Abstract

As one of the most abundant renewable resources, rice straw is an attractive lignocellulosic material for animal feeding or for the production of biochemical. An appropriate pre-treatment technique is essential for converting rice straw to rich fodder or biofuel. Based on previous work, Coprinopsis cinerea can grow on rice straw medium and therefore it is useful for the treatment of rice straw. However, little is known regarding its degradation systems and nutrition values. In this study, we firstly found that C. cinerea could grow rapidly on rice straw without any additives by the production of a series of enzymes (laccase, cellulase, and xylanase) and that the microstructure and contents of rice straw changed significantly after being treated by C. cinerea. We propose that a possible underlying mechanism exists in the degradation. Moreover, C. cinerea has a high nutrition value (23.5% crude protein and 22.2% total amino acids). Hence, fermented rice straw with mycelium could be a good animal feedstuff resource instead of expensive forage. The direct usage of C. cinerea treatment is expected to be a practical, cost-effective, and environmental-friendly approach for enhancing the nutritive value and digestibility of rice straw.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rice straw is one of the most abundant lignocellulosic waste materials worldwide, which is featured by multiple varieties, huge amounts, and extensive distributions [1]. As one of the largest agricultural countries, 700 million tons of rice straw are generated annually in China, which occupies about 20–30% of straw in the world. However, the disposition of rice straw is limited by the slow rate of degradation, low bulk density, and high content of mineral [1]. Nowadays, field burning is still the major method to dispose rice straw, which causes air pollution and affects consequently the human health [2]. Alternatively, the possibility of recycling rice straw into value added products comes into view, which could not only solve the environmental issues caused by the incineration of rice straw but also add on economical value of rice straw [3, 4].

Rice straw predominantly contains 32–43% cellulose, 19–25% hemicellulose, 5–12% lignin, 14–16% ash, and 10–12% extractives [5]. These high contents of celluloses and hemicelluloses can be hydrolyzed into their component sugars, which can be further converted into biofuels or chemicals by microbial fermentation, like bioethanol [6, 7]. However, the costs of proper pre-treatment method and production of lignocellulose-degrading enzymes have impeded the large-scale production of bio-products from rice straw. Direct utilization of raw rice straw for livestock fodder as a part of the roughage components is therefore a good alternative for saving further costs. However, the nutritional value of raw rice straw to livestock is limited by low intake, slow digestion rate, and low content of available energy and proteins [8]. Hence, pre-treatment of straw is still one of the strategies for better digestibility to livestock. Accordingly, varieties of physical, chemical, and biological treatments have been developed to improve the quality of rice straw [9, 10]. During these methods, physical treatment is still not economically efficient, especially for small-scale farms, as they require expensive machinery facilities or industrial processing. These will make these treatments unprofitable for farmers due to the low economic benefits [9]. Instead, chemical treatments appear to be more practical, as no expensive machinery is required. In contrast, chemicals can be harmful, and safety precautions are needed for their usage. Compared to physical and chemical treatments, biological methods for rice straw treatment show great potential because of their cost effectiveness, low energy requirement, and mild environmental conditions. Unfortunately, most microbes cannot grow directly on rice straw without any supplementation [11]. Even if a few microorganisms can do it, long duration of fermentation may be inevitable [1].

Coprinopsis cinerea is a model organism commonly used for the studies on developmental processes with homobasidiomycetes. In comparison to other homobasidiomycetous fungi, C. cinerea shows a relatively short life cycle, which can form fruiting bodies completely in the laboratory within 2 weeks [12]. Recently, C. cinerea was found to grow rapidly in rice straw medium (88% dry rice straw, 5% bran, 3% corn meal, 2% compound fertilizer, 1% lime, 1% sugar, and an appropriate amount of water), which may be useful in the treatment of rice straw [13]. However, little is known regarding its degradation systems and nutrition values [12, 14]. Therefore, the present study was undertaken to investigate the degradation of rice straw, the nutritious value of C. cinerea, and the effect of fermented rice straw as fodder for guinea pigs.

Materials and Methods

Strains and Culture

Coprinopsis cinerea ATCC 56838 was obtained from the College of Life Science, Nanjing Normal University, China. For petri dish cultivation, an agar block with mycelium was inoculated on the center of a dish with 9 cm diameter containing YMG medium agar (4 g yeast extract, 10 g malt extract, 4 g glucose, 12 g agar, and 1 l distilled water). The dishes were incubated at 30 °C [13]. For the cultivation in large scale, an agar block with mycelium from the YMG medium agar was inoculated on sterilized rice straw medium in a polypropylene bag (17 cm × 25 cm) and incubated at 30 °C until mycelium grew throughout the whole straw medium in the bags.

Rice Straw Preparation, Inoculation, and Culture Conditions

Rice straw used in the experiments was obtained from Anhui Province, China. The straw was cut into smaller pieces (about 6–8 cm) and soaked in water for 1 day. One hundred and fifty grams of squeezed rice straw was put in the 1000 ml Erlenmeyer flasks and sterilized for 15 min at 121 °C. Then four pieces of 5 mm agar block with mycelium were inoculated on sterilized rice straw medium and incubated at 30 °C. Five grams of fermented straw from the flasks was harvested every 3 days until 2 weeks after inoculation.

Enzymatic Assays

The fermented straw (5 g) was immediately incubated with deionized water (1 ml water per 1 g straw) after harvesting in a shaker at 200 rpm at 30 °C for 4 h. Solids were separated by centrifugation at 12,000 rpm at 4 °C for 5 min. The supernatant was analyzed for activities of manganese peroxidase, lignin peroxidase, laccase, cellulase, and hemicellulase. Protein concentrations in the enzyme preparations were determined by measuring the absorbance at 280 nm [15].

Laccase activity was determined by monitoring the A420 change, which is related to the rate of oxidation of 1 mM 2,2′-azino-bis-[3-ethyltiazoline-6-sulfonate] (ABTS) in 25 mM Na-acetate buffer (pH 3.8) [16]. The assays were performed in 1 ml cuvette at 20 ± 1 °C with adequately diluted enzyme solution. Enzyme activity (U) = (1000 × 0.18 × 0.05 × dilution × 60)/t. The time was measured while the absorption was turning from 0.15 to 0.2. t = [10 s; 20 s]. One unit of laccase activity was defined as the amount of enzyme which leads to the oxidation of 1 μmol of ABTS per minute.

Celluloytic enzymes were measured with dinitrosalicylic acid (DNS) for determination of reducing sugar [17, 18]. The reaction mixture contains 0.2 ml CMC-Na or Avicel solution (1%) and 0.2 ml enzyme solution and incubated for 30 min at 50 °C. After incubation, 0.4 ml DNS was added and the samples were incubated for 10 min at 100 °C and centrifuged at 12,000 rpm for 10 min. The absorbance at 550 nm was measured, and the data were quantified using a standard d-glucose curve. One enzyme unit was defined as the amount of protein required to release 1 μmol of reduced sugar per min. β-Glucosidase activity was determined by the p-NPG according to Zhang et al. [19].

The xylanase assay is the same as the cellulase assay with the only difference of using a xylan solution (1%) with xylose as a standard [20].

Analytical Method

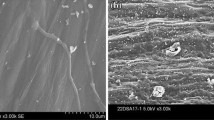

The microstructure of different treatment rice straw was observed with an analytical scanning electron microscope (SEM, Hitachi M3000, Japan). The samples were covered with gold/palladium, and images were obtained by SEM at 15 kV.

The content of cellulose, hemicellulose, and lignin fractions in rice straw were determined by the method of Vansoest et al. [21]. Cellulose was defined as the total amount of glucose, while hemicellulose was the sum of arabinose and xylose. Lignin was determined as the sum of acid-soluble residue and insoluble residue.

To quantify the content and types of soluble sugars in fermentation broth, both liquids from the flask and the supernatant of the soaked fermented straw were analyzed by a high-performance liquid chromatography (Chromeleon server monitor, P680 pump, Dionex, USA). A refractive index detector, RI101 (Shodex, USA), and an ion exchange chromatographic column (Aminex HPX-87H, 7.8 mm × 300 mm, Bio-Rad, USA) were used at a wavelength of 215 nm, and the mobile phase was 5 mM H2SO4 with the flow rate of 0.6 ml min−1 at 55 °C. Glucose was also measured by using a SBA-40C bio-sensor analyzer (Institute of Biology, Shandong, China).

To understand the nutrition value of C. cinerea, the mycelium from YMG plates were collected, ground into powder, and dried. The general composition analysis, including crude protein, crude fat, crude fiber, ash, and total carbohydrate, was determined by AOAC methods [22]. The crude protein content was quantified by the Kjeldahl method. Briefly, 1.5 g of the dried mycelia was digested in a Kjeldahl digestion flask by boiling with 25 ml of concentrated sulfuric acid and 10 g of Kjeldahl catalyst tablet until the mixture was clear. After cooling the flasks, 400 ml of cold water and 100 ml of 40% sodium hydroxide were added. The contents were distilled until 200 ml of solution was collected and mixed with 50 ml of boric acid with indicator. The solution was titrated with 0.097 mol l−1 HCl which had been standardized with sodium carbonate. The crude fat content was determined by Soxhlet extraction procedure. Dried mycelia (1 g) were extracted with petroleum ether using Soxhlet apparatus, after which petroleum ether was evaporated to dryness. The weight of crude fat was obtained from the difference between the initial and the final weight. The crude fiber content was determined by removing fat from it as described above and then by boiling consecutively with 1.25% H2SO4 and 1.25% NaOH solution. The ash content was analyzed by combusting of the residue, which was obtained at 550 °C after 24 h.

The total amino acids of proteins were analyzed according to the method established by the GB/T18246-2000 standard. For the amino acid composition of mycelium, an automatic amino acid analyzer (Hitachi, L-8900) equipped with a 60 × 4.6 mm sulfoacid cationic resin separation column (Hitachi dedicated ion exchange resin) and a 40 × 4.6 mm reaction column (emery inert material) after acid hydrolysis (6 M HCl, 110 °C, 24 h) were used. The process is completed by Jiangsu Academy of Agricultural Sciences. Tryptophan is all but destroyed in acid hydrolysis and was not determined in this study.

Guinea Pigs Experimental Procedures

Normal healthy female guinea pigs weighing 200 to 250 g were used in the experiments, which were purchased from an animals’ farm in Nanjing. The animals were kept in cages in a standard animal laboratory room. They had free access to water and food at room temperature. At the moment of experiment, guinea pigs were all of the same age and had approximately the same body weight in order to minimize biological variations [23]. The animals were divided into three groups: control, straw-fed, and straw with mycelium-fed. After a 2-week habituation period, the guinea pigs were randomly assigned to the groups. Six guinea pigs were used in each group. Prior to the experiment, daily food requirements were assessed by measuring the daily food consumption of the guinea pigs. The average daily food intake of a guinea pig included two meals per day between 9:00 and 18:00 with approximately 160 g. The guinea pigs of the control group were fed 60 g high-energy fodder in the morning and 100 g alfalfa at night, while the guinea pigs of the straw group were fed with 60 g of high-energy fodder in the morning and 100 g rice straw at night, which was replaced by 100 g rice straw with mycelium in the last group. In all groups, the daily rations were always fully consumed. Free moving space was observed for the guinea pigs. Changes of body weight were recorded every 4 days per month.

Results and Discussion

Optimization of Growth Condition for C. cinerea in Rice Straw

In our previous work, C. cinerea has shown rapid growth in sterilized rice straw medium with supplementation of nutrients. A series of research achievements, which focused on the fruiting body development, and autolysis have been reported [13, 19, 24, 25]. However, plenty of supplements, such as bran and sugar, were still needed when C. cinerea grew in rice straw, which would increase the operational costs in large-scale cultivation. Moreover, mechanisms on the degradation systems conducted by cellulolytic or ligninolytic enzymes are not elaborated, and proper methods regarding the handling of these residues are still needed. In this study, further optimization of the growth conditions for C. cinerea in rice straw was carried out. Interestingly, different from other known mushrooms species, it was found that C. cinerea can still grow rapidly on rice straw only even without any additives. And there is no apparent difference in mycelial growth and fruiting body development in sterilized rice straw with or without additives. It took only 7 days for the mycelium to grow throughout the whole straw medium in the bags, which was apparently faster than other reported white-rot or brown-rot fungi. Recently, many mushrooms have been reported regarding growth in different lignocellulosic wastes (Table 1). For instance, Pleurotus ostreatus can grow in banana agricultural waste, and the incubation time lasted for at least 15 days [27]. Phanerochaete chrysosporium can be cultivated in optimized liquid media containing 2 g of dry rice straw, and the whole fermentation period was 30 days [33]. Furthermore, C. cinerea can still grow well on unsterilized rice straw, although it showed a slower mycelial growth rate. It is known that the recalcitrant structure of lignin in lignocellulose would inhibit cell growth, and autoclave treatment when sterilizing rice straw could partially destroy these structure, which may make it easier for the mycelial to penetrate deeper into the straw cells and accelerate the hydrolysis of cellulose or hemicellulose. C. cinerea is a typical edible mushroom, and the young fruiting body has nutritional and pharmaceutical values. These results showed that C. cinerea may be a good candidate for the treatment of rice straw.

Detection of Cellulolytic, Hemicellulolytic, and Ligninolytic Enzyme Activities

For the mycelium of C. cinerea on rice straw, a series of hydrolytic enzymes are needed. So, to investigate the degrading enzymes’ profiles further, fermentation samples in different stages were collected and analyzed for different enzymatic assays. It is known that no manganese peroxidase (MnP) and lignin peroxidase (LiP) genes were found in the whole genome of C. cinerea [34]. So the activities of MnP and LiP were not detected, while laccase activity occurred on day 3 and reached a peak value of 2.21 U ml−1 on day 6, followed by a rapid reduction until day 12 (Fig. 1), showing that laccase can be the only ligninolytic enzyme for lignin degradation which occurred in the specific period. Laccase, a lignin-modifying extracellular oxidoreductase, can be used as a morphogenetic indicator, and the decrease of its enzymatic activity indicates that maximal mycelium growth was achieved [27]. Increase of laccase activity during the vegetative phase up to the appearance of fruiting bodies has been reported in Agaricus bisporus [35] and Coprinus congregates [36]. In the present study, maximum laccase activities were observed on day 6, further confirming that C. cinerea can grow rapidly in rice straw. However, considering that both polymerization and depolymerization activities exist for laccase, can the cells consume aromatic compounds generated from the lignin oxidation to promote the reaction toward depolymerization? Whether lignin was degraded with laccase alone? These questions will be addressed in the following results.

CMCase, Avicelase, and β-glucosidase activity were increased rapidly by contrast and reached the maximum on day 6 (0.51, 0.49, and 0.53 U ml−1, respectively), then tended gradually toward flattening after temporarily being decreased, while xylanase activity was increased slowly in the first 6 days, then increased significantly and reached a maximum on day 9 (0.57 U ml−1), subsequently gradually decreasing (Fig. 1). These results were significantly different from many reported studies. Low levels of CMCase and filter paper activities (less than 0.05 U mg−1) were observed in Pleurotus spp. during growth on rice straw [27]. The activities of xylanase and cellulolytic, obtained from solid-state cultivation of four white-rot fungi (Trametes versicolor, Bjerkandera adusta, Ganoderma applanatum, and Phlebia rufa) in wheat straw, were only within a low range of values (less than 0.2 U ml−1) [37]. It is reported that the growth rate of mycelial has a relationship with the enzyme activities. In the present study, both cellulolytic and hemicellulolytic activities showed high values, which may also support that C. cinerea grow rapidly in rice straw. In conclusion, it is strongly suggested that laccase, cellulase, and xylanase are essential for C. cinerea growth in rice straw. Interestingly, they may play vital roles in the different fermentation stages, respectively.

With the development of biotechnology, lignocellulosic biomass has attracted more and more attention because it can be hydrolyzed into fermentable sugars (carbohydrates), which can be further fermented into biochemicals or biofuels [4]. In order to determinate whether C. cinerea fermentation broth can be utilized for microorganism cultivation, the content and types of soluble sugars in fermentation broth were measured by HPLC. The results showed that only negligible glucose and xylose can be detected, while the maximum amount of glucose was just 0.6 g l−1, which was too low to support the growth of other microorganisms. Some strategies could be explored for further improvement of sugar concentrations. For example, combined metabolic engineering and enzyme engineering for enhancing the activities of some enzymes in order to get more content of sugars may be useful.

Changes in Compositions and Structures of the Rice Straw Treated by C. cinerea

For further detection of the degradation effect of rice straw by C. cinerea, the chemical compositions of untreated and mycelium-treated rice straw were measured. As shown in Table 2, compared to the control (untreated one), C. cinerea could decrease the contents of cellulose and hemicelluloses with decreases of 6.41 and 3.79% (P < 0.05), respectively. This decrement was probably because cellulose and hemicellulose were degraded into their component sugars via excretion of enzymes for mycelium growth. However, no big difference was observed in the contents of lignin (P > 0.05), which may be due to lack of enough enzymes for lignin degradation. As mentioned, laccase activity was only detected in the middle period of fermentation. It was suspected that the laccase was only used to destroy the structure of rice straw in order to expose cellulose and hemicellulose for the following enzymatic hydrolysis. It is known that cellulose and hemicellulose in lignocellulosic materials are densely packed by lignin network consisting of polysaccharide layers that prevent enzymatic hydrolysis [38]. The effect of the fungal treatment was different from that of chemical treatment, which can ionize the carboxylic and phenolic groups, causing the dissolution of lignin from a hemicelluloses-lignin matrix [39]. Hence, to expose the cellulose and hemicellulose for the following enzymatic action, the lignin network must be destroyed by lignin-degrading enzymes, e.g., laccase. Actually, 17 laccase-encoding genes have been found in the genomes of C. cinerea, which represents the highest amount in known white-rot and brown-rot fungi [40]. Further enzymatic assays confirmed that high laccase activities were detected when C. cinerea was growing on rice straw. Future work is still need to characterize the specific laccase gene.

In order to understand the effect of C. cinerea on rice straw microstructure, rice straw with or without C. cinerea mycelium were observed by SEM (Fig. 2). The SEM images showed that the untreated rice straw had a highly fibrillar and integrated morphology, and many pectic substance can be observed in the surface (Fig. 2a), while the mycelium-treated rice straw had a rugged and partially degraded face and many cracks and scars can be found, which possibly were due to the attack by mycelium growth of C. cinerea or the effects of extracellular enzymes secreted by C. cinerea (Fig. 2b). Chen et al. showed that removal of hemicelluloses increases the porosity of lignocellulosic materials [41], which may seem to be in accordance with our results. These results indicated that the microstructure of rice straw was altered significantly after the treatment with C. cinerea.

Fermented Straw Could Be Directly Used as Fodder for Guinea Pigs

Edible mushrooms contain mainly carbohydrates, proteins, vitamins, and minerals [42]. Studies have shown that the amino acids of the proteins in mushrooms are essential for human health and even that some mushroom proteins have antibacterial and anticancer properties [43]. However, the chemical composition and nutritional values of C. cinerea have not been reported and should be further investigated. The results of the general composition are shown in Table 3. Similar to other edible mushrooms, C. cinerea was rich in crude proteins but low in ash and fat [44]. Crude protein content of C. cinerea was found to be 23.5 ± 2.68%, which is higher than those in alfalfa. The amino acid composition in mushroom is similar to or even better than that in soy, and even for some species of mushrooms, the composition can be analogous to that of hen’s egg [45]. The composition of the amino acids in percentage is summarized in Table 4, which reveals that a total of 17 amino acids were found in the mycelium of C. cinerea. The total essential and non-essential amino acid concentrations of C. cinerea are 7.45 and 14.8%, respectively. The ratio of essential amino acids to non-essential amino acids is 0.51, which is close to the reference value of 0.6 recommended by FAO/WHO. Glutamic and aspartic acids are monosodium glutamate-like components, which contribute to the taste or palatable tastes in the most typical mushroom. Both of them were found to be the most abundant in all amino acids (4.29 and 2.41%). Among essential amino acids, leucine (1.44%) was found to be the largest constituent, followed by lysine (1.40%); nevertheless, methionine (0.31%) was found in small amounts (Table 4). Conceivably, these results indicate that C. cinerea could be a good animal feed additive in terms of varieties of nutrient components and all the essential amino acids.

In recent years, bioconversion of agriculture waste and residues (for instance, rice husk and rice straw) into animal feed has received a lot of attention, since biomass does not threaten food supplies. Proper pre-treatment of straw is highly needed for improving the digestibility of straw. Extensive research has been carried out for several decades on pre-treatment of straw using physical, chemical, and biological methods [46,47,48]. But economic benefit and social acceptance of these technologies is still impeded [49]. Therefore, biological treatments have been investigated for improvement in nutritional value of rice straw. In this study, C. cinerea can not only degrade the structure of rice straw via secreting high amounts of cellulase, hemicellulase, and laccase, the fungi also possess high nutritional value. The fermented rice straw by C. cinerea could be directly used as a feed for livestock growth. Guinea pigs were chosen to show the effects of fermented straw on their body weight. The body weight change of guinea pigs is shown in Fig. 3. In the control group, the body weight was increased to 439 g in 28 days with an average rate of 4.96 g day−1, while the data in the straw group decreased to 387 g and the average rate was only 3.11 g day−1. In contrast, the straw with mycelium group have no significant difference in the rate of weight gain (4.75 g day−1). This result indicated that feeding effect and nutritive value of the fermented rice straw with mycelium are similar to alfalfa, and substituting it for alfalfa is practical. The nutritive value of rice straw has been treated with three different edible mushrooms: P. ostreatus, Pleurotus pulmonarius, and Pleurotus tuber-regium were studied through analysis of their proximate composition and in vitro digestibility. It was observed that treatment of rice straw with different edible mushrooms improved the potential feeding value of the resultant substrate [3]. As mentioned, fungal treatment of rice straw improved not only the crude protein contents but also enhanced the digestibility: fungal treated rice straw has a good potential as feed resources for ruminant animals and could be used in combination with other feedstuffs. And the usage of expensive feed additives will be decreased, which will further reduce the production cost. Hence, it was concluded that the usage of C. cinerea treatment is expected to be a practical, cost-effective, and environmental-friendly approach for enhancing the nutritive value and digestibility of rice straw.

Conclusions

Biological pre-treatment was proved to be an effective method to improve rice straw biodegradability for biochemical production or digestibility for animal feed. The present study suggested that Coprinopsis cinerea could grow rapidly on rice straw without any additives by the secretion of a series of enzymes (laccase, cellulase, and xylanase), while the composition and microstructure of rice straw changed significantly. Therefore, a possible underlying mechanism in the degradation was proposed. Moreover, C. cinerea has a high nutrition value (23.47% crude protein and 22.21% total amino acids), and fermented rice straw with mycelium was the better feedstuff resource instead of expensive forage for animal. These findings, taken together, indicated that the direct usage of C. cinerea treatment is expected to be a practical, cost-effective, and environmental-friendly approach for enhancing the nutritive value and digestibility of rice straw.

References

Binod, P., Sindhu, R., Singhania, R. R., Vikram, S., Devi, L., Nagalakshmi, S., Kurien, N., Sukumaran, R. K., & Pandey, A. (2010). Bioethanol production from rice straw: an overview. Bioresource Technology, 101, 4767–4774.

Mussatto, S. I., & Roberto, I. C. (2004). Optimal experimental condition for hemicellulosic hydrolyzate treatment with activated charcoal for xylitol production. Biotechnology Progress, 20, 134–139.

Akinfemi, A., & Ogunwole, O. (2012). Chemical composition and in vitro digestibility of rice straw treated wih Pleurotus ostreatus, Pleurotus pulmonarius and Pleurotus tuber-regium. Slovak Journal of Animal Science, 45, 14–20.

Lim, J. S., Manan, Z. A., Alwi, S. R. W., & Hashim, H. (2012). A review on utilisation of biomass from rice industry as a source of renewable energy. Renewable and Sustainable Energy Reviews, 16, 3084–3094.

Yoswathana, N., Phuriphipat, P., Treyawutthiwat, P., & Eshtiaghi, M. N. (2010). Bioethanol production from rice straw. Energy Research Journal, 1, 26.

Alemahdi, N., Man, H. C., Abd Rahman, N., Nasirian, N., & Yang, Y. (2015). Enhanced mesophilic bio-hydrogen production of raw rice straw and activated sewage sludge by co-digestion. International Journal of Hydrogen Energy, 40, 16033–16044.

Kim, J. H., Block, D. E., Shoemaker, S. P., & Mills, D. A. (2010). Conversion of rice straw to bio-based chemicals: an integrated process using Lactobacillus brevis. Applied Microbiology and Biotechnology, 86, 1375–1385.

Van Soest, P. J. (2006). Rice straw, the role of silica and treatments to improve quality. Animal Feed Science and Technology, 130, 137–171.

Malik, K., Tokkas, J., & Kumari, R. C. A. A. N. (2015). Pretreated rice straw as an improved fodder for ruminants—an overview. Journal of Applied and Natural Science., 7, 514–520.

Ghasemi, E., Khorvash, M., Ghorbani, G. R., Emami, M. R., & Karimi, K. (2013). Dry chemical processing and ensiling of rice straw to improve its quality for use as ruminant feed. Tropical Animal Health and Production, 45, 1215–1221.

van Kuijk, S. J. A., Sonnenberg, A. S. M., Baars, J. J. P., Hendriks, W. H., & Cone, J. W. (2015). Fungal treated lignocellulosic biomass as ruminant feed ingredient: a review. Biotechnology Advances, 33, 191–202.

Kues, U. (2000). Life history and developmental processes in the basidiomycete Coprinus cinereus. Microbiology and Molecular Biology Reviews, 64, 316.

Zhou, Y., Zhang, W., Liu, Z., Wang, J., & Yuan, S. (2015). Purification, characterization and synergism in autolysis of a group of 1,3-beta-glucan hydrolases from the pilei of Coprinopsis cinerea fruiting bodies. Microbiology, 161, 1978–1989.

Moore, D., & Pukkila, P. J. (1985). Coprinus cinereus—an ideal organism for studies of genetics and developmental biology. Journal of Biological Education, 19, 31–40.

Mcdermid, K. P., Forsberg, C. W., & Mackenzie, C. R. (1990). Purification and properties of an acetylxylan esterase from Fibrobacter succinogenes S85. Applied and Environmental Microbiology, 56, 3805–3810.

Songulashvili, G., Elisashvili, V., Wasser, S. P., Nevo, E., & Hadar, Y. (2007). Basidiomycetes laccase and manganese peroxidase activity in submerged fermentation of food industry wastes. Enzyme and Microbial Technology, 41, 57–61.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Wood, T. M., & Bhat, K. M. (1988). Methods for measuring cellulase activities. Methods in Enzymology, 160, 87–112.

Zhang, W., Kang, L., Yang, M., Zhou, Y., Wang, J., Liu, Z., & Yuan, S. (2016). Purification, characterization and function analysis of an extracellular beta-glucosidase from elongating stipe cell walls in Coprinopsis cinerea. FEMS Microbiology Letters, 363, fnw120.

Tabka, M. G., Herpoel-Gimbert, I., Monod, F., Asther, M., & Sigoillot, J. C. (2006). Enzymatic saccharification of wheat straw for bioethanol production by a combined cellulase xylanase and feruloyl esterase treatment. Enzyme and Microbial Technology, 39, 897–902.

Vansoest, P. J., Robertson, J. B., & Lewis, B. A. (1991). Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 74, 3583–3597.

AOAC. (1990). Official methods of analysis. Washington DC: Association of Official Analytical Chemists.

Nageh, A., El-masry, T., Elsayad, M., Shimaa, M. E., Sally, E., & Karima, I. (2015). Effects of rice straw burning products on guinea pig lungs. African Journal of Pharmacy and Pharmacology, 9, 645–661.

Zhang, W. M., Wu, X. X., Zhou, Y. J., Liu, Z. H., Zhang, W., Niu, X., Zhao, Y., Pei, S. Y., Zhao, Y., & Yuan, S. (2014). Characterization of stipe elongation of the mushroom Coprinopsis cinerea. Microbiology, 160, 1893–1902.

Liu, Z. H., Niu, X., Wang, J., Zhang, W. M., Yang, M. M., Liu, C. C., Xiong, Y. J., Zhao, Y., Pei, S. Y., Qin, Q., Zhang, Y., Yu, Y., & Yuan, S. (2015). Comparative study of nonautolytic mutant and wild-type strains of Coprinopsis cinerea supports an important role of glucanases in fruiting body autolysis. Journal of Agricultural and Food Chemistry, 63, 9609–9614.

Jalc, D., Nerud, F., & Siroka, P. (1998). The effectiveness of biological treatment of wheat straw by white-rot fungi. Folia Microbiologica, 43, 687–689.

Reddy, G. V., Babu, P. R., Komaraih, P., Roy, K. R. R. M., & Kothari, I. L. (2003). Utilization of banana waste for the production of lignolytic and cellulolytic enzymes by solid substrate fermentation using two Pleurotus species (P. ostreatus and P. sajorcaju). Process Biochemistry, 38, 1457–1462.

Rai, S. N., Walli, T. K., & Gupta, B. N. (1989). The chemical-composition and nutritive-value of rice straw after treatment with urea or Coprinus fimetarius in a solid-state fermentation system. Animal Feed Science and Technology, 26, 81–92.

Rahman, M. M., Lourenco, M., Hassim, H. A., Baars, J. J. P., Sonnenberg, A. S. M., Cone, J. W., De Boever, J., & Fievez, V. (2011). Improving ruminal degradability of oil palm fronds using white rot fungi. Animal Feed Science and Technology, 169, 157–166.

Okano, K., Kitagawa, M., Sasaki, Y., & Watanabe, T. (2005). Conversion of Japanese red cedar (Cryptomeria japonica) into a feed for ruminants by white-rot basidiomycetes. Animal Feed Science and Technology, 120, 235–243.

Asiegbu, F. O., Paterson, A., & Smith, J. E. (1996). The effects of co-fungal cultures and supplementation with carbohydrate adjuncts on lignin biodegradation and substrate digestibility. World Journal of Microbiology and Biotechnology, 12, 273–279.

Mukherjee, R., & Nandi, B. (2004). Improvement of in vitro digestibility through biological treatment of water hyacinth biomass by two Pleurotus species. International Biodeterioration & Biodegradation, 53, 7–12.

Bak, J. S., Ko, J. K., Choi, I. G., Park, Y. C., Seo, J. H., & Kim, K. H. (2009). Fungal pretreatment of lignocellulose by Phanerochaete chrysosporium to produce ethanol from rice straw. Biotechnology and Bioengineering, 104, 471–482.

Stajich, J. E., Wilke, S. K., Ahren, D., Au, C. H., Birren, B. W., Borodovsky, M., Burns, C., Canback, B., Casselton, L. A., Cheng, C. K., Deng, J. X., Dietrich, F. S., Fargo, D. C., Farman, M. L., Gathman, A. C., Goldberg, J., Guigo, R., Hoegger, P. J., Hooker, J. B., Huggins, A., James, T. Y., Kamada, T., Kilaru, S., Kodira, C., Kues, U., Kupfert, D., Kwan, H. S., Lomsadze, A., Li, W. X., Lilly, W. W., Ma, L. J., Mackey, A. J., Manning, G., Martin, F., Muraguchi, H., Natvig, D. O., Palmerini, H., Ramesh, M. A., Rehmeyer, C. J., Roe, B. A., Shenoy, N., Stanke, M., Ter-Hovhannisyan, V., Tunlid, A., Velagapudi, R., Vision, T. J., Zeng, Q. D., Zolan, M. E., & Pukkila, P. J. (2010). Insights into evolution of multicellular fungi from the assembled chromosomes of the mushroom Coprinopsis cinerea (Coprinus cinereus). Proceedings of the National Academy of Sciences of the United States of America, 107, 11889–11894.

Wood, D. A. (1980). Inactivation of extracellular laccase during fruiting of Agaricus bisporus. Journal of General Microbiology, 117, 339–345.

Ross, I. K. (1982). The role of laccase in carpophore initiation in Coprinus congregatus. Journal of General Microbiology, 128, 2763–2770.

Dinis, M. J., Bezerra, R. M. F., Nunes, F., Dias, A. A., Guedes, C. V., Ferreira, L. M. M., Cone, J. W., Marques, G. S. M., Barros, A. R. N., & Rodrigues, M. A. M. (2009). Modification of wheat straw lignin by solid state fermentation with white-rot fungi. Bioresource Technology, 100, 4829–4835.

Iiyama, K., Lam, T. B. T., & Stone, B. A. (1994). Covalent cross-links in the cell-wall. Plant Physiology, 104, 315–320.

Nuchdang, S., Vatanyoopaisarn, S., & Phalakornkule, C. (2015). Effectiveness of fungal treatment by Coprinopsis cinerea and Polyporus tricholoma on degradation and methane yields of lignocellulosic grass. International Biodeterioration & Biodegradation, 104, 38–45.

Hatakka, A., & Hammel, K. E. (2011). Fungal biodegradation of lignocelluloses. In industrial applications (pp. 319–340). Berlin: Springer.

Chen, Y., Sharma-Shivappa, R. R., Keshwani, D., & Chen, C. (2007). Potential of agricultural residues and hay for bioethanol production. Applied Biochemistry and Biotechnology, 142, 276–290.

Reid, T., Munyanyi, M., & Mduluza, T. (2016). Effect of cooking and preservation on nutritional and phytochemical composition of the mushroom Amanita zambiana. Food Science & Nutrition, 5, 538–544.

Cheung, P. C. (2008). Nutritional value and health benefits of mushrooms. In Mushrooms as Functional Foods (pp. 73–75). USA: John Wiley & Sons, Inc.

Liu, Y. T., Sun, J., Luo, Z. Y., Rao, S. Q., Su, Y. J., Xu, R. R., & Yang, Y. J. (2012). Chemical composition of five wild edible mushrooms collected from Southwest China and their antihyperglycemic and antioxidant activity. Food and Chemical Toxicology, 50, 1238–1244.

Yin, J., & Zhou, L. (2008). Analysis of nutritional components of 4 kinds of wild edible fungi in Yunnan. Food Research and Development, 29, 133–136.

Vadiveloo, J. (2003). The effect of agronomic improvement and urea treatment on the nutritional value of Malaysian rice straw varieties. Animal Feed Science and Technology, 108, 133–146.

Selim, A. S. M., Pan, J., Takano, T., Suzuki, T., Koike, S., Kobayashi, Y., & Tanaka, K. (2004). Effect of ammonia treatment on physical strength of rice straw, distribution of straw particles and particle-associated bacteria in sheep rumen. Animal Feed Science and Technology, 115, 117–128.

Sarnklong, C., Cone, J. W., Pellikaan, W., & Hendriks, W. H. (2010). Utilization of rice straw and different treatments to improve its feed value for ruminants: a review. Asian Australasian Journal of Animal Sciences, 23, 680–692.

Devendra, C. (1997). Crop residues for feeding animals in Asia: Technology development and adoption in crop/livestock systems. In Crop residues in sustainable mixed crop/livestock farming systems (pp. 241–268). Wallingford, UK: CAB International.

Acknowledgements

The authors are thankful to Prof. Sheng Yuan, College of Life Science, Nanjing Normal University, China, for the gift of mushroom species. This work was supported by the “973” Program of China (Grant No. 2013CB733902), the National Natural Science Foundation of China (Grant No. 21306087), the Specialized Research Fund for the Doctoral Program of Higher Education (Grant No. 20123221110008), the Program for New Century Excellent Talents in University, a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions, Program for Changjiang Scholars and Innovative Research Team in University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, W., Wu, S., Cai, L. et al. Improved Treatment and Utilization of Rice Straw by Coprinopsis cinerea . Appl Biochem Biotechnol 184, 616–629 (2018). https://doi.org/10.1007/s12010-017-2579-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2579-0