Abstract

The vacuum-drying characteristics of ginger (Zingiber officinale R.) slices were investigated. Drying experiments were carried out at a constant chamber pressure of 8 kPa, and at four different drying temperatures (40 °C, 50 °C, 60 °C, and 65 °C).The effects of drying temperature on the drying rate and moisture ratio of the ginger samples were evaluated. Efficient model for describing the vacuum-drying process was chosen by fitting five commonly used drying models and a suggested polynomial was fitted to the experimental data. The effective moisture diffusivity and activation energy were calculated using an infinite series solution of Fick’s diffusion equation. The results showed that increasing drying temperature accelerated the vacuum-drying process. All drying experiments had only falling rate period. The goodness of fit tests indicated that the proposed two-term exponential model gave the best fit to experimental results among the five tested drying models. The average effective diffusivity values varied from 1.859 × 10−8 to 4.777 × 10−8 m2/s over the temperature range. The temperature dependence of the effective moisture diffusivity for the vacuum drying of the ginger samples was satisfactorily described by an Arrhenius-type relationship with activation energy value of 35.675 kJ/mol within 40–65 °C temperature range.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Drying is an important operation in ginger processing. In many places throughout the world, ginger is usually dried under open sun-drying condition (namely, open atmosphere). The open sun-drying method adversely affects the product quality in terms of color, nutrition, chemical composition, and food hygiene (Koc et al. 2004; Ergunes and Tarhan 2006).Compared to conventional atmospheric drying, vacuum drying has some distinctive characteristics such as higher drying rate, lower drying temperature, and oxygen-deficient processing environment, etc., resulting in improved quality and nutritive value of the final dried products. Since vacuum dryers operate at lower pressure, the boiling point of the water is depressed; and hence, moisture evaporation can take place at lower temperature. This aids in the preservation of heat-sensitive components of food. Moreover, the oxygen-deficient environment during vacuum drying prevents oxidative reactions. Vacuum drying has been applied to dry various fruits and vegetables (Arevalo-Pinedo and Murr 2007; Jaya and Das 2003) with superior product quality.

The objective of this work was to investigate the vacuum-drying characteristics of the sliced ginger samples, to evaluate the effect of vacuum-drying conditions on the drying process, and finally, to choose the most efficient single-layer drying model to describe the drying process.

Material and Methods

Raw Material and Experimental Setup

Fresh ginger (Zingiber officinale R.) samples were procured from a local market in Anand, India. After thorough cleaning and washing, the gingers were peeled and sliced into 5-mm thickness using a slicer. Moisture content of samples before drying was determined according to the Association of Official Analytical Chemists (AOAC) method (AOAC 1990) and was performed in triplicate.

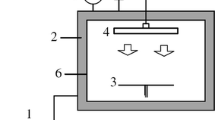

An experimental setup developed for vacuum-tray drying experiment of ginger is shown schematically in Fig. 1. Drying temperature was controlled by proportional integral derivative digital temperature controller (Vipro, Model: VDC-901, India).

Drying Process

The vacuum-tray drying of ginger slices was carried out at temperature levels, 40 °C, 50 °C, 60 °C, and 65 °C, at a constant absolute vacuum pressure of 8 kPa. The drying-process parameters were fixed after several preliminary studies. The ginger slices were spread in a single layer on sample tray in such a way that tray loading was maintained constant and kept inside the vacuum chamber. The system needed 5 to 8 min to achieve the specific vacuum pressure. The weight of the sample was recorded at predetermined time intervals by using a digital top pan balance having accuracy 0.001 g (Sartorius AG, 37075 Goettingen, Germany) continuously throughout the vacuum drying. Readings were noted till the samples reached the equilibrium i.e., when there is no more weight loss with progress in drying time. The equilibrium moisture content was found by standard hot air oven method (AOAC 1990).

Mathematical Modeling

The moisture ratio (MR) and drying rate during drying experiments were calculated using the following equations:

where M, M 0 , M e , M t and M t + dt are moisture content, initial moisture content, moisture content in equilibrium with the drying air, moisture content, moisture content at t and moisture content at t + dt (kg water/kg dry matter), respectively, and t is drying time (min).

Five drying models i.e., Henderson and Pabis (1961) model, Lewis model (Bruce 1985), Page model (Bruce 1985), modified Page model (Yaldiz et al. 2001) and two-term model (Rahman et al. 1997) were tested using SPSS (ver. 10, USA) to select the best model for describing the drying curve equation of ginger samples. The drying constants and coefficients of models were determined using a non-linear regression procedure. The correlation coefficient (R) was the primary criterion for selecting the best equation to describe the drying curve equation. In addition to R, the reduced χ 2as the mean square of the deviations between the experimental and calculated values for the models and root mean square error analysis (RMSE) was used to determine the goodness of the fit. The higher the values of the R, and lowest values of the χ 2 and RMSE, the better the goodness of the fit (Yaldiz and Ertekin 2001; Gunhan et al. 2005).

The effect of the drying temperature at constant vacuum of 8 kPa on the coefficients of the selected model and average moisture diffusivity were investigated by two-way ANOVA at 5% level of significance using a regression technique in Analysis Tool-Pak of Microsoft Excel.

Calculation of the Effective Moisture Diffusivity and Activation Energy

The drying characteristics of biological products in falling rate period is very well described by using Fick’s diffusion equation, where shrinkage was assumed to be insignificant as ginger is fibrous in nature. An analytical solution of this law in the case of drying an infinite slab of thin layer, assuming one-dimensional moisture movement without volume change, constant diffusivity, uniform initial moisture distribution, and negligible external resistance can be developed in form of equation given by Crank (1975). This can be used for various regularly shaped bodies such as rectangular, cylindrical, and spherical products, and the form of Eq. 3 can be applicable for particles with slab geometry, as in the case of sliced ginger piece by assuming uniform initial moisture distribution:

Where, D eff is the effective diffusivity (m2/s); L 0 is the half thickness of the slab (m). When the drying time becomes larger and n > 1, Eq. 3 can be further simplified to only the first term of series. A similar equation was used by earlier researchers (Elsa Uribe et al. 2009, 2010) for calculation of moisture ratio. Thus, Eq. 3 is written as follows:

Diffusivities are typically determined by plotting experimental drying data in terms of ln MR versus drying time t, because the plot gives a straight line with a slope as follows:

The activation energy of ginger slices could be obtained through an Arrhenius-type relationship, for which the average effective moisture diffusivity, Deff,avg, relates to the drying air temperature:

Where D 0 is the diffusion coefficient corresponding to infinite temperature (m2/s), E a is the activation energy (kJ/kmol), R is the universal gas constant (8.314 J/mol K), and T is the absolute drying air temperature (K).

Results and Discussion

Effect of Vacuum-Drying Conditions on Drying Process

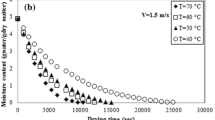

During vacuum drying, the moisture content of the sliced ginger samples was reduced from an initial value of 365.98 ± 2% (d.b.) to less than 5% (d.b.). The ANOVA test showed that the drying temperature affected the drying time significantly at 5% level of significance. The drying time needed to reach the EMC was shortened notably with an increase in drying temperature due to a larger driving force for heat and mass transfer at higher drying temperature, which is in agreement with previous reports (Lopes Filho et al. 2002; Wu et al. 2007). The effect of drying temperature on the characteristic of drying rate curves is depicted in Fig. 2 at combinations of four drying temperatures (40 °C, 50 °C, 60 °C, and 65 °C) at 8 kPa. The curves indicate that rate of removal of moisture was higher in the initial stage (up to 100% mc db), which decreased thereafter. At the initial stage of drying, the available free moisture concentration gradient was higher leading to higher drying rate. After critical moisture content, the drying rate was found to be diminished till equilibrium moisture content was reached. Effect of drying temperature on the characteristic of drying rate was found significant at P < 0.05 level with ANOVA test. The non-linear relationship was observed between drying rate and the moisture content at all process conditions. The results of ANOVA test revealed that the drying temperature has a significant influence (at 5% level of significance) on drying rate.

Drying Curve Modeling

The moisture content data at the different drying temperatures were converted to the more useful moisture ratio expression and then curve-fitting computations with the drying time were done by using five drying models. The results of statistical analysis are given in Table 1. In all cases, the values of R 2 for the models were greater than 0.93, indicating a good fit. Suitability of the models were based on the of R 2, χ 2, and RMSE values. The two-term model was found to be the best model for describing the characteristics of ginger slices, for all drying temperatures. As seen in Fig. 3, the two-term model showed good agreement with the experimental results for ginger slices at temperatures of 40 °C, 50 °C, 60 °C, and 65 °C. The values R 2 (>0.95), χ 2 (<0.001), and RMSE (<0.00) of the final drying model was found to be well within the acceptable range (Table 1).

At high initial moisture content, the initial drying rate is always higher owing to higher vapor pressure gradient, which diminishes as drying progresses. This probably had led to the two drying phases and is perfectly described by the two-term model. The two distinct drying constants clearly indicate that drying followed two falling rate periods. In the second phase of modeling, the coefficients of the two-term models were correlated with drying air temperatures using linear regression (Mohapatra and Rao 2005), and again, model suitability was checked using the aforementioned procedure. The statistical analysis results are presented in Table 1.

The coefficients were taken as the average value of the three drying constants. The drying model so generated with respect to time (t) and temperature (T) is:

The linear nature of graph (Fig. 4) plotted between the observed and predicted drying data corroborates with the fact that two-term model aptly describes the dehydration of ginger slices under vacuum at different temperatures.

Determination of Effective Moisture Diffusivity for Drying

The results have shown that internal mass transfer resistance controls the drying time due to the presence of a falling rate drying period. Therefore, the values of effective diffusivity (D eff) at different drying temperatures could be obtained by using Eqs. 4 and 5. The average values of effective diffusivities of ginger slices in the drying process at 40–65 °C varied in the range of 1.86 to 4.78 × 10−8 m2/s which is in accordance with the previous study done by German et al. 2008 for different biological materials. The values of D eff increased with the increase of drying temperature, which is in accordance with the previous studies (Mohapatra and Rao 2005; Chandrashekar 2008).

The moisture diffusivity was plotted against reciprocal of absolute temperature in Fig. 5, and the relationship was found to be Arrhenius-type as described in Eq. 5. The slope of the curve gives the E a/R, while the intercept gives the D 0 value.

From which, the activation energy for water diffusion can be found to be 35.675 kJ/mol.

Conclusions

The influence of drying temperature on modeling of drying of ginger slices was investigated in this study. Drying of ginger slices occurred in falling rate period; no constant rate period of drying was observed for the present study, which implies that moisture removal from the material was governed by diffusion phenomenon. According to statistical analysis applied to five mathematical models, the two-term model provided the best representation of ginger slices drying kinetics. The effective moisture diffusivity was found to range from 1.86 to 4.78 × 10−8 m2/s. Temperature dependence of the diffusivity was related with Arrhenius-type relationship. Activation energy was found to be 35.675 kJ/mol for drying of ginger slices within the experimental temperature range. Further investigation about the effect of initial moisture content, vacuum levels, and bed depth on drying characteristics of sliced ginger is needed for obtaining optimized conditions for the production of dried ginger.

References

Arevalo-Pinedo, A., & Murr, F. E. M. (2007). Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. Journal of Food Engineering, 80(1), 152–156.

Association of Official Analytical Chemists (AOAC). (1990). Official method of analysis (15th ed.). Virginia: Association of Official Analytical Chemists.

Bruce, D. M. (1985). Exposed-layer barley drying, three models fitted to new data up to 150 °C. Journal of Agricultural Engineering Research, 32, 337–348.

Chandrashekar, S. (2008). Modeling drying kinetics of mustard in fluidized bed. International Journal of Food Engineering, 4(3), 1–14.

Crank, J. (1975). The mathematics of diffusion. Oxford: Clarendon.

Elsa, U., Antonio, V. G., Karina, D. S., Romina, O., Jorge, S. T., & Margarita, M. (2009). Characteristics of convective drying of Pepino fruit (Solanum muricatum Ait.): application of weibull distribution. Food and Bioprocess Technology. doi:10.1007/s11947-009-0230-y (in press).

Elsa, U., Margarita, M., Antonio, V. G., Issis, Q., Rodrigo, C., & Karina, D. S. (2010). Mass transfer modeling during osmotic dehydration of Jumbo squid (Dosidicus gigas): influence of temperature on diffusion coefficients and kinetics parameters. Food and Bioprocess Technology. doi:10.1007/s11947-010-0336-2 (in press).

Ergunes, G., & Tarhan, S. (2006). Color retention of red pepper by chemical pretreatments during greenhouse and open sun drying. Journal of Food Engineering, 76, 446–452.

German, E., Marek, M., Ireneusz, B., & Magdalena, Z. (2008). Approach to calculation time-dependent moisture diffusivity for thin layered biological materials. International Communications in Heat and Mass Transfer, 35(9), 1069–1072.

Gunhan, T., Demir, V., Hancioglu, E., & Hepbasli, A. (2005). Mathematical modeling of drying of bay leaves. Energy Conversion and Management, 46, 1667–1679.

Henderson, S. M., & Pabis, S. (1961). Grain drying theory I: temperature effect on drying coefficient. Journal of Agricultural Engineering Research, 7, 85–89.

Jaya, S., & Das, H. (2003). A vacuum drying model for mango pulp. Drying Technology, 21(7), 1215–1234.

Koc, A. B., Toy, M., Hayoglu, I., & Vardin, H. (2004). Performance of a solar dryer used for red pepper drying. J. Agric. Fac. HR. U., 8(2), 57–65.

Lopes Filho, J. F., Romanelli, P. F., Barboza, S. H. R., Gabas, A. L., & Telis-Romero, J. (2002). Sorption isotherms of alligator's meat (Caiman crocodilus yacare). Journal of Food Engineering, 52(2), 201–206.

Mohapatra, D., & Rao, P. S. (2005). A thin layer drying model of parboiled wheat. Journal of Food Engineering, 66, 513–518.

Rahman, M. S., Perera, C. O., & Thebaud, C. (1997). Desorption isotherm and heat pump drying kinetics of peas. Food Research International, 30, 485–491.

Wu, L., Orikasa, T., Ogawa, Y., & Tagawa, A. (2007). Vacuum drying characteristics of eggplants. Journal of Food Engineering, 83, 422–429.

Yaldiz, O., & Ertekin, C. (2001). Thin layer solar drying of some vegetables. Drying Technology, 19, 583–596.

Yaldiz, O., Ertekin, C., & Uzun, H. I. (2001). Mathematical modelling of thin layer solar drying of Sultana grapes. Energy, 26(5), 457–465.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thorat, I.D., Mohapatra, D., Sutar, R.F. et al. Mathematical Modeling and Experimental Study on Thin-Layer Vacuum Drying of Ginger (Zingiber Officinale R.) Slices. Food Bioprocess Technol 5, 1379–1383 (2012). https://doi.org/10.1007/s11947-010-0429-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-010-0429-y