Abstract

Infrared-vacuum drying characteristics of button mushroom (Agaricus bisporus) were evaluated in a combined dryer system. The effects of drying parameters, including infrared radiation power (150–375 W), system pressure (5–15 kPa) and time (0–160 min) on the drying kinetics and characteristics of button mushroom slices were investigated. Both the infrared lamp power and vacuum pressure influenced the drying time of button mushroom slices. The rate constants of the nine different kinetic’s models for thin layer drying were established by nonlinear regression analysis of the experimental data which were found to be affected mainly by the infrared power level while system pressure had a little effect on the moisture ratios. The regression results showed that the Page model satisfactorily described the drying behavior of button mushroom slices with highest R value and lowest SE values. The effective moisture diffusivity increases as power increases and range between 0.83 and 2.33 × 10−9 m2/s. The rise in infrared power has a negative effect on the ΔE and with increasing in infrared radiation power it was increased.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The button mushroom (Agaricus bisporus) is the most widely cultivated and consumed mushroom throughout the world and it contributes about 40% of the total world production of mushroom [1, 2]. Mushrooms are extremely perishable and the shelf life of fresh mushroom is only about 24 h at ambient conditions [3]. Hence, they should be consumed or processed promptly after harvest and for this reason the mushrooms are traded mostly in processed form in the world market. Dehydration is one of the important preservation methods employed for storage of mushroom and dehydrated mushrooms are valuable ingredients in a variety of sauces and soups. As mushrooms are very sensitive to temperature, choosing the right drying method can be the key for a successful operation [1, 2, 4].

One of the oldest methods for the preservation of food is drying, which consists in removing water from the product in order to provide microbiological safety [5, 6], and the most popular drying method includes convection. In this method the drying agent supplies heat to the material and removes moisture from the material at the same time. The method itself is a low-cost one, but has the disadvantage of entailing a time-consuming process. During contact with oxygen that is present in the air, the product becomes exposed to high temperature for a long time, and such exposure reduces the content of some valuable components which readily undergo oxidation at elevated temperature. Another drawback of the convective method is the concomitant substantial shrinkage [7].

The specific heat and thermal conductivity of mushrooms was determined by Shrivastava and Datta [8] for a moisture content (MC) range of 10.24 ± 89.68% w.b. (wet basis) and temperature range of 40–70 °C. Both the thermal properties increased almost linearly with the increasing levels of input variables. The specific heat of mushrooms varied from 1.7158 to 3.9498 kJ/kg °C for the experimental range of variables studied. Multiple regression models with high R2 values were developed to correlate these properties as a function of input variables.

One of the ways to shorten the drying time is to supply heat by infrared radiation. This method of heating is especially suitable to dry thin layers of material with large surface exposed to radiation [9]. Application of infrared heating to food drying is recently of special interest because of the progress in radiator construction. Their efficiency is between 80 and 90%, the emitted radiation is in narrow wavelength range and they are miniaturized [10, 11]. Infrared radiation is transmitted through water at short wavelength, while at long wavelength, it is absorbed on the surface [12]. Infrared radiation has some advantages over convective heating. In spite of these advantages, application of infrared energy in food processing is rather scarce. It is used for heating and cooking soybeans, cereal grains, cocoa beans and nuts, ready-to-eat products, braising meat and frying [13]. Drying of seaweed, vegetables, fish flakes and pasta is also done in tunnel infrared dryers. Infrared drying found also application in food analysis to measure water content in food products [14].

Infrared drying was applied before or after freeze-drying of shiitake mushroom to shorten the drying time, to enhance the rehydration, and to better preserve the aroma compounds and color by Wang et al. [15]. The results showed that the combination of freeze-drying (for 4 h) followed by infrared drying saves 48% time compared to freeze-drying while keeping the product quality at an acceptable level. The application of infrared drying also helps produce a more porous microstructure in dried shiitake mushrooms.

In the vacuum method the contact between the material being dried and oxygen is limited. Owing to the reduced pressure, effective drying can be achieved at low temperature [16]. In recent years, infrared-vacuum drying has been investigated as a potential method for obtaining high quality dried food products, including fruits, vegetables and grains. Infrared-vacuum drying combines the advantages of both infrared heating and vacuum drying. The low temperature and fast mass transfer conferred by vacuum combined with rapid energy transfer by infrared heating generates very rapid, low temperature drying and thus it has the potential to improve energy efficiency and product quality [1]. The effect of vacuum in infrared drying operation is system specific, and for successful design and operation of an industrial infrared-vacuum drying system, knowledge of the drying characteristics of the material to be dried under a range of condition is vital [17].

Pan et al. [18] used sequential infrared and freeze-drying (SIRFD) to produce high-quality dried fruits at reduced cost. The products dried using SIRFD had better color, higher crispness, higher shrinkage but poor rehydration propensity compared to those produced by using regular freeze-drying [18].

Infrared-vacuum method, when properly applied, can be used for achieving a high-quality product. Many studies were done to process mushroom by hot air drying [1, 19–21], vacuum heat pump drying [22], osmotic dehydration [23], drying in a fluidized bed [24], infrared drying [25] and convection-microwave drying [1, 26, 27]. However, we found no report on Infrared-vacuum drying of mushroom slices in the literature. Therefore, the aim of the present work was to investigate infrared-vacuum drying characteristics of button mushroom slices in respect to drying kinetics, moisture diffusivity and color changes of the dried products.

2 Materials and methods

2.1 Sample preparation

Fresh button mushrooms (A. bisporus) were obtained from market and kept in cold storage at 4–5 °C (Table 1). Prior to drying, mushrooms (5 cm in diameter) were thoroughly washed to remove the dirt and graded by size to eliminate the variations in respect to exposed surface area. Slices of desired thickness were obtained by carefully cutting mushrooms vertically with a vegetable slicer and the slices from middle portions with characteristics mushroom shape were used for drying experiments without any pretreatments. They were immediately placed into the dryer.

Hence, drying of thin layers seems to be more efficient at far-infrared radiation (FIR 25–100 µm), while drying of thicker bodies should give better results at near-infrared radiation (NIR 0.75–3.00 µm) [14]. Slices of button mushroom with 5 mm thickness were prepared with the aid of a steel cutter. Moisture content of the samples was determined in a vacuum oven at 70 °C for 6–8 h (AOAC, method no. 934.06). The initial moisture content of the slices was ranged from 89.68% ± 0.7 (wet basis) and about 9 in dry basis. Experiments were carried out in triplicate and an arithmetic average was taken for data processing.

2.2 Infrared-vacuum drying

The button mushroom slices were dried in an infrared-vacuum dryer (Infrared radiation lamp (NIR), Philips, Germany; Vacuum oven (VO), Memmert Universal, Schwabach, Germany) (Fig. 1). The effect of infrared radiation power (at three levels 150, 250 and 375 W), system pressure (at three levels 5, 10 and 15 kPa), time (0–160 min) on the drying kinetics and characteristics of button mushrooms slice were investigated. Then the dried samples stored in an air-tight packet till the experiments.

Weight loss of samples was recorded by using a digital balance (Digital balance, LutronGM-300p, Taiwan), with a sensitivity of ±0.01 g.

2.3 Drying kinetics

The experimental moisture content data were nondimensionlized using the equation:

where MR is the dimensionless moisture ratio, Mt, M0 and Me are moisture content at any time, initial moisture content and equilibrium moisture content (kg water/kg dry matter), respectively. (Mt − Me)/(M0 − Me) was simplified to Mt/M0 as the relative humidity of drying air continuously fluctuated during drying experiments [28, 29].

Selected thin-layer drying models, detailed in Table 2, were fitted to the drying curves (MR versus time) [28, 30]. A nonlinear estimation package (Curve Expert, Version 1.34) was used to estimate the coefficients of the given models. The two criteria of statistic analysis have been used to evaluate the adjustment of the experimental data to the different models, R (correlation coefficient) and SE (standard error). A good fitting between the experimental data and the correlations is obtained when there is a combination of the high R value and the values of SE, which should be as low as possible [28].

2.4 Calculation of moisture diffusivity

In most studies carried out on drying, diffusion is generally accepted to be the main mechanism during the transport of moisture to the surface to be evaporated [28]. Fick’s second law of diffusion has been widely used to describe the drying process during the falling rate period for most food materials [31]. The solution of diffusion model, considering negligible external resistance, in terms of average moisture content, negligible shrinkage, constant diffusion coefficients and temperature, is presented for slab geometry [28]:

where MR is the moisture ratio (dimensionless); t is the drying time (s), Deff is the effective diffusivity (m2/s); and L is the half slab thickness of the slices (m). For long drying periods, Eq. (2) can be further simplified to:

The effective diffusivity was calculated through Eq. (3) by using the method of slopes. The effective diffusivities are typically determined by plotting experimental drying data in terms of lnMR versus time (as given in Eq. 3). From Eq. 3, a plot of lnMR versus time gives a straight line with a slope (K) of:

2.5 Color measurement

In order to investigate the effect of drying methods on color changes of dried button mushroom, a computer vision system was applied. Sample illumination was achieved with HP Scanner (Hp Scanjet G3110). Since the computer vision system perceived color as RGB signals, which is device-dependent, the taken images were converted into \( {\text{L}}^{*} {\text{a}}^{*} {\text{b}}^{*} \) units to ensure color reproducibility [32]. In the \( {\text{L}}^{*} {\text{a}}^{*} {\text{b}}^{*} \) space, the color perception is uniform, and therefore, the difference between two colors corresponds approximately to the color difference perceived by the human eye. \( {\text{L}}^{*} \) (lightness/darkness that ranges from 0 to 100), \( {\text{a}}^{*} \) (redness/greenness that ranges from −120 to 120) and \( {\text{b}}^{*} \) (yellowness/blueness that ranges from −120 to 120) were measured [33].

The calculation of color changes (ΔE) for total color difference was made with the following equation [33]:

In this study, the image analysis of dried button mushrooms was performed using Image J software version 1.42e, USA. The fresh button mushroom exhibited a light color, with \( {\text{L}}_{1}^{*} , {\text{a}}_{1}^{*} \) and \( {\text{b}}_{1}^{*} \) equal to 93.61, −2.55 and 14.99, respectively.

2.6 Uncertainty analysis

Uncertainty analysis is a powerful tool when it is used in the planning and design of experiments. The measurement inaccuracy in the experimental studies may occur from causes such as lack of accuracy in measurement equipment, random variation in operating condition, calibration procedure and data recording. Uncertainty of any measurement can be expressed using the general expression given below [34, 35]:

where UY is the uncertainty in the result, u1, u2, …, un are the uncertainty in the independent variables; z1, z2, …, zn are the independent variables and Y is the function of the independent variables. The drying air temperature, the relative humidity of the air drying, change of mass of drying samples are independent parameters measured in the drying experiments of button mushroom.

3 Results and discussion

3.1 Drying time

Drying under vacuum is generally performed since under vacuum, water evaporates at low temperature; hence, drying can be performed at low temperature. Hence, absorption of infrared energy by water is an important variable, which affects drying kinetics. Generally, solid materials absorb infrared radiation in a thin surface layer [36]. During drying, radiation properties of the material are changing due to decreasing water content. As a consequence, its reflectivity increases and the absorptivity decrease.

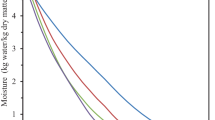

The effects of infrared power and vacuum pressure on the moisture content of button mushroom slices are shown in Figs. 2 and 3, respectively. As expected, the moisture content was decreased by increasing the power because of the increased temperature and heat transfer gradient between the air and samples. The drying times of button mushroom samples were 110, 90 and 60 min at 150, 250 and 375 W, respectively (5 kPa). In conclusion, experimental results showed that the infrared power has a significant effect on the evolution of moisture content. With increasing infrared intensity, due to the increase in sample temperature and evaporation rate and the decrease in drying time, the specific energy for drying of mushroom slices decreases.

The influence of vacuum pressure on the moisture content as a function of drying time at an infrared power of 150 W is shown in Fig. 3. It is evident that increase in vacuum pressure enhanced the drying rate. This was expected because as vacuum pressure increases, there is an accelerated removal of moisture buildup in the chamber, which consequently enhanced the drying process. In combined infrared-vacuum drying, the most important effect is to cause an increase in drying rate. In mushroom drying, the use of microwave has been found to produce poorer quality of dried mushroom products [37]. In our study, no burning of dried mushroom slices was observed even at the highest power of 375 W in combination with the various vacuum pressures. The general improved quality of the dried products using this infrared-vacuum dryer may be due to the combined effects of increased pressure gradient between the inner and outer layers of the mushrooms as well as the low temperatures maintained throughout the drying process.

Masamura et al. [38] observed increased drying rates of food products with increasing power supply to infrared heater. The increase in power might have caused a rapid increase in the temperature at surface of product, resulting into an increase in the water vapor pressure inside the product and thus in higher drying rates [39].

Vacuum drying is a unit operation in chemical and engineering process, in which moist material is dried under sub-atmospheric pressures. The lower pressure allow drying temperature to be reduced and higher quality to be obtained than with classical air conventional process at atmospheric pressure [40]. The drying time reduced from 150 to 110 min when the vacuum pressure was decreased from 150 to 50 kPa (150 W). The experimental results are consistent with the literature reports for other vegetables [41].

Microwave-vacuum dehydration characteristics of button mushroom were evaluated in a commercially available microwave oven modified to a drying system by incorporating a vacuum chamber in the cavity by Giri and Prasad [1]. The drying system was operated in the microwave power range of 115–285 W, pressure range of 6.5–23.5 kPa having mushroom slices of 6–14 mm thickness. Microwave-vacuum drying resulted in 70–90% decrease in the drying time and the dried products had better rehydration characteristics as compared to convective air drying [1].

Infrared-vacuum dryer system was developed and tested by [42] using welsh onion as a test material. The results showed that the rate of moisture reduction of the sample decreased with an increase in the power input to the far infrared radiator. This is expected as higher power input implied higher radiation intensity. However, when a very low level of the power input (40 W) was applied the required final moisture content of onion could not be achieved.

3.2 Fitting of the drying curves

The drying kinetics is often used to describe the combined macroscopic and microscopic mechanisms of mass transfer during drying, and it is affected by drying conditions, types of dryer and characteristics of materials to be dried. The drying kinetics models are essential for equipment design, process optimization and product quality improvement. Different mathematical models (Table 2) were fitted with the drying data and among the all drying models; the Page model obtained the highest R values and the lowest SE values. Estimated parameters and statistical data obtained for this model are shown in Table 3. In all the cases, the R values for the models were greater than 0.991, indicating a good fit. Figure 4 compare the experimental and the predicted moisture ratios with the quadratic model for dried button mushroom slices at 150 W and 15 kPa. It can be seen that there was a very good agreement between the experimental and predicted moisture ratio values, which are closely banding around at a 45° straight line.

Rhim and Lee [20] and Artnaseaw et al. [22] reported that the Midilli model could adequately describe the convective air drying and vacuum heat pump drying behavior of sliced shiitake mushroom.

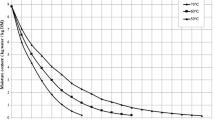

3.3 Moisture diffusivity

The effective diffusivities are determined by plotting experimental drying data in terms of lnMR versus time. The effects of infrared radiation power and vacuum pressure on the lnMR are shown in Figs. 5 and 6, respectively. The Deff values lie within in general range of 10−11–10−9 m2/s for food materials [43]. The values of Deff at different condition drying of button mushroom slice obtained by using Eq. (4) and estimated values are shown in Table 4. The effective diffusivity values of button mushroom slices were ranged from 0.83 and 2.33 × 10−9 m2/s. Effective diffusivity values increased with increasing infrared radiation power because of the rapid movement of water at high temperatures [28]. The values of Deff are comparable with the reported values of 0.85–1.75 × 10−10 m2/s for hull-less seed pumpkin at 40–60 °C [31], 0.46–3.45 × 10−10 m2/s mentioned for drying carrot in the temperature range of 60–90 °C [44], 3.0–17.12 × 10−10 m2/s for kiwi fruit at 30–90 °C [45], 3.2–11.2 × 10−9 m2/s for red bell pepper at 50–80 °C [46], 2.52–13.0 × 10−10 m2/s for curd at 45–50 °C [47], and 4.27–13.0 × 10−10 m2/s okra at 50–70 °C [48].These values are consistent with the present estimated Deff values for button mushroom slices. The results of such fitting gave a regression coefficient of 0.96 indicating that the quality of such a fitting was satisfactory.

Far-infrared drying characteristics of mushroom slices were studied by Darvishi et al. [25]. Experimental drying curves showed only a falling drying rate period. The results show that the logarithmic model is the most appropriate model for infrared drying behavior of thin-layer mushroom slices. A third-order polynomial relationship was found to correlate the effective moisture diffusivity with moisture content. The average effective moisture diffusivity increased with increasing temperature and decrease in moisture content of mushroom slices and varied from 8.039 × 10−10 to 20.618 × 10−10 m2/s.

In the case of rehydration ability it was reported that Infrared-vacuum dried carrot had lower rehydration ability when dried at a condition of shorter drying duration, e.g., at a lower drying pressure or at a higher controlled surface temperature. This is due to the fact that at these conditions dense or rigid layers formed on the sample surface; these layers prevented adsorption of water during rehydration [49].

3.4 Color measurement

Since air is transparent to infrared radiation, the process can be done at ambient air temperature. Equipment can be compact and automated with high degree of control of process parameters. This is especially important because of fast heating and possibilities of overheating of the material [12].

The fresh button mushroom exhibited a light color, with \( {\text{L}}_{1}^{*} , {\text{a}}_{1}^{*} \) and \( {\text{b}}_{1}^{*} \) equal to 93.61, −2.55 and 14.99, respectively. The results of color measurement of dried button mushroom slices at different conditions are presented in Table 5. The infrared radiation power was found to have a significant effect on the colour of button mushroom slices. The rise in power has a negative effect on the ΔE and with increasing in infrared radiation power from 150 to 375 W, it was increased from 27.33 to 33.10 (5 kPa), respectively. As shown in Table 5, the \( {\text{L}}^{*} \) values varied from 33.34 to 71.83 at different drying condition.

Swasdisevi et al. [50] examined the drying behavior of Cavendish banana slices undergoing combined far infrared and vacuum drying. The results showed that the vacuum pressure, temperature and thickness had significant effects on the drying kinetics and various qualities of the dried banana viz. color, hardness and shrinkage. It was reported that lightness decreased with increasing surface temperature, while yellowness increased with increasing surface temperature due to browning reaction occurring during drying process. Combined FIR-vacuum drying shows good potential of producing a fat-free shuck-like product from banana. In addition, the optimum condition for infrared-vacuum drting is at temperature of 50 °C, pressure of 5 kPa and thickness of 2 mm. Guiné and Barroca [51] reported that the lightest dried pumpkin was obtained by freeze drying. The results show a decrease of \( {\text{L}}^{*} \) and an increase of \( {\text{a}}^{*} \) and \( {\text{b}}^{*} \) with increasing of system power. Therdthai and Zhou [52] reported that high temperature during drying of mint leaves could lead to increase ΔE values.

3.5 Uncertainty analyses for the measurement

Table 6 lists the uncertainties of the measured parameters and total uncertainties in calculating the effective moisture diffusivity. The values of uncertainty obtained for the button mushroom drying analysis in this study were well below the acceptable limit of 5%.

4 Conclusions

The effect of vacuum in infrared drying operation is system specific, and for successful design and operation of an industrial infrared-vacuum dryer, knowledge of the drying characteristics of the material to be dried under a range of condition is essential. A drying system was fitted with near-infrared (NIR) heaters for radiative heating. The drying times of button mushroom samples were 110, 90 and 60 min at 150, 250 and 375 W, respectively. It was reduced when the system pressure was decreased. The drying characteristics were satisfactorily described by Page model with the latter providing the best representation of the experimental data. Values for the effective moisture diffusivity of button mushroom samples were obtained in the range of 0.83 and 2.33 × 10−9 m2/s. The present study also verified that the color of button mushrooms was influenced by the drying process condition (infrared power and system pressure). The rise in power has a negative effect on the ΔE and with increasing in infrared radiation power from 150 to 375 W, it was increased from 27.33 to 33.10 (5 kPa), respectively.

Abbreviations

- a:

-

Redness/greenness that ranges from −120 to 120

- b:

-

Yellowness/blueness that ranges from −120 to 120

- Deff :

-

Effective diffusivity (m2/s)

- D0 :

-

Pre-exponential factor (m2/s)

- L:

-

Half slab thickness of the slices (m)

- K:

-

Slope

- k:

-

Drying rate constants in models (1/s)

- L:

-

Lightness/darkness that ranges from 0 to 100

- MR:

-

Dimensionless moisture ratio

- Mt :

-

Moisture content at time t (kg water/kg dry matter)

- Me:

-

Equilibrium moisture content (kg water/kg dry matter)

- M0 :

-

Initial moisture content (kg water/kg dry matter)

- N:

-

Number of observations

- n:

-

Number of constants

- R:

-

Correlation coefficient

- t:

-

Drying time (min)

- ∆a:

-

a2 − a1 (redness/greenness)

- ∆b:

-

b2 − b1 (yellowness/blueness)

- ∆E:

-

Color changes

- ∆L:

-

L2 − L1 (lightness/darkness)

References

Giri S, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78:512–521

Salehi F, Kashaninejad M, Asadi F, Najafi A (2016) Improvement of quality attributes of sponge cake using infrared dried button mushroom. J Food Sci Technol 53:1418–1423. doi:10.1007/s13197-015-2165-9

Santos MV, Lespinard AR (2011) Numerical simulation of mushrooms during freezing using the FEM and an enthalpy: Kirchhoff formulation. Heat Mass Transfer 47:1671–1683. doi:10.1007/s00231-011-0831-7

Ghanbarian D, Baraani Dastjerdi M, Torki-Harchegani M (2016) Mass transfer characteristics of bisporus mushroom (Agaricus bisporus) slices during convective hot air drying. Heat Mass Transf 52:1081–1088. doi:10.1007/s00231-015-1629-9

Mathlouthi M (2001) Water content, water activity, water structure and the stability of foodstuffs. Food Control 12:409–417

Salehi F, Kashaninejad M, Akbari E, Sobhani SM, Asadi F (2016) Potential of sponge cake making using infrared-hot air dried carrot. J Texture Stud 47:34–39. doi:10.1111/jtxs.12165

Lozano J, Rotstein E, Urbicain M (1983) Shrinkage, porosity and bulk density of foodstuffs at changing moisture contents. J Food Sci 48:1497–1502

Shrivastava M, Datta A (1999) Determination of specific heat and thermal conductivity of mushrooms (Pleurotus florida). J Food Eng 39:255–260

Allanic N, Le Bideau P, Glouannec P, Deterre R (2016) An experimental study on infrared drying kinetics of an aqueous adhesive supported by polymer composite. Heat Mass Transf. doi:10.1007/s00231-016-1816-3

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Progr 2:109–119

Sadin R, Chegini G-R, Sadin H (2014) The effect of temperature and slice thickness on drying kinetics tomato in the infrared dryer. Heat Mass Transf 50:501–507. doi:10.1007/s00231-013-1255-3

Sakai N, Hanzawa T (1994) Applications and advances in far-infrared heating in Japan. Trends Food Sci Technol 5:357–362

Ratti C, Mujumdar A (1995) Infrared drying. In: Mujumdar AS (ed) Handbook of industrial drying, vol 1, 2nd edn. Marcel Dekker Inc, New York, pp 567–588

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innov Food Sci Emerg Technol 5:353–360

H-c Wang, Zhang M, Adhikari B (2015) Drying of shiitake mushroom by combining freeze-drying and mid-infrared radiation. Food Bioprod Process 94:507–517

Nawirska A, Figiel A, Kucharska AZ, Sokół-Łętowska A, Biesiada A (2009) Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. J Food Eng 94:14–20

McLoughlin C, McMinn W, Magee T (2003) Microwave-vacuum drying of pharmaceutical powders. Dry Technol 21:1719–1733

Pan Z, Shih C, McHugh TH, Hirschberg E (2008) Study of banana dehydration using sequential infrared radiation heating and freeze-drying. LWT-Food Sci Technol 41:1944–1951

Arora S, Shivhare U, Ahmed J, Raghavan G (2003) Drying kinetics of Agaricus bisporus and Pleurotus florida mushrooms. Trans Am Soc Agric Eng 46:721–724

Rhim J-W, Lee JH (2011) Drying kinetics of whole and sliced shiitake mushrooms (Lentinus edodes). Food Sci Biotechnol 20:419–427

Xanthopoulos G, Lambrinos G, Manolopoulou H (2007) Evaluation of thin-layer models for mushroom (Agaricus bisporus) drying. Dry Technol 25:1471–1481

Artnaseaw A, Theerakulpisut S, Benjapiyaporn C (2010) Drying characteristics of Shiitake mushroom and Jinda chili during vacuum heat pump drying. Food Bioprod Process 88:105–114

Ebrahim RM, Kashaninezhad M, Mirzaei HE, Khomeiri M (2009) Effect of temperature, osmotic solution concentration and mass ratio on kinetics of osmotic dehydration of button mushroom (Agaricus bisporus). J Agric Sci Nat Resour 16(1):1–10

Arumuganathan T, Manikantan M, Rai R, Anandakumar S, Khare V (2009) Mathematical modeling of drying kinetics of milky mushroom in a fluidized bed dryer. Int Agrophys 23:1–7

Darvishi H, Najafi G, Hosainpour A, Khodaei J, Aazdbakht M (2013) Far-infrared drying characteristics of mushroom slices. Chem Prod Process Model 8:107–117

Rodríguez R, Lombrana J, Kamel M, De Elvira C (2005) Kinetic and quality study of mushroom drying under microwave and vacuum. Dry Technol 23:2197–2213

Torringa E, Esveld E, Scheewe I, van den Berg R, Bartels P (2001) Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms. J Food Eng 49:185–191

Doymaz I (2011) Drying of eggplant slices in thin layers at different air temperatures. J Food Process Preserv 35:280–289

Ceylan I, Aktaş M, Doğan H (2007) Mathematical modeling of drying characteristics of tropical fruits. Appl Therm Eng 27:1931–1936

Akpinar EK, Bicer Y (2005) Modelling of the drying of eggplants in thin-layers. Int J Food Sci Technol 40:273–281

Sacilik K (2007) Effect of drying methods on thin-layer drying characteristics of hull-less seed pumpkin (Cucurbita pepo L.). J Food Eng 79:23–30

Salehi F, Kashaninejad M (2015) Effect of drying methods on rheological and textural properties, and color changes of wild sage seed gum. J Food Sci Technol 52:7361–7368. doi:10.1007/s13197-015-1849-5

Salehi F, Kashaninejad M (2014) Effect of different drying methods on rheological and textural properties of Balangu seed gum. Dry Technol 32:720–727

Khanali M, Banisharif A, Rafiee S (2016) Modeling of moisture diffusivity, activation energy and energy consumption in fluidized bed drying of rough rice. Heat Mass Transfer. doi:10.1007/s00231-016-1763-z

Lutovska M, Mitrevski V, Pavkov I, Mijakovski V, Radojčin M (2016) Mathematical modelling of thin layer drying of pear. Chem Ind Chem Eng Q 22(2):191–199

Lampinen MJ, Ojala KT, Koski E (1991) Modeling and measurements of infrared dryers for coated paper. Dry Technol 9:973–1017

Walde S, Velu V, Jyothirmayi T, Math R (2006) Effects of pretreatments and drying methods on dehydration of mushroom. J Food Eng 74:108–115

Masamura A, Sado H, Honda T, Shimizu M, Nabetani H, Nakajima M, Watanabe A (1988) Drying of potato by far infrared radiation. J Jpn Soc Food Sci Technol (Japan) 35(5):309–314

Datta A, Ni H (2002) Infrared and hot-air-assisted microwave heating of foods for control of surface moisture. J Food Eng 51:355–364

Arévalo-Pinedo A, Murr FEX (2007) Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. J Food Eng 80:152–156

Toğrul H (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77:610–619

Mongpraneet S, Abe T, Tsurusaki T (2002) Far infrared–vacuum and–convection drying of welsh onion. Trans ASAE 45:1529

Rizvi SS (1986) Thermodynamic properties of foods in dehydration. Eng Prop Foods 2:239–251

Zielinska M, Markowski M (2007) Drying behavior of carrots dried in a spout–fluidized bed dryer. Dry Technol 25:261–270

Simal S, Femenia A, Garau M, Rosselló C (2005) Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit. J Food Eng 66:323–328

Vega A, Fito P, Andrés A, Lemus R (2007) Mathematical modeling of hot-air drying kinetics of red bell pepper (var. Lamuyo). J Food Eng 79:1460–1466

Shiby V, Mishra H (2007) Thin layer modelling of recirculatory convective air drying of curd (Indian yoghurt). Food Bioprod Process 85:193–201

Doymaz İ (2005) Drying characteristics and kinetics of okra. J Food Eng 69:275–279

Nimmol C (2010) Vacuum far-infrared drying of foods and agricultural materials. J King Mongkut’s Univ Technol N Bangk 20:37–44

Swasdisevi T, Devahastin S, Ngamchum R, Soponronnarit S (2007) Optimization of a drying process using infrared-vacuum drying of Cavendish banana slices. Optimization 29:810

Guiné RP, Barroca MJ (2012) Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod Process 90:58–63

Therdthai N, Zhou W (2009) Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J Food Eng 91:482–489

Acknowledgements

This research was supported by Iran National Science Foundation (INSF) through a Grant No. 92044245 to Mahdi Kashaninejad. The authors would like to thank gratefully Iran National Science Foundation, INSF, for financial support of the research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salehi, F., Kashaninejad, M. & Jafarianlari, A. Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transfer 53, 1751–1759 (2017). https://doi.org/10.1007/s00231-016-1931-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1931-1