Abstract

The impact of high hydrostatic pressure (HP) treatment on protein aggregation and rheological properties of legume batters has been investigated. Gelatinisation/pasting and gelling profiles, rheological parameters and protein solubility of HP-hydrated chickpea (CP), green pea (GP) and soybean (SB) flours were determined. CP, GP and SB hydrated flours, at dough yield (DY) 160 and 200, were treated for 10 min at 0.1, 200, 350 or 450 MPa. Pressures of ≥350 MPa downward shifts gelatinisation temperatures in CP and GP regardless the hydration level. For all legume batters, HP provokes changes on the rheology of hydrated samples, particularly in softer batters (DY 200), leading to an increased stiff/solid character. Analysis of proteins extracted in different buffers revealed that pressures of >200 MPa induced the formation of urea-insoluble complexes, disulphide bonds and/or other strong protein aggregates. Although the extent of protein modification was dependent on the applied pressure, the results collected so far show that high HP can be used to improve the breadmaking functionality of CP, GP and SB batters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of high hydrostatic pressure (HP) treatment in food processing and preservation has been investigated over the two past decades as an alternative to the traditional heat treatment. Beside this, HP treatment offers advantages to create novel foods, textures and tastes through structural changes induced on food biopolymers—starch and proteins (Pal Kaur et al. 2012). Impact of HP treatment on starch is mainly on gelatinisation and gelling phenomena (Kim et al. 2012), while the pressure-induced changes in structure and functionality of proteins regard several modifications on protein aggregation/disaggregation (Heremans and Smeller 1998). HP treatment has pronounced effect on the folded–unfolded equilibrium of proteins, on the weakening of electrostatic and hydrophobic interactions and on the thiol/disulphide exchange reactions (Funtenberger et al. 1997). Consequently, upon treatment with HP, protein denaturation, aggregation or gelation usually occur, depending on the protein system, the applied pressure, the solution conditions and the intensity and duration of the pressure treatment (Galazka et al. 2000). It has been reported that HP treatment may represent a new frontier for improving dough machinability of oat, millet and sorghum with high nutritional value but poor breadmaking performance (Angioloni and Collar 2012a). In particular, HP changed flour viscometric features leading to increased values for viscosity parameters, concerning pasting and paste cooking and provided increased dynamic moduli values (Angioloni and Collar 2012b). HP also represents a viable strategy to perform value added mixed breads by using substantial amounts of non-wheat cereals (oat, millet and sorghum) with higher nutritional profile. HP composite breads deserved better sensory scores and exhibited higher antiradical activities despite a reduction in specific volume (wheat and oat) and faster staling kinetics (millet and sorghum) were observed (Angioloni and Collar 2012c). HP seems to promote dough structure rearrangements in wheat, oat, millet and sorghum, presumably by altering the folding/unfolding and aggregation/disaggregation equilibrium of proteins. As well, over the last decade, special emphasis has been placed on the effect of HP in gluten-free systems—starches and flours (Hüttner et al. 2009; Vallons et al. 2010; Vallons et al. 2011; Vallons and Arendt 2009).

Legumes occupy an important place in human nutrition, particularly in those countries in which the consumption of animal protein is limited (Boye et al. 2010). With protein contents double that of other cereal crops, legumes are an economical, environmentally sustainable protein source with low starch bioavailability and high-resistant starch content, to potentially improve the nutritional value of breads, bakery products and pastas (Patterson et al. 2010) in line with the current suitable dietary trends (Jones 2009). Incorporation of high levels of legumes into bakery products without any structuring agent is cost-effective and nutritionally advantageous although technologically very challenging. The absence of gluten proteins to meet dough viscoelastic and fermentative restrictions has generally constrained the incorporation of substantial quantities of non-wheat cereals (Angioloni and Collar 2012a; Brites et al. 2010) and legumes (Angioloni and Collar 2012d) into wheat dough matrices to achieve nutritional and healthy effects. Associated mixtures of legumes-wheat-structuring agents appear as an efficient strategy to make highly nutritious breads in terms of promoted dietary fibre fractions, lower and slower starch hydrolysis and decreased rapidly digestible starch and reduced expected glycaemic index. In addition, viscoelastic restrictions and sensory standards could be met (Angioloni and Collar 2012d).

Despite HP achievements in promoting dough structure formation of cereal-based systems are recently described, there is no information in the available literature about the impact of HP on legumes.

The purpose of this study was to explore the impact of HP treatment on protein aggregation and rheological properties of CP, GP and SB batters prepared at two different levels of hydration in view of their possible breadmaking application in highly replaced wheat matrices.

Materials and Methods

Materials

Commercial flours from chickpea (CP), green split pea flour roasted (GP) and defatted soybean flour (SB) were purchased from Trades (Spain). Moisture, protein, ash and fat contents of commercial flours were determined following the ICC (1976–1996) Standard methods 110/1, 105/2, 104/1 and 136, respectively. Soluble, insoluble and total fibre contents were determined according to the AOAC (1992) method 991.43 (Table 1). Two replicates were made for each flour analysis. Digestible carbohydrates were calculated by difference.

HP Treatment of Flours

Hydrated flours were prepared by mixing flour and tap water at a flour-water ratio of 1:0.6 (w/w; dough yield (DY) 160) and 1:1 (w/w; DY 200). Design factors (quantitative independent factors) were tested at four levels for HP (0, 0.1 MPa; 1, 200 MPa; 2, 350 MPa; and 3, 450 MPa) and at two levels for hydration (0, DY 160 and 1, DY 200). HP treatment procedure (Angioloni and Collar 2012b) are detailed as it follows. Hydrated flours were packed in polyethylene bags (200 × 300 mm), minimising the amount of air entrapped. Packed samples were put into a vacuum bag and vacuum-packed (MULTIVAC Thermosealer) two more times to prevent contact between pressurisation fluid and sample. Then, samples were transferred to the pressure treatment chamber (high-pressure food processor EPSI, MA). The pressurisation liquid used was a mixture of water/ethylene glycol (70:30, v/v). The pressure level, pressurisation time and temperature were controlled automatically. After 2 min approximately, the desired pressure was reached and the time course started. The samples were treated for 10 min at 20 °C under pressures of 200, 350 or 450 MPa. Pressure was increased at a rate of 150 MPa/min, maintained at the desired pressure for 10 min and released at a rate of 150 MPa/min. The temperature of the vessel of the pressure unit was thermostatically controlled at 20 °C throughout treatment. Due to compressive heating, increases in the temperature of the processing fluid by up to a maximum of 8 °C at 450 MPa were observed. Increases in the temperature of the processing fluid were transient and the set temperature ±1 °C was re-attained within 2 min of the start of treatment. Untreated samples were used as controls.

Viscometric Properties

Pasting profiles (gelatinisation, pasting, and setback properties) of freeze-dried hydrated untreated and pressure treated hydrated flours were obtained with a Rapid Visco Analyser (RVA-4, Newport Scientific, Warriewood, Australia) using ICC Standard method 162. The pasting temperature (in degree Celsius; when viscosity first increases by at least 25 cP over a 20-s period), peak time (when peak viscosity occurred), peak viscosity (maximum hot paste viscosity), holding strength or trough viscosity (minimum hot paste viscosity), breakdown (peak viscosity minus holding strength or trough viscosity), viscosity at 95 °C, viscosity at the end of the 95 °C holding period, viscosity at 50 °C, final viscosity (end of test after cooling to 50 °C and holding at this temperature), setback (final viscosity minus peak viscosity) and total setback (final viscosity minus holding strength) were calculated from the pasting curve (Fig. 1) using Thermocline v. 2.2 software (Collar 2003). For each viscometric measurement, three replicates were made.

Creep Test

Creep tests were performed at 22 °C on untreated and pressure-treated samples by using a RS1-controlled stress rheometer equipped with a Phoenix II circulating bath (Haake, Karlsruhe, Germany) using a 60-mm serrated plate-plate geometry with a 1-mm gap between plates. The upper plate was lowered and the excess of sample was trimmed off. The exposed surface was covered with a thin layer of mineral oil to prevent moisture loss during testing. Samples were rested for 5 min after loading prior to testing, to allow sample relaxation. The stresses used for the measurements (from 5 to 20 Pa, within the region of linear viscoelasticity), were applied for 180 s, sufficient for the sample to reach steady-state flow as determined by the instrument software. The creep curves of samples exhibited a typical viscoelastic behaviour combining both viscous fluid and elastic components (Steffe 1992). Creep data, in terms of creep compliance, were fitted to a Burgers model using the following equation:

where J 0 is the instantaneous compliance, J m is the viscoelastic compliance, λ is the mean retardation time and η 0 is the zero shear viscosity (Fig. 2).

Stickiness

Stickiness of untreated and pressure treated samples was measured using a TA-XTplus texture analyser (Stable Microsystems, Surrey, UK) using a Chen and Hoseney cell (Armero and Collar 1997). Dough stickiness values given are the means of five determinations.

Protein Analysis

Water- and salt-soluble proteins were extracted by using phosphate buffer containing 0.05 M NaH2PO4 and 0.1 M NaCl, pH 7.0 (buffer P). Urea-soluble proteins were extracted using buffer P with the addition of 6 M urea (buffer U). Finally, disulfide bonds were reduced by adding 0.1 M dithiothreitol (DTT) to the buffer U (buffer D). Proteins were extracted from 50 mg of freeze-dried dough dissolved in 1 ml of each buffer as previously described by Alamprese et al. (2005). Samples were incubated at 25 °C for 3.5 h under stirring. After centrifugation at 12,000×g for 1 h, the amount of extracted proteins present in the supernatants was determined according to Bradford protocol (Kruger (2002), using bovine serum albumin as standard.

Statistical Analysis

Univariate ANOVA and multivariate MANOVA analysis of data (mean comparison of samples; LSD) were performed by using Statgraphics V.7.1 program (Bitstream, Cambridge, MN).

Results and Discussion

A physicochemical approach was adopted to assess the effectiveness of HP treatment and DY on the viscoelastic structure of legume batters. Viscometric profile, dynamic and static rheological behaviour, and protein aggregation/disaggregation were measured to quantify significant differences among samples. Assuming that the effects provoked by HP treatment and DY on batter physicochemical properties may be masked, data were statistically processed separately for each legume.

Viscometric Profile of Untreated and Pressure-Treated Samples

HP treatment could change pasting and gelling behaviour of starch matrices. The mechanism of pressure induced gelatinisation is comparable to that of heat-induced gelatinisation, nevertheless slight modifications in the degradation (or disintegration) of starch granules have been reported (Kim et al. 2012). Infiltration of water into the crystalline and amorphous regions of granules leads to irreversible swelling and gelatinisation of starch granules. Subsequently, internal regions of starch granules partially gelatinise below gelatinisation onset temperatures induced from heat treatment, and granular forms of starch remains intact even after HP. On the contrary, heat-induced gelatinisation process solubilises amylose and amylopectin molecules (composing a continuous phase) and granule remnants (composing dispersed phases), both of which are responsible for the rheological and textural properties of the starch paste (Kim et al. 2012).

RVA profiles for untreated and pressure-treated batters exhibited some significant qualitative and quantitative differences (Fig. 1), according to the legume considered. The limited amount of starch present in soybean samples (Table 1) does not permit a regular RVA profile development (data not shown). RVA curves showed a dissimilar shape and a large interval of reached viscosities (from 100 cP for SB to 2,800 cP for GP), basically depending on the nature of the legumes considered. With no exception, GP batters develop higher viscometric profiles during pasting and gelling than CP batters provide (Fig. 1). During cooking cycle, mean values for viscosity of GP vs. CP were: peak viscosity (2,267 vs. 1,701 cP), holding strength (1,984 vs. 1,603 cP) and breakdown (284 vs. 98 cP). During cooling cycle, gelling characteristics (mean values) of GP vs. CP ranged from 809 to 400 cP (total setback), from 2,440 to 1,846 cP (viscosity at 50 °C) and from 2,793 to 2,003 cP (final viscosity), respectively. DY significantly affect cooking parameters, specifically breakdown (CP) and peak viscosity and holding strength (GP) (Table 2). The higher the hydration level of batters (DY 200), the lower the breakdown (36 % of reduction), and the higher the peak viscosity (11 % of increase) and holding strength (7 % of increase). Besides, HP treatment at 450 MPa significantly reduced the pasting temperature of GP batters by 6 % (Table 2). Regardless the hydration level, HP treatment at pressures of ≥350 MPa provoked an earlier pasting in chickpea and green pea samples. Pasting temperature decreases from 79 °C for untreated (0.1 MPa) to 75 °C for pressure-treated (450 MPa) chickpea samples and from 79 °C for untreated (0.1 MPa) to 72 °C for pressure-treated (450 MPa) green pea samples. Unlikely heat-induced gelatinisation, pressure-induced gelatinisation undergoes incomplete disintegration of crystalline regions within starch granules. Consequently, downward shifts in gelatinisation temperatures are often observed in HP-treated starch granules (Kim et al. 2012).

Fundamental and Empirical Rheological Properties of Untreated and Pressure-Treated Samples

Multifactor analysis of variance on creep and stickiness data allowed determining the quantitative single and 2nd order interactive effects of HP and DY on rheological parameters for chickpea, green pea and soybean batters. Significant single effects of HP and DY on relevant empirical and fundamental rheological properties of legume batters are reported in Table 3.

Instantaneous compliance (J 0), zero shear viscosity (η 0) and retardation time (λ), parameters that directly and/or indirectly assess batter stiffness/thickness characteristics, respectively showed important decrease (from 50 (soybean) to more than 95 % (green pea)) and rise (from 79 (green pea) to 94 % (soybean) and from 28 (green pea) to 58 % (soybean)) associated to the increase of pressure intensity.

Changes in the bond length, the hydration and the cavities that result from the imperfect packing in the protein interior may be expected, according to Heremans and Smeller (1998). If the pressure is high enough, cooperative changes in the secondary structure may result, an effect known as plastic or conformational effect. Pressure-induced denaturation/unfolding of the molecule are irreversible rather than reversible as observed by fluorescence techniques (Heremans and Smeller 1998). Regarding batter stickiness, the effect of HP was significant only for chickpea and green pea batters. Although all the samples gave values under 46 g (Table 3) defined as non-sticky (<100 g force) according to Chen and Hoseny (1995), HP treatment significantly reduced the stickiness values from 40 (0.1 MPa) to 28 g (450 MPa) in chickpea and from 46 (0.1 MPa) to 19 g (450 MPa) in green pea samples. The impact of DY on the batter rheological properties was smaller than that of HP treatment. The higher the hydration level, the higher the J 0 and J m (chickpea and green pea), the lower the η 0 (chickpea and soybean) and the higher the stickiness (chickpea and green pea), suggesting the role of water as a lubricant for the conformational flexibility of proteins (Heremans and Smeller 1998). As expected, HP treatment modified the rheological profile of samples enhancing the solid character of the batters, while DY increases the viscous part. These results are in good agreement to those found by Angioloni and Collar (2012b) for cereals with poor breadmaking performance (oat, millet and sorghum).

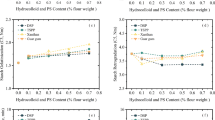

Combination of HP/DY led to variable interactive effects, which level of significance depends on the legume flour considered. Significant selected second order interactions of design factors on fundamental rheological properties are reported in Fig. 3. In general, HP treatment promotes batter structure formation only in samples prepared at DY 200. An increase in retardation time was observed for chickpea and soybean, while a big drop in instantaneous compliance and a growth in zero shear viscosity were measured in green pea batters; these phenomena were mainly evident at pressures of ≥350 MPa. On the basis of these statements, obtained results may support that the strengthening effect promoted by HP treatments on legume hydrated flours are in general achievable for pressures of ≥350 MPa. In addition, the plasticising effect of water on proteins and starch seems to play an important role (Matveeva et al. 2000).

Significant second order interactions of design factors (HP × DY) on the rheological properties of legume batters. Bars with a common capital letter are not significantly different (p < 0.05). High hydrostatic pressure (HP) levels—0 (0.1 MPa), 1 (200 MPa), 2 (350 MPa) and 3 (450 MPa); dough yield (DY) levels—0 (DY 160) and 1 (DY 200). a Chickpea. b Soybean. c Green pea. d Green pea

Impact of HP on Legumes Protein Aggregation

The effect of HP on legume proteins aggregation was studied and results related to rheological tests. Legumes incorporation into baked goods production required either the use of external structuring agents (Angioloni and Collar 2012d) or an internal rearrangement of the natural biopolymers of the matrix, especially proteins. To mimic the properties of gluten, the creation of new bond (e.g. disulphide bonds) favouring the protein network formation was recently shown to improve the baking performance of gluten-free flours (Renzetti et al. 2008).

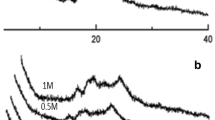

CP, GP and SB were extracted according to their solubility in different buffers (P, U and D), and the protein concentration was measured (Fig. 4). To understand the impact of HP and DY on legume proteins, proteins extracted from untreated batters (0.1 MPa) were compared with those extracted from pressure-treated batters at increasing pressures (200, 350, and 450 MPa). Overall, minor to null differences were observed in protein solubility between samples prepared at DY 160 and DY 200. The hydration level does not affect the concentration of extracted proteins regardless both the applied pressure and the legume considered. Unlike phosphate buffer extractability for small amounts of CP, GP and SB proteins, addition of urea considerably increased the amount of extracted proteins. As well, with the exception of soybean samples, no further significant increase was observed when DTT was added to the buffer U (Fig. 4). Data suggest the absence of quantifiable reticulation of CP and GP proteins by inter-protein covalent/disulphide bonds, as previously reported for rice, buckwheat, corn, oat, sorghum, quinoa and teff flours (Berti et al. 2004; Hüttner et al. 2009; Renzetti et al. 2008). Conversely, in SB pressure-treated samples the large amount of proteins extracted by reducing buffer (D) probably indicates stronger protein rearrangements after HP treatment. Formation of inter and intra protein covalent bonds and new links with others flour components can be established. HP treatment significantly reduced the amount of water and salt-soluble proteins extracted in phosphate buffer, particularly for CP (DY 200) and GP (DY 160) batters (Fig. 4). The degree of reduction depends much more on the nature of the legume considered than on the level of applied pressure. Reduced protein solubility in phosphate buffer suggests the creation of new non-covalent bonds, according to the results reported by Alamprese et al. (2005) for fresh egg pasta and by Hüttner et al. (2009) for oat batters. Regardless the type of legume, treatment at 450 MPa also produced a significant decrease in the amount of proteins extracted by urea-containing buffer. Aggregation, gelation, and/or interaction with other proteins or other flour components might be responsible for the reduced solubility. Application of HP leads to a direct modification of the prosthetic group-protein interaction via the pressure induced changes of the respective interatomic distances (Köhler et al. 1998). Molecular interactions strongly depend on distance. The case of charged groups, the ion–ion, the ion dipole, the dipole–ion, the dipole–dipole, the dipole-induced dipole and the dispersion interaction play concomitant roles. Overall, these results indicate that HP treatment of chickpea, green pea and soybean batters induced the formation of urea-insoluble aggregates. It has been described that the primary structure of proteins remains intact on HP treatment while hydrogen bonds, which stabilise the secondary structure, are enhanced at low/intermediate pressures and ruptured only at very high pressures. Significant changes in the tertiary structure of proteins, which is maintained chiefly by hydrophobic and ionic interactions, are observed at pressures of >200 MPa (Funtenberger et al. 1997). Although legume proteins, soybean included, are generally low in methionine, cysteine and tryptophan (Boye et al. 2010), it seems that disulphide bonds were formed in SB pressure-treated samples (Fig. 4). Assuming that formation of disulphide bonds occurred, achieved results indicate that HP may have promising effects on promoting structure formation of legume flours. Neither DY nor pressure treatment intensity induce changes in the amount of soybean proteins extracted in buffer D supporting that low pressures (>200 MPa) are sufficient to promote protein aggregation.

Conclusions

HP treatment appears as an efficient strategy to modify the viscoelastic properties of chickpea, green pea and soybean batters; depending on the pressure applied and hydration level, different properties/improvements can be achieved. Changes in starch and proteins induced by HP contribute to the overall improvement of the legume batters rheological properties, in terms of reduced stickiness and instantaneous compliance and increased zero shear viscosity and retardation time. The formation of protein networks induced by HP might in part explain the increase of the solid character observed in pressure-treated samples. This suggest the viability of HP treatment as an alternative to hydrocolloids/gluten for the structure rearrangement of legume batters and consequently for their incorporation, in high amount, in breadmaking systems.

References

Alamprese, C., Lametti, S., Rossi, M., & Bergonzi, D. (2005). Role of pasteurisation heat treatments on rheological and protein structural characteristics of fresh egg pasta. European Food Research and Technology, 221, 759–767.

Angioloni, A., Collar, C. (2012a). Suitability of oat, millet and sorghum in breadmaking. Food and Bioprocess Technology, doi:10.1007/s11947-012-0786-9

Angioloni, A., & Collar, C. (2012b). Promoting dough viscoelastic structure in composite cereal matrices by high hydrostatic pressure. Journal of Food Engineering, 111, 598–615.

Angioloni, A., & Collar, C. (2012c). Effects of pressure treatment of hydrated oat, finger millet and sorghum flours on the quality and nutritional properties of composite wheat breads. Journal of Cereal Science, 56, 713–719.

Angioloni, A., & Collar, C. (2012d). High legume-wheat matrices: an alternative to promote bread nutritional value meeting dough viscoelastic restrictions. European Food Research and Technology, 234, 273–284.

AOAC. (1992). Total, soluble, and insoluble dietary fiber in foods. Enzymatic-gravimetric method, MES-TRIS buffer. Official Methods of Analysis of the Association of Official Analytical Chemist, 15th ed., 3rd suppl (pp. 136–138). Arlington: Association.

Armero, E., & Collar, C. (1997). Texture properties of formulated wheat doughs. Relationships with dough and bread technological quality. Zeitschrift für Lebensmittel-Untersuchung und -Forschung A, 204, 136–145.

Berti, C., Ballabio, C., Restani, P., Porrini, M., Bonomi, F., & Lametti, S. (2004). Immunochemical and molecular properties of proteins in Chenopodium quinoa. Cereal Chemistry, 81, 275–277.

Boye, J., Zare, F., & Pletch, A. (2010). Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Research International, 43, 414–431.

Brites, C., Trigo, M. J., Santos, C., Collar, C., & Rosell, C. M. (2010). Bread from maize and composite maize-rye-wheat flour (Broa): influence of several production parameters on sensory and instrumental quality. Food and Bioprocess Technology, 3(5), 707–715.

Chen, W. Z., & Hoseny, R. C. (1995). Development of an objective method for dough. 5 stickiness. Lebensmittel-Wissenschaft und Technologie, 28, 467–473.

Collar, C. (2003). Significance of viscosity profile of pasted and gelled formulated wheat doughs on bread staling. European Food Research and Technology, 216, 505–513.

Funtenberger, S., Dumay, E., & Cheftel, J. C. (1997). High pressure promotes b-lactoglobulin aggregation through SH/S-S interchange reactions. Journal of Agriculture and Food Chemistry, 45, 912–921.

Galazka, V. B., Dickinson, E., & Ledward, D. A. (2000). Influence of high pressure processing on protein solutions and emulsions. Current Opinion in Colloid & Interface Science, 5(3–4), 182–187.

Heremans, K., & Smeller, L. (1998). Protein structure and dynamics at high pressure. Biochimica et Biophysica Acta, 1386, 353–370.

Hüttner, E. K., Dal Bello, F., Poutanen, K., & Arendt, E. K. (2009). Fundamental evaluation of the impact of high hydrostatic pressure on oat batters. Journal of Cereal Science, 49, 363–370.

ICC (1976–1996). Standard Methods of the International Association for Cereal Science and Technology 104/1, 105/2, 110/1, 136, 162. The Association: Vienna.

Jones, J. M. (2009). Nutrition: more on the GI debate. Cereal Foods World, 54(3), 138–140.

Kim, H. S., Kim, B. Y., & Baik, M. Y. (2012). Application of ultra high pressure (UHP) in starch chemistry. Critical Reviews in Food Science and Nutrition, 52, 123–141.

Köhler, M., Friedrich, J., & Fidy, J. (1998). Proteins in electric fields and pressure fields: basic aspects. Biochimica et Biophysica Acta, 1386, 255–288.

Kruger, N. J. (2002). The Bradford method for protein quantitation. In J. M. Walker (Ed.), The protein protocols handbook. Totowa: Humana Press Inc.

Matveeva, Y. I., Grinberga, Y. V., & Tolstoguzov, V. B. (2000). The plasticizing effect of water on proteins, polysaccharides and their mixtures. Glassy state of biopolymers, food and seeds. Food Hydrocolloids, 14(5), 425–437.

Pal Kaur, B., Kaushik, N., Srinivasa Rao, P. (2012). Effect of High-pressure processing on physical, biochemical, and microbiological characteristics of black tiger shrimp (Penaeus monodon). Food and Bioprocess Technology, doi:10.1007/s11947-012-0870-1, in press.

Patterson, C. A., Maskus, H., & Bassett, C. M. C. (2010). Fortifying foods with pulses. Cereal Foods World, 55(2), 56–62.

Renzetti, S., Dal Bello, F., & Arendt, E. K. (2008). Microstructure, fundamental rheology and baking characteristics of batters and breads from different gluten-free flours treated with a microbial transglutaminase. Journal of Cereal Science, 48, 33–45.

Steffe, J. F. (1992). Rheological methods in food process engineering. East Lansing: Freeman Press.

Vallons, K. J. R., & Arendt, E. K. (2009). Effects of high pressure and temperature on the structural and rheological properties of sorghum starch. Innovative Food Science & Emerging Technologies, 10, 449–456.

Vallons, K. J. R., Ryan, L. A. M., Koehler, P., & Arendt, E. K. (2010). High pressure-treated sorghum flour as a functional ingredient in the production of sorghum bread. European Food Research and Technology, 231, 711–717.

Vallons, K. J. R., Ryan, L. A. M., & Arendt, E. K. (2011). Promoting structure formation by high pressure in gluten-free flours. LWT-Food Science and Technology, 44, 1672–1680.

Acknowledgements

The authors thank the financial support of the Spanish Institutions Consejo Superior de Investigaciones Científicas (CSIC) and Ministerio de Economía y Competitividad (Project AGL2011-22669).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Angioloni, A., Collar, C. Impact of High Hydrostatic Pressure on Protein Aggregation and Rheological Properties of Legume Batters. Food Bioprocess Technol 6, 3576–3584 (2013). https://doi.org/10.1007/s11947-012-1020-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1020-5