Abstract

Oryza sativa commonly called as rice is a second major cereal crop after wheat and is thought to be originated from Asian regions that contribute about 90% of its total global production. Besides feeding populations around globe, it is also producing significant amount of lignocellulosic waste consisting of 28–45% cellulose, 12–32% hemicellulose, and 5–24% lignin along with some other biochemical constituents. Lack of management and awareness among crop producers leads to the open field burning of heaps of paddy straw that is of huge environmental concern, causing air, soil, and water pollution in nearby areas. However, the advent of new biological and technological techniques has led to the efficient in situ and ex situ management of paddy straw. The biotechnological approaches using lignocellulolytic microbes in both solid-state and submerged fermentation conditions to produce important hydrolytic enzymes using paddy straw as a biochemically rich lignocellulosic waste are gaining much attention.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keyword

- Hydrolytic enzymes

- Paddy straw (PS)

- In situ and ex situ management

- Lignocellulosic biomass

- Fermentation processes

- Solid-state fermentation (SSF)

- Submerged fermentation (smf)

- Microbes

9.1 Introduction

Rice crop commonly called as paddy is actually a grass (Gramineae) and a member of genus Oryza. The rice varieties Oryza sativa and Oryza glaberrima were originated from Asia and Africa, respectively. Other places like India and Northern Thailand have also been proposed in literature as origins of O. sativa. In addition, Yangzi valley of Southern China is also considered among the domesticated places of rice (Dobermann and Fairhurst 2002; Singh et al. 1995). Rice can be grown in a variety of environments. But higher yields are reported in dry season characterized by lesser cloud cover and more photosynthetic active rays in comparison to wet season (Dobermann and Fairhurst 2002). For various geographical areas and environments, the main rice harvesting season lasts from June through October (Zhiqiang et al. 2011). Normally, the growing season of rice crop is almost 260 days, but the most of the modern varieties commonly cultivated took relatively shorter time of about 90–110 days (Dobermann and Fairhurst 2002).

Being the most popular cereal around the globe, rice (Oryza sativa) is mostly consumed in the developing countries where it is a major diet component of population (Ramos et al. 2022). For example, in South Asia alone, rice is consumed by around 1670 million individuals (Meetei et al. 2020; Dutta et al. 2020; Urfels et al. 2020). It is estimated by FAO (Food and Agriculture Organization of UN) that 164 Mha of global land is covered by around 760 Mt of rice that are produced each year (FAO 2022). According to regional distribution, about 90% of the total global rice is produced by Asia, and the remaining is contributed by Africa and Latin America. In addition some quantity of this cereal crop is also produced in Europe but only in Mediterranean regions (Ramos et al. 2022). Specifically, 2/3 of the European rice consumption is supported mainly by European Union and Spain where 7.83 million tons of rice crop is being grown per annum (AEE_2022_WEB n.d.).

Considering abovementioned figures along with the world’s rice consumption, the post-harvest rice processing produces a blend of lignocellulosic wastes such as paddy straw (PS) in the fields and rice husk during milling process (Ramos et al. 2022). As a most consumed cereal after wheat, rice generates significant amount of waste every year (972 t/anum). According to estimates, during each harvesting season, around 6 t/ha of paddy straw (PS) is produced that is of huge environmental concern (Torregrosa et al. 2021). The production of paddy straw (PS) annually ranges from 370 to 520 million tons, making it a prevalent agri-waste globally (Van Hung et al. 2020). One of the major causes of this enormous waste production is the usage of combined harvesters in the rice fields that produce more waste as compared to manual harvesting. This is because of their inability to cut rice stems deeply, hence resulting in loose straw that offer great difficulties in operation of agricultural machinery for sowing of subsequent crop (Nagar et al. 2020).

In rural populations, rice cultivation not only provides employment opportunities but also ensures the food availability (Bhaduri et al. 2017; Nandan et al. 2021; Taneja et al. 2019). But because of the lack of adequate awareness and poor management of paddy straw (PS) generated in the fields, the farmers are left with the only option of burning this waste in the open fields. According to literature the crop residues that are burnt every year majorly constitutes waste streams from rice (40%) and then wheat (22%) and sugarcane (20%) (Nagar et al. 2020).

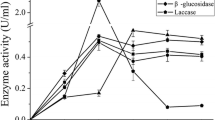

Even in this era of agricultural innovations, environmental sustainability is at greater risk due to the burning of crop residues (Bimbraw 2019; Mondal et al. 2020). High fiber content of paddy straw makes it less susceptible to biodegradation. So in order to get rid of heaps of paddy straw, burning has been considered as a cheap, affordable, and easy traditional solution but with greater social and environmental effects. For instance, open-field burning of paddy straw (PS) results in smoke that upon interaction with weather conditions cause certain respiratory diseases in nearby population. In addition to smoke, this incomplete combustion also results in emission of highly volatile and polluting organic compounds. Besides, it causes emission of several atmospheric particles. These particles badly affect the local hydrobiological cycle, climate, and aerial clarity (Grillo et al. 2020; Singh et al. 2021; Singh et al. 2020b). The pollutants that badly affect air and soil are also mentioned in Table 9.1. It is believed by farmers that PS burning is advantageous as it is helpful in the preparation of fields for subsequent cropping. It is reported by researchers that burning of PS helps in elimination of phytopathogens present in the soil (Chen et al. 2019) with reduced energy costs and results in efficient residue removal in less time (Trivedi et al. 2017; Singh et al. 2020a). On the other hand, the most common disadvantages of PS burning include air pollution and loss of microbial diversity in soil which also adversely affects agricultural sustainability (Goncharov et al. 2020). In addition, it eliminates crucial agricultural resource, namely, straw. Furthermore, it cause degradation of topsoil that lead to reduced arability of landscapes which can be replenished by efficiently recycled paddy straw (Raheem et al. 2019). Advances in science helps to avoid all these problems by both in situ and ex situ management of PS as presented in Fig. 9.1 and production of various valuable products from it (Singh and Brar 2021). Besides these, it can also be utilized in fermentation processes for the production of various multi-functional hydrolytic enzymes like cellulase, xylanase, laccase, endoglucanase, 𝛽-glucosidase, etc. The enhanced production of these enzymes is reported in the presence of medias supplemented with other residues and co-cultures of different microbes (Dhillon et al. 2011; Iyer and Chattoo 2003). The main focus of this chapter is on the production of hydrolytic enzymes utilizing paddy straw (PS) as a substrate in fermentation processes.

9.2 Paddy Straw as a Substrate

Morphologically, PS consist of cylindrical shaped stalk/stem having length ranging from 60 to 120 cm with flat-shaped and elongated leaves that are distributed alternately along the stem. Structural analysis of plant fibers shows that its complex matrix is buildup of hemicellulose, cellulose, and lignin along with other biologically active compounds. Cellulose and hemicellulose bound together by hydrogen bonds provide support to lignin which in turn serve as a natural glue. Hence, the individual plant cells in the form of this structural network provide great strength to plant (Ramos et al. 2022).

Paddy straw is actually a lignocellulosic biomass consisting of three polycarbohydrates among which hemicellulose and cellulose are aliphatic, while lignin is a natural polycyclic aromatic biopolymer. These hydrocarbon polymers can easily be distinguished on the basis of their constituent sugars. For instance, cellulose is a long linear biopolymer of β-glucose subunits that are linked by one to four glycosidic linkages. It is found both in nature and in agro-industrial wastes. Crystalline fibers are formed by high molecular mass cellulose (Razali et al. 2022). On the basis of structural configuration of carbon atoms and hydrogen bonds, cellulose is categorized as primary (trees), secondary (plants), tertiary (agri-food wastage), and quaternary (algae, bacteria, and certain marine organisms). In plants, cellulose being trapped between lignin and hemicellulose is quite difficult to separate. In addition, cellulose is abundant, cheap, and non-toxic, and owing to its complex structure, it is insoluble in some common solvents like water (Razali et al. 2022).

On the other hand, hemicellulose is a shorter heteropolymer consisting of several different polysaccharides including pentoses and hexoses like galactose, arabinose, mannose, xylose, and rhamnose and uronic acids (Goodman 2020; Qaseem et al. 2021). The structure of hemicellulose is relatively complex. These polymers have relatively low molecular weight as compared to cellulose which make them susceptible to hydrolysis under mild conditions. These are second most abundant compound that are found commonly in vegetable fibers. Owing to OH group in the structure, it is hygroscopic in nature (can form bonds with H2O). In addition, it has less degree of polymerization (80–200) than cellulose (Qaseem et al. 2021). Furthermore, according to variation in structural configuration, hemicellulose are divided into four groups, namely, xyloglucans, mannoglycans, xyloglycans, and β-glucans, with mixed linkages showing diversity in ramifications and different chains and bonds (Huang et al. 2021).

In contrast, the third biopolymer is lignin which is an aromatic hydrocarbon polymer that is composed of oxidativley coupled 4-hydroxyphenylpropanoids usually p-coumaric with synapyl and coniferyl alcohols (Ralph et al. 2004). These abovementioned polymers form very complex and stable 3D structure as illustrated in Fig. 9.2. This structure is commonly named as lignocellulose in the plant cell wall (Goodman 2020). Paddy straw also contains some amount of polyphenols. These are found naturally as secondary metabolite of plants and contain at least a single aromatic ring bound to one or more OH groups. These compounds prevent cellular oxidation and play a role in defense mechanism of plants. According to their structure, polyphenols are categorized mainly into flavonoids, stilbenes, and phenolic acids, but different others can also be found in PS (Khosravi and Razavi 2020).

In addition, minor fractions of some other soluble and insoluble components like proteins, pectin, waxes, and minerals are also present. Certain parameters like crop cultivars and varieties, soil quality, growth stage, environmental conditions, and other factors cause fluctuations in the proportion of these constituents (Kumar et al. 2018). This biochemically rich nature of paddy straw makes it a suitable substrate for enzyme production. The complete percentage compositions of all the components present in PS are depicted in Table 9.2.

For its use in fermentation processes, PS must first be converted into simpler forms through several pretreatment methods, because its complex components cannot be utilized efficiently by enzyme producing microbes. The stable complex structure of lignocellulose and other components makes it difficult to separate the individual subunits from the polymers present in plant cell wall, although various chemical, physical, or biological treatments are used individually or in combination as displayed in Fig. 9.3 to convert polymers into simpler reducing sugars and phenolic subunits. However, efficient utilization of PS-derived biomass is yet under development (Wi et al. 2013). So accumulation of PS in soil and open field burning are still commonly practiced despite their hazards to environmental sustainability (Goodman 2020).

9.3 Microbes Utilized in Process

Different types of microbes can be used in fermentation process including bacteria, fungi, yeast, and some others. Due to lignocellulosic nature of paddy straw, those microbes are preferentially utilized in fermentation process that have ability to degrade rigid complex structure of lignocellulose and to use its reduced subunits as a carbon source to produce various desired valuable bioproducts. This chapter mainly focus on the production of hydrolytic enzymes from fermentation of paddy straw. The microbes that can be used for this purpose are discussed in this section.

9.3.1 Bacteria

Bacteria being the earliest and most basic form of life on earth play a crucial role in cycling nutrients and maintaining earth’s ecology (Ho et al. 2020). It also plays significant role as a producer microbe in fermentation processes. And due to the accessibility and economy of lignocellulosic biomass, it is commonly used in fermentation media as carbon source. So in order to break down lignocellulose, bacteria use its cellulases and hemi-cellulases (Taha et al. 2015a, 2015b). Bacteria are effective microbe for this purpose because of several advantages like ease of culturing, possibilities of enhanced expression and accelerated production (Taha et al. 2015a, 2015b), shorter generation times (Muaaz-Us-Salam et al. 2020), etc. In addition, their metabolic versatility makes them able to endure environmental stress, e.g., fluctuations in pH, temperature, oxygen availability, and salinity (Daniel and Nilsson 1998). Also a recently discovered advantage is that during the latter stages of lignocellulose breakdown, bacteria might show accelerated growth which is beneficial because these stages are renowned for having components that are difficult to hydrolyze. These accelerated growth rates leads to enhanced enzyme production. Bacterial lignocellulases work in the form of multi-enzymatic complexes that are affective for complicated degradation of complex biomass (López-Mondéjar et al. 2019).

Although bacteria use a variety of methods to degrade lignocellulosic biomass, free-enzyme system is most commonly used among them. Aerobic bacteria largely use this system of free enzymes. On the other hand, anaerobic bacteria mostly utilize intricate protein complexes such as xylanosomes and cellulosomes which play role as supportive enzymes to hydrolyze complex biomass (Malgas et al. 2017).

As cellulose is most abundant and common biomolecule, so the microbes that degrade it are actually playing significant role in carbon flux in ecosphere (McDonald et al. 2012). The cellulose degrading bacteria (cellulotyic bacteria) that are mostly isolated belongs to two phylums Actinobacteria (order Actinomycetales) that are aerobic and Firmicutes (order Clostridiales) that are anaerobic. Among these two, Actinobacteria efficiently degrade cellulose because the other one is incapable of penetrating cellulosic substances (Chukwuma et al. 2021). Mechanism of cellulose degradation in aerobic and anaerobic bacteria is slightly different (Mohee et al. 2008). Aerobic bacteria do so by the action of free-cellulolytic enzymes in two steps (Singhvi and Gokhale 2019). In first step (depolymerization), it converts cellulose present in biomass into cellobiose; then in second step (fermentation), it hydrolyzes cellobiose into organic acids, hydrogen, and carbon dioxide (Hassan et al. 2019). After this, in the latter stages, bacteria dominating in the medium produce valuable products by utilizing these secondary products as carbon and energy source (Beaton et al. 2019). On the other hand, anaerobic cellulose fermentation also takes place in two steps. It involves conversion of sugars into acids or alcohol in first step and then production of biogas from these acids and/or alcohols (Hassan et al. 2019).

Following cellulose, the second most common macromolecule is lignin (Liao et al. 2020) which cannot be easily hydrolyzed and is a major deterrent to lignocellulose degradation. Streptomyces has been commonly identified as ligninolytic bacteria that belong to Actinobacteria. Some other types of bacteria that can breakdown both lignin and carbohydrate content in lignocellulose include Thermobifida fusca, Caldicellulosiruptor bescii, and Clostridium thermocellum (Lee et al. 2019). Lignolytic bacteria breakdown lignin by three ways: cavitation, tunneling, and erosion (Berg and Laskowski 2005). But the bacteria such as Proteobacteria and Actinobacteria do lignin degradation by depolymerization, catabolism of aromatic compounds, and biosynthesis of specific product. Depolymerization of lignin is distinct from hemicellulose and cellulose because of the involvement of electron transfer and redox reactions in it (Xie et al. 2016). The bacterial strains used commonly for paddy straw bioconversion are mentioned in Table 9.3.

9.3.2 Fungi

Fungal species that can degrade lignin include mostly filamentous fungi. These can be isolated from soil, plants, and lignocellulosic wastes where they are found indigenously. It is reported in various studies that brown- and white-rot fungi display effective lignocellulolytic capabilities. They have been found to degrade various lignocellulosic biomass like softwood, wheat straw, wood chips, and Bermuda grass (Alexandropoulou et al. 2017; Cohen et al. 2017; Mishra et al. 2017). In ecosystem, fungal species are the main degraders of wood in the forests. Also various fungal species are used especially for their greater lignolytic efficiencies. For example, white-rot fungus can breakdown lignin, hemicellulose, and cellulose. On the other hand, brown-rot fungus degrades hemicellulose and cellulose polymers while leaving the tougher lignin walls intact (Tsegaye et al. 2019). Despite their greater lignin degrading potential, fungi are not suitable for larger-scale operations because of their requirement for longer residence time which leads to increasing demands of larger space and higher production costs. However, chemical-free operation, eco-friendliness, and ability to work at mild temperature make them economic alternative producer microbe in fermentation processes (Tsegaye et al. 2019).

In fungi, the mechanism of degradation of lignocellulosic biomass is classified into two types, namely, oxidative and hydrolytic degradation. During oxidative-type lignin degradation, reactive species of oxygen in the form of free radicals such as hydroxyl are produced (Hammel et al. 2002). First, the mutual catalytic action of three enzymes including glyoxaline oxidase, pyranose-2 oxidase, and aryl-alcohol oxidase produces hydrogen peroxide (Martínez et al. 2009). Then these hydrogen peroxides react with iron to produce hydroxyl radicals (Fenton reaction) which act on lignin to degrade it into products of low molecular mass (Hammel et al. 2002). Some other enzymes like laccases and manganese peroxidase also catalyze lignin degradation in oxidative-type reactions (Eggert et al. 1997). In contrast, the mechanism of hydrolytic type of reaction involves the breakdown of glycosidic linkages by means of hydrolytic enzymes (Feijoo et al. 2008). Fungal species used for production of enzymes from paddy straw are indicated in Table 9.4.

9.3.3 Yeast

Saccharomyces cerevisiae commonly called as yeast is mostly used in fermentation processes. However, its inability to utilize hexose and lower metabolic activity at higher concentration of ethanol make it less suitable for fermentation operations involving lignocellulosic biomass. This is a major hindrance in its selection as producer microbe in fermentation processes. Larger-scale production of enzymes using paddy straw as lignocellulosic biomass is still poorly developed due to the unavailability of suitable producer microbe that can efficiently utilize reducing sugars like hexose and pentose (Gabriel and El-halwagi 2013).

9.4 Fermentation Process

The metabolic process of fermentation is used to convert carbohydrates to various valuable metabolites. Paddy straw is lignocellulosic in nature and is used by microbes as a carbon source in fermentation process to produce various hydrolytic enzymes as demonstrated in Fig. 9.4. On the basis of physical state of medium, fermentation is categorized into two types: solid-state and submerged fermentation. The characteristics of these types of fermentation and the microbes utilized in them are discussed below.

9.4.1 Submerged Fermentation (SmF)

SmF is a biochemical process in which microbes are cultivated in liquid medium called broth. Several industrially important enzymes have been produced by this method. This involves first the selection of a suitable microbe and then the preparation of fermentation medium containing sterilized raw material and some nutrients that are essential for the growth of microbes in the presence of sufficient oxygen. Finally, the microbe utilize these nutrients and ultimately degrade them into final product usually enzymes that are secreted into the fermentation broth (Renge et al. 2012).

Due to advancements in biotechnology, enzymes are now produced in significant proportions in larger-sized bioreactors that can accommodate volumes of around 1000 cm3. According to the time limit and operation method, submerged fermentation is further classified into batch, fed-batch, and continuous modes. Batch mode involves the addition of nutrients at the start of reaction only. Fed batch involves the addition of nutrients during the reaction, and continuous mode involves the continuous addition of nutrients and removal of broth from the system at a similar flow rate. One of the advantages of submerged fermentation is that it is a highly controlled process. All the parameters like pH, temperature, oxygen utilization, formation of carbon dioxide, etc. are optimized for efficient working of microbe and enzyme production. In downstream processing, first step mostly involves the removal of insoluble microbial biomass by centrifugation and its recycling and inactivation by its treatment with lime. Most industrially important enzymes are usually extracellular and are secreted in broth from which they can be concentrated by membrane filtration, evaporation, crystallization, etc. according to their desired application. Enzymes can be further purified by techniques like ion or gel chromatography, etc. The final enzyme produced (powdered form) can be used either in solid form (granules) or in liquid form (enzyme solutions) depending upon the required state for particular application. Mostly enzymes are immobilized on the solid support for prolonged usage (Renge et al. 2012).

Various microbes including bacteria and fungi can be used for paddy straw degradation to produce enzymes. Some microbial strains (fungi and bacteria) that can be utilized include species of Fusarium, Aspergillus, Phoma, etc. In addition, Vibrio, Cytophaga, Cellulomonas, Polyangium, Nocardia, and Streptomyces also show cellulolytic activities. Some white-rot fungi like Phanerochaete chrysosporium have also been reported in literature for this purpose. These lignolytic and cellulolytic microbes have frequently been utilized for the synthesis of enzymes such as β-glucosidase, exo- and endo-cellulases, peroxidases, laccases, etc. using lignocellulosic wastes like paddy straw in submerged fermentation conditions (Mishra and Pandey Lata 2007).

9.4.2 Solid-State Fermentation (SSF)

The other method that is used for enzyme production is solid-state fermentation. It is a type of fermentation in which microbes are cultivated on a solid support or raw materials that are in solid state with low water content such as paddy straw, wheat bran, sugar bagasse, husks, paper pulp, etc. (Renge et al. 2012; Subramaniyam and Vimala 2012).

Like submerged fermentation, SSF has some advantages like simple operation with less equipment, production of product in high concentration and volumes, and generation of less effluent. These advantages make SSF a suitable alternate to submerged fermentation. In SSF, various substrates can be used, but lignocellulosic substrates like straws, brans, and husks of wheat and rice are preferable. In addition, corn and wheat flour, pulp of sugar beet, etc. are also used. Substrate selection depends upon some factors like availability and cost of substrate. Moisture level and particle size are some other factors. For example, small-sized particles result in better proliferation of microbe on large surface area. However, too small particles cause poor growth, impeded respiration, and hence lower enzyme production as well. Similarly, larger particles result in efficient respiration, but the reduced surface area badly affects other aspects (Renge et al. 2012). In the same way, moisture of substrate also affects the rheology of medium and metabolic activity of microbe in SSF and in turn enzyme production. So, water content should be carefully maintained to minimize its detrimental effects on microbial activity. SSF have widely been employed for the synthesis of vital hydrolytic enzymes like cellulases, pectinases, proteases, and glucoamylases (Renge et al. 2012; Suganthi et al. 2011).

Microbes that are used mostly in SSF include filamentous fungi and yeast. Some species of bacteria are also used. Filamentous fungi that are mostly used include genera of Fusarium, Aspergillus, Trichoderma, Penicillium, and Rhizopus. Yeast such as Candida sp., Saccharomyces cerevisiae, and Saccharomyces boulardii are employed in SSF. Actinobacteria species used for this purpose include Streptomyces thermonitrificans and Streptomyces chattanoogensis (Hu et al. 2012; Orozco et al. 2008; Munishamanna et al. 2017). Bacterial species that are notably used in SSF include Bacillus mycoides, Bacillus megaterium, etc. Some species of Lactobacillus including L. plantarum, bulgaricus, acidophilus, delbrueckii, coryniformis, and rhamnosus are also reported to be involved in SSF (Oboh 2006; Hongzhang et al. 2011; Hsu et al. 2013; Andriani et al. 2015; Saanu and Oladiti 2018).

9.5 Hydrolytic Enzymes

9.5.1 Cellulases

Cellulase are the group of enzymes that are known for hydrolyzing β-1, 4 glycosidic bonds present in the polymeric cellulose to convert it into glucose molecules. The classes of enzymes that are included in cellulase are beta-glucosidases, endo-glucanases (endo 1, 4-β-d-glucanase), and exo-glucanases (exo 1, 4-β-d-glucanase) (Schülein 1988). Glycosyde hydrolase (GH) is a family of catalytic modules that are further categorized into several sub-classes based upon their 3D structure and sequential arrangement of amino acids. The catalytic modules of cellulase belong to this family. The enzymes of this family hydrolyze glycosidic bonds present in cellulose mainly via mechanism of acid–base catalysis. This catalysis take place by the interaction of two major enzyme residues: a nucelophile and a proton donor present at the regions of active site (Davies and Henrissat 1995). On the basis of difference in spatial arrangement of the catalytic modules in enzyme structure, the mechanism of hydrolysis may be inversion or retention. Three classes of cellulase enzymes containing particular catalytic residues do stepwise hydrolysis of cellulose polymer as follows: (1) endoglucanases contain catalytic residues belonging to GH families of mostly 74, 51, 48, 45, 44, 12, and 5–9. Endoglucanases act on cellulosic polymer to break β-1, 4 linkages to expose its reducing and non-reducing ends. The presence of catalytic module along with carbohydrate-binding module (CBM) is reported mostly in fungal endoglucanases but with few exceptions (Kubicek 2013). On the other hand, bacterial endoglucanases contain multiple catalytic modules with their CBMs (Payne et al. 2015). (2) The next step of hydrolysis is performed by exoglucanases also called as cellobiohydrolases (CBHs) containing catalytic modules that belong to GH families of 74, 48, 9, 7, 6, and 5. These enzymes cause the hydrolysis of polymeric cellulose into cellobiose by acting on the exposed non-reducing or reducing ends in the chain. A great diversity has been observed in both bacterial and fungal CBHs (Naga Padma et al. 2017). (3) The final step of cellulose hydrolysis is performed by β-glucosidases. It catalyzes the cleavage of terminal non-reducing β-d-glucosyl residues as well as the removal of β-d-glucose (Leah et al. 1995). Catalytic modules of 9, 3, and 1 GH families are present in β-glucosidases. Feedback inhibition regulates this cellulolytic process by the interaction of end product glucose with b-glucosidases. The main difference in the structure of CBHs and b-glucosidases is absence of carbohydrate binding module. At the last of this cellulose hydrolysis, glucose units are released from cellobioses (Payne et al. 2015). A diverse range of microorganism, when grown on cellulose-based material, produce cellulases as listed in Table 9.5. Most of the industrial cellulases are produced by microbial sources like fungi and bacteria. Both aerobic bacteria and aerobic fungi show similar cellulose-degrading mechanism. Cellulases are widely used in food, textile, and paper industry. Most cellulases that are used in food industry are obtained from fungal species Trichoderma and Aspergillus, while bacterial cellulases are obtained from species Paenibacillus and Bacillus (Sukumaran et al. 2005).

9.5.2 Xylanases

Hemicellulose consists of xylan that can be cleaved by using xylanases. These enzymes are secreted by microorganisms. One of these three enzymes, endoxylanases, exoxylanases, and β-xylosidases, is used to cleave the xylan, component of hemicellulose. The β-1, 4 bonds of xylan core break by endoxylanase (EC 3.2.1.8). Xylooligosaccharides are generated by non-reducing ends of xylan. These xylooligosaccharides are secreted when exoxylanase breaks down the β-1, 4 linkages of xylan. Xylose is secreted when β-xylosidase cleaves the xylooligosaccharides and xylobiose (Sukumaran 2009). Few kinds of xylanases have an extra CBM for interacting to substrates, and the catalytic component performs the majority of the enzyme’s important tasks. Carbohydrate esterases (CE) and glycoside hydrolases (GH) are two main catalytic modes of hemicellulose. The xylan core is hydrolyzed by endoxylanase, which includes catalytic cores from the GH families 8, 10, 11, 30, and 43, with GH 10 and 11 proving to be most prevalent (Collins et al. 2005). The GH10 seems to be more effective on modified xylan, and these have different substrate aspects. They could possibly include CBMs, much like cellulases (Sweeney and Xu 2012). The xylan core is randomly split by exoxylanases from the inner side, generating longer chain xylo-oligomers which then act as substrate for xylosidase enzymes. The mode of action of these enzymes makes them the members of the GH families 3, 30, 39, 43, 52, and 54. Xylanases is the name given to such two enzymes when they are combined. Xylooligosaccharides and xylobiose are affected by xylosidase or xylan-1, 4-xylosidase, which secrete xyloses (Juturu and Wu 2014). Various microbes are capable of producing xylanases as depicted in Table 9.6. Microbes such as actinomycetes, bacteria, and fungus secrete xylanases. Streptomyces, Bacillus, and Pseudomonas are the main actinomycete and bacterial species that produce xylanase (Sanghi et al. 2010; Sharma and Chand 2012). The best temperature for xylanase function is somewhere between 35 and 60 °C, whereas those produced by bacterial and actinobacterial stains are efficient throughout wider pH ranges (5.0–9.0). Because of the elevated concentration and extracellular emission of the enzyme, fungi are important sources of xylanase (Nair et al. 2008). Aspergillus species, Fusarium species, and Penicillium species are the main fungi that secrete xylanase. The fungal xylanases are more catalytically active relative to bacteria or yeast (Mandal 2015).

9.5.3 Proteases

These are the enzymes that cause the hydrolysis of polypeptides and proteins by breaking the peptide bond present between the amino acid subunits. Proteases are extensively used in various sectors which include food, drug, and detergent industries. In market, about 60% of the enzymes that are used in industries are proteases (Singh et al. 2016). The market demand for this enzyme has been increased globally by 5.3% in the years 2014–2019. And the increasing applications of protease in leather processing and bioremediation might increase its demands further more. Microorganisms (including fungi and bacteria), plants, and animals are considered as major sources from which protease can be obtained. Proteases can be categorized according to their origin, type of reactive groups bound to the catalytic sites, and their catalytic activities. Also according to the site of action along the polypeptide chain, proteases are classified into endopeptidases and exopeptidases (Rao et al. 1998). Endopeptidases hydrolyze the peptide bonds in the inner chain region, while exopeptidases do so at the ends of chain. On the basis of reactive groups linked to the active sites, proteases are categorized into six classes such as metallo, serine, cysteine, threonine, aspartic, and glutamic acid protease (Li et al. 2013). Various proteases that are obtained from plants include ficin, papain, and bromelain that are widely used at industrial scale for food applications including brewing, milk coagulation, and meat tenderization, for dihestive aid, etc. (Patel et al. 2013). Fungal proteases that are acidic in nature have ability to work efficiently in low pH environment hence playing a role in improving beer quality by balancing the profile of its amino acids (Nogent-sur-Seine, France). In the process of cheese manufacturing, proteases are used for the production of macropeptides and para casein by hydrolyzing its peptide bonds at specific sites (Salleh et al. 2006).

9.5.4 α-Amylases

These are hydrolytic enzymes that are capable of degrading starch by the hydrolysis of α-1, 4glycosidic linkages present in polysaccharides. This hydrolysis reaction result in the short-chain product called dextrins (Sindhu et al. 2017). A variety of living organisms are capable of producing α-amylases as indicated in Table 9.7. These are actually metallo-enzymes that require Ca+ ions for their structural integrity, stability, and activity (Sindhu et al. 2016). These hydrolytic enzymes are of great industrial importance with variety of applications including brewing, baking, digestive aids, and starch liquefaction (Rodríguez Couto and Ángeles Sanromán 2006). In addition, they play role in manufacturing of branched dextrins of high MW. Powdery foods and rice cakes are also prepared by α-amylases by their glazing action (Aiyer 2005). These enzymes do starch liquefaction as well which involves the conversion of starch polymer into fructose and glucose syrups. This process of starch conversion is comprised of three steps including (1) gelatinization, (2) liquefaction, and (3) saccharification. The granules of starch are dissolved to form a viscous suspension in gelatinization. Then partial hydrolysis of this suspension takes place in liquefaction which results in reduced viscosity. At last, maltose and glucose are produced in the final step of saccharification. This process of saccharification requires α-amylase enzymes of thermostable characteristic that are obtained from Bacillus stearothermophilus, B. licheniformis, and B. amyloliquefaciens (Van der Maarel et al. 2002). In ethanol preparation, α-amylases are involved in the conversion of starch to reduced sugars that are further fermented by Saccharomyces cerevisiae to alcohol. The collaborative activities of pectinases and cellulases along with α-amylases contribute to the clarity of fruit juices, yield improvement, and reduce the processing cost as well (Kumar 2015; Garg et al. 2016).

9.5.5 Pectinases

Pectinase are the hydrolytic enzymes that hydrolyze pectic polymers by breaking their glycosidic bonds. Pectin (substrate) is found in the walls/peels of fruits such as tomato, apple, pineapple, lemon, orange, and some other fruits. On the basis of their functions, pectinase are classified into pectin esterases (responsible for removal of methoxyl and acetyl groups), polygalacturonases (that catalyze hydrolysis of α-(1–4) glycosidic bonds), pectate lyase, and pectin lyase (Saadoun et al. 2013). These enzymes can be obtained from natural microbes as reported in Table 9.7, but attempts have been made by recombinant technology for their increased yield and thermostability (Rebello et al. 2017). Pectinases can attack both the hairy and smooth regions present in pectin (Pedrolli et al. 2009). On the basis of pH, these are classified as alkaline and acidic pectinases. While on the basis of site of action, these are categorized as endopeptidase (random cleavage of bonds) and exopeptodases (acting on terminal ends). Pectinases have vast range of industrial applications like food processing, bleaching of paper, remediation, etc. (Pasha et al. 2013). Pectinase give juices a relatively clear appearance with filter-ability as compared to other enzyme counterparts (Saadoun et al. 2013).

9.5.6 Laccase

Laccases are diversified group of multi-copper oxidases. They are usually called blue oxidases. These are employed in numerous industries due to their higher capabilities of oxidizing phenolic compounds. These enzymes have many applications as a biocatalyst in synthesizing various chemicals, paper bio-bleaching, bio-sensing, bioremediation, finishing fabrics, and stabilizing wines. They show distinct specificity regarding its substrates and hence have an extensive range of oxidizable substrates which is primarily dependent on the microbial origin of enzymes (Madhavi and Lele 2009). The large number of compounds can be oxidized by laccases which include aromatic-amines, ascorbates, and phenolics (Giardina et al. 2010; Madhavi and Lele 2009). For the purpose of splitting up dioxygen linkage, laccases contain four atoms of copper with four oxidized and four reduced electrons (Giardina et al. 2010). Several microbial species are known to synthesize laccases as mentioned in Table 9.7. Few fungal species are used in production of laccases by secondary metabolism during fermentation (Morozova et al. 2007). Deuteromycetes, Ascomycetes, and Basidiomycetes are well-known for the production of enzyme lacasses (Gochev and Krastanov 2007; Sadhasivam et al. 2008). Laccase can be produced from Funaliatrogii a white-rot fungus in absorbent mode of fermentation. F. rogii can produce laccase at a maximum yield of 11,900 U/L, which is 4.97 times higher than the output obtained by regular fermentation (Li et al. 2017). Transgenic laccases are produced by Bacillus licheniformis for industrial applications (Tonin et al. 2016). In last few decades, laccase production had been achieved by its heterologous expressions in various microbes. For instance, fmb-103 genes of Bacillus vallismortis were cloned in BL21 (DE3) cells of Escherichia coli to express heterologously (Sun et al. 2017).

9.5.7 Mannanase

Mannanases is an enzyme group that breakdown mannan, an integral component found in cell wall of plants along with hemicellulose (Guan et al. 2018). Mannanases is group of three enzymes that play role in hydrolyzing linear mannans. These enzymes include beta-mannanases or 1, 4-β-D mannohydrolases, beta-glucosidases or 1, 4-β-D glucoside glucohydrolases, and beta-mannosidases also called 1,4-β-D mannopyranoside hydrolases (Chauhan et al. 2012). β-Mannanases catalyze the endo-hydrolysis of mannan chains and produce short-chain products such as β-1,4-manno-oligosaccharides also called mannobiose by breaking inner glycosidic bonds (McCleary and Matheson 1983). Further hydrolysis is catalyzed by β-mannosidases. This enzyme, by its exo-hydrolysis activity, attacks the non-reducing ends of mannan polymer, hence hydrolyzing the mannobiose complex (disaccharide) into separate mannose (monomer) units (Gomes et al. 2007). Beta-glucosidase hydrolyzes the oligomers generated from hydrolysis of galactoglucomannan and glucomannan. It attacks the non-reducing terminals of their oligomers and results in individual β1, 4-glucopyranose units (Mamma et al. 2004). Several species of bacteria and fungi are reported in literature for production of variety of mannanases. Among Bacillus spp., different strains of B. subtilis produce mannanases. Some fungal organisms like Aspergillus spp. are reported as producers of mannan-degrading enzymes (Dhawan and Kaur 2007). Some other fungal and bacterial species that are known as mannanase producers include Streptomyces spp., Penicillium spp., and Clostridium spp. (Chauhan et al. 2012). Mannanase is attracting great attention in pulp and paper industries owing its hemicellulolytic capability (Clarke et al. 2000). In addition, mannanases also have a multitude of applications in textile, feed, oil, and food industries (Christgau et al. 1994; Naganagouda et al. 2009). The synthesis of mannanase utilizing lignocellulosic feedstock has also been reported by several researchers and is shown in Table 9.7.

9.6 Conclusion

The biochemically rich nature of paddy straw makes it a potential substrate for its bio-processing into numerous important biological products like hydrolytic enzymes that are significant part of most of the industrial processes. Environmental pollution and inefficient management strategies stimulate the utilization of PS in fermentation processes. Isolation of new strains of microbes having high lignocellulolytic potential and advancement in pretreatment methods along with improvements in fermentation technology has paved the way for efficient utilization of paddy waste. Although various tests have been proven effective for production of hydrolytic enzymes from PS, most of these finding are confined to lab-scale level and need further developments in order to be scaled up. In order to scale up these processes to industrial level, interdisciplinary efforts involving microbiology, biotechnology, mechanical engineering, software engineering, and analytical chemistry may be required keeping in view the economics of whole process of manufacturing and the end product cost in market.

References

AEE_2022_WEB (n.d.) Volume of grain paddy rice produced in the different Spanish autonomous communities in 2020. https://es.statista.com/estadisticas/501804/produccion-de-arroz-cascara-grano-en-comunidades-autonomas-de-espana/. Accessed 26 Aug 2023

Aikat (2012) Cellulase and xylanase production from rice straw by a locally isolated fungus Aspergillusfumigatus NITDGPKA3 under solid state fermentation—statistical optimization by response surface methodology. J Technol Innov Renew Energy. https://doi.org/10.6000/1929-6002.2012.01.01.7

Aiyer PV (2005) Amylases and their applications. Afr J Biotechnol 4(13):1525–1529

Alexandropoulou M, Antonopoulou G, Fragkou E, Ntaikou I, Lyberatos G (2017) Fungal pretreatment of willow sawdust and its combination with alkaline treatment for enhancing biogas production. J Environ Manag 203:704–713. https://doi.org/10.1016/j.jenvman.2016.04.006

Andriani Y, Safitri R, Abun (2015) Improvement protein quality of cassava peels by solid-state fermentation using cellulolytic microbial consortium. Sci Pap Anim Sci Ser 63:250–253

Anu, Kumar S, Kumar A, Kumar V, Singh B (2021) Optimization of cellulase production by Bacillus subtilis subsp. subtilis JJBS300 and biocatalytic potential in saccharification of alkaline-pretreated rice straw. Prep Biochem Biotechnol 51:697–704. https://doi.org/10.1080/10826068.2020.1852419

Beaton D, Pelletier P, Goulet RR (2019) Microbial degradation of cellulosic material and gas generation: implications for the management of low-and intermediate-level radioactive waste. Front Microbiol 10:204

Beladhadi R, Shankar K, Jayalakshmi S, Sreeramulu K (2022) Production of cocktail of lignolytic, cellulolytic and hemicellulolytic enzymes by the novel bacterium burkholderiasp SMB1 utilizing rice bran and straw: application in the saccharification of untreated agro-wastes for bioethanol production. Waste Biomass Valor 13(3):1–13. https://doi.org/10.1007/s12649-021-01607-7

Berg B, Laskowski R (2005) Decomposers: soil microorganisms and animals. Adv Ecol Res 38:73–100

Bhaduri D, Purakayastha TJ, Patra AK, Singh M, Wilson BR (2017) Biological indicators of soil quality in a long-term rice-wheat system on the Indo-Gangetic Plain: combined effect of tillage-water-nutrient management. Environ Earth Sci 76:202

Bimbraw AS (2019) Generation and impact of crop residue and its management. Curr Agric Res J 7:304–309

Bohra V, Dafale NA, Purohit HJ (2018) Paenibacilluspolymyxa ND25: candidate genome for lignocellulosic biomass utilization. 3 Biotech 8:248

Bressan M, Campagnoli E, Ferro CG, Giaretto V (2022) Rice straw: a waste with a remarkable green energy potential. Energies 15:1355. https://doi.org/10.3390/en15041355

Chauhan PS, Puri N, Sharma P, Gupta N (2012) Mannanases: microbial sources, production, properties and potential biotechnological applications. Appl Microbiol Biotechnol 93:1817–1830

Chen JH, Gong YZ, Wang SQ, Guan BZ, Balkovic J, Kraxner F (2019) To burn or retain crop residues on croplands? An integrated analysis of crop residue management in China. Sci Total Environ 662:141–150

Choudhary M, Dhanda S, Kapoor S, Soni G (2009) Lignocellulolytic enzyme activities and substrate degradation by volvariella volvacea, the paddy straw mushroom/Chinese mushroom. Indian J Agric Res 43(3):223–226

Christgau S, Andersen L, Kauppinen S, Heldt-Hansen H, Dalboege H (1994) Enzyme exhibiting mannanase activity. Patent WO1994025576A1, 10 Nov 1994

Chukwuma OB, Rafatullah M, Tajarudin HA, Ismail N (2021) A review on bacterial contribution to lignocellulose breakdown into useful bio-products. Int J Environ Res Public Health 18:6001. https://doi.org/10.3390/ijerph18116001

Clarke JH, Davidson K, Rixon JE, Halstead JR, Fransen MP, Gilbert HJ, Hazlewood GP (2000) A comparison of enzyme-aided bleaching of softwood paper pulp using combinations of xylanase, mannanase and alpha-galactosidase. Appl Microbiol Biotechnol 53:661–667

Cohen M, Lepesant G, Lamari F, Bilodeau C, Benyei P, Espadas-tormo I, Jaboeuf D, Alonso-rold M, Belandria V, Silar P, Dicko M (2017) Biomolecules from olive pruning waste in Sierra Magina engaging the energy transition by multi-actor and multidisciplinary analyses. J Environ Manag 216:204–213. https://doi.org/10.1016/j.jenvman.2017.03.067

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilicxylanases. FEMS Microbiol Rev 29(1):3–23. https://doi.org/10.1016/j.femsre.2004.06.005

Daniel G, Nilsson T (1998) Developments in the study of soft rot and bacterial decay. In: Bruce A, Palfreyman JW (eds) Forest products biotechnology. CRC Press, Boca Raton, FL, pp 37–62

Davies G, Henrissat B (1995) Structures and mechanisms of glycosyl hydrolases. Structure 3:853–859. https://doi.org/10.1016/S0969-2126(01)00220-9

Dhawan S, Kaur J (2007) Microbial mannanases: an overview of production and applications. Crit Rev Biotechnol 27:197–216

Dhillon GS, Oberoi HS, Kaur S, Bansal S, Brar SK (2011) Value-addition of agricultural wastes for augmented cellulase and xylanase production through solid-state tray fermentation employing mixed-culture of fungi. Ind Crop Prod 34:1160–1167

Dobermann A, Fairhurst T (2002) Rice straw management. Better Crops Int 16:1–11

Dutta SK, Laing AM, Kumar S, Gathala MK, Singh AK, Gaydon DS, Poulton P (2020) Improved water management practices improve cropping system profitability and smallholder farmers’ incomes. Agric Water Manage 242:106411

Eggert C, Temp U, Eriksson KL (1997) Laccase is essential for lignin degradation by the white rot fungus pycnoporuscinnabarinus. FEBS Lett 407:89–92. https://doi.org/10.1016/S0014-5793(97)00301-3

FAO (2022) Cultivos y productos de ganadería. https://www.fao.org/faostat/es/#data/QCL

Feijoo G, Moreira MT, Alvarez P, Lú-Chau TA, Lema JM (2008) Evaluation of the enzyme manganese peroxidase in an industrial sequence for the lignin oxidation and bleaching of eucalyptus Kraft pulp. J Appl Polym Sci 109(2):1319–1327. https://doi.org/10.1002/app.28084

Gabriel KJ, El-halwagi MM (2013) Modeling and optimization of a bioethanol production facility. Clean Tech Environ Policy 15(6):931–944. https://doi.org/10.1007/s10098-013-0584-8

Garg G, Singh A, Kaur A, Singh R, Kaur J, Mahajan R (2016) Microbial pectinases: an ecofriendly tool of nature for industries. 3 Biotech 6:47. https://doi.org/10.1007/s13205-016-0371-4

Gautam A, Kumar A, Bharti A, Dutt D (2018) Rice straw fermentation by Schizophyllum commune ARC-11 to produce high level of xylanase for its application in pre-bleaching. J Genet Eng Biotechnol 16:2. https://doi.org/10.1016/j.jgeb.2018.02.006

Giardina P, Faraco V, Pezzella C, Piscitelli A, Vanhulle S, Sannia G (2010) Laccases: a never-ending story. Cell Mol Life Sci 67:369–385. https://doi.org/10.1007/s00018-009-0169-1

Gochev VK, Krastanov AI (2007) Isolation of laccase producing Trichoderma sp. Bulg J Agric Sci 13:171–176

Gomes J, Terler K, Kratzer R, Kainz E, Steiner W (2007) Production of thermostable β-mannosidase by a strain of thermoascusaurantiacus: isolation, partial purification and characterization of the enzyme. Enzym Microb Technol 40:969–975

Goncharov AA, Gongalsky KB, Yazrikova TE, Kostina NV, Korobushkin DI, Makarov MI, Zaitsev AS (2020) Greenhouse gas-producing soil biological activity in burned and unburned forests along a transect in European Russia. Appl Soil Ecol 148:103491

Goodman BA (2020) Utilization of waste straw and husks from rice production: a review. J Bioresour Bioprod 5:143–162. https://doi.org/10.1016/j.jobab.2020.07.001

Grillo G, Tabasso S, Cravotto G, Van Ree T (2020) Burning biomass: environmental impact on the soil. In: Mammino L (ed) Biomass burning in Sub-Saharan Africa. Springer, Dordrecht, pp 15–30

Guan W, Xu G, Duan J, Shi S (2018) Acetone–butanol–ethanol production from fermentation of hot-water-extracted hemicellulose hydrolysate of pulping woods. Ind Eng Chem Res 57:775–783

Hammel KE, Kapich AN, Jensen KA Jr, Ryan ZC (2002) Reactive oxygen species as agents of wood decay by fungi. Enzym Microb Technol 30:445–453

Hassan H, Abd Karim K (2012) Utilization of agricultural by-products for alpha-amylase production under solid state fermentation by bacillus subtilis. Eng J 16(5):177–185. https://doi.org/10.4186/ej.2012.16.5.177

Hassan SS, Williams GA, Jaiswal AK (2019) Moving towards the second generation of lignocellulosic biorefineries in the EU: drivers, challenges, and opportunities. Renew Sust Energ Rev 101:590–599

Ho BKX, Azahari B, Yhaya MFB, Talebi A, Ng CWC, Tajarudin HA, Ismail N (2020) Green technology approach for reinforcement of calcium chloride cured sodium alginate films by isolated bacteria from palm oil mill effluent (POME). Sustainability 12:9468

Hongzhang C, Yumei W, Shuhua D (2011) Production of protein feed from sweet sorghum stalk by the two-step solid state fermentation. J Biofertil Biopestici 3:112

Hsu P-K, Liu C-P, Liu L-Y, Chang C-H, Yang S-S (2013) Protein enrichment and digestion improvement of napiergrass and pangolagrass with solid-state fermentation. J Microbiol Immunol Infect 46(3):171–179

Hu C-C, Liu L-Y, Yang S-S (2012) Protein enrichment, cellulase production and in vitro digestion improvement of pangolagrass with solid state fermentation. J Microbiol Immunol Infect 45(1):7–14

Hu J, Xue Y, Guo H, Gao MT, Li J, Zhang S, Tsang YF (2017) Design and composition of synthetic fungal-bacterial microbial consortia that improve lignocellulolytic enzyme activity. Bioresour Technol 227:247–255

Huang LZ, Ma MG, Ji XX, Choi SE, Si C (2021) Recent developments and applications of hemicellulose from wheat straw: a review. Front Bioeng Biotechnol 9:1–14. https://doi.org/10.3389/fbioe.2021.690773

Iyer G, Chattoo BB (2003) Purification and characterization of laccase from the rice blast fungus, magnaporthegrisea. FEMS Microbiol Lett 227:121–126

Joshi A, Kashyap R, Khanna S (2011) Production of xylanase by Promicromonosporasp MARS with rice straw under non sterile conditions. Process Biochem 46(8):1614–1618. https://doi.org/10.1016/j.procbio.2011.05.003

Juturu V, Wu JC (2014) Microbial exo-xylanases: a mini review. Appl Biochem Biotechnol 174:81–92. https://doi.org/10.1007/s12010-014-1042-8

Kanti A, Sudiana IM (2018) Production of phytase, amylase and cellulase by Aspergillus, Rhizophus and Neurospora on mixed rice straw powder and soybean curd residue. IOP Conf Ser Earth Environ Sci 166(1):012010. https://doi.org/10.1088/1755-1315/166/1/012010

Karthick Raja Namasivayam S, Babu M, Bharani RSA (2015) Evaluation of lignocellulosic agro wastes for the enhanced production of extracellular cellulase and xylanase by trichodermaharzianum. Nat Environ Pollut Technol 14:47–52

Kaur D, Bhardwaj NK, Lohchab RK (2017) Prospects of rice straw as a raw material for paper making. Waste Manag 60:127–139. https://doi.org/10.1016/J.WASMAN.2016.08.001

Ketsakhon P, Thammasittirong A, Thammasittirong S (2022) Adding value to rice straw waste for high-level xylanase production using a new isolate of Bacillus altitudinis RS3025. Folia Microbiol 68(1):87–99. https://doi.org/10.1007/s12223-022-00998-x

Khosravi A, Razavi SH (2020) The role of bioconversion processes to enhance bioaccessibility of polyphenols in rice. Food Biosci 35:100605. https://doi.org/10.1016/J.FBIO.2020.100605

Kogo T, Yoshida Y, Koganei K, Matsumoto H, Watanabe T, Ogihara J, Kasumi T (2017) Production of rice straw hydrolysis enzymes by the fungi Trichoderma reesei and Humicolainsolens using rice straw as a carbon source. Bioresour Technol 233:67–73. https://doi.org/10.1016/j.biortech.2017.01.075

Kubicek CP (2013) Systems biological approaches towards understanding cellulase production by Trichoderma reesei. J Biotechnol 163:133–142. https://doi.org/10.1016/j.jbiotec.2012.05.020

Kumar S (2015) Role of enzymes in fruit juice processing and its quality enhancement. Adv Appl Sci Res 6:114–124

Kumar S, Sharma HK, Sarkar BC (2011) Effect of substrate and fermentation conditions on pectinase and cellulase production by Aspergillus Niger NCIM 548 in submerged (SmF) and solid state fermentation (SSF). Food Sci Biotechnol 20:1289. https://doi.org/10.1007/s10068-011-0178-3

Kumar S, Paritosh K, Pareek N, Chawade A, Vivekanand V (2018) De-construction of major Indian cereal crop residues through chemical pretreatment for improved biogas production: an overview. Renew Sust Energ Rev 90:160–170. https://doi.org/10.1016/J.RSER.2018.03.049

Kumar S, D’Silva TC, Chandra R, Malik A, Vijay VK, Misra A (2021) Strategies for boosting biomethane production from rice straw: a systematic review. Bioresour Technol Rep 15:100813. https://doi.org/10.1016/j.biteb.2021.100813

Kumari B, Sudhakar P, Hemamalini K, Sree N, Pendyala V (2014) Studies on pectinase production by Bacillus subtilis using agro-industrial wastes. Res J Pharm Biol Chem Sci 5(6):330–339

Leah R, Kigel J, Svendsen I, Mundy J (1995) Biochemical and molecular characterization of a barley seed β-glucosidase. J Biol Chem 270:15789–15797. https://doi.org/10.1074/jbc.270.26.15789

Lee S, Kang M, Bae J-H, Sohn J-H, Sung BH (2019) Bacterial valorization of lignin: strains, enzymes, conversion pathways, biosensors, and perspectives. Front Bioeng Biotechnol 7:209

Li Q, Yi L, Marek P, Iverson BL (2013) Commercial proteases: present and future. FEBS Lett 587:1155–1163. https://doi.org/10.1016/j.febslet.2012.12.019

Li G, Liu X, Yuan L (2017) Improved laccase production by Funaliatrogii in absorbent fermentation with nutrient carrier. Biosci Bioeng 124(4):381–385. https://doi.org/10.1016/j.jbiosc.2017.05.002

Liao JJ, Latif NHA, Trache D, Brosse N, Hussin MH (2020) Current advancement on the isolation, characterization and application of lignin. Int J Biol Macromol 162:985–1024

López-Mondéjar R, Algora C, Baldrian P (2019) Lignocellulolytic systems of soil bacteria: a vast and diverse toolbox for biotechnological conversion processes. Biotechnol Adv 37:107374

Madhavi V, Lele SS (2009) Laccase: properties and applications. Bioresources 4:1694–1717

Maftukhah S, Abdullah A (2018) Cellulase enzyme production from rice straw using solid state fermentation and fungi Aspergillus niger ITBCC L74. MATEC Web Conf 156:01010. https://doi.org/10.1051/matecconf/201815601010

Mahalakshmi N, Jayalakshmi S (2016) Amylase, cellulase and xylanase production from a novel bacterial isolate achromobacter xylosoxidans isolated from marine environment. Int J Adv Res Biol Sci 3(1):230–233

Malgas S, Thoresen M, van Dyk JS, Pletschke BI (2017) Time dependence of enzyme synergism during the degradation of model and natural lignocellulosic substrates. Enzym Microb Technol 103:1–11

Mamma D, Hatzinikolaou DG, Christakopoulos P (2004) Biochemical and catalytic properties of two intracellular β-glucosidases from the fungus Penicillium decumbens active on flavonoid glucosides. J Mol Catal B Enzym 27:183–190

Mandal A (2015) Review on microbial xylanases and their applications. Int J Life Sci 4:178–187

Martínez ÁT, Ruiz-Dueñas FJ, Martínez MJ, Del Río JC, Gutiérrez A (2009) Enzymatic delignification of plant cell wall: from nature to mill. Curr Opin Biotechnol 20:348–357. https://doi.org/10.1016/j.copbio.2009.05.002

McCleary BV, Matheson NK (1983) Action patterns and substrate-binding requirements of β-d-mannanase with mannosaccharides and mannan-type polysaccharides. Carbohydr Res 119:191–219

McDonald JE, Rooks DJ, McCarthy AJ (2012) Methods for the isolation of cellulose-degrading microorganisms. Methods Enzymol 510:349–374

Meetei TT, Kundu MC, Devi YB (2020) Long-term effect of rice-based cropping systems on pools of soil organic carbon in farmer’s field in hilly agroecosystem of Manipur, India. Environ Monit Assess 192:209

Meurial D, Uthandi S (2020) Xylanolytic Bacillus flexus PSX1.isolated from earthworm casts for xylanase production and biomass conversion. Madras Agric J 107:1–4. https://doi.org/10.29321/MAJ.S.000447

Mishra BK, Pandey Lata AK (2007) Lignocellulolytic enzyme production from submerged fermentation of paddy straw. Indian J Microbiol 47(2):176–179. https://doi.org/10.1007/s12088-007-0034-6

Mishra V, Jana AK, Maiti M, Gupta A (2017) Improvement of selective lignin degradation in the fungal pretreatment of sweet sorghum bagasse using synergistic CuSO 4-syringic acid supplements. J Environ Manage 193:558–566. https://doi.org/10.1016/j.jenvman.2017.02.057

Mohee R, Unmar GD, Mudhoo A, Khadoo P (2008) Biodegradability of biodegradable/degradable plastic materials under aerobic and anaerobic conditions. Waste Manag 28:1624–1629

Mondal S, Naik SK, Haris AA, Mishra JS, Mukherjee J, Rao KK, Bhatt BP (2020) Effect of conservation tillage and rice-based cropping systems on soil aggregation characteristics and carbon dynamics in Eastern Indo-Gangetic Plain. Paddy Water Environ 18:573–586

Morozova OV, Shumakovich GP, Shleev SV, Yaropolov YI (2007) Laccase-mediator systems and their applications: a review. Appl Biochem Microbiol 43(5):523–535. https://doi.org/10.1134/S0003683807050055

Muaaz-Us-Salam S, Cleall PJ, Harbottle MJ (2020) Application of enzymatic and bacterial biodelignification systems for enhanced breakdown of model lignocellulosic wastes. Sci Total Environ 728:138741

Munishamanna KB, Suresha KB, Veena R, Subramanya S (2017) Solid state fermentation of mango peel and mango seed waste by different yeasts and bacteria for nutritional improvement. Int J Food Ferment Technol 7(1):111

Muthulakshmi C, Gomathi D, Kumar DG, Ravikumar G, Kalaiselvi M, Uma C (2011) Production, purification and characterization of protease by Aspergillus flavus under solid state fermentation. Jordan J Biol Sci 4(3):137–148

Naga Padma P, Sravani P, Mishra PN, Sneha N, Anuradha K (2017) Synergestic effects of multiple enzymes on apple juice clarification. Ind J Sci Technol 10(10):1–5. https://doi.org/10.17485/ijst/2017/v10i10/107716

Naganagouda K, Salimath PV, Mulimani VH (2009) Purification and characterization of endo-beta-1,4 mannanase from Aspergillus niger gr for application in food processing industry. J Microbiol Biotechnol 19:1184–1190

Nagar R, Trivedi SK, Nagar D, Karnawat M (2020) Impact of agriculture crop residue burning on environment and soil health. Biotica Res Today 2:171–173

Naher L, Fatin SN, Sheikh MAH, Azeez LA, Siddiquee S, Zain NM, Karim SMR (2021) Cellulase enzyme production from filamentous fungi trichoderma reesei and aspergillusawamori in submerged fermentation with rice straw. J Fungi 7:868. https://doi.org/10.3390/jof7100868

Nair SG, Sindhu R, Shashidhar S (2008) Fungal xylanase production under solid state and submerged fermentation conditions. Afr J Microbiol Res 2:82–86

Nandan R, Poonia SP, Singh SS, Nath CP, Kumar V, Malik RK, McDonald A, Hazra KK (2021) Potential of conservation agriculture modules for energy conservation and sustainability of rice-based production systems of Indo-Gangetic Plain region. Environ Sci Pollut Res 28:246–261

Neelkant KS, Shankar K, Jayalakshmi SK, Sreeramulu K (2019) Optimization of conditions for the production of lignocellulolytic enzymesby Sphingobacterium sp. ksn-11 utilizing agro-wastes under submerged condition. Prep Biochem Biotechnol 49(9):927–934. https://doi.org/10.1080/10826068.2019.1643735

Niladevi KN, Sukumaran RK, Prema P (2007) Utilization of rice straw for laccase production by Streptomyces psammoticus in solid-state fermentation. J Ind Microbiol Biotechnol 34(10):665–674. https://doi.org/10.1007/s10295-007-0239-z

Oboh G (2006) Nutrient enrichment of cassava peels using a mixed culture of saccharomyces cerevisiae and lactobacillus spp solid media fermentation techniques. Electron J Biotechnol 9(1):46–49

Orozco AL, Perez MI, Guevara O, Rodríguez J, Hernandez M, Gonzalez-Vila FJ, Polvillo O, Arias ME (2008) Biotechnological enhancement of coffee pulp residues by solid-state fermentation with streptomyces. Py-GC/MS analysis. J Anal Appl Pyrol 81(2):247–252

Pasha KM, Anuradha P, Subbarao D (2013) Applications of pectinases in industrial sector. J Pure Appl Sci Technol 16:89–95

Patel NS, Fung SM, Zanichelli A, Cicardi M, Cohn JR (2013) Ecallantide for treatment of acute attacks of acquired C1 esterase inhibitor deficiency. Allergy Asthma Proc 34(1):72–77. https://doi.org/10.2500/aap.2013.34.3620

Patela A, Divechab J, Shaha A (2021) Fomitopsismeliae CFA2, a novel brown rot for endoglucanase: emphasis towards enhanced endoglucanase production by statistical approach. Mycology 12(4):325–340. https://doi.org/10.1080/21501203.2021.1918277

Payne CM, Knott BC, Mayes HB, Hansson H, Himmel ME, Sandgren M et al (2015) Fungal cellulases. Chem Rev 115:1308–1348. https://doi.org/10.1021/cr500351c

Pedrolli DB, Monteiro AC, Gomes E, Cano CE (2009) Pectin and pectinases: production, characterization and industrial application of microbial pectinolytic enzymes. Open Biotechnol J 3:9–18. https://doi.org/10.2174/1874070700903010009

Qaseem MF, Shaheen H, Wu AM (2021) Cell wall hemicellulose for sustainable industrial utilization. Renew Sustain Energy Rev 144:110996. https://doi.org/10.1016/j.rser.2021.110996

Rahayu A, Utama P, Nurulita Y, Miranti M, Nugroho T (2019) Surfactant, nitrogen and carbon media optimization for trichoderma asperellum LBKURCC1 laccase production by flask solid state fermentation of rice straw. J Phys Conf Ser 1351(1):012030. https://doi.org/10.1088/1742-6596/1351/1/012030

Raheem A, Sajid M, Iqbal MS, Aslam H, Bilal M, Rafiq F (2019) Microbial inhabitants of agricultural land have potential to promote plant growth but they are liable to traditional practice of wheat (T. aestivum L) straw burning. Biocatal Agric Biotechnol 18:101060

Ralph J, Lundquist K, Brunow G, Lu FC, Kim H, Schatz PF, Marita JM, Hatfield RD, Ralph SA, Christensen JH, Boerjan W (2004) Lignins: natural polymers from oxidative coupling of 4-hydroxyphenyl- propanoids. Phytochem Rev 3:29–60

Ramos M, Laveriano E, Sebastian LS, Perez M, Jimenez A, Lamuela-Raventos RM, Garrigos MC, Vallverdú-Queralt A (2022) Rice straw as a valuable source of cellulose and polyphenols: applications in the food industry. Trends Food Sci Technol 131:14–27. https://doi.org/10.1016/j.tifs.2022.11.020

Rao MB, Tanksale AM, Ghatge MS, Deshpande VV (1998) Molecular and biotechnological aspects of microbial proteases. Microbiol Mol Biol Rev 62(3):597–635

Razali NAM, Mohd Sohaimi R, Othman RNIR, Abdullah N, Demon SZN, Jasmani L et al (2022) Comparative study on extraction of cellulose fiber from rice straw waste from chemo-mechanical and pulping method. Polymers 14(3):387. https://doi.org/10.3390/polym14030387

Rebello S, Anju M, Aneesh EM, Sindhu R, Binod P, Pandey A (2017) Recent advancements in the production and application of microbial pectinases: an overview. Rev Environ Sci Biotechnol 16:381–394. https://doi.org/10.1007/s11157-017-9437-y

Renge V, Khedkar S, Nandurkar NR (2012) Enzyme synthesis by fermentation method: a review. Sci Rev Chem Commun 2(4):585–590

Rodríguez Couto S, Ángeles Sanromán M (2006) Application of solid-state fermentation to food industry—a review. J Food Eng 76(3):291–302. https://doi.org/10.1016/j.jfoodeng.2005.05.022

Saadoun I, Dawagreh A, Jaradat Z, Ababneh Q (2013) Influence of culture conditions on pectinase production by Streptomyces sp. (strain J9). Int J Life Sci Med Res 3:148. https://doi.org/10.5963/LSMR0304002

Saanu AB, Oladiti OO (2018) Starter culture development from lactic acid bacteria for improved nutritive value of linamarase treated cassava peels. J Biomater Dent 2(1):1–6

Sadhasivam S, Savitha S, Swaminathan K, Lin FH (2008) Production, purification and characterization of mid-redox potential laccase from a newly isolated Trichoderma harzianum WL1. Process Biochem 43:736–742. https://doi.org/10.1016/j.procbio.2008.02.017

Salleh AB, Razak CNA, Rahman RNZRA, Basri M (2006) Protease introduction. In: Salleh AB, Rahman RNZRA, Basri M (eds) New lipases and proteases. Nova Science, New York, pp 23–39

Sanghi A, Garg N, Gupta VK, Mittal A, Kuhad RC (2010) One step purification and characterization of a cellulose free xylanase produced by alkalophilic Bacillus subtilis ASH. Braz J Microbiol 41:467–476. https://doi.org/10.1590/S151783822010000200029

Saranraj P (2011) Optimization for cellulase production by Aspergillus niger using paddy straw as substrate. Int J Adv Sci Tech Res 1(1):68–85

Saratale GD, Saratale RG, Ghodake GS, Jiang YY, Chang JS, Shin HS, Kumar G (2017) Solid state fermentative lignocellulolytic enzymes production, characterization and its application in the saccharification of rice waste biomass for ethanol production: an integrated biotechnological approach. J Taiwan Inst Chem Eng 76:51–58

Sarkar N, Aikat K (2014) Aspergillus fumigatus NITDGPKA3 provides for increased cellulase production. Int J Chem Eng 2014:959845. https://doi.org/10.1155/2014/959845

Schülein M (1988) Cellulases of trichoderma reesei. Methods Enzymol 160:234–242. https://doi.org/10.1016/0076-6879(88)60125-X

Sharifzadeh F, Dizajnejad G, Mohammadhassanpour S, Rahnama N (2020) Cellulase production by Penicillium expansum MDFS2 by solid-state fermentation of rice straw, rice bran, and wheat straw residues. Adv Res Microb Metabol Technol 2:101–108. https://doi.org/10.22104/armmt.2020.4326.1045

Sharma PK, Chand D (2012) Production of cellulase free thermostable xylanase from pseudomonas sp. XPB-6. Int Res J Biol Sci 1(5):31–41

Sindhu R, Binod P, Pandey A (2016) α-Amylases. In: Pandey A, Negi S, Soccol CR (eds) Current developments in biotechnology and bioengineering—production, isolation and purification of industrial products. Elsevier, Amsterdam, pp 3–24. https://doi.org/10.1016/B978-0-444-63662-1.00001-4

Sindhu R, Binod P, Madhavan A, Beevi US, Mathew AK, Abraham A, Pandey A, Kumar V (2017) Molecular improvements in microbial α-amylases for enhanced stability and catalytic efficiency. Bioresour Technol 245(Part B):1740–1748. https://doi.org/10.1016/j.biortech.2017.04.098

Singh L, Brar BS (2021) A review on rice straw management strategies. Nat Environ Pollut Technol 20(4):1485–1493. https://doi.org/10.46488/NEPT.2021.v20i04.010

Singh RB, Saha RC, Singh M, Chandra D, Shukla SG, Walli M, Pradhan PK, Kessels HPP (1995) Rice straw—its production and utilization in India. ICAR, New Delhi

Singh R, Mittal A, Kumar M, Mehta PK (2016) Microbial protease in commercial applications. J Pharm Chem Biol Sci 4(3):365–374

Singh P, Singh G, Sodhi GPS (2020a) Energy and carbon footprints of wheat establishment following different rice residue management strategies vis-à-vis conventional tillage coupled with rice residue burning in North-Western India. Energy 200:117554

Singh R, Yadav DB, Ravisankar N, Yadav A, Singh H (2020b) Crop residue management in rice-wheat cropping system for resource conservation and environmental protection in North-Western India. Environ Dev Sustain 22:3871–3896

Singh G, Gupta MK, Chaurasiya S, Sharma VS, Pimenov DY (2021) Rice straw burning: a review on its global prevalence and the sustainable alternatives for its effective mitigation. Environ Sci Pollut Res 28(25):32125–32155. https://doi.org/10.1007/s11356-021-14163-3

Singhvi MS, Gokhale DV (2019) Lignocellulosic biomass: hurdles and challenges in its valorization. Appl Microbiol Biotechnol 103:9305–9320

Subramaniyam R, Vimala R (2012) Solid state and submerged fermentation for the production of bioactive substances: a comparative study. Int J Sci Nat 3(3):480–486

Suganthi R et al (2011) Amylase production by Aspergillus Niger under solid state fermentation using agroindustrial wastes. Int J Eng Sci Technol 3(2):1756–1763

Sukumaran RK (2009) Bioethanol from lignocellulosic biomass, part II. Production of cellulases and hemicellulases. In: Pandey A (ed) Handbook of plant-based biofuels. CRC Press, Boca Raton, FL, pp 141–157

Sukumaran RK, Singhania RR, Pandey A (2005) Microbial cellulases—production, applications and challenges. J Sci Ind Res 64:832–844

Sun J, Zheng M, Lu Z, Lu F, Zhang C (2017) Heterologous production of a temperature and pH-stable laccase from Bacillus vallismortis FMB-103 in Escherichia coli and its application. Process Biochem 55:77–84. https://doi.org/10.1016/j.procbio.2017.01.030

Sweeney MD, Xu F (2012) Biomass converting enzymes as industrial biocatalysts for fuels and chemicals: recent developments. Catalysts 2:244–263. https://doi.org/10.3390/catal2020244

Taha M, Kadali KK, Khalid AH, Smith AT, Ball AS, Adetutu EM (2015a) An effective microplate method (biolog MT2) for screening native lignocellulosic-straw-degrading bacteria. Ann Microbiol 65:2053–2064

Taha M, Shahsavari E, Al-Hothaly K, Mouradov A, Smith AT, Ball AS, Adetutu EM (2015b) Enhanced biological straw saccharification through coculturing of lignocellulose-degrading microorganisms. Appl Biochem Biotechnol 175:3709–3728

Tamilanban R, Velayudhan SS, Ebenezer S, Harshavardhan S (2017) Purification and characterization of an extracellular cellulase produced using alkali pretreated rice straw by stenotrophomonas maltophilia. Int J Biol Res 2(4):45–54

Taneja G, Pal BD, Joshi PK, Aggarwal PK, Tyagi NK (2019) Farmers’ preferences for climate-smart agriculture—an assessment in the Indo-Gangetic plain. In: Pal BD, Kishore A, Joshi PK, Tyagi NK (eds) Climate smart agriculture in South Asia. Springer, Singapore, pp 91–111

Tonin F, Melis R, Cordes A, Sanchez-Amat A, Pollegioni L, Rosini E (2016) Comparison of different microbial laccases as tools for industrial uses. New Biotechnol 33(3):387–398. https://doi.org/10.1016/j.nbt.2016.01.007

Torregrosa A, Miguel Giner J, Velazquez-Martí B (2021) Equipment performance, costs and constraints of packaging and transporting rice straw for alternative uses to burning in the “parc natural l’albufera de val’encia” (Spain). Agriculture 11(6):570. https://doi.org/10.3390/agriculture11060570

Trivedi A, Verma AR, Kaur S, Jha B, Vijay V, Chandra R, Vijay VK, Subbarao PMV, Tiwari R, Hariprasad P, Prasad R (2017) Sustainable bio-energy production models for eradicating open field burning of paddy straw in Punjab, India. Energy 127:310–317

Tsegaye B, Balomajumder C, Roy P (2019) Microbial delignification and hydrolysis of lignocellulosic biomass to enhance biofuel production: an overview and future prospect. Bull Natl Res Cent 43:51. https://doi.org/10.1186/s42269-019-0094-x

Urfels A, McDonald AJ, Krupnik TJ, Van Oel PR (2020) Drivers of groundwater utilization in water-limited rice production systems in Nepal. Water Int 45:39–59

Van der Maarel MJEC, van der Veen B, Uitdehaag JCM, Leemhuis H, Dijkhuizen L (2002) Properties and applications of starch-converting enzymes of the α-amylase family. J Biotechnol 94:137–155. https://doi.org/10.1016/S0168-1656(01)00407-2

Van Hung N, Maguyon-Detras MC, Migo MV, Quilloy R, Balingbing C, Chivenge P, Gummert M (2020) Rice straw overview: availability, properties, and management practices. In: Gummert M, Hung N, Chivenge P, Douthwaite B (eds) Sustainable rice straw management. Springer, Cham, pp 1–13. https://doi.org/10.1007/978-3-030-32373-8_1

Vijaya C, Singaracharya MA (2005) Delignification of paddy straw by a white rot fungus, pleurotus ostrreatus. Asian J Microbiol Biotechnol Environ Sci 7(1):77–83

Wi S, Choi I, Kim K, Kim H, Bae HJ (2013) Bioethanol production from rice straw by popping pretreatment. Biotechnol Biofuels 6:166

Xie S, Ragauskas AJ, Yuan JS (2016) Lignin conversion: opportunities and challenges for the integrated biorefinery. Ind Biotechnol 12:161–167

Yuliana T, Putri NZ, Komara DZ, Mardawati E, Lanti I, Rahimah S (2020) Study of ganodermalucidum in laccase production using corncob and paddies straw substrates on submerged fermentation system. Pak J Biol Sci 23:1060–1065. https://doi.org/10.3923/pjbs.2020.1060.1065

Zabidi NAM, Foo HL, Loh TC, Mohamad R, Rahim RA (2020) Enhancement of versatile extracellular cellulolytic and hemicellulolytic enzyme productions by lactobacillus plantarum RI 11 isolated from Malaysian food using renewable natural polymers. Molecules 25:2607

Zahari N, Md Shah UK, Mohamed Asa’ari AZ, Mohamad R (2016) Selection of potential fungi for production of cellulase-poor xylanase from rice straw. Bioresources 11(1):1162–1175. https://doi.org/10.15376/biores.11.1.1162-1175

Zheng G, Yin T, Lu Z, Yannick Benz Boboua S, Li J, Zhou W (2020) Degradation of rice straw at low temperature using a novel microbial consortium LTF-27 with efficient ability. Bioresour Technol 304:123064

Zhiqiang L, Xu A, Zhao T (2011) Energy from the combustion of rice straw: status and challenges to China. Energy Power Eng 3:325–331

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Tahir, A. et al. (2024). Utilization of Paddy Straw for the Production of Hydrolytic Enzymes. In: Srivastava, N., Verma, B., Mishra, P.K. (eds) Paddy Straw Waste for Biorefinery Applications. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-99-8224-0_9

Download citation

DOI: https://doi.org/10.1007/978-981-99-8224-0_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-8223-3

Online ISBN: 978-981-99-8224-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)