pulping of dhaincha (Sesbania aculeata). Cellul. Chem. Technol. 41(7), 413 (2007)

Tsutsumi, Y., Kondo, R., Sakai, K., Imamura, H.: The difference of reactivity between syringyl lignin and guaiacyl lignin in alkaline systems. Holzforschung 49, 423–428 (1995)

Seth, R. S.; Fibre Quality Factors in Papermaking—I The Importance of Fibre Length and Strength. MRS Online Proceedings Library Archive, 197.) (1990).

Levlin, J.-E.; Söderhjelm L.; (Eds.), Pulp and Paper Testing, first edition, Helsinki, (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferdous, T., Quaiyyum, M.A. & Jahan, M.S. Characterization and Pulping of Crops Residue: Eggplant, Cassava, Okra and Mulberry Plants. Waste Biomass Valor 12, 3161–3168 (2021). https://doi.org/10.1007/s12649-020-01236-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01236-6