Abstract

Seven lipolytic genes were isolated and sequenced from a metagenomic library that was constructed following biomass enrichment in a fed-batch bioreactor submitted to high temperature (50–70°C) and alkaline pH (7–8.5). Among those sequences, lipIAF1-6 was chosen for further study and cloned in Streptomyces lividans 10–164. The G+C content within the sequence was 64.3%. The encoded protein, LipIAF1-6, was related to various putative lipases previously identified in different genome sequences. Homology of LipIAF-6 with the different lipases did not exceed 31%. The optimum pH (8.5) and temperature (60°C) of the purified enzyme were in agreement with the enrichment conditions. Furthermore, the enzyme was thermostable for as long as 30 min at 70°C. The maximum activity of the purified lipase was 4,287 IU/mg towards p-nitrophenyl (p-NP) butyrate (60°C; pH 8.5). LipIAF1-6 does not seem to need the presence of metal ions for its activity. The enzyme was slightly inhibited by 10 mM CoCl2 (14%), HgCl2 (12%), and dithiothreitol (DTT) (15%). The serine protease inhibitor phenylmethylsulphonyl fluoride (PMSF) reduced activity by 39% and 71% when incubated at concentrations of 1 and 10 mM, respectively. Finally, LipIAF1-6 was stable in different organic solvents, and against several surfactants and oxidative agents commonly found in detergent formulations. These results are quite encouraging for further use of this enzyme in different industrial processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Of all hydrolytic enzymes (EC 3), esterases (EC 3.1.1.1) and especially lipases (EC 3.1.1.3) are attracting more attention each year for multiple uses in biotechnology. Numerous papers have been published describing these enzymes’ general features, covering the different methods of lipase assays and screening, the regulation of gene expression, their mechanisms of action, their overall structure, the different methods for their purification, immobilisation techniques and even their classification [2, 3, 13, 14, 21, 23, 37, 43]. The peptidic sequence of lipolytic enzymes is recognized by the presence of the most highly conserved motif, GxSxG, bearing the active serine residue [23].

It is undeniable that, due to their ability to catalyze cleavage of triglycerides in diverse conditions, lipolytic enzymes are of great use for many applications [16, 22, 34]. These biocatalysts can be found in all living organisms, including animals, plants and microorganisms. However, it appears that microbial lipases are more suitable for industrial applications, considering their overall improved stability [13, 16, 43]. Nowadays, industrial processes often take place at temperatures of 45°C and higher, where many substrates have greater solubility. Reactions taking place at high temperature also benefit from decreased risk of contamination, and generally many reactions are more thermodynamically favoured in these conditions [16, 33, 38, 49].

Unfortunately, the industry seems to be facing some difficulties. Consequently, currently employed lipases do not always fulfill these criteria of activity and thermostability [8, 29]. Hence, efforts have been turned towards the study of extremophiles. Being constantly exposed to harsh conditions, these microorganisms are the best producers of thermostable enzymes. These bacteria, often part of the 99% of unculturable microorganisms, can be studied through metagenomics techniques [15]. Within the last 10 years, many thermostable lipases have been identified by DNA library screening [1, 6, 25]. Furthermore, the combination of metagenomics and enrichment has been shown to decrease the work required by allowing a more reasonable number of clones to be screened for identification of novel enzymes. Also, bioreactor enrichment prior to construction of the library has proven its efficacy by targeting genes that display the required characteristics [1, 4, 10, 27, 46].

Moreover, when it is time to choose the best host for screening technologies, several strains have been considered, including Escherichia coli, Pseudomonas putida and Streptomyces lividans [12, 28, 35, 41]. S. lividans is a Gram-positive bacteria, naturally living in the soil. This bacterium is GC rich and represents one of the best alternative hosts for expression of thermophilic enzymes, encoded by genes that also carry high GC content [20, 27]. Therefore, a few publications have demonstrated successful use of this bacterium for expression of heterologous proteins [9, 28, 50].

The focus of the present work is identification of alkali-thermostable lipases. The biocatalysts were identified by screening a metagenomic library constructed following enrichment of fed-batch reactors submitted to cycles of temperature and pH variations (50°C/70°C/50°C; 7/8.5/7). The success of the methodology has been demonstrated by the characterization of a first lipase, LipIAF5-2, in a previous publication [32]. The lipase LipIAF1-6 described herein is thus the second enzyme successfully expressed in Streptomyces lividans and characterized within the project. Finally, its high stability at elevated temperatures, in organic solvents and against tensioactive agents makes this novel enzyme suitable for many industrial applications.

Materials and methods

Library construction and activity screening

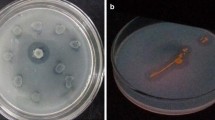

The methodology concerning the library construction, subcloning and sequence analysis has been described in detail in our previous publication [32]. E. coli strain LE392MP (Epicentre) was used as a host for construction of the metagenomic library. The biomass, enriched with meat extracts, was grown in the same kind of sequencing fed-batch reactor (SFBR) and submitted to comparable 72 h cycles of temperature change (50–70°C) and pH variation (7–8.5) for a period of 3 months prior to DNA extraction. Following this enrichment, total DNA was extracted to obtain high-molecular-weight DNA using lysozyme, freeze–thaw cycles and phenol/chloroform extractions. DNA was partially digested with BamH1 in order to generate 40-kb fragments. These fragments were ligated in pIAFS2 shuttle cosmid vector digested with BglII (INRS-Institut Armand-Frappier). Lambda phage packaging extracts were added to the ligation, and transduction was performed. Approximately 10,000 transductants were screened for lipolytic activity on 1% tributyrin/2xTY agar plates supplemented with apramycin (50 μg/ml). Candidates showing hydrolysis of the substrate after overnight incubation at 37°C were chosen for further study.

Subcloning and sequencing of the lipase gene

The positive colonies were grown overnight at 37°C in 2xTY media with 50 μg/ml apramycin. Afterwards, the cosmids were isolated using a standard phenol/chloroform protocol. The isolated cosmids were partially digested with SphI, and the generated inserts, varying in size from 1 to 10 kb, were ligated and transformed in E. coli strain DH11S. The transformants were de novo screened on 1% tributyrin/2xTY agar plates in order to identify positive colonies containing smaller fragments suitable for sequencing. Once a small fragment containing the gene conferring lipolytic activity was identified, the latter was ligated with pTZ19U commercial vector [31] and transformed once again prior to sequencing at Genome Quebec using universal M13 primers. One lipolytic gene from the cosmid lipIAF1-6 was chosen for further study. Subsequently, specific forward and reverse primers were synthesized by inserting restriction sites SphI and SacI to amplify the target DNA fragment and clone it in the appropriate vector and host strain for lipase expression.

Expression and purification

The lipase was expressed in Streptomyces lividans 10-164 strain [19] using pIAFC109 vector, which confers resistance to the antibiotic thiostrepton. Once again, culture mediums and incubation periods were as described in detail in a previous publication [32]. In summary, following a 48 h culture in rich TSB medium, the mycelium was transferred to minimal M14 medium for a 72 h period. Afterwards, the mycelium was separated from the supernatant by bulk filtration. A second filtration using a Whatman 0.2-μm nylon membrane (VWR) was used to remove smaller particles. Purification of the secreted lipase was performed using one-step hydrophobic interaction chromatography (HIC) with HiTrap Butyl Sepharose 4 Fast Flow column (Ge Healthcare). The column was equilibrated with 50 mM potassium phosphate buffer (pH 7) containing 1 M ammonium sulphate. After passage of the crude extract equilibrated with the same buffer, elution was initiated by a descending concentration of ammonium sulphate. A second gradient was applied, where rising concentrations of ethylene glycol (0–50%) allowed elution of more highly bound proteins. Collected fractions were incubated on an agar plate containing 1% tributyrin, and the positive fractions were pooled. The purity of the lipase was then confirmed by sodium dodecyl sulphate (SDS) polyacrylamide gel electrophoresis (PAGE) analysis, and a zymogram using 4-methylumbelliferyl (MUF)-butyrate (Fluka) as a substrate allowed detection of lipase activity prior to standard silver staining. The zymogram analysis was performed by incubating the gel for a period of 5 min with 100 μM substrate in Tris–HCl 50 mM (pH 7). The purified enzyme concentration was measured by Bradford method (Bio-Rad) using bovine serum albumin as standard and was then kept at 4°C until its use for characterization.

Determination of substrate specificity and effect of pH and temperature on enzyme activity and stability

All enzymatic assays were performed by using a spectrophotometer (Varian, Cary Win UV 300) connected to a thermo bath/circulator and a computer running Cary Win UV software. The following synthetic substrates purchased from Sigma were used: para-nitrophenyl fatty acyl esters of butyric acid (C4), octanoic acid (C8), decanoic acid (C10), lauric acid (C12), myristic acid (C14), palmitic acid (C16) and stearic acid (C18). These substrates were dissolved in isopropanol and added in concentrations of 0.3 mM within the cuvettes. Once the substrates were hydrolysed by purified lipase, absorbance of the liberated yellow compound was followed at 405 nm. All experiments were run in triplicate for 5 min.

The pH optimum of the purified lipase was measured by using 50 mM Tris–HCl buffer (pH 7.2–9) and 50 mM NaOH–glycine buffer (pH 9–11.3). All buffers contained 0.05% CaCl2. The assays were performed at 21°C against p-NP decanoate (p-NP C10). A standard curve of para-nitrophenol (Sigma) in the same buffers allowed correction of the data, considering the poor absorption of p-NP at lower pH. The results were expressed in relative activity, where a value of 100% was assigned to the highest activity.

In order to determine the optimal temperature of the lipase, a sample of the latter was used to hydrolyse p-NP C10 at different temperatures ranging from 25°C to 70°C in Tris–HCl 50 mM (pH 8.5) containing 0.05% CaCl2. The temperature within the cuvettes was monitored and stable for at least 5 min prior to addition of the enzyme. Likewise, thermostability was established by adding enzyme to pre-incubated Na–P buffer (pH 7.6), kept stable at various temperatures (40–90°C). After a period of incubation of 30 min, an aliquot of the lipase was taken to calculate the residual activity at the optimum temperature of the lipase in the same buffer as cited previously. Once again, the results were expressed in relative activity.

The substrate specificity of the purified lipase was examined by observing hydrolytic activity towards the different p-NP fatty acyl esters listed previously. The assays were performed at the pH and temperature optimum of the enzyme. The activity, expressed in international units, corresponds to μmol of p-NP liberated per minute in the above conditions.

Effect of various compounds on lipase stability and activity

Various metal ions (CaCl2, CoCl2, CuCl2, MgCl2, MnCl2, HgCl2 and ZnCl2) and three potential inhibitors [ethylenediamine tetraacetic acid (EDTA), DTT and PMSF] were used at concentrations of 1 and/or 10 mM to investigate their effect on lipase activity. The stability of the lipase was also evaluated in different organic solvents and against tensioactive agents commonly used in detergent formulations. Two different concentrations (10% and 30%) of acetonitrile, dimethyl sulphoxide (DMSO), ethanol, methanol, acetone and isopropanol were incubated with the enzyme for 1 h at room temperature in 50 mM Tris–HCl buffer (pH 7) without any more additives. Similarly, 1% and 5% of various agents found in detergents (sodium dodecyl sulphate, Triton X-100, Tween 80, peroxide, sodium borate and sodium carbonate) were incubated with the lipase in the same buffer. Residual activity was then calculated in 50 mM Tris–HCl buffer (pH 8.5) containing 0.05% CaCl2 at 60°C against p-NP decanoate.

Results

Screening for lipolytic activity and sequencing of the positive clones

Following construction of the metagenomic library, about 10,000 clones were screened on tributyrin/agar plates in order to identify colonies exhibiting lipolytic activity. The primary screening led to the identification of seven clones presenting a clear halo around the colonies. The isolation of the corresponding cosmids (~40 kb) and the subsequent steps of restriction digestion and subcloning led to the sequencing of small inserts containing seven open reading frames (ORF) encoding possible lipolytic enzymes (results not shown). The first observation was that all identified genes carried high GC content (between 64.3% and 69.9%). The molecular weight of the encoded proteins varied from 20 to 57.8 kDa. Moreover, all proteins bore the conserved pentapeptide GxSxG, typical of lipolytic enzymes. NCBI BLASTp search results demonstrated that all the positive clones identified were novel and presented no more then 49% identity with other lipases. After purification and characterization of the lipase LipIAF5-2 [32], the ORF lipIAF1-6 was chosen for expression and characterization of a second novel lipolytic enzyme.

Amino acid sequence analysis of LipIAF1-6

The amino acid sequence of LipIAF1-6 (GenBank accession no. HM049169) was recovered from a 2,527-pb contig (Fig. 1). No other ORF upstream of the lipase gene was identified. However, the C-terminal sequence of a protein showing homology with an acyl-CoA thioesterase II was observed. Although this sequence was incomplete, BLASTx results demonstrated that part of the encoded protein showed homology with Plesiocystis pacifica STR-1 (62% identity out of 129 amino acids). These results do not conclusively determine the microorganism of origin, demonstrating that the DNA fragment comes from an uncultured bacterium. Furthermore, the LipIAF1-6 sequence was analysed in detail prior to polymerase chain reaction (PCR) and cloning. The first analysis was conducted using SignalP 3.0 Server in order to establish whether the sequence contained a signal peptide. The results concluded, with high probability, that a 27-amino-acid-long signal peptide allowed secretion of the protein. Following this analysis, the sequence of the mature protein was compared with other proteins known from universal databases. Of all homologous sequences identified after the BLASTp search, five lipase sequences were aligned with LipIAF1-6 using ClustalW2 software. On comparison of the complete sequences of the mature proteins, the percentage of identical amino acids varied from 21% to 31% (Table 1). Furthermore, considering actual knowledge on the position of all three catalytic residues (Ser, Asp, His) within the lipase from Pseudomonas mendocina (Accession number 2FX5_A) [44], the sequence alignment was used to identify the possible positions of those residues in LipIAF1-6 (Fig. 2). Consequently, the active serine site is thought to be in position S117 of the mature protein. This serine is surrounded by other residues that follow the GxSxG conserved motif. Also, D166 and H195 are the putative positions for the aspartate and histidine residues of the catalytic triad (Fig. 2).

Amino acid alignment of LipIAF1-6 lipase with the most related lipolytic enzymes from P. mendocina (2FX5_A), P. stutzeri A1501 (YP_001174476), an uncultured bacterium (AAF87662), Geobacillus sp. Y412MC10 (ZP_03040339) and T. fusca YX (YP_288943.1). Identical, conserved and semi-conserved residues are marked by asterisk, colon and period, respectively. The conserved residues present in the catalytic triad (Ser, Asp, His) are marked by black dots

Expression and purification of LipIAF1-6

The sequence analysis of LipIAF1-6 presented many clues to the function of the enzyme, and so the latter was amplified by PCR and expressed in Streptomyces lividans 10-164 as described previously. Since the enzyme is thought to be secreted, the proteins in the supernatant were analysed by SDS–PAGE. Zymogram analysis using MUF-butyrate as substrate was a simple assay to determine the presence of a lipolytic enzyme in the crude extract. Fortunately, in the culture conditions used for the enzyme expression, no lipases are secreted by the wild-type strain that does not contain the gene of interest. A fluorescent band after the zymogram analysis was visible around the corresponding molecular weight (27.4 kDa) of the protein (Fig. 3, lanes 1 and 2). The nature of the protein hydrolysing the substrate MUF-butyrate was confirmed to be LipIAF1-6 by mass spectrometry analysis (results not shown). Purification of LipIAF1-6 was performed in a single step using HIC HiTrap Butyl Sepharose 4 Fast Flow column. The flow-through collected after the passage of the crude extract was kept to assess the presence of any lipolytic activity. The results demonstrated that the total amount of the enzyme was bound to the column, since no activity was observed in the flow-through. Elution of LipIAF1-6 started when the concentration of ammonium sulphate in the buffer was zero, although it seemed that its affinity to the ligand was high, because a second peak of protein corresponding to LipIAF1-6 was observed when ethylene glycol was applied on the column. Overall, the fractions containing the purified protein were pooled, and the Bradford method was performed to determine the amount of purified protein. Afterwards, spectrophotometric assays were performed at room temperature, using Tris–HCl 50 mM buffer (pH 8.5) containing 0.05% CaCl2 and p-NP decanoate as substrate. Both the crude and purified samples were assayed to determine the yield of purification. In total, 31 mg proteins was applied on the column, and 15 mg LipIAF1-6 was collected after purification. This single step was sufficient to recover 91.7% of the enzyme. Furthermore, the purification factor was established to be 1.9. Finally, the purity of the enzyme was confirmed by silver-stained SDS–PAGE before characterization of the enzyme (Fig. 3, lane 4).

Effect of pH and temperature on enzyme activity and stability

The effect of pH and temperature on activity was determined spectrophotometrically by monitoring the activity of the lipase towards p-NP decanoate. The activity of LipIAF1-6 was maximal in Tris–HCl buffer 50 mM (pH 8.5) containing 0.05% CaCl2. The lipolytic activity was still high between pH 8 and 9.5 but started to drop at more alkaline pH (Fig. 4). When pH was below 8, the activity was very low; about 60% of activity was lost when compared with the activity at pH 8.5 (100% value). The activity and stability of the enzyme at various temperatures are shown in Fig. 5. The enzyme preferred high temperatures between 50°C and 70°C. The 100% value was attributed to a temperature of 60°C. Between temperatures of 45°C and 70°C, more then 80% of activity was retained. On the contrary, at temperatures of 40°C and below, hydrolysis of p-NP decanoate was reduced (Fig. 5). Furthermore, when the enzyme was incubated for 30 min at temperatures ranging from 40°C to 70°C before the spectrophotometric assays, it was observed that its activity was identical to that of the control kept on ice (Fig. 5). However, after being incubated for 30 min at 80°C, the enzyme lost about 70% of activity.

Substrate specificity

Substrate specificity of the purified enzyme against different fatty acid esters of p-nitrophenyl was assessed at 60°C in Tris–HCl 50 mM (pH 8.5) with CaCl2. The results demonstrated that LipIAF1-6 can hydrolyse a broad range of triglycerides (Fig. 6). All chain lengths from 4 to 18 carbons were cleaved, although the preference was for p-NP C4 (4,287 IU/mg) and p-NP C5 (3,548 IU/mg). Activity towards substrates with longer chain lengths (p-NP C16 and p-NP C18) was still significant: 2,422 and 2,145 IU/mg, respectively (Fig. 6).

Effect of various compounds on enzyme stability and activity

LipIAF1-6 showed no significant increase or decrease of activity when incubated with 10 mM CaCl2 (107%), CuCl2 (96%), MgCl2 (96%), MnCl2 (105%), ZnCl2 (104%) and EDTA (95%). However, CoCl2, HgCl2 and DTT slightly inhibited the enzyme, reducing activity to 86%, 88% and 85% at 10 mM concentration, respectively. Furthermore, PMSF, a known inhibitor of serine proteases, inhibited LipIAF1-6 activity, which only retained 61% and 29% of activity after incubation with 1 and 10 mM concentrations. As for the effect of other compounds, the activity of the lipase was unchanged when the incubation took place with 10% water-miscible solvents. When the concentration was increased to 30%, acetonitrile, ethanol, methanol and acetone seemed to increase the activity towards p-NP C10 (Table 2). Finally, the effect of tensioactive and oxidative agents was evaluated. All tested compounds had a stimulating effect on the hydrolytic activity following incubation at 1% of the agents. The activating effect was still observed when exposed to 5% of the same agents, except for Tween 80 and Triton X-100, which highly inhibited the enzyme, leaving only 26% and 13% residual activity (Table 3).

Discussion

In the present study, screening of 10,000 clones on tributyrin (C4:0) allowed sequencing of seven different ORFs encoding lipolytic enzymes. The metagenomic library was constructed following extraction of biomass that had been submitted to high temperature (50–70°C) and alkaline pH (7–8.5) in the hope of identifying lipases that would catalyze fatty acids in these conditions. The first observation was that the seven ORFs all presented high G+C content, often found in the genome of thermophilic bacteria [20, 27]. LipIAF1-6 represents the second enzyme to be characterized within this project. Its optimum temperature (60°C) and pH (8.5) of activity are similar to the optimum conditions (60°C and 10.5) observed for LipIAF5-2 in our previous study [32]. Both lipases were novel, presenting only slight similarity with other known lipolytic enzymes. Furthermore, the two lipases presented characteristics corresponding to the enrichment conditions. These results demonstrate, as in other publications, that enrichment technologies are useful to favour the growth of adapted microorganisms encoding biocatalysts with target characteristics [7, 11, 17, 41]. The analysis of the biochemical properties of the enzyme also demonstrated that LipIAF1-6 was stable for at least 1 h at 60°C (results not shown) and for 30 min at 70°C, a characteristic that is important for many commercial applications [33, 38, 49]. The hydrolytic activity of the novel lipase extended to all experimented substrates, although there was a marked preference for the soluble substrate p-NP butyrate. The hydrolytic activity towards this substrate was evaluated to be 4,287 IU/mg, which is quite high compared with the activity of some other thermophilic lipases; for example, the lipase characterized by Elend et al. [10] presented 513 IU/mg at 45°C and pH 7.2. Another isolated lipase, LipG, showed 458.8 IU/mg using p-NP palmitate as a substrate at 37°C [26]. Finally, thermostable lipase LipA from Geobacillus presented 3,586 IU/mg when assayed at 55°C and pH 7 [46]. Several indications tend to classify LipIAF1-6 with lipases rather than esterases. First of all, the sequence of the conserved pentapeptide GHSQG is more common in lipases than in esterases [14]. Moreover, esterases are usually unable to hydrolyse insoluble substrates (>C10). Other experiments have shown that the newly isolated lipase does not depend on the presence of metal ions for its activity, since most of the cations tested did not significantly affect the hydrolytic activity. This hypothesis is also confirmed by the fact that LipIAF1-6 was not affected by the chelator EDTA, unlike known lipases which need various cations to enhance their activity [27, 36, 45]. The lipase was only slightly inhibited by 10 mM HgCl2 (12%) and DTT (15%), which suggests that disulphide bridges are not essential for lipase activity. The only compound that altered LipIAF1-6 activity was the serine protease inhibitor, PMSF. The residual activities after 1 h of incubation with 1 and 10 mM were 61% and 29%, respectively. PMSF usually binds covalently to the serine residue of the catalytic triad. However, many lipases contain a mobile structure called the lid, which covers the active site in aqueous solution, preventing, in some cases, PMSF inhibition [23, 27]. LipIAF1-6 is not totally inhibited by PMSF, as an esterase would be [24, 39, 48]. Also, some lipases have shown a preference for fatty acids having long carbon chains and were also affected by the inhibitor [40]. The interaction between the inhibitor and the lipase must depend on several factors, including their three-dimensional (3D) conformation at the time of inactivation. Finally, the overall stability of thermophile enzymes should also be accompanied by high stability in solvents and also against surfactants [33]. These features are of critical importance when using lipase for biotransformation in non-aqueous media or, in the case of surfactants, for the detergent industry [13, 16, 22, 26, 44]. The experiments conducted on LipIAF1-6 have demonstrated its high stability in all organic solvents tested at concentrations of 10% and 30%. Other thermostable lipases have shown similar stability in organic solvents [42, 47]. Finally, detergent formulations often contain different tensioactive and oxidative agents. The lipase LipIAF1-6 was activated by SDS, Tween 80 and Triton X-100 (1%) after 1 h incubation at room temperature. Similarly, other compounds commonly found in detergents, such as H2O2, sodium borate and sodium carbonate, also enhanced the enzyme activity. Unfortunately, higher concentrations of Tween 80 and Triton X-100 (5%) almost completely inhibited (26% and 13% residual activity, respectively) the enzyme after 1 h incubation. Detergents have similar properties to the natural substrates of the lipases, and the surfactant–enzyme interaction could displace the lid and activate the enzyme activity, or modify the 3D structure of the enzyme, thus inhibiting its activity. All these interactions depend on many factors, including the critical micelle concentrations of the surfactants [18, 35]. Ultimately, this study has allowed the rapid identification of novel enzymes, and the high stability of LipIAF1-6 in various conditions justifies the potential interest of this lipase for many industrial applications.

References

Abdel-Fattah YR, Gaballa AA (2008) Identification and over-expression of a thermostable lipase from Geobacillus thermoleovorans Toshki in Escherichia coli. Microbiol Res 163(1): 13–20. doi:10.1016/j.micres.2006.02.004

Alloue WA, Aguedo M, Destain J, Ghalfi H, Blecker C et al (2008) Les lipases immobilisées et leurs applications. Biotechnol Agron Soc Environ 12(1):57–68

Arpigny JL, Jaeger KE (1999) Bacterial lipolytic enzymes: classification and properties. Biochem J 343:177–183

Bora L, Kalita MC (2007). Production and optimization of thermostable lipase from a thermophilic Bacillus sp. LBN 4. Int J Microbiol 4(1)

Boston M, Requadt C, Danko S, Jarnagin A, Ashizawa E et al (1997) Structure and function engineered Pseudomonas mendocina lipase. Methods Enzymol 284:298–317

Choo DW, Kurihara T, Suzuki T, Soda K, Esaki N (1998) A cold-adapted lipase of an Alaskan psychrotroph, Pseudomonas sp. strain B11–1: gene cloning and enzyme purification and characterization. Appl Environ Microbiol 64(2):486–491

Cowan D, Meyer Q, Stafford W, Muyanga S, Cameron R, Wittwer P (2005) Metagenomic gene discovery: past, present and future. Trends Biotechnol 23(6):321–329. doi:10.1016/j.tibtech.2005.04.001

Demirjian DC, Moris-Varas F, Cassidy CS (2001) Enzymes from extremophiles. Curr Opin Chem Biol 5(2):144–151

Diaz M, Ferreras E, Moreno R, Yepes A, Berenguer J, Santamaria R (2008) High-level overproduction of Thermus enzymes in Streptomyces lividans. Appl Microbiol Biotechnol 79(6):1001–1008. doi:10.1007/s00253-008-1495-1

Elend C, Schmeisser C, Leggewie C, Babiak P, Carballeira JD et al (2006) Isolation and biochemical characterization of two novel metagenome-derived esterases. Appl Environ Microbiol 72(5):3637–3645. doi:10.1128/Aem.72.5.3637-3645.2006

Entcheva P, Liebl W, Johann A, Hartsch T, Streit WR (2001) Direct cloning from enrichment cultures, a reliable strategy for isolation of complete operons and genes from microbial consortia. Appl Environ Microbiol 67 (1):89–99. doi:10.1128/AEM.67.1.89-99.2001

Fan Z, Yue C, Tang Y, Zhang Y (2009) Cloning, sequence analysis and expression of bacterial lipase-coding DNA fragments from environment in Escherichia coli. Mol Biol Rep 36(6):1515–1519. doi:10.1007/s11033-008-9344-y

Fickers P, Destain J, Thonart P (2008) Les lipases sont des hydrolases atypiques: principales caractéristiques et applications. Biotechnol Agron Soc Environ 12(2):119–130

Fojan P, Jonson PH, Petersen MTN, Petersen SB (2000) What distinguishes an esterase from a lipase: a novel structural approach. Biochimie 82(11):1033–1041

Handelsman J (2004) Metagenomics: application of genomics to uncultured microorganisms. Microbiol Mol Biol Rev 68(4):669. doi:10.1128/Mbr.68.4.669-685.2004

Hasan F, Shah AA, Hameed A (2006) Industrial applications of microbial lipases. Enzyme Microbiol Technol 39(2):235–251. doi:10.1016/j.enzmictec.2005.10.016

Healy FG, Ray RM, Aldrich HC, Wilkie AC, Ingram LO, Shanmugam KT (1995) Direct isolation of functional genes encoding cellulases from the microbial consortia in a thermophilic, anaerobic digester maintained on lignocellulose. Appl Microbiol Biotechnol 43(4):667–674

Henne A, Schmitz RA, Bomeke M, Gottschalk G, Daniel R (2000) Screening of environmental DNA libraries for the presence of genes conferring lipolytic activity on Escherichia coli. Appl Environ Microbiol 66(7):3113–3116

Hurtubise Y, Shareck F, Kluepfel D, Morosoli R (1995) A cellulase/xylanase-negative mutant of Streptomyces lividans 1326 defective in cellobiose and xylobiose uptake is mutated in a gene encoding a protein homologous to ATP-binding proteins. Mol Microbiol 17(2):367–377

Ishida M, Yoshida M, Oshima T (1997) Highly efficient production of enzymes of an extreme thermophile, Thermus thermophilus: a practical method to overexpress GC-rich genes in Escherichia coli. Extremophiles 1(3):157–162

Jaeger KE, Dijkstra BW, Reetz MT (1999) Bacterial biocatalysts: molecular biology, three-dimensional structures, and biotechnological applications of lipases. Ann Rev Microbiol 53:315–351

Jaeger KE, Eggert T (2002) Lipases for biotechnology. Curr Opin Biotechnol 13(4):390–397

Jaeger KE, Ransac S, Dijkstra BW, Colson C, van Heuvel M, Misset O (1994) Bacterial lipases. FEMS Microbiol Rev 15(1):29–63

Kademi A, Ait-Abdelkader N, Fakhreddine L, Baratti J (2000) Purification and characterization of a thermostable esterase from the moderate thermophile Bacillus circulans. Appl Microbiol Biotechnol 54(2):173–179

Kim YJ, Choi GS, Kim SB, Yoon GS, Kim YS, Ryu YW (2006) Screening and characterization of a novel esterase from a metagenomic library. Protein Expr Purif 45(2):315–323. doi:10.1016/j.pep.2005.06.008

Lee MH, Lee CH, Oh TK, Song JK, Yoon JH (2006) Isolation and characterization of a novel lipase from a metagenomic library of tidal flat sediments: evidence for a new family of bacterial lipases. Appl Environ Microbiol 72(11):7406–7409. doi:10.1128/Aem.01157-06

Li H, Zhang X (2005) Characterization of thermostable lipase from thermophilic Geobacillus sp. TW1. Protein Expr Purif 42(1):153–159. doi:10.1016/j.pep.2005.03.011

Li X, Qin L (2005) Metagenomics-based drug discovery and marine microbial diversity. Trends Biotechnol 23(11):539–543. doi:10.1016/j.tibtech.2005.08.006

Lorenz P, Eck J (2005) Metagenomics and industrial applications. Nat Rev Microbiol 3(6):510–516. doi:10.1038/nrmicro1161

Lykidis A, Mavromatis K, Ivanova N, Anderson I, Land M et al (2007) Genome sequence and analysis of the soil cellulolytic actinomycete Thermobifida fusca YX. J Bacteriol 189(6):2477–2486. doi:10.1128/JB.01899-06

Mead DA, Szczesna-Skorupa E, Kemper B (1986) Single-stranded DNA ‘blue’ T7 promoter plasmids: a versatile tandem promoter system for cloning and protein engineering. Protein Eng 1(1):67–74

Meilleur C, Hupe JF, Juteau P, Shareck F (2009) Isolation and characterization of a new alkali-thermostable lipase cloned from a metagenomic library. J Ind Microbiol Biotechnol 36(6):853–861

Niehaus F, Bertoldo C, Kahler M, Antranikian G (1999) Extremophiles as a source of novel enzymes for industrial application. Appl Microbiol Biotechnol 51(6):711–729

Pandey A, Benjamin S, Soccol CR, Nigam P, Krieger N, Soccol VT (1999) The realm of microbial lipases in biotechnology. Biotechnol Appl Biochem 29:119–131

Rajendhran J, Gunasekaran P (2008) Strategies for accessing soil metagenome for desired applications. Biotechnol Adv 26(6):576–590. doi:10.1016/j.biotechadv.2008.08.002

Rashid N, Shimada Y, Ezaki S, Atomi H, Imanaka T (2001) Low-temperature lipase from psychrotrophic Pseudomonas sp. strain KB700A. Appl Environ Microbiol 67(9):4064–4069

Rosenau F, Jaeger KE (2000) Bacterial lipases from Pseudomonas: regulation of gene expression and mechanisms of secretion. Biochimie 82(11):1023–1032

Rossi M, Ciaramella M, Cannio R, Pisani FM, Moracci M, Bartolucci S (2003) Extremophiles 2002. J Bacteriol 185(13):3683–3689. doi:10.1128/Jb.185.13.3683-3689.2003

Ruiz C, Javier Pastor FI, Diaz P (2003) Isolation and characterization of Bacillus sp. BP-6 LipA, a ubiquitous lipase among mesophilic Bacillus species. Lett Appl Microbiol 37(4):354–359

Salameh MA, Wiegel J (2007) Purification and characterization of two highly thermophilic alkaline lipases from Thermosyntropha lipolytica. Appl Environ Microbiol 73(23):7725–7731. doi:10.1128/AEM.01509-07

Schmeisser C, Steele H, Streit WR (2007) Metagenomics, biotechnology with non-culturable microbes. Appl Microbiol Biotechnol 75(5):955–962. doi:10.1007/s00253-007-0945-5

Sharma AK, Tiwari RP, Hoondal GS (2001) Properties of a thermostable and solvent stable extracellular lipase from a Pseudomonas sp. AG-8. J Basic Microbiol 41 (6):363–366. doi:10.1002/1521-4028(200112)41:6<363::AID-JOBM363>3.0.CO;2-C

Sharma R, Chisti Y, Banerjee UC (2001) Production, purification, characterization, and applications of lipases. Biotechnol Adv 19 (8):627–662

Sibille N, Favier A, Azuaga AI, Ganshaw G, Bott R et al (2006) Comparative NMR study on the impact of point mutations on protein stability of Pseudomonas mendocina lipase. Protein Sci 15(8):1915–1927. doi:10.1110/Ps.062213706

Snellman EA, Sullivan ER, Colwell RR (2002) Purification and properties of the extracellular lipase, LipA, of Acinetobacter sp. RAG-1. Eur J Biochem 269(23):5771–5779

Soliman NA, Knoll M, Abdel-Fattah YR, Schmid RD, Lange S (2007) Molecular cloning and characterization of thermostable esterase and lipase from Geobacillus thermoleovorans YN isolated from desert soil in Egypt. Process Biochem 42(7):1090–1100. doi:10.1016/j.procbio.2007.05.005

Sugihara A, Ueshima M, Shimada Y, Tsunasawa S, Tominaga Y (1992) Purification and characterization of a novel thermostable lipase from Pseudomonas cepacia. J Biochem 112(5):598–603

Tesch C, Nikoleit K, Gnau V, Gotz F, Bormann C (1996) Biochemical and molecular characterization of the extracellular esterase from Streptomyces diastatochromogenes. J Bacteriol 178(7):1858–1865

van den Burg B (2003) Extremophiles as a source for novel enzymes. Curr Opin Microbiol 6(3):213–218. doi:10.1016/S1369-5274(03)00060-2

Wang GYS, Graziani E, Waters B, Pan WB, Li X et al (2000) Novel natural products from soil DNA libraries in a streptomycete host. Organic Lett 2(16):2401–2404. doi:10.1021/Ol005860z

Yan YL, Yang J, Dou YT, Chen M, Ping SZ et al (2008) Nitrogen fixation island and rhizosphere competence traits in the genome of root-associated Pseudomonas stutzeri A1501. Proc Natl Acad Sci USA 105(21):7564–7569. doi:10.1073/pnas.0801093105

Acknowledgments

This work was funded by a Strategic Grant from the Natural Sciences and Engineering Research Council of Canada. A. Côté is a recipient of a scholarship from Fondation Armand-Frappier. We are grateful to Raymonde Jetté, Guillaume Brault and François-Xavier Lussier for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Côté, A., Shareck, F. Expression and characterization of a novel heterologous moderately thermostable lipase derived from metagenomics in Streptomyces lividans . J Ind Microbiol Biotechnol 37, 883–891 (2010). https://doi.org/10.1007/s10295-010-0735-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0735-4