Abstract

A novel procedure, dispersive solid-phase extraction coupled with ultra-high-performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS), was developed for the determination of eugenol in aquatic products (shrimp, crab, and carp). Aquatic products were extracted with acetonitrile and primarily purified by dispersive solid-phase extraction with graphitized carbon black as absorbent. The pretreated acetonitrile extract was detected by UHPLC-MS/MS. UHPLC was carried out on Dikma Endeavorsil C18 (30 mm × 2.1 mm, 1.8 μm) column eluted by methanol and water (80:20 v/v) at a rate of 0.30 mL min−1. Tandem mass spectrometry was performed by electrospray ionization in negative ion mode to identify and quantify eugenol during multiple reaction monitoring. Under optimized analytical conditions, the matrix-matched spiked calibration sample demonstrates good linearity between 5.0 and 500.0 μg kg−1 with a linear regression coefficient of 0.9996. The average recovery of eugenol from aquatic products is 95.3–103.4% at spiked levels between 5 and 50 μg kg−1 with a relative standard deviation (n = 6) less than 5.4%. The limits of detection and quantification for eugenol were calculated to be 1.47 and 4.91 μg kg−1, respectively. In comparison with those reported, the proposed method has advantages in low detection limit, high recovery, and short analysis time, meeting the requirements for the determination of trace eugenol residue in aquatic products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Eugenol was widely applied in aquatic products because of its antibacterial, antifungal, antioxidant, and other properties (Renault et al. 2011). In order to ensure the integrity of the appearance of live aquatic products, dealers tend to anesthetize fish with eugenol to avoid the danger of colliding in the transportation process (Yang et al. 2016). However, it has also been reported that eugenol leaves a residue on the skin of fish, and finally in human body through food cycle (Daniel and Adam 2015), which is indirectly harmful to the health and life of consumers and the economy of the aquatic products. Therefore, a novel, reliable, sensitive, and efficient method for the determination of eugenol in aquatic products is highly demanded.

There is no maximum residue limit (MRL) for eugenol in the commercial aquatic products in European Union and America, and eugenol is permitted to be used as a kind of stupefacient with MRL of 50 μg kg−1 in the commercial aquatic products in Japan (The Japanese Positive List System 2014). According to Chinese Pharmacopeia 2015, eugenol could be determined by gas chromatography (GC). However, the MRL of eugenol in the commercial aquatic products is not compulsorily demanded in China. Therefore, the detection of eugenol content in varying aquatic products is of considerable importance, and the development of precise methods is imperative.

There are many methods reported for the determination of eugenol, including GC (Liao et al. 2013; Zhang et al. 2015), high-performance liquid chromatography (HPLC) (Vishruta et al. 2013; Yu 2006; Dighe et al. 2005), gas chromatography-mass spectrometry (GC-MS) (Li et al. 2015; Yu 2015), high-performance liquid chromatography-tandem mass spectrometry (HPLC-MS) (Zhang et al. 2012), and high-performance capillary electrophoresis (HPCE) (Lin et al. 2006). Even though these analytical methods for the determination of eugenol remains were developed, the procedures for sample pretreatment are very important to obtain sensitive and accurate results, because the detection of trace amounts of eugenol in aquatic products is difficult.

Samples for the detection of pesticides and veterinary drugs are normally pretreated by liquid-liquid extraction (LLE) (Evita et al. 2015), matrix solid-phase dispersion (MSPD) (Jorge et al. 2016), solid-liquid phase extraction (SLE), solid-liquid phase extraction and solid-phase purification (SLE-SPP), dispersive liquid-liquid microextraction based on the solidification of a floating organic droplet followed (DLLME-SFO) (Sun et al. 2015), etc. As for samples for the detection of eugenol, they are usually pretreated by liquid-liquid extraction (LLE) (Zhang et al. 2012) and solid-phase extraction (SPE) (Yu 2015). SPE is the most frequently employed pretreatment method for the concentration and purification of target chemicals, whose efficiency directly depends on the particle size and the surface area of the sorbent (Sun et al. 2015). Dispersive solid-phase extraction (DSPE) is an alternative to conventional SPE (Zhang and Xu 2014; Xiong et al. 2015), which is based on the addition of sorbent material into the extract of target chemicals to remove the concomitants. DSPE has advantaged over SPE in simple operation, little solvent, safety, and high efficiency, directly applicable to original liquid samples or the solvent extracts of various solid samples (Xu et al. 2016a,b; Ali et al. 2015; Zolfaghar et al. 2016).

Because of its sensitivity, selectivity, and low interference under multiple reaction monitoring (MRM) mode, ultra-high-performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS) is the most suitable technique for multi-residue determination of pesticides and veterinary drugs. Thus, it is widely used in respect of food security check and environment monitoring, etc. (Gao et al. 2015; Li et al. 2016; Pang et al. 2016; Xu et al. 2016a,b). Aimed at a method that not only enrich the trace anesthetic but also reduce the matrix effect effectively, we developed a novel method for the determination of eugenol in aquatic products by DSPE coupled with UHPLC-MS/MS.

In this study, aquatic products (shrimp, crab, and carp) were extracted with acetonitrile. After pretreatment by DSPE with graphitized carbon black (GCB) as adsorbent, the extract was subjected to UHPLC-MS/MS for the identification and quantification of eugenol in spiked and real shrimp, crab, and carp samples. Experimental results validate the feasibility of the proposed method.

Materials and Methods

Materials

Eugenol of 99% purity was purchased from the Agro-Environmental Protection Institute, Ministry of Agriculture (Tianjin, China). Primary secondary amine sorbent (PSA) was obtained from CNW Technologies (CNW, Germany). Octadecylsilane chemical-bonded silica gel adsorbent (C18) and GCB were obtained from Supelco (Supelco, USA). Octanechemical-bonded silica gel adsorbent (C8), amino-bonded silica gel (NH2), Florisil, Al2O3, and silicon dioxide (silicone) were purchased from Agela (Tianjin, China). Microporous membrane (0.22 μm) was obtained from Dikma Technologies (Beijing, China). Methanol and acetonitrile (HPLC grade) were purchased from Fisher Scientific (Fair Lawn, NJ, USA). Crab, shrimp, and carp were purchased from Dongan Market (Daqing, China). Watsons water (Watson Group Hong Kong Ltd., China) was used for UHPLC-MS/MS.

Chromatography Conditions

Chromatographic separation of target analyte was achieved using a Dikma Endeavorsil C18 (30 mm × 2.1 mm, 1.8 μm) with an in-line filter in front of the column. The mobile phase was a mixture of methanol and water (80:20, v/v) with a flow rate of 0.30 mL min−1. The temperature of the column was 30 °C, and the injection volume was 5 μL.

Mass Spectrometry Conditions

The identification and the quantification of eugenol were done with electrospray ionization in negative ion mode (ESI−) with MRM. Typical ion source parameters were set as follows: gas temperature 300 °C, drying gas flow 5.1 L min−1, sheath gas temperature 250 °C, sheath gas flow 11.0 L min−1, nozzle voltage 500 V, capillary voltage 3500 V, and nebulizing gas pressure 35 psi. The collision gas was highly pure nitrogen, and the nebulizer gas as well as sheath gas in the ESI source was normal nitrogen. The collision energy of quantitative ion and qualitative ion was 20 and 32 eV, respectively. The ratio of mass to charge (m/z) for precursor ion was recorded in the range of 0 to 200.

Instrumentation and Software

Chromatographic analysis was performed on 1290-6460 UHPLC-MS/MS system (Agilent Co., USA) equipped with an ESI source and installed MassHunter 6.0 (Agilent Co., USA). Negative ion mode and MRM were applied. The samples were treated with IKA T25 Homogenate machine (Eika Equipment Co., Germany), Z36HK centrifuge (HERNIE Co., Germany), and vorrex-2 vortex agitator (SI Digital Co., USA).

Sample Preparation

Two grams of crab (shrimp or carp) was added into a 50-mL Teflon centrifuge tube, and then, 0.2 g sodium chloride, 1.0 g anhydrous magnesium sulfate, and 15 mL acetonitrile were successively added. After vortex agitating for 1 min, the 50-mL centrifuge tube was centrifuged for 5 min at 10,000 rpm. The upper 5 mL supernatant was further transferred into a 15-mL Teflon centrifuge tube, and then, 100 mg GCB was added. After vortex agitating for 3 min, the 15-mL centrifuge tube was centrifuged for 5 min at 10,000 rpm. The obtained supernatant was filtered through 0.22-μm microporous membrane and then injected into Dikma Endeavorsil C18 column for UHPLC-MS/MS analysis.

Results and Discussion

Optimization of Mass Spectrometry Conditions

One hundred micrograms per liter standard solution of eugenol was prepared and employed to optimize mass spectrometry conditions. Quantitative analysis of eugenol was carried out on UHPLC-MS/MS with methanol and water as mobile phase. Because eugenol is easily ionized by releasing a proton to form anion in water solution, [M-H]− (m/z 163.1) quasi-molecular ion has strong response in negative mode electrospray ionization; thus, [M-H]− was chosen as parent ion, and the m/z was recorded ranging from 0 to 200.

Varying fragmenting voltages (70, 75, 80, 85, 90, 95, 100, 105, 110 V) were investigated on MS2 SIM, and it was found that [M-H]− (m/z 163.1) had the strongest signal when the fragmenting voltage was set to 90 V.

The relationship between collision energy and product ion was studied under collision energy of 15, 20, 25, 30, 35, 40, 45, and 50 eV, respectively. Because of their non-interference and strong signal, two product ions (m/z 163.1/121.1, 163.1/148.1) were chosen for quantitative and qualitative analyses. The quantitative ion (m/z 163.1/148.1) was generated when collision energy was set to 20 eV, and the qualitative ions (m/z 163.1/148.1163.1/121.1) were formed when collision energy was set to 32 eV.

Optimization of Chromatography Conditions

It is well known that the increase in HPLC column temperature would lead to the decrease in retention time. In this work, varying column temperatures (22, 24, 26, 28, 30, 32, and 34 °C) were evaluated in line with the retention time and recovery of eugenol, because the highest recovery was achieved at 30 °C; the column temperature was kept at 30 °C in HPLC analysis.

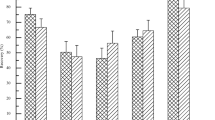

The mobile phase was a mixture of organic phase (acetonitrile or methanol) and Watsons water. It is found that eugenol gained much stronger response in methanol than in acetonitrile system under the same HPLC conditions. Therefore, methanol-water system was exploited as mobile phase in this study. Shown in Fig. 1 is the relationship between the fraction of methanol-water mobile phase and the intensity of eugenol response. It is obvious that the intensity of eugenol response is highest when the fraction of methanol to water is 80:20 (v/v).

When UHPLC-MS/MS is applied to the detection of eugenol with ESI, the flow rate of mobile phase has great effect on the symmetry of eugenol signal peak as well as the recovery of eugenol and then finally affects the accuracy of final result. Normally, the recovery is decreased with the increase in the flow rate of mobile phase. Shown in Fig. 2 is the relationship between the flow rate of methanol-water mobile phase and the symmetry of eugenol signal peak. It could be seen that the symmetry of eugenol signal peak is best when the flow rate is 0.30 mL min−1. Comprehensive consideration of the symmetry of chromatographic peak, the recovery and intensity of eugenol, and the flow rate of mobile phase was finally set to 0.30 mL min−1.

Optimization of DSPE

Methanol and acetonitrile are commonly used for the extraction of eugenol from aquatic products, and their dosage has important effect on the extraction efficiency of eugenol. Shown in Fig. 3 is the relationship between the dosage of extraction solvents (methanol and acetonitrile) and the recovery of eugenol for 2.0 g referring sample. It can be seen that acetonitrile demonstrates higher recovery of eugenol than methanol. Therefore, acetonitrile was proved to be a better extraction solvent for eugenol than methanol. On the other hand, it can also be seen that the recovery of eugenol is highest when 15 mL acetonitrile is used as extraction solvent. Therefore, 15 mL acetonitrile was adopted for 2.0 g sample to be tested in the following analyses.

DSPE is normally employed to purify matrix with PSA, C18, GCB, et al. as sorbents. According to the difference in matrices, some sorbents could get rid of the interference of pigment, organic acid, sugar, and lipid from matrix. It was reported that PSA was a good sorbent to remove sugar, phenols, and fatty acids. In contrast, C18 and GCB were good sorbents to remove fat and pigment from matrix, respectively (Liu et al. 2015a,b). In this work, eight sorbents (PSA, C18, GCB, C8, Al2O3, silicone, NH2, Florisil) were tested to check their recovery capability towards eugenol. The above eight adsorbents were accurately weighed, and 25, 50, 100, 150, 200, and 250 mg of them were put into 48 50-mL centrifuge tubes, respectively. After 5 mL eugenol spiked carp matrix with spiked level of 100 μg kg−1 was added, these centrifuge tubes were subjected to vortex agitating and centrifugation to achieve supernatants for UHPLC-MS/MS analyses. Shown in Fig. 4 is the recovery of eugenol dependence on the kinds and dosages of varying sorbents. In line with their recovery of eugenol, these sorbents could be divided into two groups: group I (PSA, C18, Al2O3, Florisil, and silicone) and group II (GCB, NH2, and C8). Group I displayed much higher adsorption ability towards eugenol than group II, resulting in group II of much higher recovery of eugenol than group I. Moreover, for group I, the recovery of eugenol was successively decreased with the increase of sorbent dosage. In sharp contrast, no obvious recovery of eugenol dependence on the dosage was observed for the sorbents in group II.

In group II, NH2 and C8 nearly have no adsorption towards organism and protein. Thus, they are not applicable to the removal of organic materials. Whereas, GCB not only can remove the pigment in the river crab and shrimp but also can absorb some organic materials. When the GCB-treated samples were subjected to ultraviolet absorption and mass spectrometry analyses, it was found that even though the UV signal decreased obviously, the intensity of total ion chromatogram of eugenol was nearly unchanged. Therefore, GCB was employed as sorbent in our DSPE treatment.

Acetonitrile is soluble in water and easily isolated from its aquous solution by adding sodium chloride and anhydrous magnesium sulfate, leading to higher recovery of eugenol. First of all, the amount of sodium chloride was optimized. When 0.2 g sodium chloride was added to 2 g sample to be tested, 86% eugenol could be recovered. Subsequently, the recovery of eugenol dependence on the dosage of anhydrous magnesium sulfate and sodium chloride was investigated. As can be seen from Fig. 5, the recovery of eugenol was increased to 97% when the ratio of anhydrous magnesium sulfate to sodium chloride is 5:1 (w/w). Therefore, 1.00 g anhydrous magnesium sulfate along with 0.2 g sodium chloride was mixed with 2.0 g samples to be tested before they were subjected to acetonitrile extraction.

Method Validation

The acetonitrile extract of eugenol-free shrimp was taken as matrix and spiked at set concentrations at level of 5, 20, 50, 100, 250, 500, and 1000 μg kg−1 of target eugenol to achieve a series of matrix-matched calibration curves. The linear relationship between the mass spectroscopic peak area (A) and the eugenol concentration in spiked sample (C, μg kg−1) was good in the range of target eugenol of 5–500 μg kg−1, and the linear equation automatically fitted by instrument software was as followed with a correlation coefficient of 0.9996.

Whereas, the limits of detection (LOD) and the limits of quantification (LOQ) were as follows:

where σ is the relative standard deviation (RSD) of blank sample directly obtained by UHPLC-MS/MS analyses and k is the slope of calibration curves. The LOD was calculated to be 1.47 μg kg−1 and the LOQ to be 4.91 μg kg−1 for eugenol in the matrix standards.

To estimate the quantitative accuracy of the proposed method, eugenol-free real samples (crab, shrimp, and carp) were analyzed with spiked concentration levels of 5, 20, and 50 μg kg−1, respectively. Under the optimized conditions established above, the recovery and relative standard deviation of eugenol were calculated and listed in Table 1. It can be seen that the recovery ranges from 95.3 to 103.4% and the RSD from 1.6 to 5.4%.

Matrix Effect

Matrix effect (ME) is mainly owing to the endogenous components of the sample to be tested. Since ESI source is highly susceptible to the endogenous components including natural organic matter, salts, and ion pair reagents in the matrix, the signals from target component might be discriminated or elevated, leading to unfaithful results. Because of such significant interference of the matrix effect to the analysis of the target component, it is imperative to investigate the ME when a novel analytical method is established.

ME in different aquatic products could be calculated by the following equation:

where A, B, and C are signals out from standard solution, real sample, and matrix-matched standard, respectively.

Shown in Table 2 are the calculated results of the ME and the precision (RSD, n = 6) of the proposed method in different aquatic products spiked at three levels. It is obvious that matrix has the strongest discriminating effect on the detection of eugenol for river crab samples, which might be owing to the discrimination out of the coexisting endogenous components on the detection of eugenol. Furthermore, such discriminating effect gets stronger and stronger with the decrease in the spiked concentration level of eugenol. In comparison with that on the detection of river crab sample, matrix has much weaker discriminating or elevating effect on the detection of eugenol for shrimp and carp samples. Among the three aquatic products spiked at three levels, shrimp samples demonstrate the smallest matrix effect (103.6) when the spiked concentration of eugenol is at a level of 20 μg L−1. In this study, the matrix standards were prepared with eugenol-free aquatic products and used to eliminate the ME and to quantitatively analyze the eugenol retained in aquatic products.

Comparison of the Proposed Method with Others

Listed in Table 3 are the experimental results of SPE-GC/MS, RP-HPLC, GC/MS, LC-MS/MS (Dighe et al. 2005; Li et al. 2015; Yu 2015; Zhang et al. 2012), and the proposed method. In comparison with those reported methods for the determination of eugenol, the proposed method has some advantages in lower detection limit, higher recovery rate, and shorter extracting time.

Real Aquatic Product Sample Analysis

To evidence the performance of the present method applicable to the detection of eugenol in aquatic products, real and spiked samples were analyzed with the proposed procedure. The edible sections of crab, shrimp, and carp were ground with a machine and then accurately weighted. After the pretreatment processing as described above in the section of sample preparation, these samples were subjected to UHPLC-MS/MS analyses under the optimized chromatography and mass spectrometry conditions. Shown in Fig. 6 are the MRM chromatograms of crab, shrimp, carp, and eugenol reference standard samples. It can be seen that eugenol is not detectable in the market crab, shrimp, and carp. Furthermore, the recovery of eugenol reference standard samples is good enough for the analysis of eugenol, indicative of the accuracy and reliability of the proposed method.

Conclusion

A method combined DSPE with UHPLC-MS/MS was developed for the determination of eugenol in aquatic products. Among the eight adsorbents applied in the DSPE procedure, GCB displayed specially high efficiency to remove organic materials. The identification and the quantification of eugenol by UHPLC-MS/MS evidence that the advantages of the proposed method lie in low detection limit, high recovery, and short analysis time, offering a novel and applicable procedure for the analysis of trace eugenol in aquatic products.

References

Ali AAN, Nina N, Mir AF (2015) Determination of three antidepressants in urine using simultaneous derivatization and temperature-assisted dispersive liquid-liquid microextraction followed by gas chromatography-flame ionization detection. Biomed Chromatogr 29:1094–1102

Daniel C, Adam PMJ (2015) Evaluation of different concentration doses of eugenol on the behaviour of Nephrops norvegicus. Aquaculture 442(1):78–85

Dighe VV, Gursale AA, Sane RT, Menon S, Patel PH (2005) Quantitative determination of eugenol from Cinnamomum tamala Nees and Eberm leaf powder and polyherbal formulation using reverse phase liquid chromatography. Chromatographia 61:443–446

Evita B, Rosmalina RT, Yohanes SR, Willy CN, Retno Y (2015) Development of validated method using QuEChERS technique for organochlorine pesticide residues in vegetable. Procedia Chemistry 16:229–236

Gao J, Wang J, Zuo M, Ma J, Cui J (2015) A highly sensitive method for simultaneous determination of the quaternary ammonium pesticides chlormequat and mepiquat in pears and potatoes by modified QuEChERS-high performance liquid chromatography-tandem mass spectrometry. RSC Adv 5:5895–5903

Jorge Y, Paula R, Mansilla HD, Bravo M, Quiroz W (2016) Speciation analysis of organotin compounds (OTCs) by a simultaneous hydride generation-liquid/liquid extraction and GC-MS determination. Microchem J 126:460–465

Li JC, Zhang J, Liu Y (2015) Optimization of solid-phase-extraction cleanup and validation of quantitative determination of eugenol in fish samples by gas chromatography-tandem mass spectrometry. Anal Bioanal Chem 407:6563–6568

Li WW, Marsha MK, Graham SE, Starr JM (2016) Measurement of pyrethroids and their environmental degradation products in fresh fruits and vegetables using a modification of the quick easy cheap effective rugged safe (QuEChERS) method. Talanta 151:42–50

Liao HY, Zhu LJ, Zhuang YD, Li CJ, Zhang Y, Han KD (2013) Determination of eugenol in mainstream cigarette smoke by gas chromatography-mass spectrometry. Chinese Journal of Tobacco Science&Technology 9:68–71

Lin WF, Wu XL, Chen ZG, Li QW, Cai PX, Mo JH (2006) Determination of eugenol in several Chinese herbal medicines by capillary electrophoresis with high frequency conductivity method[J]. Chem J Chin Univ 27:2070–2072

Liu J, Tong L, Meng W, Zhao Y, Yu Z (2015a) Determination of 135 pesticides and their metabolites in Angelica sinensis by ultra-fast liquid chromatography-tandem mass spectrometry coupled with solid-phase extraction. Chin J Chromatogr 33:1257–1268

Liu T, Yang D, Dong M et al (2015b) Determination of pyrethroid residues in fresh tea leaves by dispersive solid phase extraction and gas chromatography[J]. Chinese Journal of Pesticide Science 17:571–578

Pang NN, Wang TL, Hu JY (2016) Method validation and dissipation kinetics of four herbicides in maize and soil using QuEChERS sample preparation and liquid chromatography tandem mass spectrometry. Food Chem 190:793–800

Renault S, Daverat F, Pierron F, Gonzalez P, Dufour S, Lanceleur L, Schäfer J, Baudrimont M (2011) The use of eugenol and electro-narcosis as anaesthetics: transcriptional impacts on the European eel (Anguilla anguillaL). Ecotoxicol Environ Saf 74:1572–1577

Sun J, Xu X, Li CM, Luo Q, Wang DH (2015) Simultaneous determination of thirty-five pesticides and transformation products in surface water using solid phase extraction combined with ultra-performance liquid chromatography-tandem mass spectrometry. Chin J Anal Chem 43:1145–1153

The Japanese Positive List System for Agricultural Chemical Residues in Foods (2014) MRLs updated on January, http://www.ffcr.or.jp/zaidan/FFCRHOME.nsf/pages/MRLs-p

Vishruta DT, Rojison K, Monica K, Anand S, Laxman P, Murali B (2013) A validated RP-HPLC-UV/DAD method for simultaneous quantitative determination of rosmarinic acid and eugenol inOcimum sanctum L. Original article 4:1–5

Xiong W, Cheng CS, Yang YL (2015) Determination of total chromium in tea samples bysuspension dispersive solid phase extraction combined with silver nanoparticles and using flame atomic absorption spectrometry. Anal Methods 7:2093–2099

Xu X, Long N, Lv JN, Wang LL, Zhang MH, Qi XY, Zhang L (2016a) Functionalized multiwalled carbon nanotube as dispersive solid-phase extraction materials combined with high-performance liquid chromatography for thiabendazole analysis in environmental and food samples. Food Anal Methods 9:30–37

Xu X, Zhang XM, Duhoranimana E, Zhang Y, Shu P (2016b) Determination of methenamine residues in edible animal tissues by HPLC-MS/MS using a modified QuEChERS method: validation and pilot survey in actual samples. Food Control 61:99–104

Yang YB, Xia YT, Ai XH, Yang XL (2016) Anaesthetic efects of eugenol on Acipenser gueldenstaedti. Chinese Fishery Quality and Standards 6:17–21

Yu XP (2006) HPLC determination of the content of camphor and eugenol in Tincture camphor and chloral hydrate. Chinese Journal of Pharmaceutical Analysis 26:1835–1837

Yu Y (2015) Determination of eugenol residue in fish meat by gas chromatography-mass spectrometry. Chinese Journal of Fuzhou University (Natural Science Edition) 43:266–270

Zhang Y, Xu H (2014) Determination of triazoles in tea samples using dispersive solid phase extraction combined with dispersive liquid-liquid microextraction followed by liquid chromatography-tandem mass spectrometry. Food Anal Methods 7:189–196

Zhang Z, Ren F, Zhang P (2012) Determination of capsaicinoids and eugenol in waste-edible-oil by liquid-liquid extraction and liquid chromatography tandem mass spectrometry. Chin J Chromatogr 30:1108–1112

Zhang XX, Liang JR, Zhao WN, Hao QF, Sun WJ, Wang Y (2015) Determination of cinnamaldehyde and eugenol in Ruikeweirui disinfectant fluid by GC method. Chinese Journal of Northwest University (Natural Science Edition) 45:257–260

Zolfaghar A, Alireza F, Mohammad B (2016) Efficient sample preparation method based on solvent-assisted dispersive solid-phase extraction for the trace detection of butachlor in urine and waste water samples. J Sep Sci 00:1–8

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This work was funded by Scientific Planning Guide Project of Daqing (No. szdfy-2015-50) and the School Cultivation Subject of Heilongjiang Bayi Agricultural University (No. XZR2014-17).

Conflict of Interest

The authors indicate that they have no financial relationship with the organization that sponsored the research. Peng Sun declares that he has no conflict of interest. Yuling Gao declares that she has no conflict of interest. Yongfu Lian declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Sun, P., Gao, Y. & Lian, Y. Determination of Eugenol in Aquatic Products by Dispersive Solid-Phase Extraction and Ultra-High-Performance Liquid Chromatography-Tandem Mass Spectrometry. Food Anal. Methods 10, 3217–3224 (2017). https://doi.org/10.1007/s12161-017-0882-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0882-6