Abstract

A gene coding for lipase (Tm1350) from the hyperthermophilic bacterium Thermotoga maritima MSB8 was cloned and overexpressed by Escherichia coli. The enzyme can degrade substrates with both short and long acyl chain lengths. The apparent Km and Vmax values for p-nitrophenyl butyrate were 8 mM and 333 U/mg, respectively. The enzyme displayed optimal activity at pH 7.5 and 70 °C, maintained 66 % of the original activity after 8 h of incubation, and its half-lives at pHs 9 and 10 were 8 and 1 h. The activity of Tm1350 was stimulated up to 131 or 151 % of the original activity by incubating with 4 M urea or 20 % (v/v) methanol, and 90.1 or 70.2 % of the activity was maintained after 8 h incubation of the enzyme in 20 or 75 % (v/v) of the methanol, showing potential for biodiesel production. The activity of the enzyme without cysteine residue was stimulated up to 618 and 550 % of the original activity by incubating with dithiothreitol (DTT) and reduced glutathione (GSH) at a concentration of 1 mM. However, the circular dichroism spectra of the enzyme have no obvious change after DTT treatment. It is speculated that DTT interacts with potential residues in some key active sites without influence of structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lipases are ubiquitous enzymes and catalyze the cleavage and formation of ester bonds, with low-energy consumption, broad substrate specificity, and high regio- and stereo-selectivity [1], which have been used for production of foods, oils, fats, chiral compounds, leather, cosmetics, biodiesel, etc. [2]. However, almost all carboxylic ester hydrolases are mesophilic enzymes not suitable for harsh industrial processes, such as organic solvents, high temperature, and alkali [3]. Enzymes from hyperthermophiles are promising candidates because of their high intrinsic thermal and chemical stability [4, 5]. Therefore, production of the enzymes from thermophiles becomes a hot topic.

Recently, some carboxylic ester hydrolases had been isolated and characterized from hyperthermophiles, some of which had been completely sequenced. Those enzymes showed different thermal stability and stability in organic solvents [6, 7]. The thermostability allows a higher operation temperature, which has many advantages, such as increasing the solubility of hydrophobic substrates, reducing the viscosity of the matrix, and improving the efficiency of reaction [8]. Stability and activity in organic solvents are important properties of an enzyme if it is to be used as a biocatalyst in the industry. For example, methanolysis of triacylglycerols (TAGs) by lipase is considered as one of the effective reactions for production of biodiesel fuel [9, 10]. However, lipases are easy to be inactivated by MeOH [11, 12], which limits the development of biodiesel fuel using enzyme. Considering biocatalytic applications, it is of great interest to study the specificity and selectivity of novel enzymes.

In this study, the expression and identification of a new lipase (Tm1350) from Thermotoga maritima was reported, which is more stable at high temperature, alkaline conditions, or in some organic solvents such as methanol, showing great potential in biochemical industry, such as biodiesel production

Materials and Methods

Chemicals and Strains

The genomic DNA of T. maritima was obtained from Professor Weilan Shao at Jiangsu University. Restriction enzymes, PrimeSTAR HS DNA polymerase, and DNA ligase were purchased from TaKaRa Biotechnology (Dalian, China). Nickel columns were purchased from GenScript (Nanjing, China). p-Nitrophenyl esters were obtained from Sigma (St. Louis, USA). All other chemicals were analytical grade and purchased from Sangon (Shanghai, China). The plasmid pET-28a was used as an expression vector, and Escherichia coli DH5α and BL21- Codon Plus (DE3) RIL were used as the cloning and expression hosts, respectively.

Cloning of the Lipase Tm1350 Gene

The gene coding for the lipase Tm1350 (GenBank accession no. NP_229151.1) from T. maritima was amplified by PCR with the forward primer (CGCGGATCCATGA GAATGAACATCCAGAAACACG) (underline: BmaH I) and the reverse primer (CCGCTCGAGTTATTTCCCTCCGAGTTTTTCGAGAC) (underline: Xho I) using the genomic DNA of T. maritima as template. The procedures of PCR reaction were conducted: (1) 94 °C, 3 min; (2) 30 cycles of: 98 °C 10 s, 58 °C 10 s, and 72 °C 1 min; and (3) 72 °C 10 min. The PCR product (780 bp) and plasmid pET-28a were digested with BamH I and Xho I and extracted from an agarose gel, then the digested products were combined with DNA ligase, and the resulting plasmid, which was called pET28a–Tm1350, was transformed into E. coli DH5α. The transformants were subsequently plated onto LB agar plates containing 50 μg/ml of kanamycin. Colonies were picked, and the plasmids were purified with plasmid DNA purification kits. The plasmids were sequenced to ensure that no unintended mutation had occurred before transformed into E. coli BL21.

Expression and Purification of the Recombinant Enzyme

One percent of the overnight culture of E. coli BL21 harboring the recombinant plasmid pET28a–Tm1350 was inoculated into 500 mL of LB broth containing 50 mg/L kanamycin. Cells were cultured at 37 °C with shaking at 220 rpm. When the OD600 reached 0.6, 0.1 mM IPTG was added to induce the expression of the recombinant protein. After induction for 5 h at 37 °C, cells were harvested by centrifugation. The harvested cells were resuspended in buffer (50 mM Tris–HCl, pH 8.0, 50 mM NaCl) and disrupted by sonication. The disrupted cells were centrifuged at 8000×g for 10 min at 4 °C, and the supernatant was then loaded on a nickel column (GenScript, Nanjing, China). Three bed volumes of binding buffer (100 mM NaH2PO4, 10 mM Tris–HCl, pH 8.0) were added to the nickel column, followed by the addition of three bed volumes of wash buffer (100 mM NaH2PO4, 10 mM Tris–HCl, 10 mM imidazole, pH 8.0). The recombinant enzymes were eluted with elution buffer (100 mM NaH2PO4, 10 mM Tris–HCl, 100 mM imidazole, pH 8.0), then dialyzed in buffer A (50 mM PBS, pH 7.5) overnight to remove imidazole before concentration using a microfilter (Micro-con YM-10, Millipore Corp, Bedford, MA).

Enzymatic Activity Assay

Analysis of optical density (OD) at 405 nm was used for determination of enzyme activity with p-nitrophenyl esters as substrate, as previously described [13]. The standard reaction mixture, consisting of 50 mM sodium phosphate (pH 7.5) and enzyme (7.5 μg/ml), was pre-incubated at 70 °C for 10 min. Adding p-nitrophenyl butyrate (pNP-B), p-nitrophenyl caprate (p-NP-C), p-nitrophenyl dodecanoate (p-NP-D), p-nitrophenyl palmitate (p-NP-P), and olive oil to the reaction buffers respectively, the reactions initiated. After incubation at 70 °C for 2 min, the enzyme activity was measured by UV absorption at 405 nm. One unit of enzyme activity was defined as the amount of enzyme releasing 1 μmol of p-nitrophenyl per minute under the above conditions. In order to eliminate the influence of the background hydrolysis of the substrate, the following controls were applied: (1) the compounds of the corresponding reaction mixture and the reaction conditions were same and (2) the enzyme Tm1350 was replaced by the sodium phosphate buffer (pH 7.5).

For kinetic studies, the initial velocities of the enzymatic reaction were examined by varying the concentration of p-NP-butyrate (from 0.5 to 5 mM). Values of the Michaelis constants (Km) and maximal velocity (Vmax) were obtained by mathematical calculations according to Lineweaver-Burk. The extinction coefficient (ε405) for pNP-C4 was 16,540 M−1 cm−1.

Effect of Temperatures and pH on Enzyme Activity and Stability

The effect of temperature was determined by enzyme activity assays at various temperatures ranging from 30 to 90 °C in 50 mM sodium phosphate buffer (pH 7.5) with pNP-B as substrate. The thermostability of the purified enzyme was examined by incubation of the enzyme in 50 mM sodium phosphate buffer (pH 7.5) at three different temperatures (60, 70, and 80 °C) for different time intervals ranging from 0 to 8 h. Samples were dispensed out at different time intervals during incubation and quickly frozen prior to being determined. Relative activity was calculated by defining original activity (70 °C) as 100 %.

The effect of pH on the enzyme activity was determined in various buffers ranging from pH 3 to pH 9 at 70 °C. Buffers included 50 mM of sodium citrate (pH 3.0–4.0), sodium acetate (pH 4.0–6.0), sodium phosphate (pH 6.0–8.0), and Tris–HCl (pH 8.0–9.0). The temperature was constantly maintained at to 70 °C. The pH stability of the purified enzyme was examined by pre-incubating the enzyme in four different buffers (pH 7.0, pH 8.0, pH 9.0, and pH 10.0) at 70 °C for different time intervals ranging from 0 to 8 h. Samples were pipetted out at different time intervals during incubation and quickly frozen prior to being determined. Relative activity was calculated by defining the respective original activity as 100 %. Residual activities were measured by the standard assay as described above. In order to eliminate the influence of the background hydrolysis of the substrate under different conditions, the same samples without enzymes were used as controls.

Effect of Various Chemical Reagents on Enzyme Activity

The effects of various chemical reagents on enzyme activity were examined by adding different metal salts (Na+, K+, Mg2+, Co2+, Ni2+, Ca2+, Mn2+, Cu2+, Fe2+, Fe3+, Zn2+, 1 and 10 mM), EDTA (1 and 10 mM), phenylmethylsulfonyl fluoride (PMSF, 1 mM), reducing reagents (dithiothreitol (DTT), glutathione (GSH), 1 mM), urea (4 and 8 M), and surfactants (Tween-20, Tween-80, Triton X-100, 1 %, V/V) to the assay solution, which consisted of the enzyme (3 μg/ml) and sodium phosphate buffer (50 mM, pH 7.5). The reaction mixtures were incubated at room temperature for 60 min, and residual enzyme activity was measured by the standard assay as described above. The enzyme activity without additives was taken as the control and defined as 100 % activity.

Effect of Different Concentrations of DTT or GSH on Enzyme Activity

The effect of DTT or GSH on the enzyme activity was examined by adding DTT or GSH at different concentrations to the assay solution, which consisted of the purified enzyme (3 μg/ml) and 50 mM sodium phosphate buffer (pH 7.5). The reaction mixture was incubated at room temperature for 60 min, and the residual enzyme activity was measured by the standard assay as described above. The enzyme activity without additives was taken as the control and defined as 100 % activity.

Effect of DTT on Enzyme Conformation

Because the activity of the enzyme without cysteine residue was rapidly stimulated by DTT or GSH, the causes of the effect of DTT on the enzyme activity were explored by determination of the conformational changes using circular dichroism. Experiments were performed with a J-815 spectropolarimeter (Jasco). Proteins were dialyzed against ultrapure water (pH 7.0) at final concentration of 5 μg/ml with or without 1 mM DTT. Far-UV spectra were recorded between 190 and 270 nm. The machine settings were 1 nm bandwidth, 0.5 s response, 0.05 nm data pitch, 50 nm/min scan speed, and 10 mm cell length.

Effect of Organic Solvent on Enzyme Stability

The enzyme was incubated with the presence of organic solvents (20 %, V/V) in 50 mM sodium phosphate buffer (pH 7.5) at room temperature with shaking at 220 rpm for 1 h in screw-capped tubes, and the samples were removed from the aqueous phase for activity determination.

The methanol stability of the enzyme was examined by pre-incubating the enzyme with different concentrations of methanol (0, 20, and 75 %) in 50 mM sodium phosphate buffer (pH 7.5) at room temperature with shaking at 220 rpm. Samples were dispensed out at different time intervals ringing from 0 to 8 h and quickly frozen prior to being determined. Residual activities were measured by the standard assay, as described above. Relative activity was calculated by defining the respective original activity as 100 %. In order to eliminate the influence of the background hydrolysis of the substrate in different organic solvent reaction buffers, a reference sample of identical composition in the absence of enzymes was used as a control.

Results and Discussion

Amino Acid Sequence Comparisons

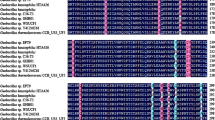

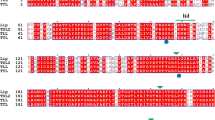

The Tm1350 gene encodes a protein with a theoretical molecular weight of 28,490 D. The homologs of Tm1350 were searched by BLAST in the NCBI database, which shows that the Tm1350 was monoglyceride lipase. Sequences were aligned using Clustal W and manually checked, which showed that Tm1350 had high similarity to lysophospholipases and lipases from Brevibacillus, which exhibited 47 % identity to a lysophospholipase from Pyrococcus furiosus (pfLys) [14], a lysophospholipase from Thermococcus kodakarensis KOD1 (TkLys) (47 %) [15], a lipase from Brevibacillus brevis (BbLipase) (35 %), and a lipase from Brevibacillus sp. BC25 (BC25Lipase) (37 %). Based on the alignment, the Tm1350 was predicted to be a lipase harboring a G-X-S-X-G motif and an α/β hydrolase fold, which are both characteristics for lipolytic enzymes. The catalytic triad of Tm1350 can be assigned to Ser86, Asp202, and His232 (Fig. 1).

Multiple sequence alignment for Tm1350 and its homologs. An alignment was carried out using Clustal W program with manual adjusting. Arrowheads indicate amino acids constituting the catalytic triad. Completely conserved residues are shown by black rectangles and conserved residues are covered by gray shadow. Abbreviation: Tm1350 from Thermotoga maritima MSB8 (NP_229151.1), Pflys from Pyrococcus furiosus (WP_011011597.1), TkLys from Thermococcus kodakarensis KOD1 (YP-183412.1), BbLipase from Brevibacillus brevis (WP_017250291.1), BC25Lipase from Brevibacillus sp. BC25 (WP_007716817.1)

Overexpression and Purification of Tm1350

The Tm1350 gene was inserted into the expression vector pET-28a, which was named pET28a–Tm1350, and transformed into E. coli BL21-CodonPlus (DE3) RIL successfully. Overexpression and purification of the enzyme were demonstrated by SDS-PAGE with high purity and 32.3 kD of apparent molecular mass (Fig. 2), which is consistent with the molecular mass calculated from the predicted amino acid sequence. The purification procedure is shown in Table 1. The purification process resulted in 8.2-fold purification factor and a yield of 47.6 % of the enzyme with specific activity of 64.3 U/mg using pNP-C4 as substrate in 50 mM sodium phosphate buffer (pH 7.5) at 70 °C.

Enzyme activity was determined using pNP-butyrate rather than olive oil as substrate because higher activity can be detected with the former (Fig. 3a). In general, main lipases hydrolyze the long chain fatty acids (≥C10) [16]. The lipase Tm1350 exhibited the highest activity on pNP-B among the substrates tested and also had good effect on long chain substrates, which exhibited 50 % activity on olive oil. The results were similar to the lipase from Streptomyces lividans, which also showed a preference for p-NP-B, and the lipase FCLip1 from hyperthermophilic bacterium Fervidobacterium changbaicum CBS-1 preferentially hydrolyzed middle-length acyl chains, especially p-nitrophenyl caprate [13, 17]. The Km and Vmax (OD) values for p-NP-butyrate were obtained by mathematical calculations according to Lineweaver-Burk (Fig. 3b). The Km and Vmax values were 8 mM and 333 U/mg respectively (the concentration of enzyme was 7.5 μg/ml).

Activity assay of Tm1350. a The effect of substrate length on Tm1350 activity, which was determined using p-NP-butyrate, p-nitrophenyl caprate, p-NP-dodecanoate p-NP-palmitate, and olive oil as substrates. Relative activity was calculated by defining the activity of using p-NP-butyrate as substrate as 100 %. b Lineweaver-Burk: Effect of the concentrations of p-NP-butyrate on velocity of Tm1350. The assays were carried out a as described under “Materials and Methods”

Effects of Temperature on Enzyme Activity and Stability

The optimum temperature of the enzyme Tm1350 was tested at various temperatures, ranging from 30 to 90 °C, in 50 mM sodium phosphate buffer (pH 7.5) (Fig. 4a). The optimum activity of the Tm1350 was detected at 70 °C and showed more than half of maximal activity from 50 to 100 °C, which was higher and broader on temperature range than the esterase Tm0053 or Tm1160 from T. maritima [18, 19]. The activity at 80 °C was 85.3 % of the maximum activity, which conformed to the T. maritima’s optimal growth temperature of approximately 80 °C.

a Temperature optima of Tm1160. Activity at 70 °C (optimum temperature) was taken as 100 %. b Thermostability of Tm1350. The residual enzyme activity was measured after incubation at 60 °C (black boxes), 70 °C (red circle), and 80 °C (blue triangle), respectively. Relative activity was calculated by defining original activity (70 °C) as 100 %

The thermostability of Tm1350 was detected at three different temperatures (60, 70, and 80 °C) by measuring the residual activity with increasing incubation time up to 8 h (Fig. 4b). The major activity was maintained at 70 °C within 60 min, and more than 50 % activity was maintained at 70 °C within 8 h. The activity of Tm1350 retained 50 % of the original activity after 30 min of incubation at 80 °C, which was similar to the esterase Tm1160 [18]. The reason for the fast drop of enzyme activity might be the high temperature disrupts the conformation of the enzyme, thereby leading to decreased affinity sites for substrate [18]. Tm1350 showed higher thermostability than other thermostable carboxylic ester hydrolases, such as the lipase from Bacillus sp. strain 42, whose half-life was 45 min under the optimum temperature (70 °C) [20]. The half-life of the esterase from Thermoanaerobacter was 90 min at 70 °C [21]. The half-life of the lipase from Aneurinibacillus thermoaerophilus strain HZ was 80 min at 70 °C [22].

Effect of pH on Enzyme Activity and Stability

Activities were determined in various buffers from pH 3 to pH 9 at 70 °C (Fig. 5a). Tm1350 had maximal activity in sodium phosphate (pH 7.5) and had low activity in acidic solution and little activity at pH 4.0. The activity in Tris–HCl buffer (pH9.0) was 80 % of the maximum activity.

a pH optima of Tm1350. Activity at pH 7.5 was taken to be 100 %. b Alkaline tolerance of Tm1350. The residual activity was measured after incubation of the enzyme at pH 7.0 (black boxes), 8.0 (red circle), 9.0 (blue triangle), and 10.0 (green inverted triangle). Relative activity was calculated by defining respective original activity as 100 %

The alkali resistance of Tm1350 was detected at four different pH values (7.0, 8.0, 9.0, and 10.0) with increasing incubation time up to 8 h by measuring the residual activity (Fig. 5b). Most activity of Tm1350 was maintained at 70 °C within 1 h, and more than 50 % of the activity was maintained after 8 h of incubation in buffer except at pH 10.0, and the half-life of the enzyme incubating in pH 10.0 buffer solution was 60 min, which was extraordinarily longer than other hyperthermophilic enzymes observed with 90 min half-life (70 °C, pH 9.0) [22] or 286 min half-life (pH 8.0, 55 °C) [23]. The lipase reported by Dannert was incubated at 60 °C for 30 min that only retained 48.5 % of the original activity at 60 °C. These results showed that Tm1350 was more tolerant to heat or alkali.

Effect of Metal Ions, EDTA, and Surfactants or Reductants on Enzyme Activity

The effect of various metal ions on the Tm1350 activity was investigated by the standard assay (Table. 2). The activity of Tm1350 was not significantly affected by incubating with Na+, K+, Mg2+, Co2+, Ni2+, and EDTA, indicating the enzyme was not a metalloprotein. At 1 mM concentration, Ca2+ and Mn2+ were found to stimulate the enzyme activity up to 125 and 120 % compared to the control, and the effect remained roughly the same at 10 mM concentration. Cu2+, Fe2+, Fe3+, and Zn2+ had inhibitory effect on the enzyme activity, respectively retained 55.3, 68, 82.3, and 78 % of its activity after treatment at 1 mM concentration. However, when the metal ion concentration increased to 10 mM, Tm1350 was strongly inhibited by Cu2+(23.7 %), Fe2+(31.6 %), Fe3+(39.1 %), and Zn2+ (30.3 %). The result was similar to some studies; for example, the activity of Tm1160 esterase was stimulated by Ca2+ and Mn2+ and inhibited by Cu2+ and Fe2+ [18]. Leow et al. and Masomian et al. showed that the activity of lipases were inhibited by Cu2+, Fe3+, and Zn2+ respectively [22, 24]. The inhibition effect by transition metal ions (Cu2+, Fe2+, Fe3+, and Zn2+) on the enzyme might show that metal ions would change solubility and behavior of the ionized fatty acids at interfaces, which influence the catalytic properties of the enzyme itself [25].

The effect of surfactants (Tween 20, Tween 80, and Triton-X100), urea, PMSF, DTT, and GSH on the enzyme activity was determined by the standard assay (Table 3). Activity was reduced 43 % by incubating with PMSF (1 mM), which indicated Tm1350 belonged to the serine group. The activity of Tm1350 was partially inhibited by PMSF that might be caused by modification of an essential serine residue that makes the change of enzyme conformation directly or indirectly [16, 26]. The enzyme activity were reduced 47, 35, and 33 % by incubating with Tween 20, Tween 80, and Triton-X100 (1 %, V/V). The activity of 130.6 % reported after incubation with 4 M urea indicates that Tm1350 is highly stable to urea which may affect protein folding. The enzyme activity was stimulated up to 618 and 550 % by incubating with DTT or GSH at a concentration of 1 mM. Reasonable explanation of the effect is that the enzyme is naturally reduced in cytoplasm considering T. maritima is an obligate anaerobic bacterium. DTT and GSH are reducing agents, which make the heterologous-overexpressed enzyme recovered to its natural state. To investigate the impact of DTT on the enzyme further, circular dichroism was used to determine the enzyme conformational change by DTT.

Effect of DTT on the Activity and Conformation of the Enzyme

The effect of DTT and GSH on the enzyme activity was examined by adding DTT and GSH at different concentrations to the assay solution (Table. 4). The activity of Tm1350 was up to 162, 618, and 321 % of the control by incubating with DTT at concentrations of 0.1, 1, and 10 mM and stimulated up to 157, 550, and 518 % of the control by incubating with GSH at concentrations of 0.1, 1, and 10 mM, respectively.

In this study, the CD spectra in far-UV region were recorded, which showed no significant changes after 1 mM DTT treatment, except for the change of the peak at 198 nm (Fig. 6). Amino acid sequence analysis of the TM1350 showed no cysteine. The results agreed that thiol-disulfide exchange is not the only mechanism whereby DTT can alter protein function [27]. Zhuo and Dixon [28] had found that the role of sulfhydryl reagents was the chelation of small amounts of inhibitory metal ions that were present in plastic laboratory ware in which Zn2+ was one of the main contaminants. In this work, Zn2+, Cu2+, Fe2+, and Fe3+ had inhibition effect on Tm1350 activity; however, Tm1350 activity is insensitive to EDTA, so the mechanism that DTT as metal chelator is not suited for the Tm1350. The study of Cleland [28, 29] had showed that DTT may act as a general reducing agent, and the study of Alliegro [27] had showed that DTT can interact with protein domains in the absence of cysteine residues. It has been reported that positive bands at 198 nm in the characteristic CD spectra are assigned to π0 → π* transitions of polypeptide chains. Therefore, the CD spectra indicated that the π0 → π* amide transitions of the enzyme might be sensitive to DTT, which may be the reason why DTT could increase the activity of Tm1350 [30, 31].

The nature Tm1350 may be reduced within T. maritima, while some key active site residues can be oxidized during overexpression in E. coli or the process of purification. It is possible that DTT and GSH interacted with protein domains including these key active site residues. The activity of Tm1350 decreased when the concentration of DTT exceed 1 mM, which may be that the functional domains of Tm1350 would be covered with DTT molecules which could sterically hinder substrate-binding sites [27]. Because of the saturation of reduction, the activity of Tm1350 was almost unchanged by incubating with GSH at concentrations of 1 and 10 mM. The results showed that the activation of the enzyme was caused by the reduction of some key active site residues without thiol-disulfide exchange, and these key residues deserve further investigation.

Effect of Organic Solvent on Enzyme Stability

The effects of various organic solvents (20 %) on the Tm1350 stability were assayed by measuring the residue activity (Table. 5). The enzyme activity increased 51 % by incubating with methanol, but reduced 34 and 54 % by incubating with DMSO or ethanol and reduced 69 % by incubating with isopropanol and acetone, which was similar to the esterase EstF4K that showed to be quite stable in the presence of 30 % (v/v) methanol and displayed low activity in the presence of 30 % (v/v) DMSO and acetone [32]. Non-polar solvents had a remarkable inhibitory effect on the enzyme activity, such as diethyl ether, trichloromethane, and n-hexane. The result was similar to the esterase Tm1160 with very low activity in the presence of the non-polar solvents and with different activity in polar organic solvents [18]. The effect of organic solvents on enzyme activity differs from enzyme to enzyme, and there was no clear correlation between the solubility of an organic solvent in water and the activity or stability of lipolytic enzymes in its presence [33]. Hyperthermophilic enzymes are more rigid than their mesophilic homologues at mesophilic temperatures, and denaturants, detergents, and solvents often activate hyperthermophilic enzymes at suboptimal temperatures because of increasing the flexibility of enzyme. This could be the reason why 4 M urea and methanol could increase the activity of Tm1350 [34].

The activity of Tm1350 after 8 h incubation in 20 or 75 % of methanol maintained 90.1 or 70.2 % of the original activity respectively (Fig. 7). Enzyme catalysis in organic solvents needs the right amount of water, which directly affects the activity of enzyme. If the amount of water is too large in the reaction system, the catalytic behavior should be changed, which leads to the change of the reaction balance, even losing the catalytic activity [35, 36]. It may be speculated that the moisture content was higher than the optimal water amount in reaction system; the flexibility of the enzyme structure became too large, leading to the change of enzyme conformation and deactivation. The Tm1350 is a thermophilic and alkali-resistant lipase; the activity was stimulated by incubating with methanol and more stable in methanol, which makes it a very attractive enzyme for production of biodiesel fuel.

Conclusion

In this study, the lipase from T. maritima was cloned, purified, and characterized for the first time. The purified recombinant Tm1350 had high activity and extreme stability at high temperatures and alkaline condition or after incubating with methanol, which demonstrated that Tm1350 is a thermophilic-, alkali-, and methanol-tolerant lipase, showing great potential in biochemical industry, such as biodiesel production. In addition, the activity of Tm1350 increased obviously by reducing agent, such as DTT or GSH. This shows that thiol-disulfide exchange is not the only mechanism whereby DTT can improve the protein function and that oxidized side chains of some non-disulfide amino acid residues would be reduced, which would be important to catalytic sites, and these key residues should be subjects for future investigation.

References

Bell, P. J. L., Sunna, A., Gibbs, M. D., Curach, N. C., Nevalainen, H., & Bergquist, P. L. (2002). Prospecting for novel lipase genes using PCR. Microbiology-Sgm, 148, 2283–2291.

Miroliaei, M., & Nemat-Gorgani, M. (2002). Effect of organic solvents on stability and activity of two related alcohol dehydrogenases: a comparative study. International Journal of Biochemistry & Cell Biology, 34, 169–175.

Lima, V. M. G., Krieger, N., Mitchell, D. A., Baratti, J. C., de Filippis, I., & Fontana, J. D. (2004). Evaluation of the potential for use in biocatalysis of a lipase from a wild strain of Bacillus megaterium. Journal of Molecular Catalysis B-Enzymatic, 31, 53–61.

Lee, E. S., Kim, H. W., Kim, D. E., Kim, Y. H., Nam, S. W., Kim, B. W., & Jeon, S. J. (2013). Gene expression and characterization of thermostable glutamate decarboxylase from Pyrococcus furiosus. Biotechnology and Bioprocess Engineering, 18, 375–381.

Gomes, J., & Steiner, W. (2004). The biocatalytic potential of extremophiles and extremozymes. Food Technology and Biotechnology, 42, 223–235.

Levisson, M., van der Oost, J., & Kengen, S. W. M. (2009). Carboxylic ester hydrolases from hyperthermophiles. Extremophiles, 13, 567–581.

Kim, S. B., Lee, W., & Ryu, Y. W. (2008). Cloning and characterization of thermostable esterase from Archaeoglobus fulgidus. Journal of Microbiology, 46, 100–107.

Mozhaev, V. V. (1993). Mechanism-based strategies for protein thermostabilization. Trends in Biotechnology, 11, 88–95.

Shimada, Y., Watanabe, Y., Sugihara, A., & Tominaga, Y. (2002). Enzymatic alcoholysis for biodiesel fuel production and application of the reaction to oil processing. Journal of Molecular Catalysis B-Enzymatic, 17, 133–142.

Ognjanovic, N., Bezbradica, D., & Knezevic-Jugovic, Z. (2009). Enzymatic conversion of sunflower oil to biodiesel in a solvent-free system: process optimization and the immobilized system stability. Bioresource Technology, 100, 5146–5154.

Gudiukaite, R., Gegeckas, A., Kazlauskas, D., & Citavicius, D. (2014). Influence of N- and/or C-terminal regions on activity, expression, characteristics and structure of lipase from Geobacillus sp. 95. Extremophiles, 18, 131–145.

Chaiyaso, T., Seesuriyachan, P., Zimmermann, W., & H-Kittikun, A. (2012). Purification and characterization of lipase from newly isolated Burkholderia multivorans PSU-AH130 and its application for biodiesel production. Annals of Microbiology, 62, 1615–1624.

Cote, A., & Shareck, F. (2010). Expression and characterization of a novel heterologous moderately thermostable lipase derived from metagenomics in Streptomyces lividans. Journal of Industrial Microbiology & Biotechnology, 37, 883–891.

Chandrayan, S. K., Dhaunta, N., & Guptasarma, P. (2008). Expression, purification, refolding and characterization of a putative lysophospholipase from Pyrococcus furiosus: retention of structure and lipase/esterase activity in the presence of water-miscible organic solvents at high temperatures. Protein Expression and Purification, 59, 327–333.

Cui, Z. C., Wang, Y. H., Pham, B. P., Ping, F. F., Pan, H. Y., Cheong, G. W., Zhang, S. H., & Jia, B. L. (2012). High level expression and characterization of a thermostable lysophospholipase from Thermococcus kodakarensis KOD1. Extremophiles, 16, 619–625.

Jaeger, K. E., Dijkstra, B. W., & Reetz, M. T. (1999). Bacterial biocatalysts: molecular biology, three-dimensional structures, and biotechnological applications of lipases. Annual Review of Microbiology, 53, 315–351.

Cai, J. G., Xie, Y. A., Song, B., Wang, Y. P., Zhang, Z. M., & Feng, Y. (2011). Fervidobacterium changbaicum Lip1: identification, cloning, and characterization of the thermophilic lipase as a new member of bacterial lipase family V. Applied Microbiology and Biotechnology, 89, 1463–1473.

Wei, T., Feng, S. X., Mao, D. B., Yu, X., Du, C. C., & Wang, X. H. (2013). Characterization of a new thermophilic and acid tolerant esterase from Thermotoga maritima capable of hydrolytic resolution of racemic ketoprofen ethyl ester. Journal of Molecular Catalysis B-Enzymatic, 85–86, 23–30.

Kakugawa, S., Fushinobu, S., Wakagi, T., & Shoun, H. (2007). Characterization of a thermostable carboxylesterase from the hyperthermophilic bacterium Thermotoga maritima. Applied Microbiology and Biotechnology, 74, 585–591.

Hamid, T. H. T. A., Eltaweel, M. A., Rahman, R. N. Z. R. A., Basri, M., & Salleh, A. B. (2009). Characterization and solvent stable features of Strep-tagged purified recombinant lipase from thermostable and solvent tolerant Bacillus sp strain 42. Annals of Microbiology, 59, 111–118.

Zhang, J., Liu, J. F., Zhou, J., Ren, Y. Y., Dai, X. Y., & Xiang, H. (2003). Thermostable esterase from Thermoanaerobacter tengcongensis: high-level expression, purification and characterization. Biotechnology Letters, 25, 1463–1467.

Masomian, M., Rahman, R. N. Z. R. A., Salleh, A. B., & Basri, M. (2013). A new thermostable and organic solvent-tolerant lipase from Aneurinibacillus thermoaerophilus strain HZ. Process Biochemistry, 48, 169–175.

Vafiadi, C., Topakas, E., Biely, P., & Christakopoulos, P. (2009). Purification, characterization and mass spectrometric sequencing of a thermophilic glucuronoyl esterase from Sporotrichum thermophile. Fems Microbiology Letters, 296, 178–184.

Leow, T. C., Abd Rahman, R. N. Z. R., Basri, M., & Salleh, A. B. (2007). A thermoalkaliphilic lipase of Geobacillus sp T1. Extremophiles, 11, 527–535.

Lesuisse, E., Schanck, K., & Colson, C. (1993). Purification and preliminary characterization of the extracellular lipase of Bacillus subtilis 168, an extremely basic pH-tolerant enzyme. European Journal of Biochemistry, 216, 155–160.

Arpigny, J. L., & Jaeger, K. E. (1999). Bacterial lipolytic enzymes: classification and properties. Biochemical Journal, 343(Pt 1), 177–183.

Alliegro, M. C. (2000). Effects of dithiothreitol on protein activity unrelated to thiol-disulfide exchange: for consideration in the analysis of protein function with Cleland’s reagent. Analytical Biochemistry, 282, 102–106.

Zhuo, S., & Dixon, J. E. (1997). Effects of sulfhydryl regents on the activity of lambda Ser/Thr phosphoprotein phosphatase and inhibition of the enzyme by zinc ion. Protein Engineering, 10, 1445–1452.

Cleland, W. W. (1964). Dithiothreitol, a new protective reagent for Sh groups. Biochemistry, 3, 480–482.

Ranjbar, B., & Gill, P. (2009). Circular dichroism techniques: biomolecular and nanostructural analyses—a review. Chemical Biology and Drug Design, 74, 101–120.

Wallace, B. A., & Janes, R. W. (2001). Synchrotron radiation circular dichroism spectroscopy of proteins: secondary structure, fold recognition and structural genomics. Current Opinion in Chemical Biology, 5, 567–571.

Ouyang, L. M., Liu, J. Y., Qiao, M., & Xu, J. H. (2013). Isolation and biochemical characterization of two novel metagenome-derived esterases. Applied Biochemistry and Biotechnology, 169, 15–28.

Ogino, H., Nakagawa, S., Shinya, K., Muto, T., Fujimura, N., Yasuda, M., & Ishikawa, H. (2000). Purification and characterization of organic solvent-stable lipase from organic solvent-tolerant Pseudomonas aeruginosa LST-03. Journal of Bioscience and Bioengineering, 89, 451–457.

Vieille, C., & Zeikus, G. J. (2001). Hyperthermophilic enzymes: sources, uses, and molecular mechanisms for thermostability. Microbiology and Molecular Biology Reviews, 65, 1–43.

Triantafyllou, A. O., Adlercreutz, P., & Mattiasson, B. (1993). Influence of the reaction medium on enzyme activity in bio-organic synthesis: behaviour of lipase from Candida rugosa in the presence of polar additives. Biotechnology and Applied Biochemistry, 17(Pt 2), 167–179.

Bousquet, M. P., Willemot, R. M., Monsan, P., & Boures, E. (1999). Enzymatic synthesis of unsaturated fatty acid glucoside esters for dermo-cosmetic applications. Biotechnology and Bioengineering, 63, 730–736.

Acknowledgments

We thank Professor Milton H. Saier, Jr. in UCSD very much for the kind help of revision. This study was supported by the National Key Basic Research Program of China (973 Program, No. 2011CBA00800), the Open Funding Project of National Key Laboratory of Biochemical Engineering, and the Key Agriculture Support Project of Jiangsu Province, China (No. BE2013400).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, R., Chen, H., Ni, Z. et al. Expression and Characterization of a Novel Thermo-Alkalistable Lipase from Hyperthermophilic Bacterium Thermotoga maritima . Appl Biochem Biotechnol 176, 1482–1497 (2015). https://doi.org/10.1007/s12010-015-1659-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1659-2