Abstract

The effects of 10-MeV E-beam (0, 1, 3, 5, and 7 kGy) irradiation and vacuum packaging on extending the shelf-life of grass carp surimi stored at 4 °C were evaluated basing on the total viable counts (TVC), physiochemical 2-thiobarbituric acid reactive substance (TBARS), total base nitrogen (TVB-N), biogenic amines (BAs), texture (TPA) and color, and sensory changes in surimi samples. The results showed that comparing the control samples, the TVC and TVB-N content in surimi were significantly (p < 0.05) decreased by irradiation with different doses. Irradiation significantly (p < 0.05) inhibited the increase of putrescine (PUT), cadaverine (CAD), histamine (HIM), and tyramine (TYM) contents during storage. However, these parameters were significantly (p < 0.05) increased with storage time. After irradiation, the samples generally had higher lightness and lower a * and b * values and lower hardness and chewiness significantly (p < 0.05). Based on the sensory analysis, unfavorable ‘metal odor’ or ‘irradiated odor’ was observed in surimi irradiated at 5 and 7 kGy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Grass carp (Ctenopharyngodon idellus) is one of the most economically important species of cultured fish, and the amount of its product in China was approximately 4.08 million tons, constituting 21.4 % of the total freshwater-farmed fish annual output (Chu et al. 2010). Fish surimi is a high-protein and low-fat food that has a unique texture and taste. It is also a value-added food produced from low-cost fish (Venugopal and Shahidi 1995). Like all fish products, surimi is susceptible to microbial spoilage and autolytic degradation (Teixeira et al. 2014). Currently, frozen storage is commonly used to reduce spoilage and biochemical degradation. However, undesirable changes in color, flavor, and texture may occur during frozen storage (Osako et al. 2005). Therefore, surimi requires appropriate preservation approaches to extend its shelf-life. Additionally, the consumer preference for minimally processed and additive-free foods has triggered the development of novel processing and preservation methods, i.e., E-beam irradiation.

E-beam is a non-thermal physical technology that inactivates microorganisms and enzymes by radiation. The advantages of E-beam include no chemical residues and short processing times (Li et al. 2015). Additionally, E-beam irradiation uses electricity, as opposed to radioisotopes (60Co or 137Cs) to generate ionizing energy. Therefore, E-beam is a controllable food processing application. Nonetheless, the application of E-beam irradiation in food is restricted in food due to its limited penetration capability (Farkas and Mohacsi-Farkas 2011). To broaden the application of E-beam in food industry, 10-MeV electron linear accelerator has been commonly utilized. A 10-MeV electron linear accelerator (power >10 kW) can penetrate deeper into food products than a 5-MeV electron linear accelerator, making it a suitable processing method for high-density food products.

Many studies reported that E-beam irradiation has the potential to prolong the shelf-life of fishery product without affecting the edible quality and nutritional value (Medina et al. 2009). E-beam irradiation suppresses the formation of biogenic amines in fresh trout stored at 3.5 °C (Krizek et al. 2012) and does not significantly affect the color of fresh salmon fillet (Yagiz et al. 2010). At low-dose irradiation levels, E-beam can reduce the number of pathogenic bacteria (Arvanitoyannis et al. 2009). Additionally, vacuum packaging is widely used in food preservation because it inhibits oxidation. Low-dose irradiation combined with vacuum packaging extends the shelf-life and maintains the quality of Atlantic salmon fillets (Yang et al. 2014a, b). Therefore, E-beam combined with vacuum packaging can potentially extend the shelf-life of surimi.

The effects of E-beam irradiation on the microbial inactivation in surimi (Jaczynski and Park 2003) and on the texture characteristics, 2-thiobarbituric acid value, and total volatile basic nitrogen content in Alaska Pollock surimi have been reported (Jaczynski and Park 2004). However, the shelf-life of irradiated and vacuum-packaged grass carp surimi has not been documented. This study evaluated the effects of E-beam irradiation combined with vacuum packaging on the shelf-life, microbial activity, biogenic amine content, chemical parameters, texture, color, and sensory characteristics of grass carp surimi during storage at 4 °C.

Materials and Methods

Fish Sample and Surimi Preparation

A total of 12 fresh grass carps (12 fish, 15 kg) were purchased from a local market (Century Mart, Hangzhou, China). The grass carps were de-gutted, peeled, eviscerated, washed with deionized water, and minced. The surimi paste was homogenized for 2 min with 20 g/kg salt. Proximate composition analyses of fish samples were carried out by the following AOAC methods (AOAC 2005). The compositions of surimi were 77.92 ± 0.21 % moisture, 17.76 ± 0.39 % protein, 0.21 ± 0.02 % carbohydrates, 0.8 ± 0.39 % fat, and 1.23 ± 0.02 % ash. Subsequently, a number of 360 samples were transferred into 360 polyvinylidene chloride dishes (1 cm thick and 3.5 cm diameter) and individually vacuum-packaged in 120 polythene bags (9.3 mL O2/m2/24 h at 0 °C) (Yang et al. 2014a, b) and stored at 4 °C prior to irradiation treatment.

E-Beam Treatment

The samples were transported in dry ice to an E-beam facility located in Shanghai Academy of Agricultural Sciences within 2 h. The samples were subjected to E-beam irradiation at the dosage of 0 (control), 1, 3, 5, and 7 kGy at ambient temperature using a 10-Mev electron linear accelerator (ESS-010-03, IHI Co., Tokyo, Japan). For the determination of the actual absorbed dose, one dosimeter was attached to the surface and another was attached to the bottom of each sample prior to irradiation. Based on the dosimeter data, the actual doses absorbed by the samples were determined to be 0 (control), 1.13, 3.26, 5.87, and 7.68 kGy. After irradiation, all surimi samples were transported in dry ice back to the laboratory. The E-beam-treated samples were stored at 4 °C for 0, 3, 6, 9, and 12 days prior to analyses. All treatments were performed in triplicate.

Biogenic Amine Analysis

Eight biogenic amines (BAs), i.e., putrescine (PUT), cadaverine (CAD), histamine (HIM), spermine (SPM), spermidine (SPD), tyramine (TYM), tryptamine (TRM), and phenylethylamine (PHM), were analyzed using a Waters Nova-pack C18 column (Ozogul et al. 2002) with internal standard. Irradiated surimi (2 g) was homogenized with 20 mL hydrochloric acid solution (0.1 mol/L) containing 0.2 % TDPA, centrifuged at 10,000g for 10 min at 4 °C, and subjected to derivatization with dabsyl chloride (Ozogul et al. 2002). Chromatographic separation was performed using a gradient elution of ammonium acetate (0.1 mol L−1, solvent A) and acetonitrile (100 %, solvent B) (min/%A: 0/50, 25–35/10, 35–45/10, 45–60/50). Flow rate was 0.9 mL/min. The column temperature and detection wavelength were 30 °C and 254 nm, respectively. BA standards (phenylethylamine, tryptamine, putrescine, cadaverine, histamine, tyramine, spermidine, spermine) were purchased from Hitachi Limited (Tokyo, Japan). All experiences were performed in triplicate.

Total Volatile Basic Nitrogen Analysis

Total volatile basic nitrogen (TVB-N) was measured by the micro-diffusion method (Antonacopoulos and Vyncke 1989; Santos et al. 2013). Irradiated surimi (5 g) was homogenized with 250 mL deionized water. Three drops of methyl silicone oil and 2 g of magnesium oxide were added. A steam distillation process was performed in a Micro-Kjeldahl unit. The resulting distillate was titrated with 0.05 M HCl. TVB-N was expressed as milligrams of nitrogen per 100 g of E-beam-treated surimi:

Thiobarbituric Acid Reactive Substances

Thiobarbituric acid reactive substances (TBARS) were determined by the method reported by Gomes et al. (2003). A pink complex forms when two thiobarbituric acid (TBA) molecules react with one malondialdehyde (MDA) molecule. Absorbance was measured at 535 nm. TBARS were expressed as milligrams of MDA per kilogram of sample.

Microbiological Analysis

Total viable count (TVC) was determined by the pour plate method (Goulas and Kontominas 2007). Surimi sample (5 g) was transferred aseptically to a sterile bag and homogenized with 45 mL of sterile 0.85 % NaCl solution for 120 s in a BagMixer (400VW, Interscience, Bretèche, France). The homogenized sample was serially diluted (1:10); 1 mL of each dilution (10−3, 10−4, 10−5) was spread on a plate count agar, which was incubated at 30 °C for 72 h. TVC was determined by counting the colony-forming units.

Textural Profile Analysis

Textural profile analysis (TPA) was performed on a Textual Analyzer (TA-XT2i, Scientific, Measuring systems, Middlesex, UK) coupled with a probe (SMS-P/5) (Kudre and Benjakul 2014). The parameters included a speed of 3 mm/s, a compression range of 5 mm, and a compression time interval of 5 s. The collected data was analyzed by Textual Expert Exceed version 1.22. Prior to TPA, the samples were placed at ambient temperature for 1 h. Each sample was analyzed for six times

Color Evaluation

Whiteness was determined in a HunterLab (CM-400d, Konica Minolta, Tokyo, Japan). L * (lightness), a * (redness/greenness), and b * (yellowness/blueness) parameters were measured. Whiteness was calculated by the following equation,

Sensory Analysis

Sensory analysis was carried out as reported by Manju et al. (2007). An aliquot of 10 g of each sample was boiled for 15 min and cooled down to ambient temperature for sensory analysis by five highly trained panelists. Sensory testing was conducted in the sensory laboratory equipped with a round table for training sessions in the morning (10.00–12.00). Panelists scored for color, odor, flavor, general acceptability, and texture using a nine-point hedonic scale (1, dislike extremely to 9, like extremely). A sensory score of 5 represented the borderline of acceptability. All testings were performed in triplicate.

Statistical Analyses

All experiments were performed in triplicate. Data were expressed as mean ± standard deviation (SD) and analyzed by one-way analysis of variance (ANOVA) using SPSS 19.0. Statistical significance was set to p < 0.05.

Results and Discussion

BAs

BAs, which are produced by the action of microbial and endogenous amino acid decarboxylase enzymes, may cause adverse health problems in consumers. Eight BAs were evaluated in this study (Table 1). Most BAs were significantly (p < 0.05) affected by E-beam treatment and storage time. Irradiation at 1, 3, 5, and 7 kGy significantly (p < 0.05) decreased PUT, CAD, HIM, and TYM contents. On the other hand, SPM, SPD, and TRM contents were not significantly affected by E-beam treatment (p > 0.05). Phenylalanine (PHE) was not detected in either the control or irradiated samples at 0 day. After 3 days of storage, the PHE contents of surimi samples irradiated at 5 and 7 kGy were 0.11 ± 0.05 mg/100 g and 0.17 ± 0.03 mg/100 g, respectively; however, PHE was not detected in samples irradiated at 0, 1, or 3 kGy. On the other hand, during storage, total BA content significantly (p < 0.05) increased with time. The total BA content of the control samples increased from 6.68 ± 1.19 mg/100 g (day 0) to 58.15 ± 7.58 mg/100 g (day 12). In the irradiated surimi samples, the maximum total BA content was 15.75 ± 1.35 mg/100 g at 1 kGy and the minimum total BA content was 10.35 ± 1.66 mg/100 g at 7 kGy.

At the beginning of storage, CAD and SPM were the major BAs (62 % of the total amount of BAs) in the control samples. During storage, PUT and HIM rapidly increased. At the end of storage, PUT, CAD, HIM, and TYM were the major BAs in both the control (>90%) and the irradiation-treated samples (>60%). Zhang et al. (2013) also reported that PUT, CAD, and TYM were the main BAs in silver carp sausage during storage. Similar results have been reported in black carp muscle (Fan et al. 2014).

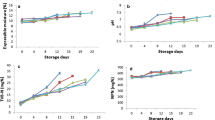

HIM and TYM are toxic compounds. The maximum tolerance level of HIM is 100–200 mg/kg in different fish species in the European Union (Mohamed et al. 2009). In China, the maximum recommended level of 300 mg/kg for HIM has been established in fish (Wang et al. 2015); however, no specific legislation exists in China regarding surimi. PUT and CAD are considered to be potentially toxic to consumers (Shalaby 1996). HIM, TYM, PUT, and CAD contents in the irradiated group were significantly lower than those in the control group, which could be attributed to the synthesis of free radicals, which affect the structure (Ozden et al. 2007; Ozogul and Ozden 2013) and activity of microbial enzymes (Fig. 1). The results revealed that irradiation (1, 3, 5, and 7 kGy) inhibited BA formation during storage. Similarly, Krizek et al. (2012) reported that trout flesh subjected to E-beam and vacuum packing had lower PUT, CAD, and TYM contents than the non-irradiated samples.

TVC

As shown in Fig. 1, TVC decreased with irradiation in a dose-dependent manner. On day 0, the TVC of the control group was 5.12 log CFU/g. After treatment with 1, 3, 5, and 7 kGy E-beam irradiation, the TVC decreased to 3.46, 2.79, 1.27, and 0.63 log CFU/g, respectively. The control samples had a TVC of 7.23 log CFU/g after 3 days of storage, which was higher than the recommended acceptable limit for fish products (7 log CFU/g) (Chouliara et al. 2005). However, TVC of irradiated surimi samples was <7 log CFU/g. After 9 days of storage, TVC of the 1 kGy-irradiated surimi sample reached 7.32 log CFU/g. After 12 days of storage, TVC increased to 9.62 log CFU/g in the control sample, 8.32 log CFU/g in 1-kGy, 6.73 log CFU/g in 3-kGy, 4.48 log CFU/g in 5-kGy, and 2.27 log CFU/g in 7-kGy irradiated samples. The results revealed that irradiation combined with vacuum packaging is effective for the inhibition of microbial growth. Previous studies have reported that E-beam irradiation at 2 kGy was effective in decreasing TVC below 3 log CFU/g in chicken after 14 days of storage at 4 °C (Adu-Gyamfi et al. 2008). TVC in minced meat prepared from pork and beef was significantly reduced by irradiation and vacuum packaging (Farkas and Andrássy 1993).

TVB-N

TVB-N is an indicator of the degree of spoilage in fish products and mainly results from bacterial growth and endogenous enzymes (Fan et al. 2009). TVB-N values of 5–20 mg N per 100 g are indicative of good quality, whereas values of 30–35 mg N/100 g are generally regarded as the limit of acceptability (Papadopoulos et al. 2003). At day 3 of storage (Table 2), TVB-N decreased significantly in the irradiation group. The initial TVB-N value in the control group was 14.80 mg/100 g. After 12 days of storage, TVB-N was 41.44 mg/100 g in the control sample, 30.03 mg/100 g in 1-kGy, 26.15 mg/100 g in 3-kGy, 20.72 mg/100 g in 5-kGy, and 21.36 mg/100 g in 7-kGy irradiated samples. After 12 days of storage, TVB-N of surimi sample was significantly high in both control and irradiated groups. TVB-N formation in surimi can be significantly decreased (p < 0.05), which may be due to inhibition of microbial counts and enzyme activity caused by irradiation and vacuum packaging. Moreover, the low temperature decreased the capacity of bacteria for oxidative deamination of nonprotein nitrogen compounds (Banks et al. 1980). The inhibition of TVB-N formation was also observed in salmon fillet (Yang et al. 2014a, b).

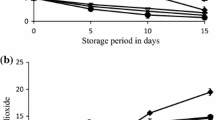

TBARS

There was a dose-dependent and significant increase in TBARS in all samples during storage (Table 2). Different from the TVC and TVB-N results, higher levels of TBARS were obtained in irradiated than in control samples. The initial TBARS value (in mg MDA equivalents/kg) was 0.24 in the control sample, 0.34 in 1-kGy, 0.39 in 3-kGy, 0.36 in 5-Gky, and 0.37 mg in 7-Gky irradiated samples. At the end of storage, the control group had 0.46 mg MDA equivalents/kg versus 0.54 mg MDA equivalents/kg in the irradiation group. This can be caused by lipid oxidation induced by hydroxyl radicals generated by ionizing irradiation and the formation of carbonyls, decomposition of peroxides, and the interaction compounds with nucleophilic molecules (Aubourg et al. 2004). Similarly, Hocaoglu et al. (2012) reported that shrimp irradiated with 1, 3, and 5 kGy had higher TBARS than the control sample; after a 3-day storage period, TBARS of the control sample increased from 1.21 mg/kg to 7.28 mg per kg. Park et al. (2010) observed that TBARS of beef sausages irradiated at 5, 10, and 15 kGy were higher than those of the control group.

TPA and Color Attributes

Texture is an important attribute of grass carp surimi quality. There were significant differences (p < 0.05) in hardness and chewiness between the irradiated and control groups; however, there were no significant differences (p > 0.05) in springiness, cohesiveness, and adhesiveness until day 3 of storage (Table 3). Hardness and chewiness were significantly (p < 0.05) lower in the irradiated group than in the control group (Table 4). During storage, hardness, springiness, and chewiness decreased, probably due to protein degradation and muscle firmness reduction (Xu et al. 2014).

L *(lightness), a *(redness/greenness), b *(yellowness/blueness), and whiteness of the control and irradiated surimi samples are shown in Table 2. With increasing irradiation dose, L * and whiteness increased; however, the increase in whiteness was not significant up to 3 kGy. During storage, L * and whiteness decreased in all samples (p < 0.05). L * and whiteness in the irradiated samples were higher than those of the control samples after 12 days of storage. However, a * and b * were lower in the irradiated samples than in the control samples. Moreover, during storage, b * increased (p < 0.05) in all samples concomitant with the reduction in L * and whiteness. This phenomenon might be attributed to protein degradation and/or lipid oxidation and the formation of Maillard reaction products of yellowish brown color (Riebroy et al. 2007).

Sensory Evaluation

Sensory analysis was based on appearance, texture, odor, and flavor. Samples were deemed acceptable if they had scores >5 (Manju et al. 2007). In general, the scores decreased in both the control and irradiated sample, during the storage period. Initially, the control and irradiated samples had sensory scores in the range of 6.6–8 (data not shown), which gradually decreased to 1–5.4 on day 12 of storage. The increase in TVC, TBARS, and TVB-N may explain the decreasing trend in sensory scores. Even though the initial sensory scores of surimi irradiated with 5 and 7 kGy were 7 and 6.6, respectively, they were still considered unacceptable because of the presence of ‘irradiated odor’ or ‘metal odor.’ Cabeza et al. (2009) reported that sausages irradiated with 1 kGy reached higher sensory scores than those treated with 2 and 3 kGy.

Conclusion

In conclusion, the combination of E-beam irradiation and vacuum packaging has a positive effect on the shelf-life of grass carp surimi stored at 4 °C. E-beam irradiation could effectively inhibit the microbial growth in grass carp surimi with no obvious deterioration in its biochemical characteristics. By irradiation, the shelf-life of vacuum-packed surimi was prolonged from less than 3 days to 12 days. Based on the biochemical and sensory analysis, a dosage of 3 kGy was proposed to be optimum for maintaining the edible quality of grass carp surimi using the 10-MeV electron linear accelerator.

References

Adu-Gyamfi, A., Nketsia-Tabiri, J., & Bah, F. A. (2008). Radiosensitivities of bacterial isolates on minced chicken and poached chicken meal and their elimination following irradiation and chilled storage. Radiation Physics and Chemistry, 77(2), 174–178.

Antonacopoulos, N., & Vyncke, W. (1989). Determination of volatile basic nitrogen in fish: a third collaborative study by the West European Fish Technologists’ Association (WEFTA). Zeitschrift für Lebensmittel-Untersuchung und -Forschung, 189(4), 309–316.

AOAC. (2005). Official methods of analysis (18th ed.). Washington DC: Association of Official Analytical Chemists.

Arvanitoyannis, I. S., Stratakos, A., & Mente, E. (2009). Impact of irradiation on fish and seafood shelf life: a comprehensive review of applications and irradiation detection. Critical Reviews in Food Science and Nutrition, 49(1), 68–112.

Aubourg, S. P., Perez-Alonso, F., & Gallardo, J. M. (2004). Studies on rancidity inhibition in frozen horse mackerel (Trachurus trachurus) by citric and ascorbic acids. European Journal of Lipid Science and Technology, 106(4), 232–240.

Banks, H., Nickelson, R., & Finne, G. (1980). Shelf-life studies on carbon-dioxide packaged finfish from the Gulf of Mexico. Journal of Food Science, 45(2), 157–162.

Cabeza, M. C., de la Hoz, L., Velasco, R., Cambero, M. I., & Ordonez, J. A. (2009). Safety and quality of ready-to-eat dry fermented sausages subjected to E-beam radiation. Meat Science, 83(2), 320–327.

Chouliara, I., Sawaidis, L. N., Riganakos, K., & Kontominas, M. G. (2005). Shelf-life extension of vacuum-packaged sea bream (Sparus aurata) fillets by combined gamma-irradiation and refrigeration: microbiological, chemical and sensory changes. Journal of the Science of Food and Agriculture, 85(5), 779–784.

Chu, P. J., Wu, S. Y., Chen, K. C., He, J. L., Yerokhin, A., & Matthews, A. (2010). Nano-structured TiO2 films by plasma electrolytic oxidation combined with chemical and thermal post-treatments of titanium, for dye-sensitised solar cell applications. Thin Solid Films, 519(5), 1723–1728.

Fan, W., Sun, J., Chen, Y., Qiu, J., Zhang, Y., & Chi, Y. (2009). Effects of chitosan coating on quality and shelf life of silver carp during frozen storage. Food Chemistry, 115(1), 66–70.

Fan, H. B., Luo, Y. K., Yin, X. F., Bao, Y. L., & Feng, L. G. (2014). Biogenic amine and quality changes in lightly salt- and sugar-salted black carp (Mylopharyngodon piceus) fillets stored at 4 degrees C. Food Chemistry, 159, 20–28.

Farkas, J., & Andrássy, É. (1993). Interaction of ionising radiation and acidulants on the growth of the microflora of a vacuum-packaged chilled meat product. International Journal of Food Microbiology, 19(2), 145–152.

Farkas, J., & Mohacsi-Farkas, C. (2011). History and future of food irradiation. Trends in Food Science & Technology, 22(2–3), 121–126.

Gomes, H. D. A., da Silva, E. N., do Nascimento, M. R. L., & Fukuma, H. T. (2003). Evaluation of the 2-thiobarbituric acid method for the measurement of lipid oxidation in mechanically deboned gamma irradiated chicken meat. Food Chemistry, 80(3), 433–437.

Goulas, A. E., & Kontominas, M. G. (2007). Combined effect of light salting, modified atmosphere packaging and oregano essential oil on the shelf-life of sea bream (Sparus aurata): biochemical and sensory attributes. Food Chemistry, 100(1), 287–296.

Hocaoglu, A., Demirci, A. S., Gumus, T., & Demirci, M. (2012). Effects of gamma irradiation on chemical, microbial quality and shelf life of shrimp. Radiation Physics and Chemistry, 81(12), 1923–1929.

Jaczynski, J., & Park, J. W. (2003). Microbial inactivation and electron penetration in surimi seafood during electron beam processing. Journal of Food Science, 68(5), 1788–1792.

Jaczynski, J., & Park, J. W. (2004). Physicochemical changes in Alaska pollock surimi and surimi gel as affected by electron beam. Journal of Food Science, 69(1), C53–C57.

Krizek, M., Matejkova, K., Vacha, F., & Dadakova, E. (2012). Effect of low-dose irradiation on biogenic amines formation in vacuum-packed trout flesh (Oncorhynchus mykiss). Food Chemistry, 132(1), 367–372.

Kudre, T. G., & Benjakul, S. (2014). Effects of bambara groundnut protein isolates and microbial transglutaminase on textural and sensorial properties of surimi gel from sardine (Sardinella albella). Food and Bioprocess Technology, 7(6), 1570–1580.

Li, S. L., Kundu, D., & Holley, R. A. (2015). Use of lactic acid with electron beam irradiation for control of Escherichia coli O157:H7, non-O157 VTEC E-coli, and Salmonella serovars on fresh and frozen beef. Food Microbiology, 46, 34–39.

Manju, S., Jose, L., Gopal, T. K. S., Ravishankar, C. N., & Lalitha, K. V. (2007). Effects of sodium acetate dip treatment and vacuum-packaging on chemical, microbiological, textural and sensory changes of Pearlspot (Etroplus suratensis) during chill storage. Food Chemistry, 102(1), 27–35.

Medina, M., Cabeza, M. C., Bravo, D., Cambero, I., Montiel, R., Ordonez, J. A., Nunez, M., & Hoz, L. (2009). A comparison between E-beam irradiation and high pressure treatment for cold-smoked salmon sanitation: microbiological aspects. Food Microbiology, 26(2), 224–227.

Mohamed, R., Livia, S. S., Hassan, S., Soher, E. S., & Ahmed-Adel, E. B. (2009). Changes in free amino acids and biogenic amines of Egyptian salted-fermented fish (Feseekh) during ripening and storage. Food Chemistry, 115(2), 635–638.

Osako, K., Hossain, M. A., Kuwahara, K., & Nozaki, Y. (2005). Effect of trehalose on the gel-forming ability, state of water and myofibril denaturation of horse mackerel Trachurus japonicus surimi during frozen storage. Fisheries Science, 71(2), 367–373.

Ozden, O., Inugur, M., & Erkan, N. (2007). Preservation of iced refrigerated sea bream (Sparus aurata) by irradiation: microbiological, chemical and sensory attributes. European Food Research and Technology, 225(5–6), 797–805.

Ozogul, F., & Ozden, O. (2013). The effects of gamma irradiation on the biogenic amine formation in sea bream stored in ice. Food and Bioprocess Technology, 6(5), 1343–1349.

Ozogul, F., Taylor, K. D. A., Quantick, P., & Ozogul, Y. (2002). Biogenic amines formation in Atlantic herring (Clupea harengus) stored under modified atmosphere packaging using a rapid HPLC method. International Journal of Food Science and Technology, 37(5), 515–522.

Papadopoulos, V., Chouliara, I., Badeka, A., Savvaidis, I. N., & Kontominas, M. G. (2003). Effect of gutting on microbiological, chemical, and sensory properties of aquacultured sea bass (Dicentrarchus labrax) stored in ice. Food Microbiology, 20(4), 411–420.

Park, J. G., Yoon, Y., Park, J. N., Han, I. J., Song, B. S., Kim, J. H., Kim, W. G., Hwang, H. J., Han, S. B., & Lee, J. W. (2010). Effects of gamma irradiation and electron beam irradiation on quality, sensory, and bacterial populations in beef sausage patties. Meat Science, 85(2), 368–372.

Riebroy, S., Benjakul, S., Visessanguan, W., Tanaka, M., Erikson, U., & Rustad, T. (2007). Effect of irradiation on properties and storage stability of Som-fug produced from bigeye snapper. Food Chemistry, 103(2), 274–286.

Santos, J., Lisboa, F., Pestana, N., Casal, S., Alves, M. R., & Oliveira, M. (2013). Shelf life assessment of modified atmosphere packaged turbot (Psetta maxima) fillets: evaluation of microbial, physical and chemical quality parameters. Food and Bioprocess Technology, 6(10), 2630–2639.

Shalaby, A. R. (1996). Significance of biogenic amines to food safety and human health. Food Research International, 29(7), 675–690.

Teixeira, B., Marques, A., Mendes, R., Goncalves, A., Fidalgo, L., Oliveira, M., Saraiva, J. A., & Nunes, M. L. (2014). Effects of high-pressure processing on the quality of sea bass (Dicentrarchus labrax) fillets during refrigerated storage. Food and Bioprocess Technology, 7(5), 1333–1343.

Venugopal, V., & Shahidi, F. (1995). Value-added products from underutilized fish species. Critical Reviews in Food Science and Nutrition, 35(5), 431–453.

Wang, Y. L., Li, F., Zhuang, H., Chen, X., Li, L. H., Qiao, W. W., & Zhang, J. H. (2015). Effects of plant polyphenols and alpha-tocopherol on lipid oxidation, residual nitrites, biogenic amines, and N-nitrosamines formation during ripening and storage of dry-cured bacon. LWT--Food Science and Technology, 60(1), 199–206.

Xu, G. C., Tang, X., Tang, S. H., You, H. B., Shi, H. W., & Gu, R. B. (2014). Combined effect of electrolyzed oxidizing water and chitosan on the microbiological, physicochemical, and sensory attributes of American shad (Alosa sapidissima) during refrigerated storage. Food Control, 46, 397–402.

Yagiz, Y., Kristinsson, H. G., Balaban, M. O., Welt, B. A., Raghavan, S., & Marshall, M. R. (2010). Correlation between astaxanthin amount and a* value in fresh Atlantic salmon (Salmo salar) muscle during different irradiation doses. Food Chemistry, 120(1), 121–127.

Yang, Z., Wang, H. Y., Wang, W., Qi, W. Y., Yue, L., & Ye, Q. F. (2014a). Effect of 10 MeV E-beam irradiation combined with vacuum-packaging on the shelf life of Atlantic salmon fillets during storage at 4 degrees C. Food Chemistry, 145, 535–541.

Yang, Z., Wang, W., Wang, H. Y., & Ye, Q. F. (2014b). Effects of a highly resistant rice starch and pre-incubation temperatures on the physicochemical properties of surimi gel from grass carp (Ctenopharyn Odon Idellus). Food Chemistry, 145, 212–219.

Zhang, Q. L., Lin, S. L., & Nie, X. H. (2013). Reduction of biogenic amine accumulation in silver carp sausage by an amine-negative Lactobacillus plantarum. Food Control, 32(2), 496–500.

Acknowledgments

This study was supported by the National High Technology Research and Development Projects 863 (2011AA100804), Ministry of Agriculture of China National Natural Science Foundation (201103007), and National Science and Technology Support Program (2014BAA03B00).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Hf., Wang, W., Zhang, Sf. et al. Influence of 10-MeV E-Beam Irradiation and Vacuum Packaging on the Shelf-Life of Grass Carp Surimi. Food Bioprocess Technol 9, 830–838 (2016). https://doi.org/10.1007/s11947-016-1675-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1675-4