Abstract

The immobilization of S. passalidarum in calcium alginate beads for second-generation ethanol production (2G ethanol) was evaluated in a medium that simulated a hemicellulosic hydrolysate of sugarcane bagasse pretreated with diluted sulfuric acid in terms of sugar composition. Three sets of sequential batch fermentations (SBF) were carried out with free cells or immobilized cells in high (HSC) and moderate (MSC) initial sugar concentration (120 and 70 g/L, respectively). SBF were characterized by five consecutive batches performed in shaker, at 30 °C and 110 rpm. Better results were observed for the SBF with immobilized cells in MSC medium when compared to HSC (Y’P/S of 0.27 ± 0.02 and 0.19 ± 0.03 g/g, respectively), in the second batch cycle. The value for YP/S in MSC was similar to the obtained with free cells (0.30 ± 0.02 to 0.33 ± 0.02 g/g). However, QP was lower for MSC with immobilized cells, reaching 0.81 ± 0.04 g/L.h in the second batch, while for free cells the QP varied from 1.06 ± 0.02 to 1.16 ± 0.22 g/L.h. A technique for determining the concentration of immobilized cells in the alginate beads was applied, which made it possible to determine the specific rates for the SBF performed. According to the results obtained, it was possible to demonstrate that S. passalidarum can be immobilized in calcium alginate and reused through SBF, with performance similar to free cells, which can be a good strategy for fermentation of hemicellulosic hydrolysates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ethanol from lignocellulosic biomass — called second-generation ethanol (2G ethanol) — has been identified as an interesting alternative to the use of fossil fuels and a viable option to increase fuel production without exploring food feedstocks nor expand the cultivated area [1, 2]. The production of 2G ethanol is divided into four main stages: (1) pre-treatment, (2) hydrolysis, (3) fermentation, and (4) distillation. The pre-treatment with diluted sulfuric acid is one of the treatments used in industry and consists in the solubilization of hemicelluloses, ensuring high recovery of pentoses in the liquid fraction (hemicellulosic hydrolysate) and obtaining a pulp rich in cellulose and with a high content of lignin (cellulignin) [3]. This solid fraction can be hydrolyzed to obtain a liquor rich in glucose that is easily fermented by Saccharomyces cerevisiae yeasts; however, the fermentation of hemicellulosic hydrolysate, whose sugar composition is about 65–85% xylose and 15–35% glucose, is a bottleneck in the 2G process [4]. Hemicellulosic hydrolysate obtained from sugarcane bagasse pretreated with 0.5% (v/v) of sulfuric acid solution was characterized as the following composition (g/L): 3.60 glucose, 25.14 xylose, 2.37 arabinose, 3.94 acetic acid, 0.45 furfural, 0.23 formic acid, and 0.15 coumaric acid [5].

Since hemicellulosic hydrolysate sugar composition is mostly xylose, the application of xylose-fermenting yeasts, such as Spathaspora passalidarum, is necessary in order to use this fraction of the process. S. passalidarum is found in nature in symbiotic associations with wood-boring beetles and is able to metabolize xylose, cellobiose, glucose, and maltose. This yeast is capable of fermenting xylose in media with different dissolved oxygen conditions (anaerobic or microaerobic), in addition to co-fermenting the other sugars mentioned [6], and has demonstrated great potential in the production of 2G ethanol, mainly due to its capacity to consume xylose at higher rates and present better performance in hemicellulosic hydrolysates when compared to other xylose-fermenters yeasts [7,8,9,10]. However, xylose uptake rate is still slow thus, operating in systems with high cell density and that promote the reuse of these cells could increase productivity and contribute to increasing the rate of xylose consumption [11]. Moreover, S. passalidarum is a Crabtree-negative yeast which means that the excess of aeration causes the increase of cell production, as a result of the favor of oxidative pathway and detrimental effect on ethanol production [12]. Furthermore, the catabolic repression effect, characterized by sequential consumption of glucose followed by xylose, is reported in the literature for this microorganism [7, 12, 13] and has been widely discussed for fermentations with S. passalidarum in which glucose and xylose are used as the main carbon sources [14]. Catabolic repression is observed in the metabolism of most microorganisms and is the phenomenon that occurs when the consumption of glucose present in the medium prevents the expression of genes that encode enzymes for the metabolization of other sugars [15]. This is an issue that must be solved to improve the 2G ethanol production process, and the results obtained for immobilized cells are promising for this purpose.

The use of S. passalidarum for the industrial production of bioethanol follows some other challenges such as the possibility of contamination by other microorganisms, as reported by Collograi et al. [16], and the need for specific nutrients during fermentation in order to increase production, such as yeast extract. Another difficulty is the need for aeration during the process, as observed by Bonan et al. [12] in which the concentration of oxygen available in the fermentation medium is very important for the production of ethanol, as result of Crabtree-negative characteristics, and this factor can make the process more expensive [3]. Furthermore, one of the biggest challenges in using hemicellulosic hydrolysate is the presence of inhibitors, such as acetic acid, furfural, hydroxymethylfurfural, and phenolic compounds, that hinder its fermentation. These compounds act in different ways in cell metabolism by decreasing the energy for growth and production, causing interference in enzyme activity, damaging the cell membrane, and resulting in the death of microorganisms [17,18,19,20]. Soares et al. [10], for example, highlighted the strong inhibition of acid acetic and furfural on S. passalidarum, and Morales et al. [21] even tried to develop a more robust strain to overcome acetic acid inhibition. Detoxification, high cell density, fed batch processes, genetic engineering, and cell immobilization have been used as strategies in the 2G ethanol industry, aiming to minimize the effect of inhibitors in the fermentation process [20, 22] and to contribute for high xylose uptake rate, by allowing higher cell densities application [23]. Immobilization protect cells against toxic compounds, in addition to improving aspects that are often limiting, such as long operating times, stability, difficulty in recovering and reusing microorganisms, and better functionality in continuous systems [24, 25].

Immobilization can occur through covalent bonding, adsorption or entrapment processes. The method of entrapment is based on the physical trapping of cells within the interior of the matrix [26]. This methodology is the most used because it is simple to perform, capable of retaining a large number of cells in a small volume, besides presenting low toxicity for them. However, there are negative points in the use of this methodology, such as diffusion of substrates and metabolic products through the support and reduction of conversion rates. Thus, it is necessary to optimize the particle size of the support, the diffusivity of the species, and the cellular concentration in order to minimize these effects [27]. The matrix most used for cell immobilization is calcium alginate, due to its biocompatibility and the speed in the gelling process. This material is extracted from seaweed and is composed of D-mannuronic (M) and L-guluronic (G) acids joined by glycosidic bonds. The proportion and distribution of components are determining factors for the mechanical and gelling properties of the formed gel [26, 28]. The beads of calcium alginate are formed by emulsification or extrusion. The procedure for obtaining the beads starts with the preparation of the mixture of cell suspension and sodium alginate (2–4% w/v). Then, this mixture is dripped in calcium chloride (20–100 mM), which is the gelling solution. The interaction between sodium alginate and calcium chloride promotes the formation of beads [29].

Studies have been carried out using the immobilization of microorganisms to improve the process of obtaining 2G ethanol, using both synthetic mediums and hydrolysates. Milessi et al. [23] evaluated the behavior of free and immobilized S. cerevisiae T18 in synthetic xylose combined to different acetic acid concentrations (0 to 8 g/L). They observed that immobilized cell performance was in general superior, and acetic acid effect was reduced. Moreover, fermentation time decreased from 120 h, for free cells, to 12 h, for immobilized cells, and when immobilized T18 yeast was recycled, 10 batches were performed without reduction in ethanol and productivity (17 g/L of ethanol and yield of 0.44 g/g). Talebnia et al. [30] studied the performance of S. cerevisiae CBS 8066 in a synthetic glucose medium in 10 sequential batches. Ethanol productivity did not suffer any variation throughout batches and was 5.15 ± 0.17 g/L.h. Mishra et al. [31] immobilized S. cerevisiae in calcium alginate beads and performed fermentations using non-detoxified rice straw hydrolysate. The results showed that the immobilization resulted in the stability of the process between the third and the 17th cell recycling, reaching good parameters of the fermentation (approximately 30 g/L of ethanol with 90% yield). Pathania et al. [32] used a co-culture of S. cerevisiae and Scheffersomyces stipitis immobilized in sodium alginate beads to ferment apple pomace hemicellulosic hydrolysate. The authors compared the immobilized cells and free cell fermentations and found that there was an increase of approximately 30% in the final concentration of ethanol when the process was carried out with immobilized cells. Fermentation yield was also improved with immobilized cells, resulting in a 58% yield, against only 45% for free cells.

Cell immobilization has potential to be an alternative to overcome the existing challenges in process for obtaining 2G ethanol, like the necessity of aeration, the need for cell robustness against hemicellulosic hydrolysate inhibitors [3], and the increase in xylose uptake rate [33], since this strategy promote protection from the action of toxic compounds [2], improving sugar consumption while decreasing catabolic repression [34]. Besides it allows the use of high cell concentration and easier cell reutilization [31, 35]. The objective of this study was to immobilize S. passalidarum for the first time, in calcium alginate beads, apply it in five sequential batches fermentation of synthetic medium that simulate hemicellulosic hydrolysate sugar proportion — moderate (MSC) and high (HSC) sugar concentration —, analyze sugar uptake rates and ethanol production as well as other fermentation parameters, and compare results to a free cell experiment (in MSC).

Materials and Methods

Microorganism Strain

The strain used was Spathaspora passalidarum NRRL Y-27907 [36]. The microorganism was stored in YPDX medium (1% yeast extract; 2% peptone; 1% dextrose; and 1% xylose, in w/v) with glycerol (1:1 v/v) at − 80 °C.

Cell Propagation for a High Cell Density Yeast Solution

S. passalidarum was reactivated by adding 2 mL of stock cells in 0.1 L of YPDX medium, and incubated for 24 h, at 30 °C and 150 rpm (Tecnal — TE424) [37]. After that, 15 mL of this culture (corresponding to 10% of total volume) were transferred to the inoculum medium containing (g/L): 5 yeast extract, 5 peptone, 1.32 dextrose, 12 xylose, 2.3 urea, 2 KH2PO4, and 0.3 MgSO4.7H2O [37] and incubated under the same conditions [37]. The propagation occurred in, approximately, thirty 0.5 L Erlenmeyer flasks with 0.2 L of working volume. The medium composition was adapted based on Santos et al. [37], and contained (g/L) 30 glucose, 3 yeast extract, 5 peptone, 30 dextrose, 5 urea, and 2 KH2PO4. Propagation was carried out at 150 rpm, 30 °C and 40 h with a pulse of 15 g/L of glucose at 15 h. After finishing this process, the entire volume was separated by centrifugation (Quimis Q222T) at 3000 × g for 5 min. Supernatant was discarded and biomass washed with sterile distilled water and then separated again under the same conditions. The concentrated cells were resuspended in sterile distilled water and stored under refrigeration for later use. The concentration of the resulting cell suspension after centrifugation step was 142 g/L.

S. passalidarum Immobilization in Calcium Alginate

An amount of 35 mL of cell suspension obtained in the propagation system was added to 25 mL of 4.8% sodium alginate sterile solution, resulting in a solution with 2% alginate and a total cell mass of 4 g, corresponding to 20 g/L of cells in the fermentation. This mixture was dripped (2 mL/h) with a 3-mm internal diameter silicone hose and a peristaltic pump (Watson-Marlow 120S) in 2% CaCl2 to produce the beads [38,39,40]. Beads were kept in 2% CaCl2 solution for 16 h to cure [31]. Afterward, the alginate beads were washed with sterile distilled water and used for fermentation and recycling. The beads obtained from the 60 mL mixture were counted, resulting in 940.

Sequential Batch Fermentation with Cell Recycling

Two sets of sequential batch fermentations (SBF) were performed by using immobilized S. passalidarum cells and one with free cells. The first set for immobilized cell fermentations was based on high initial sugars content (HSC) with, approximately 120 g/L of sugars (Table 1). The second one with moderate initial sugars (MSC) had approximately 70 g/L of sugars (Table 1). SBF with free cells had ~ 85 g/L of initial sugar content (Table 1). Five sequential batch fermentations were carried out in 500-mL Erlenmeyer flasks (in triplicate for immobilized cells and duplicate for free cells), with 200 mL of working volume for all conditions tested. The initial concentration of cells in the fermentation medium was defined as 20 g/L for all conditions tested, and the composition of the medium to HSC, MSC immobilized and free cells SBF was (g/L): 3.0 yeast extract, 2.3 urea, 0.1 CaCl2, and 1.0 MgSO4.7H2O. Sugar content for HSC and MSC were based on Nikolic et al. [28] and Neitzel et al. [11], respectively. A proportion of around 30% glucose and 70% xylose was applied in all fermentations according to Neitzel et al. [11], with the aim to simulate sugars content of hemicellulosic hydrolysate obtained from sugarcane bagasse sulfuric acid pre-treatment [41]. Sugar content for each SBF performed is presented in Table 1.

Sixty mL of cell immobilized beads were used in 200 mL of useful volume, based on Mishra et al. [31]. SBF were carried out in a shaker (Tecnal TE-424), at 30 °C, 24 h, according to Neitzel et al. [11] and Bonan et al. [14] and 110 rpm, according to Su et al. [42]. At the end of each batch with immobilized cells, beads were separated with a sieve and washed with distilled water and then added in a new medium to perform the next batch. For free cell fermentation, the medium was centrifuged (Quimis Q222T, 3000 × g), precipitated material was washed as described before, supernatant was discarded, and the biomass was added in a new medium to perform the next batch.

At each fermentation, samples were collected at times 0, 6 (only for MSC immobilized cells fermentations), 12, 18, and 24 h for analytical sugar and products determinations by high performance liquid chromatography (HPLC) [37] and pH. The immobilized cell concentration was determined at the beginning and end of each batch as described in the next topic. At the end of batches 3 and 5, beads were sampled for morphological analysis in a scanning electron microscope (SEM).

Determination of Immobilized Cell Concentration by Spectrophotometry

The concentration of immobilized cells within calcium alginate beads at the initial (0 h) and final (24 h) time of each batch was determined by dissolving 5 beads into 10 mL of 1% sodium citrate [43]. The spectrophotometer (Hitachi U-2900) was used to determine the absorbance of prepared mixtures at 600 nm wavelength. From this data, the cell mass contained into the 5 beads sampled could be achieved using Eq. 1.

where m5 is the cells mass in 5 beads, AbsM is the mixture absorbance, FD is the dilution factor, \({abs}_{B}\) is the blank absorbance, VM is the mixture volume (0.01 L), and 0.2305 is the standard curve decline.

To determine the cell concentration of samples collected during fermentation, Eq. 2 was used.

where the number of total beads is 940, the number of sampled beads is 5, and VF is the total fermentation volume (0.02 L).

Determination of Free Cell and Analyte Concentration

Free cell concentration was determined by spectrophotometer at 600 nm wavelength. Based on a standard absorbance versus dry cell weight relation previously established by our team, it was possible to estimate dry cell weight content. The concentrations of xylose, glucose, ethanol, acetic acid, xylitol, and glycerol were determined by HPLC as described by Bonan et al. [14]. For this purpose, the samples of the fermentation medium were centrifuged at 8000 × g for 10 min, and the supernatant was separated and filtered on 0.22 µm filters (PVDF membrane) for analysis in the liquid chromatograph (LC-20A Shimadzu). The technique was performed using an Aminex HPX-87H column (300 mm × 1.00 UM, 7.8 mm × 9 µm, Bio-Rad), with a flow of 0.6 mL/min and with detector and column temperature equal to 50 °C and 5 mM sulfuric acid solution as mobile phase.

Morphological Analysis of Calcium Alginate Beads

The morphology of calcium alginate beads containing the S. passalidarum cells was analyzed by scanning electron microscopy (SEM). The preparation of beads consisted of submersion in 2.5% glutaraldehyde for 2 h to fix the cells and washed with phosphate-buffered saline (PBS) solution. Afterwards, they were dehydrated with ethanol solution (10, 30, 50, 70, 80, 90, and 100%) for 20 min each [44]. Posteriorly, samples were dried using critical point dryer equipment (Leica), and they were mounted on a carbon tape under aluminum stubs and covered with a thin layer of gold. The evaluation of beads was carried in a Jeol scanning electron microscope, model JSM – 6390 LV from the Central Laboratory of Electronic Microscopy (LCME) of the Federal University of Santa Catarina, using micrographs at magnifications between 25 and 5000 × , and electron beams with 10 kV of energy. Image J® software was used for measuring beads pores sizes. The pore diameters were determined by measuring 20 pores for the controls and 50 pores for batches 3 and batches 5 experiments.

Fermentation Kinetic Parameters

The ethanol yield factor (YP/S, g/g) was calculated by ethanol produced (g/L), which corresponds to the difference between final and initial ethanol concentration divided by the sugars consumed (g/L). The modified yield factor (Y’P/S, g/g) was calculated by ethanol produced (g/L) divided by the initial sugar concentration (g/L). The cell yield factor (YX/S, g/g) was calculated by cell produced, which corresponds to the difference between final and initial cell concentration, divided by the sugars consumed. The theoretical percentage yields (ɳ, %) was calculated from the yield factor divided by the theoretical yield of ethanol production (0.511 g/g), multiplied by 100. Ethanol productivity was calculated by metabolite produced (g/L) divided by the fermentation time (h). The specific rates (µXyl, µGlu and µEtOH, g/g.h) were calculated by a second-degree polynomial arrange for each component and divided by the cell concentration on that time. The kinetic data of the fermentations were submitted to analysis of variance (ANOVA), and the means were compared by the Tukey test (p < 0.05), using OriginPro software 8.5 (OriginLab, USA).

Results and Discussion

SBF with Immobilized and Free S. passalidarum Cells

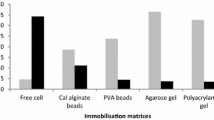

Figure 1 shows the concentration profiles of glucose, xylose, cells, and ethanol for SBF with free cells (Fig. 1a) and immobilized cells (Fig. 1b and c). The cell concentration for the immobilized cells is presented as total cells in the fermentations, which corresponds to the sum of the immobilized cells inside the calcium alginate beads and the cells suspended in the medium (desorbed). In this section, a comparison between free (Fig. 1a) and immobilized cells fermented at moderate (MSC) initial sugar concentration (Fig. 1b) will be made, due to similar initial sugar concentration of these two sets of SBF (~ 70 and ~ 85 g/L) and similar proportion between glucose and xylose (~ 0.21 ± 0.01 and ~ 0.31 ± 0.02). It is possible to observe that glucose was totally consumed in all conditions and all batches (Fig. 1). The simultaneous consumption of xylose and glucose was observed for fermentation with immobilized cells (Fig. 1b) between 0 and 6 h of fermentation. This behavior was observed only for this condition due to the greater number of samples collected, which does not discard the possibility that the same behavior may have occurred in fermentations with free cells. Long et al. [36] and Hou [22] reported the same behavior for sugar consumption, who used free cells of S. passalidarum at the initial concentration of 1.23 g/L. However, the effect of catabolite repression, characterized by the sequential consumption of glucose and xylose, is reported in the literature for this microorganism [23, 34, 40, 41]. Catabolite repression is observed in the metabolism of most microorganisms and is the phenomenon that occurs when the consumption of glucose present in the environment prevents the expression of genes that encode enzymes for the metabolization of other sugars [15].

In Fig. 1a it is still possible to observe that xylose consumption was practically complete for SBF with free cells in MSC, with the maximum value for residual sugar being 4.33 ± 0.25 g/L in B1. In contrast, 24 h of fermentation was not sufficient for the complete consumption of xylose for SBF in MSC with immobilized cells, with a maximum residual sugar of 29.54 ± 2.50 g/L in B5 (Fig. 1b). For the assay with free cells, the reuse of the cells seems to have improved xylose consumption, since in B1 there was residual xylose and in B2 this sugar was consumed after 18 h, while from B3 to B5 the complete consumption of xylose occurred before 18 h of fermentation. This behavior was not observed for SBF in MSC with immobilized cells (Fig. 1b), in which the reuse of the cells hindered the consumption of xylose, causing incomplete sugar consumption over the course of the batches. A possibility to try and bypass the incomplete sugar consumption could be letting the experiment run longer than 24 h in each batch.

The final concentration of ethanol obtained for SBF (Table 2) was higher for the free cells, when compared to MSC immobilized cells and reaching its maximum value in B1 (35.5 ± 0.01 g/L). The concentration was slightly lower in the other batches, but remained approximately constant, ranging from 29.82 to 31.43 g/L. For SBF with immobilized cells (Fig. 1b), the highest concentration obtained was in B2 (21.60 ± 1.34 g/L), with a decrease in subsequent batches. It was possible to observe that the ethanol production profile for free cells changes when sugar consumption changes from glucose to xylose, which does not happen with immobilized cells, which remain at the same production rate (slope of ethanol production).

According to Ndubuisi et al. [45], although immobilization in calcium alginate gives advantages to the fermentation process, such as ease of reuse and cell protection against inhibitors and stressful environmental conditions, the support may present resistance to mass transfer, making it difficult to use for many batches. It could explain the difference between the consumption of sugars between SBF with free cells and immobilized cells, as well as the difficulty in metabolizing xylose for fermentation with immobilized cells, highlighted in the final batches (B4 and B5). Mass transfer can be hampered by immobilization in alginate, impairing the transport of substrate. Portugal-Nunes et al. [46] investigated the effect of S. stipitis immobilization for ethanol production. They reported that the calcium alginate support limited the mass transfer based on the difference in glucose uptake rate between the free and immobilized cell fermentations. According to these authors, the glucose uptake rate was 1.5 times higher for free cells in relation to immobilized cells.

Another important nutrient for 2G ethanol production by S. passalidarum that deserves attention is oxygen. Microorganisms that have the Crabtree effect produce ethanol when sugar concentrations are high, even in aerobic conditions. S. passalidarum is a Crabtree-negative yeast, and cell production increases with higher aeration, and the choice to produce ethanol or cells depends on the concentration of O2 available to the cells [12, 47]. In this sense, Table 2 also presents YX/S for MSC immobilized and free cell fermentations. The values were calculated by the ratio between cells produced and substrate consumed. For MSC immobilized cells, the parameter was separated, using cell concentrations from Fig. 2, in order to specify the growth of immobilized cells inside the beads and free cells in the medium (the ones that leaked from beads). YX/S for MSC free cell fermentations decreased during the batches as they reached 0.04 ± 0.01 g/g in B1 and 0.01 ± 0.01 g/g in B5 (Table 2). An opposite behavior was observed for MSC immobilized fermentations, in which YX/S increased from 0.03 ± 0.00 to 0.15 ± 0.05 for free cells (the ones that leaked from beads) and from 0.03 ± 0.00 to 0.10 ± 0.03 for immobilized cells, showing that sugars deviated from ethanol production to cell growth in a more expressive way in this experiment. It is possible that alginate beads improved oxygen transfer coefficient, kLa, in the Erlenmeyer flasks, as they acted as impellers and assisted in the oxygen solubilization. Moreover, each batch was performed with a new medium that also had dissolved oxygen, and flasks were open for sampling, thus introducing oxygen into the system. According to Sarrouh and da Silva [48], supports with high density influence break down oxygen bubbles formed in the fermentation medium and improve oxygen transfer rate, explaining why YX/S values were higher in MSC immobilized fermentations than MSC free cells. Bonan et al. [14] highlighted that S. passalidarum metabolic pathways are affected by the excess of oxygen in the medium combined with the Pasteur effect, where there is a deviation of sugars from ethanol production to cell growth, caused by the reduction of glycolytic pathway flux. The higher the YX/S value, the higher is the deviation of sugars between metabolic paths. Also, the increase in YX/S for MSC confirms the cell growth differences observed in Fig. 2, where B5 reached the highest cell concentration when compared all batches.

Cell concentration for SBF with free cells (Fig. 1a) was approximately 20 g/L at the beginning of B1. Low cell growth was observed in the five SBF with free cells, and all SBF showed constancy for the initial cell concentration (approximately 20 g/L), probably due to O2 limitation caused by bioreactor choice (shaker) [10, 47]. It is important to highlight that there was no purge in SBF with free cells, and all the cells present in the previous batch were transferred to a subsequent batch.

Cell concentration for SBF with immobilized cells (Fig. 2) showed an increase in free cells higher than that observed for the free cells system (Fig. 1a). This behavior may have occurred due to the leakage of the cells closer the surface of the support, and subsequently budding when these cells are free in the culture medium, where O2 availability probably was superior to the O2 supply inside alginate beads pores.

Table 2 shows the kinetic parameters of SBF with free cells and immobilized cells in MSC. For SBF with immobilized cells, it is possible to observe that the first three batches (B1, B2, and B3) did not present significant differences between them, but B4 and B5 were different the first batches and between themselves in relation to sugar consumption. It is also possible to notice the decrease in the percentage of sugar consumption with the increase in the number of batches.

The ethanol concentration produced (Table 2) for SBF with free cells did not show any significant difference between them. There was an increase in ethanol concentration from B1 to B2 (13.76 ± 1.34 g/L and 21.59 ± 1.34 g/L, respectively) in SBF for immobilized cells in MSC; however, the concentration reached levels close to B1 for cycles B3, B4, and B5. The best results were observed for SBF with cells that have already undergone at least one reuse in batches, similar to that reported by Lee et al. [38], who studied the production of first-generation ethanol by S. cerevisiae cells immobilized in 2% (w/v) calcium alginate. These authors reused the immobilized cells for five successive batches and compared the assay using free cells. They observed that among the five batches with immobilized cells, the best results were obtained in B3, which had a shorter fermentation time (10 h) and a 100% substrate-to-product conversion factor the theory stoichiometry, 1.13 times greater than for free cells. Neitzel et al. [11] reported improved ethanol production and xylose specific uptake rate by S. passalidarum free cells in fermentations carried out during five repeated fed-batch fermentation with a medium simulating hemicellulosic hydrolysate in sugar content and proportions.

By analyzing the results presented in Table 2, YP/S and QP for SBF with free cells did not show a significant difference between batches, ranging from 0.30 ± 0.06 to 0.33 ± 0.02 g/g and 1.06 ± 0.02 to 1.16 ± 0.22 g/L.h, respectively. Yield also showed no significant difference and remained in the range of 58.07 ± 3.70 to 65.40 ± 3.68% for these fermentations. Neitzel et al. [11] carried out successive fed-batch fermentations with free cells (initial cell concentration of 90 g/L) of S. passalidarum. They observed significant differences in kinetic parameters along fed-batches, and values for YP/S and QP were 0.39 to 0.46 g/g.L and 1.29 to 1.79 g/L.h for first and fifth fed-batches, respectively [11]. In the present work, SBF with immobilized cells in MSC attained the highest YP/S and QP in B2, 0.30 ± 0.02 g/g and 0.81 ± 0.04 g/L.h, significantly different from the values obtained in the other batches (Table 2). In relation to yield, B2 also presented the maximum value of this parameter, 59.28 ± 4.21%, and significantly different from the others. In the fermentation of coffee mucilage hydrolysate by S. cerevisiae cells immobilized in calcium alginate, Orrego et al. [39], using 50 g/L of initial sugar concentration, obtained 0.33 ± 0.01 g/g and 0.94 ± 0.07 g/L.h for conversion factor and productivity, respectively, values similar to those observed in the present work. Gajula et al. [49] used S. stipitis cells immobilized on sorghum stalks to produce bioethanol from peanut shell hydrolysate. When comparing the assays with free and immobilized cells, the best results for YP/S, Qp and ethanol titer were obtained for the immobilized cells (0.47 g/g, 0.243 g/L.h and 20.45 g/L, respectively). In addition, Gajula et al. [49] did not observe any significant variation in the fermentation parameters until the fifth batch utilizing the reused cells.

The polymers used for cell immobilization can hinder the mass transfer of sugars and ethanol between the medium and the cells. Xylose is a monosaccharide formed by five carbons, a pentose, and when used as a carbon source by yeasts such as S. passalidarum, it is converted to xylitol by the enzyme xylose reductase (XR), which uses NADPH or NADH as a cofactor. Xylitol is oxidized to D-xylulose by xylitol dehydrogenase (XDH), which requires NAD+ as a coenzyme to carry out the reaction. The dependence of different cofactors by XR and XDH to carry out the reactions generates a redox imbalance and the necessity of oxygen for metabolism. The lack of recycling of NAD+ causes the interruption of the xylose metabolization and, consequently, causes the accumulation of xylitol. The need for oxygen occurs because, in anaerobiosis, NADPH is still produced in the pentose pathway, but NADH cannot be reoxidized [14, 50]. Xylulokinase (XK) phosphorylates D-xylulose to D-xylylose-5-phosphate, which is metabolized in the pentose-phosphate-pathway to glucose-6-phosphate. In the Embden-Meyerhof-Parnas pathway, glucose-6-phosphate is converted to pyruvate, which under aerobic conditions is oxidized in the tricarboxylic acid cycle and under anaerobic conditions or with low oxygen concentration is converted to acetaldehyde and then to ethanol by the enzyme alcohol dehydrogenase (ADH) and pyruvate decarboxylase (PDC), which promote the reoxidation of NADH [14, 51]. Therefore, when there is not enough sugar and oxygen reaching the cells inside the beads, fermentation and cell growth are highly impaired.

As discussed, immobilized systems limit mass transfer, impair the metabolic activity of yeast and decrease the production of ethanol and YP/S, when compared to systems with free cells [52], as observed in the present work. The concentration of polymers used for cell immobilization also influences sugar consumption, as observed by Lee et al. [38], who studied the immobilization of S. cerevisiae in calcium alginate in concentrations of 2 and 2.5%. Ercan et al. [40] also evaluated the immobilization of S. cerevisiae in calcium alginate in concentrations of 2, 2.5, and 3%. Both authors reported that the best results were obtained when the concentration of 2% alginate was used, the same concentration used in the present work. In this sense, the surface immobilization method (adsorption or covalent bonding to the support) presents an alternative to overcome mass transfer problems observed for immobilization with calcium alginate (wrapping/encapsulation method) for the production of 2G ethanol by S. passalidarum. Singh et al. [53] compared the performance of S. cerevisiae cells immobilized in calcium alginate and sugarcane bagasse. They observed better results for immobilization in bagasse (YP/S of 0.44 g/g, Qp of 0.42 g/L.h and ethanol titer of 15.40 g/L). The authors also reported that bagasse allowed the use of the cells for ten cycles, without losses in parameters, while the alginate beads could be recycled for only four fermentations. Moreover, Singh et al. [53] highlighted that there is no barrier between cells and fermentation medium, which expressively reduces mass transfer difficulties that were observed in this work. Furthermore, without the polymer barrier, sugar and oxygen are more likely to be controlled and maintained in optimum levels needed for S. passalidarum metabolism.

The production of xylitol for fermentations with free cells (data not shown) reached a maximum value in B1 (7.67 ± 0.54 g/L). The production of this co-product decreased as the cells were reused in subsequent batches. This same behavior was observed for fermentation with immobilized cells in MSC, but reaching even lower xylitol concentrations, with the maximum value observed in B1 (3.24 ± 0.11 g/L). The concentration of both glycerol and acetic acid obtained was low for both conditions studied. The final concentration of glycerol obtained in fermentations with immobilized cells was approximately constant for batches, ranging from 0.24 ± 0.01 to 0.28 ± 0.05 g/L. The concentration of acetic acid for fermentations with free cells reached its maximum value in B1 (0.29 ± 0.04 g/L). Glycerol is one of the by-products produced in the metabolism of glucose and xylose by S. passalidarum and is very important for obtaining various products in the cosmetics, drugs, and food industries, among others. Yeasts produce glycerol from the reduction of dihydroxyacetone phosphate to glycerol-3-phosphate with the aid of the enzyme glycerol-3-phosphatase [3]. The production of glycerol associated with ethanol production was low compared to other literature reports [7, 54].

Figure 3 shows specific xylose (μXyl) and glucose (μGlu) uptake rates, and specific ethanol production rate (μEtOH) for free and immobilized S. passalidarum cells fermented in MSC. For free cells (Fig. 3a), it was possible to observe the same behavior reported by Portugal-Nunes et al. [46], where μGlu increased along with batch fermentations and it was higher than that observed for immobilized cells. On the other hand, μXyl and μEtOH did not show significant difference along with batches for SBF with free cells.

Regarding μXyl, μGlu, and μEtOH for SBF with immobilized cells in MSC (Fig. 3b), few studies in the literature discuss these variables for cells entrapped in beads. However, due to the methodology applied in the present work, it was possible to calculate these variables. In Fig. 3b is possible to note a constant behavior of μXyl, μGlu, and μEtOH along SBF, proving the stability of the support along with fermentations.

Immobilized S. passalidarum Cell Fermentation in Moderate and High Initial Sugar Content

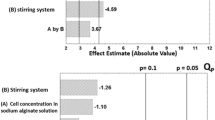

Five consecutive batches (B1, B2, B3, B4, and B5) were performed in a moderate (MSC) and a high (HSC) initial sugar concentration for 2G ethanol production. The comparison between the two sets of SBF with immobilized cells was performed from the analysis of the influence of the initial substrate concentration on the modified yield (Y'P/S) (Fig. 4a), residual sugar concentration (Fig. 4b), volumetric productivity (QP) (Fig. 4c), and specific rate of xylose consumption (µXyl), in which the maximum values were considered (Fig. 4d), and the alginate bead structure (Fig. 5).

Morphological analysis of the alginate beads before any batch (control), after three batches (batch 3) and after five batches (batch 5), where a MSC control external surface, b MSC after batch 3 external surface, c MSC after batch 5 external surface, d MSC control internal surface, e MSC after batch 3 internal surface, f MSC after batch 5 internal surface, g HSC control external surface, h HSC after batch 3 external surface, i HSC after batch 5 external surface, j MSC control internal surface, k HSC after batch 3 internal surface, l HSC after batch 5 internal surface

It is possible to observe that the ethanol production profile was similar in both tests (Fig. 4). The sugar concentration influenced more clearly in B1 and B5, in which the concentration of ethanol obtained was quite different, obtaining, respectively, 22.84 ± 0.70 and 17.71 ± 1.81 g/L for HSC (Fig. 1c) and 13.76 ± 1.33 and 15.47 ± 4.35 g/L for MSC (Fig. 1b); however, in all batches the highest final concentration of ethanol was obtained in the test with the highest sugar concentration.

By analyzing the Y'P/S values (Fig. 4a and Table 3), it can be noted that no significant difference between B1 and B2 was observed when comparing HSC and MSC. However, for B2, B3, and B4, all values achieved were higher for MSC. As previously cited, Singh et al. [53] evaluated calcium alginate as immobilization support for S. cerevisiae and observed a decrease in the values of the parameters YP/S Qp, ethanol title, and conversion of sugars to ethanol along SBF in hydrolysate of microwave alkali pretreated sugarcane bagasse.

For Qp (Fig. 4c and Table 3) all values were equal or statistically higher for HSC, when compared with MSC. Nikolic et al. [28] evaluated the influence of the initial concentration of glucose (98, 125, 150, and 176 g/L) in the fermentation with free cells. They observed that the highest concentration of ethanol (9% w/w) was achieved in the highest initial sugar concentration. In both tests (MSC and HSC), the Qp values decreased when comparing the initial and final batches. The same behavior was observed by Singh et al. [53] in the use of S. cerevisiae cells immobilized in calcium alginate, in which 0.33 g/L.h was obtained in B1 and 0.27 g/L.h in B4.

Regarding the residual sugar concentration (Fig. 4b) in both MSC and HSC, there was an increase in concentration throughout the batches, with the values obtained in B5 approximately double that of B1. Higher residual sugar values were obtained for the HSC, in which for all batches, the values were at least 2.34 times higher than MSC. The highest ratio between values was obtained in B2 in which the residual sugar concentration of HSC was 5.18 times that of MSC. Maximum µxylose values were statistically equal or higher when compared to MSC (Table 3). MSC showed higher µxylose along SBF.

Some metabolites can have an inhibitory action on cells, depending on their concentration in the medium, including the carbon sources used. When the substrate is present in inhibitory levels, sugar consumption and product formation rates are decreased. Nikolic et al. [28] highlighted that high concentrations of the substrate can cause an osmotic shock of yeast cells and decrease heat and mass transfer. Thus, the lower µxylose and increased residual sugar concentration for HSC can be related to these factors. Nikolic et al. [28] evaluated the initial sugar concentrations of 150, 176, and 200 g/L for immobilized cells of S. cerevisiae, and a decrease in the ethanol titer was observed for fermentation with 200 g/L, caused by substrate inhibition. Ozmihci and Kargi [55] evaluated the effect of substrate concentration (ranging between 52 and 312 g/L) on the production of bioethanol from cheese whey powder using free K. marxianus cells and observed a decrease in the consumption rate of sugar in concentrations above 75 g/L of initial sugar concentration, due to substrate inhibition.

The limitations found for the production of ethanol in the fermentation with immobilized cells are probably related to the rate of substrate and product transfer between medium and support and to the capacity of sugar metabolization by the yeast. The specific ethanol production rate had small variation over time, which possibly shows that substrate diffused into the supports and had contact with cells were immediately consumed in both trials. The differences in parameters observed for MSC and HSC suggest that the increase in the residual substrate concentration may have occurred due to the greater imbalance between the medium and the interior of the support caused by the high concentration of sugar in the medium. An alternative to improving non-time-dependent parameters is increasing the fermentation time, since residual sugars were observed in both tests, with a higher concentration in the HSC. Another alternative would be a fed-batch regime as proposed by Nikolic et al. [28] and Ozmihci and Kargi [55], or a continuous fluidized bed reactor.

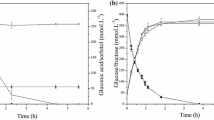

The morphology of the external and internal calcium alginate beads used in SBF is shown in Fig. 5. For the beads production, a concentration of 2% of calcium alginate, based on Ercan et al. [40], was used, and 3 mm of diameter beads were obtained. The control samples (Fig. 5a, d and Fig. 5g, j for MSC and HSC, respectively) correspond to the fresh alginate beads, which contained S. passalidarum but that had not been used in any batch. There was a gel layer on the surface of the sphere that joins the yeast cells in both controls, forming a dense structure with few pores, as also observed by Malik et al. [56]. The internal section referring to the controls (Fig. 5d, j) showed that the cell immobilization was successful in the support, observing the cells involved by it along the bead. After three successive batches (Fig. 5b, h) and after five batches (Fig. 5c, i), it was possible to observe the beads’ external images, an increase in the porosity of the material in both conditions studied. The deterioration of the beads can be explained by the increase in the concentration of free cells in the fermentation medium, as can be observed for both MSC (Fig. 2a) and HSC (Fig. 2b) fermentations, since the cells were naturally capable of transiting between the pores of the support, and the cells located in the surface had their path facilitated by the pores, that were only observed in this region [56]. With the increase of cells reutilization, the porosity also increased and more cells were desorbed. As well as porosity, pore size increased with bead reutilization. The diameter measured for control and batch 5 were, respectively, 1.84 ± 0.32 and 2.52 ± 0.53 µm for MSC and 2.01 ± 0.39 and 2.49 ± 0.60 µm for HSC. The increase in porosity, pore size, and cell leakage may have occurred due to the mechanical wear of support during the reutilization of beads. In order to decrease beads mechanical wear during fermentation, a possibility is the production of bigger than 3 mm beads, as suggested by Mishra et al. [31]. The authors tested beads diameters of 3, 4, and 5 mm and noticed the 4-mm beads did not show any disintegration up to 25 fermentation batches and also reached the higher ethanol yield (90.43%) in 10th batch, while 3 mm and 5 mm reached only 82% and 62%, respectively. Mishra et al. [31] uses genetically modified yeast strains of S. cerevisiae to ferment rice straw hydrolysate.

The evolution of CO2 can explain the occurrence of the observed detrition and increased porosity during the fermentation process. The greater the production of ethanol, the greater the production of CO2 by cellular metabolism, which needs to be eliminated. Thus, the transfer of gas through the support may have contributed to the increased porosity. Apparently, the higher porosity did not facilitate mass transfer since no direct interference was observed between the increase in porosity and the pattern of sugar consumption and ethanol production. Other than that, since the pores were only observed in the beads surface, they made the access easier, both for cells to leak and sugar to enter the bead, in the superficial layer. Therefore, the mass transfer was still difficult in the interior of the bead where more cells were located, considering the surface cells leakage. When comparing the two tests (MSC and HSC), there was no visible variation between the behavior of the porosity and the increase in the concentration of sugar concentration, in both cases the beads deterioration was similar with the batches, and similar values of free cell concentrations were observed, for MSC (Fig. 2a) and HSC (Fig. 2b).

Conclusion

S. passalidarum was immobilized in calcium alginate for 2G ethanol production in a medium simulating hemicellulosic hydrolysate obtained from sugarcane bagasse in terms of sugar composition. The immobilization method with calcium alginate showed easy execution, good cost–benefit, and viability for use with the studied yeast cells, generating an unprecedented response for S. passalidarum immobilization studies. Moreover, it was possible to develop a quantification method for immobilized cells. Results were better for free cells; however immobilized cells in moderate sugar concentration (MSC) still presented a good performance considering they had mass transfer difficulties due to the support. This works proved that S. passalidarum immobilization is possible, validates its use in five sequential fermentation batches, and opens a range of possibilities for the use of immobilized S. passalidarum, including in different fermentation mediums and conditions. Moreover, further studies of the mass diffusion through the calcium alginate beads and fermentations in a less ideal medium (hemicellulosic hydrolysates) are interesting, in order to verify diffusion of substrate and O2 and behavior against inhibitors, respectively. The search for new supports is a possibility in order to guarantee fermentation conditions, especially the O2 concentration, which is extremely necessary for xylose consumption by this yeast; therefore, continuous fluidized bed systems could be an alternative to assist in the transfer of this nutrient. Thereby, considering that research on immobilized cells for 2G ethanol is very limited, these findings may contribute to the lignocellulosic biomass fermentation industry.

References

Mohd Azhar SH, Abdulla R, Jambo SA, Marbawi H, Gansau JA, Mohd Faik AA, Rodrigues KF (2017) Yeasts in sustainable bioethanol production: a review. Biochem Biophys Rep 10:52–61. https://doi.org/10.1016/j.bbrep.2017.03.003

Karagoz P, Bill RM, Ozkan M (2019) Lignocellulosic ethanol production: evaluation of new approaches, cell immobilization and reactor configurations. Renew Energy 143:741–752. https://doi.org/10.1016/j.renene.2019.05.045

Martinez-Jimenez FD, Neitzel T, Biazi LE, Pereira IO, dos Santos LV, da Costa AC, Ienczak JL (2021) Exploiting the non-conventional yeast Spathaspora passalidarum as a platform for hemicellulosic hydrolysate conversion into bioproducts: a mini review. Bioenergy Res. https://doi.org/10.1007/s12155-021-10257-5

Rocha GJM, Martin C, Soares IB, Maior AMS, Baudel HM, De Abreu CAM (2011) Dilute mixed-acid pretreatment of sugarcane bagasse for ethanol production. Biomass Bioenerg 35:663–670. https://doi.org/10.1016/j.biombioe.2010.10.018

Dionísio SR, Santoro DCJ, Bonan CIDG, Soares LB, Biazi LE, Slininger PJ, Rabelo SC, Ienczak JL (2021) Second-generation ethanol process for integral use of hemicellulosic and cellulosic hydrolysates from diluted sulfuric acid pretreatment of sugarcane bagasse. Fuel 304:1–9. https://doi.org/10.1016/j.fuel.2021.121290

Riley R, Haridas S, Wolfe KH, Lopes MR, Hittinger CT, Göker M, Salamov AA, Wisecaver JH, Long TM, Calvey CH, Aerts AL, Barry KW, Choi C, Clum A, Coughlan AY, Deshpande S, Douglass AP, Hanson SJ, Klenk HP, La Butti KM, Lapidus A, Lindquist EA, Lipzen AM, Meier-Kolthoff JP, Ohm RA, Otillar RP, Pangilinan JL, Peng Y, Rokas A, Rosa CA, Scheuner C, Sibirny AA, Slot JC, Stielow JB, Sun H, Kurtzman CP, Blackwell M, Grigoriev IV, Jeffries TW (2016) Comparative genomics of biotechnologically important yeasts. Proc Natl Acad Sci U S A 113:9882–9887. https://doi.org/10.1073/pnas.1603941113

Nakanishi SC, Soares LB, Biazi LE, Nascimento VM, Costa AC, Rocha GJM, Ienczak JL (2017) Fermentation strategy for second generation ethanol production from sugarcane bagasse hydrolyzate by Spathaspora passalidarum and Scheffersomyces stipitis. Biotechnol Bioeng 114:2211–2221. https://doi.org/10.1002/bit.26357

de Fátima Rodrigues de Souza R, Dutra ED, Leite FCB, Cadete RM, Rosa CA, Stambuk BU, Stamford TLM, de Morais Jr A (2018) Production of ethanol fuel from enzyme-treated sugarcane bagasse hydrolysate using d-xylose-fermenting wild yeast isolated from Brazilian biomes. 3 Biotech 8:312. https://doi.org/10.1007/s13205-018-1340-x

Selim KA, Easa SM, El-Diwany AI (2020) The xylose metabolizing yeast Spathaspora passalidarum is a promising genetic treasure for improving bioethanol production. Fermentation 6:33. https://doi.org/10.3390/FERMENTATION6010033

Soares LB, Bonan CIDG, Biazi LE, Dionísio SR, Bonatelli ML, Andrade ALD, Renzano EC, Costa AC, Ienczak JL (2020) Investigation of hemicellulosic hydrolysate inhibitor resistance and fermentation strategies to overcome inhibition in non-saccharomyces species. Biomass Bioenerg 137:105549. https://doi.org/10.1016/j.biombioe.2020.105549

Neitzel T, Lima CS, Biazi LE, Collograi KC, Carvalho da Costa A, Vieira dos Santos L, Ienczak JL (2020) Impact of the Melle-Boinot process on the enhancement of second-generation ethanol production by Spathaspora passalidarum. Renew Energy 160:1206–1216. https://doi.org/10.1016/j.renene.2020.07.027

Bonan CIDG, Biazi LE, Dionísio SR, Soares LB, Tramontina R, Sousa AS, de Oliveira Filho CA, Costa AC, Ienczak JL (2020) Redox potential as a key parameter for monitoring and optimization of xylose fermentation with yeast Spathaspora passalidarum under limited-oxygen conditions. Bioprocess Biosyst Eng 43:1509–1519. https://doi.org/10.1007/s00449-020-02344-2

Biazi LE, Martínez-Jimenez FD, Bonan CIDG, Soares LB, Morais ER, Ienczak JL, Costa AC (2020) A differential evolution approach to estimate parameters in a temperature-dependent kinetic model for second generation ethanol production under high cell density with Spathaspora passalidarum. Biochem Eng J 161:107586. https://doi.org/10.1016/j.bej.2020.107586

Bonan CIDG, Tramontina R, dos Santos MW, Biazi LE, Soares LB, Pereira IO, Hoffmam ZB, Coutouné N, Squina FM, Robl D, Ienczak JL (2021) Biorefinery platform for Spathaspora passalidarum NRRL Y-27907 in the production of ethanol, xylitol, and single cell protein from sugarcane bagasse. BioEnergy Res. https://doi.org/10.1007/s12155-021-10255-7

Farias D, Maugeri-Filho F (2021) Sequential fed batch extractive fermentation for enhanced bioethanol production using recycled Spathaspora passalidarum and mixed sugar composition. Fuel 288:119673. https://doi.org/10.1016/j.fuel.2020.119673

Collograi KC, da Costa AC, Ienczak JL (2019) Effect of contamination with Lactobacillus fermentum I2 on ethanol production by Spathaspora passalidarum. Appl Microbiol Biotechnol 103:5039–5050. https://doi.org/10.1007/s00253-019-09779-y

Marton JM, Felipe MGA, Silva JBA, Pessoa AJ (2006) Evaluation of the activated charcoals and adsorption conditions used in the treatment of sugarcane bagasse hydrolysate for xylitol production. Braz J Chem Eng 23:9–21. https://doi.org/10.1590/S0104-66322006000100002

Modig T, Lidén G, Taherzadeh MJ (2002) Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem J 363:769–776. https://doi.org/10.1042/0264-6021:3630769

Mussatto SI, Roberto IC (2004) Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: a review. Bioresour Technol 93:1–10. https://doi.org/10.1016/j.biortech.2003.10.005

Taherzadeh MJ, Karimi K (2011) Fermentation inhibitors in ethanol processes and different strategies to reduce their effects. In: Biofuels: Alternative Feedstocks an Conversion Process, 1st ed. Elsevier Inc., pp 287–311

Morales P, Gentina JC, Aroca G, Mussatto SI (2017) Development of an acetic acid tolerant Spathaspora passalidarum strain through evolutionary engineering with resistance to inhibitors compounds of autohydrolysate of Eucalyptus globulus. Ind Crops Prod 106:5–11. https://doi.org/10.1016/j.indcrop.2016.12.023

Robak K, Balcerek M (2020) Current state-of-the-art in ethanol production from lignocellulosic feedstocks. Microbiol Res 240:126534. https://doi.org/10.1016/j.micres.2020.126534

Milessi TS, Perez CL, Zangirolami TC, Corradini FAS, Sandri JP, Foulquié-Moreno MR, Giordano RC, Thevelein JM, Giordano RLC (2020) Repeated batches as a strategy for high 2G ethanol production from undetoxified hemicellulose hydrolysate using immobilized cells of recombinant Saccharomyces cerevisiae in a fixed-bed reactor. Biotechnol Biofuels 13:1–12. https://doi.org/10.1186/s13068-020-01722-y

Behera S, Ray RC (2015) Batch ethanol production from cassava (Manihot esculenta Crantz .) flour using Saccharomyces cerevisiae cells immobilized in calcium alginate. Ann Microbiol 65:779–783. https://doi.org/10.1007/s13213-014-0918-8

Rodríguez-Restrepo YA, Orrego CE (2020) Immobilization of enzymes and cells on lignocellulosic materials. Environ Chem Lett 18:787–806. https://doi.org/10.1007/s10311-020-00988-w

Lu J, Peng W, Lv Y, Jiang Y, Xu B, Zhang W, Zhou J, Dong W, Xin F, Jiang M (2020) Application of cell immobilization technology in microbial cocultivation systems for biochemicals production. Ind Eng Chem Res 59:17026–17034. https://doi.org/10.1021/acs.iecr.0c01867

Thu B, Smidsrød O, Skjak-Brk G (1996) Alginate gels - some structure-function correlations relevant to their use as immobilization matrix for cells. Prog Biotechnol 11:19–30. https://doi.org/10.1016/S0921-0423(96)80004-9

Nikolić S, Mojović L, Pejin D, Rakin M, Vukašinović M (2010) Production of bioethanol from corn meal hydrolyzates by free and immobilized cells of Saccharomyces cerevisiae var. ellipsoideus. Biomass Bioenerg 34:1449–1456. https://doi.org/10.1016/j.biombioe.2010.04.008

Zhu Y (2007) Immobilized cell fermentation for production of chemicals and fuels. In: Bioprocessing Value-Added Products from Renewable Resources. Elsevier BV, pp 373–396

Talebnia F, Niklasson C, Taherzadeh MJ (2005) Ethanol production from glucose and dilute-acid hydrolyzates by encapsulated S. cerevisiae. Biotechnol Bioeng 90:345–353. https://doi.org/10.1002/bit.20432

Mishra A, Sharma AK, Sharma S, Bagai R, Mathur AS, Gupta RP, Tuli DK (2016) Lignocellulosic ethanol production employing immobilized Saccharomyces cerevisiae in packed bed reactor. Renew Energy 98:57–63. https://doi.org/10.1016/j.renene.2016.02.010

Pathania S, Sharma N, Handa S (2017) Immobilization of co-culture of Saccharomyces cerevisiae and Scheffersomyces stipitis in sodium alginate for bioethanol production using hydrolysate of apple pomace under separate hydrolysis and fermentation. Biocatal. Biotransformation 35:450–459. https://doi.org/10.1080/10242422.2017.1368497

Abbi M, Kuhad RC, Singh A (1996) Bioconversion of pentose sugars to ethanol by free and immobilized cells of Candida shehatae (NCL-3501): fermentation behaviour. Process Biochem 31:555–560. https://doi.org/10.1016/s0032-9592(95)00104-2

Ishola MM, Ylitervo P, Taherzadeh MJ (2015) Co-utilization of glucose and xylose for enhanced lignocellulosic ethanol production with reverse membrane bioreactors. Membranes (Basel) 5:844–856. https://doi.org/10.3390/membranes5040844

Kashid M, Ghosalkar A (2018) Critical factors affecting ethanol production by immobilized Pichia stipitis using corn cob hemicellulosic hydrolysate. Prep Biochem Biotechnol 48:288–295. https://doi.org/10.1080/10826068.2018.1425715

Nguyen NH, Suh S-O, Marshall CJ, Blackwell M (2006) Morphological and ecological similarities: wood-boring beetles associated with novel xylose-fermenting yeasts, Spathaspora passalidarum gen. sp. nov. and Candida jeffriesii sp. nov. Mycol Res 110:1232–1241. https://doi.org/10.1016/J.MYCRES.2006.07.002

Santos SC, de Sousa AS, Dionísio SR, Tramontina R, Ruller R, Squina FM, Vaz Rossell CE, da Costa AC, Ienczak JL (2016) Bioethanol production by recycled Scheffersomyces stipitis in sequential batch fermentations with high cell density using xylose and glucose mixture. Bioresour Technol 219:319–329. https://doi.org/10.1016/j.biortech.2016.07.102

Lee KH, Choi IS, Kim YG, Yang DJ, Bae HJ (2011) Enhanced production of bioethanol and ultrastructural characteristics of reused Saccharomyces cerevisiae immobilized calcium alginate beads. Bioresour Technol 102:8191–8198. https://doi.org/10.1016/j.biortech.2011.06.063

Orrego D, Zapata-Zapata AD, Kim D (2018) Ethanol production from coffee mucilage fermentation by S. cerevisiae immobilized in calcium-alginate beads. Bioresour Technol Rep 3:200–204. https://doi.org/10.1016/j.biteb.2018.08.006

Ercan Y, Irfan T, Mustafa K (2013) Optimization of ethanol production from carob pod extract using immobilized Saccharomyces cerevisiae cells in a stirred tank bioreactor. Bioresour Technol 135:365–371. https://doi.org/10.1016/j.biortech.2012.09.006

Lima CS, Neitzel T, de Oliveira PI, Rabelo SC, Ienczak JL, Roberto IC, Rocha GJM (2021) Effect of the sugarcane bagasse deacetylation in the pentoses fermentation process. Bioenergy Res. https://doi.org/10.1007/s12155-020-10243-3

Su YK, Willis LB, Jeffries TW (2015) Effects of aeration on growth, ethanol and polyol accumulation by Spathaspora passalidarum NRRL Y-27907 and Scheffersomyces stipitis NRRL Y-7124. Biotechnol Bioeng 112:457–469. https://doi.org/10.1002/bit.25445

Puligundla P, Poludasu RM, Rai JK, Reddy Obulam VS (2011) Repeated batch ethanolic fermentation of very high gravity medium by immobilized Saccharomyces cerevisiae. Ann Microbiol 61:863–869. https://doi.org/10.1007/s13213-011-0207-8

Berti FV, Srisuk P, Da Silva LP, Marques AP, Reis RL, Correlo VM (2017) Synthesis and characterization of electroactive Gellan gum spongy-like hydrogels for skeletal muscle tissue engineering applications. Tissue Eng Part A 23:1–12. https://doi.org/10.1089/ten.tea.2016.0430

Ndubuisi IA, Qin Q, Liao G, Wang B, Moneke AN, Ogbonna JC, Jin C, Fang W (2020) Effects of various inhibitory substances and immobilization on ethanol production efficiency of a thermotolerant Pichia kudriavzevii. Biotechnol Biofuels 13:1–12. https://doi.org/10.1186/s13068-020-01729-5

Portugal-Nunes D, Nogué VSI, Pereira SR, Craveiro SC, Calado AJ, Xavier AMRB (2015) Effect of cell immobilization and PH on Scheffersomyces stipitis growth and fermentation capacity in rich and inhibitory media. Bioresour Bioprocess 2:1–9. https://doi.org/10.1186/s40643-015-0042-z

Agbogbo FK, Coward-Kelly G (2008) Cellulosic ethanol production using the naturally occurring xylose-fermenting yeast, Pichia stipitis. Biotechnol Lett 30:1515–1524. https://doi.org/10.1007/s10529-008-9728-z

Sarrouh BF, Da Silva SS (2008) Evaluation of the performance of a three-phase fluidized bed reactor with immobilized yeast cells for the biotechnological production of xylitol. Int J Chem React Eng 6:1–15 . https://doi.org/10.2202/1542-6580.1816

Gajula C, Chandel AK, Konakalla R, Rudravaram R, Pogaku R, Mangamoori LN (2011) Fermentation of groundnut shell enzymatic hydrolysate for fuel ethanol production by free and sorghum stalks immobilized cells of Pichia stipitis NCIM 3498. Int J Chem React Eng 9:1–17. https://doi.org/10.1515/1542-6580.2514

Hahn-Hägerdal B, Jeppsson H, Skoog K, Prior BA (1994) Biochemistry and physiology of xylose fermentation by yeasts. Enzyme Microb Technol 16:933–943. https://doi.org/10.1016/0141-0229(94)90002-7

Kuhad RC, Gupta R, Khasa YP, Singh A, Zhang YHP (2011) Bioethanol production from pentose sugars: current status and future prospects. Renew Sustain Energy Rev 15:4950–4962. https://doi.org/10.1016/j.rser.2011.07.058

Nordmeier A, Chidambaram D (2018) Use of Zymomonas mobilis immobilized in doped calcium alginate threads for ethanol production. Energy 165:603–609. https://doi.org/10.1016/j.energy.2018.09.137

Singh A, Sharma P, Saran AK, Singh N, Bishnoi NR (2013) Comparative study on ethanol production from pretreated sugarcane bagasse using immobilized Saccharomyces cerevisiae on various matrices. Renew Energy 50:488–493. https://doi.org/10.1016/j.renene.2012.07.003

Cadete RM, Melo MA, Dussán KJ, Rodrigues RCLB, Silva SS, Zilli JE, Vital MJS, Gomes FCO, Lachance MA, Rosa CA (2012) Diversity and physiological characterization of D-xylose-fermenting yeasts isolated from the Brazilian Amazonian Forest. PLoS ONE 7:e43135. https://doi.org/10.1371/journal.pone.0043135

Ozmihci S, Kargi F (2007) Kinetics of batch ethanol fermentation of cheese-whey powder (CWP) solution as function of substrate and yeast concentrations. Bioresour Technol 98:2978–2984. https://doi.org/10.1016/j.biortech.2006.10.005

Malik K, Salama ES, El-Dalatony MM, Jalalah M, Harraz FA, Al-Assiri MS, Zheng Y, Sharma P, Li X (2021) Co-fermentation of immobilized yeasts boosted bioethanol production from pretreated cotton stalk lignocellulosic biomass: Long-term investigation. Ind Crops Prod 159:113122. https://doi.org/10.1016/j.indcrop.2020.113122

Acknowledgements

The authors acknowledge the Central Laboratory of Electron Microscopy (LCME) from the Federal University of Santa Catarina (UFSC).

Funding

This work was supported in part by grants and fellowships from FAPESC (funded student: co-author Eduardo Zanella), CNPq (process number 308389/2019–0), CAPES (process number 88882.345331/2019–01), and FINEP (process no 01.09.0566.00/1421–08).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

da Silveira, J.M., Soares, L.B., Cesca, K. et al. Immobilization of Spathaspora passalidarum NRRL Y-27907 in Calcium Alginate Aiming the Production of Second-Generation Ethanol. Bioenerg. Res. 15, 264–279 (2022). https://doi.org/10.1007/s12155-021-10309-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10309-w