Abstract

A sacrificial template, Fe-MIL-88 is used to synthesize Ni–Fe layered double hydroxide (Ni–Fe LDH). The metal-organic framework (Fe-MIL-88) is synthesized from the precursors, ferric nitrate and terephthalic acid. Electrocatalytic oxidation of kojic acid (KA) is realized by Ni–Fe LDH film which is coated on a glassy carbon electrode (GC). Under the optimized conditions, amperometry measurements at the Ni–Fe LDH coated GC as a function of KA concentration demonstrates a sensitive determination of KA. The calibration curve shows two linear ranges, 1–1500 µM and 1500–4500 µM for the KA determination. Detection limit for the KA determination is estimated as 0.73 µM. The practical applicability of this method is confirmed by measuring the KA concentration present in various real samples.

Graphic abstract

A new sensor for the determination kojic acid is developed based on Ni–Fe layered double hydroxide which is synthesized through the Fe-MIL-88 templated route. Further, the synthesized material is used for the determination of kojic acid present in different brands of commercial tomato sauces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Designing specific layered double hydroxides (LDHs) with tailor-made properties to suit the desired applications have drawn great attention due to their potential applications in biotechnology, energy storage, separation science, adsorbents, photochemistry, electrochemistry, etc.1,2,3,4,5,6,7,8,9,–10 Generally, LDHs are synthetic lamellar solids with metal cations (trivalent and divalent) and anions (n-valent). Their general formula can be given as [M 2+1−y M 3+y (OH)2]y+ [(An−)y/n, y H2O].11 LDHs can be synthesized by conventional methods like ion-exchange, co-precipitation, and hydrothermal methods.12,13 However, these methods are not efficient in controlling the morphology, surface area, and particle size of the LDHs.13 Due to this limitation, the application of LDHs as catalysts, adsorbents, and electrode modifiers are limited.14 To overcome this drawback and to explore their electrocatalytic properties, a new Ni–Fe LDH which is synthesized using a template based on Fe(III) metal-organic framework (MOF) is reported. This new Ni–Fe LDH is envisaged to exhibit high surface area, high adsorption capacity, and enhanced catalytic activity. Kojic acid (KA), otherwise known as 5-hydroxy-2-(hydroxymethyl)-4-pyrone (based on IUPAC recommended nomenclature) is globally used as an antioxidant, food additive, or preservative.15,16,–17 KA is generally extracted from the fungal genus Aspergillus.15,16,–17 However, its safety assessment is controversial due to carcinogenicity, teratogenicity, and embryotoxicity.18,19 Therefore, monitoring of KA concentration levels is very important due to its human health issues, food safety, and quality control aspects.18,20 Real-time monitoring/determination of KA can be achieved by several techniques like ion-pair liquid chromatography, capillary electrophoresis, fluorimetry and electrochemical methods.21,22,23,–24 Among these methods, the electrochemical method generally receives great attention since it can offer a sensitive, selective, simple, and cost-effective route for many target analyte determinations.25,26,–27 Accordingly, in this work, we report an electrochemical method for the quantitative assay of KA using a MOF templated Ni–Fe LDH for the first time.

2 Experimental

2.1 Materials and reagents

N,N-dimethylformamide (DMF), poly(vinyl alcohol), nickel acetate tetrahydrate and benzene-1,4-dicarboxylic acid were supplied by S.D. Fine Chemicals, India. Potassium ferrocyanide, potassium ferricyanide, potassium chloride, K2HPO4, KH2PO4, and ferric nitrate were procured from Qualigens, India. Kojic acid (KA) was obtained from Himedia, India. Stock solutions of K2HPO4 and KH2PO4 were used for the preparation of 0.1 M pH 7.0 phosphate buffer. Triple distilled water was used for electrochemical experiments.

Fe-MIL-88 and Ni–Fe LDH were synthesized hydrothermally as described before in our previous publication.14 The synthesis of Fe-MIL-88 is carried out using a mixture of benzene-1,4-dicarboxylic acid and ferric nitrate in DMF-ethanol-water mixture. The mixture was ultra-sonicated, stirred, refluxed at 80 °C under the stirring condition for 12 h, and finally subjected to centrifugation (8000 rpm). The obtained precipitate (Fe-MIL-88) was washed multiple times with a mixture of ethanol-water and then dried for 24 h at 60 °C. Synthesis of Ni–Fe LDH was accomplished by mixing the required amounts of Fe-MIL-88 (0.02 g) and nickel acetate tetrahydrate (0.2 M) in DMF. This mixture was then subjected to ultra-sonication and refluxed with stirring at 85 °C for 4 h. Further, DMF and water were added to the mixture and refluxed at 120 °C for an additional 12 h. Then the mixture was cooled to room temperature and centrifuged to get the Ni–Fe LDH. The formed Ni–Fe LDH was filtered, washed with a large amount of water, and dried for 5 h at 120 °C.14,28

2.2 Apparatus

X-ray diffraction (XRD) patterns (BRUKER D8 X-ray diffractometer with Cu Kα line (0.159 nm), X-ray photoelectron spectroscopy (XPS, AMICUS spectrometer, UK), scanning electron microscopy (SEM) (SEM VEGA 3 TESCAN at 30 kV) and transmission electron microscopy (TEM) (TECNAI 20 G2 FEI microscope; 120 kV) analyses were carried out for the characterization of the materials. Cyclic voltammetry, amperometry, and chronoamperometry measurements were accomplished with CHI-660C electrochemical workstation (CH Instruments, USA). Glassy carbon (GC) or modified GC, platinum wire and saturated calomel electrode i.e. Hg/Hg2Cl2/KCl(sat.) were used as working, counter, and reference electrodes, respectively. GC electrode surface is modified either with Fe-MIL-88 or Ni–Fe LDH. The colloid of the respective materials (0.1 wt%) with poly(vinyl alcohol) (0.01 wt%) were prepared and typically 20 µL of the colloid was drop coated and dried for 4 h to get the modified GC electrodes. The modified electrodes were represented as GC/Fe-MIL-88 or GC/Ni–Fe LDH. It should be noted that the present work reports the construction of Fe-MIL-88 or Ni–Fe LDH film prepared on GC electrodes. However, carbon paste electrodes (CPEs) using the Fe-MIL-88 or Ni–Fe LDH materials were already constructed, characterized, and demonstrated for the efficient water oxidation in alkaline medium.14

3 Results and Discussion

3.1 Characterization of Ni–Fe LDH

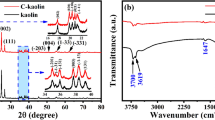

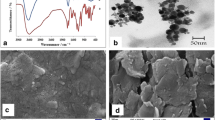

Detailed characterization of Fe-MIL-88 and Ni–Fe LDH were elaborately discussed based on the results of TEM, XRD patterns, and XPS in our earlier study.14 The powder XRD data are provided in supplementary information, Table S1 (Supplementary Information).14 The powder XRD patterns of Fe-MIL-88 show peaks at the 2θ values of 8.9°, 16.2°, and 17.3° which can be attributed to (002), (103), and (200) planes of Fe-MIL-88, respectively (Table S1, Supplementary Information).14 Ni–Fe LDH shows additional peaks at the 2θ values 11.7°, 23.7°, 34.8°, 39.5°, 59.5°, and 61.0° which are ascribed to various crystal planes of Ni–Fe LDH, respectively (Table S1, Supplementary Information).14 Spindle shaped morphology of Fe-MIL-88 and porous layered structure of Ni–Fe LDH are revealed from the SEM and TEM analyzes (Figure S1, Supplementary Information).14 The XPS of Fe 2p1/2 (726.1 eV) and Fe 2p3/2 (712.6 eV) in both Fe-MIL-88 and Ni–Fe LDH materials confirm the +3 oxidation state of Fe (Table S2, Supplementary Information,).14 Similarly, the XPS of Ni 2p3/2 (856.7 and 851.8 eV) and Ni 2p1/2 (872.3 eV) in Ni–Fe LDH confirm the presence of +2 and +3 oxidation states of Ni (Table S2, Supplementary Information).14 The FT-IR spectrum14 of Ni–Fe LDH displays peaks at 1107 and 876 cm−1 which can be corroborated to the deformation of –OH. A peak around 876 cm−1 is also observed14 owing to the out of plane deformation of carbonate species present in the Ni–Fe LDH.14 Electrochemical impedance analyzes of CPEs based on these materials were already reported.14 In the present study, electrochemical impedance analyzes are carried out with the Fe-MIL-88 and Ni–Fe LDH film modified electrodes to understand the electron transfer activities within the film. Aqueous ferrocyanide/ferricyanide redox couple (10.0 mM K3[Fe(CN)6] and 10.0 mM K2[Fe(CN)6]) is used as a probe and the analyzes are carried out with 0.1 M KCl by applying 0.2 V at GC/Fe-MIL-88 and GC/Ni–Fe LDH electrodes (Figure 1). The cyclic voltammetry (CV) responses of the probe at GC/Fe-MIL-88 and GC/Ni–Fe LDH are also recorded (inset (i) of Figure 1). Both GC/Fe-MIL-88 and GC/Ni–Fe LDH electrodes show redox peaks corresponding to [Fe(CN)6]3−/4− redox process. GC/Fe-MIL-88 shows a slightly low peak current with a ΔEp value of 140 mV while the GC/Ni–Fe LDH electrode shows a high peak current with a ΔEp value of 180 mV. These results suggest that the electrical conductivity inside the Ni–Fe LDH film is greater than the Fe-MIL-88 film (based on high current obtained at GC/Ni–Fe LDH electrode). Nyquist plots demonstrate that two different physicochemical processes take place at the electrode-solution interface which may be referred as charge transfer phenomena inside the sheets of Ni–Fe LDH or Fe-MIL-88 and a heterogeneous electron transfer process between the modified electrode and the electrolyte solution.29 A suitable Randle’s equivalent circuit is identified (inset (ii) of Figure 1) which relies on the experimentally observed data. As per the Randle’s equivalent circuit, it possesses three resistance components, the resistance of electrolyte (R1), charge transfer resistance (Rct), and resistive part of the mass transfer (Rp), mass transfer resistance (Zd), the capacitance of the film (Cdl) and two constant phase elements (Q1 and Q2). The Ni–Fe LDH displays a semicircle with a lesser diameter than the Fe-MIL-88 indicating lower Rct value than that of the Fe-MIL-88. This low Rct leads to a fast electron transfer process at GC/Ni–Fe LDH electrode. Presence of Ni3+ in the Ni–Fe LDH and/or the broad interlayer space of Ni–Fe LDH may cause increased conductivity within the film.14,30

3.2 Electrochemical determination of KA

Cyclic voltammograms are recorded in phosphate buffer (0.1 M, pH 7.0) with and without KA (100 µM) using GC, GC/Fe-MIL-88, and GC/Ni–Fe LDH electrodes (Figure 2). No significant redox behavior is noticed in the absence of KA at all the electrodes (inset of Figure 2). However, in the presence of KA, a well-defined voltammetric peak is observed due to the efficient electro-oxidation of KA at all the three electrodes (Figure 2a′–2c′). At bare GC and GC/Fe-MIL-88 electrodes (Figure 2a′ and 2b′), KA is oxidized at 0.79 V with a low current. At GC/Ni–Fe LDH electrode, KA is oxidized at 0.75 V with a high current. Thus, GC/Ni–Fe LDH exhibits low oxidation peak potential and high peak current for KA electro-oxidation in comparison to bare GC and GC/Fe-MIL-88 electrodes which indicate the efficient electrocatalytic activity of GC/Ni–Fe LDH. This electrocatalytic activity may be due to the involvement of Ni3+ present in Ni–Fe LDH.

Efficient electrocatalytic oxidation of KA at the GC/Ni–Fe LDH electrode may lead to a sensitive determination of KA which can be verified by amperometry using the GC/Ni–Fe LDH electrode. The amperometry responses arising from successive additions of KA are recorded (Eapplied: 0.6 V) in 0.1 M pH 7.0 phosphate buffer (Figure 3A). The calibration curve from the amperometry responses is drawn for KA determination which shows two linear responses (Figure 3B). The first linear response is spread over the KA concentration range from 1.0 µM to 1.5 mM and the next linear range is observed from 1.5 to 4.5 mM. The sensitivity and detection limit for the KA determination are found to be 0.032 µA µM−1 cm−2 and 0.73 µM, respectively. On increasing the concentration above 1.5 mM of KA, the rate of the electrocatalytic reaction may become slow due to saturation of the active catalytic sites31 which results in a decreased sensitivity of the second linear region of the calibration plot. The sensitivity of the present method is comparable to many of the recently reported methods.15,17,32,33,34,35,36,–37 Although certain methods show slightly high sensitivity, they exhibit a narrow linear calibration range.15,35 Thus, the present method demonstrates higher sensitivity and wider linear calibration range than the previous methods for the determination of KA.15,35,37 Therefore, the present method is comparable or superior with previously reported methods for KA determination as shown in Table 1. 32,33,34,35,36,–37

(A) Amperometric response of GC/Ni–Fe LDH with successive additions of KA (1, 5, 10, 20, 30, 50, 100, 200, 300, 500, 1000, 1500, 2000, 2500, 3000, 3500, 4000 and 4500 µM) into 0.1 M phosphate buffer. Expanded view from 1 to 30 µM additions of KA is shown in the inset. (B) Calibration curve showing the two linear ranges (1–1500 µM and 1500–4500 µM) for KA determination with error bars.

3.3 Chronoamperometry of KA oxidation

The oxidation of KA is further studied by chronoamperometry to understand the kinetics of the GC/Ni–Fe LDH electrode process and shown in Figure 4. From the slope of the plot shown in the inset of Figure 4, the value of the catalytic rate constant (KC) is calculated to be 1.96 × 105 M−1 s−1 using equation 1.17

where Icat (catalytic current) is the anodic oxidation currents measured in the presence of different concentrations of KA and IL (limiting current) is the current obtained in the absence of KA. Cb is the bulk concentration of KA and t is the time. The value of KC for KA oxidation agrees practically with other reported values.17

Based on the above studies and in line with the literature,38 the mechanism of electrocatalytic oxidation of KA by the Ni–Fe LDH may be postulated as displayed in equations 2–4.

In the given mechanism, Ni(II)-Fe LDH is electrochemically oxidized to Ni(III)-Fe LDH and KA is chemically oxidized to KA(ox) by the electrogenerated Ni(III)-Fe LDH involving one electron and one proton. The oxidized KA (KA(ox)) undergoes further reaction to produce 6,6′-bis(5-hydroxy-2-(hydroxymethyl)-4H-pyran-4-one as the final product (equation 4).39

3.4 Reproducibility, stability, and interference studies

The reproducibility of the GC/Ni–Fe LDH electrode is analyzed by determining 100 µM KA three times. The relative standard deviation for the three determinations is calculated as 5.6% which reveals an acceptable reproducibility. The storage stability of GC/Ni–Fe LDH is tested by keeping the electrode under the room temperature condition for 7 days and comparing the CV response of the first and seventh days for the determination of 100 µM KA. On the seventh day, GC/Ni–Fe LDH exhibits 95.0% of the initial signal (first-day current response), which reveals reasonable stability of the GC/ Ni–Fe LDH.

The selectivity of the GC/Ni–Fe LDH electrode towards the determination of 100 µM KA is analyzed in the presence of several possible interferents (Figure 5). The influence of possible coexisting common salts (2.0 mM of each salt like KNO3, MgCl2, CaCl2, NaHCO3, Ni(NO3)2 and HgCl2) and biomolecules (1.0 mM of each compound like caffeine, glucose, aspartic acid, alanine, and glutamic acid) in the determination of KA is investigated (Figure 5).34 Many of the added interferents exhibit negligible influence (less than ±5%) during the determination of 100 µM KA. Few interferents show a signal change slightly higher than ± 5%, however, less than 10% indicating the high selectivity of this method. Thus, GC/Ni–Fe LDH can be used for the reliable quantitative determination of KA.

3.5 Determination of KA in different tomato sauces

The realistic use of the sensor is established by analyzing KA present in the commercially available tomato sauces, A (Tombo), B (Kissan), and C (Maggi pichkoo). The samples (sauce A, B, and C) were diluted with water and analyzed using GC/Ni–Fe LDH electrode in 0.1 M phosphate buffer. Tomato sauce may contain Fe3+, ascorbic acid, oxalic acid, gallotannic acid, etc. However, they are estimated to be present in a very small amount. Therefore, these interferents cannot affect the response due to KA. The amperometry current response is measured for all three sauces (alone and also spiked with standard KA). The results are illustrated in Table 2. Reasonable recovery justifies the use of the GC/Ni–Fe LDH electrode for the estimation of KA in real samples. The results are comparable with the previously reported methods.21,40

4 Conclusions

Fe-MIL-88 is used as a template to synthesize Ni–Fe LDH. Based on the efficient electrocatalytic oxidation of KA by Ni–Fe LDH, the quantitative determination of KA is realized. The performance characteristics of the GC/Ni–Fe LDH electrode with those of the earlier reports revealed that the proposed sensor exhibits low overpotential for the oxidation of KA. The quantitative determination of KA is not affected even in the presence of many possible interfering compounds. It could be useful for the direct determination of KA in real samples without any pretreatments.

References

Chen H, Mousty C, Cosnier S, Silveira C, Moura J J G and Almeida M G 2007 Highly sensitive nitrite biosensor based on the electrical wiring of nitrite reductase by [ZnCr-AQS] LDH Electrochem. Commun. 9 2240

Kameyama T, Okazaki K I, Takagi K and Torimoto T 2009 Stacked-structure-dependent photoelectrochemical properties of CdS nanoparticle/layered double hydroxide (LDH) nanosheet multilayer films prepared by layer-by-layer accumulation Phys. Chem. Chem. Phys. 11 5369

Zhao Y, He S, Wei M, Evans D G and Duan X 2010 Hierarchical films of layered double hydroxides by using a sol-gel process and their high adaptability in water treatment Chem. Commun. 46 3031

Radha A, Kamath P V and Shivakumar C 2007 Conservation of order, disorder and crystallinity during anion-exchange reactions among layered double hydroxides (LDHs) of Zn with Al J. Phys. Chem. B 111 3411

Dixit M, Jayashree R S, Kamath P V, Shukla A K, Kumar V G and Munichandraiah N 1999 Electrochemically impregnated aluminum stabilized alpha nickel hydroxide batteries Electrochem. Solid State Lett. 2 170

Zadeh H A, Kohansal S and Sadeghi G H 2011 Selective solid-phase extraction and spectrofluorometric determination of salicylic acid in pharmaceutical and biological samples Talanta 84 368

Shan D, Wang Y N, Zhu M J, Xue H G, Cosnier S and Wang C Y 2009 Development of a high analytical performance-xanthine biosensor based on layered double hydroxides modified-electrode and investigation of the inhibitory effect by allopurinol Biosens. Bioelectron. 24 1171

Qiu J B 1995 Anionic clay modified electrodes: electrochemical activity of nickel(II) sites in layered double hydroxide films. J. Electroanal. Chem. 395 159

Reichle W T 1986 Synthesis of anionic clay minerals (mixed metal hydroxides, hydrotalcite) Solid State Ion. 22 135

Yao L, Wei D, Yan D and Hu C 2015, ZnCr Layered double hydroxide (LDH) nanosheets assisted formation of hierarchical flower-like CdZnS@LDH microstructures with improved visible-light-Driven H2 production Chem. Asian J. 10 630

Tonelli D, Scavetta E and Giorgetti M 2013 Layered-double-hydroxide-modified electrodes: electroanalytical applications Anal. Bioanal. Chem. 405 603

Wang Q and O’Hare D 2012 Recent advances in the synthesis and application of layered double hydroxide (LDH) nanosheets Chem. Rev. 112 4124

Jiang Z, Li Z, Qin Z, Sun H, Jiao X and Chen D 2013 LDH nanocages synthesized with MOF templates and their high performance as supercapacitors Nanoscale 5 11770

Yadav D K, Ganesan V, Sonkar P K and Gupta R 2017 Templated synthesis of nickel@iron layered double hydroxide for enhanced electrocatalytic water oxidation: towards the development of non-precious-metal catalysts ChemElectroChem 4 3134

Buleandra M, Rabinca A A, Tache F, Moldovan Z, Stamatin I, Mihailciuc C and Ciucu A A 2017 Rapid voltammetric detection of kojic acid at a multi-walled carbon nanotubes screen-printed electrode Sens. Actuat. B-Chem. 241 406

Ma X and Chao M 2014 Study on the electrochemical properties of kojic acid at a poly(glutamic acid)-modified glassy carbon electrode and its analytical application Food Anal. Methods 7 1458

Sheikhshoaie M, Sheikhshoaie I and Ranjbar M 2017 Analysis of kojic acid in food samples uses an amplified electrochemical sensor employing V2O5 nanoparticle and room temperature ionic liquid J. Mol. Liq. 231 597

Gao Z, Su R, Qi W, Wang L and He Z 2014 Copper nanocluster-based fluorescent sensors for sensitive and selective detection of kojic acid in food stuff Sens. Actuat. B-Chem. 195 359

Chusiri Y, Wongpoomchai R, Kakehashi A, Wei M, Wanibuchi H, Vinitketkumnuan U and Fukushima S 2011 Non-genotoxic mode of action and possible threshold for hepatocarcinogenicity of kojic acid in F344 rats Food Chem. Toxicol. 49 471

Blumenthal C Z 2004 Production of toxic metabolites in Aspergillus niger, Aspergillus oryzae, and Trichoderma reesei: justification of mycotoxin testing in food grade enzyme preparations derived from the three fungi Toxicol. Pharmacol. 39 214

Shih Y 2001 Simultaneous determination of magnesium l-ascorbyl-2-phosphate and kojic acid cosmetic bleaching products by using a microbore column and ion-pair liquid chromatography J. AOAC Int. 84 1045

Lin Y H, Yang Y H and Wu S M 2007 Experimental design and capillary electrophoresis for simultaneous analysis of arbutin, kojic acid and hydroquinone in cosmetics J. Pharm. Biomed. Anal. 44 279

Song P, Xiang Y, Xing H, Zhou Z, Tong A and Lu Y 2012 Label-free catalytic and molecular beacon containing an abasic site for sensitive fluorescent detection of small inorganic and organic molecules Anal. Chem. 84 2916

Vachalkova A, Bransova J, Brtko J, Uher M and Novotny L 1996 Polarographic behavior of kojic acid and its derivatives, determination of potential carcinogenicity and correlation of these properties with their other attributes Neoplasma 43 265

Ziyatdinova G K, Budnikov G K and Pogoreltsev V I 2004 Electrochemical determination of lipoic acid J. Anal. Chem. 59 324

Yashin Y I and Yashin A Y 2004 Analysis of food products and beverages using high-performance liquid chromatography and ion chromatography with electrochemical detectors J. Anal. Chem. 59 1237

Mohammadizadeh N, Mohammadi S Z and Kaykhaii M 2018 Carbon paste electrode modified with ZrO2 nanoparticles and ionic liquid for sensing of dopamine in the presence of uric acid J. Anal. Chem. 73 685

Wu Y, Luo H and Wang H 2014 Synthesis of iron(III)-based metal–organic framework/graphene oxide composites with increased photocatalytic performance for dye degradation RSC Adv. 4 40435

Shi S, Fang Z and Ni J 2005 Electrochemical impedance spectroscopy of marmatite-carbon paste electrode in the presence and absence of Acidithiobacillus ferrooxidans Electrochem. Commun. 7 1177

Li B Y, Hasin P and Wu Y 2010 NixCo3−xO4 nanowire arrays for electrocatalytic oxygen evolution Adv. Mater. 22 1926

Rastogi P K, Ganesan V and Krishnamoorthi S 2014 Palladium nanoparticles incorporated polymer-silica nanocomposite based electrochemical sensing platform for nitrobenzene detection Electrochim. Acta 147 442

Yang Z, Yin Z and Chen F 2011 A novel kojic acid amperometric sensor based on hollow CuO/Fe2O3 hybrid microspheres immobilized in chitosan matrix Electrochim. Acta 56 1089

Liu J, Zhou D, Liu X, Wu K and Wan C 2009 Determination of kojic acid based on the interface enhancement effects of carbon nanotube/alizarin red S modified electrode Colloids Surf. B 70 20

Wang L, Qi W, Su R and He Z 2014 Sensitive and efficient electrochemical determination of kojic acid in foodstuffs based on graphene-Pt nanocomposite-modified electrode Food Anal. Methods 7 109

Ma X and Chao M 2014 Study on the electrochemical properties of kojic acid at a poly(glutamic acid)-modified glassy carbon electrode and its analytical application Food Anal. Methods 7 1458

Filho L C S F, Brownson D A C, Filho O F and Banks C E 2013 Exploring the origins of the apparent “electrocatalytic” oxidation of kojic acid at graphene modified electrodes Analyst 138 4436

Wang Y, Zhang D and Wu J 2012 Electrocatalytic oxidation of kojic acid at a reduced graphene sheet modified glassy carbon electrode J. Electroanal. Chem. 664 111

Hai B and Zou Y 2015 Carbon cloth supported NiAl-layered double hydroxides for flexible application and highly sensitive electrochemical sensors Sens. Actuat. B-Chem. 208 143

Bastidas F, Urzua U and Vicuna R 2002 Oxidation of kojic acid catalyzed by manganese peroxidase from Ceriporiopsis subvermispora in the absence of hydrogen peroxide Appl. Biochem. Biotechnol. 101 31

Yang X and Zhang H 2007 Sensitive determination of kojic acid in foodstuffs using PVP (polyvinylpyrrolidone) modified acetylene black paste electrode Food Chem. 102 1223

Acknowledgements

Generous financial support from DST-ASEAN (IMRC/AISTDF/R&D/P-16/2018) and DST (SR/NM/NS-2012/2013(G)), New Delhi is gratefully acknowledged. DKY acknowledges UGC, New Delhi for Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yadav, D.K., Ganesan, V., Gupta, R. et al. Sensitive determination of kojic acid in tomato sauces using Ni–Fe layered double hydroxide synthesized through Fe-MIL-88 metal-organic framework templated route. J Chem Sci 132, 69 (2020). https://doi.org/10.1007/s12039-020-01777-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12039-020-01777-2