Abstract

In this study, the application of high-pressure processing of sorghum batters was investigated in order to evaluate the potential of pressure-treated sorghum as a gluten replacement in the production of sorghum breads. For this purpose, sorghum batters were treated at pressures from 200 to 600 MPa at 20 °C, and the microstructure was investigated using scanning electron microscopy. Furthermore, the rheological properties of the control and pressure-treated batters were determined. The results revealed weakening of the batter structure at pressures ≤300 MPa. Addition of a blocker of free thiol groups indicated that protein depolymerization played a role in this strength decrease. At pressures >300 MPa, the batter consistency increased, mainly due to pressure-induced gelatinization of starch. Furthermore, freeze-dried sorghum batters treated at 200 MPa (weakest batter) and at 600 MPa (strongest batter) were added to a sorghum bread recipe, replacing 2 and 10% of untreated sorghum flour. The results showed a delayed staling for breads containing 2% of sorghum treated at 600 MPa. However, adding 10% resulted in a low specific volume and poor bread quality. The quality of breads containing different amounts of sorghum treated at 200 MPa was not significantly different from the control bread.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Celiac disease is an inflammatory disorder of the upper small intestine triggered by the ingestion of certain wheat proteins and related proteins in rye and barley [1]. At present, the only effective treatment is a permanent withdrawal of gluten from the diet. Sorghum is often recommended as a safe food for celiac patients and provides a good basis for gluten-free breads and other baked product. Furthermore, sorghum is one of the most drought-tolerant cereals and with an increasing world population and decreasing water supplies, and it represents an important crop for future use [2]. The use of gluten-free flours, such as sorghum, in the development of leavened breads is technologically difficult, as their proteins do not possess the viscoelastic properties typically found in gluten. When kneading/mixing wheat flour with water, gluten proteins enable the formation of cohesive viscoelastic dough that is capable of holding gas produced during fermentation and oven-rise, resulting in the typical fixed open foam structure of wheat bread after baking [3]. To improve the texture, mouth-feel, acceptability and shelf-life of gluten-free breads, their production requires polymeric substances that mimic the viscoelastic properties of gluten in bread, such as starches [4], dairy ingredients [5], hydrocolloids [6] and enzymes [7–9]. In addition, there is a growing interest in physical modification of cereal flours using innovative processing techniques. High-pressure processing has been identified as a potential area for food texture engineering [10]. High-pressure treatment alters the structure of biopolymers such as proteins and starch, providing the possibility to produce foods with novel textures. Therefore, pressure treatment of gluten-free cereal products may represent a valuable alternative to improve baking performance of gluten-free cereals. Ahmed et al. [11] studied the effect of pressure treatment of basmati rice slurries and found gelatinization of starch and denaturation of proteins and pointed out the important role played by the combination of starch and proteins in the pressure-induced changes in basmati rice slurries. Bárcenas et al. [12] reported that yeasted wheat dough treated in the range of 50–200 MPa resulted in breads with different appearance and technological character and suggested that high pressure could be an alternative technique for obtaining novel textured cereal-based products. Furthermore, it has been shown that high-pressure treatment has the potential to improve the functionality of gluten-free flours such as buckwheat, white rice, teff and oat batters in terms of baking performance [13, 14]. Hüttner et al. [15] observed positive effects on bread quality when 10–40% of untreated oat flour was replaced by oat batter treated at 200 MPa.

The objectives of this work were to determine the effect of different pressure levels on the microstructural and rheological characteristics of batters from sorghum flour. To the best of our knowledge, this is the first study reporting pressure-induced effects on these batters. Furthermore, the impact of freeze-dried pressure-treated sorghum batters at different addition levels on the quality characteristics of sorghum breads was studied.

Experimental

Materials

The sorghum flour (tan plant, white grained variety) used in this study was obtained from Twin Valley Mills, LLC, Ruskin, Nebraska, USA. Flour suspensions (40% w/w) were mixed with a Glutomatic (Perten instruments), using tap water or a 1 g/L N-ethylmaleimide solution (NEM, obtained from Sigma–Aldrich).

High-pressure treatment

Flour suspensions (40% w/w) were vacuum-packed in polyethylene bags (100 × 150 mm; Miller Pack Ltd., Finglas, Dublin 11, Ireland). Packed samples were vacuum-packed two more times to prevent contact between pressurization fluid and the suspension. The pressure treatment was performed using a Stansted Fluid Power Iso-lab 900 High Pressure Food Processor (Stansted Fluid Power, Stansted, Essex, UK) as described by Huppertz et al. [16]. The samples were treated at 200, 300, 400, 500 or 600 MPa. Pressure was increased at a rate of 300 MPa/min, maintained at the desired pressure for 10 min and released at a rate of 300 MPa/min. The temperature of the vessel of the pressure unit was thermostatically controlled at 20 °C throughout treatment. Due to compressive heating, increase in the temperature of the processing fluid by up to a maximum of 40 °C at 600 MPa was observed; increase in the temperature of the processing fluid was transient, and the set temperature ±1 °C was reattained at the end of the treatment. Untreated samples were used as control.

Scanning electron microscopy

Freeze-dried samples were mounted on aluminium stubs (Agar Scientific Ltd., England) covered with double-sided carbon tape (Agar Scientific Ltd., England) and sputter-coated with gold in a vacuum evaporator (E5175 Large Chamber “Cool” sputter Coater, Quorum Technologies Ltd, UK). Prepared samples were viewed in a JEOL 5510 scanning electron microscope (JEOL, Tokyo, Japan) at 3–5 kV using 10-mm working distance.

Rheological measurements

The rheological measurements of the control and pressure-treated samples were carried out immediately after the pressure treatment using a rotational rheometer (Physica MCR 301, Anton Paar GmbH, Stuttgart, Germany) using a parallel plate geometry (50 mm diameter). The temperature, initially set at 30 °C, was regulated by a circulating water bath and a peltier heating system. After loading, the sample was trimmed and left to rest for 5 min. The tests performed on the samples were as follows:

-

(1)

An amplitude sweeps (strain = 0.001–100%) at a constant frequency (10 Hz) and temperature (30 °C) to determine the limits of the linear viscoelastic range (data not shown).

-

(2)

A frequency sweep (ω = 50–1 Hz) at a constant deformation and temperature (30 °C) within the linear viscoelastic range. The storage modulus (G′), the loss modulus (G″), the complex modulus (G *) and the damping factor (tanδ) were monitored. Each test was performed at least in triplicate.

-

(3)

A temperature sweep at a constant deformation (within the linear viscoelastic range) and a constant frequency (10 Hz). For this test, the sample perimeter was covered with a thin layer of petroleum jelly to prevent dehydration. After equilibration at the initial temperature (30 °C) for 5 min, the samples were heated at a rate of 7.8 °C/min to the final temperature of 95 °C. After a holding time of 5 min at this temperature, the samples were cooled at a rate of 7.8 °C/min to the initial temperature at which they were held for another 5 min. Data were collected every 10 s and the complex modulus (G *) was monitored, resulting in a pasting profile. Changes in G * of the suspensions were evaluated in terms of onset (T o) and peak (T p) temperatures. Furthermore, onset (\( G_{\text{o}}^{*} \)) and peak (\( G_{\text{p}}^{*} \)) complex moduli were extracted from the pasting profiles. The holding strength (HS) was determined as the complex modulus at the end of the holding phase at 95 °C. The cold paste consistency (CPC) was determined as the final complex modulus at the end of the holding phase at 30 °C. Each test was performed at least in triplicate.

Bread making

For bread production, pressure-treated sorghum flour suspensions were freeze-dried and ground (using a mortar) to pass a 1-mm sieve. The control formulation consisted of 100 parts flour, 110 parts water, 2 parts of salt (Salt Union, West Point, UK), 1.5 parts of sugar (Siucra, Carlow, Ireland) and 2 parts of dried baker’s yeast (Pante, Puratos, Groot-Bijgaarden, Belgium). The amount of flour was interpreted as flour weight basis. For the baking trials with pressure-treated flour, 2 or 10% of sorghum flour was replaced by flour pre-treated with 200 or 600 MPa for 10 min. For bread production, dried baker’s yeast was dissolved in a solution of water and sugar at 30 °C and pre-fermented in a proofer (Koma BV, Roermond, The Netherlands) at 30 °C and 85% rh for 10 min. The remaining dry ingredients were placed in a Kenwood mixing bowl (Chef Classic KM 336, Kenwood, Hampshire, UK). The pre-fermented yeast was added to the dry ingredients before mixing. Mixing was performed with a paddle tool (K beater) for 2 min at slow/medium speed (level 2 out of 6). After 30 s of mixing, the mixing was stopped and the mixing bowl was scraped. The batters were scaled to 90 g into pup loaf baking tins (190 mL volume; 3.5 cm height; 4.5 × 9 cm bottom; 5.5 × 10 cm top) and proofed at 30 °C and 85% rh for 30 min. Baking was performed at 220 °C top and 230 °C bottom heat for 20 min in a deck oven (MIWE, Arnstein, Germany). The oven was pre-injected with steam (0.3 L of water) and after loading, the oven was steamed again with 0.7 L of water. After baking, the loaves were depanned and cooled for 90 min on cooling racks at room temperature. All baking trials were done in triplicate. Six loaves were prepared for each trial.

Bread evaluation

Standard baking tests were conducted on three loaves for each bread type: control breads, breads containing 1, 2 and 10% of flour treated at 200 MPa and breads containing 1, 2 and 10% of flour treated at 600 MPa. The remaining 3 loaves were packed as previously described by Nunes et al. [5] for further analysis after 72 h of storage. Loaves were weighed, and loaf volume was measured by rape seed displacement. Loaf specific volume (mL/g) and bake loss (%) were calculated. Subsequently, breads were sliced using a slice regulator to obtain uniform slices of 20-mm thickness. Texture profile analysis (TPA) of the crumb was performed on three slices taken from the centre of the loaves after 2 h and additionally after 72 h of storage. TPA was performed using a universal testing machine TA-XT2I (Stable Microsystems, Surrey, UK) equipped with a 25-kg load cell and a 10-mm aluminium cylindrical probe. Pre-test speed, test speed and post-test speed were 2 mm/s, trigger force was 20 g, distance was 5 mm (25% compression) and wait time between first and second compression cycle was 5 s. TPA crumb hardness, adhesiveness, cohesiveness and chewiness were extracted from the curves. All measurements were repeated in triplicate for each bread type.

Statistical analysis

In order to assess the differences between samples at different measurement points, a two-sided t-test for independent samples (Statistica 7.0 StatSoft, Inc., USA) with a significance level of 0.05 was used.

Results

Visual appearance and microstructure of untreated and pressure-treated sorghum flour suspensions

Treatment of sorghum batters at high pressure clearly affected the visual appearance of the sorghum batters. The untreated as well as the batters treated at 200 and 300 MPa were cake-batter-like. At higher pressures, the batters became more solid. Effects of high pressure on sorghum batters were investigated using SEM. The micrographs of untreated batter and batter treated at different pressures are shown in Fig. 1. No differences between the untreated, the 200 MPa-treated and the 300 MPa-treated samples were visible. Treatment with pressures ≥400 MPa resulted in microstructural changes. The starch granules became swollen and deformed; however, even after treatment with 600 MPa, their granular structure remained intact.

Rheological properties of untreated and pressure-treated sorghum flour suspensions

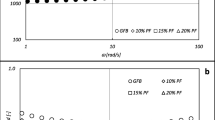

Frequency sweep experiments (curves not shown) performed under dynamic conditions (i.e. in the linear viscoelastic range) showed that at all pressures, the G′ was higher than G″ (results not shown), in the whole range of frequencies (50–1 Hz). G′, the storage modulus, is a measure of the solid or elastic character of the material and G″, the loss modulus, a measure of its liquid or viscous character. In order to visualize the differences in the viscoelastic properties, tanδ (G″/G′) and G * ((G′2 + G″2)1/2) were calculated. G * and tanδ of all flour–water suspensions at different pressures at 7.84 Hz frequency are summarized in Fig. 2. Two different rheological responses of the sorghum flour suspensions to the applied pressure were observed. When the treatment was performed at pressures up to 300 MPa, the structure weakened, as indicated by a significant decrease in G * and a significant increase in tanδ. The weakest batter structure was obtained for samples treated at 200 MPa, with a maximal G * of 0.34 MPa and a minimal tanδ of 0.209. However, batters treated at pressures above 300 MPa became more and more elastic (decreasing tanδ), which led to a significantly increased resistance to deformation (increasing G *) at pressures ≥400 MPa.

Whether pressure-induced thiol-disulphide interchange reactions in the sorghum proteins play a role in the rheological changes has been studied by the addition of NEM to the flour–water suspensions. NEM blocks initially free thiol groups, inhibiting the pressure-induced polymer formation by disulphide bonds [17]. The effects of NEM addition on the rheological properties of control and pressurized batters are shown in Fig. 2. Adding NEM to the batter before treatment did not significantly change the rheological properties. However, the results showed that samples without free thiol groups respond differently to the pressure treatments. No significant weakening of the structure at low pressures was observed for NEM-containing samples, and no significant differences were found between the rheological parameters of the untreated samples and the suspensions treated at 200 MPa. At pressures above 300 MPa, a batter strengthening effect was observed, similar to the samples without NEM. Although a significantly higher consistency was obtained for the NEM-containing samples after treatment with 500 MPa compared to the batters without NEM, the extent of strengthening after treatment with 600 MPa was the same for both the NEM-containing and pure water suspensions.

Pasting profiles of untreated and pressure-treated sorghum flour suspensions

The pasting profiles of untreated sorghum flour–water suspensions and suspensions treated at 200 and 600 MPa determined by temperature sweeps are shown in Fig. 3. Statistical analysis of all pasting parameters was also performed and is summarized in Table 1. The onset and peak temperatures (T o and T p, resp.) of the pasting profiles were determined as the temperatures at which the suspension consistency starts to increase and reaches a maximum, respectively. The thermal profile of the sorghum flour treated at 600 MPa did not show an increase in consistency during the heating phase (Fig. 3). Therefore, pasting temperatures could not be determined, and complete pressure-induced gelatinization was assumed. Treatment of the flour suspension at 200 MPa resulted in a significantly lower onset consistency (\( G_{\text{o}}^{*} \)), while the peak consistency (\( G_{\text{p}}^{*} \)) was significantly higher compared to the control. However, pasting temperatures were not significantly influenced by the treatment at 200 MPa (Table 1). Upon further heating above T p and during the holding phase at 95 °C, a decrease in consistency due to disintegration of swollen starch granules and shear thinning [18] was observed (Fig. 3). The holding strength, determined as the consistency at the end of the holding phase at 95 °C, significantly increased with increasing treatment pressure. Contrarily, the cold paste consistency (CPC, the complex modulus at the end of the cooling phase) significantly decreased with increasing severity of the pressure treatment, with CPC of 196.67 MPa, 148.67 MPa and 100.85 MPa for the control samples and suspensions pressurized at 200 and 600 MPa, respectively.

Bread analysis

Bread analysis revealed that replacing 2 or 10% of the sorghum flour by freeze-dried sorghum suspensions treated at 200 MPa did not significantly change the specific loaf volume and bake loss compared to the control breads (Table 2). Incorporation of 10% of sorghum flour treated at 600 MPa resulted in reduced bread quality with significantly lower specific volume, while no differences were observed in bake loss. Furthermore, breads containing 2% of the 600 MPa-treated flour appeared similar to the control breads. After 2 h of cooling, no significant differences in crumb hardness were observed for all the breads containing pressure-treated flour compared to the control breads (Table 2). However, after the 72-h storage period, crumb hardness values of breads containing 600 MPa-treated sorghum flour showed significant differences depending on the addition level: the increase in hardness was significantly lower for breads containing 2%, while the breads containing 10% showed a significantly higher staling rate. The staling rates of breads containing different amounts of sorghum flour treated at 200 MPa were not significantly different compared to the control (Table 2).

Discussion

The use of gluten-free flours in the development of breads is technologically difficult, as their proteins do not possess the viscoelastic properties typically found in gluten. Consequently, gluten-free batters lack the ability to retain gas and produce a light baked product. The aim of the present study was to determine the effect of high pressure on the rheological properties of sorghum flour–water suspensions and to investigate the potential of freeze-dried pressure-treated sorghum batters as gluten substitute at different addition levels. Frequency sweep analysis revealed two separate rheological responses of sorghum batters to the applied pressure. When the treatment was performed at pressures ≤300 MPa, the increase in the viscous component of the batters was more pronounced and the structure weakened (as shown by the increase in tanδ and a decrease in G *, Fig. 2). Contrarily, treatment at higher pressures (>300 MPa) resulted in a strengthening of the batters as they became more and more elastic. Similar rheological changes caused by high pressures were observed by Hüttner et al. [13] for oat batters and by Vallons et al. [14] for teff batters. It was suggested that the overall rheological response can be explained by modification in the flour major components starch and protein [13]. Vallons and Arendt [19] previously reported that pressure treatment induces gelatinization of sorghum starch between 300 and 600 MPa. Due to swelling of granules and leaching of amylose, the complex viscosity of the sorghum starch suspension increased [19]. Therefore, gelatinization of starch granules is most likely the factor responsible for the increase in sorghum batter strength at pressures above 300 MPa observed in this study. However, pressure treatment also changes the structure and functional properties of proteins, as previously reviewed by Winter [20]. The sensitivity of protein structure to pressure is mostly due to the modification of non-covalent interactions as well as of disulphide bonds [17]. According to Funtenberger et al. [21], thiol/disulphide interchange reactions occurred via the nucleophilic attack of a disulphide bond by the ionized S−-form of a thiol group. Therefore, blocking free thiol groups by NEM inhibits the thiol/disulphide interchange reactions occurring in proteins upon pressurization. Kieffer et al. [22] previously observed for wheat gluten that if no free thiol groups are present, no effect of high pressure can be found. The frequency sweep results (Fig. 2) showed that blocking free thiol groups had little effect on the batter structural strength at higher pressures, confirming starch gelatinization as the main strengthening factor. However, the weakening at pressures ≤300 MPa did not occur when NEM was added to the suspension, indicating that thiol/disulphide interchange reactions in sorghum proteins play an important role in the decreased strength. Decreased gluten strength at low pressures was previously observed by Kieffer et al. [22], and depolymerization of protein by cleavage of disulphide bonds was given as a possible cause. Overall, it can be concluded that at 200 MPa, batters with the lowest consistency are obtained, probably due to depolymerization of disulphide bonds, while at 600 MPa, the strongest batters were obtained, mainly due to pressure-induced gelatinization of starch. Therefore, these two pressures were selected for further rheological testing and for the baking trials.

Pasting profiles of the sorghum flour–water suspensions (Fig. 3) confirmed complete pressure-induced gelatinization of starch after treatment with 600 MPa, as no increase in consistency was observed for these samples upon subsequent pasting [19, 23]. The potential of pre-gelatinized starch or flour as gluten substitute was previously reported [4, 24–27]. Defloor et al. [4] observed improved crumb structure, improved gas holding capacity and decreased staling rate when extruded starch was incorporated (12–15%) in breads from cassava. They stated that the effect of the pre-gelatinized material is due to an increase in viscosity of the fermenting batter, resulting in an increase of the critical buoyant size of the gas cells. The results of this study showed a lower staling for sorghum breads containing 2% of sorghum treated at 600 MPa. However, adding 10% resulted in a low specific volume and consequently poor bread quality.

Treatment at 200 MPa does not cause gelatinization of sorghum starch [19]. However, the pasting profiles of the samples treated at 200 MPa were significantly different from the profile of the untreated samples. Treatment of the flour suspension at 200 MPa resulted in a significantly lower \( G_{\text{o}}^{*} \), while \( G_{\text{p}}^{*} \) was significantly higher compared to the control. These results can be explained by protein depolymerization occurring at low pressures. As discussed before, treatment at 200 MPa resulted in batter weakening, causing a lower \( G_{\text{o}}^{*} \). In addition, disintegration of protein aggregates at 200 MPa would allow for more extensive swelling of the starch granules upon subsequent pasting, resulting in higher \( G_{\text{e}}^{*} \) [27]. Previously, sorghum breads of superior quality were obtained with sourdough addition, and the improvements were related to protein degradation and the formation of stronger starch gels upon baking [28]. In addition, Hüttner et al. [15] observed improved bread volume and decreased staling rate of oat breads containing oat batter treated at 200 MPa. However, in this study, no differences were observed between the control breads and the breads containing different addition levels of sorghum treated at 200 MPa (Table 2). Thus, batter weakening due to treatment at 200 MPa did not improve the functionality of sorghum flour, and the positive effects of pressure-induced protein weakening on oat breads previously described by Huttner et al. [15] were not observed.

Overall, the results of this study suggest that pressure treatment has the potential to delay staling in gluten-free products. Breads in this study were prepared without hydrocolloids (to avoid a synergetic effect). Therefore, further studies are required to look at the effect of pressure-treated sorghum addition on larger size breads and to investigate possible beneficial effects when hydrocolloids are included.

References

Catassi C, Fasano A (2008) Celiac disease. In: Arendt EK, Dal Bello F (eds) Gluten-free cereal products and beverages. Elsevier Press, UK

Taylor JNR, Schober TJ, Bean SR (2006) Novel food and non-food uses for sorghum and millets. J Cereal Sci 44:252–271

Arendt EK, Moririssey A, Moore MM, Dal Bello F (2008) Gluten-free breads. In: Arendt EK, Dal Bello F (eds) Gluten-free cereal products and beverages. Elsevier Press, UK

Defloor I, De Geest C, Schellekens M, Martens A, Delcour JA (1991) Emulsifiers and/or extruded starch in the production of breads from cassava. Cereal Chem 68:323–327

Nunes MHB, Ryan LAM, Arendt EK (2009) Effect of low lactose dairy powder addition on the properties of gluten-free batters and bread quality. Eur Food Res Technol 229:31–41

Lazaridou A, Duta D, Papageaorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J Food Eng 79:1033–1047

Moore MM, Heinboeckel M, Ulmer HM, Arendt EK (2006) Network formation in gluten-free breads with application of transglutaminase. Cereal Chem 83:26–36

Renzetti S, Dal Bello F, Arendt EK (2008) Microstructure, fundamental rheology and baking characteristics of batters and breads form different gluten-free flours treated with a microbial transglutaminase. J Cereal Sci 48:33–45

Renzetti S, Arendt EK (2009) Effects of oxidase and protease treatments on the breadmaking functionality of a range of gluten-free flours. Eur Food Res Technol 229:301–317

Michel M, Autio K (2001) Effects of high pressure on protein- and polysaccharide-based structures. In: Hendrickx MEG, Knorr D (eds) Ultra high pressure treatments of foods. Kluwer Academic/Plenum Publishers, New York

Ahmed J, Ramaswamy HS, Ayad A, Alli I, Alvarez P (2007) Effect of high-pressure treatment on rheological, thermal and structural changes in Basmati rice flour slurry. J Cereal Sci 46:148–156

Bárcenas ME, Altamirano-Fortoul R, Rosell CM (2010) Effect of high pressure processing on wheat dough and bread characteristics. LWT, Food Sci Technol 43:12–19

Hüttner EK, Dal Bello F, Poutanen K, Arendt EK (2009) Fundamental evaluation of the impact of high hydrostatic pressure on oat batters. J Cereal Sci 49:363–370

Vallons KJR, Ryan LAM, Arendt EK (in press) Promoting structure formation by high pressure in gluten-free flours. LWT, Food Sci Technol

Hüttner EK, Dal Bello F, Arendt EK (2010) Fundamental study on the effect of hydrostatic pressure treatment on the bread-making performance of oat flour. Eur Food Res Technol 230:827–835

Huppertz T, Fox PF, Kelly AL (2004) High pressure-induced denaturation of α-lactalbumin and β-lactoglobulin in bovine milk and whey: a possible mechanism. J Dairy Res 71:489–495

Schurer F, Kieffer R, Wieser H, Koehler P (2007) Effect of hydrostatic pressure and temperature on the chemical and functional properties of wheat gluten II. Studies on the influence of additives. J Cereal Sci 46:39–48

Thomas DJ, Atwell WA (1999) Starch analysis methods. In: Starches. Eagan Press, St. Paul, USA, pp 13–24

Vallons KJR, Arendt EK (2009) Effects of high pressure and temperature on the structural and rheological properties of sorghum starch. Innovat Food Sci Emerg Technol 10:449–456

Winter R (2003) Advances in high pressure bioscience and biotechnology II. Springer, Berlin/Heidelberg/New York

Funtenberger S, Dumay E, Cheftel JC (1997) High pressure promotes β-lactoglobulin aggregation through SH/S-S interchange reactions. J Agric and Food Chem 45:912–921

Kieffer R, Schurer F, Köhler P, Wieser H (2007) Effect of hydrostatic pressure and temperature on the chemical and functional properties of wheat gluten: studies on gluten, gliadin and glutenin. J Cereal Sci 45:285–292

Oh HE, Pinder DN, Hemar Y, Anema SG, Wong M (2008) Effect of high-pressure treatment on various starch-in-water suspensions. Food Hydrocoll 22:150–155

Clerici MTPS, El-Dash AA (2006) Extruded rice flour as a gluten substitute in the production of rice bread. ALAN 56:288–294

Kulp K, Hepburn FN, Lehmann TA (1974) Preparation of bread without gluten. Baker’s Dig 48:34–37

Satin M (1988) Bread without wheat. New Sci April 28:56–59

Champenois Y, Rao MA, Walker LP (1998) Influence of gluten on the viscoelastic properties of starch pastes and gels. J Sci Food Agric 78:119–126

Schober TJ, Bean SR, Boyle DL (2007) Gluten-free sorghum bread improved by sourdough fermentation: biochemical, rheological, and microstructural background. J Agric Food Chem 55:5137–5146

Acknowledgments

Funding for this research was provided under the Irish National Development Plan, through the Food Institutional Research Measure, administrated by the Department of Agriculture, Fisheries & Food, Ireland, 2006–2010. The authors wish to thank Jim McNamara for his excellent technical assistance and Christina Klose for her assistance with the gold coating. Further, the authors would like to acknowledge the Electron Microscopy Facility, BioSciences Institute, University College Cork, for assistance in preparing and imaging material for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vallons, K.J.R., Ryan, L.A.M., Koehler, P. et al. High pressure–treated sorghum flour as a functional ingredient in the production of sorghum bread. Eur Food Res Technol 231, 711–717 (2010). https://doi.org/10.1007/s00217-010-1316-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-010-1316-5

) and sorghum batters treated at 200 MPa (

) and sorghum batters treated at 200 MPa ( ) and 600 MPa (

) and 600 MPa ( ) with the complex modulus (G

*) given as function of temperature

) with the complex modulus (G

*) given as function of temperature