Abstract

In this study, the influence on the dough sheet’s overall quality induced by phosphate salts and hydrocolloids was evaluated. To clarify the internal structure of wheat dough, thermomechanical and rheological properties were performed on the dough, whereas the texture and cooking properties were evaluated on dough sheets. Results from the mixolab analysis showed a linear relationship between the content of hydrocolloids and phosphate salts (ranging from 0.1–0.7%) and key parameters, including gluten strength (C2), starch gelatinization (C3), and dough stability. These results were consistent with rheological measurement for storage G’ and loss G” moduli. The power-law model indicated that the dough possessed stronger and slower relaxation properties. The addition of sodium pyrophosphate and xanthan notably enhanced the hardness, springiness, and chewiness of texture properties. Microstructural analysis revealed that the internal molecules of dough sheets exhibited tighter interaction, resulting in low porosity and continuous network. Our study highlights the essential role of phosphate salts and hydrocolloids in improving the quality of wheat products. Additionally, we gained a deeper understanding of the change in the internal structure of dough sheets during the boiling process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

According to a report from the United Nations Food and Agriculture Organization (FAO), the total global wheat production in 2021 was 769.7 million tons, with 67% of it being consumed as food [1]. Wheat dough is transformed into different forms, such as noodles and bread, using various cooking methods like steaming, boiling, and baking. Similar to the preparation and processing of noodles, dumplings have been a traditional Chinese delicacy and considered as an important staple food for several centuries. Dough sheets, which have similar lengths and widths, are a crucial ingredient in both dumpling and noodle preparations. However, noodles typically have very narrow widths and longer lengths than dough sheets [2]. Dough sheets typically have a four-fold symmetry and can resemble circular or rectangular shapes, with an approximate thickness of 1 mm. During the preparation of dough sheets for dumplings, starch granules become embedded in the gluten matrix, which forms a complex polymer. However, in the subsequent boiling process, the structure of the protein-starch matrix of dough sheets tend to be disrupted or weakened, resulting in reduced viscoelasticity of the dough sheets and and an increase in cooking loss [3]. Additionally, the presence of large gaps in the gluten polymers and an unstable network contribute to issues such as cloudy soup and foaming with a soft texture and poor taste during the boiling process [4]. Therefore, there is a significant need for strategies to improve the quality of dough sheets and overcome undesired changes that occur during water boiling.

Hydrocolloids are a type of polymer that consists of long chains and hydroxyl groups derived from natural substances, including plant roots, algae, microorganisms, and animals [5]. The content and hydration properties of hydrocolloids added to wheat flour products are crucial for improving their quality. Due to the strength and stability of wheat flour dough induced by hydrocolloids, the viscoelasticity of the dough is improved, and the bread prepared has a stable internal structure and mouthfeel [6]. In addition, the inclusion of hydrocolloids such as xanthan, guar gum, and alginate has been used to reduce the cooking loss rate and turbidity in noodles during the boiling process [7]. Xanthan gum and carrageenan significantly enhance hydrophilic interactions, leading to improved cooking yield, while locust bean gum enhances the texture of the boiled noodles with an increased hardness [8]. Despite the wide range of functions hydrocolloids perform in enhancing the behavior of bread and noodles, there has been relatively little research conducted on their impact on dough sheets during the boiling process.

Recently, there has been significant interest in the use of phosphate salts to improve the quality of food and industrial applications. These salts serve as buffering, chelating, dispersing, and water retention agents [9]. Disodium Phosphate and sodium pyrophosphate have been found to contribute to the peak viscosity of wheat flour. This leads to noodles with lower hardness and higher stickiness [10]. Sodium tripolyphosphate has been shown to improve the surface color and reduce cooking loss in whole wheat noodles after the boiling process. Sodium hexametaphosphate and sodium dihydrogen phosphate strengthen the dough network structure and increase the boiled noodle hardness [11]. Meanwhile, it is necessary to conduct systematic studies on the overall quality of dough sheets modified by phosphate salts during the boiling process and their impact on the gluten network in the microstructure.

To better understand the cross-linking of the gluten network and the properties of dough sheets, quantitative characterization and calculation of gluten changes can be achieved through microstructure observation methods [12]. Additionally, an X-ray scan can be used to explore the porosity changes and construct a 3D model to evaluate the gluten network structure and process quality of wheat production [1, 13]. This paper aimed to investigate the impact of hydrocolloids and phosphate salts on the development of wheat flour dough and the subsequent effects of boiling dough sheets. Specifically, we examined the thermomechanical properties, rheological behavior, processing quality, and microstructure of the dough sheets with various types and additional contents of phosphate salts and hydrocolloids. Our study is to determine how these additions impact the microstructure of dough and dough sheets during the boiling process.

Materials and Methods

Materials

Wheat flour was purchased from the JinShaHe Group (Hebei province, China). The content of protein and ash was determined as 12.4% and 0.73%. Hydrocolloids and phosphate salts were used in this study, including Xanthan, Guar gum, TSPP, and DSP, and were from Henan Quanji Bioengineering Co., Ltd. All other chemicals used were of analytical grade.

Preparation of the Dough and Sheets

The dough sheets were prepared according to the previous report [14]. The control group consisted of 200 g wheat flour (14% wet base) and 90 mL deionized water. Each type of hydrocolloid and phosphate salt, including Xanthan, Guar gum, TSPP, and DSP, was added at levels of 0.1%, 0.3%, 0.5%, and 0.7% (flour weight basis). Then, the flour was put into a mixer (5KSM95CWH, KitchenAid, USA) to form a dough at speed 2 for 6 min. The prepared dough was rested for 20 min in a wake-up box (JXFD 8, Dongfu Jiuheng, Beijing, China, 35 °C, relative humidity 75%). Then, the rested dough was passed into a sheeting machine (DMT-5, Fuxing, Yantai, China) for sheeting and folding. Subsequently, the folded dough underwent four further reductions with the adjustment of the roll gap of the machine (3 mm, 2 mm, and 1 mm). Finally, the 1.0 mm thick dough sheet was cut into a circular piece with a diameter of 70 mm.

Mixolab Measurements

A Mixolab analyzer (Chopin Technologies, France) was used to test the mixing and starch pasting properties of the dough. The dough sample was prepared by adding hydrocolloids (Xanthan, Guar gum), and phosphate salts (TSPP, and DSP), within the concentrations range of 0%, 0.1%, 0.3%, 0.5%, and 0.7% (based on the weight of flour). The Mixolab measured parameters according to the AACC International Approved Method 54–60.01, which include water absorption, dough development time, dough stability time, weakening of protein network, starch gelatinization, and retrogradation [15].

Rheological Measurements

For rheological measurements, the dough sample was prepared at a 1.1 Nm torque value under the Mixolab, followed by a creep-recovery test [16]. Dynamic rheology of dough samples was analyzed by the rheometer (MCR302, Anton Paar, Germany) equipped with a 25 mm diameter probe. For the dynamic oscillatory frequency sweep measurement, 2.0 g of dough samples were placed onto a test platform. The measurement was performed from 0.1 Hz-100 Hz to determine the G’ and G’’ of each dough sample at a constant strain amplitude (γ = 0.1%) in the linear viscoelastic regime.

Creep recovery tests were conducted following the dynamic oscillatory frequency sweep onto the dough. The creep compliance Jc(t) of the dough was measured at fixed stress (σ0 = 250 Pa) for 180 s, after which the stress was removed, and the recovery compliance Jr(t) of the dough was analyzed for 360 s. Parameters of G‘(ω), G“(ω), Jc(t), and Jr(t) for each dough were done in triplicate.

Power-Law Gel Model and Model Fitting

The dough was identified as a power-law material, and data from dough rheology are processed based on the shear modulus of the dynamic oscillatory frequency sweep tests and creep recovery tests. Referring to the previous experimental method [17], the data points of G’ and G’’ in the same frequency are fitted to the corresponding power-law gel model expression (1) (2) to obtain the model parameters gel intensity (S) and index (n).

Equations (3) (4) was used to model the Jc(t) and Jr(t) of dough to derive the model parameters for the creep and recovery phases.

Textural Profile Analysis of Dough Sheets

The boiled dough sheets were cut into a cuboid (15 mm×15 mm×1 mm) and were taken into a texture analyzer (TA. XT-plus, SMS Co., London, UK). The settings for the TPA were: Probe: P /36R; Pretest speed: 1 mm/s; Test speed: 1 mm/s; Post-test speed: 2 mm/s; Strain: 75%; Pressure: 5 N/ g. The mean values were obtained by conducting at least six analyses for each sample.

Cooking Properties of Dough Sheets

The cooking properties were analyzed by a determination method [18]. Dough sheets (= 7.2 ± 0.1 g) were cooked in sufficient boiling water for 8 min. The boiled sheets were removed from the boiled water, cooled with the running water for 30 s, drained on the kitchen paper to absorb the moisture on the surface for 2 min, then weighed and recorded. The cooking yield was processed according to formula (5). The boiled water was collected in the beaker and dried to a constant weight at 105 °C. The cooking loss rate can be calculated according to formula (6).

Scanning Electron Microscopy (SEM)

The sample particles were observed by scanning electron microscopy (TM-3000, Hitachi, Japan). The samples were freeze-dried and fixed with conductive adhesive to make them evenly dispersed. After vacuum gold spraying treatment, the sample was placed in the electron microscope stage at 1500 × magnification.

Confocal Laser Scanning Microscopy (CLSM) Analysis

The network structure of the dough and dough sheets was visualized using CLSM. After cryo-embedding with Leica Tissue Freezing Medium, the sample was sliced into Sect. (20 μm) using a freezing microtome (Leica CM 1850, Germany). The sections were stained with Rhodamine B (0.025%) for 1 min. Subsequently, the dyed sample was rinsed with deionized water and covered with a coverslip [19]. The CLSM images and variations in the gluten network structure were analyzed and quantified using the software Angio Tool.

Porosity of the Dough

The pore distribution in the doughs, prepared with DSP, TSPP, xanthan, and guar gum at a 0.5% addition, was observed using an X-ray microscopy scanner. The experiment was carried out immediately after the preparation of the dough sample. The scintillator had a pixel size of 2 μm/pixel resolution. The test involved a peak energy of 40 kV and a regulated current of 100 µA. The scanning technique included a 360° rotation with 0.8° rotation steps, and each frame for image acquisition had an exposure time of 0.35 s. Subsequently, Avizo software (version 2020.1, VSG, France) was utilized for 3D reconstruction [1].

Statistical Analysis

Each sample mixed with DSP, TSPP, xanthan, and guar gum was repeated three times in the experiment. The experimental data were processed and analyzed using SPSS 23.0 and Office 2019. The experimental results were expressed as mean ± standard deviation, and different letters in the same column showed significant differences (P < 0.05). Origin 2021 plotting software was used to plot and fit the charts.

Results and Discussion

Effect of the Phosphate Salts and Hydrocolloids on the Large Strain Rheological Properties of Wheat Flour Dough

To measure the thermal-mechanical properties of dough, the Mixolab instrument is commonly used. With the addition of hydrocolloid and phosphate salts, changes in the torque (N·m) applied to the blade can significantly determine the strength of the protein network and the gelatinization behavior of the starch in the dough. Experimental results have shown that these tests can provide a relatively accurate prediction for the quality of dough-based products [20].

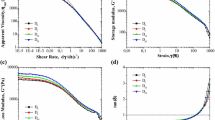

Effects of phosphate salts and hydrocolloids on the mixolab parameters of wheat flour doughs. (a) water absorption. (b) dough mechanical weakening (C2), dash lines fitted linear: y = -0.112d x + 0.464A, r2 = 0.987 (dark green), y = 0.219b x + 0.451A, r2 = 0.969 (green), y = 0.10ax + 0.459A, r2 = 0.932 (yellow), y = 0.06c x + 0.450A, r2 = 0.811 (orange). (c) starch gelatinization (C3) dash lines fitted linear: y = 0.132d x + 1.672B, r2 = 0.875 (dark green), y = 0.330b x + 1.616D, r2 = 0.983 (green), y = 0.447a x + 1.652C, r2 = 0.975 (yellow), y = 0.150c x + 1.700A, r2 = 0.983 (orange). (d) starch retrogradation (C5), (e) dough development time (C1 time), and (f) dough stability, dash lines fitted linear: y = -2.004d x + 4.473A, r2 = 0.927 (dark green), y = 10.856a x + 4.870A, r2 = 0.928 (green), y = 7.586b x + 4.451A, r2 = 0.959 (yellow), y = 0.621c x + 4.520A, r2 = 0.721 (orange)

Our study found that the water absorption of doughs with added hydrocolloids exhibited different trends (Fig. 1a). The specific mixolab parameters of wheat flour doughs were showed in Table S3. Specifically, the water absorption of dough sharply increased with the increasing xanthan content in the dough, while guar gum did not change significantly. The water absorption values with added different level of xanthan (ranging from 0.1 to 0.7%) increased from 59.4 to 62.5%, and for the guar gum the values ranged from 59.4 to 59.7%. This result confirmed previous farinograph assays that demonstrated a positive relationship between water absorption and hydrocolloid addition [21, 22]. With regard to the two types of phosphate salts, the water absorption of DSP groups, except for those with 0.1% addition content, increased with the increasing addition, while the TSPP showed a significant decreasing tendency. This may be due to the presence of phosphate in the form of negative ions and metal ions in the system, which improves the water absorption efficiency and gelatinization ability of starch. However, the decrease of TSPP led to an increase in the interaction between water and solid phase components (such as gluten matrix and starch). The mobility of water in the dough was reduced, resulting in a decrease in water absorption [11].

When the addition content was fixed, the effect of hydrocolloids and phosphate salts on water absorption showed a clear ranking (i.e., Xanthan> Guar> DSP> TSPP). This is because the internal structure of xanthan gum contains an anionic branched mannoglucuronoglucan, whereas the guar gum is composed of neutral branched galactomannan. The enhancement of the hydration of the dough is attributed to these two soluble high molecular weight substances [23].

The mechanical weakening of the dough (C2) showed a clear linear relationship with the addition of hydrocolloids and phosphate salts (Fig. 1b). The slope value in the linear fitting equation indicates that the dough was more sensitive to the addition of xanthan gum, guar gum, and TSPP compared to DSP. Notably, the modifications induced by these three additives were more effective than DSP. The starch gelatinization (C3) of doughs prepared by the hydrocolloid and phosphate salts did not show significant differences but exhibited an increasing linear relationship. This indicated that the addition of hydrocolloids and phosphate salts promotes starch gelatinization and starch particle swelling. Starch gelatinization was changed more dramatically under the addition of xanthan and TSPP compared to guar gum and DSP (Fig. 1c). During the starch retrogradation period, the addition of TSPP, xanthan, and guar gum did not show a linear relationship and presented a fluctuation situation (Fig. 1d). As the amount of DSP increased, the starch retrogradation (C5) decreased and eventually stabilized. Xanthan and guar gum both reached a trough at the addition content of 0.1%. The changes in C5 values with the addition of xanthan and guar gum indicated that low content of both hydrocolloids exhibited good resistance to starch retrogradation in a dough system [24, 25]. With increasing hydrocolloid content, the starch retrogradation of the dough system has slowly increased, leading to the arrangement of starch molecules in an orderly manner and the generation of a dense and stable network structure [26].

The gluten strength of the dough was characterized by the dough development time (C1 time) and dough stability, which were time-dependent parameters. The effect of hydrocolloids and phosphate salts on the development time of doughs was shown in Fig. 1e, indicating significant variation. With the increased DSP content, the development time continuously increased during the dough formation process, indicating that the dough sample became soft and viscous. Under these conditions, the system was weakly alkaline with partial charges introduced, which made the gluten network structure stretch and relax with increased viscosity and decreased dough strength [27]. This phenomenon was also verified by the slope of the linear fitting equation. The dough stability ranked as TSPP > Xanthan > guar gum > DSP when the phosphate salts and hydrocolloid content were fixed (Fig. 1f). In conclusion, phosphate salts and hydrocolloids have a wide range of potential to manipulate the viscoelasticity of the dough.

Effect of the Phosphate Salts and Hydrocolloids on the Small Strain Rheological Properties of Wheat Flour Dough

The rheological characteristics of the doughs were measured by using small deformation measurements, specifically dynamic oscillatory frequency sweep and creep recovery tests. The linear and non-linear parameters of G’ and G” were used to reflect the elastic and viscosity characteristics of the dough. The G’ of the dough and G” were determined by preparing a dough sample with 0% content, 0.5% xanthan gum, 0.5% guar gum, 0.5% TSPP, and 0.5% DSP.

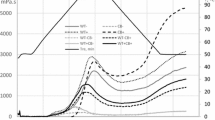

The linear viscoelastic behavior of doughs, with G’ and G” plotted against angular frequency(ω) was shown in Fig. 2. Across the frequency range, G’ was higher than G” for all doughs, whether DSP, TSPP, xanthan, and guar gum added or not. This result indicated that all doughs presented a solid-like behavior [28]. The power-law gel model was used to linearly fit the dynamic frequency sweep, with R2 values ranging from 0.94 to 0.99. For all the types of hydrocolloids and phosphate salts, the mean values of G’ and G” were 11033–25700 Pa and 4113–7850 Pa over 1 Hz. When compared to the control group, the G’ and G” were significantly higher with the addition of TSPP, xanthan, and guar gum, indicating that these additives could improve the dough’s elasticity. The increase in G’ may be due to the formation of disulfide bonds induced by phosphate salts, the polymerization of anions in xanthan gum, the linearly extended conformation in the guar gum molecule, and the amino group of the gluten protein, which could further promote cross-linking of protein molecules [29, 30]. However, the addition of DSP resulted in lower G’ and G” values than the control group, as shown in Fig. 2a. This is consistent with the results obtained from mixolab, which showed a gradual increase in viscosity. The various types of phosphate salts weaken the solid-like properties of the gluten protein system while enhancing its viscosity. Therefore, the degree of influence on dough’s rheological properties is ranked as TSPP> xanthan> guar gum> DSP.

To investigate the non-linear viscoelastic characteristics of doughs, the Jc (t) and Jr (t) of the doughs were measured. The variation range of DSP, TSPP, xanthan gum, and guar gum at a 0.5% addition amount is consistent with the trend of dynamic vibration. The higher the values of the Jc (t) and Jr (t), and the weaker the strength of the doughs, the greater the deformation of the doughs under stress [31]. The ranking of dough strength is TSPP> xanthan> guar gum> DSP (Fig. 3). The power-law gel model was used to fit the creep and recovery stages of dough, resulting in slightly discrete fits compared to the dynamic frequency sweep (R2 = 0.86–0.99). However, the non-linear curves were not well fitted during the recovery stage (t = 180–200 s). This finding is consistent with previous studies on whole wheat dough [32]. Overall, the power-law gel model is a useful tool for characterizing the linear or non-linear viscoelasticity of dough with different types of hydrocolloids and phosphate salts.

The compliance as a function of time (t) for doughs prepared by adding a range of phosphate salts and hydrocolloids. Red lines are the fitted curve by the power-law gel model for the creep compliance Jc(t) (0 to 180 s) and recovery compliance Jr(t) (180 to 540 s) of doughs with Eqs. (3) and (4). Error bars show ± 1 SD, n = 3

The parameters obtained from the model were used to characterize the rheological properties of the dough added with different phosphate salts and hydrocolloids (Table S1). Gel strength (S) reflects the overall strength of the dough, while gel index (n) describes the relaxation behavior of the dough. When the wheat dough was mixed with DSP, the gel strength S’, S’’, Sc, Sr decreased significantly from 0 to 0.5%. At low concentrations of DSP, the dough viscosity tended to increase due to starch gelatinization. The decrease in gel index (n) value, which is opposite to gel strength (S), implied that the dough had a slower relaxation time. Moreover, the addition of TSPP resulted in the greatest increase in dough strength.

The addition of xanthan and guar gum showed a significant increase in dough strength. When the hydrocolloid content was fixed, higher values of S’, S’’, Sc, and Sr were observed for the dough prepared with xanthan. Dynamic oscillatory frequency sweep and creep recovery experiments of dough rheology properties confirm a positive correlation trend between gel strength and dough strength [17]. Compared to the phosphate salts and the hydrocolloids, the ranking of dough strength was TSPP > Xanthan > guar gum > DSP. The results showed that xanthan gum and guar gum had a stronger strengthening effect and a slower relaxation time on the dough (Table S1). This could be attributed to the strong binding affinity of xanthan gum, which potentially decreases the mobility of water molecules and interferes with gluten-water interactions. The linear extension conformation of guar gum makes its dough strength weaker than xanthan gum. Hence, the type of hydrocolloids determines its degree of interaction with water and gluten proteins in the system, which affects the relaxation behavior and strength of the dough [25]. The strength of the dough is determined by the balance between gluten network cross-linkage and starch gelatinization, which can be modified by phosphate salts. The TSPP could improve the numbers of disulfide bonds to enhance the protein network structure, result the strength of dough. According to the data of n and S, the relaxation time of the dough is shortened by the addition of DSP, leading to an increase in dough stickiness and attenuation of strength with a soft texture [33].

Effect of the Phosphate Salts and Hydrocolloids on the Texture and Cooking Properties of Dough Sheets

The textural parameters obtained are summarized in Table 1. In the phosphate salts group, the effect of TSPP was more significant than that of DSP. The hardness of dough sheets with DSP and TSPP added did not show a significantly linear decline, which is slightly different from the finding of a previous study [10]. Compared to the control group, the hardness of boiled dough sheets modified by the phosphate salts increased slightly, with the maximum values observed at 0.5% addition. The springiness, cohesiveness, gumminess, and chewiness showed a downward tendency induced by increasing DSP. The effect of TSPP on the TPA index of boiled dough sheets fluctuated without an obvious linear growth trend. The phosphate salts could significantly improve the texture of the noodles with a soft taste by strengthening the gelatinizing properties of starch, while different types of phosphate salts could enhance the gluten network. The results from both mixolab and rheological tests confirmed that the texture of dough sheets was influenced by the effect of the phosphate salts. This suggests that the hardness and springiness of the dough sheets were determined by the balance between the starch gelatinization and the strength of the dough. On one hand, the presence of phosphate salts contributes to an augmentation in the number of disulphide bonds within the dough, thereby reinforcing the gluten network structure. This reinforcement is evident as both DSP and TSPP result in heightened hardness and chewiness of the dough sheets. While phosphate salts also play a role in enhancing the starch gelatinization properties. Specifically, TSPP and DSP contribute to an improvement in starch pasting viscosity, ultimately imparting a softer texture to the dough sheets. However, the induction of TSPP resulted in a greater degree of hardness enhancement of the dough sheets compared to the promotion of starch pasting. This finding was similar to the results of previous studies, which may be due to the fact that TSPP affects the pH in the system, which is similar to the isoelectric point of gluten (pI = 7.1) [12].

As for hydrocolloids groups, the addition of xanthan gum resulted in an increase in hardness from 7462.99 g to 10918.21 g, an increase in gumminess from 5422.85 to 7346.17, and a significant increase in the springiness, cohesiveness, and chewiness. Xanthan and guar gum were found to improve the internal network structure of the dough sheets by interacting with the gluten network through hydrogen bonding and hydrophobic force, ultimately resulting in a more compact complex.

Cooking yield and cooking loss rate are important indicators for measuring cooking quality. The addition of DSP resulted in a gradual reduction in the cooking yield, with the minimum value of 185.15% observed at a 0.3% level (Table 1). The changing trend of TSPP was found to be similar to that of DSP. It has been reported that the addition of a certain amount of phosphate salts could improve the water-holding capacity of dough sheets [34]. The addition of xanthan gum has a significant impact on the boiling water absorption of dough sheets. Except for the dough sheet with 0.1% xanthan gum content, the cooking yield of the boiled dough sheets decreased from 189.68 to 177.96% as the amount of xanthan added increased. On the other hand, the addition of guar gum did not show a significant effect on the cooking yield of the dough sheet. Interacted with water through hydrogen bonding, the addition of xanthan and guar gum could form a gel to wrap the starch inside. The gel formation could inhibit the swelling and water absorption of starch, resulting in a decrease in cooking yield.

Phosphate salts, such as DSP and TSPP, were previously thought to strengthen the network structure by promoting the formation of disulfide bonds and reducing the leaching of amylose, thus avoiding the dissolution of the contents. However, the alkalinity of DSP and TSPP leads to an increase in the pH of the dough sheet when added in higher amounts during the cooking process. This elevated pH can trigger the dissolution of soluble proteins, specifically α-gliadins and γ-gliadins, resulting in an increased cooking loss rate [35]. In contrast, the addition of hydrocolloids has been shown to reduce the cooking loss. Hydrocolloids form strong interactions with gluten proteins and starch granules through hydrogen bonding and hydrophobic interaction within the dough sheet system. This creates a compact and cross-linked of internal network structure, effectively reducing the dissolution of starch granules and protein during the cooking [8, 36].

Effect of the Phosphate Salts and Hydrocolloids on the Microstructural Properties of Wheat Flour Dough and Dough Sheets

The microstructures of wheat flour dough and boiled dough sheets prepared with the addition of 0.5% xanthan and 0.5% TSPP were presented in Fig. 4. Compared with the control group (Fig. 4a), the SEM images of doughs with 0.5% TSPP and xanthan gum showed a more continuous network structure and a denser gluten protein matrix (PM). Within the dough, starch granules (SG) become entrapped within the gluten network (Fig. 4b, c). The inclusion of phosphate salts and hydrocolloids leads to a stronger interaction between gluten proteins and starch granules. Consequently, the starch granules are better embedded within the gluten network as indicated by previous studies [37].

Within the dough sheets, a gel network was formed as a result of the random aggregation of gelatinized starch and heat-denatured gluten (Fig. 4d, e, f). The microstructure of the control group’s dough sheets showed an obvious network pattern with large cross-sectional pores and an uneven distribution. The introduction of phosphate could strengthen the gluten network. Furthermore, the incorporation of xanthan notably enhanced the internal system of the dough sheets, creating a compact and smooth network (Fig. 4f).

Scanning Electron Microscopic (SEM) images of wheat flour doughs and dough sheets prepared by adding a range of phosphate salts and hydrocolloids. Doughs: (a) Control, (b) 0.5% TSPP, (c) 0.5% Xanthan gum. Dough sheets: (d) Control, (e) 0.5% TSPP, (f) 0.5% Xanthan gum. SG: starch granules. PM: protein matrix

As shown in Fig. 5(a), the control group of dough had large pores and a loose network. Compared to the control, the protein network (PN) of the dough with the addition of TSPP was more compact with fewer pores. This indicates that phosphate salts could help to form highly cross-linked and more continuous gluten network structures. The dough stability time was prolonged, and the PN structure was strengthened by promoting disulfide and hydrogen bond formation induced by phosphates salts [11]. With the addition of TSPP, the PN of the boiled dough sheets was more closely crosslinked with large pores. The large pores inside the boiled dough sheets and the pores in the structure make it difficult to effectively control amylopectin and soluble protein, which is also the reason for the high cooking loss rate of the phosphate group. The incorporation of hydrocolloids also contributed to the reinforcement of the PN, resulting in a more uniform and continuous structure. With the addition of xanthan, the interaction between water and gluten protein was promoted in the dough system. Meanwhile, the complex polymer formatted in the doughs through the cross-linking of cluster-like structural domains, which also contributed to a compact network [38]. The addition of xanthan showed a tightly cross-linked and uniformly ordered network structure for the boiled dough sheets. A continuous and uniform PN could effectively limit water immersion and reduce cooking loss [29].

The CLSM images obtained from both the dough and dough sheets were subjected to quantitative analysis using the ‘AngioTool’ software, as illustrated in Fig. 5. The obtained data encompassed nine parameters (Table S2), including total gluten length, average protein length, the total number of junctions, total number of endpoints, gluten width, branching rate, end-point rate, the gluten area and percentage area of the gluten network. Notably, the total gluten length of the gluten network in dough mixed with TSPP and xanthan exceeded that of the control group by 50.33 × 103 μm and 47.44 × 103 μm, respectively, in contrast to the control group (25.42 × 103 μm). Meanwhile, the number of gluten junctions in dough mixed with TSPP and xanthan significantly increased from 335.5 to 1185.5 and 1055 when compared to the control group. This finding is consistent with the results of the dough sheet samples mixed with TSPP and xanthan. It is noteworthy that the gluten length generally was related to an increase in the number of gluten connections, which determined the cross-linking level of gluten protein [39]. In addition, in the dough mixed with TSPP and xanthan, the branching rate was 2.46 × 10− 3 and 2.33 × 10− 3 higher than the control group’s 1.10 × 10− 3. Simultaneously, the values for gluten width decreased from 11.92 to 9.56 and 9.54, respectively. It’s worth noting that the changes in branching rate, gluten width, and lacunarity in the dough sheet are comparatively less pronounced than those observed in the dough. These findings collectively suggest that the gluten network with high branching rates and smaller protein widths exhibited a greater degree of crosslinking and aggregation. The end-point rate, regarded as an indicator to evaluate cohesion and consistency in the gluten network, has no significant growth trend.

Laser scanning confocal microscope (CLSM) images of wheat flour doughs and dough sheets prepared by adding a range of phosphate salts and hydrocolloids. Doughs: (a) Control, (b) 0.5% TSPP, (c) 0.5% Xanthan gum and dough sheets, (d) Control, (e) 0.5% TSPP, (f) 0.5% Xanthan gum, white arrow: Pores and protein network (PN)

The presence of pores could be considered as defects to disturb the formation of network structure when water and protein mix together. This disruption ultimately affects the quality characteristics of dough sheets. By using the Avizo software, it becomes possible to fill the pores and eliminate any irregular shapes outside the dough. As a result, a cube-shaped 3D model representing the pores in the dough, with a 0.5% addition of DSP, TSPP, xanthan, and guar gum was successfully established (Fig. 6).

In our results, the presence of pores co-existed with an irregular and less compact network structure of the gluten-filled granules. Compared with the control group (Fig. 6a), the porosity of dough samples containing DSP and TSPP was 9.42% and 5.82% (Fig. 6b, c). Notably, the addition of TSPP results in a significant enhancement of the gluten network, leading to a reduction in porosity. A high lacunarity value indicates the presence of more gaps of varying sizes within the internal network. Such high porosity contributes to a more irregular and less compact gluten structure [40]. Similarly, xanthan gum and guar gum had similar effects, with porosities of 6.77% and 7.82%, respectively. The distribution of pore bubbles was relatively uniform, resulting in an orderly and stable network structure inside.

Conclusion

In this study, the impact of phosphate salts and hydrocolloids on the rheological, microstructural, and cooking properties of dough and dough sheets was investigated. The results revealed a linear relationship between the parameters of dough mechanical weakening, starch gelatinization, and dough stability. The small deformation test demonstrated a significant increase in the G′ and G′′ values of the dough when TSPP and xanthan were added. Specifically, with the addition of TSPP and xanthan gum, the dough showed a stronger dough strength and less relaxation time. The phosphate salts and hydrocolloids generally facilitate internal cross-linking to enhance the texture and cooking properties of boiled dough sheets. Furthermore, SEM, CLSM, and X-ray scans revealed that TSPP and xanthan strengthened the gluten network, causing a profound interaction between starch granules and gluten protein. This interaction led to a narrowing of gaps between gluten protein and forming a continuous and dense network structure. Overall, the TSPP and xanthan have a significant effect on dough sheet quality in the boiling process, and the internal network structure was improved.

Data Availability

No datasets were generated or analysed during the current study.

References

S. Liu, Y. Jiang, B. Xu, S. Jiang, Food Chem. 404 (Pt A). 134359 (2023). https://doi.org/10.1016/j.foodchem.2022.134359

T. Liu, M. Niu, G.G. Hou, Food Chem. 305, 125500 (2020). https://doi.org/10.1016/j.foodchem.2019.125500

E. Aydin, D. Gocmen, Food Sci. Biotechnol. 20(2), 507–511 (2011). https://doi.org/10.1007/s10068-011-0070-1

S. Zhang, X. Sun, X. Xu et al., J. Cereal Sci. 108, 103584 (2022). https://doi.org/10.1016/j.jcs.2022.103584

S. Kraithong, A. Theppawong, S. Lee, R. Huang, Food Hydrocoll. 142, 108821 (2023). https://doi.org/10.1016/j.foodhyd.2023.108821

E. Zannini, D.M. Waters, E.K. Arendt, Eur. Food Res. Technol. 238(5), 763–771 (2014). https://doi.org/10.1007/s00217-014-2161-8

H.-L. Tan, T.-C. Tan, A.M. Easa, Int. J. Food Sci. Tech. 53(7), 1603–1610 (2018). https://doi.org/10.1111/ijfs.13742

H.-L. Tan, T.-C. Tan, A.M. Easa, Food Hydrocoll. 108, 105996 (2020). https://doi.org/10.1016/j.foodhyd.2020.105996

M. Obadi, J. Zhang, B. Xu, Food Res. Int. 157, 111278 (2022). https://doi.org/10.1016/j.foodres.2022.111278

M. Chen, L. Wang, H. Qian et al., Food Chem. 283, 353–358 (2019). https://doi.org/10.1016/j.foodchem.2019.01.049

T.T. Zhao, X.N. Guo, K.X. Zhu, Food Chem. 384, 132481 (2022). https://doi.org/10.1016/j.foodchem.2022.132481

M. Zhang, M. Ma, T. Yang, M. Li, Q. Sun, Food Hydrocoll. 123 (2022). https://doi.org/10.1016/j.foodhyd.2021.107114

Z. Germishuys, M. Manley, Innov. Food Sci. Emerg. 73 (2021). https://doi.org/10.1016/j.ifset.2021.102766

H. Fan, F. Fu, Y. Chen, M. Liu, Z. Ai, K. Bian, J. Cereal Sci. 93, 102936 (2020). https://doi.org/10.1016/j.jcs.2020.102936

N. Wang, G.G. Hou, A. Dubat, LWT-Food Sci. Technol. 82, 147–153 (2017). https://doi.org/10.1016/j.lwt.2017.04.025

X. Sun, Z. Bu, B. Qiao, P. Drawbridge, Y. Fang, Food Chem. 410, 135447 (2023). https://doi.org/10.1016/j.foodchem.2023.135447

X. Sun, F. Pei, Y. Fang, Food Chem. 370, 130976 (2022). https://doi.org/10.1016/j.foodchem.2021.130976

R. Huang, K. Huang, X. Guan, J. Zhang, P. Zhang, J. Cereal Sci. 108 (2022). https://doi.org/10.1016/j.jcs.2022.103542

M. Zhang, M. Ma, R. Jia, T. Yang, Q. Sun, M. Li, Food Chem. 386, 132853 (2022). https://doi.org/10.1016/j.foodchem.2022.132853

M. Mastromatteo, M. Guida, A. Danza et al., Food Res. Int. 51(2), 458–466 (2013). https://doi.org/10.1016/j.foodres.2013.01.004

S. Singh, N. Singh, Food Hydrocoll. 33(2), 342–348 (2013). https://doi.org/10.1016/j.foodhyd.2013.04.007

M. Kundu, B.S. Khatkar, N. Gulia, Food Chem. 226, 95–101 (2017). https://doi.org/10.1016/j.foodchem.2016.12.046

D. Keita, G. Léger, N. Bordenave, Food Res. Int. 147, 110478 (2021). https://doi.org/10.1016/j.foodres.2021.110478

M.J. Correa, C. Ferrero, Starch - Stärke. 67(3–4), 338–347 (2015). https://doi.org/10.1002/star.201400116

J. Li, Y. Zhu, M.P. Yadav, J. Li, Food Chem. 271, 165–173 (2019). https://doi.org/10.1016/j.foodchem.2018.07.192

M. Chaisawang, M. Suphantharika, Food Hydrocoll. 20(5), 641–649 (2006). https://doi.org/10.1016/j.foodhyd.2005.06.003

N. Ni, Z. Wang, F. He et al., Process. Biochem. 49(4), 631–636 (2014). https://doi.org/10.1016/j.procbio.2014.01.017

Y.-Y. Feng, T.-H. Mu, M. Zhang, M.-M. Ma, Int. J. Biol. Macromol. 148, 1–10 (2020). https://doi.org/10.1016/j.ijbiomac.2019.12.225

J. Sun, M. Chen, X. Hou et al., Food Chem. 358, 129895 (2021). https://doi.org/10.1016/j.foodchem.2021.129895

G.K. Sandhu, S. Simsek, F.A. Manthey, Int. J. Food Sci. Tech. 50(8), 1922–1932 (2015). https://doi.org/10.1111/ijfs.12813

A.G. Yovchev, A.K. Stone, P. Hucl, M.G. Scanlon, M.T. Nickerson, Cereal Chem. 94(3), 513–518 (2017). https://doi.org/10.1094/CCHEM-09-16-0240-R

X. Sun, F. Koksel, M.T. Nickerson, M.G. Scanlon, Food Hydrocoll. 98, 105129 (2020). https://doi.org/10.1016/j.foodhyd.2019.05.030

B.-K. Baik, M.-R. Lee, Cereal Chem. 80(3), 304–309 (2003). https://doi.org/10.1094/cchem.2003.80.3.304

C. Biliaderis, T. Maurice, J. Vose, J. Food Sci. 45(6), 1669–1674 (1980). https://doi.org/10.1111/j.1365-2621.1980.tb07586.x

T. Ukai, Y. Matsumura, R. Urade, J. Agr, Food Chem. 56(3), 1122–1130 (2008). https://doi.org/10.1021/jf0725676

C.M. Rosell, J.A. Rojas, C. Benedito de, Barber, Food Hydrocoll. 15(1), 75–81 (2001). https://doi.org/10.1016/S0268-005X(00)00054-0

M.J. Correa, E. Ferrer, M.C. Añón, C. Ferrero, Food Hydrocoll. 35, 91–99 (2014). https://doi.org/10.1016/j.foodhyd.2013.04.020

M. Azeem, T.H. Mu, M. zhang, LWT. 142, 110970 (2021). https://doi.org/10.1016/j.lwt.2021.110970

Z.-B. Cao, C. Yu, Z. Yang, J.-J. Xing, X.-N. Guo, K.-X. Zhu, Food Hydrocoll. 119, 106842 (2021). https://doi.org/10.1016/j.foodhyd.2021.106842

X. Gao, T. Liu, M. Ding et al., Food Chem. 240, 626–633 (2018). https://doi.org/10.1016/j.foodchem.2017.07.165

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (2022YFD2100202, 2022YFD2100204), the National Natural Science Foundation of China (32272418), the General Project of Natural Science Research in Universities of Jiangsu Province (21KJB550004), Jiangsu Province Key Research and Development Program (Modern Agriculture) Project (BE2021370), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Contributions

Kaidong Wei: Conceptualization, Data curation, Formal analysis, Writing – original draft. Xuan Hu: Formal analysis, Writing – original draft. Xin Zheng: Formal analysis. Guanglei Li: Conceptualization, Formal analysis, Writing – review & editing, Supervision. Peng Li: Formal analysis. Jian Yuan: Formal analysis, Supervision. Changrui Xing: Conceptualization, Formal analysis, Writing – review & editing, Supervision. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

All the authors declare that he has no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, K., Hu, X., Zheng, X. et al. Effects of Phosphate Salts and Hydrocolloids on Rheological, Microstructural, and Cooking Properties of Dough Sheets During Boiling Process. Food Biophysics 19, 585–597 (2024). https://doi.org/10.1007/s11483-024-09842-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-024-09842-w