Abstract

One of the major applications of cellulases is to produce fermentable sugars from lignocellulosic biomass for biofuels production. The filamentous fungus Trichoderma reesei is known to be hyper producer of cellulases and hemicellulases and it is widely used for commercial scale production of these enzymes using novel fermentation techniques. Some of the T. reesei industrial strains produce over 100 g/l of cellulases. However, there are still technical and economic constraints to the development of cheap commercial cellulase production process. Here, we bring together and discuss the results on T. reesei as cellulase producer, the different kinds of enzymes it expresses, recent genomic, genetic, and metabolic engineering approaches that have helped to improve the biomass degrading enzyme mixture and the strategies adopted to reduce the cost of enzymes during fermentation process. Current efforts and some future perspectives for reducing the cost of enzymes by using cheaper substrates, recycling enzyme during the hydrolysis and fermentation process, and on-site enzyme production in the biorefinery facility are also discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

4.1 Introduction

Import of crude oil in United States (US) and European Union (EU) alone constituted 60 and 80 %, respectively, in 2009. Other developing countries like India and China are completely dependent on foreign oil to meet their liquid transportation fuel demand. In recent years, an increase in the cost of crude oil has initiated extensive research and development to produce large-scale alternate liquid transportation fuels from renewable resources. In the US, the Department of Energy (DOE) has set a goal of producing 60 billion gallons of renewable fuels per year by 2030. In the EU there is a mandate to produce 25 % of its transportation fuel using renewable resources by 2030 (Himmel et al. 2007). Production of ethanol from sugarcane juice (Brazil) and corn starch (US) has almost reached its full capacity and both methods are often criticized for using feedstock for food to make biofuels. The only sustainable alternative substrate for making ethanol is lignocellulosic biomass. The primary sources of lignocellulosic biomass include agricultural wastes (corn stover, sorghum, sugarcane bagasse, rice straw, wheat straw, empty fruit bunch from oil palm and date palm, Agave bagasse from tequila industry), Perennial grasses (switchgrass, miscanthus), woody biomass, and municipal solid waste (Gomez et al. 2008).

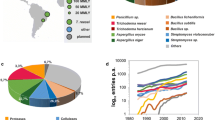

A biorefinery is a facility that produces fuels and chemicals from lignocellulosic biomass using a combination of process technologies (Fig. 4.1). The sugar polymers (cellulose and hemicellulose) present in biomass are depolymerized by efficiently degrading glycosidic bonds using microbial enzymes followed by microbial fermentation of sugars to fuels and chemicals (Menon and Rao 2012). This concept resembles a petroleum refinery, which produces different fuels and chemicals from crude oil. Compared to a petroleum refinery, producing fuels and chemicals in a biorefinery has several advantages: energy security, environmental benefits, and sustainability (Huber and Dale 2009; Fitzpatrick et al. 2010). Technologies for several different aspects of the biorefinery process are currently being developed. They include: (i) biomass production (breeding, cultivation, harvesting); (ii) transportation of biomass; (iii) biomass storage and preprocessing; (iv) pretreatment; (v) enzyme hydrolysis; (vi) microbial fermentation, and (vii) product separation (Balan et al. 2012). Though ethanol is projected to be widely produced in the biorefinery, other fuels and chemicals are also pursued using biological processing route. Some of the chemicals produced using biological route could be transformed to higher value products using a hybrid combination of biochemical and catalytic routes (Ohara 2003). Depending on geographical location and availability of feedstock, the biorefinery can be operated as a large centralized facility or as smaller decentralized facility (Sanders et al. 2007; Lyko et al. 2009).

Biorefinery process flow diagram for producing biofuels and biochemical. Here, two different scenarios of enzyme production are shown (a) On-site enzyme production and (b) Centralized enzyme production. SHF: separate hydrolysis and fermentation; SSCF: simultaneous saccharification and co-fermentation; UHS: unhydrolyzed solids

Several microbes could naturally grow on a wide variety of biomass substrates by efficiently degrading cellulose and hemicellulose and are a good source for new lignocellulosic biomass degrading enzymes. Enzymes that are needed to hydrolyze sugar polymers are cellulases and hemicellulases (Bouws et al. 2008; Kumar et al. 2008). Scientists have been looking for several hypercellulase/hemicellulase producing strains for quite some time. One of the best hyper producers of extracellular cellulolytic enzymes is the mesophilic, filamentous fungus, Trichoderma reesei (Trichoderma viride), first recognized during World War II, when it destroyed cotton fabric US Army tents (Cherry and Fidantsef 2003a, b). The genome sequence of T. reesei QM6a was published in 2008 (Martinez et al. 2008a, b). For commercial production of enzymes, several T. reesei strains (Rut-30, RL-P37, and MCG-80) have been developed and are currently being used in the industry (Merino and Cherry 2007). Some of these industrial strains produce more than 100 g/l of cellulase/hemicellulase enzymes (Cherry and Fidantsef 2003a, b).

Typical enzyme concentrations used to hydrolyze cellulose are 15–30 filter paper units of cellulase per g of cellulose. On the other hand, for starch hydrolysis 0.2 k Novo unit of amylase per g and 3.26 amyloglucosidase units of glucoamylase per g are needed. This shows that enzyme concentration needed for cellulose degradation is 40-fold to 100-fold higher than that of starch hydrolysis. As a result, the cost of enzymes for cellulose degradation is much higher and it is considered as one of the key bottlenecks for producing fuels and chemicals from lignocellulosic biomass. Several efforts are underway to reduce the cost and maximize enzyme production yield (Carroll and Somerville 2009; Wilson 2009). Some of the strategies include (i) improving the performance of the enzymes by increasing the specific activity (through direct evolution and site directed mutagenesis) and thereby minimizing enzyme dosage (ii) reducing the cost of enzyme production improving cellulase titers during fermentation (through process engineering approaches using cheap substrates including biomass, producing enzymes near biorefinery or expressing enzymes in plants). An overview of T. reesei as a cellulase producer, different kinds of enzymes they express, recent genomic, genetic, and metabolic engineering approaches that have helped to improve the biomass degrading enzyme mixture, and strategies pursued to reduce the cost of enzymes are presented in this chapter.

4.2 Cellulase and Hemicellulase Genes in Trichoderma reesei

4.2.1 T. reesei Genome: General Characteristics

T. reesei has a genome with a sequence length of around 34 Mbp (Martinez et al. 2008a, b). Gene modeling using a combination of homology and ab initio method predicted 9,129 genes in the genome with an average gene length of 1,793 (bp), and 3.1 exons per gene. Among the 9,129 genes, only 200 genes encode glycoside hydrolases (GHs). The GH genes’ number was surprisingly low considering the plant polysaccharide degradation efficiency of T. reesei. It was also indicated that the set of plant degrading enzymes of T. reesei is smaller than any other sequenced plant cell wall degrading fungus. T. reesei also has less carbohydrate-binding module (CBM)-containing proteins among the Sordariomycetes. Totally, ten cellulases are encoded in the T. reesei genome including two cellobiohydrolases (CBHI/CEL7A and CBHII/CEL6) and eight endoglucanases (EGII/CEL5A, EGVIII/CEL5B, EGI/CEL7B, CEL12A/CEL12A, EGV/CEL45A, EGIV/CEL61A, EGVII/CEL61B) (Table 4.1). The T. reesei genome also contains 16 hemicellulases and among the pectin degrading enzymes, only members of the GH28 family were found. Only seven cellulases (CBHI, CBHII, EGI, EGII, EGIII, EGIV, and EGV) and two β-glucosidases (BGLI and BGLII) have been characterized (Amore and Faraco 2012; Aro et al. 2005). Two major endo-β-1,4-xylanases XYNI and XYNII (EC 3.2.1.8) (Törrönen et al. 1992; 1994); and one β-xylosidase, BXLI (EC 3.2.1.37) (Herrmann et al. 1997a, b) have been characterized. The secretory mechanism of extracellular enzymes is not yet fully understood, but an analysis of the membrane trafficking system suggests that T. reesei has a very diverse system (Martinez et al. 2008a, b).

4.2.2 T. reesei Genome Encoded Cellulases and Hemicellulases

Cellobiohydrolases (CBHs): CBHs comprise 80–85 % of the total secreted cellulase protein and the major cellobiohydrolase component, CBHI, accounts for 50–60 % (Gritzali and Brown Ross 1979). CBHI and CBHII have a molecular weight of 57 and 56 kDa, respectively, and act on cellulose chains from non-reducing and reducing ends (Sun et al. 2008a, b; Teeri 1997). They both have a cellulose-binding domain (CBD) and a catalytic domain (CD), which is also observed in many other cellulases. CBHII contains two essential Gly residues located at positions 212 and 217 which take part in the initial binding sites with predominantly hydrogen bonds (Divne et al. 1998). There are two steps for glycosidic hydrolysis by CBHI producing cellobiose as the main product. A nucleophilic substitution at the anomeric C1 atom is involved in both steps. In the first step, a negatively charged carboxyl group in Glu 217 acts as a nucleophile with general acid-catalytic assistance from the carboxyl residue forming a glycosyl-enzyme intermediate. In the second step, water attacks this intermediate with general base-catalytic assistance from the deprotonated carboxyl residue, displacing the nucleophile (Divne et al. 1998). In the tunneled active site of CBHI, there are many H-bonds and indole-glycosyl interactions create a large steric confinement which may be the main factor explaining why substituted celluloses, like carboxymethyl cellulose (CMC), are poor substrates for CBHI (Divne et al. 1998).

Endoglucanases (EGs): EGs comprise around 10–15 % of the total secreted protein by T. reesei (Gritzali and Brown Ross 1979). EGI has a sequence that is 45 % identical to CBHI and the respective proteins have similar folding pattern suggesting a common ancestor (Penttilä et al. 1986). The EGI protein contains 437 aminoacidic residues and has a molecular weight of around 46–58 kDa (Messner et al. 1988; Penttilä et al. 1986). The secretion of this protein is directed by a signal peptide of 22 aa which is cleaved in the mature protein at the N-terminal. It is heavily glycosylated near the C-terminal (Penttilä et al. 1986). EGIII is believed to have evolved by divergent evolution from a common ancestor from Schizophyllum commune (Saloheimo et al. 1988). It contains relatively long introns and encodes a protein (EG3) whose main product is cellodextrins with a degree of polymerization of 2–5 with a turnover rate of 10–200 per minute (Saloheimo et al. 1988). Like CBHI and EGI, EGIV contains a CBD near the C-terminal and has a MW of ~56 kDa. Unlike most EGs, EGIV’s main byproduct is cellobiose, but it was deemed as an EG because of its ability to hydrolyze CMC, which cannot be hydrolyzed by CBHs (Karlsson et al. 2001; Saloheimo et al. 1997). EGIV has a molecular mass of 57 kDa and has an endoglucanase activity that is very small compared to EGI (Karlsson et al. 2001). EGV encodes a relatively small protein of 242 amino acids (aa) (MW of 22.8 kDa) whose catalytic core is also small compared to other cellulases (Saloheimo et al. 1994). Its shape is believed to be rod-like, which may enable the enzyme to penetrate the cellulose fibers better than other cellulases (Saloheimo et al. 1994).

β-glucosidases (BGLs): BGLs do not technically belong to the cellulases because they do not directly act on cellulose but are commonly included in the cellulase complex because of their synergetic effect with CBHs and EGs. The role of BGLs is hydrolysis of cellobiose and short cello-oligomers into glucose. It appears that β-glucosidase gene expression is regulated separately from CBHs and EGs (Jackson and Talburt, 1988). T. reesei produces intracellular (Inglin et al. 1980), extracellular (Chen et al. 1992) and mycelium associated β-glucosidase (Jackson and Talburt 1988). The bgl1 gene encodes an extracellular β-glucosidase while the bgl2 gene product is an intracellular β-glucosidase (Mach et al. 1995, 2006; Saloheimo et al. 2002). It has been shown that the bgl1 gene product is required for rapid induction of the cellulase complex (Fowler and Brown 1992). When sophorose is used as an inducer, the β-glucosidase from the bgl1 gene is secreted. However, when methyl- β-o-glucoside or gentiobiose is used as an inducer, β-glucosidase is typically mycelium-associated and the protein produced was not associated with bgl1 gene (Mach et al. 1995). The levels of β-glucosidase are also correlated to fungal morphology. In vegetative hyphae there are very low levels of β-glucosidase while in conidiogenous cells or germinating conidia high levels of β-glucosidase are found. Based on this, it was postulated that conidia formation and germination may be coupled with β-glucosidase formation (Jackson and Talburt 1988).

Xylanases (XYNs): The two endo-β-1,4-xylanases, XYNI and XYNII, contribute around 90 % of the xylanase activity in the T.reesei enzyme complex (Rauscher et al. 2006). XYNI and XYNII have a MW of 19 and 21 kDa, and an optimum pH range of 2.5–4.0 and 4.5–5.5, respectively (Törrönen et al. 1992). The xyn2 gene codes for a protein of 223 aa having two N-glycosylation sites and contains one intron of 108 nucleotides (Saarelainen et al. 1993). Xyn1 and xyn2 have very similar gene sequences except for the first 100 N-terminal aa’s, and the secondary structure of both xylanases consists of primarily β-sheets (Törrönen et al. 1992). Throughout most of these types of xylanases, the aa’s are typically conserved at the positions of the β-turns, suggesting a common ancestor (Törrönen et al. 1992). β-xylosidase production by T. reesei was also reported (Herrmann et al. 1997a, b).

4.3 Random Mutagenesis of T. reesei—Cellulase Hyper-Producer Strains

Random mutagenesis by treating a microorganism with mutagens (e.g. N-nitroguanidine or UV light) and then screening for the mutants with desired features is a widely used method and an efficient way to obtain a desired microbial strain. This method has been successfully applied to T. reesei strains development. Because of the worldwide interests in alternative fuels production from cellulosic biomass, cellulase production and T. reesei strain development was of great interest in 1970 s and 1980 s (Peterson and Nevalainen 2012). Random mutagenesis was widely used at that time for improving cellulase production/activity, reducing catabolite repression and alleviating end-product inhibition.

The success of random mutation highly depends on the screening/selection method used. Montenecourt and Eveleigh (1979) summarized the screening methodologies for cellulases production strains. Different substrates together with colony inhibitors oxgall and Phosfon D were used for screening the mutants with desired cellulase activities. For instance, to screen a mutant with enhanced production of all the cellulases, acid swollen cellulose was used as the substrate, while CMC was used as the substrate for selection of a mutant with high endoglucanase activities. Several efficient plate screening techniques were developed for selecting β-glucosidase producer mutants. For instance, one method was developed using esculin and ferric ammonium citrate in the agar medium. β-glucosidase splits esculin into glucose and esculetin which reacts with ferric ammonium citrate and forms a black precipitate. Another method applied cellobiose and 2-deoxyglucose. The mutants that could not produce β-glucosidase must use 2-deoxyglucose which is toxic and causes the death of the mutants, while the mutants producing β-glucosidase are able to utilize cellobiose. For screening a mutant with the catabolite de-repression feature, high concentrations of a catabolite repressor (e.g. glucose or glycerol) were applied in the selection medium. The use of 2-deoxyglucose is particularly useful because it can be used as a catabolite repressor as well as an antimetabolite (Montenecourt and Eveleigh 1979).

A successful case of random mutagenesis on T. reesei was conducted by Mandels et. al. (1971), who irradiated the conidia of QM6a with high energy electrons generated by a linear accelerator and then screened the mutants in a cellulose medium. A mutant strain QM9123 was isolated, which secretes twice as much cellulase as the wild type, QM6a (Mandels et al. 1971). Later, another mutant QM 9414 was obtained, which has an even higher capacity of cellulase production (Mandels 1975). Another random mutagenesis effort generated the renowned hypercellulolytic strain RUT-C30 (Peterson and Nevalainen 2012). The native strain QM6a was first treated by UV light and then a catabolite repression resistant mutant M7 was isolated. Further mutagenesis by N-nitroguanidine and screening on an acid swollen cellulose plate with oxgall, Phosfon D and 5 % glycerol led to the isolation of NG14, which produced around 20 times the filter paper activity compared to QM6a (Montenecourt and Eveleigh 1977, 1979; Peterson and Nevalainen 2012). Subsequent mutagenesis on NG14 using UV light and selection on cellobiose and a 2-deoxyglucose medium obtained RUT-C30, which is a catabolite de-repression strain that produces 15–20 times higher cellulase activity than QM6a (Montenecourt and Eveleigh 1979).

4.4 Metabolic Engineering and Protein Engineering

Several transformation systems (e.g., agrobacterium-mediated transformation) have been developed for efficient manipulation of T. reesei (Guangtao et al. 2010; Steiger et al. 2011; Yao et al. 2007). Metabolic engineering of T. reesei for cellulase and hemicellulase production have been focusing on study and manipulation of transcriptional regulators (Kubicek et al. 2009). Protein engineering research for improving individual cellulase/hemicellulase includes rational design and direct evolution (Zhang et al. 2006; Wen et al. 2009). Several detailed reviews have been published in the past on protein engineering (Chandel et al. 2012; Peterson and Nevalainen 2012; Elkins et al. 2010). In some cases, point mutations were done to improve the thermo tolerance or specific activity of the enzymes. In many other instances, cellulose and hemicellulose degrading enzymes with multiple activities could be produced using gene-fusion techniques. Since cellulase comprise of catalytic, linker, and cellulose-binding domains, there can be n-number of possibilities of mixing and matching different domains to create novel enzymes with superior activities. Though T. reesei have 12 β-glucosidases in their genome, most of them were found to be intracellular and secreted enzyme had lesser cellobiase activities. Companies like Novozyme (http://www.novozymes.com) and Genencor International Inc. (http://www.genencor.com) have already developed a genetically modified T. reesei strain that shows higher β-glucosidase activity. Though several synergistically acting enzymes from other organisms are expressed in T. reesei for improving their enzyme activity, the details are yet to be revealed (Gusakov 2011).

4.4.1 Transcriptional Regulators

Production of cellulases and hemicellulases by T.reesei is tightly regulated by transcriptional regulators and requires an inducer (e.g., cellulose and lactose) for cellulase/hemicellulase gene expression to occur (Kubicek et al. 2009). Currently, three positive transcriptional activators (Xyr1, Ace2, and the Hap2/3/5 complex) and two negative regulators (Ace1and Cre1) have been identified. Xyr1 is a central regulatory protein which belongs to the class of zinc binuclear cluster proteins. All inducible cellulase promoters were found containing consensus sequences for Xyr1 (Kubicek et al. 2009). Xyr1 not only activates the most important hydrolase genes involved in the degradation of xylan and cellulose, including cbh1, cbh2, egl1, bgl1, xyn1, xyn2 and bxl1 (Mach-Aigner et al. 2008; Pucher et al. 2011), but it is also involved in the regulation of xylose and lactose metabolism (Seiboth et al. 2007; Stricker et al. 2006). It was found by Mach-Aigner et al. (2008) that the xyr1 gene was not induced by any cellulases inducers. However, Portnoy et al. (2011) indicated that it was induced by lactose and D-galactose. Xyr1 transcription was repressed by Ace1 as well as by glucose through carbon catabolite repression mediated by Cre1 (Mach-Aigner et al. 2008). Deletion of the xyr1 gene results in elimination of all cellulase and some hemicellulase production (Akel et al. 2009). Although it is well known that Xyr1 is the main regulator for cellulase and hemicellulase production, how to use this transcriptional regulator for producing cellulase and hemicellulase at a higher yield is still under investigation (Kubicek et al. 2009).

Cre1 has two zinc fingers of the C2H2 type involved in base recognition (Ilmen et al. 1996; Strauss et al. 1995) and it confers negative regulation of transcription. Unlike Xyr1, Cre1 only has direct control of some major hydrolases, most notably cbh1 and xyn1, whereas other hydrolytic genes such as cbh2, xyn2, and bgl1 are not Cre1 regulation dependent (Ilmen et al. 1996; Mach et al. 1995; Margolles-Clark et al. 1997). It has been illustrated that in the presence of glucose, Cre1 binds to specific sites in the cbh1 promoter and hence it represses cellulase production (Ilmen et al. 1996). Deletion or modification of cre1 is a way to resolve the catabolite repression issue (Nakari-Setala et al. 2009). The hypercellulolytic strain T. reesei Rut-C30 was found having a truncated cre1 gene which is the reason for its catabolite derepression property (Ilmen et al. 1996; Nakari-Setala et al. 2009; Peterson and Nevalainen 2012). Zou et al. (2012) substituted the binding sites of Ace2 and Hap2/3/5 for the Cre1 binding sites within the cbh1 promoter and thus improved the efficiency of the promoter.

Transcription factors Ace1, Ace2, and Hap2/3/5 complex are also involved in the regulation of cellulase formation in T. reesei. Ace1 has been described as a cellulase repressor (Aro et al. 2003) while Ace2 is described to promote cellulase production (Aro et al. 2001). Ace1, containing three Cys2His2 –type zinc fingers, is a repressor of cellulase and xylanase genes (Aro et al. 2003). It binds to eight sites in the cbh1 promoter containing the core sequence 5’AGGCA (Saloheimo et al. 2000). An increase of all the main cellulase and xylanase expression was observed for the Δace1 strain when cultured on sophorose and cellulose (Aro et al. 2003), which may be due to the fact that Ace1 also acts as a repressor of xyr1, as mentioned before (Mach-Aigner et al. 2008). Ace1 also competes with Xyr1for binding sites in the xyn1 promoter and thus it represses the transcription of xyn1 (Rauscher et al. 2006).

Ace2 is a zinc binuclear cluster protein like Xyr1. In contrast to Ace1, expression of Ace2 helps to increase cellulase expression (Aro et al. 2001). Deletion of ace2 leads to lower transcript levels of major cellulases (CBHI, CBHII, EGI, and EGII) and xylanase (XYNII) when cellulose was used as an inducer, but it was unaffected when sophorose was used as an inducer (Aro et al. 2001). Ace2 binds to the strong cbh promoter at the 5’-GGCTAATAA site (Aro et al. 2001), and it has been suggested that phosphorylation and dimerization are needed for the binding of Ace2 to the target promoter (Stricker et al. 2008).

Hap2/3/5 complex binds to a CCAAT box of cbh2-activating element (CAE) in the cbh2 promoter and acts as a transcriptional enhancer (Zeilinger et al. 2001).

4.4.2 Rational Design and Direct Evolution of Individual Cellulase/Hemicellulase

The idea of rational design is to modify the aminoacidic sequence of a protein in order to achieve dramatic impacts on the protein performance (Sheehan and Himmel 1999). Rational design for improving cellulases requires detailed information of the protein structure, protein structure/function relationships and how the protein interacts with the substrate to make the catalysis reaction to occur (Zhang et al. 2006). Site-directed mutagenesis, secondary structure element exchange, and whole domain exchange of fusion proteins are examples of how protein modifications can be achieved. The success of enzyme enhancement (e.g., increased activity) is usually limited to well-understood proteins, and is commonly applied to the amino acidic sites near the active site or the binding pocket in the 3-dimensional structure (Zhang et al. 2006). Based on the limited understanding of insoluble cellulose substrates, reaction complexity of the cellulase enzymes and the arsenal of enzymes needed to work in synergy to degrade lignocellulosic biomass, the cellulase complex needs much more investigation before effective methods can be developed. Cellulases working on the insoluble substrates have a complex mechanism to degrade the cellulose. For instance, six steps were proposed for CBHI of T. reesei to work on cellulose: binding to substrate via CBM (carbohydrate-binding module), recognizing a reducing end of a cellulose chain, threading the cellulose chain, forming a catalytically active complex, hydrolyzing the cellulose, and expulsing the product (Chundawat et al. 2011). Because of the complexity of their action, site-directed mutagenesis has met some difficulties toward improving the properties of the cellulases (Zhang et al. 2006). However, there are few successful cases concerning cellulases from fungi. For example, Wohlfahrt et al. improved the pH stability of the CBHII from T. reesei by mutagenesis of the non-active site residues (Wohlfahrt et al. 2003). Voutilainen et al. enhanced the thermo stability and activity of a CBHI from another fungus, Talaromyces emersonii, by introducing an additional disulfide bridge to the catalytic module (Voutilainen et al. 2010). Chen et al. increased the thermo stability of a xylanase from Aspergillus niger F19 by introducing five arginine substitutions and a disulfide bond to the enzyme (Chen et al. 2010).

Direct evolution mimics the natural random mutation and selection through recombinant DNA technology. It does not require the knowledge of enzyme structure and enzyme-substrate interactions, but relies on the screening method for evaluating the mutants (Zhang et al. 2006). CMC plus Congo red staining is a widely applied screening method for endoglucanase mutants (Lin et al. 2011). The Endoglucanase activity can be determined by the “halos” on the solid agar plates in which higher hydrolysis correlates with the size of the halos. DNA techniques that have been applied for directed evolution include family shuffling, DNA shuffling, error-prone Polymerase Chain Reaction (PCR), and SCHEMA (Lin et al. 2011). Improved enzyme activity, thermostability, and pH adaptability are the desired characteristics (Goedegebuur et al. 2005; Han et al. 2009; Lin et al. 2011; Trivedi et al. 2011; Wang et al. 2005; Xia and Wang 2009). For instance, Nakazawa et al. (2009) carried out directed evolution of T. reesei EGIII using error-prone PCR and selected a mutant exhibiting broader pH stability, better thermo stability as well as higher activity when compared to the wild type EGIII. Moreover, Hokanson et al. (2011) enhanced the thermo stability of the GH11 xylanase II from T. reesei through a directed evolution method.

4.5 Fermentation Technologies for Enzyme Production

4.5.1 Nutrients for T. reesei Growth and Enzyme Production

T. reesei is a mesophilic fungus having the metabolic pathways to utilize all the lignocellulose carbohydrates (Amore and Faraco 2012) and little nutrient requirements for growth (Mandels and Weber 1969). Hence, it can grow fairly easily on most carbon sources. Its growth rate is rapid on glucose, fructose, and glycerol and relatively slow on cellulose and lactose (Messner and Kubicek 1991). Glucose was shown to give higher cell biomass yield when compared to lactose, arabinose, or their mixtures (Xiong et al. 2004a). Nevertheless, glucose is a repressor of cellulase production via the action of Cre1. However, cellulase expression was still seen in a glucose medium after glucose was depleted with no inducer present (Ilmen et al. 1997). Oligosaccharides released from the cell walls of the starving fungus or sophorose generated from the glucose by the action of β-glucosidase were possibly acting as inducers in this case (Ilmen et al. 1997). When grown on carbohydrates, the fungus produces acidic compounds and the growth continues until pH drops below 2.5. In contrast, when grown on peptone the pH increases and growth continues until the pH reaches 7.5 (Mandels and Weber 1969). T. reesei can produce cellulases in a defined medium with simple nutrient salts and cellulose, but the addition of peptone has been shown to improve protein production. In another study, peptone was shown to have little effect on improvement of cellulase activity but increased β-glucosidase activity (Esterbauer et al. 1991). Tween 80, a commonly used surfactant, has been shown to increase cellulase production. It was theorized that this increase is due to loosening of the T. reesei cell wall and thus facilitating the entrance and exit of compounds from the cell (Reese and Maguire 1969).

4.5.2 Inducers for Cellulase and Hemicellulase Production

Cellulose and xylan were thought to be the natural inducers for cellulase and hemicellulase production. When considering the insoluble nature of xylan and cellulose, which are unable to enter the fungal cell, it has been suggested that the natural inducer was low molecular weight hydrolysis products (such as oligosaccharides and their derivatives), which can penetrate the cell and affect the fungal metabolism (Haltrich et al. 1996). Commonly used inducers including sophorose, lactose, and sorbose are discussed here.

The disaccharide sophorose is a very powerful soluble inducer of T. reesei cellulases and it was suggested to be the natural inducer (Sternberg and Mandels 1979; Sternberg and Mandels 1982). It has been demonstrated that the formation of sophorose from cellobiose was mediated by the trans-glycosylation activity of β-glucosidase (Vaheri et al. 1979). In addition, when β-glucosidase was inhibited, a substantial decrease in the synthesis of EGs was observed with cello-oligodextrins but not with sophorose as inducers (Kubicek 1987). These results further indicate the importance of β-glucosidase and sophorose in the induction of hydrolytic enzymes.

Lactose (D-galactosyl- β-1,4-D-glucoside) is another widely used cellulase inducer. A clear advantage of lactose compared to cellulose as an inducer is its solubility, yet lactose consumption has been shown to be slower and cellulase yields were lower compared to cellulose (Warzywoda et al. 1983). Because natural lactose only occurs in the milk of mammals, it is unlikely that it is the natural inducer for cellulose production (Kubicek et al. 2009). Extracellular hydrolysis of lactose into D-galactose and D-glucose is the initial step of lactose catabolism in T. reesei. The extracellular hydrolysis of lactose raised the question of the potential of the monomers ability to induce cellulase expression (Kubicek et al. 2009). Seiboth et al. (2003) found that neither D-glucose nor D-galactose or any mixture of these two resulted in cellulase induction even when the carbon catabolite repressor Cre1 was absent. Based on this, it is believed that the stereospecificity of the D-galactopyranose which is released from the cleavage of lactose by β-galactosidase plays a key role in the induction of cellulase by lactose (Kubicek et al. 2009).

Monosaccharides generally inhibit cellulase expression through carbon catabolite repression via the action of Cre1 or through end-product feedback inhibition. The only monosaccharide found to have a cellulase-inducing effect is L-sorbose (Kawamori et al. 1986; Nogawa et al. 2001). Sorbose affects cellulase formation at a transcriptional level and has been proposed to inhibit β-1,3-glucan synthetase, which changes the composition of the fungus cell wall and reduces the degradation of inducers (Nogawa et al. 2001).

XYNI and XYNII are not co-regulated, but are both formed in the presence of xylan or xylobiose, but only one is formed in the presence of sophorose (Hrmová et al. 1986; Senior et al. 1989). Cellulose, sophorose, xylan, xylobiose, and L-arabitol can induce expression of most of the tested hemicellulase genes including two β-xylanases, β-mannase, acetyl xylan esterase, β-xylosidase, and many others (Margolles-Clark et al. 1997). In the presence of glucose, most of the hemicellulase genes are repressed but de-repressed expression was observed once glucose was depleted (Margolles-Clark et al. 1997). Xyn2 transcription occurs at a low basal level when the fungus is grown on glucose as the sole carbon source and is elevated in the presence of xylan, xylobiose, or sophorose (Zeilinger et al. 1996).

4.5.3 Fermentation Conditions

The culture medium pH is a critical factor affecting many aspects of T. reesei fermentation including germinating time, growth rate, morphology, and enzyme production. Germination time is the shortest in the pH range of 3–5 and elongated when the pH becomes too acidic or alkaline (Lejeune et al. 1995). Maximal growth rate is also in the pH range of 3–5 with decreased growth rate in more acidic or alkali medium (Brown and Zainudeen 1977; Lejeune et al. 1995). On cellulose and xylan-based media, it was observed that cellulase production is favored at a pH around 4.0 while xylanase production favored at a pH around 7.0 (Bailey et al. 1993). In another study on lactose medium, the highest xylanase activity was observed at pH 6.0 and optimum cellulase production at a pH range of 4.0–5.0 (Xiong et al. 2004b). Different xylanases also favor different pH. Xiong et al. (2004b) found that XYNI favors pH 4.0, XYNIII favors pH 6.0, and XYNII favors both. Relatively high production of β-glucosidase was also found at high pH values (Juhász et al. 2004).

Agitation rate also plays a crucial role in enzyme production. Enzyme production is an energy intense reaction and requires a lot of ATPs. High agitation rate typically results in high dissolved oxygen level and hence facilitates aspiration and ATP production. However, high agitation rate also causes high shear stress and affects hyphae growth (Ahamed and Vermette 2010). When a 2.6 L fermenter is used, the optimal agitation speed for cellulase production was determined to be 300 rpm (Mukataka et al. 1988). In contrast to the total cellulase activity, the optimal agitation speed for endoglucanase and β-glucosidase production was 200 and 400 rpm, respectively (Mukataka et al. 1988). Effect of culture media composition is also known to have significant impact on cellulase production by T. reesei (Ahamed and Vermette 2008, 2010).

4.5.4 Morphology

Filamentous fungi are able to develop three major morphologies during submerged fermentation: pellets, mycelial aggregates (clumps), and filamentous mycelia (Cox et al. 1998). In bioreactors, the filamentous or clump mycelia are undesirable because they increase the viscosity of the medium and also wrap around the impellers. The pellet form is a desirable morphology, especially for industrial production, not only because of the reduced viscosity but also due to the improved culture rheology (enhanced mass and oxygen transfer) and the reduced energy cost for agitation and aeration (Suijdam et al. 1980). Numerous factors in the fermentation affect the fungus morphology, including agitation speed (see above), medium, pH, polymer additives, surface active agents, and inoculum size (Metz and Kossen 1977; Papagianni 2004; Ferreira Susana et al. 2009). It has been postulated that increasing the number of tips of hyphae increases protein production (Juge et al. 1998; Pluschkell et al. 1996) because it is believed that in filamentous fungus, protein secretion occurs at the tip of growing hyphae (Peberdy 1994; Punt et al. 1994). Since the tips are more porous, they allow proteins to exit more easily through the cell wall (Punt et al. 1994; Wosten et al. 1991). Correlation between fungal physiology and cellulase production is yet to be clearly understood. Several articles have shown that cellulase production is directly influenced by the fungal morphology during fungal fermentation (Grimm et al. 2005 and Ferreira Susana et al. 2009).

4.6 Current Efforts and Future Perspective of Reducing the Cost of Enzymes

Costs for producing enzymes used to hydrolyze pretreated biomass represent about one-third of the total hydrolysis processing cost (Walker and Wilson 1991; Lynd et al. 2005). It has been projected that the cost of enzymes is 2665 dollars per mega gram. Over the past 30 years, the cost of enzymes has been considerably decreased, but it is still considered to be high. About 10–20 Filter Paper Unit (FPU) of enzymes is required per gram of cellulose to achieve 90 % sugar conversion in 72 h (Chandel et al. 2012; Peterson and Nevalainen 2012). Though some of the reported T. reesei QM 6a strains produce an enzyme concentration of about 20 FPU ml−1 at a rate of 150 FPU L−1h−1, the cost of pure cellulose substrate used in the process is very high. Several efforts have been taken to lower the cost of enzymes as described below.

4.6.1 Enzyme Production Using Lignocellulosic Biomass

One of the main sources for the high cost of cellulase production is the substrate cost. Currently, pure cellulose power and inorganic salts are used as media with artificial inducers (Qu et al. 1991). Several artificial inducers (like lactose, cellobiose) are used in the industry to induce cellulase and hemicellulase production in T. reesei (Table 4.2). In order to reduce the cost of enzyme production, these artificial inducers could be replaced by natural inducers. The oligosaccharides produced during the hydrolysis of cellulose play important roles in the natural cellulase induction (Ladisch et al. 1981). Pure cellulosic materials (avicel, cotton, filter paper) have often been used both as substrates and as the source of inducers during fermentation processes for cellulase production (Lee and Fan 1983; Ahamed and Vermette 2008). Several limitations do exist while using solid substrates, such as an increase in viscosity and problematic agitation and reduced oxygen transfer efficiency of the bioreactors. To overcome these problems, lower solid concentrations are often used to get higher cellulase yields (Szengyel et al. 1997). If a cheap source of oligosaccharides is available, they could be directly used for induction. In many cases both native and pretreated biomass are used for induction (Dashtban et al. 2011). For pretreated biomass, a longer lag phase was observed when compared to controls with media containing glucose (Lo et al. 2005; Juhasz et al. 2005; Lau et al. 2012). These lag phases were attributed to the presence of inhibitory products produced during pretreatment (Palmqvist et al. 1997; Chundawat et al. 2010). When Ammonia Fiber Expansion (AFEXTM) pretreated wash stream was used as inducing medium, more hemicellulases were produced when compared to cellulases. Also, continuous culture produces more enzymes than batch culture, since oligosaccharides are known to be hydrolyzed before the cell concentration is high enough to produce a high concentration of cellulases (Lo et al. 2010).

Many researchers are looking for cheap sources of substrate like clarifier sludge and digester fine from paper mill, pretreated sugarcane bagasse, sorghum straw, corn stover (Yu and Koo 1999; Szakacs and Tengerdy 1997) for producing enzymes. In a larger lignocellulosic biorefinery, pretreated biomass could be used to produce enzymes that will substantially reduce the cellulase production costs.

4.6.2 Improvement of the Fermentation Process

4.6.2.1 Batch Versus Fed Batch Substrate Loading

Concentration of substrate and how the substrates are loaded during fermentation can influence the cellulase enzyme productivity. It has been reported that as the substrate concentration in the fermentation tank increases, the cellulase productivity raises: 2–3FPU/ml at 2 % substrate loading and 1–15 FPU/ml at 8 % substrate loadings (Esterbauer et al. 1991). Also, higher cellulase concentrations and volumetric rates were reported for fed batch fermentation when compared to batch fermentation (Hendy et al. 1984).

4.6.2.2 Solid State Fermentation (SSF) Versus Submerged Fermentation (SmF)

SSF process is done by growing the microbes on moist solid materials in the absence of free water. Here the substrate used in the process is used slowly and steadily. Although this method is best suited for fungus, the residence time for the process is too long and product separation is tedious. On the other hand, SmF process is done using free flowing liquid substrate or in substrate slurry. This is best studied for bacteria and the separation and purification of product is much easier (Bailey and Tähtiharju 2003; Subramaniyam and Vimala 2012). Most of the cellulase production in the industry is done using SmF. However, most of the aerobic microorganisms produce cellulases at high titers during SSF which is similar to natural environment. About 10-fold reduction in production cost has been reported when cellulases were produced in SSF when compared to SmF (Singhania et al. 2010). This is due to several advantages SSF have which include high volumetric productivity, higher titer of enzymes, lesser waste generation, low catabolic repression. Given its advantages, SSF could be promising technology for the future.

4.6.3 Fast Downstream Processing for Maximum Product Recovery

Downstream processing of enzymes could account for 50 % of the total cost of enzyme production. Traditional technologies used in the industry are centrifugation (solid liquid separation), filtration, and ultrafiltration (to remove waste and concentrate the enzymes) (Beilen and Li 2002). Efficient enzyme bioseparation process will bring down the cost of enzyme production. Some of the advanced technologies include two-phase extraction, reverse micelle extraction, cloud-point extraction, and field-assisted (electric, magnetic, and acoustic) separation methods (Keller et al. 2001; Karumanchi et al. 2002).

4.6.4 Recycling Enzymes During Bioconversion

One of the strategies to reduce the cost of enzyme is recycling the enzyme during the enzyme hydrolysis step (Tu et al. 2007). The most economical way to recover the enzyme after hydrolysis is done by re-adsorption of free cellulases onto fresh lignocellulosic substrates. About 80–85 % of enzymes activities could be removed using this approach (Lee et al. 1995). In few cases, ultrafiltration methods were also used to retain almost all the enzyme which could be used for subsequent cycle of enzyme hydrolysis. In another study, about 30–50 % of enzymes have been demonstrated to be recycled after each cycle of hydrolysis process using fast Separate Hydrolysis and Fermentation (SHF) and Simultaneous Saccharification and Co-Fermentation (SSCF) process which takes just two days to complete both hydrolysis and fermentation process when compared to traditional process which takes close to 10 days (Galbe and Zacchi 1993; Lynd et al. 2005; Jin et al. 2012).

4.6.5 Other Approaches to Reduce the Cost of Enzyme Production

There are two models widely followed for supplying enzymes to the biorefinery (Fig. 4.1). The first includes production of enzymes in a centralized large-scale processing facility which concentrates and formulates the enzymes and ships them to the different biorefinery locations. There are several drawbacks to this approach. Pure substrates, like cellulose and inducers, add additional costs to the process, ultrafiltration techniques used to concentrate the enzymes are energy intensive and shipping enzyme solution are very inefficient. The second approach includes production of enzymes at the site of the biorefinery. In this approach, there are several advantages, such as concentration of the enzymes is unnecessary, the pretreated substrate available in the biorefinery can be used as substrate for enzyme production and there are no shipping costs. Many enzyme companies are trying to adopt the second approach in order to reduce the cost of enzymes for making biofuels.

References

Ahamed A, Vermette P (2008) Culture-based strategies to enhance cellulase enzyme production from Trichoderma reesei RUT-C30 in bioreactor culture conditions. Biochem Eng J 40:399–407

Ahamed A, Vermette P (2010) Effect of mechanical agitation on the production of cellulases by Trichoderma reesei RUT-C30 in a draft-tube airlift bioreactor. Biochem Eng J 49:379–387

Akel E, Metz B, Seiboth B, Kubicek CP (2009) Molecular regulation of Arabinan and L-Arabinose metabolism in Hypocrea jecorina (Trichoderma reesei). Eukaryot Cell 8:1837–1844

Amore A, Faraco V (2012) Potential of fungi as category I consolidated bio-processing organisms for cellulosic ethanol production. Renew Sustain Energy Rev 16:3286–3301

Aro N, Saloheimo A, Ilmen M, Penttila M (2001) ACEII, a novel transcriptional activator involved in regulation of cellulase and xylanase genes of Trichoderma reesei. J Biol Chem 276:24309–24314

Aro N, Ilmen M, Saloheimo A, Penttila M (2003) ACEI of Trichoderma reesei is a repressor of cellulase and xylanase expression. Appl Environ Microbiol 69:56–65

Aro N, Pakula T, Penttila M (2005) Transcriptional regulation of plant cell wall degradation by filamentous fungi. FEMS Microbiol Rev 29:719–739

Bailey M, Tähtiharju J (2003) Efficient cellulase production by Trichoderma reesei in continuous cultivation on lactose medium with a computer-controlled feeding strategy. Appl Microbiol Biotechnol 62:156–162

Bailey MJ, Buchert J, Viikari L (1993) Effect of pH on production of xylanase by Trichoderma reesei on xylan-and cellulose-based media. Appl Microbiol Biotechnol 40:224–229

Balan V, Kumar S, Bals B, Chundawat SPS, Jin M, Dale BE (2012) Biochemical and thermochemical conversion of switchgrass to biofuels. In: Monti A (ed) Switchgrass: a valuable biomass crop for energy, chapter 7. Springer-Verlag London Ltd., pp 153–186

Beilen JBV, Li Z (2002) Enzyme technology: an overview. Curr Opin Biotechnol 13:338–344

Bigelow M, Wyman CE (2002) Cellulase production on bagasse pretreated with hot water. Appl Biochem Biotech 98–100:921–934

Bouws H, Wattenberg A, Zorn H (2008) Fungal secretomes–nature’s toolbox for white biotechnology. Appl Microbiol Biotechnol 80:381–388

Brown D, Zainudeen M (1977) Growth kinetics and cellulase biosynthesis in the continuous culture of Trichoderma viride. Biotechnol Bioeng 19(7):941–958

Carroll A, Somerville C (2009) Cellulosic biofuels. Annu Rev Plant Biol 60:165–182

Chandel AK, Chandrasekhar C, Silva MB, daSilva SS (2012) The realm of cellulases in biorefinery development. Crit Rev Biotechnol 32:187–202

Chen H, Hayn M, Esterbauer H (1992) Purification and characterization of two extracellular β-glucosidase from Trichoderma reesei. Biochimica et Biophysica Acta (BBA)-Protein Struct Mole Enzymol 1121:54–60

Chen XZ, Xu SQ, Zhu MS, Cui LS, Zhu H, Liang YX, Zhang ZM (2010) Site-directed mutagenesis of an Aspergillus niger xylanase B and its expression, purification and enzymatic characterization in Pichia pastoris. Process Biochem 45(1):75–80

Cherry JR, Fidantsef AL (2003a) Directed evolution of industrial enzymes: an update. Curr Opin Biotechnol 14:438–443

Cherry JR, Fidantsef AL (2003b) Directed evolution of industrial enzymes: an update. Curr Opin Biotechnol 14:438–443

Chundawat SP, Vismeh R, Sharma LN, Humpula JF, da Sousa Costa L, Chambliss CK, Jones AD, Balan V, Dale BE (2010) Multifaceted characterization of cell wall decomposition products formed during ammonia fiber expansion (AFEX) and dilute acid based pretreatments. Bioresource Technol 101:8429–8438

Chundawat SPS, Beckham GT, Himmel ME, Dale BE (2011) Deconstruction of lignocellulosic biomass to fuels and chemicals. In: Prausnitz JM (ed) Annual review of chemical and biomolecular engineering, vol 2, pp 121–145

Colina A, Ferrer A, Urribarri L (2009) Producción de celulasas por Trichoderma reesei Rut C-30 en diferentes substratos celulósicos. Rev Téc Ing Univ Zulia 32:152–159

Cox P, Paul G, Thomas C (1998) Image analysis of the morphology of filamentous micro-organisms. Microbiology 144:817–827

Dashtban M, Buchkowski R, Qin W (2011) Effect of different carbon sources on cellulase productionby Hypocrea jecorina (Trichoderma reesei) strains. Int J Biochem Mol Biol 2:274–286

Divne C, Ståhlberg J, Teeri TT, Jones TA (1998) High-resolution crystal structures reveal how a cellulose chain is bound in the 50 Å long tunnel of cellobiohydrolase I from Trichoderma reesei. J Mol Biol 275:309–325

Elkins JG, Raman B, Keller M (2010) Engineered microbial systems for enhanced conversion of lignocellulosic biomass. Curr Opin Biotechnol 21:657–662

Esterbauer H, Steiner W, Labudova I, Hermann A, Hayn M (1991) Production of Trichoderma cellulase in laboratory and pilot scale. Bioresource Technol 36:51–65

Ferreira Susana MP, Duarte AP, Queiroz JA, Domingues FC (2009) Influence of buffersystems on Trichoderma reesei Rut C-30 morphology and cellulase production. Electron J Biotechnol 12. ISSN: 0717-3458

Fitzpatrick M, Champagne P, Cunningham MF, Whitney RA (2010) A biorefineryprocessing perspective: treatment of lignocellulosic materials for the production of value-added products. Bioresource Technol 101:1822–8915

Fowler T, Brown RD (1992) The BGL1 gene encoding extracellular beta-glucosidase from Trichoderma Reesei is required for rapid induction of the cellulase complex. Mol Microbiol 6:3225–3235

Galbe M, Zacchi G (1993) Simulation of processes for conversion of lignocellulosics. In: Saddler JN (ed) Bioconversion of forest and agricultural plant residues, CAB International, Wallingford, pp 291–342

Goedegebuur F, Dankmeyer L, Gualfetti P, Kelemen B, Larenas E, Neefe F, Teunissen P, Mitchinson C (2005) Improving the thermal stability of cellobiohydrolases I (Cel7A) from T. reesei by site directed evolution. J Biotechnol 118:S130–S130

Gomez LD, Steele-King CG, McQueen-Mason SJ (2008) Sustainable liquid biofuels from biomass:the writing’s on the wall. New Phytol 178:473–485

Grimm LH, Kelly S, Krull R, Hempel DC (2005) Morphology and productivity of filamentous fungi. Appl Microbiol Biotechnol 69:375–384

Gritzali M, Brown Ross D (1979) The cellulase system of Trichoderma In: Hydrolysis of cellulose: mechanisms of enzymatic and acid catalysis, vol 181, American Chemical Society, Washington, DC, pp 237–260

Guangtao Z, Seiboth B, Wen C, Yaohua Z, Xian L, Wang TH (2010) A novel carbon source-dependent genetic transformation system for the versatile cell factory Hypocrea jecorina (anamorph Trichoderma reesei). Fems Microbiol Lett 303(1):26–32.

Gusakov A (2011) Alternatives to Trichoderma reesei in biofuel production. Trends Biotechnol 29:419–425

Haltrich D, Nidetzky B, Kulbe KD, Steiner W, Župančič S (1996) Production of fungal xylanases. Bioresource Technol 58:137–161

Han ZL, Han SY, Zheng SP, Lin Y (2009) Enhancing thermostability of a Rhizomucor miehei lipase by engineering a disulfide bond and displaying on the yeast cell surface. Appl Microbiol Biotechnol 85:117–126

Hendy Na, Wilke CR, Blanch HW (1984) Enhanced cellulase production in fed-batch culture of Trichoderma reesei C30. Enzyme Microb Technol 6:73–77

Herrmann MC, Vrsanska M, Jurickova M, Hirsch J, Biely P, Kubicek CP (1997a) The beta-D-xylosidase of Trichoderma reesei is a multifunctional beta-D-xylan xylohydrolase. Biochem J 321(Pt 2):375

Herrmann MC, Vrsanska M, Jurickova M, Hirsch J, Biely P, Kubicek CP (1997b) The beta-D-xylosidase of Trichoderma reesei is a multifunctional beta-D-xylan xylohydrolase. Biochem J 321:375–381

Himmel ME, Ding S-Y, Johnsons DK, Adney WS, Nimlos MR, Brady JW et al (2007) Biomass recalcitrance: engineering plants and enzymes for biofuel production. Science 315:804–807

Hokanson CA, Cappuccilli G, Odineca T, Bozic M, Behnke CA, Mendez M, Coleman WJ, Crea R (2011) Engineering highly thermostable xylanase variants using an enhanced combinatorial library method. Protein Eng Des Sel 24:597–605

Hrmová M, Biely P, Vršanská M (1986) Specificity of cellulase and β-xylanase induction in Trichoderma reesei QM 9414. Arch Microbiol 144:307–311

Huber GW, Dale BE (2009) Grassoline at the pump. Sci Am 301:52–59

Ilmen M, Saloheimo A, Onnela ML, Penttila ME (1997) Regulation of cellulase gene expression in the filamentous fungus Trichoderma reesei. Applied and Environmental Microbiology 63(4):1298–1306

Inglin M, Feinberg BA, Loewenberg JR (1980) Partial purification and characterization of a new intracellular beta-glucosidase of Trichoderma reesei. Biochem J 185:515

Jackson MA, Talburt DE (1988) Mechanism for β-glucosidase release into cellulose-grown Trichoderma reesei culture supernatants. Exp Mycol 12:203–216

Jin M, Gunawan C, Uppugundla N, Balan V, Dale BE (2012) A novel integrated biological process for cellulosic ethanol production featuring high ethanol productivity, enzyme recycling, and yeast cells reuse. Energy Environ Sci 5:7168–7175

Juge N, Svensson B, Williamson G (1998) Secretion, purification, and characterisation of barley alpha-amylase produced by heterologous gene expression in Aspergillus niger. Appl Microbiol Biotechnol 49:385–392

Juhasz T, Szengyel Z, Reczey K, Siika-Aho M, Viikari L (2005) Characterization of cellulases and hemicellulases produced by Trichoderma reesei on various carbon sources. Process Biochem 40:3519–3525

Juhász T, Szengyel Z, Szijártó N, Réczey K (2004) Effect of pH on cellulase production of Trichoderma ressei RUT C30. Appl Biochem Biotechnol 113:201–211

Karlsson J, Saloheimo M, Siika-aho M, Tenkanen M, Penttila M, Tjerneld F (2001) Homologous expression and characterization of Cel61A (EG IV) of Trichoderma reesei. Eur J Biochem 268:6498–6507

Karumanchi RSMS, Doddamane SN, Sampangi C, Todd PW (2002) Field-assisted extraction of cells, particles and macromolecules. Trends Biotechnol 20:72–78

Kawamori M, Morikawa Y, Takasawa S (1986) Induction and production of cellulases by L-Sorbose in Trichoderma Reseei. Appl Microbiol Biotechnol 24:449–453

Keller K, Friedman T, Boxman A (2001) The bioseparation needs of tomorrow. Trends Biotechnol 19:438–441

Kubicek CP (1987) Involvement of a conidial endoglucanase and a plasma-membrane-bound beta-glucosidase in the induction of endoglucanase synthesis by cellulose in Trichodermareesei. J Gen Microbiol 133:1481–1487

Kubicek CP, Mikus M, Schuster A, Schmoll M, Seiboth B (2009) Metabolic engineering strategies for the improvement of cellulase production by Hypocrea jecorina. Biotechnol Biofuels 2:19

Kumar R, Singh S, Singh OV (2008) Bioconversion of lignocellulosic biomass: biochemical and molecular perspectives. J Indian Microbiol Biotechnol 35:377–391

Ladisch MR, Hong J, Voloch M, Tsao GT (1981) Cellulase kinetics. In: Wolfe R, Hollaender A, Rabson R, Rodgers P, San Pietro A, Valentine R (eds) Trends in the biology of fermentation for fuels and chemicals. Plenum Publishing, New York, pp 55–83

Lau MW, Bals BD, Chundawat SPS, Jin M, Gunawan C, Balan V, Jones D, Dale BE (2012) An integrated paradigm for cellulosic biorefineries: utilization of lignocellulosic biomass as self-sufficient feedstocks for fuel, food precursors and saccharolytic enzyme production. Energy Environ Sci 5:7100–7110

Lee YH, Fan LT (1983) Kinetic studies of enzymatic hydrolysis of insoluble cellulose: (II) analysis of extended hydrolysis times. Biotechnol Bioeng 25:939–966

Lee D, Alex H, Yu C, Saddler JN (1995) Evaluation of cellulase recycling strategies for the hydrolysis of lignocellulosic substrates. Biotechnol Bioeng 45:328–336

Lejeune R, Nielsen J, Baron G (1995) Influence of pH on the morphology ofTrichoderma reeseiqm 9414 in submerged culture. Biotechnol Lett 17:341–344

Lin HL, Li WG, Guo CH, Qu SH, Ren NQ (2011) Advances in the study of directed evolution for cellulases. Front Environ Sci Eng China 5:519–525

Lo C-M, Zhang Q, Lee P, Ju L-K (2005) Cellulase production by Trichoderma reesei using sawdust hydrolysate. Appl Biochem Biotechnol 121–124:561–573

Lo C-M, Zhang Q, Callow NV, Ju L-K (2010) Cellulase production by continuous culture of Trichoderma reesei Rut C30 using acid hydrolysate prepared to retain more oligosaccharides for induction. Bioresource Technol 101:717–723

Lyko H, Deerberg G, Weidner E (2009) Coupled production in biorefineries combined use of biomass as a source of energy, fuels and materials. J Biotechnol 142:78–86

Lynd LR, van Zyl WH, McBride JE, Laser M (2005) Consolidated bioprocessing of cellulosic biomass: an update. Curr Opin Biotechnol 16:577–583

Mach RL, Seiboth B, Myasnikov A, Gonzalez R, Strauss J, Harkki AM, Kubicek CP (1995) The bgl1 gene of trichoderma-reesei QM-9414 encodes an extracellular, cellulose-inducible beta-glucosidase involved in cellulase induction by sophorose. Molecular Microbiology 16(4):687–697

Mach RL, Seiboth B, Myasnikov A, Gonzalez R, Strauss J, Harkki AM, Kubicek CP (2006) The bgl1 gene of Trichoderma reesei QM 9414 encodes an extracellular, cellulose-inducible ß-glucosidase involved in cellulase induction by sophorose. Mol Microbiol 16:687–697

Mach-Aigner AR, Pucher ME, Steiger MG, Bauer GE, Preis SJ, Mach RL (2008) Transcriptional regulation of xyr1, encoding the main regulator of the xylanolytic and cellulolytic enzyme system in Hypocrea jecorina. Appl Environ Microbiol 74:6554–6562

Mandels M (1975) Microbial sources of cellulase. Biotechnol Bioeng Symp 5:81–105

Mandels M, Weber J (1969) The production of cellulases. Adv Chem Ser 95:391–414

Mandels M, WebeR J, Parizek R (1971) Enhanced cellulase production by a mutant of Trichoderma viride. Appl Microbiol 21:152

Margolles-Clark E, Tenkanen M, Söderlund H, Penttilä M (1996) Acetyl xylan esterase from Trichoderma reesei contains an active-site serine residue and a cellulose-binding domain. Eur J Biochem 237:553–560

Margolles-Clark E, Tenkanen M, Luonteri E, Penttilä M (1996b) Three α-Galactosidase genes of Trichoderma reesei cloned by expression in yeast. Eur J Biochem 240:104–111

Margolles-Clark E, Ihnen M, Penttilà M (1997) Expression patterns of ten hemicellulase genes of the filamentous fungus Trichoderma reesei on various carbon sources. J Biotechnol 57:167–179

Martinez D, Berka RM, Henrissat B et al (2008a) Genome sequencing and analysis of the biomass degrading fungus Trichoderma reesei (syn. Hypocrea jecorina). Nat Biotechnol 26:553–560

Martinez D, Berka RM et al (2008b) Genome sequencing and analysis of the biomass-degrading fungus Trichoderma reesei (syn. Hypocrea jecorina). Nat Biotechnol 26:553–560

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals and biorefinery concept. Prog Energy Combust Sci 38:522–550

Merino ST, Cherry J (2007) Progress and challenges in enzyme development for biomass utilization. Adv Biochem Eng/Biotechnol 108:95–120

Messner R, Kubicek CP (1991) Carbon source control of cellobiohydrolase I and II formation by Trichoderma reesei. Appl Environ Microbiol 57:630–635

Messner R, Gruber F, Kubicek CP (1988) Differential regulation of synthesis of multiple forms of specific endoglucanases by Trichoderma reesei QM9414. J Bacteriol 170:3689–3693

Metz B, Kossen NWF (1977) The growth of molds in the form of pellets–a literature review. Biotechnol Bioeng 19:781–799

Montenecourt B, Eveleigh D (1977) Preparation of mutants of Trichoderma reesei with enhanced cellulase production. Appl Environ Microbiol 34:777–782

Montenecourt BS, Eveleigh DE (1979) Selective screening methods for the isolation of high yielding cellulase mutants of Trichoderma reesei. In: Hydrolysis of cellulose: mechanisms of enzymatic and acid catalysis, vol 181, American Chemical Society, Washington, DC, pp 289–301

Mukataka S, Kobayashi N, Sato S, Takahashi J (1988) Variation in cellulases constituting components from Trichoderma reesei with agitation intensity. Biotechnol Bioeng 32:760–763

Nakari-Setala T, Paloheimo M, Kallio J, Vehmaanpera J, Penttila M, Saloheimo M (2009) Genetic modification of carbon catabolite repression in Trichoderma reesei for improved protein production. Appl Environ Microbiol 75:4853–4860

Nakazawa H, Okada K, Onodera T, Ogasawara W, Okada H, Morikawa Y (2009) Directed evolution of endoglucanase III (Cel12A) from Trichoderma reesei. Appl Microbiol Biotechnol 83:649–657

Nogawa M, Goto M, Okada H, Morikawa Y (2001) L-Sorbose induces cellulase gene transcription in the cellulolytic fungus Trichoderma reesei. Curr Genet 38:329–334

Ohara H (2003) Biorefinery: a mini review. Appl Microbiol Biotechnol 62:474–477

Ouyang J, Yan M, Kong D, Xu L (2006) A complete protein pattern of cellulase and hemicellulase genes in the filamentous fungus Trichoderma reesei. Biotechnol J 1:1266–1274

Palmqvist E, Hahn-Hägerdal B, Szengyel Z, Zacchi G, Rèczey K (1997) Simultaneous detoxification and enzyme production of hemicellulose hydrolysates obtained after steam pretreatment. Enzyme Microb Technol 20:286–293

Papagianni M (2004) Fungal morphology and metabolite production in submerged mycelial processes. Biotechnol Adv 22(3):189–259

Peberdy JF (1994) Protein secretion in filamentous fungi—trying to understand a highly productive black-box. Trends Biotechnol 12:50–57

Penttilä M, Lehtovaara P, Nevalainen H, Bhikhabhai R, Knowles J (1986) Homology between cellulase genes of Trichoderma reesei: complete nucleotide sequence of the endoglucanase I gene. Gene 45:253–263

Peterson R, Nevalainen H (2012) Trichoderma reesei RUT-C30-thirty years of strain improvement. Microbiology-Sgm 158:58–68

Pluschkell S, Hellmuth K, Rinas U (1996) Kinetics of glucose oxidase excretion by recombinant Aspergillus niger. Biotechnol Bioeng 51:215–220

Portnoy T, Margeot A, Seidl-Seiboth V, Le Crom S, Ben Chaabane F, Linke R, Seiboth B, Kubicek CP (2011) Differential regulation of the cellulase transcription factors XYR1, ACE2, and ACE1 in Trichoderma reesei strains producing high and low levels of cellulase. Eukaryot Cell 10:262–271

Poutanen K (1988) An α-L-arabinofuranosidase of Trichoderma reesei. J Biotechnol 7:271–281

Pucher ME, Steiger MG, Mach RL, Mach-Aigner AR (2011) A modified expression of the major hydrolase activator in Hypocrea jecorina (Trichoderma reesei) changes enzymatic catalysis of biopolymer degradation. Catal Today 167:122–128

Punt PJ, Veldhuisen G, Vandenhondel C (1994) Protein targeting and secretion in filamentous fungi. Antonie Van Leeuwenhoek Int J Gen Mole Microbiol 65:211–216

Qu Y, Zhao X, Gao P et al (1991) Cellulase production from spent sulfite liquor and papermill waste fiber. Appl Biochem Biotechnol 28–29:363–368

Rauscher R, Wurleitner E, Wacenovsky C, Aro N, Stricker AR, Zeilinger S, Kubicek CP, Penttila M, Mach RL (2006) Transcriptional regulation of xyn1, encoding xylanase I, in Hypocrea jecorina. Eukaryot Cell 5:447–456

Reese E, Maguire A (1969) Surfactants as stimulants of enzyme production by microorganisms. Appl Microbiol 17:242–245

Rodriguez-Gomez D, Lehmann L, Schultz-Jensen N, Bjerre AB, Hobley TJ (2012) Examining the potential of plasma-assisted pretreated wheat straw for enzyme production by Trichoderma reesei. Appl Biochem Biotechnol 166:2051–2063

Saarelainen R, Paloheimo M, Fagerström R, Suominen PL, Nevalainen KMH (1993) Cloning, sequencing and enhanced expression of the Trichoderma reesei endoxylanase II (pI 9) gene xln2. Mole Gen Genet MGG 241:497–503

Saloheimo M, Lehtovaara P et al (1988) EGIII, a new endoglucanase from Trichoderma reesei: the characterization of both gene and enzyme. Gene 63:11–21

Saloheimo A, Henrissat B, Hoffrén A-M, Teleman O, Penttilä M (1994) A novel, small endoglucanase gene, egl5, from Trichoderma reesei isolated by expression in yeast. Mole Microbiol 13:219–228

Saloheimo M, Nakari-SetäLä T, Tenkanen M, Penttilä M (1997) cDNA cloning of a Trichoderma reesei cellulase and demonstration of endoglucanase activity by expression in yeast. Eur J Biochem 249:584–591

Saloheimo A, Aro N, Ilmen M, Penttila M (2000) Isolation of the ace1 gene encoding a Cys(2)-His(2) transcription factor involved in regulation of activity of the cellulase promoter cbh1 of Trichoderma reesei. J Biol Chem 275:5817–5825

Saloheimo M, Kuja-Panula J, Ylosmaki E, Ward M, Penttila M (2002) Enzymatic properties and intracellular localization of the novel Trichoderma reesei beta-glucosidase BGLII (Cel1A). Appl Environ Microbiol 68:4546–4553

Sanders J, Scott E, Weusthuis R, Mooibroek H (2007) Bio-refinery as the bioinspired process to bulk chemicals. Macromol Biosci 7:105–117

Seiboth B, Hartl L, Pail M, Fekete E, Karaffa L, Kubicek CP (2003) The galactokinase of Hypocrea jecorina is essential for cellulase induction by lactose but dispensable for growth on d-galactose. Mol Microbiol 51:1015–1025

Seiboth B, Gamauf C, Pail M, Hartl L, Kubicek CP (2007) The d-xylose reductase of Hypocrea jecorina is the major aldose reductase in pentose and d-galactose catabolism and necessary for beta-galactosidase and cellulase induction by lactose. Mol Microbiol 66:890–900

Seiboth B, Ivanova C, Seidl-Seiboth V (2011)Trichoderma reesei: a fungal enzymeproducer for cellulosic biofuels. In: Dos Santos Bernardes MA (ed) Biofuel production-recent developments and prospects, Intech, Rijeka, ISBN: 978-953-307-478-8

Senior DJ, Mayers PR, Saddler JN (1989) Production and purification of xylanases. Plant cell wall polymers biogenesis and biodegradation. ACS symposium Series ACS Publications, pp 644–653

Sheehan J, Himmel M (1999) Enzymes, energy, and the environment: a strategic perspective on the US Department of Energy’s Research and Development Activities for Bioethanol. Biotechnol Prog 15:817–827

Shin CS, Lee JP, Lee JS, Park SC (2000) Enzyme production of Trichoderma reesei Rut C-30 on various lignocelluloses substrates. Appl Biochem Biotech 84–86:237–245

Singhania RR, Sukumaran RK, Patel AK, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme Microb Technol 46:541–549

Steiger MG, Vitikainen M et al (2011) Transformation system for Hypocrea jecorina (Trichodermareesei) that favors homologous integration and employs reusable bidirectionally selectable markers. Appl Environ Microbiol 77:114–121

Sternberg D, Mandels GR (1979) Induction of cellulolytic enzymes in Trichoderma-reesei by sophorose. J Bacteriol 139:761–769

Sternberg D, Mandels GR (1982) β-glucosidase induction and repression in the cellulolytic fungus, Trichoderma reesei. Exp Mycol 6:115–124

Strauss J, Mach RL, Zeilinger S, Hartler G, Stoffler G, Wolschek M, Kubicek CP (1995) Crel, the carbon catabolite repressor protein from Trichoderma reesei. FEBS Lett 376:103–107

Stricker AR, Grosstessner-Hain K, Wurleitner E, Mach RL (2006) Xyr1 (xylanase regulator 1) regulates both the hydrolytic enzyme system and D-xylose metabolism in Hypocrea jecorina. Eukaryot Cell 5:2128–2137

Stricker AR, Trefflinger P, Aro N, Penttila M, Mach RL (2008) Role of Ace2 (Activator of Cellulases 2) within the xyn2 transcriptosome of Hypocrea jecorina. Fungal Genet Biol 45:436–445

Subramaniyam R, Vimala R (2012) Solid state and submerged fermentation for the production of bioactive substances: a comparative study. Int J Sci Nat 3:480–486

Suijdam J, Kossen N, Paul P (1980) An inoculum technique for the production of fungal pellets. Appl Microbiol Biotechnol 10:211–221

Sun WC, Cheng CH, Lee WC (2008a) Protein expression and enzymatic activity of cellulases produced by Trichoderma reesei Rut C-30 on rice straw. Process Biochem 43:1083–1087

Sun W-C, Cheng C-H, Lee W-C (2008b) Protein expression and enzymatic activity of cellulases produced by Trichoderma reesei Rut C-30 on rice straw. Process Biochem 43:1083–1087

Szakacs G, Tengerdy RP (1997) Lignocellulolytic enzyme production on pretreated poplar wood by filamentous fungi. World J Microb Biotechnol 13:487–490

Szengyel Z, Zacchi G (2000) Effect of acetic acid and furfural on cellulase production of Trichoderma reesei RUT C30. Appl Biochem Biotechnol 89:31–42

Szengyel Z, Zacchi G, Reczey K (1997) Cellulase production based on hemicellulose hydrolysate from steam-pretreated willow. Appl Biochem Biotech 63–65:351–362

Szengyel Z, Zacchi G, Varga A, Réczey K (2000) Cellulase production of Trichoderma reesei Rut C 30 using steam-pretreated spruce hydrolytic potential of cellulases on different substrates. Appl Biochem Biotech 84–86:679–691

Szijarto N, Szengyel Z, Lidén G, Réczey K (2004) Dynamics of cellulase production by glucose grown cultures of Trichoderma reesei Rut-C30 as a response to addition of cellulose. Appl Biochem Biotech 113:115–124

Teeri TT (1997) Crystalline cellulose degradation: new insight into the function of cellobiohydrolases. Trends Biotechnol 15:160–167

Thygesen A, Thomsen AB, Schmidt AS, Jorgensen H, Ahring BK, Olsson L (2003) Production of cellulose and hemicellulose degrading enzymes by filamentous fungi cultivated on wetoxidizedwheat straw. Enzyme Microb Technol 32:606–615

Törrönen A, Mach RL, Messner R, Gonzalez R, Kalkkinen N, Harkki A, Kubicek CP (1992) The two major xylanases from Trichoderma reesei: characterization of both enzymes and genes. Nat Biotechnol 10:1461–1465

Törrönen A, Harkki A, Rouvinen J (1994) Three-dimensional structure of endo-1,4-beta-xylanase II from Trichoderma reesei: two conformational states in the active site. EMBO J 13:2493–2501

Trivedi N, Gupta V, Kumar M, Kumari P, Reddy CRK, Jha B (2011) An alkali-halotolerant cellulase from Bacillus flexus Isolated from green seaweed Ulva lactuca. Carbohydr Polym 83:891–897

Tu M, Chandra RP, Saddler JN (2007) Evaluating the distribution of cellulases and the recycling of free cellulases during the hydrolysis of lignocellulosic substrates. Biotechnol Prog 23:398–406

Vaheri M, Leisola M, Kauppinen V (1979) Transglycosylation products of cellulase system of Trichodermareesei. Biotechnol Lett 1:41–46

Voutilainen SP, Murray PG, Tuohy MG, Koivula A (2010) Expression of Talaromyces emersonii cellobiohydrolase Cel7A in Saccharomyces cerevisiae and rational mutagenesis to improve its thermostability and activity. Protein Eng Des Sel 23:69–79

Walker LP, Wilson DB (1991) Enzymatic hydrolysis of cellulose: an overview. Bioresource Technol 36:3–14

Wang T, Liu X, Yu Q, Zhang X, Qu Y, Gao P (2005) Directed evolution for engineering pH profile of endoglucanase III from Trichoderma reesei. Biomol Eng 22:89–94

Warzywoda M, Ferre V, Pourquie J (1983) Development of a culture medium for large-scale production of cellulolytic enzymes by Trichoderma reesei. Biotechnol Bioeng 25:3005–3011

Wen Z, Liao W, Chen S (2005) Production of cellulase by Trichoderma reesei from dairy manure. Bioresource Technol 96:491–499

Wen F, Nair NU, Zhao H (2009) Protein engineering in designing tailored enzymes and microorganisms for biofuels. Curr Opin Biotechnol 20:412–419

Wilson DB (2009) Cellulases and biofuels. Curr Opin Biotechnol 20:295–299

Wohlfahrt G, Pellikka T, Boer H, Teeri TT, Koivula A (2003) Probing pH-dependent functional elements in proteins: modification of carboxylic acid pairs in Trichoderma reesei cellobiohydrolase Cel6A. Biochemistry 42:10095–10103

Wosten HAB, Moukha SM, Sietsma JH, Wessels JGH (1991) Localization of growth and secretion of proteins in aspergillus-niger. J Gen Microbiol 137:2017–2023

Xia T, Wang Q (2009) Directed evolution of Streptomyces lividans xylanase B toward enhanced thermal and alkaline pH stability. World J Microbiol Biotechnol 25:93–100

Xiong H, Turunen O, Pastinen O, Leisola M, von Weymarn N (2004a) Improved xylanase production by Trichoderma reesei grown on L-arabinose and lactose or d-glucose mixtures. Appl Microbiol Biotechnol 64:353–358

Xiong H, von Weymarn N, Leisola M, Turunen O (2004b) Influence of pH on the production of xylanases by Trichoderma reesei Rut C-30. Process Biochem 39:731–736

Xiong H, von Weymarn N, Turunen O, Leisola M, Pastinen O (2005) Xylanase production by Trichoderma reesei Rut C-30 grown on L-arabinose-rich plant hydrolysates. Bioresource Technol 96:753–759

Yao HZ, Xiao LW, Tian HW, Qiao J (2007) Agrobacterium-mediated transformation (AMT) of Trichoderma reesei as an efficient tool for random insertional mutagenesis. Appl Microbiol Biotechnol 73:1348–1354

Yu X, Koo YM (1999) Cellulase production by Trichoderma reesei Rut C-30 with batchand fed-batch fermentation. Food Ferment Ind 25:16–19

Zeilinger S, Mach RL, Schindler M, Herzog P, Kubicek CP (1996) Different inducibility of expression of the two xylanase genes xyn1 and xyn2 in Trichoderma reesei. J Biol Chem 271:25624–25629

Zeilinger S, Ebner A, Marosits T, Mach R, Kubicek CP (2001) The Hypocrea jecorina HAP 2/3/5 protein complex binds to the inverted CCAAT-box (ATTGG) within the cbh2 (cellobiohydrolase II-gene) activating element. Mol Genet Genomics 266:56–63

Zhang YHP, Himmel ME, Mielenz JR (2006) Outlook for cellulase improvement: screening and selection strategies. Biotechnol Adv 24:452–481

Zou G, Shi SH et al (2012) Construction of a cellulase hyper-expression system in Trichoderma reesei by promoter and enzyme engineering. Microb Cell Fact 11:21

Acknowledgments

This work was supported by U.S. Department of Energy through the DOE Great Lakes Bioenergy Research Center (GLBRC) Grant DE‐FC02‐07ER64494. We would like to thank James Humpula from Biomass conversion research laboratory located at Michigan State University, East Lansing for giving his valuable suggestion while drafting this chapter.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Balan, V., Jin, M., Culbertson, A., Uppugundla, N. (2013). The Saccharification Step: Trichoderma Reesei Cellulase Hyper Producer Strains. In: Faraco, V. (eds) Lignocellulose Conversion. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-37861-4_4

Download citation

DOI: https://doi.org/10.1007/978-3-642-37861-4_4

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-37860-7

Online ISBN: 978-3-642-37861-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)