Abstract

The development of new cost-effective bioprocesses for the production of cellulolytic enzymes is needed in order to ensure that the conversion of biomass becomes economically viable. The aim of this study was to determine whether a novel sequential solid-state and submerged fermentation method (SF) could be validated for different strains of the Trichoderma genus. Cultivation of the Trichoderma reesei Rut-C30 reference strain under SF using sugarcane bagasse as substrate was shown to be favorable for endoglucanase (EGase) production, resulting in up to 4.2-fold improvement compared with conventional submerged fermentation. Characterization of the enzymes in terms of the optimum pH and temperature for EGase activity and comparison of the hydrolysis profiles obtained using a synthetic substrate did not reveal any qualitative differences among the different cultivation conditions investigated. However, the thermostability of the EGase was influenced by the type of carbon source and cultivation system. All three strains of Trichoderma tested (T. reesei Rut-C30, Trichoderma harzianum, and Trichoderma sp INPA 666) achieved higher enzymatic productivity when cultivated under SF, hence validating the proposed SF method for use with different Trichoderma strains. The results suggest that this bioprocess configuration is a very promising development for the cellulosic biofuels industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The enzymatic hydrolysis of biomass is considered one of the most sustainable technologies for the production of cellulosic ethanol. Cellulolytic enzymes are capable of breaking down cellulose polymers into soluble sugars that can be converted into ethanol by means of microbial fermentation. However, cellulosic ethanol production is still not profitable on an industrial scale. Difficulties that need to be overcome are related to the effectiveness and the high cost of the enzymatic cocktails [1]. For this reason, much remains to be done concerning the development of new cost-effective bioprocesses for cellulolytic enzymes production. In addition to the high demand for cellulolytic enzymes in the biofuels industry, such enzymes are widely applied in the pulp and paper, textile, food and beverages, detergent, and animal feed industries [2]. On-site production of enzymes is a potential strategy that could be used to reduce costs, since there is less need to stabilize the enzyme preparations, hence avoiding the expenses associated with transport and long-term storage [3–6]. The development of a microbial enzyme production bioprocess in which the carbon source is a lignocellulosic material from a stream within the ethanol process is a potential configuration that could enable on-site enzyme production. This would contribute to cost reduction as well as to the production of more specific enzymatic cocktails suitable for degrading the same type of biomass. Among the lignocellulosic materials that can be used for cellulosic ethanol production and as substrates for enzyme production, sugarcane bagasse is especially attractive in Brazil, where it is readily available in large amounts at the sugarcane mills [7].

In terms of the choice of microorganism for enzyme production, the filamentous fungus Trichoderma reesei (teleomorph Hypocrea jecorina) is widely used for the industrial production of cellulolytic enzyme cocktails due to its very high protein secretion capacity [8–12]. Different cultivation methods have been used for cellulase production by T. reesei, such as submerged fermentation (SmF) and solid-state fermentation (SSF) [2]. Each of these cultivation systems has its own advantages and disadvantages associated with the environmental and operational conditions. Nevertheless, SSF more closely resembles the natural environment of the fungus, because T. reesei grows naturally on solid cellulosic material. The application of SSF for industrial enzyme production has received increasing attention over the past 20 years, and various studies have described the use of this technique to produce enzymes involved in biomass deconstruction [2, 13]. From the environmental perspective, the benefit of SSF is related to the use of agro-industrial residues as solid substrates acting as sources of both carbon and energy. However, industrial-scale production of enzymes by SSF still faces technical limitations [14, 15]. On the other hand, SmF is the most widely used cultivation method for industrial enzyme production, because the operational techniques and the control of environmental factors (such as temperature and pH) are well established.

In recent work [16], we proposed a novel cultivation methodology that combines the advantages of the two conventional cultivation processes (SmF and SSF). The technique, called sequential fermentation (SF), is based on the use of a lignocellulosic material, such as sugarcane bagasse, as the inducer substrate for pre-culture preparation, employing an SSF step followed by a transition to SmF. The results of the study showed that the SF process was superior to conventional SmF for cultivations using both shake flasks and aerated bubble column bioreactors. The endoglucanase volumetric productivity values were threefold higher for the bubble column bioreactor using the new method for cultivation of Aspergillus niger. The novel SF methodology therefore offers a promising alternative bioprocess strategy for enzyme production, which should be further investigated.

In light of the earlier findings, the aim of the present work was to determine whether the new sequential fermentation method could be validated for other fungi, such as different strains of Trichoderma cultivated using sugarcane bagasse as carbon source for cellulase production. In order to achieve this, comparisons were made of cultivations performed using the SF and conventional SmF methods. Evaluation was made of the influence of fungal strain, cultivation method, and sugarcane bagasse pretreatment on enzyme production. The enzymatic cocktails obtained were characterized in terms of optimum pH and temperature, as well as stability.

Methods

Fungal Strains

Three Trichoderma strains were used in the present study. The first was a T. reesei Rut-C30 strain that had been purchased from the Centre for Agricultural Bioscience International culture collection in the UK (IMI number: 345108). The second was a strain of Trichoderma sp (INPA 666) obtained from the Embrapa Tropical Agroindustry collection (CNPAT, Fortaleza, Brazil). The third strain was a Trichoderma harzianum P49P11 isolated from the Amazon forest [17] and deposited at the Embrapa Food Technology microorganism collection (Rio de Janeiro, Brazil). Plate assays showing the production of cellulolytic enzymes by the Trichoderma strains has been previously reported [12]. All strains were grown on plates of potato dextrose agar at 30 °C.

Culture Conditions

Submerged Fermentation (SmF)

In the conventional submerged fermentation process, the pre-culture was initiated with a conidia suspension of 107 spores/mL, which was transferred to Erlenmeyer flasks containing 100 mL of nutrient medium, adapted from Mandels and Sternberg [18], and enriched with 30 g/L of glucose. The composition of the medium (in % w/v) was as follows—0.14 % (NH4)2SO4, 0.20 % KH2PO4, 0.03 % CaCl2, 0.02 % MgSO4·7H2O, 0.50 % peptone, 0.20 % yeast extract, 0.03 % urea, 0.10 % Tween 80, and 0.10 % of salt solution (5 mg/L FeSO4·7H2O, 1.6 mg/L MnSO4·H2O, 1.4 mg/L ZnSO4·7H2O, and 2.0 mg/L CoCl2). The incubation was carried out for 48 h at 30 °C with stirring at 200 rpm. A volume of pre-culture suspension corresponding to 10 % (w/v) was transferred to the culture medium and supplemented with 10 g/L of glucose and 1 % (w/v) of either untreated sugarcane bagasse (UB) or steam-explosion-pretreated sugarcane bagasse (PB) that had been donated by a local sugarcane mill (Usina Nardini, São Paulo, Brazil). The cultivations were performed for 72 h at 30 °C and 200 rpm. The cultivation broth was then filtered and centrifuged at 10,000 rpm for 10 min, and the crude enzymatic extract was stored at −18 °C for further analysis. All cultivation experiments were carried out in triplicate, and the data were calculated as means ± standard deviations. The mean values obtained for each condition were analyzed statistically using Origin software.

Sequential Fermentation (SF)

In the sequential cultivation method (SF), the pre-culture was initiated as solid-state fermentation (SSF), using 5 g of dry sugarcane bagasse (either UB or PB) as solid substrate. In the SSF cultivation step, the moisture was adjusted to 70 % (v/v) by the addition of nutrient medium. A concentration of 107 spores/g of dry bagasse was added, and the culture was maintained as SSF under static conditions for 24 h at 30 °C. The pre-culture cultivation was continued as SmF after addition of a volume of nutrient medium enriched with 30 g/L of glucose (40 parts of nutrient medium per gram of dry solid). The SmF step was performed in an orbital shaker for 48 h at 30 °C and 200 rpm. A volume of pre-culture suspension corresponding to 10 % (v/v) was transferred to the culture medium supplemented with 10 g/L of glucose and 1 % (w/v) of either UB or PB, and the cultivation for cellulase production was performed as described above. After 72 h, the broth was filtered and centrifuged at 10,000 rpm for 10 min, and the crude enzymatic extract was stored at −18 °C prior to further analysis. All cultivation experiments were carried out in triplicate, and the data were calculated as means ± standard deviations. The mean values obtained for each condition were analyzed statistically using Origin software.

Experimental Design for pH and Temperature Characterization Study

A full factorial design followed by response surface analysis was used to evaluate the effects of two variables (pH and temperature), as well as their possible interaction, on the endoglucanase activity present in the crude enzymatic cocktail. A central composite design (CCD) was used, comprising of 11 runs, with four cube points, four axial points, and three central points. The experiments were carried out in random order. The dependent (response) variable was the endoglucanase activity. The factors and levels investigated are shown in Table 1. Statsoft v. 7.0 software was used for data analysis including analysis of variance (ANOVA) and the plotting of response surfaces.

Enzyme Assays

Endoglucanase (EGase), filter paper cellulase (FPase), and β-glucosidase activities were assayed in the presence of carboxymethylcellulose (CMC) (Sigma, USA), Whatman No. 1 filter paper strips, and cellobiose (Sigma, USA), respectively, using the standard method proposed by Ghose [19]. In the case of β-glucosidase activity, quantification of the glucose released was performed with an enzymatic kit for glucose measurement (Doles, Brazil). Exoglucanase activity was determined by mixing 0.1-mL volumes of the suitably diluted enzyme extract with 0.9 mL of 1 % (w/v) Avicel solution in sodium citrate buffer (50 mM, pH 4.8). The mixture was incubated at 50 °C for 60 min. Xylanase activity was measured using the method described by Bailey and Poutanen [20]. The reducing sugar concentration was determined by the dinitrosalicyclic acid (DNS) method [21]. All enzymatic analyses were carried out in duplicate. One unit of EGase, FPase, or xylanase corresponded to 1 μmol of reducing sugars released per minute of reaction. The total protein concentration in the crude extracts was determined by the method described by Bradford [22], using bovine serum as a standard.

In the experiments conducted to identify the optimum pH and temperature for the EGase activity of the crude extracts described in Section “Experimental Design for pH and Temperature Characterization Study,” the reaction mixture was incubated at different pHs (from 2.5 to 6.5) and temperatures (from 20 to 90 °C), which were selected according to the experimental design (Table 1).

Hydrolysis of a Synthetic Substrate

The degree of hydrolysis of the synthetic substrate (low viscosity CMC at a 2 % (m/v) ratio) was evaluated during a period of 24 h, using the pH and temperature conditions described for the central point of the experimental design (Table 1). The reducing sugars released after incubation for 10 min and for 2, 4, 6, 12, and 24 h were measured using the DNS method [21].

Enzyme Stability and Inactivation

The thermal stability of EGase was evaluated by measuring the residual enzymatic activity after incubation of the crude supernatant at 50 °C for a total period of 24 h. Sampling was performed after time intervals of 10 min and 2, 4, 6, 12, and 24 h. At the end of the incubation period, the test tubes containing the enzymes were immediately cooled by placing them on ice. Measurement of EGase activity was performed under standard pH (4.8) and temperature (50 °C) conditions.

The single-step non-first-order model proposed by Sadana and Henley [23] was fitted to the experimental data. This model considers that a single-step inactivation leads to a final state, exhibiting a residual activity that is very stable (the protein shows no further unfolding and/or inactivation). The model can be described by the expression:

Where A/A 0 is the dimensionless activity, α is the ratio between the specific activity of the final state and the specific activity of the initial state, and k is the first-order deactivation rate constant (per time). The parameter k describes the unfolding (or inactivation) process, and the parameter α reflects the long-term level of activity [23]. The biocatalyst half-life was then calculated using the fitted model.

Results and Discussion

Validation of the Sequential Fermentation for T. reesei Rut-C30

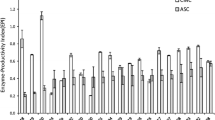

In the earlier work by Cunha et al. [16], encouraging results were obtained for the production of cellulase by A. niger cultivated under sequential solid-state and submerged cultivation. It was therefore of great interest to investigate whether the proposed SF cultivation method could also be applied to other genera of filamentous fungi, such as the industrially important T. reesei Rut-C30 strain. In order to evaluate the validity of the SF method for T. reesei Rut-C30, a set of conventional SmFs were carried out in parallel. This enabled comparison of the efficiencies of the two methods for cellulase production under similar conditions of pH, temperature, and carbon source (Fig. 1). The effect of using UB or PB as carbon source was also investigated.

A significantly higher EGase activity was achieved when T. reesei was cultivated under SF, compared with conventional SmF. Furthermore, the use of steam-explosion-pretreated sugarcane bagasse (PB) also favored EGase production, compared with the use of UB as carbon source. The EGase activity values varied from 159 ± 6 (SmF) to 670 ± 36 IU/L (SF) using UB, and from 650 ± 8 (SmF) to 945 ± 66 IU/L (SF) using PB (Fig. 1). These differences in cultivation conditions corresponded to up to sixfold improvements in EGase production.

A possible explanation for the increases in EGase activity could be differences in the morphology of the Trichoderma fungi because, in SF, there was a predominance of filamentous dispersed mycelia while, in the conventional SmF process, there was early formation of fungal pellets. Cunha et al. [16] reported that A. niger also developed dispersed filamentous growth morphology under SF cultivation. This difference in fungal morphology was due to the pre-culture conditions because, in SF, the cell development began on a solid medium. However, it is not possible to draw firm conclusions concerning a relationship between fungal morphology and cellulase production, because of the existence of many other factors that might influence the cultivation process. For example, Ahamed and Vermette [24] evaluated the effects of culture medium composition on the growth, mycelia morphology, and cellulase production of T. reesei Rut-C30 and found a positive correlation between the total mycelia, the number of tips, and the volumetric enzyme productivity. Domingues et al. [25] also reported that, under conditions that induced pellet formation in T. reesei Rut-C30 cultivated under SmF, there were decreases in protein concentration and cellulase activity. Another possible reason for the higher EGase activity achieved under SF is that the solid medium used in the SSF pre-culture step could act as an inducer for cellulase production during the early stage of cell development, hence contributing to enzyme production.

In experiments in which SF was carried out using steam-exploded-sugarcane bagasse (PB), EGase activities increased by up to 1.4 times, compared with use of UB, while increases of up to 4.2-fold were observed in the case of SmF. This can be explained by the fact that the pretreatment process makes a substantial contribution to the breakdown of the lignocellulosic structure [26]. Consequently, the accessibility of the cellulose components to fungal development is enhanced, compared with untreated sugarcane bagasse. Rodriguez-Zuniga et al. [27] reported that use of liquid hot water-pretreated sugarcane bagasse resulted in higher cellulase and xylanase activities, compared with untreated bagasse, when A. niger was cultivated under SSF. This was due to structural modifications in the pretreated bagasse that assisted the adherence and penetration of the fungal hyphae.

The findings showed that the SF cultivation method and the use of a pretreated type of sugarcane bagasse were both directly related to an increase in enzymatic activity. The sequential cultivation method was able to improve EGase production by T. reesei Rut-C30, which confirmed the advantages of the novel cultivation procedure and validated its use with this fungus that is considered a reference strain for cellulase production.

Effect of pH and Temperature on EGase Activity

Characterization of the enzymes produced by different cultivation methods is necessary in order to identify qualitative and quantitative differences between enzymatic cocktails. Here, the effects of pH and temperature on the EGase activity in the crude enzymatic cocktails obtained using SF and SmF were evaluated under different conditions, selected according to a central composite design. Table 1 presents the experimental conditions and the corresponding responses for EGase activity in the crude enzymatic extracts obtained during cultivation of T. reesei Rut C-30 under SmF and SF, using either UB or PB as carbon source. Run 12 employed the standard conditions used in EGase assays (pH 4.8 and temperature of 50 °C) and was performed for comparative purposes.

The ANOVA analysis of EGase activity for all the crude enzymatic extracts (Table 2) resulted in correlation coefficients (R) exceeding 0.80 and F-test values (F measured/F critical) that varied from 2.92 to 6.91. This enabled model prediction with a 90 % level of confidence. As an illustration, the coefficients obtained for the SF-PB enzymatic extract were used to describe the response surface plot for EGase activity as a function of pH and temperature (Fig. 2). The response surface plots for the other cultivation conditions tested showed similar shapes (data not shown).

For all enzymatic extracts, both pH and temperature (within the ranges tested) showed a statistically significant influence on EGase activity, which was not observed for the synergistic effect between temperature and pH. The response surface plots obtained for each cultivation condition indicated that higher values of EGase activity were obtained in the experiments carried out using pH values in the range from 3.5 to 5.5, and temperatures between 42 and 67 °C, for all enzymatic extracts. An advantage of using the experimental design methodology was that pH and temperature ranges were identified for optimum enzyme activity, which can enable greater flexibility during bioprocess development [28].

The results revealed no qualitative differences between the enzymatic extracts obtained using the different cultivation conditions, in terms of the optimum pH and temperature for EGase activity. However, it is important to note that the analytical assay used here for the quantification of EGase activity is unable to discriminate between the different types of endoglucanase. For instance, analytical methodologies such as zymography assays and fluorophore-assisted carbohydrate electrophoresis were used to analyze the glycoside hydrolyses secreted by A. niger cultured in media containing different carbon sources [29]. Regarding the Trichoderma genus, eight endoglucanases belonging to different hydrolase families have been identified in the T. reesei genome, with endoglucanases I (Cel7B) and II (Cel5A) usually secreted in higher amounts [8]. Nevertheless, Cel7B is the major endoglucanase, accounting for 6–10 % of the total cellulase proteins from T. reesei [11].

In recent work concerning the characterization of T. reesei endoglucanase II, Samanta et al. [30] observed that the recombinant EGase was most active at pH 5.0 and 55 °C, in agreement with the pH and temperature optima found here. de Castro et al. [31] reported an optimum pH of 5.1 and temperature range of 52–57 °C for cellulases from T. reesei Rut-C30, which is also in agreement with the present results. Nevertheless, the wider optimum ranges of pH (from 3.5 to 5.5) and temperature (from 42 to 67 °C) observed here for all the enzymatic extracts could be advantageous in hydrolysis processes.

Hydrolysis of a Synthetic Substrate

The temporal profiles of the concentrations of reducing sugars released during hydrolysis were investigated in a set of experiments performed using low-viscosity CMC as substrate. Figure 3 shows the concentration of reducing sugars (micromoles per milliliter) released during the hydrolysis of CMC carried out using the same experimental conditions (pH 4.5 and temperature of 55 °C) as the central point of the CCD used to evaluate the effects of pH and temperature on EGase activity. The concentration of products increased throughout the 24-h period, using the extracts produced by all combinations of cultivation methods (SmF and SF) and sugarcane bagasse types (UB and PB). The hydrolysis was more effective using the extracts produced from SF with PB, which resulted in the concentration of reducing sugars reaching 66 ± 7 μmol/mL. These results confirmed the higher EGase activity observed for the enzymes from the SF–PB cultivation. The enzymatic extract from SmF–UB showed a lower maximum concentration of products (13 ± 2 μmol/mL), although the temporal trend was similar to that of the other cultivations.

The profile of product formation during the action of the EGase enzyme was used to evaluate the effect of cultivation method (SmF or SF) on the performance of the enzymatic extracts produced using pretreated or untreated sugarcane bagasse. Despite significant differences between the values of reducing sugars, the trend of increasing product concentration was the same for all enzymatic extracts, indicating that there were no differences between the enzymes in terms of their ability to hydrolyze a synthetic substrate.

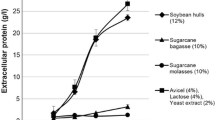

Thermostability and Deactivation Studies

Thermostability is a highly desirable quality of industrial enzymes. One way of determining thermostability is to measure the enzyme activity half-life at elevated temperatures [11]. Here, the crude extracts produced using SmF and SF with UB and PB as substrates were incubated at 50 °C for a period of 24 h. Figure 4 shows the residual activities as a function of time, fitted using the model of Sadana and Henley [23]. Table 3 presents the results for the model parameters k and α, together with the EGase half-life and the coefficient of determination (R 2).

The EGase enzymes of the crude extract produced under SmF using UB were up to two times more stable than those produced by SF using the same carbon source, with half-lives (t 1/2) of 17 h (SmF–UB) and 8 h (SF–UB). A smaller impact of the cultivation method on enzyme stability was observed for cultivations using the pretreated sugarcane bagasse, where t 1/2 of 6 and 4 h were obtained for EGase enzymes from the SmF–PB and SF–PB extracts, respectively. The SmF extracts were therefore 1.5 times more stable than the SF extracts.

One of the preferred sugarcane bagasse pretreatment processes is steam explosion, which causes substantial breakdown of the lignocellulosic structure. The hemicellulose fraction is hydrolyzed by the acetic and other acids released during the pretreatment [26]. In the present study, although the EGase activity was higher for SF–PB, the enzymes in this fermentation broth were less stable than those produced using untreated sugarcane bagasse. A possible explanation is that the release of inhibitors such as lignin-derived phenolics during the steam explosion process could have negatively affected the stability of the enzymes produced using this material as carbon source. It has been reported previously that cellulase enzymes can be inhibited or deactivated by phenolic compounds [32, 33].

In the thermostability studies conducted by Saqib et al. [34], comparison was made between the crude extracts obtained from SSF and SmF, which revealed higher thermostability of the EGases from SSF. It was suggested that the primary structures of the enzymes in the endoglucanase preparations could have differed, raising new questions about possible structural differences in the enzymes produced under the two fermentation processes. In the present work, despite the fact that SF included an initial solid-state step during preparation of the pre-culture, greater enzyme stability was achieved using SmF. A possible explanation is the additional amount of sugarcane bagasse used in the solid-state step of the SF pre-culture. The fact that the sugarcane was not washed before the cultivations could have had a negative effect on the stability of the enzymes produced by the SF method. However, studies of lignocellulosic biomass hydrolysis have indicated that washing and filtration of liquid hot water-pretreated biomass can improve the enzymatic digestibility of cellulose by removing inhibitors [35]. Therefore, the release of inhibitory compounds during the fungal cultivation process might be able to be avoided by including a washing step after the sugarcane bagasse pretreatment. Recently, Ximenes et al. [36] reported that the use of bio-abatement for the removal of enzyme inhibitors released during lignocellulose pretreatment yielded improved enzyme hydrolysis. Thus, further research will be necessary to select the most appropriate strategy to overcome this stability limitation observed here when using pretreated bagasse as carbon source.

The extracts produced by T. reesei can show varying thermostability, depending on the culture conditions and the strains employed. According to Viikari et al. [11], the T. reesei cellulase system is rapidly inactivated at temperatures above 45 °C. Samanta et al. [30] investigated the effect of temperature on a recombinant EGase enzyme and reported that the enzymes remained active for 60 min at 55 °C. The endoglucanase activity was mostly retained for up to 40 min at 60 °C and then diminished appreciably. Nevertheless, a hyperglycosylation effect could have interfered in this result.

Problems involving thermal stability might be able to be mitigated using alternative strategies to improve performance when these enzymes are employed with substrates requiring longer hydrolysis times. For example, Viikari et al. [11] produced individual cloned thermostable enzymes using a modified strain of T. reesei. Process strategies to remove inhibitors from the pretreated biomass employed in the cultivation media could also be applied.

Validation of Sequential Fermentation for Different Trichoderma Strains and Comparison of Multi-enzyme Production

Comparison of SF with SmF for three different Trichoderma strains (T. reesei Rut-C30, T. harzianum, and T. sp INPA 666) considered the activity values for EGase, xylanase, β-glucosidase, Avicelase, and FPase, as well as the total protein concentration, obtained after 72 h of cultivation using PB as carbon source (Table 4). The enzyme productivities were mostly much higher for the SF cultivation method, so the proposed methodology could therefore be considered validated for use with the different Trichoderma strains.

In the case of xylanase activity, the highest value using SF was observed for T. sp INPA 666 (3993 ± 57 IU/L). The T. reesei Rut-C30 strain showed xylanase activity similar to that displayed by T. harzianum P49P11, with values of 2048 ± 39 and 2022 ± 3 IU/L, respectively. These results for xylanase were comparable to the findings of [16], who obtained a xylanase activity of 1961 ± 102 IU/L for A. niger under SF cultivation in a bubble column reactor.

The highest EGase activity was achieved by T. harzianum P49P11 under SF cultivation (1,668 ± 131 IU/L). This value was almost two times higher than achieved with T. reesei Rut-C30 (944 ± 66 IU/L) and T. sp INPA 666 (833 ± 13 IU/L). In the preliminary study by Cunha et al. [16], EGase activity of 1,052 ± 34 IU/L was achieved with A. niger under SF cultivation in shake flasks. It is important to point out that in the Cunha et al. [16] study, the relevant parameters of the SF process, such as substrate moisture content, pH, temperature, and inoculum size were optimized for the filamentous fungus A. niger. It is therefore believed that, in the case of the Trichoderma strains, even higher activity values could be achieved following further optimization of operational conditions for this fungal genus.

The other enzymatic activities evaluated (β-glucosidase, Avicelase, and FPase) showed the highest values for T. harzianum P49P11 cultivated under SF. In terms of total protein, the highest value was obtained for T. reesei Rut-C30 (738 ± 26 mg/L). This means that a comparison made in terms of the specific activity values would show even greater superiority of the extract obtained using T. harzianum P49P11.

In work by de Castro et al. [31] with a T. harzianum IOC-4038 strain cultivated under SmF using a pretreated sugarcane bagasse, the maximum activity values obtained were 559 (EGase), 97 (FPase), and 745 IU/L (β-glucosidase). The T. harzianum IOC-4038 fermentation was found to be faster than for T. reesei Rut-C30, and the extract showed a better balance of enzymes. In another study performed with a Trichoderma atroviride 676 strain under SmF using sugarcane bagasse as substrate, the best results were obtained after 3–4 days fermentation, with 1,900 IU/L of EGase, 250 IU/L of FPase, and 170 IU/L of β-glucosidase [37]. It was also shown that T. atroviride 676 was able to produce the cellulolytic enzymes more efficiently than T. reesei Rut-C30. The T. harzianum P49P11 wild-type strain used here was previously isolated from the Amazon rainforest and also showed superior capacities for xylanase and cellulase production [3, 17]. This finding emphasizes the importance of enzyme-prospecting research to identify opportunities for enhancing the activity of enzyme preparations.

In summary, all three strains of Trichoderma showed the same trend of achieving higher enzymatic production when cultivated using SF, compared with SmF, hence extending the validation of sequential fermentation to different Trichoderma strains. An important additional consideration is that further enhancement of enzymatic activities might be achieved after full optimization of the SF process conditions for strains of the genus Trichoderma.

Conclusions

A new sequential cultivation methodology was validated for T. reesei Rut-C30, which is considered a reference strain for cellulase production. The use of steam-explosion-pretreated sugarcane bagasse (PB) was shown to be more favorable for EGase production, compared with UB. Characterization of the extracts in terms of the effects of pH and temperature on EGase activity, as well as the hydrolysis profiles obtained for a synthetic substrate, revealed no qualitative differences among the different cultivations tested. However, the enzymes produced using the SmF–UB procedure showed greater thermostability, compared with those obtained under the other cultivation conditions. This indicated the need for further optimization in relation to the removal of inhibitors. Overall, the SF cultivation method for enzyme production was superior to conventional SmF for three different Trichoderma strains.

References

Klein-Marcuschamer, D., Oleskowicz-Popiel, P., Simmons, B. A., & Blanch, H. W. (2012). The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnology and Bioengineering, 109, 1083–1087.

Singhania, R. R., Sukumaran, R. K., Patel, A. K., Larroche, C., & Pandey, A. (2010). Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme and Microbial Technology, 46, 541–549.

Delabona, P., Farinas, C., da Silva, M., Azzoni, S., & Pradella, J. (2012). Use of a new Trichoderma harzianum strain isolated from the Amazon rainforest with pretreated sugar cane bagasse for on-site cellulase production. Bioresource Technology, 107, 517–521.

Sorensen, A., Teller, P. J., Lubeck, P. S., & Ahring, B. K. (2011). Onsite enzyme production during bioethanol production from biomass: screening for suitable fungal strains. Applied Biochemistry and Biotechnology, 164, 1058–1070.

Kovacs, K., Macrelli, S., Szakacs, G., & Zacchi, G. (2009). Enzymatic hydrolysis of steam-pretreated lignocellulosic materials with Trichoderma atroviride enzymes produced in-house. Biotechnology for Biofuels, 2, 11.

Rana, V., Eckard, A. D., Teller, P., & Ahring, B. K. (2014). On-site enzymes produced from Trichoderma reesei RUT-C30 and Aspergillus saccharolyticus for hydrolysis of wet exploded corn stover and loblolly pine. Bioresource Technology, 154, 282–289.

Furlan, F. F., Tonon, R., Pinto, F., Costa, C. B. B., Cruz, A. J. G., Giordano, R. L. C., & Giordano, R. C. (2013). Bioelectricity versus bioethanol from sugarcane bagasse: is it worth being flexible? Biotechnology for Biofuels, 6, 12.

Gusakov, A. V. (2011). Alternatives to Trichoderma reesei in biofuel production. Trends in Biotechnology, 29, 419–425.

Hasunuma, T., Okazaki, F., Okai, N., Hara, K. Y., Ishii, J., & Kondo, A. (2013). A review of enzymes and microbes for lignocellulosic biorefinery and the possibility of their application to consolidated bioprocessing technology. Bioresource Technology, 135, 513–522.

Jourdier, E., Cohen. C., Poughon, L., Larroche, C., Monot, F., Ben Chaabane, F. (2013). Cellulase activity mapping of Trichoderma reesei cultivated in sugar mixtures under fed-batch conditions. Biotechnology for Biofuels, 6.

Viikari, L., Alapuranen, M., Puranen, T., Vehmaanpera, J., & Siika-Aho, M. (2007). Thermostable enzymes in lignocellulose hydrolysis. In L. Olsson (Ed.), Biofuels. Advances in biochemical engineering–Biotechnology (Vol. 108, pp. 121–145). Berlin: Springer-Verlag Berlin.

Florencio, C., Couri, S., Farinas, C.S. (2012). Correlation between agar plate screening and solid-state fermentation for the prediction of cellulase production by Trichoderma strains. In Enzyme Research. pp. 7:7.

Barrios-Gonzalez, J. (2012). Solid-state fermentation: physiology of solid medium, its molecular basis and applications. Process Biochemistry, 47, 175–185.

Farinas, C., Vitcosque, G., Fonseca, R., Neto, V., & Couri, S. (2011). Modeling the effects of solid state fermentation operating conditions on endoglucanase production using an instrumented bioreactor. Industrial Crops and Products, 34, 1186–1192.

Thomas, L., Larroche, C., & Pandey, A. (2013). Current developments in solid-state fermentation. Biochemical Engineering Journal, 81, 146–161.

Cunha, F. M., Esperanca, M. N., Zangirolami, T. C., Badino, A. C., & Farinas, C. S. (2012). Sequential solid-state and submerged cultivation of Aspergillus niger on sugarcane bagasse for the production of cellulase. Bioresource Technology, 112, 270–274.

Delabona, P., Pirota, R., Codima, C., Tremacoldi, C., Rodrigues, A., & Farinas, C. (2012). Using Amazon forest fungi and agricultural residues as a strategy to produce cellulolytic enzymes. Biomass & Bioenergy, 37, 243–250.

Mandels, M., & Sternberg, D. (1976). Recent advances in cellulase technology. Journal of Fermentation Technology, 54, 267–286.

Ghose, T. K. (1987). Measurement of cellulase activities. Pure & Applied Chemistry, 59, 257–268.

Bailey, M. J., & Poutanen, K. (1989). Production of xylanolytic enzymes by strains of Aspergillus. Applied Microbiology and Biotechnology, 30, 5–10.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Bradford, M. M. (1976). Rapid and sensitive method for quantification of microgram quantities of protein utilizing principle of protein-dye binding. Analytical Biochemistry, 72, 248–254.

Sadana, A., & Henley, J. P. (1987). Single-step unimolecular non-1st-order enzyme deactivation kinetics. Biotechnology and Bioengineering, 30, 717–723.

Ahamed, A., & Vermette, P. (2009). Effect of culture medium composition on Trichoderma reesei's morphology and cellulase production. Bioresource Technology, 100, 5979–5987.

Domingues, F. C., Queiroz, J. A., Cabral, J. M. S., & Fonseca, L. P. (2000). The influence of culture conditions on mycelial structure and cellulase production by Trichoderma reesei Rut C-30. Enzyme and Microbial Technology, 26, 394–401.

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y. Y., Holtzapple, M., & Ladisch, M. (2005). Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresource Technology, 96, 673–686.

Rodriguez-Zuniga, U. F., Neto, V. B., Couri, S., Crestana, S., & Farinas, C. S. (2014). Use of spectroscopic and imaging techniques to evaluate pretreated sugarcane bagasse as a substrate for cellulase production under solid-state fermentation. Applied Biochemistry and Biotechnology, 172, 2348–2362.

Farinas, C., Loyo, M., Baraldo, A., Tardioli, P., Neto, V., & Couri, S. (2010). Finding stable cellulase and xylanase evaluation of the synergistic effect of pH and temperature. New Biotechnology, 27, 810–815.

Xing, S., Li, G. L., Sun, X. L., Ma, S., Chen, G. J., Wang, L. S., & Gao, P. J. (2013). Dynamic changes in xylanases and beta-1,4-endoglucanases secreted by Aspergillus niger An-76 in response to hydrolysates of lignocellulose polysaccharide. Applied Biochemistry and Biotechnology, 171, 832–846.

Samanta, S., Basu, A., Halder, U. C., & Sen, S. K. (2012). Characterization of Trichoderma reesei endoglucanase II expressed heterologously in Pichia pastoris for better biofinishing and biostoning. Journal of Microbiology, 50, 518–525.

de Castro, A. M., Pedro, K., da Cruz, J. C., Ferreira, M. C., Leite, S. G. F., & Pereira, N. (2010). Trichoderma harzianum IOC-4038: a promising strain for the production of a cellulolytic complex with significant beta-glucosidase activity from sugarcane bagasse cellulignin. Applied Biochemistry and Biotechnology, 162, 2111–2122.

Ximenes, E., Kim, Y., Mosier, N., Dien, B., & Ladisch, M. (2010). Inhibition of cellulases by phenols. Enzyme and Microbial Technology, 46, 170–176.

Ximenes, E., Kim, Y., Mosier, N., Dien, B., & Ladisch, M. (2011). Deactivation of cellulases by phenols. Enzyme and Microbial Technology, 48, 54–60.

Saqib, A. A. N., Hassan, M., Khan, N. F., & Baig, S. (2010). Thermostability of crude endoglucanase from Aspergillus fumigatus grown under solid state fermentation (SSF) and submerged fermentation (SmF). Process Biochemistry, 45, 641–646.

Kim, Y., Mosier, N. S., & Ladisch, M. R. (2009). Enzymatic digestion of liquid hot water pretreated hybrid poplar. Biotechnology Progress, 25, 340–348.

Cao, G. L., Ximenes, E., Nichols, N. N., Zhang, L. Y., & Ladisch, M. (2013). Biological abatement of cellulase inhibitors. Bioresource Technology, 146, 604–610.

Grigorevski-Lima, A. L., Quadros de Oliveira, M. M., do Nascimento, R. P., da Silva Bon, E. P., & Rodrigues Coelho, R. R. (2013). Production and partial characterization of cellulases and xylanases from Trichoderma atroviride 676 using lignocellulosic residual biomass. Applied Biochemistry and Biotechnology, 169, 1373–1385.

Acknowledgments

The authors thank the Brazilian agencies Fapesp, Capes, and CNPq for financial support, and the staff of Embrapa Instrumentation for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Florencio, C., Cunha, F.M., Badino, A.C. et al. Validation of a Novel Sequential Cultivation Method for the Production of Enzymatic Cocktails from Trichoderma Strains. Appl Biochem Biotechnol 175, 1389–1402 (2015). https://doi.org/10.1007/s12010-014-1357-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1357-5