Abstract

To replace petroleum-based fuels, fast-growing microalgae are currently receiving attention as alternative sources of fuels. In this study, twelve microalgae strains from three genera representing oleaginous microalgae, namely Botryococcus, Scenedesmus and Chlorella, were screened. The selected strains from each genus were applied in integrated lipid production and phytoremediation of secondary effluent from palm oil mill. Among the strains tested, Chlorella sp. C-MR was the most suitable strain to be cultivated in the effluent, due to its high growth rate and high lipid productivity. The optimal conditions for lipid production were: dilution of effluent at 1:1 (COD 1266 mg/L) and light intensity of 40 μmol/m2 s. The semi-continuous cultivation of this microalga was effective for sustained lipid production (0.19–0.24 g/L) and pollutant removal, i.e., COD removal (58–65 %), nitrogen removal (71–99 %) and phosphorus removal (42–64 %). The microalgal lipids contained mainly saturated fatty acids (>85 %), which are suitable for producing biodiesel with high cetane number and oxidative stability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Oleaginous microalgae are renewable oil sources for the 3rd generation biodiesels. This is due to the prospects of high biomass yield without requiring any arable land, and the ability to utilize both inorganic carbon (carbon dioxide) and organic carbon sources (glucose, acetate, etc.) to synthesize lipids [1]. They can then contribute to solving two major problems: air pollution by carbon dioxide, and future crises due to a shortage of energy sources. In addition, many microalgae are able to grow in wastewaters, under highly saline and alkaline conditions, tolerate fluctuating temperatures, high carbon dioxide concentrations and varying light intensities [2]. However, the major barrier to the commercialization of algae-derived biodiesel is the high production cost. Therefore, there is a need to develop low cost microalgae cultivation processes.

In the primary treatment of wastewater, materials that settle or float are removed. The primary effluent is further subjected to a secondary treatment that removes the residual organics and suspended solids. However, the secondary effluent may still contain high levels of nitrogen and phosphorus. On the one hand, these compounds need to be removed in the tertiary treatment, and on the other hand they are suitable and cost-effective for microalgae cultivation. Therefore, the incorporation of oleaginous microalgae cultivation into wastewater treatment systems would offer the combined advantages of treating wastewater and simultaneously producing inexpensive microalgal lipids. Wastewater treatment by microalgae cultures has several major advantages: it rests on the principles of natural ecosystems and is therefore not environmentally hazardous; it causes no secondary pollution, as long as the biomass produced is reused; and it allows for an efficient recycling of nutrients [3].

Among the oleaginous microalgae, Botryococcus is a well-known microalgal genus that is capable of accumulating lipids at a high 25–38 % level based on dry biomass, and that effectively removes nutrients even from wastewater [4–6]. Scenedesmus is another microalgal genus that has been widely used for pollutant removal from wastewaters [7, 8], and for lipid production at a level of 31–33 % based on dry biomass [9]. Some species of Chlorella are capable of consuming organic forms of carbon in addition to inorganic pollutants. This can be an advantage when using wastewater streams containing carbon residues and inorganic pollutants, such as digested dairy manure [7, 10]. Moreover, some of these species can accumulate lipids up to contents of 28–43 % [11–15]. There are several research groups reporting the cultivation of microalgae in palm oil mill effluent (POME) [16–18] and some of them reviewing the possibility of coupling microalgae cultivation with lipid production [19, 20]. However, only few of them cultivated the microalgae in POME for lipid production. Ogugua Nwuche et al. [21] studied the use of POME as medium for cultivation of Chlorella sorokiniana C212 in flask scale with 100 mL culture volume. In their study, external nitrogen source (urea at 60 mg/L) was added in the sterilized POME to stimulate the growth of this strain and its lipid content was only 156 mg/g-cell (15.6 %). Kamyab et al. [22] compared the growth of Chlorella pyrenoidosa in sterilized Bold’s Basal Medium (BBM) added with POME at different concentrations. The medium added with POME gave a lower biomass compared to that of the control indicating the inhibition effect of the POME. To optimize lipid production, the carbon-to-total nitrogen ratio of the medium was adjusted to be 100:6 which was about five times of the original one (100:32). Neither nitrogen nor phosphorus removal by this microalgae was reported. Apart from these two strains, other oleaginous species might have potential to be cultivated in POME with higher ability to remove pollutants and produce lipids.

This study aimed to cultivate potential oleaginous microalgae in a secondary effluent for lipid production and pollutant removal. Twelve oleaginous microalgae strains from three genera, namely Botryococcus, Scenedesmus and Chlorella, were firstly screened based on their high lipid productivity. The selected strains from each genus were cultivated in the secondary effluent from a palm oil mill. The most suitable strain for cultivation in the secondary effluent was chosen. The cultivation conditions were then optimized to maximize the lipid productivity. Semi-continuous cultivation of the microalgae was performed, assessing the sustained lipid production and pollutant removal. The microalgal lipid was extracted and studied for its fatty acid composition.

Materials and Methods

Materials

Three genera, namely Botryococcus, Scenedesmus and Chlorella representing highly lipid-accumulating microalgae were studied. Water samples with microalgae were collected with a plankton net (10–12 µm × 7–9 µm sieve size) from a water reservoir at Hatyai Campus, Prince of Songkla University (PSU), on October 10th 2012; at a pond in the Hatyai central park (HYP), Songkhla Prefecture on October 10th 2012; at Lake Talenoi (SKL), Songkhla Prefecture on November 5th 2012; at final effluent pond of a seafood-processing plant (WWP), Songkhla Prefecture on November 25th 2012; and at Lake Taleiban (BNL) and Kaorayamangsa (RYL), Satun Prefecture on December 4th 2012. Marine Chlorella sp. (MR) was obtained from the National Institute of Coastal Aquaculture, Thailand. Colonies of microalgae in the water samples were detected under a microscope, and individual colonies were isolated with a glass micropipette. Each colony was washed at least three times with sterile modified Chu 13 medium containing 0.2 g KNO3 as a nitrogen source, 0.04 g K2HPO4 as a phosphorus source, 0.1 g citric acid, 0.01 g Fe citrate, 0.1 g MgSO4·7H2O, 0.036 g NaHCO3, and 1 mL of trace metal solution per 1 L. The trace metal solution consisted of 2.85 g H3BO3, 1.8 g MnCl2·4H2O, 0.02 g ZnSO4·7H2O, 0.08 g CuSO4·5H2O, 0.08 g CoCl2·6H2O, and 0.05 g Na2MoO4·2H2O per 1 L, pH was 6.8 [5]. The isolated microalgae were identified based on their morphological structures. The cultures were incubated at 30 ± 2 °C and air-aerated with a flow rate of 0.01 mL/min, under 40 μmol/m2 s light intensity with 16:8 h light:dark cycle.

The wastewater used in this study was the secondary effluent from a palm oil mill (Songkhla, Thailand). The characteristics of the secondary effluent were as follows: pH 7.78, chemical oxygen demand (COD) 2533 mg/L, total nitrogen 400 mg/L, phosphorus 70 mg/L and oil and grease 75 mg/L. The secondary effluent was one-fold diluted and filtered through a mesh to remove suspended solids, and pH was adjusted to 6.8 before sterilization in an autoclave at 121 °C for 15 min.

Algal Cultures

The isolates were grown in 500-mL Erlenmeyer flasks containing 400 mL of modified Chu 13 medium, with agitation at 125 rpm at 30 ± 2 °C under 40 μmol/m2 s light intensity, and 16:8 h light:dark cycle for 7 days. The initial cell concentration was approximately 106 cells/mL (0.12–0.14 g/L). The dry biomass and lipid content were measured. The specific growth rate (μ) was calculated as follows:

where C 0 is the initial dry biomass concentration (g/L) and C is the dry biomass concentration (g/L) at any later time t [23].

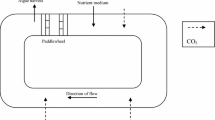

The batch and semi-continuous cultivations were performed in 2 L stirred tank photobioreactors with 1.5 L working volume. The cultures were incubated at 30 ± 2 °C and agitated at 125 rpm under 40 μmol/m2 s light intensity, with 16:8 h light:dark cycle. As a sufficient supply of CO2 is necessary to support the microalgae growth, the pH controller was used to monitor the CO2 consumption by the microalgae and to control the feeding of CO2. When the culture pH increases due to the CO2 consumption by the microalgae, the controller will switch on the solenoid valve to feed CO2 (10 % mixed with air) at a flow rate of 0.5 volume gas per volume medium per min (vvm) to decrease the pH to the set-point (6.8). This pH–stat feeding strategy allows the adequate feeding of CO2 without oversupply that causes the rapid drop of the pH. The biomass concentration and lipid content were estimated daily. During the cultivation, 500 mL of medium was withdrawn and replaced with the same volume of fresh medium at 7-day intervals.

Analytical Methods

Biomass was harvested by centrifugation of the culture sample at 1585×g for 15 min. The pellets were then washed twice with distilled water and dried at 60 °C in a hot air oven, until a constant weight was obtained. Extraction of lipids from the biomass was performed according to the procedure of Folch et al. [24], with slight modifications. The lipids were extracted with a mixture of chloroform:methanol (2:1, v/v) for 1 h. The extracted lipids were centrifuged to obtain a clear supernatant and the solvent was removed by evaporation under vacuum. Chlorophyll in the fresh algal cells was extracted with acetone. The amount of chlorophyll in the extract was determined by measuring the optical densities at 645 and 663 nm with a spectrophotometer, and using the following equation [25]:

The chlorophyll content of the algal cells (mg/g) was calculated by dividing the chlorophyll concentration (mg/L) by the dry cell matter concentration (g/L).

The secondary effluent from palm oil mill was characterized in terms of chemical oxygen demand (COD), total nitrogen, and total phosphorus, according to standard methods [26]. The method for converting lipids into fatty acid methyl esters (FAMEs) involved hydrolysis of the lipids followed by esterification [27]. The fatty acid compositions of the FAME were analyzed using a HP6850 Gas Chromatograph equipped with a cross-linked capillary FFAP column (length 30 m, 0.32 mm I.D, 0.25 µm film thickness) and a flame ionization detector. The operating conditions were as follows: inlet temperature 290 °C; oven temperature initially 210 °C held for 12 min, then ramped to 250 °C at 20 °C/min; then held for 8 min; and the detector temperature was 300 °C. The fatty acid compositions were identified by comparing their retention times with known pure standards including C8:0, C9:0, C10:0, C11:0, C12:0, C13:0, C14:0, C15:0, C16:0, C17:0, C18:0, C18:1, C18:2, C18:3, C20:0, C20:1, C22:0, C22:1, C24:0, C24:1 with the detection limit of 1.5 μg/mL. All experiments were done in triplicate. The statistical significance of the results was evaluated by one way ANOVA (analysis of variance) and Duncan’s multiple range test (P < 0.05) using the software SPSS version 10.

Results and Discussion

Growth and Lipid Productivity of the Isolates in Modified Chu 13 Medium

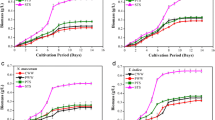

Growth and lipid content profiles of the twelve isolates representing three genera are shown in Fig. 1. Scenedesmus spp. (Fig. 1b) and Botryococcus spp. (Fig. 1c) grew well in the modified Chu 13 medium, with the high specific growth rates of 0.28–0.43 and 0.38–0.41 day−1, respectively. The Chlorella spp. grew at a slightly lower specific growth rate of 0.23–0.29 day−1 (Fig. 1a). However, Chlorella spp. showed the highest lipid content of 28–32 % based on dry biomass weight, followed by Botryococcus spp. (17–28 %) and Scenedesmus spp. (15–24 %). The lipid contents of Chlorella spp. were comparable to those previously reported for other strains [5, 28, 29]. Other than lipid content, the lipid productivity is also a key parameter affecting the commercial viability of the process. The results of lipid productivity, in terms of grams per liter of culture medium per day, were then evaluated. Although Chlorella spp. grew slightly slower than Scenedesmus spp. and Botryococcus spp., the lipid productivities of these strains were comparable at 13–17 mg L−1 day−1 compensating differences in the lipid contents. It should be noted that there were only slight differences in lipid productivity between strains in the same genus. As Chlorella sp. C-MR, Botryococcus sp. B-HYP and Scenedesmus sp. S-PSU were the fastest growing strains and gave the highest lipid productivities in the respective genera, they were selected for further study of the potential to be cultivated in the secondary effluent from a palm oil mill.

Growth and lipid production profiles of twelve algal isolates representing three genera. These include (A) Chlorella spp., (B) Scenedesmus spp. and (C) Botryococcus spp. The microalgae were cultivated in modified Chu 13 medium (pH 6.8) at 30 ± 2 °C with agitation at 125 rpm under 40 μmol/m2 s light intensity, and 16:8 h light:dark cycle for 7 days. The initial cell concentration was approximately 106 cells/mL. Different letters on the bars indicate significant differences between strains of the same genus

Cultivation of Selected Strains in Secondary Effluent

The feasibility of cultivating most suitable strains from each genus, i.e., Chlorella sp. C-MR, Botryococcus sp. B-HYP and Scenedesmus sp. S-PSU in the one-fold diluted secondary effluent from palm oil mill was studied (Fig. 2a). Only Chlorella sp. C-MR grew well with the considerably high specific growth rate of 0.33 h−1. This suggests it has potential to be cultivated in the secondary effluent from palm oil mill, which would be a low-cost culture medium. Similarly, several studies have found that Chlorella spp. grew well in agro-industrial wastewaters [7], in wastewater from digested dairy manures [10], and in piggery wastewater [12]. Chlorella sp. C-MR was chosen for further studies due to its ability to grow and produce lipids in the secondary effluent.

a The impact of using one-fold diluted effluent on growth and lipid production of three selected microalgae, namely Chlorella sp. C-MR, Botryococcus sp. B-HYP and Scenedesmus sp. S-PSU. b Effect of effluent dilution, c effect of salt concentration, and d effect of light intensity on growth and lipid production of the selected Chlorella sp. C-MR. Different letters on the bars indicate significant differences between treatments

Figure 2b shows the cultivation of Chlorella sp. C-MR using non-diluted, one-fold and two-fold diluted secondary effluents. The non-diluted effluent inhibited cell growth and lipid production of Chlorella sp. C-MR. This could be due to the presence of phenols and some organic acids in non-diluted effluent that could be toxic to the microalgae at high concentration [16, 21]. Another possibility would be due to the reduced light penetration since the undiluted effluent had dark brown color. When the effluent was one-fold diluted, Chlorella sp. C-MR grew well and gave the highest lipid productivity of 28.5 mg/L day. However, the two-fold diluted effluent gave lower specific growth rate and lower lipid productivity. This was probably because the nitrogen concentration was below the optimal level for cell growth when the effluent was two-fold diluted (<50 mg/L). It has been reported that the optimal levels of nitrogen concentration for microalgal growth were in the range of 50–112 mg/L (urea at concentrations of 0.2–0.25 g/L; nitrate at concentrations of 0.2–0.4 g/L) [30–32]. Thus, sufficient supply levels of nutrients are required for rapid cell growth and high lipid production by the microalgae. As the specific growth rate of Chlorella sp. C-MR in the one-fold diluted effluent was comparable to that obtained in the modified Chu 13 medium (Fig. 1a), it could be suggested that the one-fold diluted effluent could be used as a sole medium for the cultivation of Chlorella sp. C-MR. It should be noted the treated effluent may be recycled and used for dilution instead of the use of fresh water.

Some microalgae have been reported to not only survive in fresh water, but to also adapt to large variations in salinity. Microalgae with such halotolerance are suitable for cultivation under conditions with high salinity. The cellular compositions of the microalgae are also affected by the salinity [33]. It has been reported that salt concentration at 1–2 % [31, 34] could increase the lipid content of the microalgae. However, at higher salt concentration the microalgae growth drastically decreased and hence the overall lipid productivity was reduced. Therefore, the effects of salinity on the specific growth rate and the lipid productivity of Chlorella sp. C-MR were studied by adding salt at 1 and 2 % concentrations into the one-fold diluted effluent (Fig. 2c). Although the addition of salt slightly promoted the lipid accumulation, it retarded the cell growth and hence reduced the lipid productivity. It has been reported that the microalgae response to high salinity by enhancing production of neutral and polar lipid to reduce membrane fluidity and permeability, which could help microalgae to cope up osmotic balance under high salinity [35]. Recently, Pancha et al. [34] have reported the effect of salinity stress on the Na+ content in the microalgae. The addition of salt significantly increased the Na+/K+ and Na+/Ca2+ ratios in the cells, which affect the ion homeostasis and normal functioning of the cells. Several studies have also reported that the lipid content of microalgae slightly increased with the addition of salt [36–38]. Although some microalgae can grow well despite added salt (0.15 N), they tend to accumulate a lower content of lipids than the control [39].

The effects of light intensity on the specific growth rate and the lipid productivity of Chlorella sp. C-MR, cultivated in one-fold diluted effluent, are shown in Fig. 2d. The growth of Chlorella sp. C-MR increased when the light intensity was increased from 40 to 54 μmol/m2 s. A further increase in light intensity did not encourage the growth of this strain. Although the growth of Chlorella sp. C-MR was enhanced at moderate light intensity of 54 μmol/m2 s, its lipid content drastically reduced and hence the lipid productivity became lower than that at 40 μmol/m2 s.

This is in contrast to prior reports showing high light intensities as favorable for both lipid and hydrocarbon contents, rather than for biomass [5, 40]. From these results, it could be concluded that the optimal levels of light intensity for cell growth and for lipid accumulation are different. It should be noted that rapid biomass gain with high lipid content would increase the efficiency of lipid extraction and reduce the downstream processing costs.

Semi-continuous Cultivation of Chlorella sp. C-MR in the Secondary Effluent

To produce large amounts of microalgal biomass and lipids, the cultivation of Chlorella sp. C-MR in the secondary effluent was scaled up to a 2 L stirred tank photobioreactor with a working volume of 1.5 L. The process was operated in batch mode for 7 days and in semi-continuous mode thereafter. It should be noted that a sufficient supply of CO2 is necessary for optimal microalgal growth. However, if CO2 is supplied in excessive amounts the pH will drop rapidly, and the unsuitable pH level will cause low biomass productivity. Hence, the pH of the culture was controlled around set-point 6.8 by injecting CO2 in response to signals from a pH sensor. Through this strategy the CO2 feed was sufficient with steady pH. The microalgal growth, lipid and chlorophylls contents, and pollutant removals are shown in Fig. 3. The microalgal biomass and lipids in the batch culture during first 7 days reached 0.46 ± 0.05 g/L and 0.19 ± 0.04 g/L, respectively. These were slightly better than with a flask supplemented with air (Fig. 2d), probably due to the adequate supply of CO2 using the pH–stat control system. The lipid content during this period was stable at 38–42 %. In addition to the lipids, the microalgae also produce a variety of pigments, especially chlorophyll used to capture light energy from the sun. The concentration of cellular photosynthetic components depends on the extent of photoautotrophic metabolism [23]. In this study, the chlorophyll content gradually decreased from 56 to 18 mg/g dry biomass during first 7 days of cultivation. It has been reported that the presence of organic carbon may alter the photosynthetic metabolism and reduce the production of photosynthetic pigments [6, 41–43]. Similarly, Xu et al. [11] showed that the soluble lipid compounds from photoautotrophic cells of Chlorella protothecoides appeared blackish green with chlorophyll as the major component, whereas the lipid-soluble compounds from the heterotrophic cells (grown on organic carbon without light) appeared in a state of light yellow grease. Cheirsilp and Torpee [14] also found that the chlorophyll contents in mixotrophic cultures (grown on organic carbon with light) of Chlorella spp., Nannochloropsis sp. and Cheatoceros sp. were lower than those in photoautotrophic cultures. The COD, nitrogen and phosphorus removals by Chlorella sp. C-MR during this period were 64.8, 71.2 and 60.3 %, respectively. The oil and grease in the effluent based medium before and after microalgae cultivation were not significantly different (P > 0.05). They were 46.7 ± 5.8 and 41.7 ± 3.6 mg/L, respectively. It has been reported that some species of Chlorella can consume organic carbon in addition to inorganic nutrients in their metabolic processes [44]. Most characteristics of palm oil mill effluent after secondary treatment meet the discharge standard for wastewater except nitrogen content. The discharge standard for nitrogen content is 200 mg/L. Therefore, palm oil millers favor the culture of microalgae as a tertiary treatment for further removal of nitrogen and reutilizing the effluent to generate renewable energies [19].

During semi-continuous cultivation, a portion of the culture is withdrawn at intervals to recover generated biomass and products, while fresh medium is added to supply nutrients. Furthermore, time is not wasted in non-productive activities such as cleaning and re-sterilization. In the semi-continuous cultivation of Chlorella sp. C-MR, the first fill-and-withdraw operation was done at day 7 and repeated four times during the 35 days of cultivation. As shown in Fig. 3, the microalgae grew vigorously during the five cycles of cultivation, but the growth became slow during the 4th and 5th cycles. During the 1st, 2nd and 3rd cycles, the specific growth rates were 0.267, 0.237 and 0.174 day−1 and the lipid productivities were 33, 41 and 15 mg/L day, respectively. The lipid content was highest at 43 % on day 11 before it decreased to 33.3 % on day 14. It should be noted that the lipid content decrease observed after the 2nd cycle likely was due to internal degradation of stored lipids. The chlorophyll content continuously decreased to the level of 6–15 mg/g. The pollutant removal was most effective during the 2nd cycle and still effective until the 4th cycle.

Table 1 shows the biomass, specific growth rate, lipid content and lipid productivity of several microalgae cultivated in various wastewaters. Although Scenedesmus sp. LX1 could accumulate lipids up to 31–33 %, it gave very low biomass of 0.11 g/L and low specific growth rate of 0.2 day−1 in the secondary effluent. This was attributed to the low phosphorus concentration in the secondary effluent [9]. Among the three strains that grew well in wastewater, namely Scenedesmus quadricauda SDEC-13 [8], Nannochloropsis sp. [45] and Chlorella ellipsoidea YJ1 [13], it was C. ellipsoidea YJ1 that performed the best in term of high lipid content (43 %) and S. quadricauda SDEC-13 that performed the best in term of high lipid productivity (68.2 mg/L day). Recently, Wang et al. [15] found that Chlorella pyrenoidosa could grow well in piggery wastewater, when the wastewater is appropriately diluted. However, C. pyrenoidosa accumulated lipids only up to 14 %. This might be due to the too high total nitrogen of the wastewater that favored cell growth rather than lipid accumulation. This current study has shown that it is possible to cultivate Chlorella sp. C-MR in the secondary effluent of a palm oil mill and to produce lipids in semi-continuous mode. The Chlorella sp. C-MR grew well and accumulated comparable lipid contents to those in the previous studies.

Another aspect that should be taken into account would be the use of non-sterile POME for microalgae cultivation [46]. The non-sterile POME could be inoculated with the desired microalgae with the aim of initiating growth and dominating the culture. However, over time other microorganisms might compete the inoculated specie and reduce the lipid yields. Some microalgae have been reported that they can survive and grow well at high pH > 9 and be commonly the dominant species in soda lakes [47] and some of them can grow well in high saline waters [48]. Therefore, the further cultivation of this microalga using non-sterile POME should be investigated for the biodiesel production purposes. In addition, the contribution of other indigenous microorganisms in removal of organics and nutrients and lipid production should also be evaluated.

Fatty Acid Composition of Microalgal Lipids

The lipids extracted from Chlorella sp. C-MR were converted to fatty acid methyl esters (FAMEs) and their compositions were determined. The major constituents were three long-chained saturated fatty acids, namely palmitic acid (C16:0) (63 %), stearic acid (C18:0) (17 %) and linoceric acid (C24:0) (8 %). The total saturated fatty acids contributed over 85 %, while the unsaturated fatty acids were oleic acid (C18:1) and linoleic acid (C18:2) at only 5 and 3 %, respectively. These results are consistent with those of Converti et al. [12], who reported that Chlorella spp. accumulated a high proportion of saturated fatty acids. It should be noted that the biodiesel derived from Chlorella sp. C-MR lipids in this current study were highly saturated and would therefore provide high cetane number (CN), low NOx emissions, short ignition delay time, and high oxidative stability to biodiesel [49].

Conclusions

In this study, twelve oleaginous microalgae strains from three genera, namely Chlorella, Scenedesmus and Botryococcus, grew well and accumulated high lipid contents in modified Chu 13 medium. However, only Chlorella sp. C-MR grew and accumulated high lipid content in the secondary effluent from a palm oil mill. The optimal conditions for lipid production by Chlorella sp. C-MR were determined. The semi-continuous cultivation of this microalga was effective for sustained lipid production and pollutant removal. The extracted microalgal lipid contained mainly saturated fatty acids suggesting high potential for use as biodiesel feedstock.

References

Chisti, Y.: Biodiesel from microalgae. Biotechnol. Adv. 25, 294–306 (2007)

Borowitzka, M.A.: Commercial production of microalgae: ponds, tanks, tubes and fermenters. J. Biotechnol. 70, 313–321 (1999)

An, J.Y., Sim, S.J., Lee, J.S., Kim, B.W.: Hydrocarbon production from secondarily treated piggery wastewater by the green alga Botryococcus braunii. J. Appl. Phycol. 15, 185–191 (2003)

Sawayama, S., Minowa, T., Dote, Y., Yokoyama, S.: Growth of the hydrocarbon-rich microalgae Botryococcus braunii secondarily treated sewage. Appl. Microbiol. Biotechnol. 29, 145–148 (1992)

Tansakul, P., Savaddiraksa, Y., Prasertsan, P., Tongurai, C.: Cultivation of the hydrocarbon-rich alga, Botyococcus braunii in secondary treated effluent from a sea food processing plant. Thai J. Agric. Sci. 38(1–2), 71–76 (2005)

Yeesang, C., Cheirsilp, B.: Low-cost production of green microalga Botryococcus braunii biomass with high lipid content through mixotrophic and photoautotrophic cultivation. Appl. Biochem. Biotechnol. 174, 116–129 (2014)

Gonzalez, L.E., Can-izares, R.O., Baena, S.: Efficiency of ammonia and phosphorus removal from a Colombian agroindustrial wastewater by the microalgae Chlorella vulgaris and Scenedesmus dimorphus. Bioresour. Technol. 60, 259–262 (1997)

Han, L., Pei, H., Hu, W., Jiang, L., Ma, G., Zhang, S., Han, F.: Integrated campus sewage treatment and biomass production by Scenedesmus quadricauda SDEC-13. Bioresour. Technol. 175, 262–268 (2015)

Xin, L., Hong-Ying, H., Jia, Y.: Lipid accumulation and nutrient removal properties of a newly isolated freshwater microalga, Scenedesmus sp. LX1, growing in secondary effluent. New Biotechnol. 27, 59–63 (2010)

Wang, L., Wang, Y.K., Chen, P., Ruan, R.: Semi-continuous cultivation of Chlorella vulgaris for treating undigested and digested dairy manures. Appl. Biochem. Biotechnol. 162, 2324–2332 (2010)

Xu, H., Miao, X., Wu, Q.: High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J. Biotechnol. 126, 499–507 (2006)

Converti, A., Casazza, A.A., Ortiz, E.Y., Perego, P., Borghi, M.D.: Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem. Eng. Process. 48, 1146–1151 (2009)

Yang, J., Li, X., Hu, H.-Y., Zhang, X., Yu, Y., Chen, Y.: Growth and lipid accumulation properties of a freshwater microalga, Chlorella ellipsoidea YJ1, in domestic secondary effluents. Appl. Energy 88, 3295–3299 (2011)

Cheirsilp, B., Torpee, S.: Enhanced growth and lipid production of microalgae under mixotrophic culture condition: effect of light intensity, glucose concentration and fed-batch cultivation. Bioresour. Technol. 110, 510–516 (2012)

Wang, H., Xiong, H., Hui, Z., Zeng, X.: Mixotrophic cultivation of Chlorella pyrenoidosa with diluted primary piggery wastewater to produce lipids. Bioresour. Technol. 104, 215–220 (2012)

Hadiyanto, M.C., Soetrisnanto, D.: Phytoremediations of palm oil mill effluent (POME) by using aquatic plants and microalgae for biomass production. J. Environ. Sci. Technol. 6(2), 79–90 (2013)

Kamyab, H., Din, M.F.M., Keyvanfar, A., Majid, M.Z.A., Talaiekhozani, A., Shafaghat, A., Lee, C.T., Shiun, L.J., Ismail, H.H.: Efficiency of microalgae Chlamydomonas on the removal of pollutants from palm oil mill effluent (POME). Energy Procedia 75, 2400–2408 (2015)

Tan, C.H., Cheah, W.Y., Ling, T.C., Show, P.L., Juan, J.C., Chang, J.S.: Algae cultivation in wastewater for biodiesel: a review. Chem. Eng. Trans. 45, 1393–1398 (2015)

Lam, M.K., Lee, K.T.: Renewable and sustainable bioenergies production from palm oil mill effluent (POME): win–win strategies toward better environmental protection. Biotechnol. Adv. 29, 124–141 (2011)

Kamarudin, K.F., Tao, D.G., Yaakob, Z., Takriff, M.S., Rahaman, M.S.A., Salihon, J.: A review on wastewater treatment and microalgal by-product production with a prospect of palm oil mill effluent (POME) utilization for algae. Der. Pharm. Chem. 7, 73–89 (2015)

Ogugua Nwuche, C., Chidimma Ekpo, D., Nwoye Eze, C., Aoyagi, H., Chukwuma Ogbonna, J.: Use of palm oil mill effluent as medium for cultivation of Chlorella sorokiniana. Br. Biotechnol. J. 4, 2231–2927 (2014)

Kamyab, H., Din, M.F.M., Lee, C.T., Keyvanfar, A., Shafaghat, A., Majid, M.Z.A., Ponraj, M., Yun, T.X.: Lipid production by microalgae Chlorella pyrenoidosa cultivated in palm oil mill effluent (POME) using hybrid photo bioreactor (HPBR). Desalin. Water Treat. 55, 3737–3749 (2015)

Cerón García, M.C., Sánchez Mirón, A., Fernández Sevilla, J.M., Molina Grima, E., García Camacho, F.: Mixotrophic growth of the microalga Phaeodactylum tricornutum influence of different nitrogen and organic carbon sources on productivity and biomass composition. Process Biochem. 40, 297–305 (2005)

Folch, J., Lees, M., Stanley, G.H.S.: A simple method for the isolation and purification of total lipides from animal tissues. J. Biol. Chem. 226, 497–509 (1957)

Becker, E.W.: Microalgae: biotechnology and microbiology. Cambridge University Press, New York (1994)

A.P.H.A.: Standard methods for the examination of water and wastewater. American Public Health Association, Washington DC (2005)

Jham, G.N., Teles, F.F.F., Campos, L.G.: Use of aqueous HCl/MeOH as esterification reagent for analysis of fatty acids derived from soybean lipids. J. Am. Oil Chem. Soc. 59, 132–133 (1982)

Okada, S., Murakami, M., Yamaguchi, K.: Hydrocarbon composition of newly isolated strains of the green microalga Botryococcus braunii. J. Appl. Phycol. 7, 555–559 (1995)

Dayananda, C., Sarada, R., Usha Rani, M., Shamala, T.R., Ravishankar, G.A.: Autotrophic cultivation of Botryococcus braunii for the production of hydrocarbons and exopolysaccharides in various media. Biomass Bioenergy 31, 87–93 (2007)

Arumugam, M., Agarwal, A., Arya, M.C., Ahmed, Z.: Influence of nitrogen sources on biomass productivity of microalgae Scenedesmus bijugatus. Bioresour. Technol. 131, 246–249 (2013)

Xia, L., Rong, J., Yang, H., He, Q., Zhang, D., Hu, C.: NaCl as an effective inducer for lipid accumulation in freshwater microalgae Desmodesmus abundans. Bioresour. Technol. 161, 402–409 (2014)

Li, Y., Horsman, M., Wang, B., Wu, N., Lan, C.Q.: Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl. Microbiol. Biotechnol. 81, 629–636 (2008)

Derenne, S., Metzger, P., Largeau, C., Van Bergen, P.F., Gatellier, J.P., Damste, J.S.S., De Leeuw, J.W., Berkaloff, C.: Similar morphological and chemical variations of in Ordovician sediments and cultured Botryococcus braunii as a response to changes in salinity. Organ. Geochem. 19, 299–313 (1992)

Pancha, I., Chokshi, K., Maurya, R., Trivedi, K., Patidar, S.K., Ghosh, A., Mishra, S.: Salinity induced oxidative stress enhanced biofuel production potential of microalgae Scenedesmus sp. CCNM 1077. Bioresour. Technol. 189, 341–348 (2015)

Yang, H., He, Q., Rong, J., Xia, L., Hu, C.: Rapid neutral lipid accumulation of the alkali-resistant oleaginous Monoraphidium dybowskii LB50 by NaCl induction. Bioresour. Technol. 172, 131–137 (2014)

Ben-Amotz, A., Torbene, T.G., Thomas, W.H.: Chemical profile of selected species of microalgae with emphasis on lipids. J. Phycol. 21, 72–81 (1985)

Hart, B.T., Bailey, P., Edwards, R., Hortlek, K., James, K., McMohan, A., Meredith, C., Swading, K.: A review of the salt sensitivity of the Australian fresh water biota. Hydrobiologia 2, 105–144 (1991)

Banerjee, A., Sharma, R., Chisti, Y., Banerjee, U.C.: Botryococcus braunii: a renewable source of hydrocarbons and other chemicals. Crit. Rev. Biotechnol. 22, 245–279 (2002)

Qin, J.: Bio-hydrocarbons from algae: impacts of temperature, light and salinity on algae growth. A report for the rural industries research and development corporation, Australia (2005)

Metzger, P., Largeau, C.: Chemicals of Botryococcus braunii. In: Cohen, Z. (ed.) Chemicals from microalgae, pp. 205–260. Taylor & Francis, London (1999)

Marquez, F.J., Sasaki, K., Kakizono, T., Nishio, N., Nagai, S.: Growth characteristics of Spirulina platensis in mixotrophic and heterotrophic conditions. J. Ferment. Bioeng. 5, 408–410 (1993)

Ogbonna, J.C., Tanaka, H.C.: Cyclic autotrophic/heterotrophic cultivation of photosynthetic cells: a method of achieving continuous cell growth under light/dark cycles. Bioresour. Technol. 65, 62–72 (1998)

Villarejo, A., Orús, M.I., Martínez, F.: Coordination of photosynthetic and respiratory metabolism in Chlorella vulgaris UAM 101 in the light. Physiol. Plant. 94, 680–686 (1995)

Martínez, M.E., Camacho, F., Jimnez, J.M., Espinola, J.B.: Influence of light intensity on the kinetic and yield parameters of Chlorella pyrenoidosa mixotrophic growth. Process Biochem. 32, 93–98 (1997)

Jiang, L., Luo, S., Fan, X., Yang, Z., Guo, R.: Biomass and lipid production of marine microalgae using municipal wastewater and high concentration of CO2. Appl. Energy 88, 3336–3341 (2011)

Schenk, P.M., Hall, S.R.T., Stephens, E., Marx, U.C., Mussgnug, J.H., Posten, C., Kruse, O., Hankamer, B.: Second generation biofuels: high-efficiency microalgae for biodiesel production. Bioenergy Res. 1, 20–43 (2008)

Belkin, S., Boussiba, S.: Resistance of Spirulina platensis to ammonia at high pH values. Plant Cell Physiol. 32, 953–958 (1991)

Borowitzka, M.A., Hallegraeff, G.M.: Economic importance of algae. In: McCarthy, P.M., Orchard, A.E. (eds.) Algae of Australia: introduction, pp. 594–622. ABRS, Canberra (2007)

Antolin, G., Tinaut, F.V., Briceno, Y.: Optimisation of biodiesel production by sunflower oil transesterification. Bioresour. Technol. 83, 111–114 (2002)

Acknowledgments

This work was financially supported by the Prince of Songkla University (PSU) and the Thai government under Grant No. AGR560094S. Also thanks to the PSU research and development office (RDO) and Assoc. Prof. Seppo Karrila, Ph.D. (Chem Eng) for suggestions to rectify this article. The first and fourth authors are supported by Thai Research Fund under Grant No. RTA5780002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheirsilp, B., Tippayut, J., Romprom, P. et al. Phytoremediation of Secondary Effluent from Palm Oil Mill by Using Oleaginous Microalgae for Integrated Lipid Production and Pollutant Removal. Waste Biomass Valor 8, 2889–2897 (2017). https://doi.org/10.1007/s12649-016-9751-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9751-6