Abstract

Purpose

The feather is a valuable protein resource. The feather is the major waste by-product resulting from the poultry processing plants. Therefore, increasing the values of poultry feather waste has a significant effect in the environment.

Methods

In this study, the physicochemical and functional properties as well as the antioxidant activities of the feather protein hydrolysates (FPHs) obtained by acid hydrolysis after 100 min (FPH100), 200 min (FPH200) and 300 min (FPH300) were investigated.

Results

The results showed that FPH100, FPH200 and FPH300 presented high protein content 74.04%, 71.05% and 73.94%, respectively. All FPHs had a good solubility and possessed some interfacial properties, governed by their concentrations. The antioxidant activities of the different FPHs were evaluated using various in vitro antioxidant assays such as 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical-scavenging activity, total antioxidant capacity, reducing power and β-carotene bleaching. FPH100 generally showed a greater antioxidant activity across all the considered methods. The DPPH IC50 of FPH100 values were found to be 0.47 ± 0.011 mg/mL. Moreover, the FPH100 exhibited notable total antioxidant capacity and strong reducing power.

Conclusions

Our results suggested that FPHs could be a new potential source for preparing natural antioxidants applied in food, pharmaceutical and cosmetic preparations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

The method of feathers hydrolysis used in this work was cheaper than enzymatic hydrolysis to be applied to the industrial scale and increase the industrial waste value. The functional properties, the total antioxidant activity and the antioxidant assay using the β-carotene bleaching of feather protein hydrolysates have also been studied for the first time.

Introduction

The feather is the most important waste by-product resulting from poultry processing plants, reaching billions of tons annually worldwide. Specifically, the Tunisian contribution is about 20,000 tons. This by-product presents 10% of the total weight of poultry [1]. The feather is a rich protein source because it is the most abundant keratinous in nature, representing 80–90% of the total composition of the feather [2]. Keratin has a high stable mechanical structure attributed to the high degree of cross-linking by disulfide bonds, hydrogen bonds and hydrophobic interactions [3, 4].

Therefore, increasing the values of poultry feather waste has had a significant effect on the environment and attracted much interest for research in the last few years. Studies have been carried out to produce feather protein hydrolysate by different treatments such as enzymatic hydrolysis [5,6,7], chemical-enzymatic treatment [8] and thermo-chemical treatment [9].

Many artificially synthesized antioxidants, such as butylated hydroxyanisole (BHA), butylated hydroxytoluene (BHT) and tertbutylhydroquinone (TBHQ), characterized by a strong antioxidant activity, have been used as food additives to prevent its deterioration and protect it against serious diseases caused by oxidation or free radical reactions. However, the use of these chemical substances has been increasingly limited over time due to toxic and carcinogenic effects on animals and humans health, causing its restriction in many countries [10].

This has enhanced an increasing interest in natural antioxidants which can be applied safely. Several hydrolysed proteins from animal protein as well as many plants have been found to have an antioxidant activity [11,12,13,14]. Besides, the feather hydrolysate has also proven to be good antioxidant sources [5, 6, 15, 16]. In addition to its antioxidative activity, other bioactivities, such as inhibitory activities toward angiotensin I-converting enzyme and dipeptidyl peptidase-IV, have been demonstrated in feather protein hydrolysate [6].

In the present study, the functional properties and the antioxidant activities of feather protein hydrolysis by thermo-chemical treatment were investigated.

Materials and Methods

Reagents

Butylated hydroxyanisole (BHA), 2,2-diphenyl-1-picrylhydrazyl (DPPH) and β-carotene were purchased from Sigma Chemical Co. (St. Louis, MO, USA). All the other reagents and chemicals used (potassium ferricyanide, trichloroacetic (TCA), ferric chloride (FeCl3), sodium hydroxide and other solvents) were of an analytical grade. All the solutions were freshly prepared in distilled water.

Materials

Poultry feathers were obtained fresh from a poultry processing plant located in Sfax, Tunisia. Feathers were washed thoroughly with distilled water, treated in boiling water for 20 min, dried at 90 °C for 5 h and finally stored at room temperature until use.

Preparation of Feather Protein Hydrolysate

Protein hydrolysate from feathers was prepared by the method reported in our previous study [17], with a slight modification. The poultry feather (25 g) was suspended in 500 mL of 0.5 N sulphuric acid solution in jacketed glass reactor at a temperature up to 90 °C and 500 rpm stirring rate for three different times (100, 200 and 300 min). The hydrolysis reaction was stopped by adjusting pH to 7.0 with 4 N NaOH. The obtained mixture was centrifuged at 5000g for 30 min and filtered under vacuum. Being dialyzed against distilled water for 3 days to remove inorganic salts, protein hydrolysate was prepared by drying at 40 °C, and then stored at − 20 °C for further use.

Determination of Peptide Concentration

The peptide concentrations (mg/mL) were determined using Biuret’s method [18]. Standards of 1–5 mg/mL bovine serum albumin (BSA) were essayed to calculate the sample peptide concentrations.

Physicochemical Properties

Proximate Composition

The moisture and ash content were analysed according to the AOAC [19] standard methods 950.46 and 920.153, respectively. The samples total nitrogen content was determined using the Kjeldahl method. Crude protein was measured by multiplying the total nitrogen content with 6.25 factor. Fat was determined by samples extraction with hexane using the soxhlet extraction method. All measurements were performed in triplicate.

Water Activity Determination

The water activity (aw) was measured with the apparatus aw Rotronic Hygropalm (HP23-AW-A, Bassersdorf). The measurements were carried in a plastic capsule with samples and the aw values were obtained after stability at 25 °C.

Color Test

The color parameters measurement was conducted using a handheld colorimeter (model chroma meter CR-410, Konica Minolta, Inc, Japan). The color parameters L*, a* and b* showed lightness (100 = white, 0 = black), redness (positive = redness, negative = greenness) and yellowness (positive = yellowness, negative = blueness), respectively. A standard white plate with reflectance values of L* = 93.68, a* = − 0.69, b* = − 0.88, was used as reference. The color analyses results were average of three measurements of the samples taken at different points at ambient temperature.

Determination of Mineral Analysis

Analyses of calcium (Ca), magnesium (Mg), sodium (Na) and potassium (K) mineral contents in raw feather and FPHs were carried out using the inductively coupled plasma optical emission spectrophotometer (Thermo scientific, ICE 3000 series, AA spectrometer, made in UK) according to the method [20]. The phosphorus content (P) was determined by the phosphomolybdate method [21].

Functional Properties

Solubility

The solubility was determined according to the previous method [22] with a slight modification. Briefly, 10 mg of FPHs was dissolved in 8 mL of distilled water and the pH of the mixture was adjusted to 2, 4, 6, 8, 10 and 12 with either 1 N HCl or 1N NaOH. The volume of solutions was made up to 10 mL by distilled water. The mixture was stirred at 5000g for 30 min at room temperature (25 °C). Peptides content in the supernatant was determined using Biuret’s method [18]. The peptides solubility was calculated as follows:

Surface Tension Measurement

The FPHs surface tension was measured using a tensiometer (Gibertini, TSD Digital tensiometer, Italy). 20 mL of FPHs at different concentrations (0.2%, 0.3%, 0.4% and 0.5%) were poured into 50 mL glass beaker placed into the tensiometer platform. A platinum wire ring was submerged into the solution and then slowly pulled through the liquid/air interface, to measure the surface tension (mN m−1).

Water-Holding and Fat-Binding Capacities

The water-holding capacity was measured by the previous method [23] with a slight modification. 1 g of FPHs was placed in a 10-mL distilled water tube then held at room temperature for 60 min and the solution was mixed every 5 min. The FPHs mixture was centrifuged at 5000g for 15 min. The upper layer was eliminated and the centrifuge tube was drained for 30 min a 50 °C on a filter paper after tilting to a 45° angle.

The fat-binding capacity was measured by the previous method [23]. 0.5 g of FPHs was mixed with 10-mL soybean oil. The solution was mixed then held at room temperature for 60 min and mixed every 5 min. The FPHs mixture was centrifuged at 5000g for 30 min. The upper layer was removed and the centrifuge tube was drained on a filter paper.

The water holding and fat binding capacities were expressed as grams of water or oil bound per 100 g of FPHs on a dry basis.

Emulsifying Properties

The FPHs emulsion activity index (EAI) and the emulsion stability index (ESI) were investigated according to the method of Pearce and Kinsella [24] with some modifications. 10 mL of FPHs solution at different concentrations (0.5%, 1%, 2% and 3%; w/v) were homogenised with 3.4 mL of soy bean oil for 1 min at 25 °C using Ultra-Turax T 25 Basic (IKA Werke GmbH & Co., Staufen, Germany). 50 µL of the emulsion was pipetted from the bottom of the container and dispersed into 4950 µL 0.1% SDS solution at 0 and 10 min after homogenisation. The absorbance of the solution was measured at 500 nm against 0.1% blank solution SDS using a spectrophotometer (optizen POP, UV/VIS spectrophotometer, Mecasys CO., Ltd., Korea). The absorbance values of the different solutions were measured immediately (A0) and 10 min after emulsion formation (A10), they were used to determine the EAI and ESI:

where \(\Delta A\) is (A0− A10) and t = 10 min.

Foaming Properties

The foaming expansion (FE) and the foaming stability (FS) were evaluated as previously described [25] with a slight modification. Four concentrations were tested: 0.5%, 1%, 2% and 3%. Ten mL of FPHs solutions for each concentration was transferred into 50 mL graduated cylinder. To incorporate the air in the solutions, they were homogenised for 1 min using an Ultra-Turax T 25 Basic (IKA Werke GmbH & Co., Staufen, Germany). Foaming expansion was determined by means of the descent in foam volume at t = 0 min, calculated as follows:

where VT is the total volume after homogenisation at 0 min and V0 is the initial volume before homogenisation.

The stability of the formed foam was measured as the volume of foam remaining after 30 min.

where Vt is the total volume after 30 min held at room temperature.

Antioxidant Activity

DPPH Radical Scavenging Assay

DPPH radical scavenging activity of the samples was investigated according to the previous method [26]. 500 µL of each sample at different concentrations (0.2, 0.5, 1, 2, 3, 4 and 5 mg/mL) was mixed with 375 µL of absolute ethanol and 125 µL DPPH solution (0.02% dissolved in absolute ethanol). A control was prepared by mixing all reagents except for the distilled water which was used instead of the sample. For each concentration, a blank solution containing 500 µL of samples and 500 µL of absolute ethanol was also prepared. The mixture was shaken vigorously with vortex and then kept in the dark for 60 min at room temperature. The BHA was used as a positive control. The absorbance of the reaction mixture was recorded at 517 nm. Higher free scavenging activity was indicated by lower absorbance of the reaction mixture. The DPPH radical scavenging activity was calculated using the following equation:

where Ab is the absorbance of blank sample, Ac is the control absorbance and As is the absorbance of the sample.

Total Antioxidant Capacity

This antioxidant assay is based on the reduction of Mo (VI) to Mo (V) by the sample and the subsequent formation of a green phosphate/Mo (V) complex at acidic pH. The assay was determined according to the previous method [27]. 100 µL of samples at different concentrations were mixed with 1 mL of reagent solution (0.6 M sulphuric acid, 28 mM sodium phosphate and 4 mM ammonium molybdate). The mixture was incubated at 90 °C for 90 min and then cooled to room temperature before the measurement of the absorbance at 695 nm against the control. The control solution contained 100 µL of distilled water and 1 mL of reagent solution. The BHA was used as a positive standard. The total antioxidant activity was expressed in α-tocopherol using the following equation:

where A is the absorbance at 695 nm and C is the concentration of α-tocopherol (µmol/L).

Reducing Power Capacity

The FPHs reducing power was measured by the previous method [28]. An aliquot of 500 µL of the sample at different concentrations (0.5–5 mg/mL) was mixed with 1.25 mL of sodium phosphate buffer (0.2 M, pH6.6) and 1.25 mL of 1% (w/v) potassium ferricyanide solution. After the mixture incubation at 50 °C for 30 min, 1.25 mL of 10% (w/v) trichloroacetic acid was added and the mixture was centrifuged at 3000g for 10 min. A aliquot (1.25 mL) of the supernatant from each sample mixture was mixed with 1.25 mL of distilled water and 0.25 mL of 0.1% ferric chloride solution. The absorbance was measured at 700 nm after incubation for 10 min at room temperature. The BHA was used as a reference. The control was prepared in the same way, except for the distilled water which was used instead the sample. A higher reducing power was indicated by a higher absorbance of the mixture.

Determination of the Antioxidant Activity by β-Carotene-Linoleic Acid Assay

The FPHs capacity to prevent the bleaching of β-carotene was determined as previously described [29]. An emulsion of β-carotene-linoleic acid was prepared freshly before each experiment. In brief, 0.5 mg of β-carotene in 1 mL chloroform was mixed with 25 µL of linoleic acid and 200 µL of Tween 40 and the chloroform was evaporated under vacuum at 40 °C using a rotary evaporator. Then 100 mL of distilled water was added and the mixture was vigorously stirred. An aliquot of 2.5 mL of the β-carotene-linoleic acid emulsion was added to test tubes containing 0.1 mL of the sample at different concentrations (2–10 mg/mL) and the mixtures incubated at 50 °C for 2 h. A control consisting of distilled water instead of the sample and the absorbance was measured at 470 nm against a blank containing β-carotene-linoleic acid emulsion without β-carotene reagent. The BHA was used as a positive standard. The relative antioxidant activity was calculated as follows:

where A0 and At are the absorbance of the sample at t = 0 and t = 2 h, respectively. A00 and At0 are the absorbance of the control at t = 0 and t = 2 h, respectively.

Hemolytic Activity

The FPHs hemolytic activity was determined by the Dathe’s method [30] with some modifications. In brief, 5 mL of bovine blood were centrifuged at 3500g for 10 min to isolate erythrocytes. They were, then, washed three times with 10 mM sodium phosphate, pH 7.5, containing NaCl 9 g/L (NaCl/Pi). The cell concentration of stock suspension was adjusted to 109 cells/mL. The cell suspension (12 µL), along with various amounts of stock solution fractions and buffer, were pipetted into Eppendorf tubes to give a final volume of 50 µL. The Eppendorf tubes with 2.5 × 108 cells/mL were then incubated at 37 °C for 40 min. After centrifugation at 5000g for 5 min, 30 µL of supernatant was diluted in 500 µL water. The absorbance of the diluted solution was measured at 420 nm. The obtained absorbance after treating erythrocytes with only NaCl/Pi and SDS (0.2%) was taken as 0% and 100%, respectively.

Statistical Analysis

All the experiments were performed in triplicate. The data were presented as mean ± SD. All the statistical analyses were performed using the Statistical Package for the Social Sciences (SPSS) version 20. The comparison of means was evaluated using the analysis of variance (ANOVA) followed by a Tukey post hoc test. The differences were considered significant at p < 0.05.

Results and Discussion

Feather Protein Hydrolysates Production

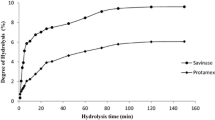

The proteolysis process different methods, like the chemical treatment, enzymatic hydrolysis and microbial fermentation, may generate some peptides with a stronger bioactivity compared to the initial materials. In this work, the chemical treatment showed stronger abilities to hydrolyse the feather protein, which proceeded at a rapid rate during the initial phase and then slowed down until reaching a stationary phase. The FPHs peptide concentrations were measured across time and the maximum soluble peptides production was 34 mg/mL, achieved after 300 min (Fig. 1). This chemical treatment produced higher peptide concentrations in a shorter period than that obtained by the feathers enzymatic hydrolysis [5] that did not exceed 13 mg/mL after 48 h.

FPHs Physicochemical Composition

The FPHs physicochemical composition was determined and compared to that of the raw feather as shown in Table 1. The production yield of protein from the feather after 100 min (11.81%) was significantly (p < 0.05) lower than that obtained after 200 and 300 min (> 32%). The FPHs protein content at different hydrolysis times 100, 200 and 300 min was high (> 70%) resulting from the solubilisation of the protein during hydrolysis. The high protein content and yield of protein production may provide an incentive for its commercial use as a source of protein. The FPHs showed a lower fat content (1.1%), moisture (> 7%) and aw value (0.3) which may contribute to the microbiological stability of the product and prevent it against lipid oxidation [31]. The FPHs had a (p < 0.05) higher ash content than that of a raw feather. The ash contents were 12.10%, 12.43% and 12.04% in FPH100, FPH200 and FPH300, respectively. These results are close to those found in feather protein hydrolysate prepared by enzymatic hydrolysis (10.68%) [5].

The raw feathers and FPHs consisted of different minerals at different levels as shown in Table 1. Na, Ca, and K were found at high concentrations, while P and Mg were found at a low level. The Na level in the FPHs samples (> 3.4 g/100 g) was higher than in raw feathers (0.2 g/100 g) with a significant difference (p < 0.05). The increase in the sodium ion may be due to the NaOH added during the neutralisation to adjust the pH to 7.0. The apparent metal ions could act as pro-oxidants in the hydrolysate. Jemil et al. [32] reported that Na and K were abundant in fish meat and fish meat hydrolysates.

Color is one of the esthetic properties that determine the suitability of FPHs to their intended application. Compared to the FPHs, the raw feather was the lightest (L* = 91.87), less red (a* = 0.045) and similar yellowness (b* = 19.76). FPHs turned into brownished color during the hydrolysis reaction. Indeed, the FPH300 was significantly (p < 0.05) darker (L* = 66.04) than that of FPH200 and FPH100.

Functional Properties of FPHs

Solubility

The solubility is one of the most important functional properties of protein hydrolysate. A good protein solubility is required in various functional applications, like emulsions and foams. High soluble proteins have a homogeneous dispersibility of the molecules in colloidal systems and improve the interfacial properties [33].

The FPHs solubilities at different hydrolysis times in the pH range of 2–12 are shown in Fig. 2. FPH100, FPH200 and FPH300 share solubility profiles, exhibiting a U shaped curve in which they have higher solubility values at both alkaline and acidic pH levels. All hydrolysates were soluble over a wide pH range with more than 75% solubility except at pH 4. The FPH100 was more soluble than FPH300 and FPH200 in all pH levels from 2 to 12. Moreover, in acidic conditions (pH 2), the FPH100 protein solubility was 90% and increased rapidly above pH 6 to reach 95% at pH 10. In general, the degradation of proteins to smaller peptides leads to more soluble products [34].

The lowest FPHs solubility was achieved at pH 4. Sea by-product hydrolysates also showed the lowest solubility at pH 4 [35, 36]. The minimum solubility corresponds to the isoelectric point. At this pH, the protein molecules exhibit a minimum interaction with the solvent, their net charge is weak enough to approximate the polypeptide chains, which clump together, thus resulting in a decrease in solubility.

Surface Tension

The dynamic surface tension is expected to be a major determining factor for foamability since a better decreasing rate directly reflects a better adsorption and then a better stabilization against coalescence [37].

The FPHs ability to lower the interfacial tension between two phases at different concentrations (0.2%, 0.3%, 0.4% and 0.5%) were investigated (Fig. 3). The FPHs were able to decrease the interfacial tension relative to water (72 mN/m), indicating that these FPHs were surface-active. Interfacial tension decreased with the increase of FPHs concentrations. The statistical analyses have revealed that at a 0.3% concentration, the interfacial tension for FPH100 (36 mN/m) was significantly (p < 0.05) greater than that of FPH200 (48 mN/m) and FPH300 (49 mN/m). At 0.5% concentration, FPH100, FPH300 and FPH200 reached an interfacial tension of 35.2, 35.4 and 36.4 mN/m, respectively.

Water-Holding and Fat-Binding Capacities

The water-holding and fat-binding capacities are functional properties that are closely linked to texture by the interaction between components, including water and oil. The FPHs water-holding and fat-binding capacities were investigated (Table 2). A significant difference (p < 0.05) was observed between the FPHs water holding (0.75 ± 0.04, 1.08 ± 0.08 and 0.57 ± 0.03 g H2O g−1 sample for FPH100, FPH200 and FPH300, respectively). The fat-binding capacities of FPH100, FPH200 and FPH300 were in capacity the order of 1.95 ± 0.12, 2.45 ± 0.08 and 2.61 ± 0.14 g oil g−1 sample, respectively. These values were significantly (p < 0.05) different. The water-holding capacity could be affected by the amount of hydrophilic amino acids and the fat-binding capacity depends on the exposure degree of the hydrophobic residues.

Emulsifiant Properties

The FPHs EAI and ESI at different concentrations (0.5%, 1%, 2% and 3%; w/v) are shown in Fig. 4A, B. Both EAI and ESI increased with the FPHs concentrations increase. The emulsifiant properties increase with high protein concentration is the result of a higher protein adsorption to the surface of oil droplets, where a thin film was formed stabilizing the droplets from coalescing and reducing the interfacial tension. Due to their ability to form strong interfacial films, the protein hydrolysates have often been used as ingredients to stabilize oil-in-water food emulsions. The protein hydrolysates are surface-active materials and promote an oil-in-water emulsion because of their hydrophobic and hydrophilic groups and charges [34]. However, in the same sample concentration of FPH100, FPH200 and FPH300 significant differences (p < 0.05) in EAI and ESI were noticed. FPH300 reached the highest EAI at overall tested concentrations and the highest ESI at concentrations of 0.5 and 1%, whereas FPH200 reached the highest ESI at concentrations of 2 and 3%. The EAI increase with the hydrolysis reaction time seemed to be due to a high correlation between peptides size and emulsification properties.

The emulsion [emulsion capacity (A) and emulsion stability (B)] and the foaming [foaming capacity (C) and foaming stability (D)] properties of FPHs at different concentrations. Feather protein hydrolysates were obtained by acid hydrolysis after 100 min (FPH100), 200 min (FPH200) and 300 min (FPH300). Each bar represents a mean ± SD from three analyses. Different letters within the same concentration indicate significant differences (p < 0.05)

FPHs Foaming Properties

Three factors, including transportation, penetration and reorganization of molecules at the air–water interface governed the foam formation [38]. The protein foaming capacity was improved by reducing the interfacial tension and making it more flexible, through exposing more hydrophobic residues [39]. Foam stability was enhanced by the protein concentration, the viscosity of the aqueous phase and the film thickness.

Foam expansion (FE) recorded for various FPHs concentrations (0.5%, 1%, 2% and 3%) are shown in Fig. 4C. The FE has increased with the rise of the protein hydrolysate concentration. In addition, there was a significant difference (p < 0.05) between FPH100, FPH200 and FPH300 at the concentrations of 0.5%, 1% and 3%. FPH100 has the highest FE values at all hydrolysate concentrations except at the 1% concentration. The FE of FPH100, FPH200 and FPH300 increased from 80 to 130%, 70 to 110% and 55 to 115% when hydrolysate concentrations increased from 0.1 to 3%, respectively, which indicated the promising application of FPH for the improving of functional properties in different food formulations. These results were higher than those found in protein hydrolysate prepared from round scad (70% at 3% concentration) [40]. The increase in protein concentration resulted in a higher rate of diffusion and a denser foam because of an increase in the interfacial films thickness [41].

After whipping, the foam expansion was monitored for 30 min indicating the FPHs foam stability (FS) at different concentrations (Fig. 4D). At all the used concentrations, the foaming stability decreased significantly with time. Also, the FS increased with the increasing FPHs concentrations. Although FPH100 has the highest FE, FPH300 showed the best foam stability with 50% after 30 min at 3% concentration. This value was higher than that observed in the study of shrimp hydrolysate (42.2%) at the same concentration [36] and lower than that obtained by porcine cerebral hydrolysate (70%) at concentration of 2% [22]. The FPHs FS improved by the concentration increase was the result of the formation of stiffer foam developed from high viscosity [42].

FPHs Antioxidant Activity

It is widely known that antioxidants can act through different mechanisms and the use of a single method to evaluate the antioxidant activity cannot provide a clear idea about its real antioxidant potential. Therefore, the use of various antioxidant methods, including 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical-scavenging activity, total antioxidant capacity, reducing power and β-carotene bleaching, for the evaluation of the antioxidant activity is recommended [43].

DPPH Radical Scavenging Activity

The radical scavenging method is one of the most used assays to investigate the free radical scavenging effects of antioxidants. The DPPH is a stable free radical that shows maximum absorbance at 517 nm in ethanol. When the DPPH encounters a proton-donating substance such as an antioxidant, the radical will be scavenged by changing colour from purple to yellow and the absorbance will be reduced [44]. The decrease in absorbance is an indicative measure for radical-scavenging activity.

A concentration-dependent assay was carried out with FPHs and the results are presented in Fig. 5A. The results clearly indicate that all the tested FPHs exhibited high antioxidant activity against DPPH and the scavenging activity of all hydrolysates increased with the hydrolysate concentration increase. Our findings are in line with previous works [5, 16] who reported that the DPPH scavenging activity increased with increasing concentrations.

Antioxidant activities of FPHs at different concentrations. A DPPH free radical-scavenging activities; B total antioxidant activity; C reducing power and D inhibition of β-carotene bleaching. FPH100, FPH200 and FPH300 are the feather protein hydrolysates obtained after 100, 200 and 300 min, respectively. Values are given as mean of triplicate determinations

Among the different hydrolysates, FPH100 exhibited the highest radical scavenging activity value (94.4% at 5 mg/mL), which is very close to that of BHA (95.1% at 5 mg/mL).

The concentration inhibiting 50% of the free radical DPPH (IC50) was determined. Higher free radical scavenging ability was indicated by the lower IC50. There were significant differences (p < 0.05) between FPHs at different hydrolysis times. FPH100 showed potent DPPH radical scavenging effects (IC50 = 0.47 mg/mL), followed by FPH300 (IC50 = 0.75 mg/mL) then FPH200 (IC50 = 1.43 mg/mL).

These results show that feather protein hydrolysates, possibly contain small peptides and free amino acid with relative low molecular weight (MW), which act as electron donors and convert free radical to more stable products [45]. Changes in size, level and composition of the free amino acids and small peptides affect the antioxidant activity.

It is worth noting that FPH100, produced in this study, exhibited a high DPPH radical scavenging activity which is in line with the previous results [5, 15, 16] using enzymatic hydrolysis recording 0.3 mg/mL, 0.5 mg/mL and 0.39 mg/mL of IC50.

Total Antioxidant Capacity

The phosphomolybdate method is a quantitative method that evalutes the antioxidant capacity. The results of the total antioxidant activity are shown in Fig. 5B. All hydrolysates showed an increase of their antioxidant activity with the concentration increase. At the 5 mg/mL concentration, FPH100 showed (p < 0.05) the best antioxidant effect (60.65 µmol/mL α-tocopherol equivalents), followed by FPH300 and FPH200. BHA was found to have more efficiency (p < 0.05) (193.50 µmol/mL α-tocopherol equivalents) at the same concentration. No data for the total antioxidant activity performed on FPH have been reported in the literature.

Reducing Power

The reducing power assay is often used to evaluate the ability of an antioxidant to donate electrons or hydrogen [44, 46]. In this assay, the yellow colour of the test solution changes to various shades of blue, depending on the reducing power of each hydrolysate. The presence of antioxidants in the samples results in the reduction of the Fe3+/ferricyanide complex to the ferrous form. Therefore, the Fe2+ concentration can be monitored by measuring the formation of Perl’s Prussian blue at 700 nm. It has been widely accepted that a higher absorbance means a stronger reducing power.

Figure 5C shows the FPHs reducing power at differents concentrations (0.5–5 mg/mL) compared to BHA as a positive standard. The reducing power of all hydrolysates increased linearly with the concentrations increase. FPH300 and FPH100 showed stronger and close activities (p < 0.05) with an approximate absorbance value of 1.21 and 1.12 at 5 mg/mL concentration, respectively. Our findings are in line with other published studies on feather protein hydrolysate [5, 16]. The reducing power results revealed that FPHs possibly contained peptides and amino acids which functioned as electron donors and could react with free radicals to form stable products and terminate the radical chain reaction. Although the synthetic BHA presents the highest antioxidant activity, natural antioxidants are of a growing interest.

Measurement of β-Carotene-Linoleic Acid Assay

The antioxidant assay using the β-carotene bleaching is widely used to investigate the antioxidant activity of bioactive compounds because β-carotene is extremely susceptible to free radical-mediated oxidation of linoleic acid. In the absence of an antioxidant, β-carotene undergoes rapid discoloration, which results in a reduction of the sample absorbance with the reaction time. The presence of an antioxidant may hinders the bleaching extent by neutralising the linoleic hydroperoxyl radicals formed in the system. To our knowledge, no data for β-carotene bleaching inhibition performed on feather protein hydrolysate have been reported in the literature.

The FPHs potential to minimize the β-carotene reduction is displayed in Fig. 5D. The antioxidant activities of FPH100, FPH200 and FPH300 at 10 mg/mL concentrations were 79.76%, 79.16% and 76.33%, respectively. Furthermore, as can be seen in Fig. 5D, all FPHs showed dose dependency as the activity increased with the increasing hydrolysate concentration. However, The BHA displayed a significantly (p < 0.05) higher antioxidant activity than that of the FPHs.

Hemolytic Activity

The FPHs hemolytic activities were tested on bovine erythrocytes. Each sample was assayed at two concentrations (2 and 5 mg/mL). No hemolysis was observed for all the FPHs concentrations (data not shown). These results provide support for the non-toxicity of these protein hydrolysates from feathers even when applied at high concentrations. In fact, these results are similar to those previously reported for the fish protein hydrolysates [47].

Conclusion

The study revealed the practical relevance of FPHs as a good source of desirable quality of peptides and amino acids. FPHs have desirable solubility, foaming and emulsification properties. FPHs were found to be effective antioxidants in different in vitro assays. A dose-dependent effect between hydrolysate concentration and antioxidant activity was found. The results of this study indicate that FPH100 exhibited a good antioxidant activity compared to FPH200 and FPH300. However, further works should be achieved to purify and identify antioxidant peptides from FPHs and determine their biological activities in vivo.

References

Grazziotin, A., Pimentel, F.A., de Jong, E.V., Brandelli, A.: Nutritional improvement of feather protein by treatment with microbial keratinase. Anim. Feed Sci. Technol. 126, 135–144 (2006). https://doi.org/10.1016/j.anifeedsci.2005.06.002

Papadopoulos, M.C.: Processed chicken feathers as feedstuff for poultry and swine. A review. Agric. Wastes. 14, 275–290 (1985). https://doi.org/10.1016/S0141-4607(85)80009-3

Agrahari, S., Wadhwa, N., et al.: Degradation of chicken feather a poultry waste product by keratinolytic bacteria isolated from dumping site at Ghazipur poultry processing plant. Int J Poult Sci. 9, 482–489 (2010)

Paul, T., Halder, S.K., Das, A., Bera, S., Maity, C., Mandal, A., Das, P.S., Mohapatra, P.K.D., Pati, B.R., Mondal, K.C.: Exploitation of chicken feather waste as a plant growth promoting agent using keratinase producing novel isolate Paenibacillus woosongensis TKB2. Biocatal. Agric. Biotechnol. 2, 50–57 (2013). https://doi.org/10.1016/j.bcab.2012.10.001

Fakhfakh, N., Ktari, N., Haddar, A., Mnif, I.H., Dahmen, I., Nasri, M.: Total solubilisation of the chicken feathers by fermentation with a keratinolytic bacterium, Bacillus pumilus A1, and the production of protein hydrolysate with high antioxidative activity. Process Biochem. 46, 1731–1737 (2011). https://doi.org/10.1016/j.procbio.2011.05.023

Fontoura, R., Daroit, D.J., Correa, A.P.F., Meira, S.M.M., Mosquera, M., Brandelli, A.: Production of feather hydrolysates with antioxidant, angiotensin-I converting enzyme- and dipeptidyl peptidase-IV-inhibitory activities. New Biotechnol. 31, 506–513 (2014). https://doi.org/10.1016/j.nbt.2014.07.002

Grazziotin, A., Pimentel, F.A., Jong, E.V.D., Brandelli, A.: Poultry feather hydrolysate as a protein source for growing rats. Braz. J. Vet. Res. Anim. Sci. 45, 61–67 (2008)

Dalev, P.G.: Utilisation of waste feathers from poultry slaughter for production of a protein concentrate. Bioresour. Technol. 48, 265–267 (1994). https://doi.org/10.1016/0960-8524(94)90156-2

Coward-Kelly, G., Chang, V.S., Agbogbo, F.K., Holtzapple, M.T.: Lime treatment of keratinous materials for the generation of highly digestible animal feed: 1. Chicken feathers. Bioresour. Technol. 97, 1337–1343 (2006). https://doi.org/10.1016/j.biortech.2005.05.021

Laguerre, M., Lecomte, J., Villeneuve, P.: Evaluation of the ability of antioxidants to counteract lipid oxidation: existing methods, new trends and challenges. Prog. Lipid Res. 46, 244–282 (2007). https://doi.org/10.1016/j.plipres.2007.05.002

Phongthai, S., D’Amico, S., Schoenlechner, R., Homthawornchoo, W., Rawdkuen, S.: Fractionation and antioxidant properties of rice bran protein hydrolysates stimulated by in vitro gastrointestinal digestion. Food Chem. 240, 156–164 (2018). https://doi.org/10.1016/j.foodchem.2017.07.080

Shavandi, A., Hu, Z., Teh, S., Zhao, J., Carne, A., Bekhit, A., Bekhit, A.E.-D.A.: Antioxidant and functional properties of protein hydrolysates obtained from squid pen chitosan extraction effluent. Food Chem. 227, 194–201 (2017). https://doi.org/10.1016/j.foodchem.2017.01.099

Suwal, S., Ketnawa, S., Liceaga, A.M., Huang, J.-Y.: Electro-membrane fractionation of antioxidant peptides from protein hydrolysates of rainbow trout (Oncorhynchus mykiss) byproducts. Innov. Food Sci. Emerg. Technol. 45, 122–131 (2018). https://doi.org/10.1016/j.ifset.2017.08.016

Zhang, M., Mu, T.-H.: Identification and characterization of antioxidant peptides from sweet potato protein hydrolysates by Alcalase under high hydrostatic pressure. Innov. Food Sci. Emerg. Technol. 43, 92–101 (2017). https://doi.org/10.1016/j.ifset.2017.08.001

Kumar, D.M., Priya, P., Balasundari, S.N., Devi, G., Rebecca, A.I.N., Kalaichelvan, P.T.: Production and optimization of feather protein hydrolysate from Bacillus sp. MPTK6 and its antioxidant potential. Middle East J. Sci. Res. 11, 900–907 (2012)

Wan, M.-Y., Dong, G., Yang, B.-Q., Feng, H.: Identification and characterization of a novel antioxidant peptide from feather keratin hydrolysate. Biotechnol. Lett. 38, 643–649 (2016). https://doi.org/10.1007/s10529-015-2016-9

Ben Hamad Bouhamed, S., Kechaou, N.: Kinetic study of sulphuric acid hydrolysis of protein feathers. Bioprocess. Biosyst. Eng. 40, 715–721 (2017). https://doi.org/10.1007/s00449-017-1737-7

Gornall, A.G., Bardawill, C.J., David, M.M., et al.: Determination of serum proteins by means of the biuret reaction. J. Biol. Chem. 177, 751–766 (1949)

AOAC: Official Methods of Analysis, 17th edn. Association of Official Agricultural Chemists, Arlington (2000)

AOAC: Official Methods of Analysis, 16th edn. Association of Official Agricultural Chemists, Washington (1999)

AOAC: Official Methods of Analyses. Association of Official Agricultural Chemists, Washington D.C (1990)

Zou, Y., Wang, W., Li, Q., Chen, Y., Zheng, D., Zou, Y., Zhang, M., Zhao, T., Mao, G., Feng, W., Wu, X., Yang, L.: Physicochemical, functional properties and antioxidant activities of porcine cerebral hydrolysate peptides produced by ultrasound processing. Process Biochem. 51, 431–443 (2016). https://doi.org/10.1016/j.procbio.2015.12.011

Lin, M.J.Y., Humbert, E.S., Sosulski, F.W.: Certain functional properties of sunflower meal products. J. Food Sci. 39, 368–370 (1974). https://doi.org/10.1111/j.1365-2621.1974.tb02896.x

Pearce, K.N., Kinsella, J.E.: Emulsifying properties of proteins: evaluation of a turbidimetric technique. J. Agric. Food Chem. 26, 716–723 (1978). https://doi.org/10.1021/jf60217a041

Shahidi, F., Han, X.-Q., Synowiecki, J.: Production and characteristics of protein hydrolysates from capelin (Mallotus villosus). Food Chem. 53, 285–293 (1995). https://doi.org/10.1016/0308-8146(95)93934-J

Bersuder, P., Hole, M., Smith, G.: Antioxidants from a heated histidine-glucose model system. I: investigation of the antioxidant role of histidine and isolation of antioxidants by high-performance liquid chromatography. J. Am. Oil Chem. Soc. 75, 181–187 (1998). https://doi.org/10.1007/s11746-998-0030-y

Prieto, P., Pineda, M., Aguilar, M.: Spectrophotometric quantitation of antioxidant capacity through the formation of a phosphomolybdenum complex: specific application to the determination of vitamin E. Anal. Biochem. 269, 337–341 (1999). https://doi.org/10.1006/abio.1999.4019

Yıldırım, A., Mavi, A., Kara, A.A.: Determination of antioxidant and antimicrobial activities of Rumex crispus L. extracts. J. Agric. Food Chem. 49, 4083–4089 (2001). https://doi.org/10.1021/jf0103572

Koleva, I.I., van Beek, T.A., Linssen, J.P.H., de Groot, A., Evstatieva, L.N.: Screening of plant extracts for antioxidant activity: a comparative study on three testing methods. Phytochem. Anal. 13, 8–17 (2002). https://doi.org/10.1002/pca.611

Dathe, M., Schümann, M., Wieprecht, T., Winkler, A., Beyermann, M., Krause, E., Matsuzaki, K., Murase, O., Bienert, M.: Peptide helicity and membrane surface charge modulate the balance of electrostatic and hydrophobic interactions with lipid bilayers and biological membranes. Biochemistry. 35, 12612–12622 (1996). https://doi.org/10.1021/bi960835f

Kristinsson, H.G., Rasco, B.A.: Biochemical and functional properties of atlantic Salmon (Salmo salar) muscle proteins hydrolyzed with various alkaline proteases. J. Agric. Food Chem. 48, 657–666 (2000). https://doi.org/10.1021/jf990447v

Jemil, I., Jridi, M., Nasri, R., Ktari, N., Salem, R.B.S.B., Mehiri, R., Hajji, M., Nasri, M.: Functional, antioxidant and antibacterial properties of protein hydrolysates prepared from fish meat fermented by Bacillus subtilis A26. Process Biochem. 49, 963–972 (2014). https://doi.org/10.1016/j.procbio.2014.03.004

Zayas, J.F.: Solubility of proteins. In: Zayas, J.F. (ed.) Functionality of Proteins in Food, pp. 6–75. Springer, Berlin, (1997)

Gbogouri, G.a., Linder, M., Fanni, J., Parmentier, M.: Influence of hydrolysis degree on the functional properties of salmon byproducts hydrolysates. J. Food Sci. 69, C615–C622 (2004). https://doi.org/10.1111/j.1365-2621.2004.tb09909.x

Klompong, V., Benjakul, S., Kantachote, D., Shahidi, F.: Antioxidative activity and functional properties of protein hydrolysate of yellow stripe trevally (Selaroides leptolepis) as influenced by the degree of hydrolysis and enzyme type. Food Chem. 102, 1317–1327 (2007). https://doi.org/10.1016/j.foodchem.2006.07.016

Sila, A., Sayari, N., Balti, R., Martinez-Alvarez, O., Nedjar-Arroume, N., Moncef, N., Bougatef, A.: Biochemical and antioxidant properties of peptidic fraction of carotenoproteins generated from shrimp by-products by enzymatic hydrolysis. Food Chem. 148, 445–452 (2014). https://doi.org/10.1016/j.foodchem.2013.05.146

Marinova, K.G., Basheva, E.S., Nenova, B., Temelska, M., Mirarefi, A.Y., Campbell, B., Ivanov, I.B.: Physico-chemical factors controlling the foamability and foam stability of milk proteins: sodium caseinate and whey protein concentrates. Food Hydrocoll. 23, 1864–1876 (2009). https://doi.org/10.1016/j.foodhyd.2009.03.003

Hailing, P.J., Walstra, P.: Protein-stabilized foams and emulsions.Crit. Rev. Food Sci. Nutr. 15, 155–203 (1981). https://doi.org/10.1080/10408398109527315

Mutilangi, W.A.M, Panyam, D., Kilara, A.: Functional properties of hydrolysates from proteolysis of heat-denatured whey protein isolate. J. Food Sci. 61, 270–275 (1996). https://doi.org/10.1111/j.1365-2621.1996.tb14174.x

Thiansilakul, Y., Benjakul, S., Shahidi, F.: Compositions, functional properties and antioxidative activity of protein hydrolysates prepared from round scad (Decapterus maruadsi). Food Chem. 103, 1385–1394 (2007). https://doi.org/10.1016/j.foodchem.2006.10.055

Sánchez, C.C., Patino, J.M.R.: Interfacial, foaming and emulsifying characteristics of sodium caseinate as influenced by protein concentration in solution. Food Hydrocoll. 19, 407–416 (2005). https://doi.org/10.1016/j.foodhyd.2004.10.007

Lawal, O.S.: Functionality of African locust bean (Parkia biglobossa) protein isolate: effects of pH, ionic strength and various protein concentrations. Food Chem. 86, 345–355 (2004). https://doi.org/10.1016/j.foodchem.2003.09.036

García-Moreno, P.J., Batista, I., Pires, C., Bandarra, N.M., Espejo-Carpio, F.J., Guadix, A., Guadix, E.M.: Antioxidant activity of protein hydrolysates obtained from discarded Mediterranean fish species. Food Res. Int. 65, 469–476 (2014). https://doi.org/10.1016/j.foodres.2014.03.061

Shimada, K., Fujikawa, K., Yahara, K., Nakamura, T.: Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. J. Agric. Food Chem. 40, 945–948 (1992). https://doi.org/10.1021/jf00018a005

Wu, H.-C., Chen, H.-M., Shiau, C.-Y.: Free amino acids and peptides as related to antioxidant properties in protein hydrolysates of mackerel (Scomber austriasicus). Food Res. Int. 36, 949–957 (2003). https://doi.org/10.1016/S0963-9969(03)00104-2

Yıldırım, A., Mavi, A., Oktay, M., Kara, A.A., Algur, ÖF., Bilaloǧlu, V.: Comparison of antioxidant and antimicrobial activities of Tilia (Tilia Argentea Desf Ex DC), sage (Salvia Triloba L.), and black tea (Camellia sinensis) extracts. J. Agric. Food Chem. 48, 5030–5034 (2000). https://doi.org/10.1021/jf000590k

Sila, A., Nedjar-Arroume, N., Hedhili, K., Chataigné, G., Balti, R., Nasri, M., Dhulster, P., Bougatef, A.: Antibacterial peptides from barbel muscle protein hydrolysates: activity against some pathogenic bacteria. LWT-Food Sci. Technol. 55, 183–188 (2014). https://doi.org/10.1016/j.lwt.2013.07.021

Acknowledgements

This research was supported by the Tunisian Ministry of Higher Education, Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ben Hamad Bouhamed, S., Krichen, F. & Kechaou, N. Feather Protein Hydrolysates: A Study of Physicochemical, Functional Properties and Antioxidant Activity. Waste Biomass Valor 11, 51–62 (2020). https://doi.org/10.1007/s12649-018-0451-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0451-2